Novel integrated flow channel membrane shell

A flow channel membrane, a new type of technology, applied in membrane technology, semi-permeable membrane separation, osmotic/dialysis water/sewage treatment, etc., can solve problems such as hidden danger of equipment leakage, maintenance or repair difficulty, etc., to save pipeline materials and The effect of space, reduction of engineering quantity, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

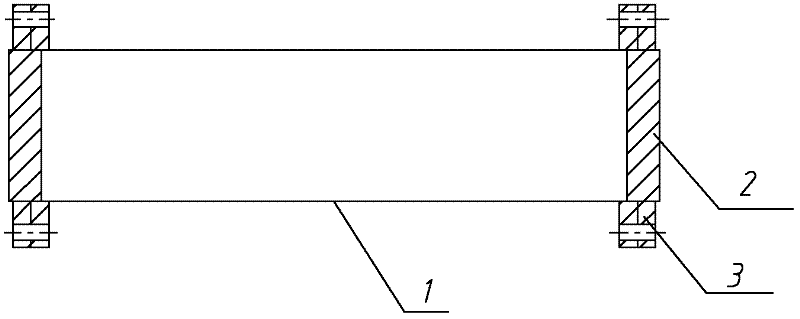

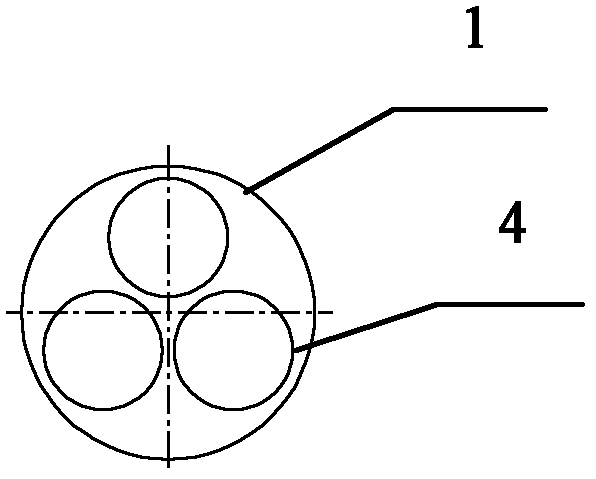

[0034] Such as figure 1 , figure 2 As shown, a new type of integrated flow channel membrane shell, including a pressure vessel 1, two end caps 2, a flange 3 connecting the pressure vessel 1 and the end cap 2, and three membrane elements 4 are evenly arranged in the pressure vessel 1 , so that three membrane elements 4 are connected in parallel, and the raw water port (not shown in the figure) and the water production port (not shown in the figure) in the end cover 2 at one end are connected with the raw water port (not shown in the figure) of the set membrane element 4 , the water production port (not shown in the figure) is connected correspondingly, and the concentrated water port (not shown in the figure) and the water production port (not shown in the figure) of the other end cover 2 are connected with the concentrated water port (not shown in the figure) of the membrane element 4 provided. Not shown in the figure), the water production port (not shown in the figure) is ...

Embodiment 2

[0039] Such as figure 1 , Figure 6As shown, a new type of integrated flow channel membrane shell, including a pressure vessel 1, two end caps 2, a flange 3 connecting the pressure vessel 1 and the end cap 2, and eight membrane elements 4 are evenly arranged in the pressure vessel 1 , so that eight membrane elements 4 are connected in series, and the raw water port and water production port in the end cover 2 at one end are connected with the raw water port and water production port of the set membrane element 4 correspondingly, and the concentrated water port in the end cover 2 at the other end is , the water production port and the concentrated water port and the water production port of the set membrane element 4 are connected correspondingly.

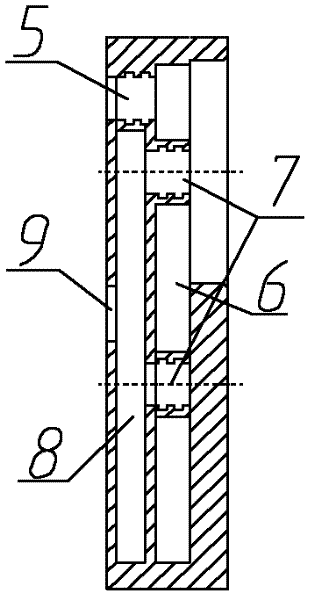

[0040] Such as Figure 7 , Figure 8 , Figure 9 As shown, when performing reverse osmosis and nanofiltration treatment, the raw water enters the raw water port of the first membrane element 4 from the total raw water port 5 in ...

Embodiment 3

[0044] Such as figure 1 , Figure 10 As shown, a new type of integrated flow channel membrane shell, including a pressure vessel 1, two end caps 2, a flange 3 connecting the pressure vessel 1 and the end cap 2, 16 membrane elements 4 are evenly arranged in the pressure vessel 1 , among which, 16 membrane elements 4 are 2 series combinations connected in parallel and then connected in series with 1 series combination, each of the 5 membrane elements 4 in the first two parallel combinations of the 3 series combinations are connected in series, and the remaining 6 membrane elements 4 Connect the raw water port and water production port in the end cover 2 of one end to the raw water port and water production port of the set membrane element 4 correspondingly, and connect the concentrated water port and water production port in the end cover 2 of the other end to the set water port. The concentrated water port and the produced water port of the membrane element 4 are connected cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com