Patents

Literature

85results about How to "Guaranteed Restore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

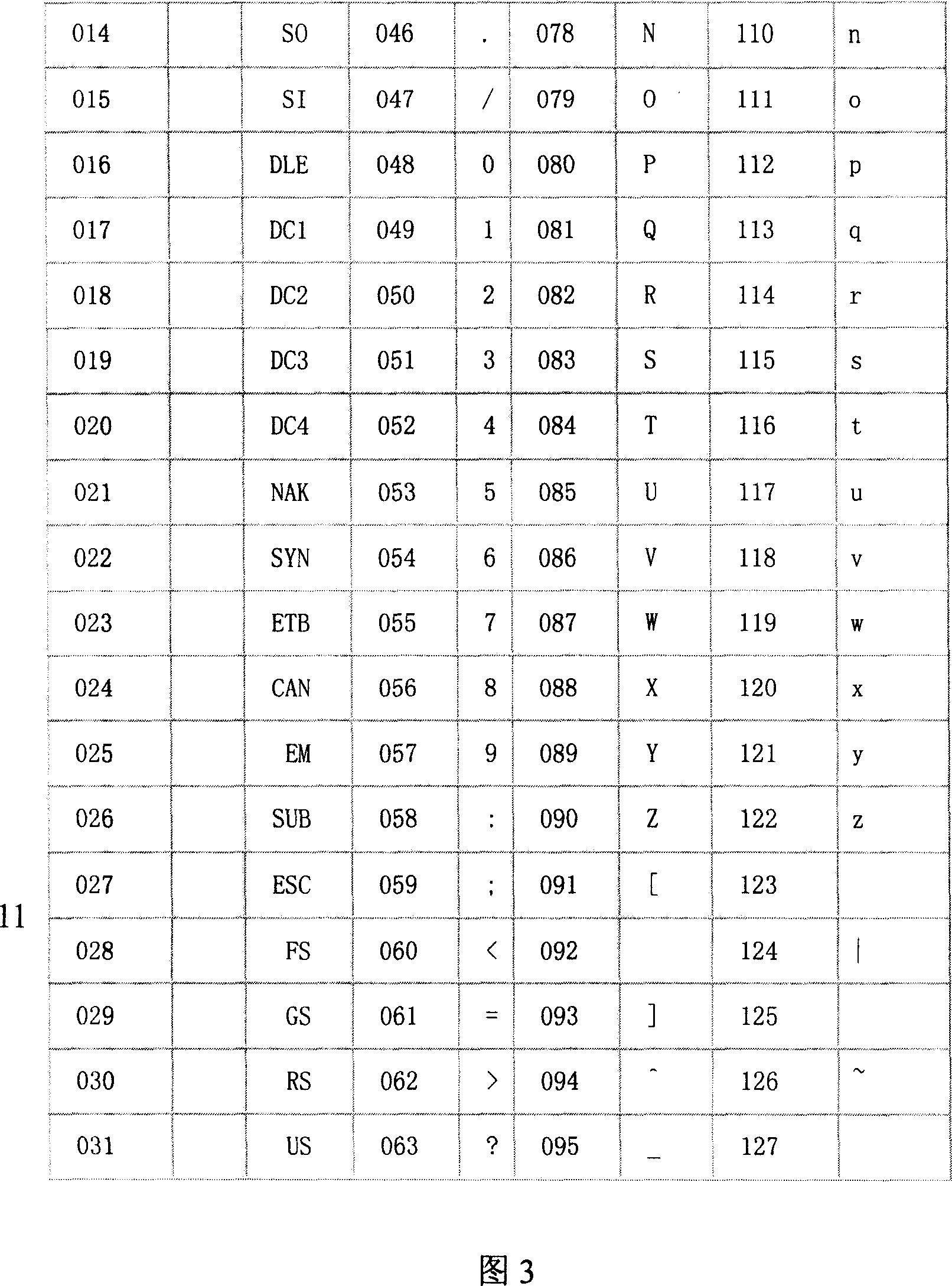

Patent Type

Patent Status

Application Year

Inventor

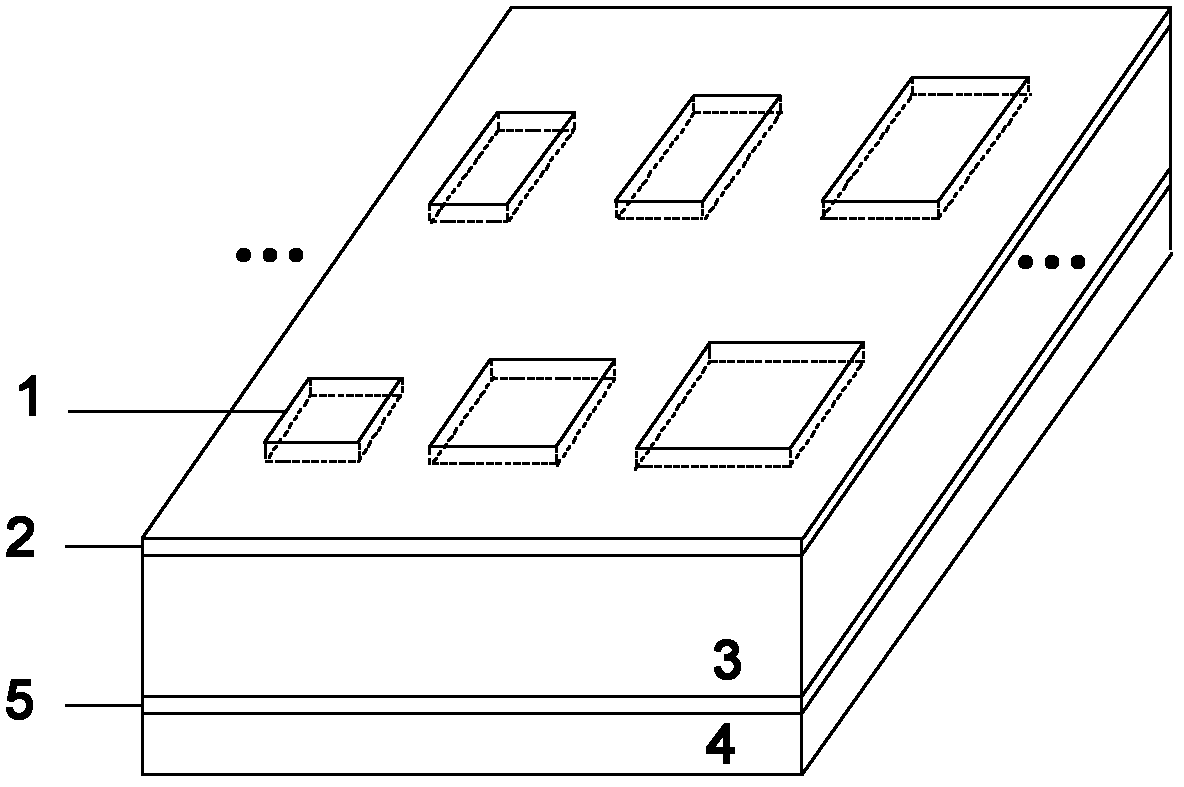

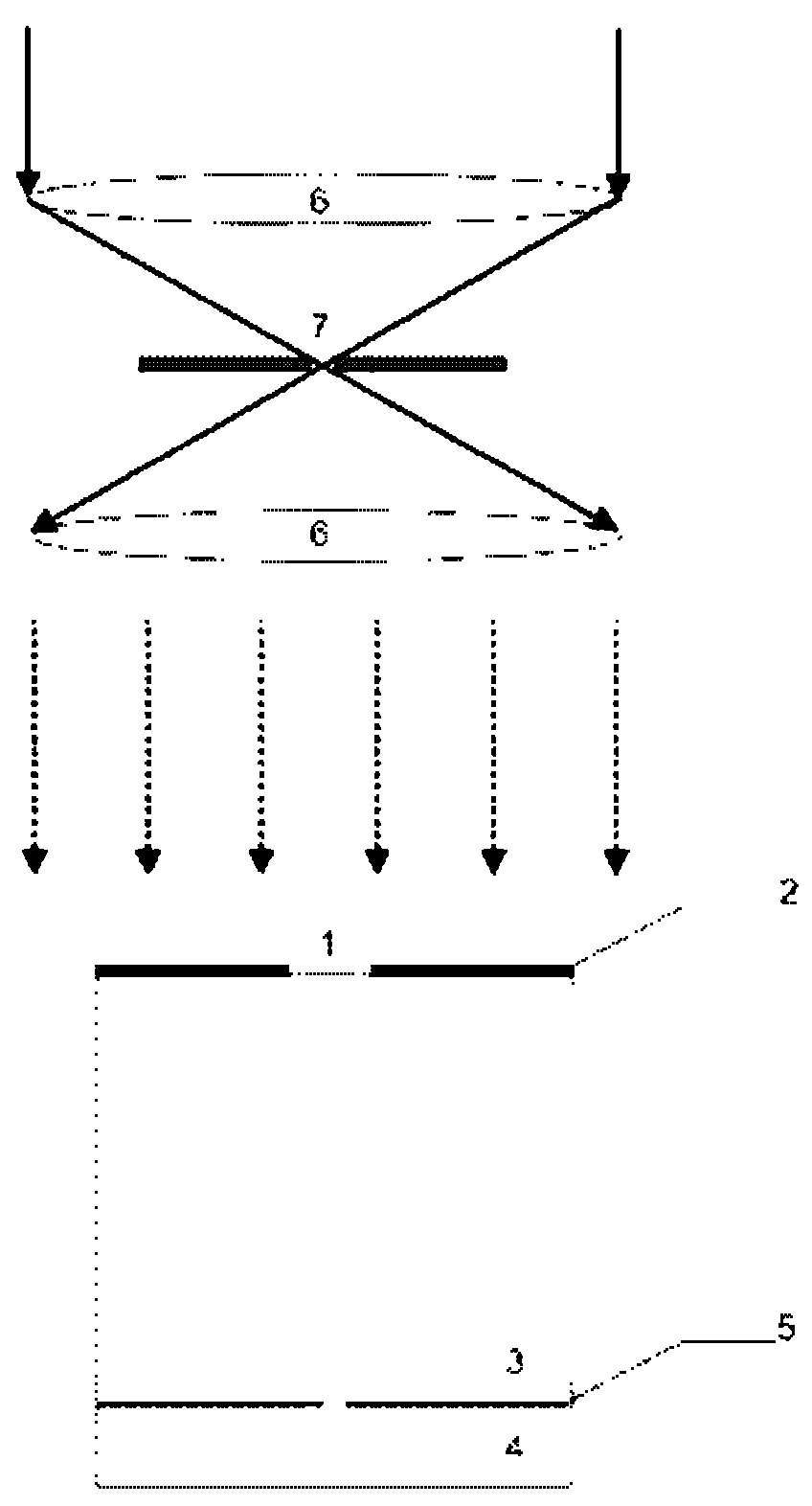

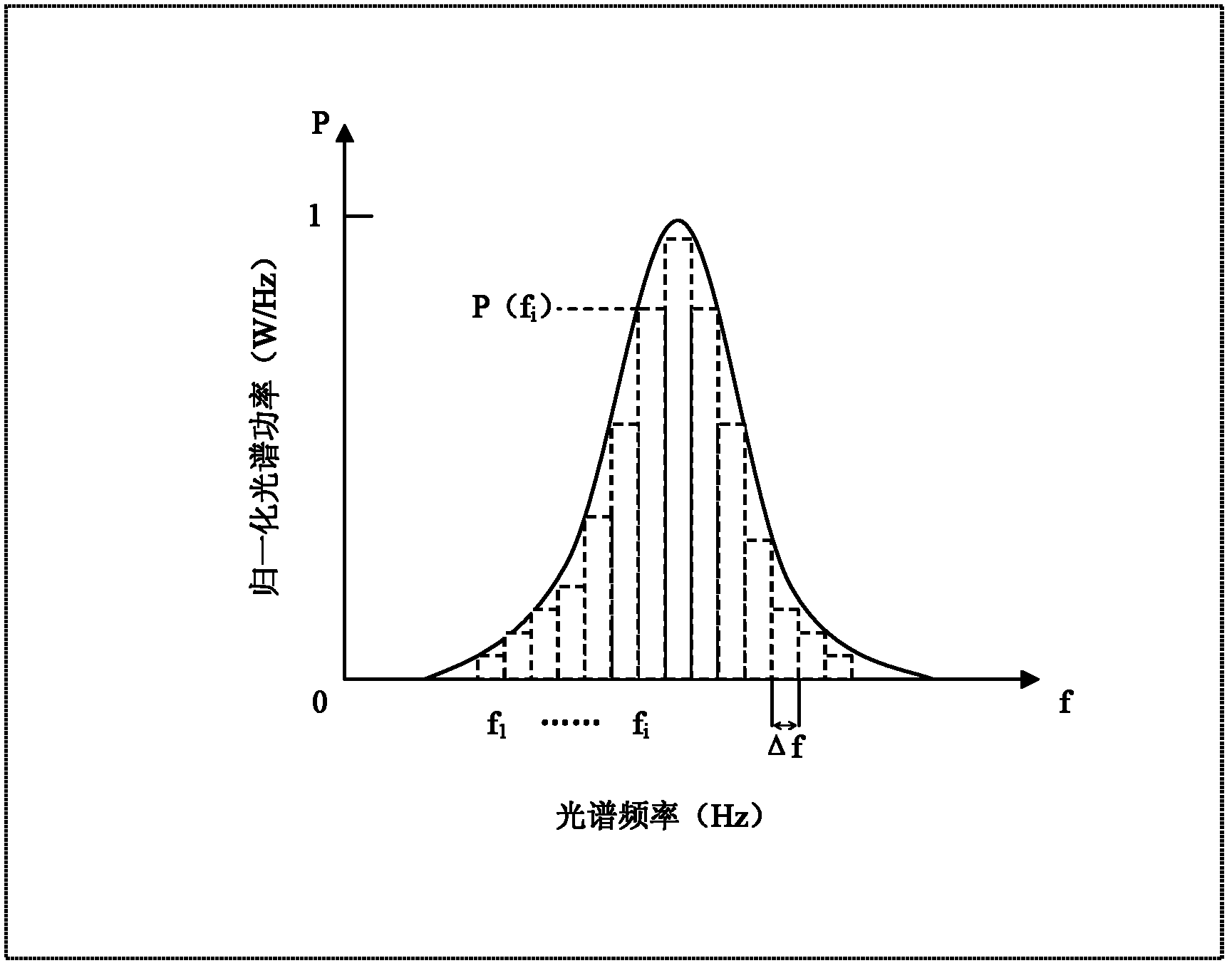

Miniature spectrograph with diffraction hole array structure and high resolution spectrum reconstruction method thereof

InactiveCN102564586AStrong anti-vibration interference abilityImprove performanceRadiation pyrometrySpectrum investigationOptical spectrometerSpectrograph

The invention provides a miniature spectrometer with a diffraction hole array structure and a high resolution spectrum reconstruction method thereof. The diffraction hole array structure miniature spectrometer basically comprises a miniature diffraction hole two-dimensional array, a base, a detecting array chip, a glare shield, and light transmitting holes, wherein the miniature diffraction hole two-dimensional array is constructed on a light blocking layer on the base surface and different in hole size. The base is made of transparent materials. The detecting array chip which corresponds to the base is arranged below the base, and one diffraction hole corresponds to one pixel member of the detecting array chip. The glare shield is arranged between the base and the detecting array chip and covers most area of each charge coupled device (CCD) pixel member. A series of light transmitting holes with the same hole size are arranged on the glare shield, each diffraction hole directly aligns to each light transmitting hole, and each CCD pixel member is below each diffraction hole. Due to the fact that diffraction phenomena occurs after incident light passes through the diffraction holesabove the base, the corresponding CCD pixel members below the diffraction holes can detect a certain diffraction light power. The hole size of each diffraction hole on the array is different, the diffraction light power detected by the corresponding CCD pixel members below is also different, and the spectral information of the incident light can be obtained only by inverting the data detected by each CCD pixel member.

Owner:NANJING FANGYUAN GLOBAL DISPLAY TECH

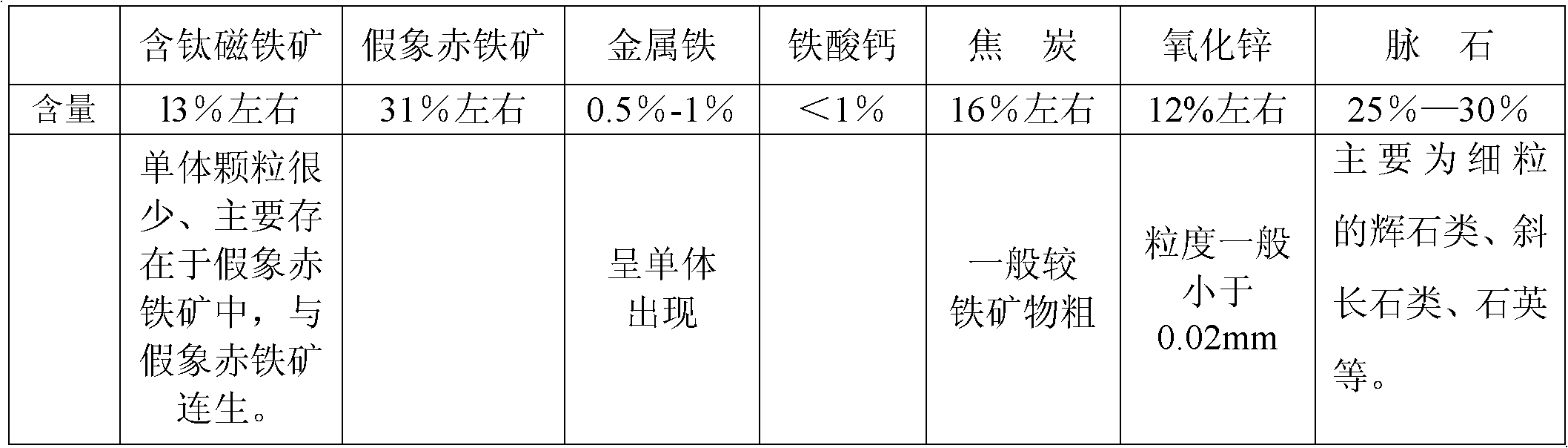

Technological method for extracting zinc by roasting blast furnace gas mud by virtue of rotary kiln

InactiveCN102127645AReduce in quantityReduce mass ratioRotary drum furnacesProcess efficiency improvementSlagZinc

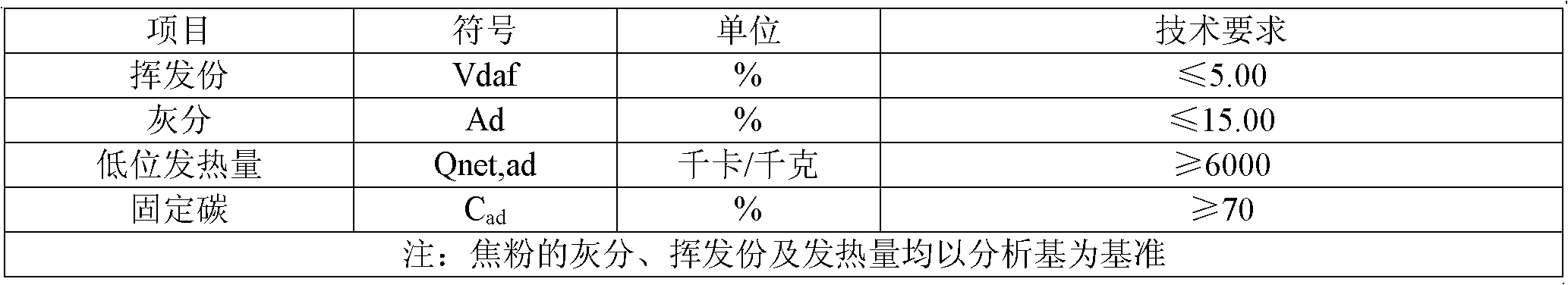

The invention discloses a technological method for extracting zinc, in particular to a technological method for extracting zinc by roasting blast furnace gas mud by virtue of a rotary kiln, belonging to the technical field of metallurgy production. By applying the technological method provided by the invention, zinc oxide in the gas mud can be thoroughly reduced, and the production cost is low. The technological method comprises the following steps of: a) burdening, namely adding coke powder with the mass ratio of 16-20% into the gas mud and mixing to be uniform; b) checking, namely carrying out a sampling test on the calorific value of mixture of the gas mud and the coke powder which are uniformly mixed, wherein the acceptable calorific value is 1600-2000 kcal / kg; c) roasting and reducing, namely directly sending the qualified mixture of the gas mud and the coke powder into a kiln body of the rotary kiln to be roasted and reduced, thus zinc oxide particles and metallized slag are generated; and d) collecting, namely collecting the zinc oxide particles at the tail of the kiln and discharging residual metallized slag from the head of the kiln.

Owner:PANZHIHUA GANGCHENG GROUP

Less slag decarbonization refining method used in top-bottom combined blowing converter

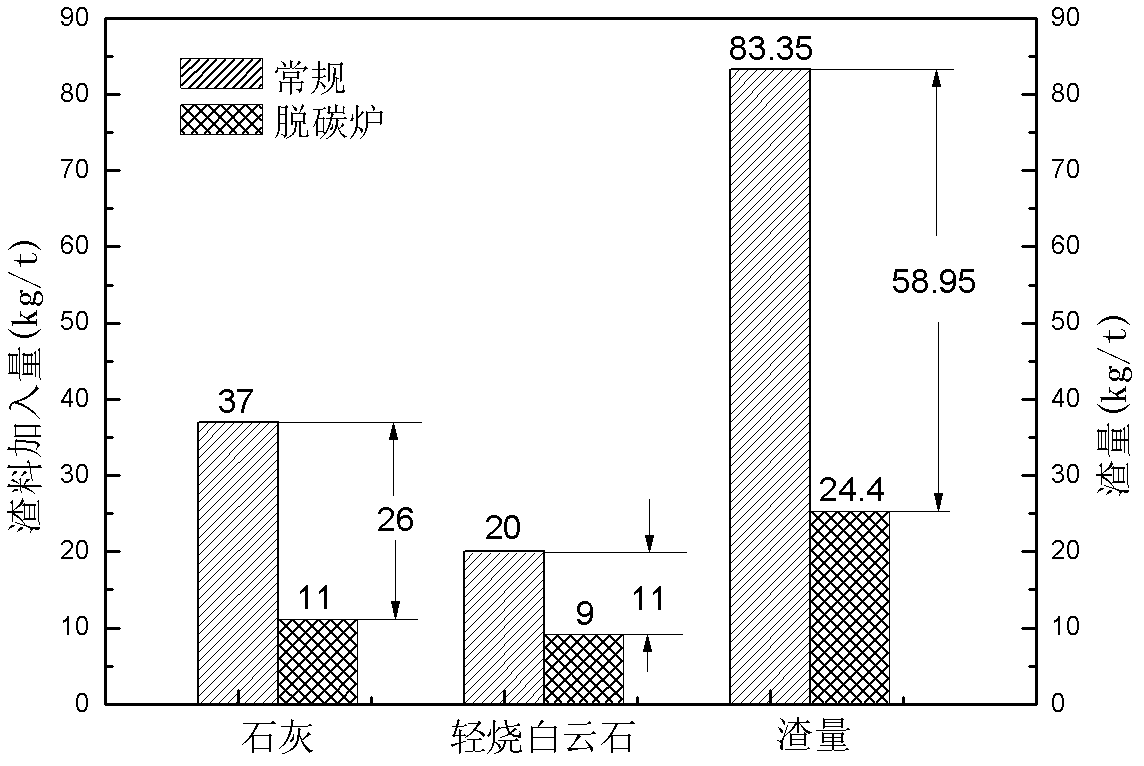

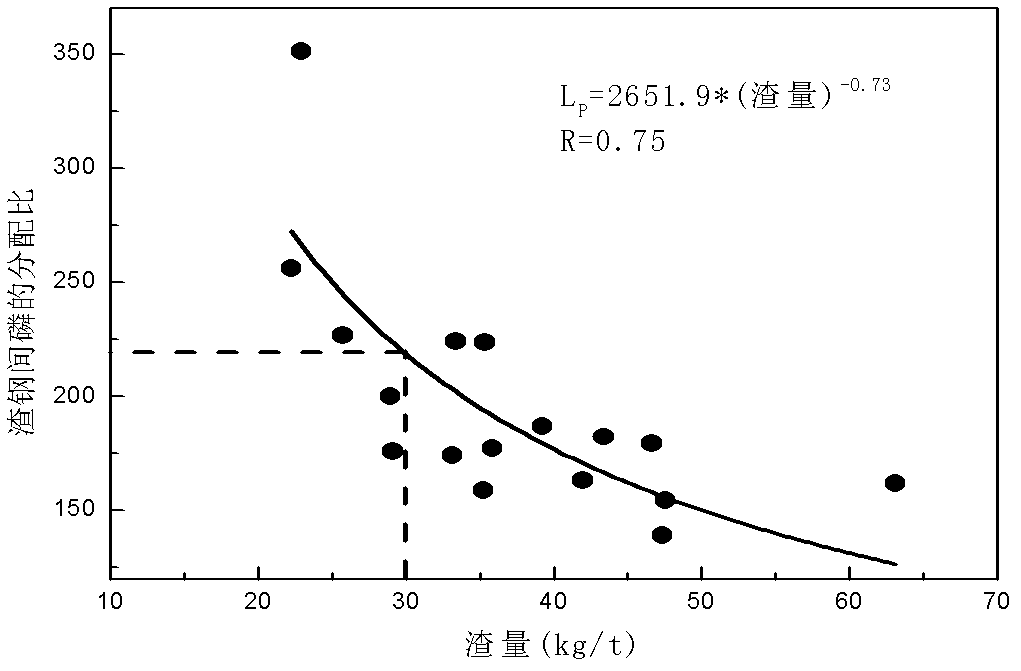

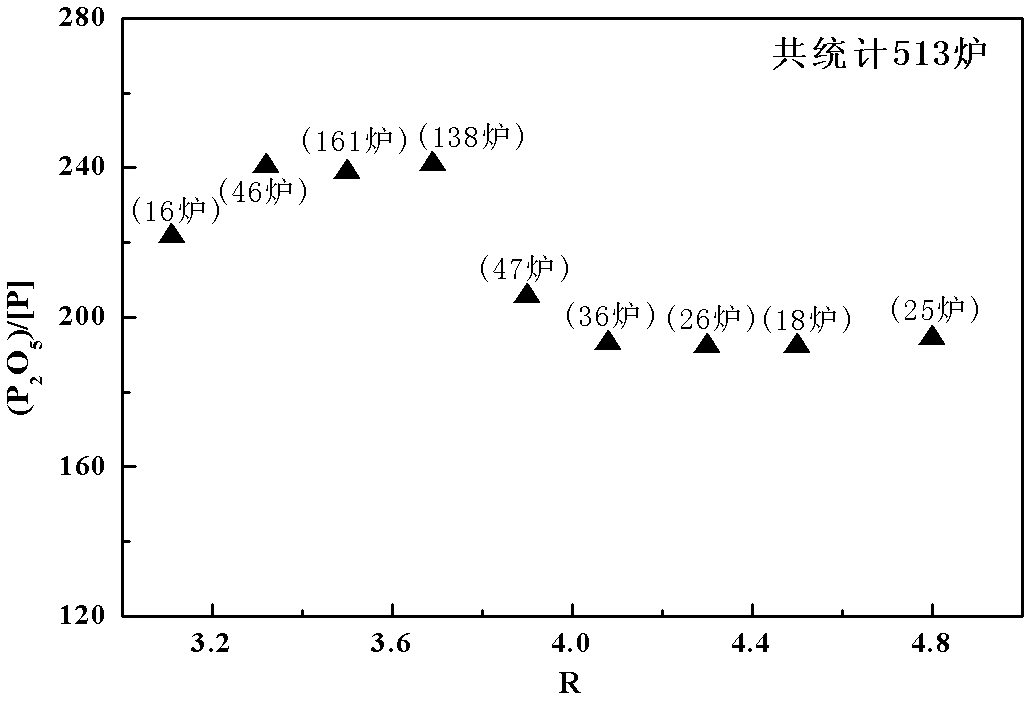

InactiveCN102424885ASolve caloric deficitOxygen supply time shortenedManufacturing convertersAlkalinitySteelmaking

The invention relates to a less slag decarbonization refining method used in a top-bottom combined blowing converter. The invention belongs to the technical field of top-bottom combined blowing converter steelmaking. A steelmaking slag amount is strictly controlled, a slagging technology is modified, high-alkalinity slag with R no less than 3.5 is formed as quickly as possible, technological parameters such as steel carbon content and end point temperature are appropriately controlled, a phosphorus distribution ratio LP among the slag steel is no smaller than 200, a melting pool dephosphorization rate is maintained at a value no less than 80%, such that low-phosphorus steel with [P] no larger than 0.008% is produced. Calculated according to phosphorus balance, when semi-steel [P] is no larger than 0.03%, and end point [P] is no larger than 0.008%, the dephosphorization rate during the steelmaking procedure is no larger than 0.022%, such that the P2O5 amount is 0.5kg / t. If the slag amount is controlled at a value no larger than 30kg / t, the P2O5 content in the slag is no larger than 1.6%. When the phosphorus distribution ratio LP among the slag steel is no smaller than 200, in the steel balanced with slag, [P] is no larger than 0.008%. The method is suitable to be used in decarbonization refining of molten iron pretreated by a three-removing process in the top-bottom combined blowing converter. The method is advantaged in that: through the improvement of the converter availability, an oxygen supplying time is controlled in 11min, a smelting period is no larger than 25min, a daily smelting amount is no less than 40 times / furnace, such that a problem of insufficient decarbonization furnace heat is solved.

Owner:CENT IRON & STEEL RES INST

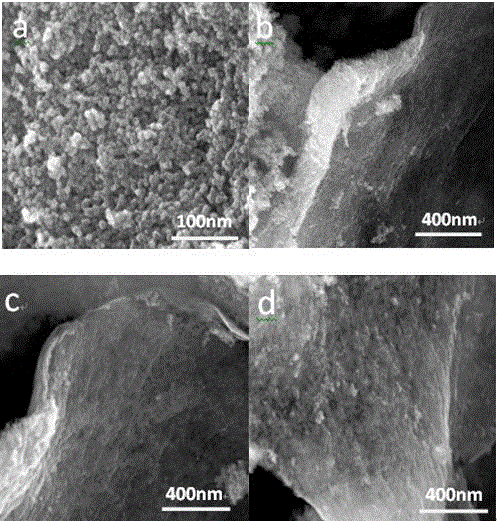

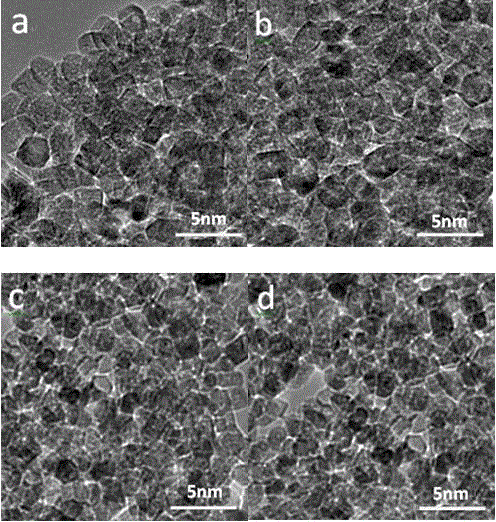

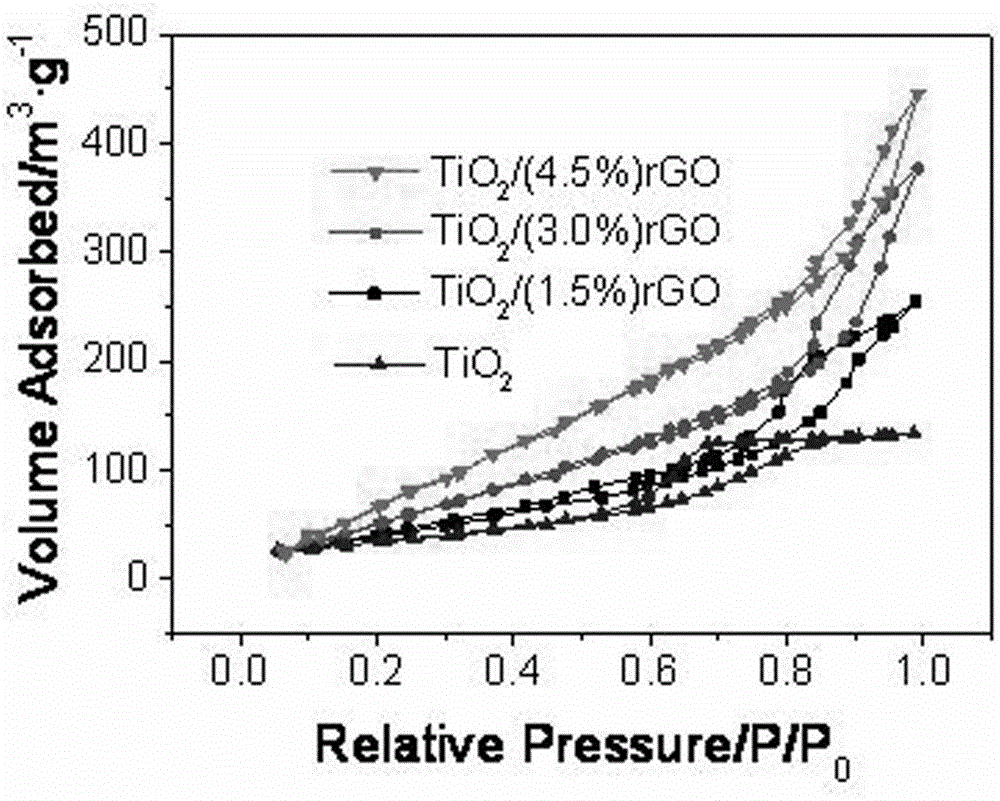

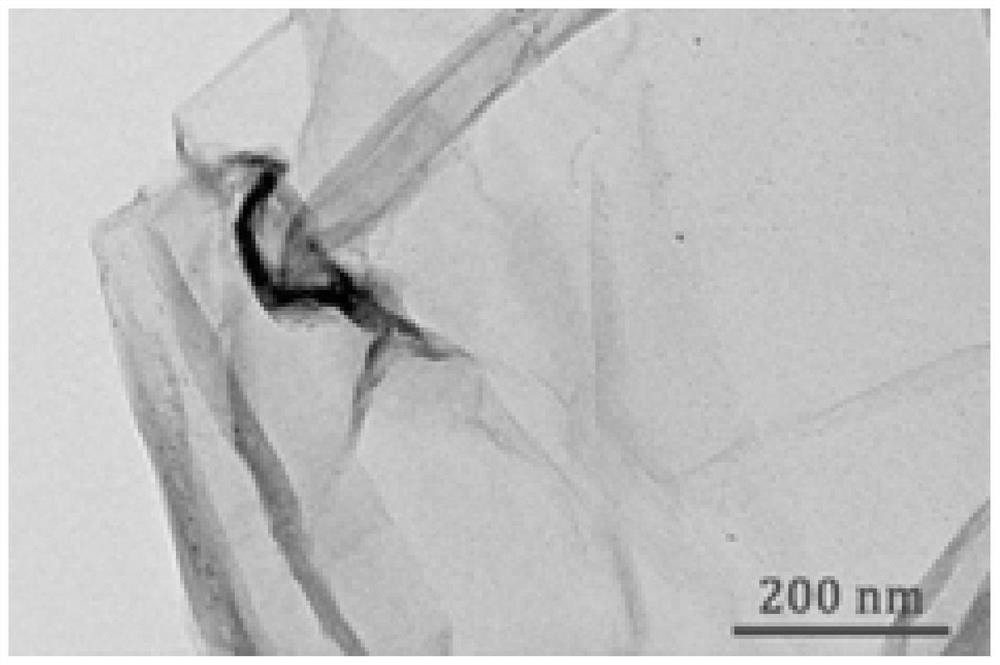

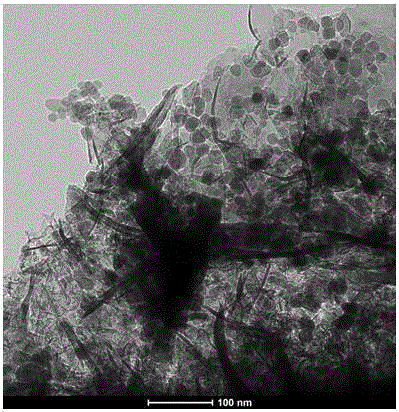

TiO2/rGO composite material having high-efficiency electrocatalytic oxygen reduction performance

InactiveCN104607167AGuaranteed RestoreUniform particlesPhysical/chemical process catalystsCell electrodesHigh selectivityGraphite oxide

The invention relates to a TiO2 / rGO composite material having the high-efficiency electrocatalytic oxygen reduction performance, and belongs to the technical field of an electrocatalytic material. According to the composite material, anatase phase modified nano-TiO2 (N and F are co-doped in nano-TiO2 crystal lattices) is attached onto the surface of reduced graphene oxide, wherein the mole content of the reduced graphene oxide is 1.5-4.5%, and the mole contents of N and F in the modified nano-TiO2 are 1.07-1.19% and 0.95-1.04% respectively. Compared with simple modified nano-TiO2, the composite material has the high electrocatalytic oxygen reduction performance in an oxygen-saturated 0.1M KOH solution, the onset oxidation potential is about -0.2V, and the maximum oxygen reduction current can reach 10<-5>mA.cm<-2>. Besides, the composite material has the advantages of stable electrocatalytic oxygen reduction performance and high selectivity.

Owner:UNIV OF JINAN

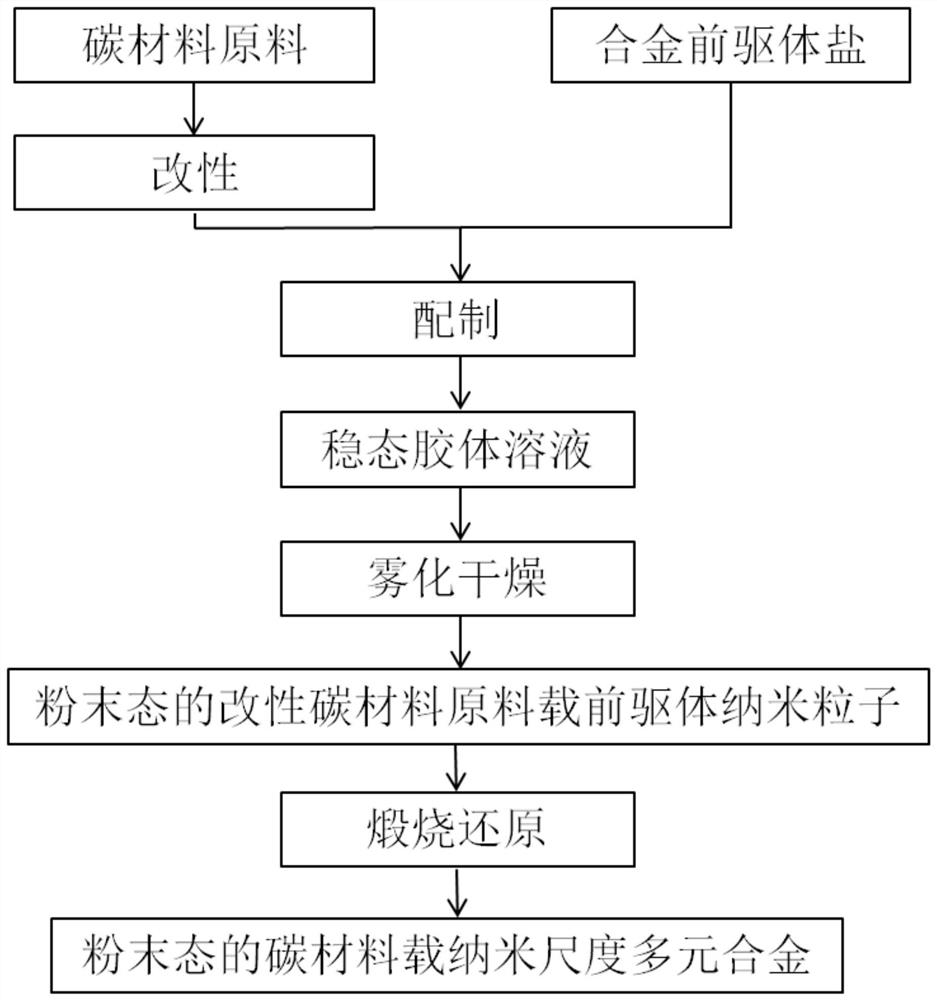

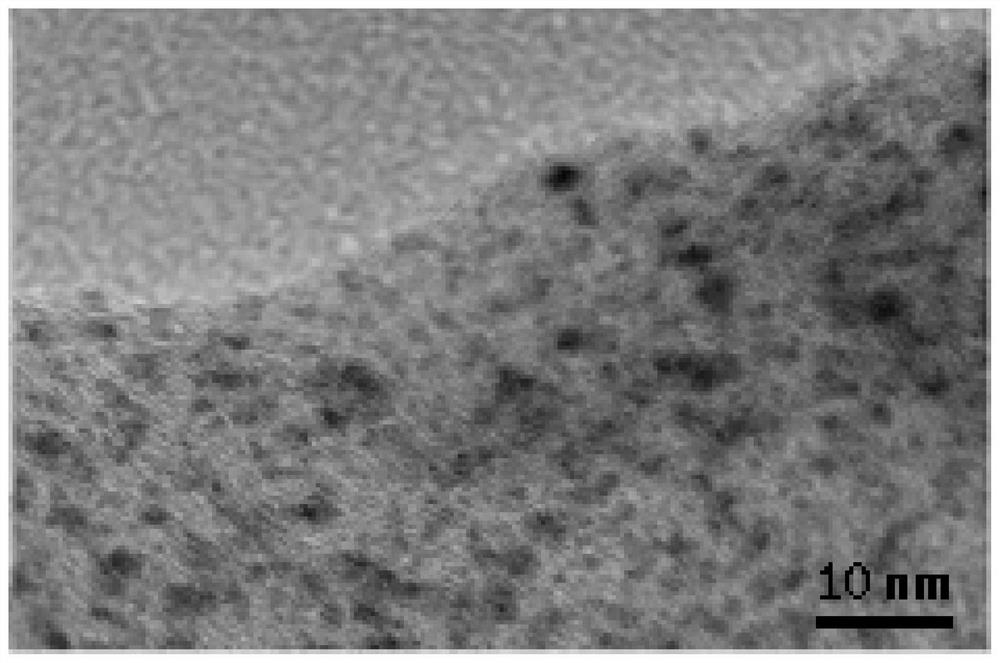

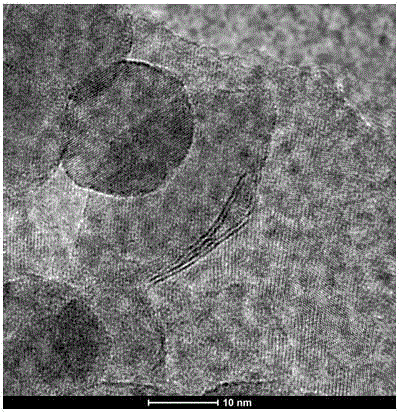

Preparation method of carbon material loaded nano-scale multi-component alloy

InactiveCN112077331AImprove hydrophilicityHigh specific surface areaMaterial nanotechnologyCarbon fibresModified carbonAlloy

The invention discloses a preparation method of a carbon material loaded nano-scale multi-component alloy. The method comprises the following steps that firstly, a carbon material raw material is modified and prepared with alloy precursor salt to obtain a steady-state colloid solution; secondly, the steady-state colloid solution is atomized and dried to obtain modified carbon material raw materialloaded precursor nano-particles; and thirdly, the modified carbon material raw material loaded precursor nano-particles are calcined and reduced to obtain the powder-state carbon material loaded nano-scale multi-component alloy. According to the method, the modified carbon material raw material is prepared with the alloy precursor salt, the mixture is atomized and dried, thus the alloy precursorsalt forms nano-particles to be uniformly loaded on the surface of the carbon material raw material, then calcining and reducing are carried out, the carbon material loaded nano-scale multi-componentalloy is obtained, the nano-scale multi-component alloy is uniformly dispersed on the surface of a carbon material, a single-phase structure or a multi-phase structure is formed, and the alloy has theadvantages of being large in specific surface area, multiple in metal active site and stable in phase structure, and has an excellent application potential in the field of catalytic materials.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

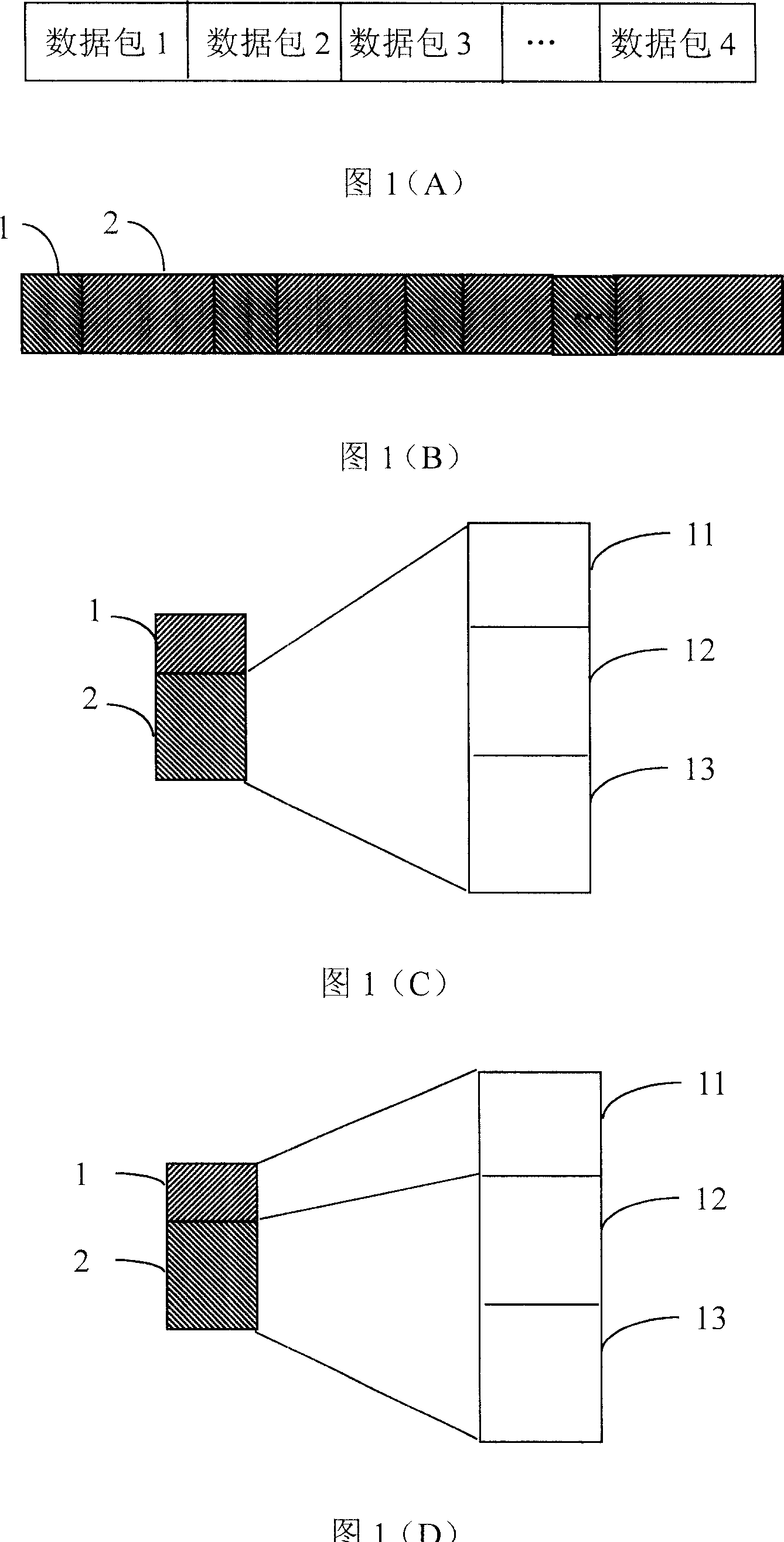

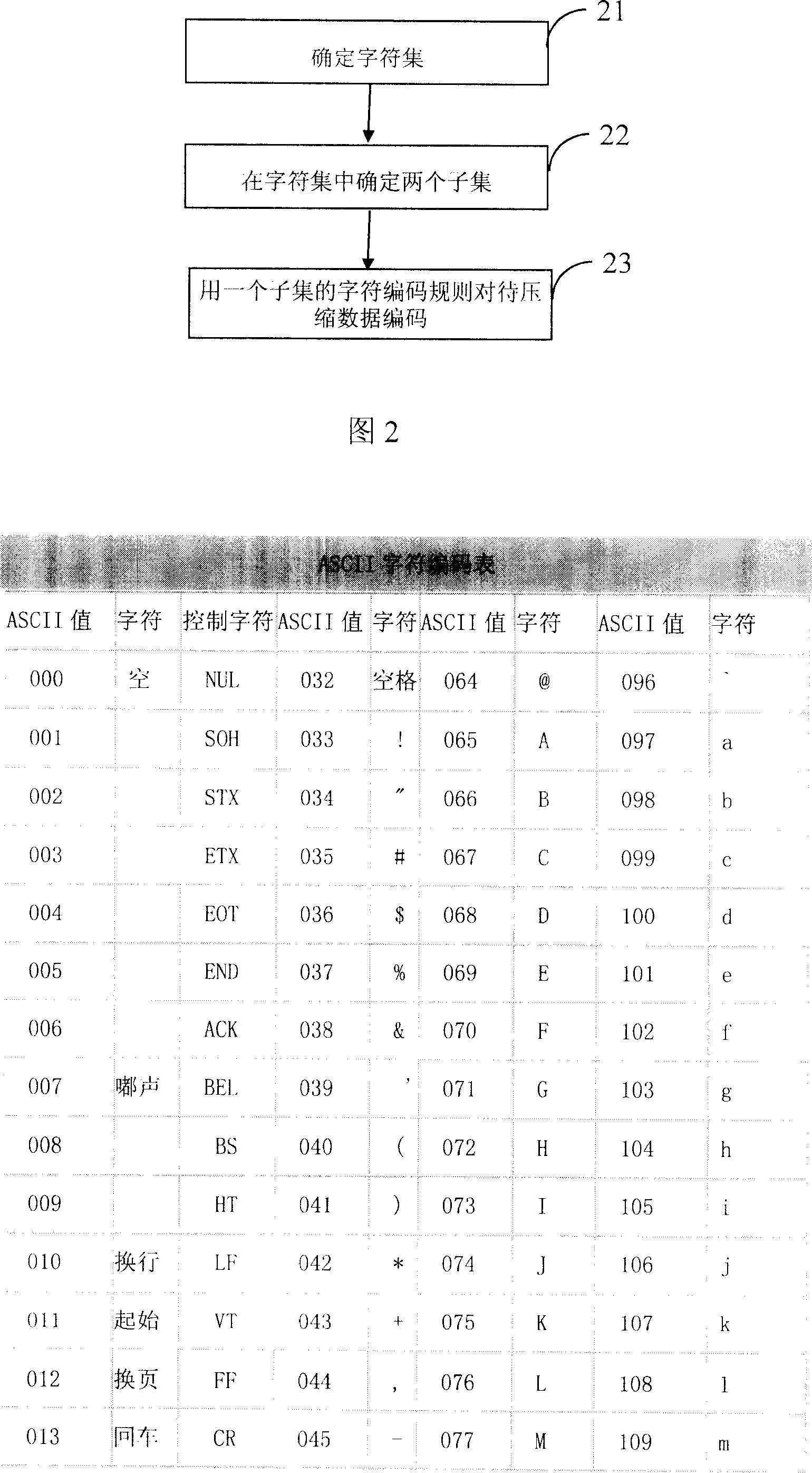

Method for preprocessing data to be compressed and compressed data transmission method

InactiveCN1937582AGuaranteed recoveryGuaranteed RestoreError preventionCode conversionPretreatment methodAlgorithm

The invention discloses a method for preprocessing to-be-compressed data, comprising: selecting a character set having at least two character subsets with different codes; using character coding rules of the first character subset to code binary stream of the to-be-compressed data and convert the binary stream into character stream, where the characters in the character stream are ones in the first character subset. And it can assure the control data and actual data sent to the receiving end are clearly differentiated, thus assuring the decoded control data decompresses the actual data, effectively recovering or reducing the actual data. And it also discloses a method for transmitting the compressed data produced by the preprocessing method above.

Owner:白杰 +2

Aluminothermy self-propagating gradient reduction and slag-washing and refining-based method for preparing ferrotungsten

The invention provides an aluminothermy self-propagating gradient reduction and slag-washing and refining-based method for preparing ferrotungsten. The method comprises: (1) aluminothermy self-propagating gradient reduction: first manner, dividing raw materials into a plurality of batches, putting the first batch of materials into a reaction furnace, igniting the materials from the top with magnesium powder to trigger a self-propagating reaction, and adding other batches of materials in succession till the reaction is complete; second manner, uniformly mixing the raw materials expect for aluminum powder, adding into a continuous blender mixer at a uniform flow rate, meanwhile adding the aluminum powder into the continuous blender mixer at a flow rate with a progressively decreased gradient, and simultaneously introducing the uniformly mixed raw materials into the reaction furnace for aluminothermy self-propagating reaction till all materials are totally reacted; (2) performing heat preservation and melting to obtain upper layer aluminum oxide base molten slag and lower alloy melt; (3) jetting refined slag in the lower alloy melt for stirring, slag-wash and refining; and (4) cooling the refined high temperature melt to room temperature to remove the upper layer molten slag to obtain the ferrotungsten.

Owner:NORTHEASTERN UNIV

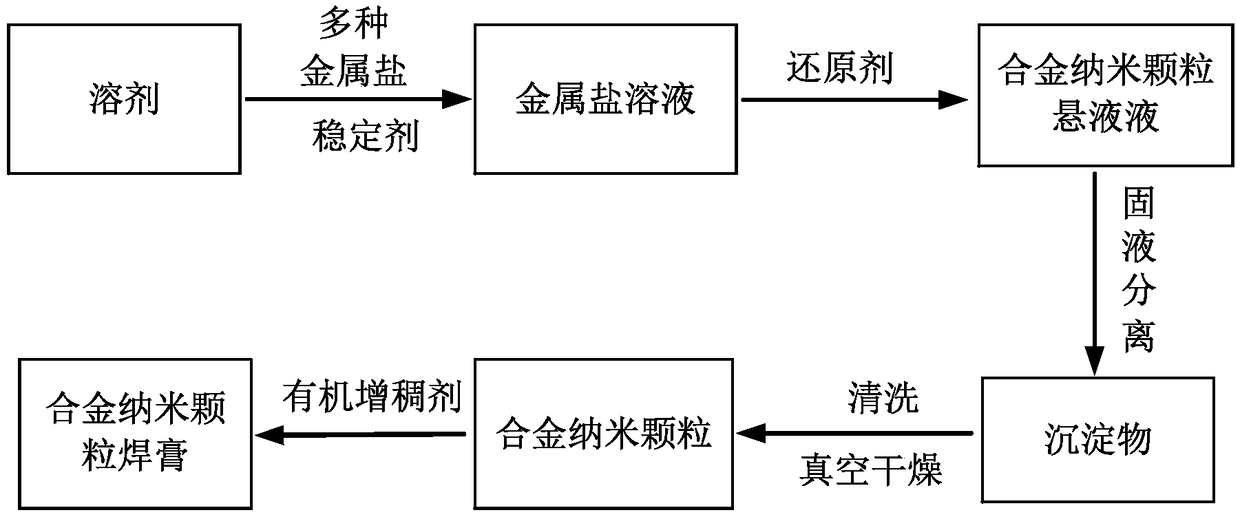

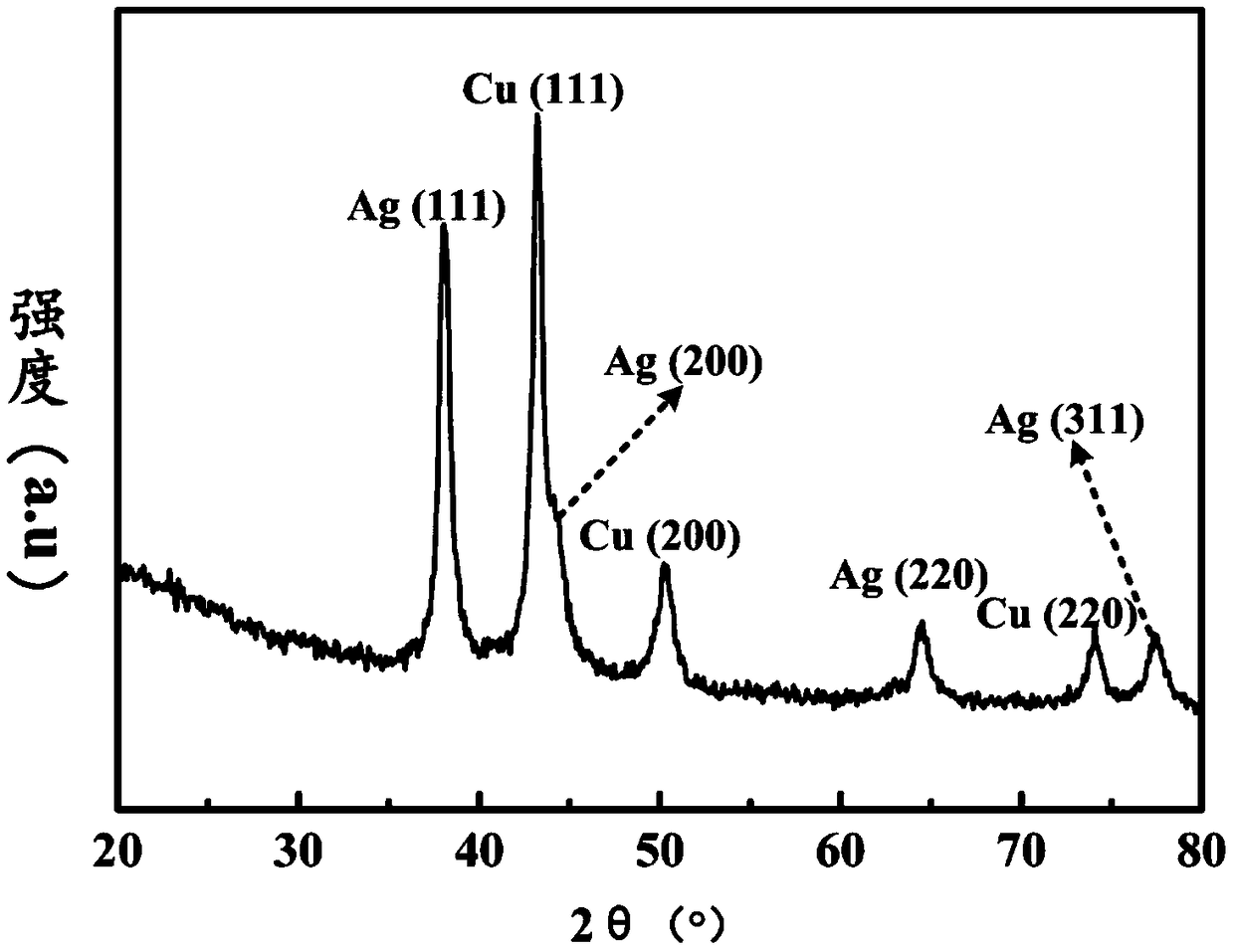

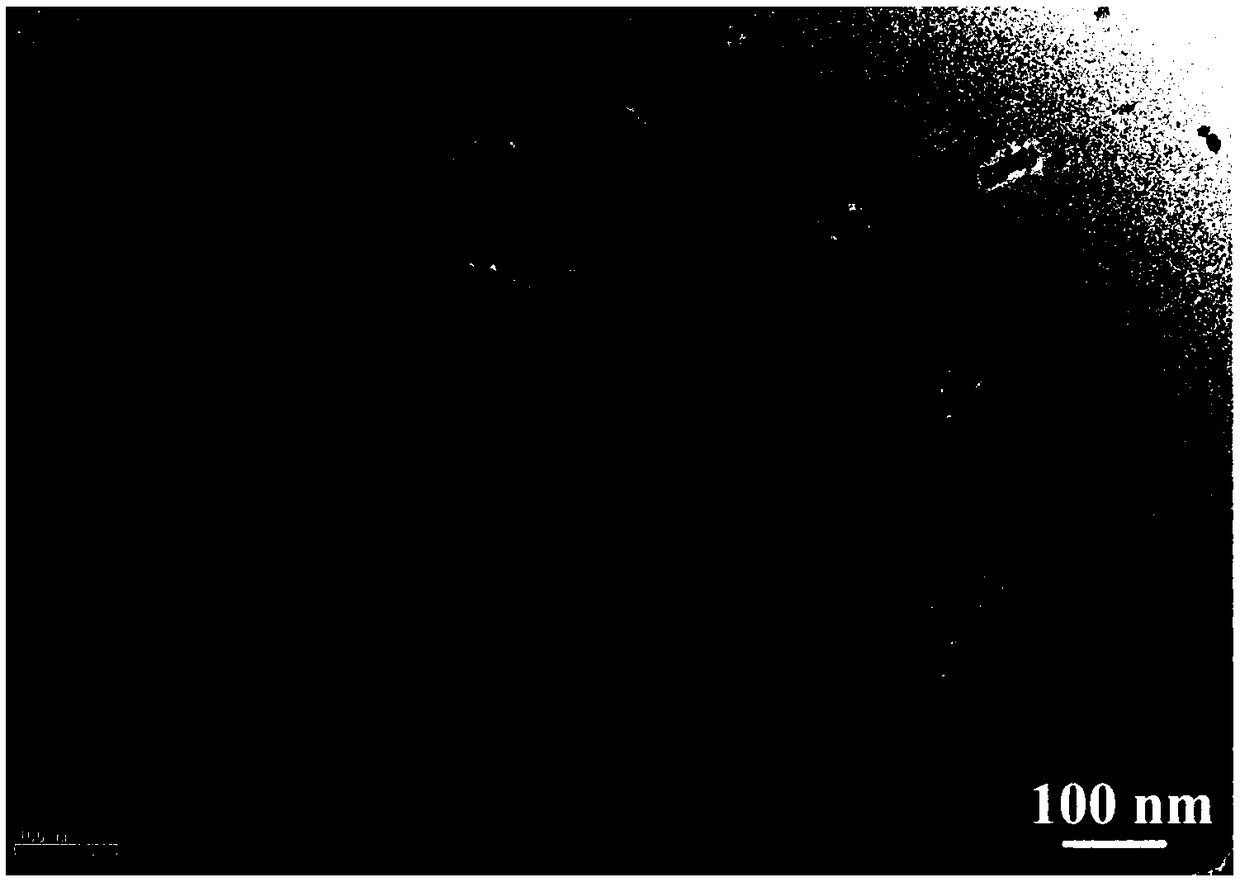

Alloy nanometer particle soldering paste and preparation method thereof

InactiveCN109352206ASimple processProcess parameters are easy to controlWelding/cutting media/materialsSoldering mediaAlloyCleansing Agents

The invention belongs to the field of nanometer technology and microelectronic packaging and discloses alloy nanometer particle soldering paste and a preparation method thereof. The method includes the specific steps that metal salt and a stabilizing agent are completely dissolved in a solvent to prepare a metal salt solution, a reducing agent is added in the metal salt solution and is stirred, and is enabled to perform a full reaction, and an alloy nanometer particle suspension is acquired; the alloy nanometer particle suspension is subjected to solid-liquid separation, precipitate is obtained, the precipitate is washed with a washing agent, and then drying is performed so that alloy nanometer particles can be obtained; and the alloy nanometer particles are added into an organic thickening agent, and after vacuum stirring and bubble removing treating, the alloy nanometer particle soldering paste is made. According to the alloy nanometer particle soldering paste and the preparation method thereof, the alloy nanometer particles are prepared by adopting a liquid phase reducing method, the process is simple, control is easy, and cost is low; and the stabilizing agent is added in whilethe metal salt solution is prepared, agglomeration and oxidization of the particles can be effectively avoided, and the oxidization resistance of the alloy nanometer particles is enhanced.

Owner:HUAZHONG UNIV OF SCI & TECH

Database backup verification method and device

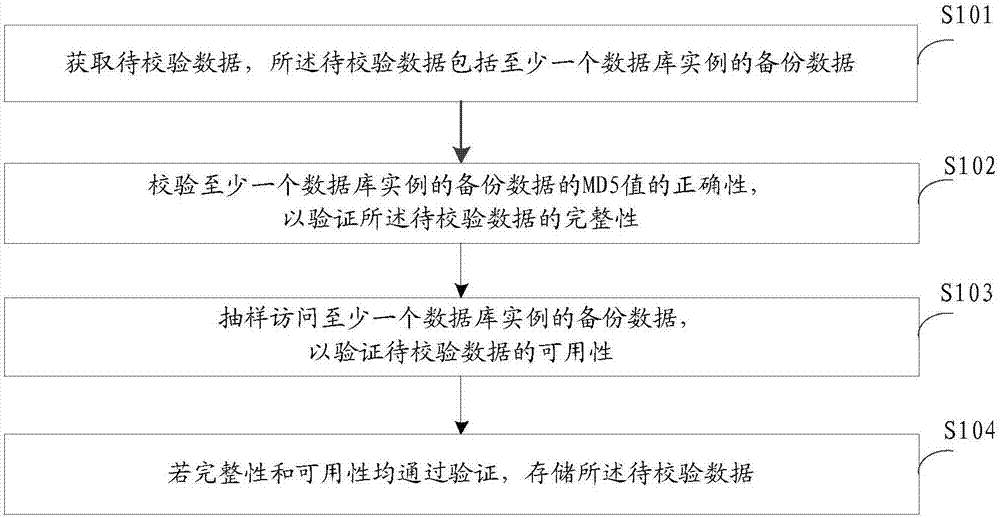

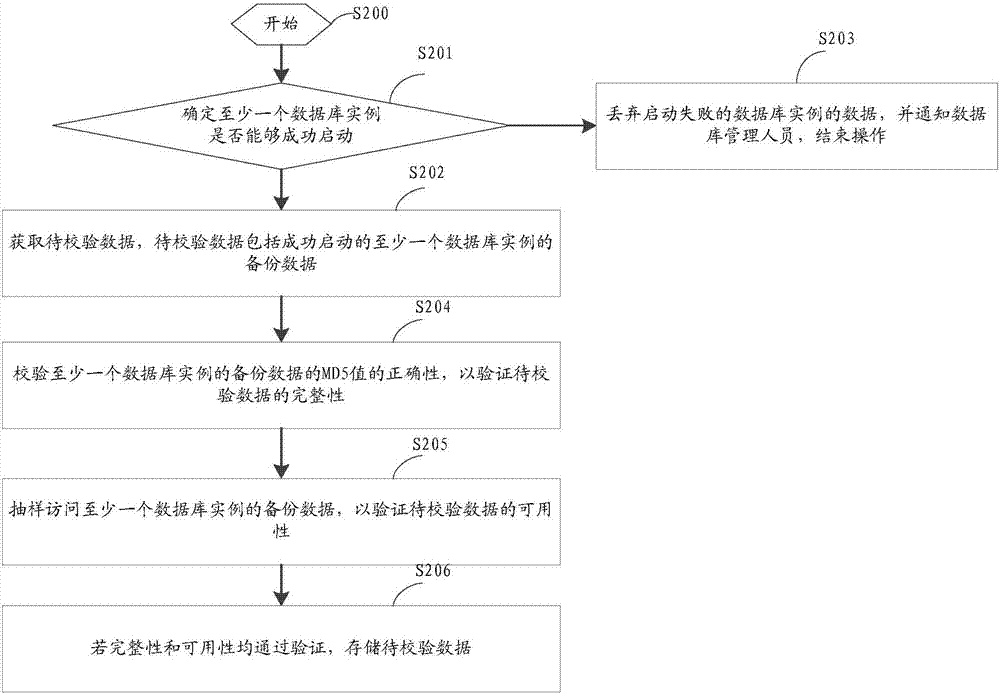

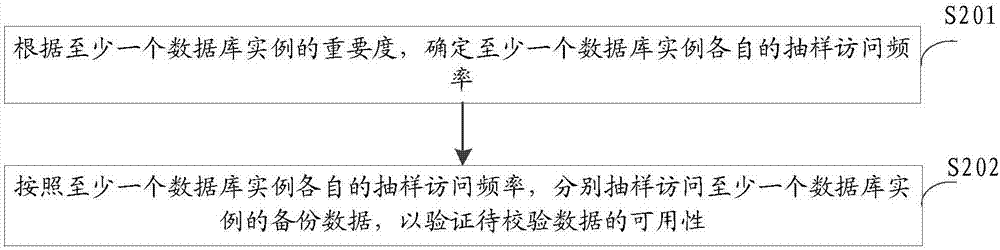

ActiveCN107193683AVerify availabilityAccurate and effectiveRedundant data error correctionRedundant operation error correctionDatabase backupOriginal data

Embodiments of the invention provide a database backup verification method and device. The method comprises the following steps of: obtaining to-be-verified data, wherein the to-be-verified data comprises backup data of at least one database instance; verifying the correctness of MD5 values of backup data of the at least one database instance so as to verify the integrity of the to-be-verified data; sampling and accessing the backup data of the at least one database instance so as to verify the availability of the to-be-verified data; and if both the integrity and availability pass, storing the to-be-verified data. According to the method and device provided by the embodiments of the invention, the effectiveness of the backup data can be verified so as to ensure that original data can be restored through the backup data.

Owner:北京龙之心科技有限公司

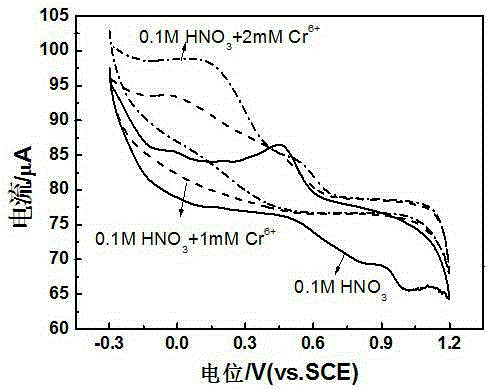

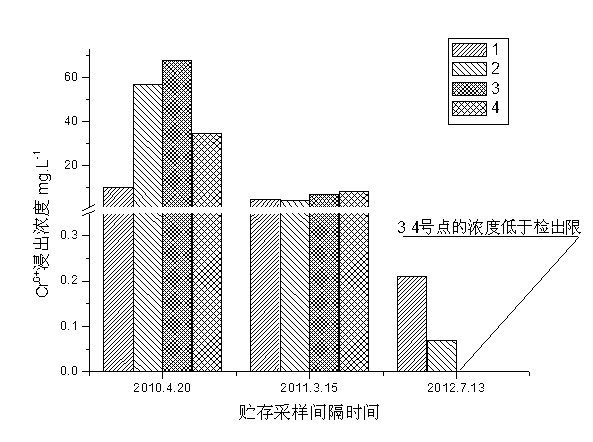

Preparing method of molybdenum sulfide compound and application of molybdenum sulfide compound in detecting hexavalent chromium in water

ActiveCN105259243ALarge specific surface areaImprove catalytic performanceMaterial electrochemical variablesIonSal ammoniac

The invention relates to a preparing method of a molybdenum sulfide compound and application of the molybdenum sulfide compound in detecting hexavalent chromium in water, and belongs to the technical field of detection of water environments. In the nitrogen atmosphere, ferric chloride hexahydrate and iron dichloride tetrahydrate are dissolved in deionized water and heated with the temperature maintained for 5-10 minutes, then ammonium hydroxide is used for adjusting the pH of the mixed system to 7.5-8.5, then aging and magnetic separation are carried out, and the solid phase is taken and washed with deionized water, dried and ground to obtain ferroferric oxide powder; deionized water containing the ferroferric oxide powder is mixed with a dihydrated molybdenum sulfate and thiourea solution for a reaction; reaction products are taken, washed with ethyl alcohol and deionized water and then dried, and the molybdenum sulfide compound carried by ferromagnetic ferroferric oxide particles is obtained. A detection method is low in cost, simple, reliable and high in sensitivity, and the specific content of hexavalent chromium with the hexavalent chromium ion concentration within the range of 0.5-328 micro mol.dm-3 can be accurately detected.

Owner:YANGZHOU UNIV

Production method of instant fruit and vegetable shortcakes

The invention provides a production method of instant fruit and vegetable shortcakes. The method comprises the following steps: pre-processing vegetable and fruits, respectively crushing and pulping, mixing the above obtained fruit pulp with the above obtained vegetable pulp, adding inulin, natural fructose syrup, white granulated sugar and a natural lemon juice, blending, homogenizing to obtain a mixture, pouring the mixture into a die supporting box, and carrying out vacuum freeze drying to obtain the instant fruit and vegetable shortcakes. The fruit and vegetable pulps and other raw materials are mixed according to a specific ratio and undergo vacuum freeze drying to make the fruits and vegetables form a novel and instant fruit and vegetable shortcake food, so the kind of the fruit and vegetable products in the market is enriched. The fruit and vegetable shortcakes made through the production method maximally reserve nutritional components in the fruits and vegetables without loss of the nutritional components or destroys of the color or the taste, and solve the problem of flavor change of the fruit and vegetable fruits, induced by present production technologies; and the fruit and vegetable shortcakes produced through the method also have the advantages of low water content, light weight, easy storage, and convenient transportation and carrying.

Owner:四川江茂食品有限公司

Method for preparing titanium alloys based on aluminum heat self-propagating gradient reduction and slag wash refining

ActiveCN107151752AShort processReduce energy consumptionProcess efficiency improvementTitanium alloyRutile

The invention discloses a method for preparing titanium alloys based on aluminum heat self-propagating gradient reduction and slag wash refining, and belongs to the technical field of titanium-aluminum alloys. The method comprises the following steps: after raw materials are pretreated, the raw materials are weighed according to a mass ratio of rutile or high titanium slag or titanium dioxide to aluminum powder to V2O5 powder to CaO to KClO3 of 1.0: (0.60-0.24): (0.042-0.048): (0.12-0.26): (0.22-0.30); the aluminum heat self-propagating reaction is performed by adopting a gradient heating mode to obtain high-temperature melts; the gradient reduction smelting is performed; the insulation melt separation is performed after charging; then, CaF2-CaO-TiO2-V2O5 base refining slag is added in the high-temperature melts for slag wash refining; and finally, the slag is removed to obtain the titanium alloys. The method has such advantages as short flow, low energy consumption, simple operation and easy control of Al and V contents in the alloys.

Owner:NORTHEASTERN UNIV LIAONING

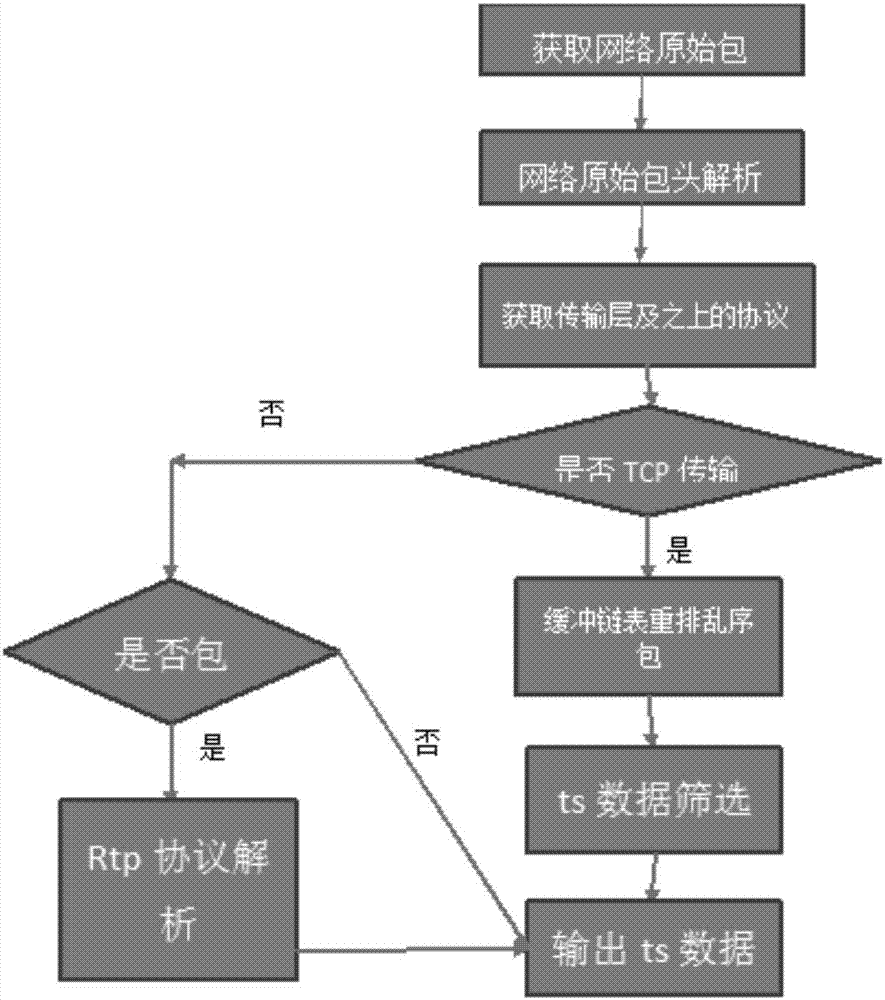

Method and system for intelligently acquiring video data in network

InactiveCN107395639ASolve the problem of crawling causing greater difficultyReduce overheadData switching networksTransmission protocolTransmission time delay

The invention provides a method and system for intelligently acquiring video data in a network. Data from an MAC address layer to a final protocol layer is obtained through network sniffing, an IP packet header is removed, each layer of message is analyzed, whether a transmission protocol is a TCP or a UDP is judged, the messages are processed respectively, and video data screening is carried out through an algorithm. By means of the method and system, signaling layer data and application layer data of each OTT application can be synchronously captured, and the problem that due to anomaly and ageing of transmission environments or network firmware, complex factors such as long transmission time delay, disordered packets and repeated packets appear, and accordingly the video data is difficult to capture is solved.

Owner:天津艾科仪科技有限公司

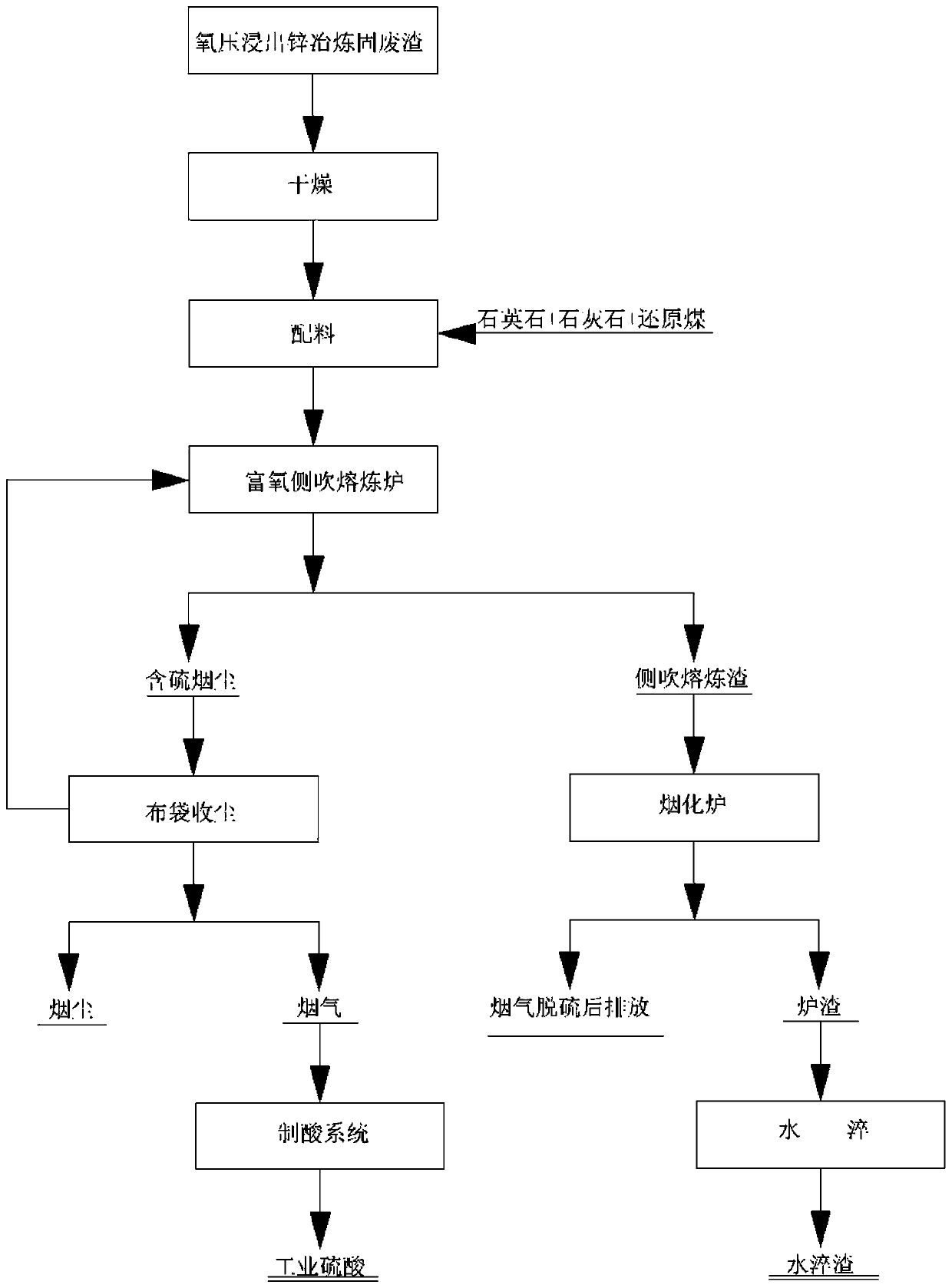

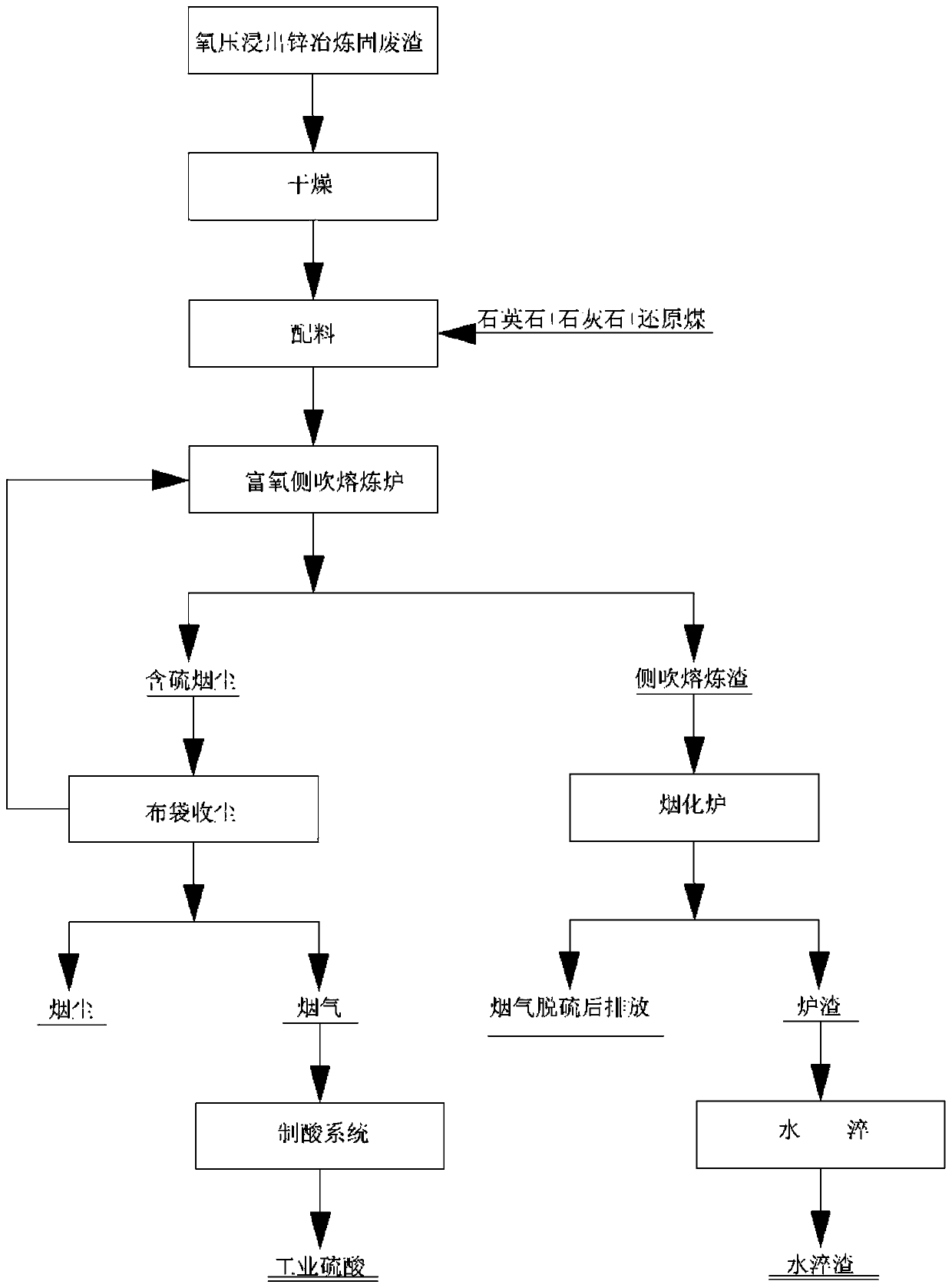

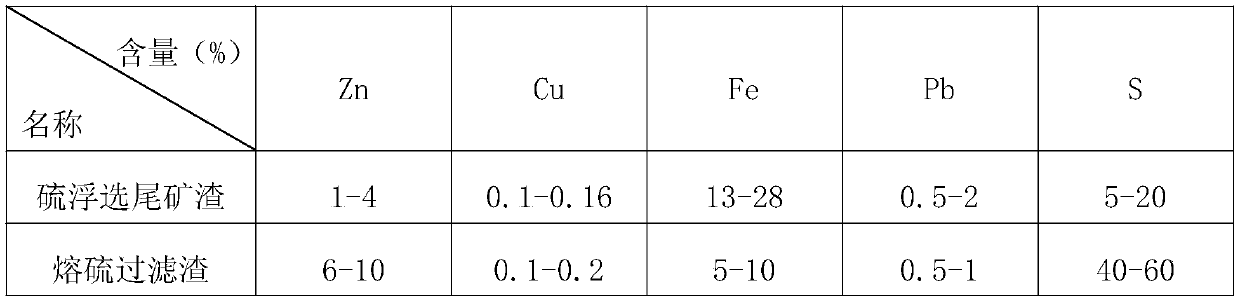

Method for preparing secondary zinc oxide from oxygen pressure leached zinc smelting solid waste residues

InactiveCN111118303ASolve problems such as intractableReduce energy consumptionProcess efficiency improvementIndiumChemical reaction

The invention discloses a method for preparing secondary zinc oxide from oxygen pressure leached zinc smelting solid waste residues. The method comprises the following steps that oxygen pressure leached zinc smelting solid waste residues are dried until the water content is 15% or below, and the solid waste residues are granulated by using a granulator; the solid waste residues are mixed with limestone, quartz stone and reducing coal, and are sent to an oxygen-enriched side-blown furnace; oxygen-enriched air is blown into a furnace during smelting, and chemical reactions such as sulfur makingand slagging are completed; sulfur in the slag generates SO2, and the SO2 enters an acid making system through a flue gas pipeline to produce industrial sulfuric acid; the molten slag is blown by a fuming furnace, secondary zinc oxide products are produced from smoke dust, and the fuming furnace slag is subjected to innocent treatment. According to the method, the problems that the smelting solidwaste produced in the zinc-oxygen pressure leaching process is difficult to stack and transport, valuable metal in the leaching residues cannot be recycled and the like are solved, and harmless treatment of the zinc-oxygen pressure leaching smelting solid waste is achieved. The method has the advantages that valuable metals such as lead, zinc, indium, germanium and silver can be recovered, industrial-grade secondary zinc oxide products can be prepared, the technological process is simple, the recovery rate of the valuable metals is high, and the energy consumption is low.

Owner:WESTERN MINING CO LTD +3

Method for refining ferro-titanium on basis of aluminothermy self-propagating gradient reduction and wash heat

The invention provides a method for refining ferro-titanium on basis of aluminothermy self-propagating gradient reduction and wash heat. The method comprises the steps that firstly, aluminothermy self-propagating gradient reduction is carried out, wherein according to the first manner, raw materials are divided into multiple batches, the materials in the first batch are put into a reaction furnace, magnesium powder is ignited from the top of a material so as to trigger the self-propagating reaction, and materials in other batches are added successively until the reaction is finished; according to the second manner, raw materials except for the aluminum powder are evenly mixed and are added into a continuous mixing machine with the uniform flow speed, meanwhile, the aluminum powder is added into the continuous mixing machine with the gradient progressively-decreasing flow sped, and the evenly-mixed raw materials are continuously introduced into a reaction furnace at the same time to be subject to the aluminothermy self-propagating gradient reduction until all the materials are subject to complete reaction; secondly, heat preservation smelting is carried out to obtain upper layer alumina-base slag and lower layer alloy melt; thirdly, refining slag is sprayed and blown into the lower layer alloy melt for stirring, slag washing and refining; fourthly, the high-temperature melt obtained after refining is cooled to the room temperature, and upper layer melting slag is removed so as to obtain the ferro-titanium.

Owner:NORTHEASTERN UNIV

Method of smelting high-strength welding wire steel ER80-G from vanadium-containing molten iron

ActiveCN108588326AHigh yieldEfficient removalManufacturing convertersProcess efficiency improvementFerrosiliconSemi-steel

The invention discloses a method of smelting high-strength welding wire steel ER80-G from vanadium-containing molten iron, which includes the steps of: loading the vanadium-containing molten iron in avanadium extract converter for dephosphorization; after tapping is finished, adding hot-state steel ladle casting residue to a semi-steel ladle by 10-20 kg per ton of steel; loading dephosphorized semi-steel into a smelting converter, adding thread cut head or casting blank cut head waste steel, performing dual-slag operation in the converter to perform smelting, and performing refining in an LFrefining furnace; after the treatment, hoisting the steel to a continuous casting step, wherein the casting operation is protected during the whole course of the continuous casting. In the invention,the vanadium-containing molten iron is subjected to the double-dephosphorization, wherein the content of phosphorus in steel is effectively reduced by means of the dual-slag method; by using a non-aluminum-based deoxidant, generation of Al2O3 impurity in the steel is reduced. A mixture of aluminum powder and ferrosilicon powder is added during the refining heating process in several batches at small batch size, so that sulfur content of the steel is effectively reduced and impurities are removed. The method supplies a strong guarantee to cleanness of molten steel and castability of the continuous casting, and finally achieves the object of smelting the high-strength welding wire steel ER80-G from vanadium-containing molten iron.

Owner:HEBEI IRON AND STEEL

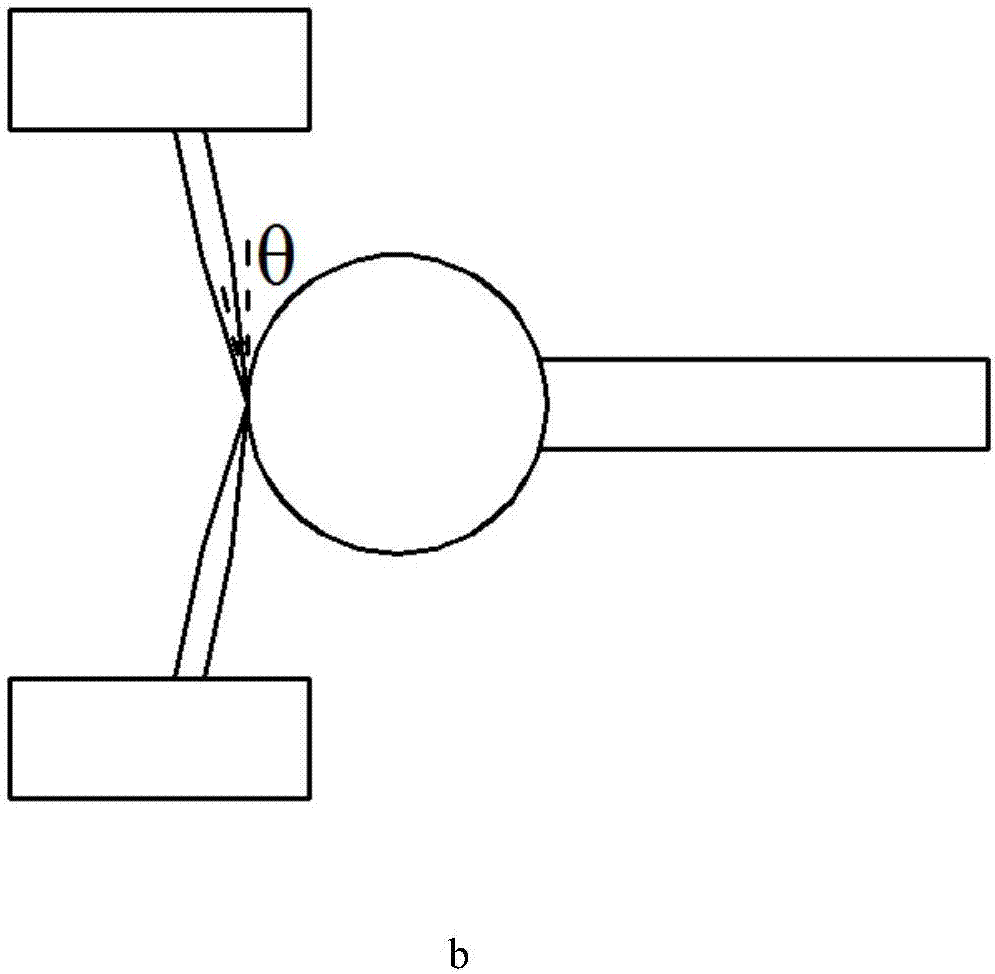

Method for high-precision measurement of sphericity of micro-spherical probe of nanometer three-coordinate measuring machine

InactiveCN107218879AEliminate radial errorsRealize high-precision measurementElectric/magnetic contours/curvatures measurementsPoint coordinate measurementsMicrosphereSpherical probe

The invention discloses a method for high-precision measurement of the sphericity of the micro-spherical probe of a nanometer three-coordinate measuring machine. A tungsten probe with large length-to-diameter ratio and a quartz tuning fork are combined. Scanning probe heads with nanometer-level resolution are constructed based on a precision micro stage. During measurement, the two scanning probe heads are driven by the micro stage to scan the large-section contour of a microsphere in the x-axis direction in a differential manner. Radial error generated in the scanning process can be automatically eliminated in a differential manner, and thus, accurate parameters of the large-section contour of the microsphere can be obtained. After the microsphere is rotated a certain angle, the measurement is repeated to acquire multiple sets of parameters of the large-section contour. A three-dimensional spatial contour of the microsphere is constructed through fitting according to feature points obtained. The geometric parameters of the microsphere are calculated based on the three-dimensional spatial contour. Thus, high-precision measurement of the sphericity of the microsphere is realized. The method has the characteristics of small measuring force, wide measuring range, and high measuring precision.

Owner:HEFEI UNIV OF TECH

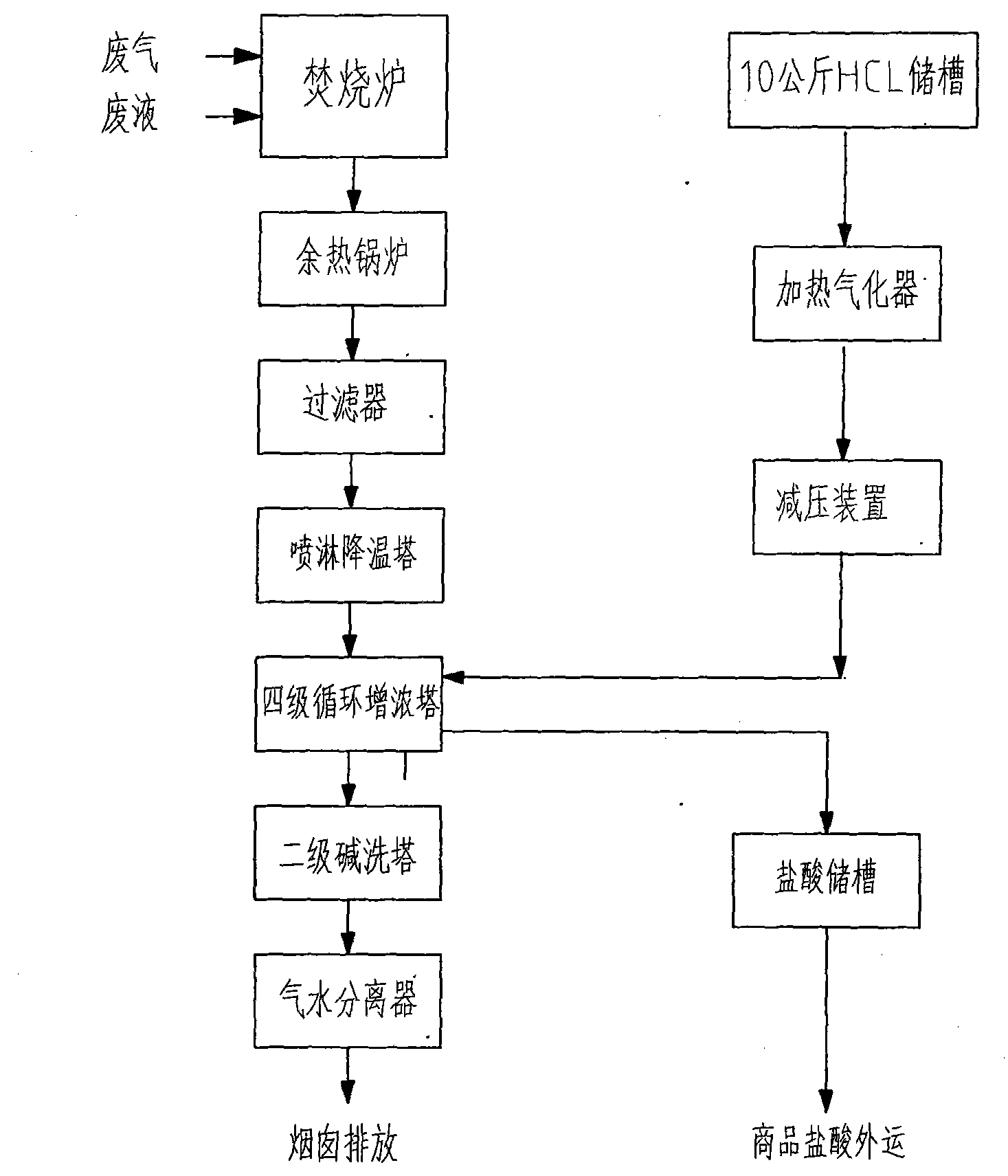

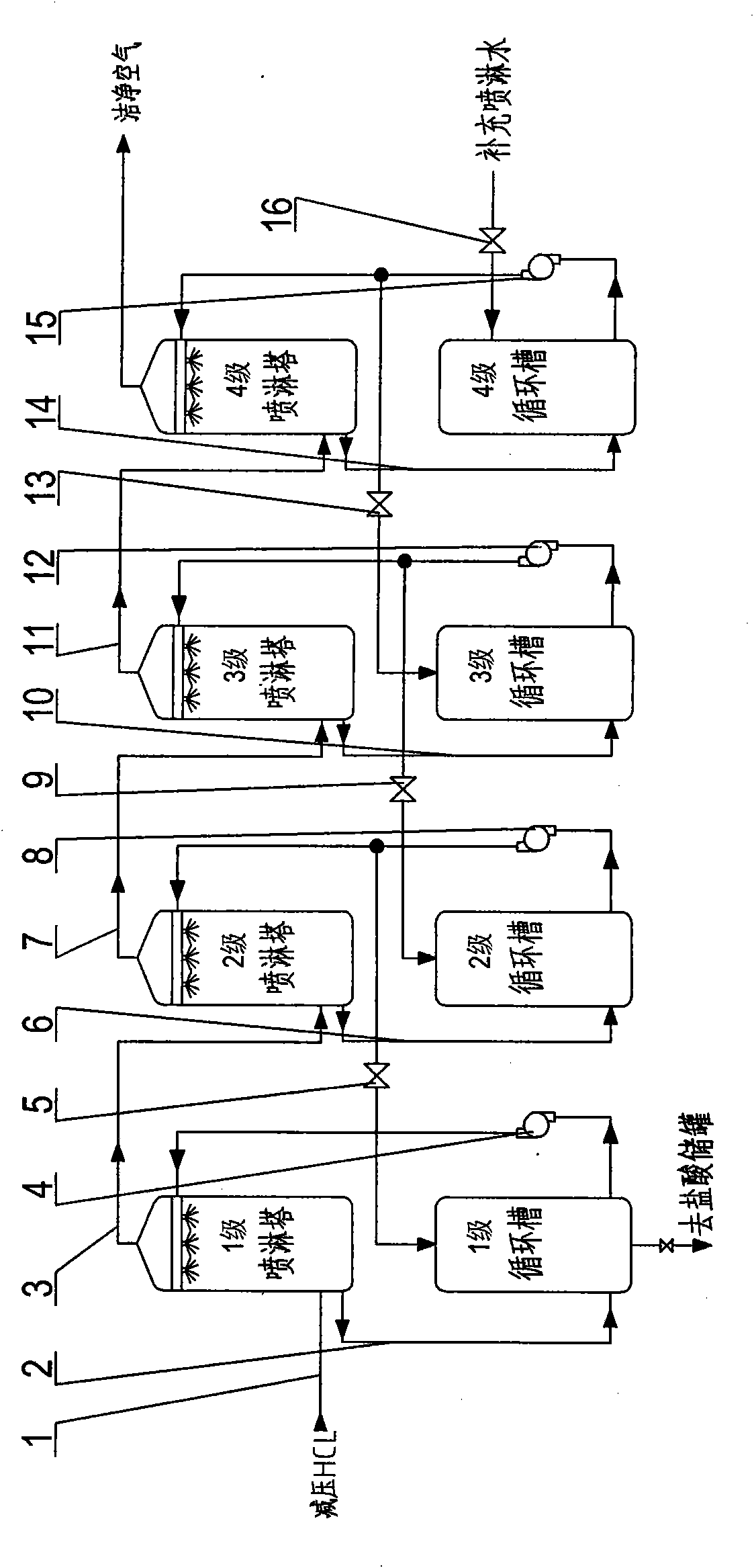

Decompression acid making process of polysilicon 10barg HCl (hydrogen chloride) tail gas

InactiveCN102009952AGuarantee normal productionSolve the thorny problemChlorine/hydrogen-chlorideTransformation unitPolycrystalline silicon

The invention relates to a decompression acid making process of polysilicon 10barg HCl (hydrogen chloride) tail gas, in particular to a specific process technology by which gasification, decompression and water absorption are carried out on 10barg liquid chlorine hydride separated and extracted from the production of polysilicon, thus the tail gas becomes hydrochloric acid and is further recycled. The production process is as follows: heating the liquid chlorine hydride with the pressure of 10barg and the purity of 99%, which is separated and purified by a polysilicon production tail gas recovery unit, to 10-20 DEG C through a heating gasifier, leading the liquid HCl to change from the liquid state to the gas state; then decompressing gas HCl with the pressure of 10barg to 0.1-0.5barg through a decompression device; further introducing the HCl into a spray absorption device for carrying out the water absorption; carrying out circulating counter-current multi-stage concentration and absorption; and producing and preparing the hydrochloric acid with the concentration of 26-31%. In the production process of the polysilicon, as the hydrochloric acid is prepared by exhausting the 10barg HCl separated and purified by the tail gas recovery unit to an HCl thickening absorption device of a waste gas and waste liquid treatment system when a fault occurs in the TCS (trichlorosilane) synthesis, a reasonable treatment way is found out for the 10barg HCl during an accident, thereby ensuring the normal production of a reduction unit, a transformation unit and the tail gas recovery unit, and enhancing the anti-accident capacity of a polysilicon production line.

Owner:SHAANXI TIANHONG SILICON IND

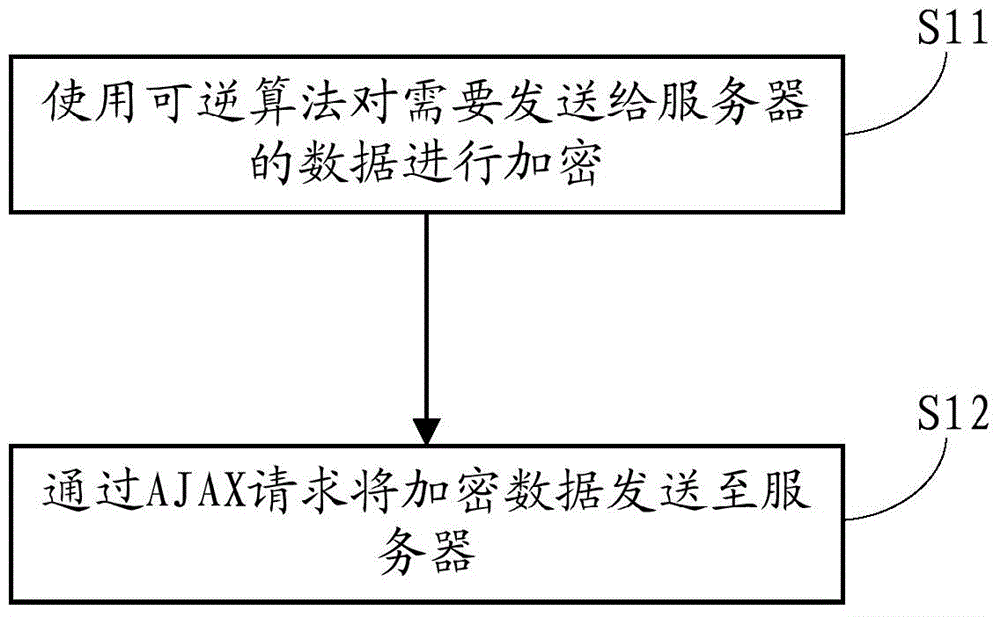

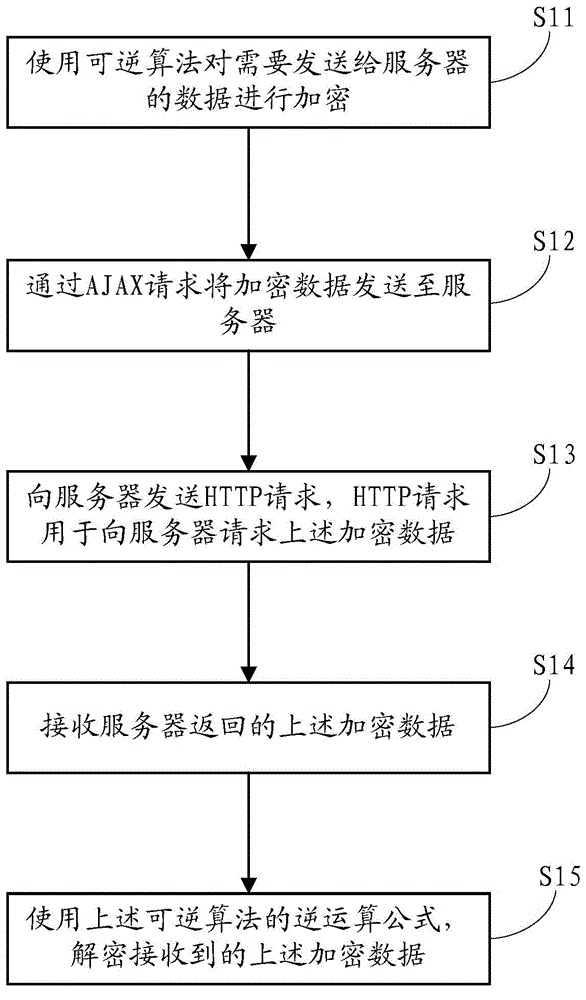

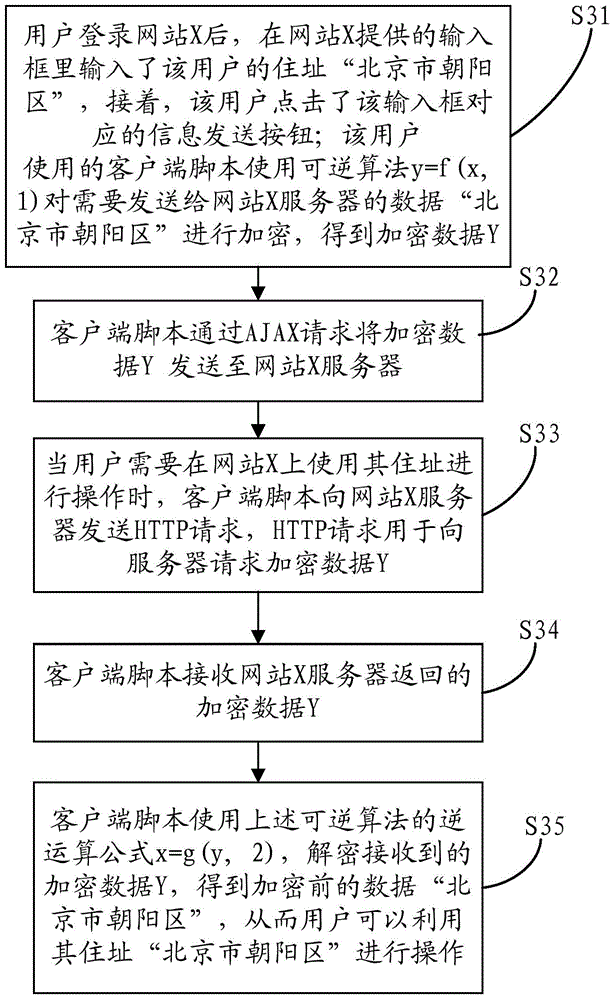

Data exchange method and device thereof based on HTTP protocol

InactiveCN104954344AEnsure safetySave network resourcesUser identity/authority verificationData exchangeHypertext Transfer Protocol over Secure Socket Layer

The present invention relates to a data exchange method based on an HTTP protocol and a data exchange device based on an HTTP protocol to solve the safety problem in AJAX technology transmission data based on the HTTP protocol, and the transmission safety of user data can be ensured while the use of a HTTPS protocol is avoided. The method comprises the steps of using a reversible algorithm to encrypt data which is needed to be sent to a server to obtain encrypted data and sending the encrypted data to the server via an AJAX request. According to the technical scheme, the safe transmission of the data in the AJAX technology transmission data based on the HTTP protocol is ensured.

Owner:XIAOMI INC

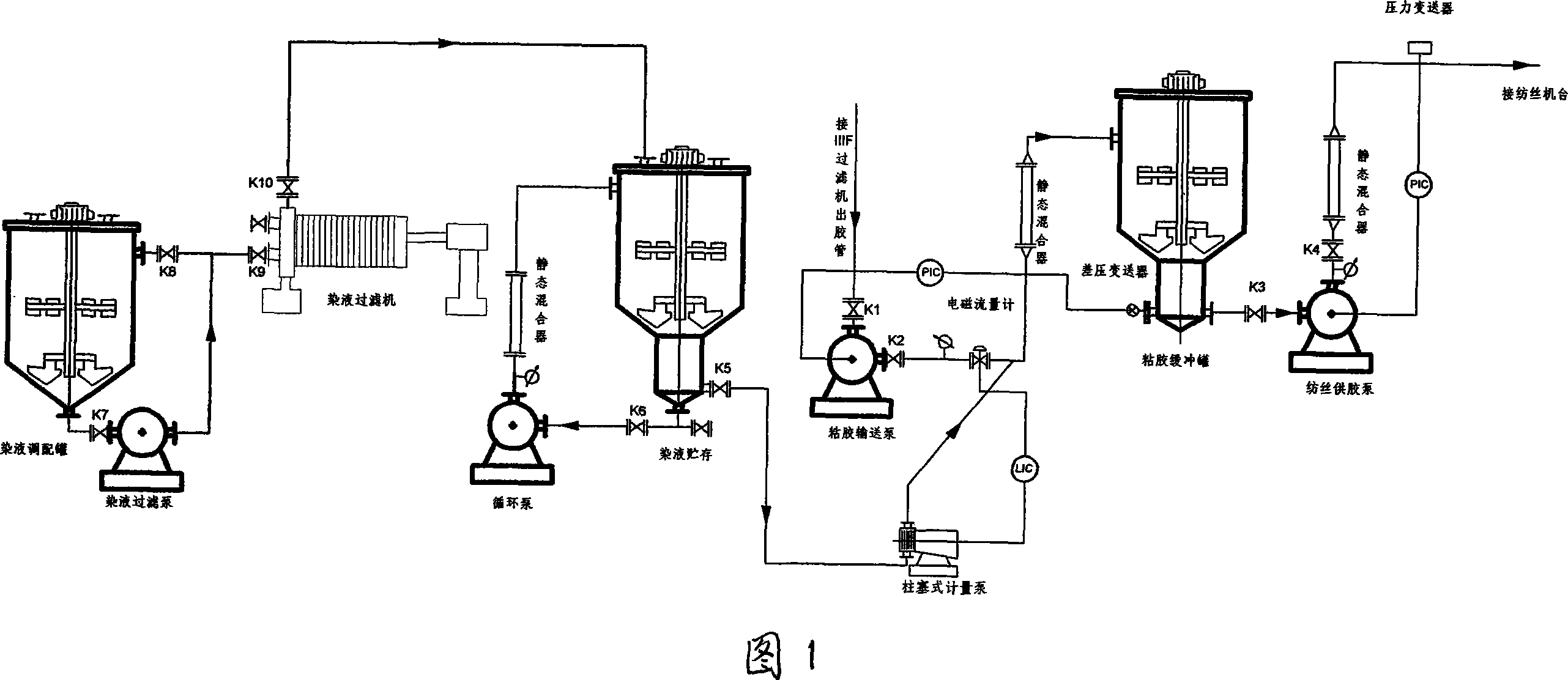

Spinning and dyeing method for viscose

InactiveCN101058898AGuaranteed RestoreGuaranteed recovery before spinningMonocomponent cellulose artificial filamentCelluloseTextile dyeing

The present invention discloses a dyeing method of textile dyeing cellulose viscose, in order to overcome the drawbacks of the prior dyeing method can not guarantee the oxidation-reduction process be controlled effectively in colored cellulose viscose production. The method adds reducing agent and oxidizer into color paste, adds the standby color paste into viscose, the dyeing viscose is prepared after mixing fully, then the dyeing viscose forms reduced thread-line after ejected from spinnerette; in the textile process of reduced thread-line from forming to degumming or when the textile process is completed, the thread-line starts color development on the role of oxidant and acids or alkali, the color is fixed into desired color after reaction is completed. The invention breaks the traditional technology of the traditional ordinary cellulose viscose is colored before textile and is dyed and finished in late processes, it can achieve single filament dyeing, improve dyeing uniformity, color stability and color brightness of thread-line, and achieve the use standard of cotton embroidery thread, as well as decrease production costs significantly; the follow-up processing is pollution-free, the color of produces is bright, dyeing is uniform, hand feeling is comfortable and application is wide.

Owner:YIBIN HIEST FIBER

Sulfur-carbon positive pole material for lithium-sulfur secondary battery and preparation method of sulfur-carbon positive pole material

ActiveCN106058208ASmall particlesRelieve interfacial surface tensionNon-aqueous electrolyte accumulator electrodesLi-accumulatorsChemical synthesisCooking & baking

The invention discloses a sulfur-carbon positive pole material for a lithium-sulfur secondary battery and a preparation method of the sulfur-carbon positive pole material. The method comprises the following steps: (1) adding poloxamer into anhydrous ethanol, carrying out warm / thermal dissolving, adding thermosetting liquid-state phenol-formaldehyde resin into the transparent solution, and carrying out room-temperature stirred dissolving so as to prepare a solution I; (2) adding sodium thiosulfate and sodium sulfide into the solution I, carrying out stirring for a few minutes, then, adding dilute sulfuric acid, and carrying out a stirred reaction for a period of time so as to prepare sol II; (3) pouring the sol II into a culture dish, putting the culture dish into a baking oven, carrying out constant-temperature standing, and then, carrying out roasting in a tube type furnace so as to produce coarse granules of the sulfur-carbon positive pole material; (4) dispersing the coarse granules into fine granules of the sulfur-carbon positive pole material by a liquid-nitrogen ball milling method. A sulfur positive pole material prepared by a chemical synthesis method is uniformly formed in inside walls of mesoporous carbon, so that the volume expansion of sulfur and the loss of sulfur active substances in an electrolyte are effectively inhibited, the efficiency of electron conduction is increased, and the electric properties are improved.

Owner:TIANJIN B&M SCI & TECH

Method for biologically detoxifying hexavalent chromium in contaminated soil

ActiveCN102941224BGuaranteed RestoreSimple processContaminated soil reclamationEdaphicEnvironmental chemistry

Owner:济南云水腾跃环保科技有限公司

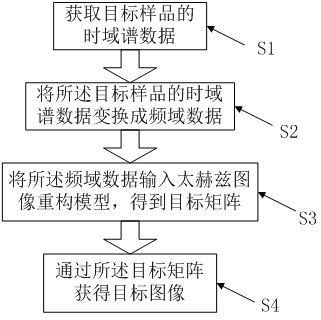

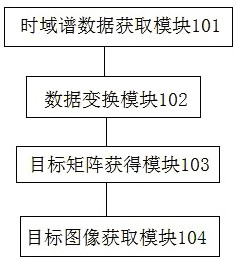

Terahertz image reconstruction method and device, storage medium and terminal

InactiveCN112233201AGuaranteed RestoreSmall amount of calculationImage enhancementReconstruction from projectionTime domainImage restoration

The invention discloses a terahertz image reconstruction method and device, a storage medium and a terminal. The method comprises the steps of obtaining time domain spectrum data of a target sample; converting the time domain spectrum data of the target sample into frequency domain data; inputting the frequency domain data into a terahertz image reconstruction model to obtain a target matrix; andobtaining a target image through the target matrix. According to the technical scheme, the terahertz image reconstruction model is simple, and the whole terahertz image reconstruction process is lowerin calculated amount and higher in efficiency while the terahertz image restoration effect is ensured.

Owner:JIHUA LAB

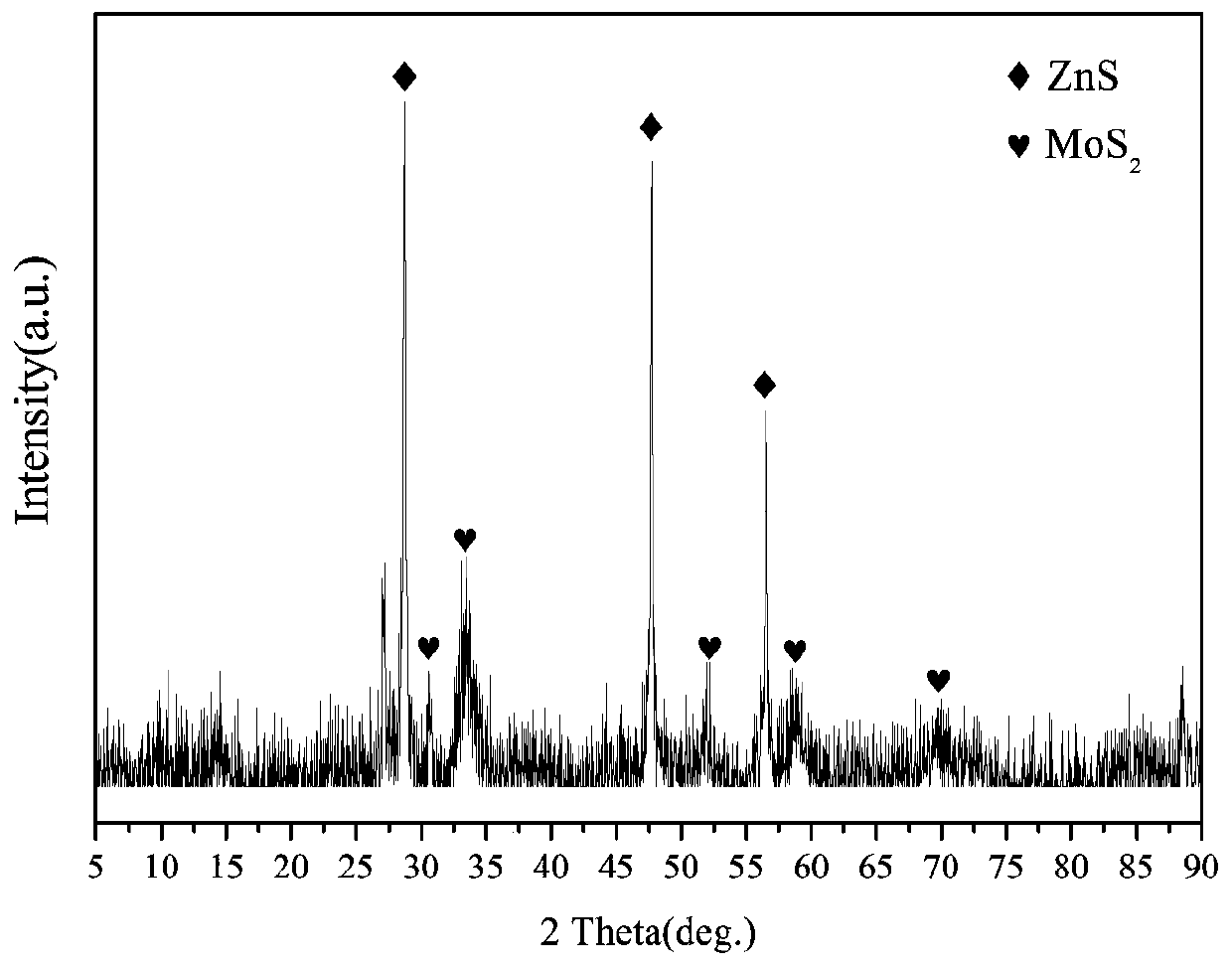

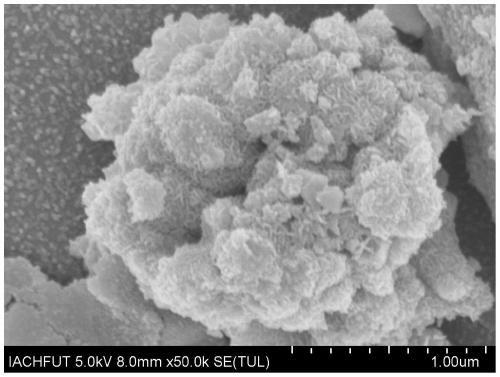

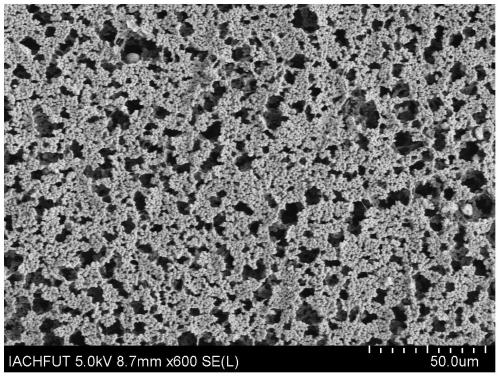

Preparation and application of polymer carrier coated transition metal doped molybdenum sulfide nanoparticle composite catalytic material

InactiveCN110038640ALow priceStrong hydrogen evolution abilityOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsChemistryPollutant

The invention discloses preparation and an application of a polymer carrier coated transition metal doped molybdenum sulfide nanoparticle composite catalytic material. The composite catalytic materialuses a polymer as a carrier and is coated with transition metal doped molybdenum sulfide nanoparticles. The composite catalytic material has the advantages of excellent performance, high mechanical strength, large specific surface area, rich aperture structure and strong hydrophilic property. An integrated formic acid coupled catalytic reactor constructed based on the composite catalytic materialcan efficiently reduce heavy metal hexavalent chromium pollutants.

Owner:HEFEI UNIV OF TECH

Method for preparing ferroboron based on thermit self-propagating gradient reduction and slag-washing refining

ActiveCN107326254ASignificant progressSignificant advantagesProcess efficiency improvementChemical reactionThermal insulation

The invention relates to a method for preparing ferroboron based on a thermit self-propagating gradient reduction and slag-washing refining, and belongs to the technical field of ferroalloy. The method comprises the steps that after raw materials are preprocessed, by mass, 1.0 part of boric anhydride, 1.33-4.49 parts of Fe2O3 powder, 1.22-2.29 parts of aluminum power and 0.6-3.2 parts of CaO are weighed; then a thermit self-propagating reaction is conducted by adopting the mode of gradient feeding to obtain high temperature molten liquid, and gradient reduction smelting is conducted; after feeding is completed, thermal-insulation melt separation is conducted; and CaO-CaF2 base refining slag is added into the high temperature molten liquid, and the ferroboron is obtained after slag is removed. The gradient-feeding method achieves controlling over the reaction process and the temperature and thorough reducing of metallic oxides, and moreover, the smaller the gradients of the aluminum coefficients are, the fewer aluminum residues in the alloy molten liquid are; slag-washing refining achieves thorough chemical reaction of a slag-metal interface and slag-metal separation, and the recovery rate of boron is enhanced; and meanwhile, the temperature of the molten liquid is reduced, the system reaction heat is utilized, and energy consumption is reduced.

Owner:NORTHEASTERN UNIV

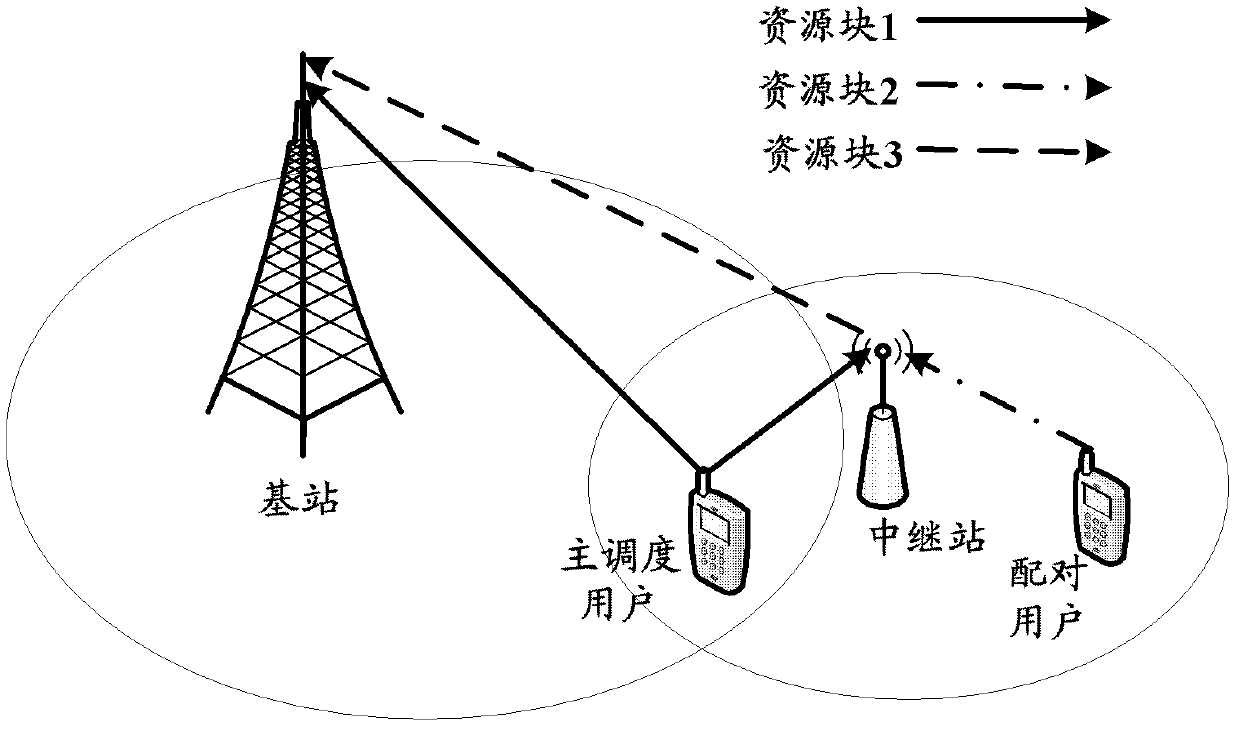

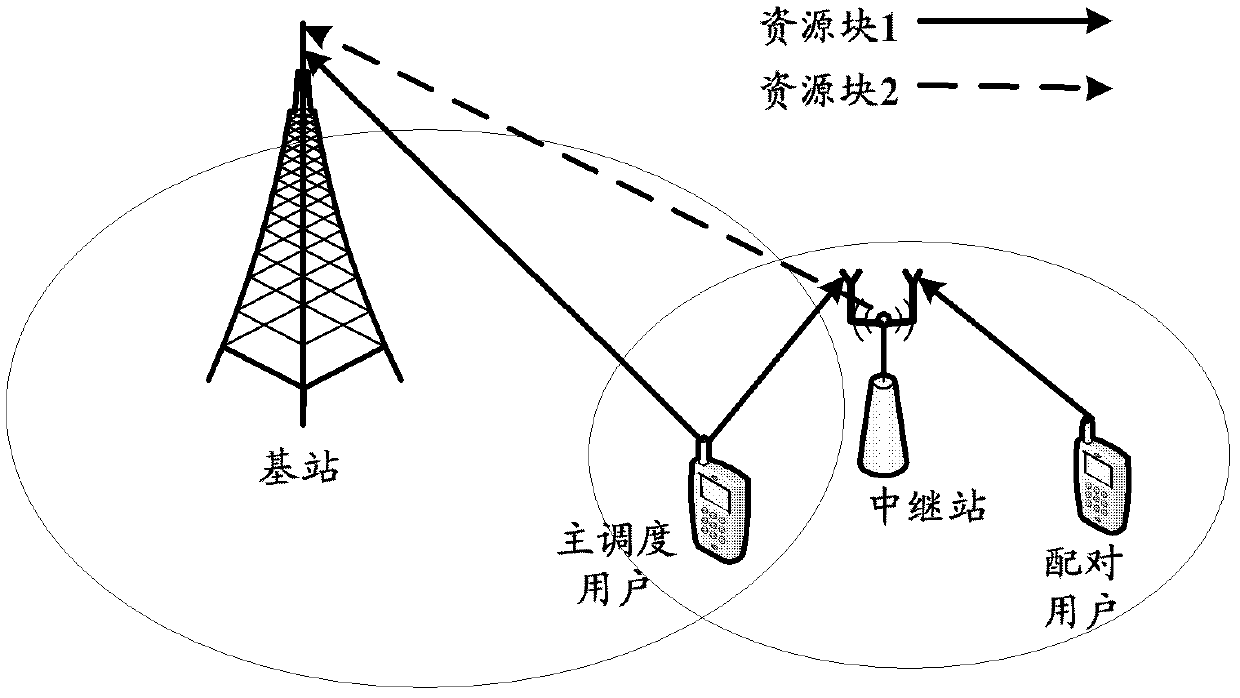

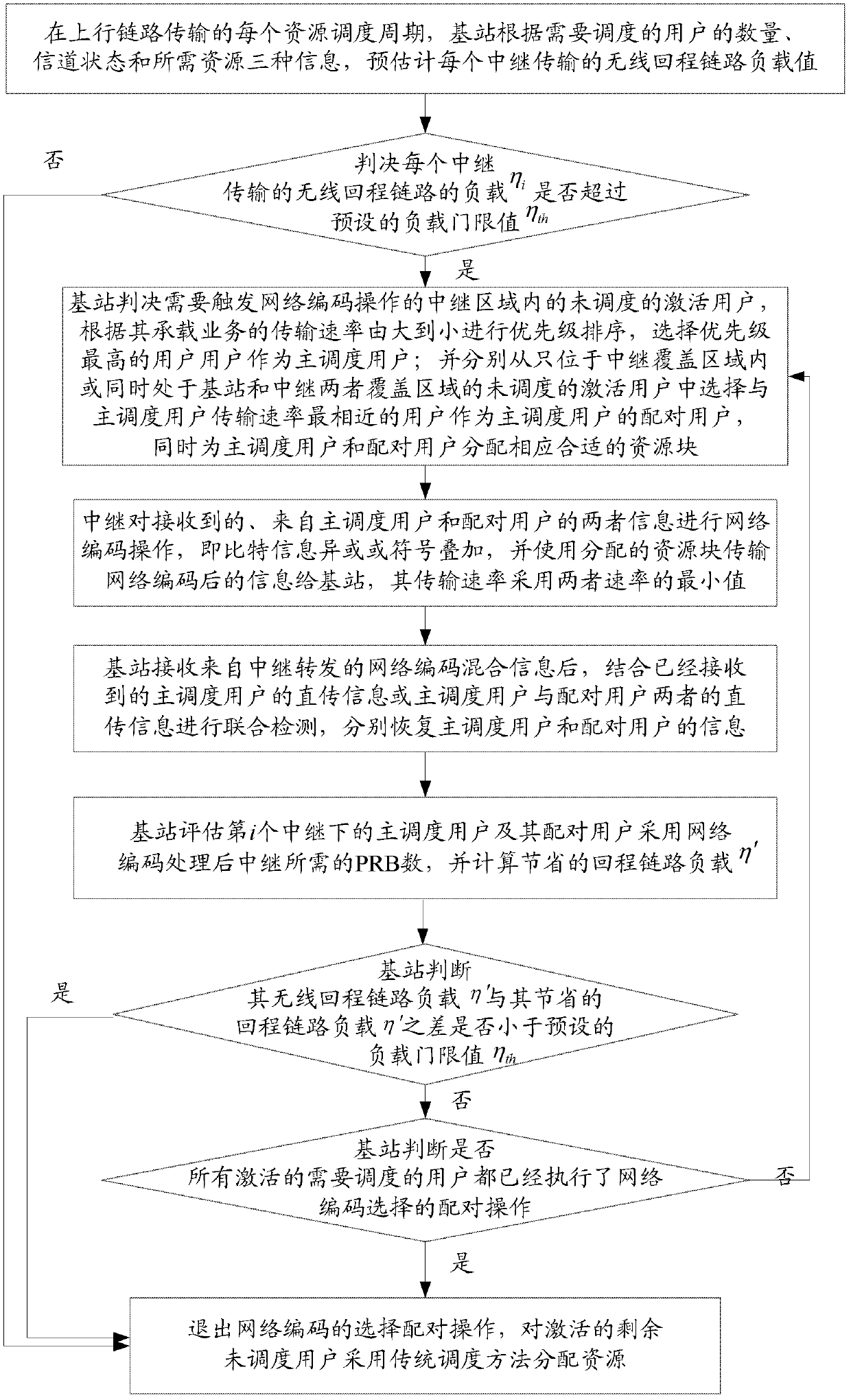

Adaptive collaborative transmission method for backhaul links of wireless relay

ActiveCN102438246AGuaranteed RestoreGuaranteed recoveryActive radio relay systemsNetwork planningFrequency spectrumDiversity scheme

The invention relates to an adaptive collaborative transmission method for backhaul links of a wireless relay. When a plurality of users access a base station through the wireless relay, if the resource occupation of the backhaul links exceeds a preset threshold, the relay carries out network coding processing on partial direct information of users and partial forwarded information of the users, then, sends the information to the base station by adopting single wireless resources, so that the resource occupation of the backhaul links is reduced at the same that the number of target users of relay service is increased, and the transmission performance of a wireless relay system is improved; and the base station further carries out centralized scheduling on users who adopt the network coding processing, and detects and recovers received network coding mixed information and direct information from the users, and the diversity gain can be obtained without increasing additional system overhead. With the adoption of the method, the problem that the resources of the backhaul links of a new-generation broadband mobile communication system are limited is solved, the wireless relay is ensured to be capable of expanding coverage and reducing the decrease of the spectrum efficiency caused by the introduction of the relay.

Owner:江西省智慧物联研究院有限公司

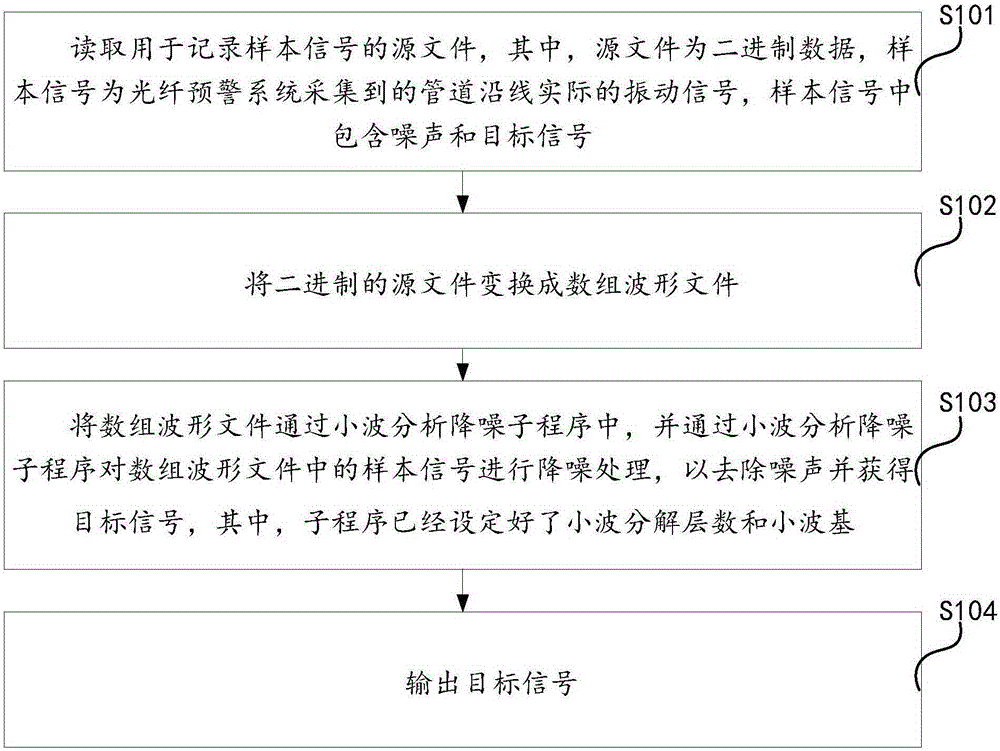

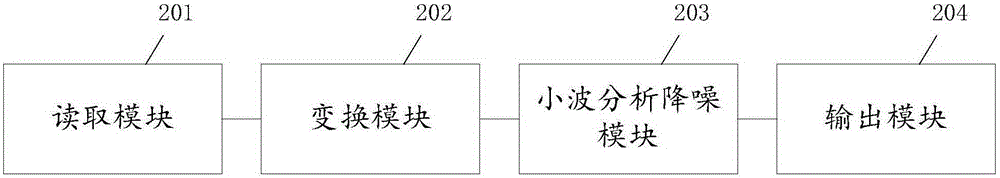

Optical fiber early warning system noise reduction method and device based on wavelet analysis

ActiveCN105156901APrecise positioningEasy to describePipeline systemsEarly warning systemArray data structure

The invention discloses an optical fiber early warning system noise reduction method and device based on wavelet analysis. The method and device are applied to an optical fiber early warning system of an oil pipeline. The method comprises the steps of reading source files used for recording sample signals, converting the binary source files into multiple sets of wave files, inputting the sets of wave files to a wavelet analysis noise reduction subprogram and obtaining target signals after noise reduction is carried out on the sample signals in the sets of wave files through the wavelet analysis noise reduction subprogram, and outputting the target signals. By means of the method and device, the accuracy and the effectiveness of warning information provided by the optical early warning system are guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

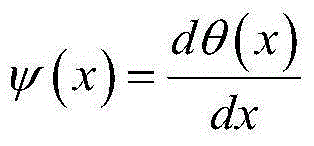

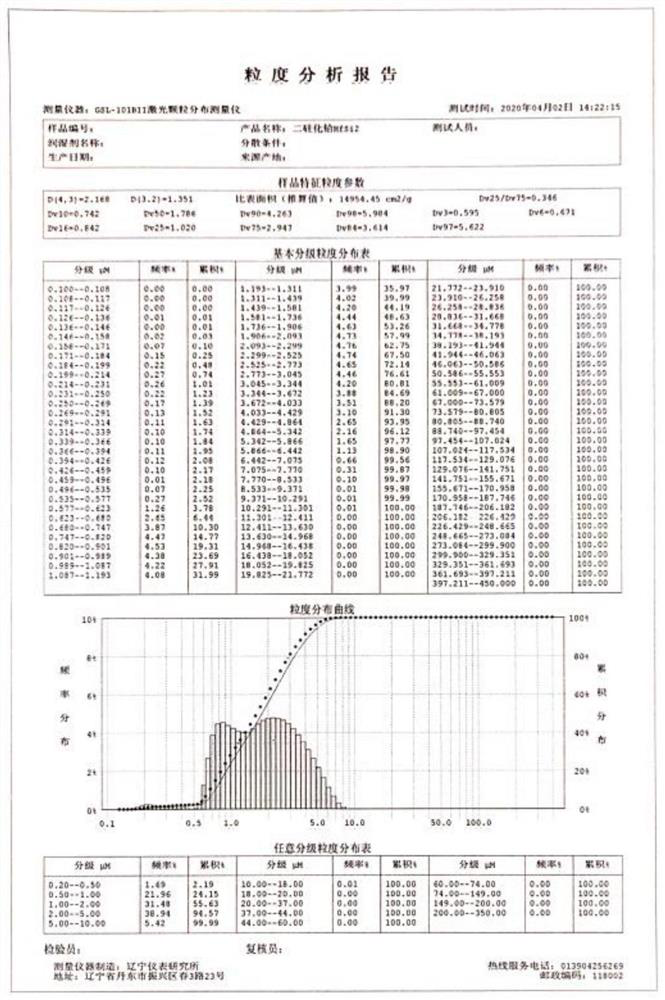

Production process of hafnium disilicide

The invention discloses a production process of hafnium disilicide. The production process comprises the following steps: ball-milling and mixing zirconium dioxide powder and silicon powder under a vacuum condition, briquetting by using a hydraulic machine, sintering and finishing in a vacuum sintering furnace, removing white silicon dioxide powder coated on the surface of hafnium, ball-milling ina vacuum ball mill, adding sodium hydroxide, adding distilled water with the temperature of 60 DEG C, and drying to obtain silicon-containing hafnium powder; detecting the content of silicon in the silicon-containing hafnium powder, adding silicon powder according to the content of silicon in the hafnium powder, carrying out ball milling for 5 hours in a vacuum ball mill under the protection of inert argon, putting into a vacuum self-propagating combustion furnace, vacuumizing, heating a thermal electrode, igniting the hafnium powder, making the hafnium powder and the silicon powder carry outa self-propagating combination reaction to obtain hafnium disilicide. Hafnium dioxide powder is used as a raw material, and the raw material cost is lower than sponge hafnium cost; according to the method, the whole process is reasonable in technology and suitable for industrial production, the obtained hafnium disilicide product is high in purity, and the alloying degree can reach 100%.

Owner:辽宁中色新材科技有限公司

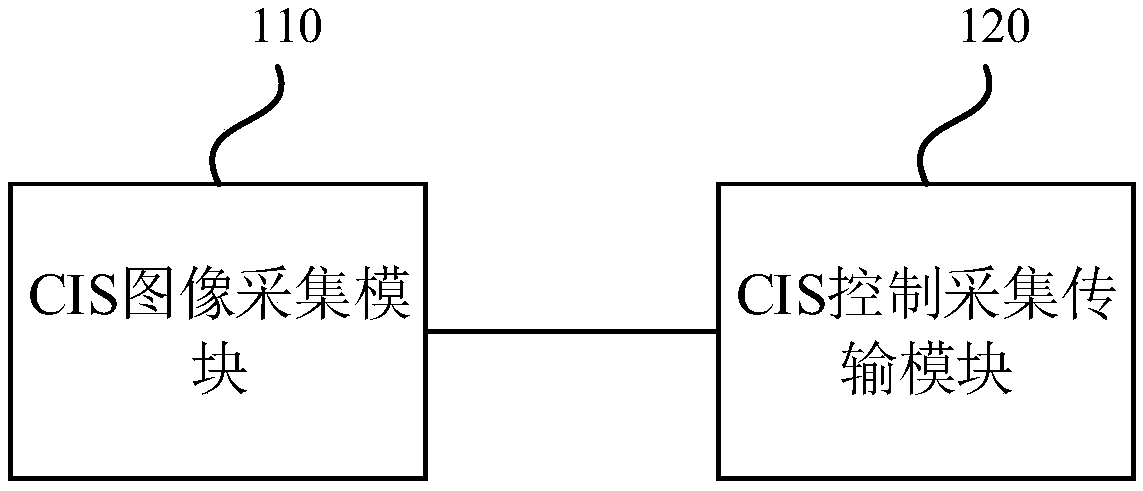

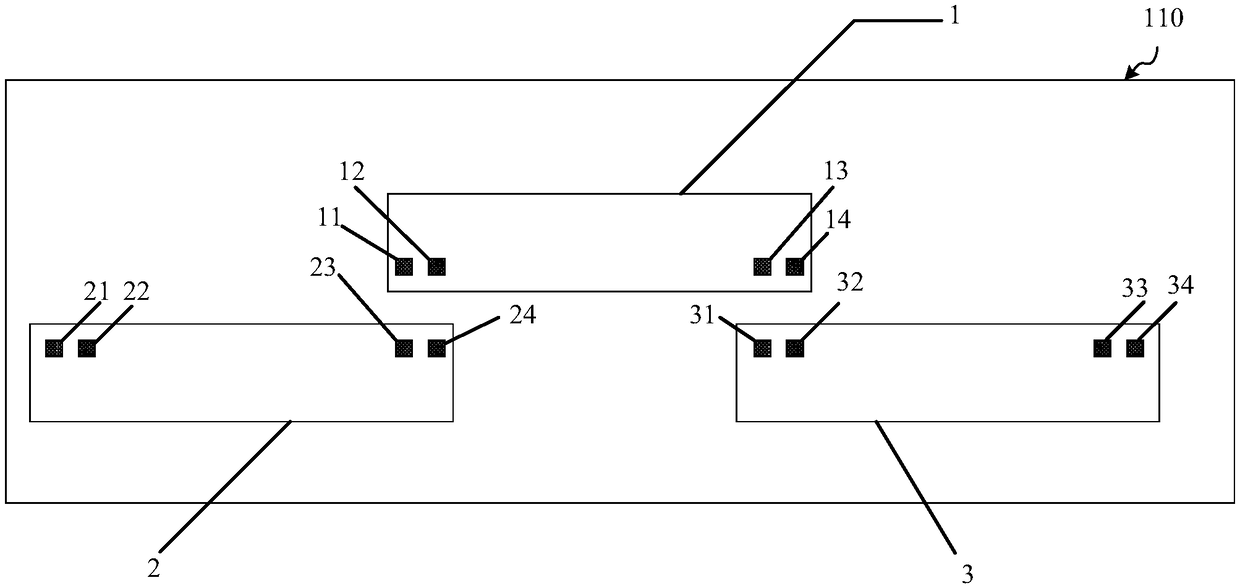

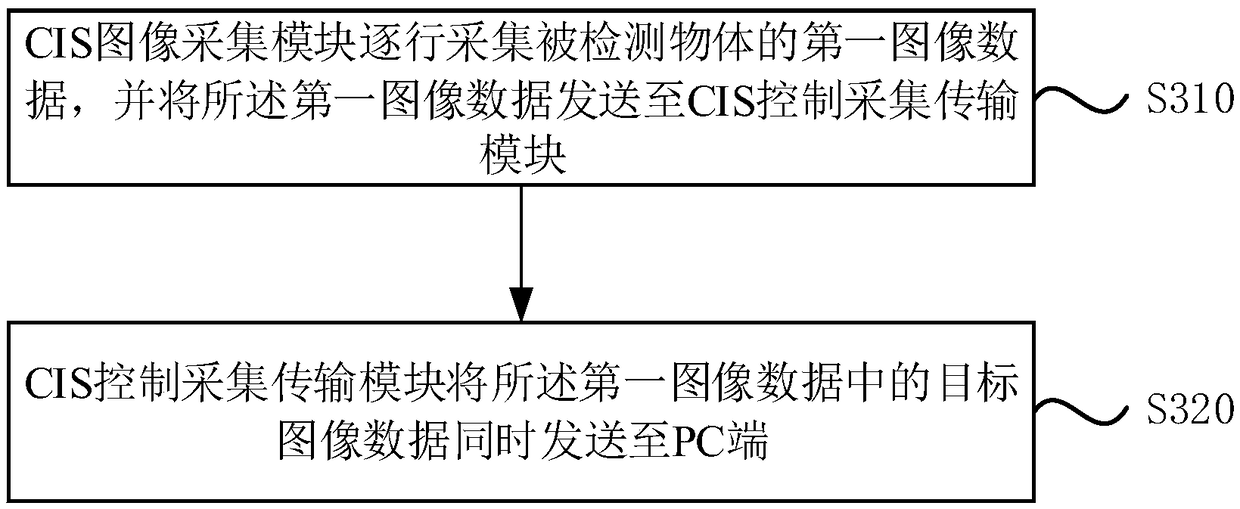

CIS camera, and image processing method based on CIS camera

ActiveCN108632534AGuaranteed RestoreImprove detection accuracyImage enhancementTelevision system detailsImaging processingComputer science

The embodiment of the invention discloses a CIS camera, and an image processing method based on the CIS camera. The CIS camera comprises a CIS image collection module and a CIS control, collection andtransmission module, wherein the CIS image collection module comprises at least three image sensors, and the image sensors are arranged in triangle; the CIS image collection module is connected withthe CIS control, collection and transmission module, and the CIS image collection module collects first image data of a detected object row by row and sends the first image data to the CIS control, collection and transmission module; and the CIS control, collection and transmission module sends target image data in the first image data to a PC terminal at the same time, wherein the target image data comprise the image data corresponding to the same horizontal location of the detected objected in each row of image data collected by each image sensor arranged in the triangle. By adoption of thetechnical scheme provided by the embodiment of the invention, the detection accuracy can be effectively improved.

Owner:江苏阿瑞斯智能设备有限公司

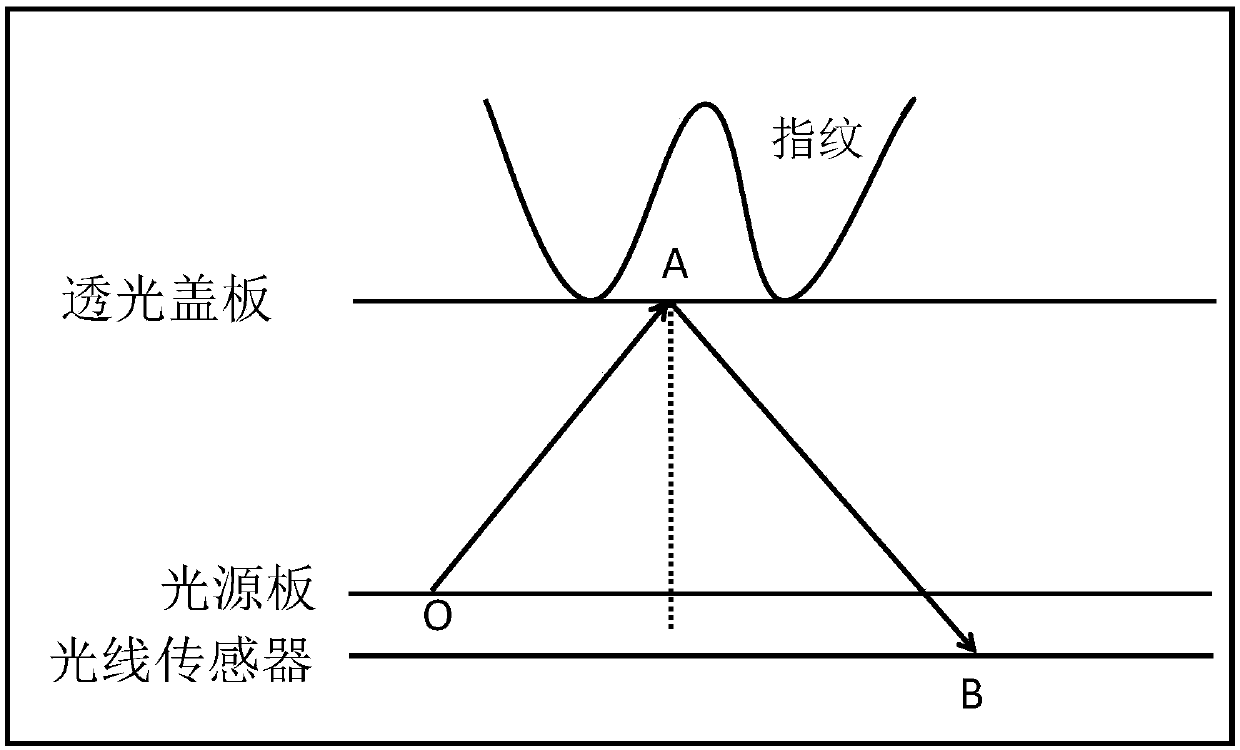

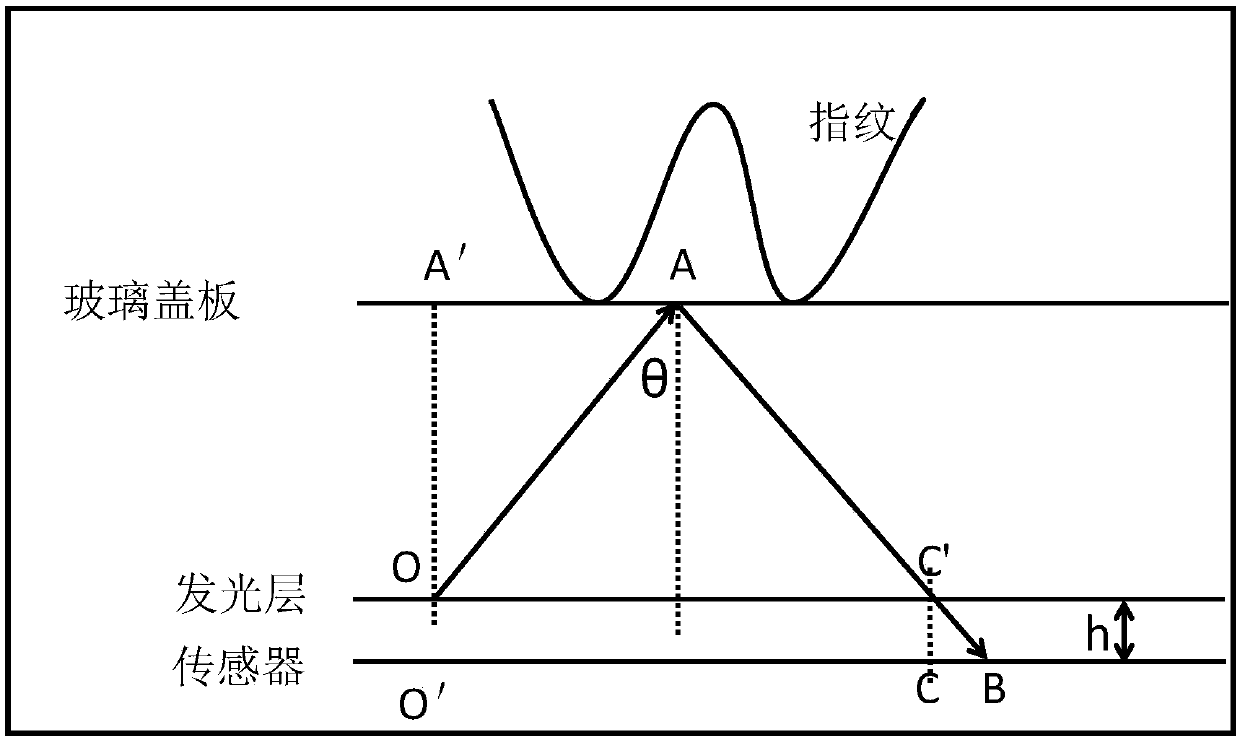

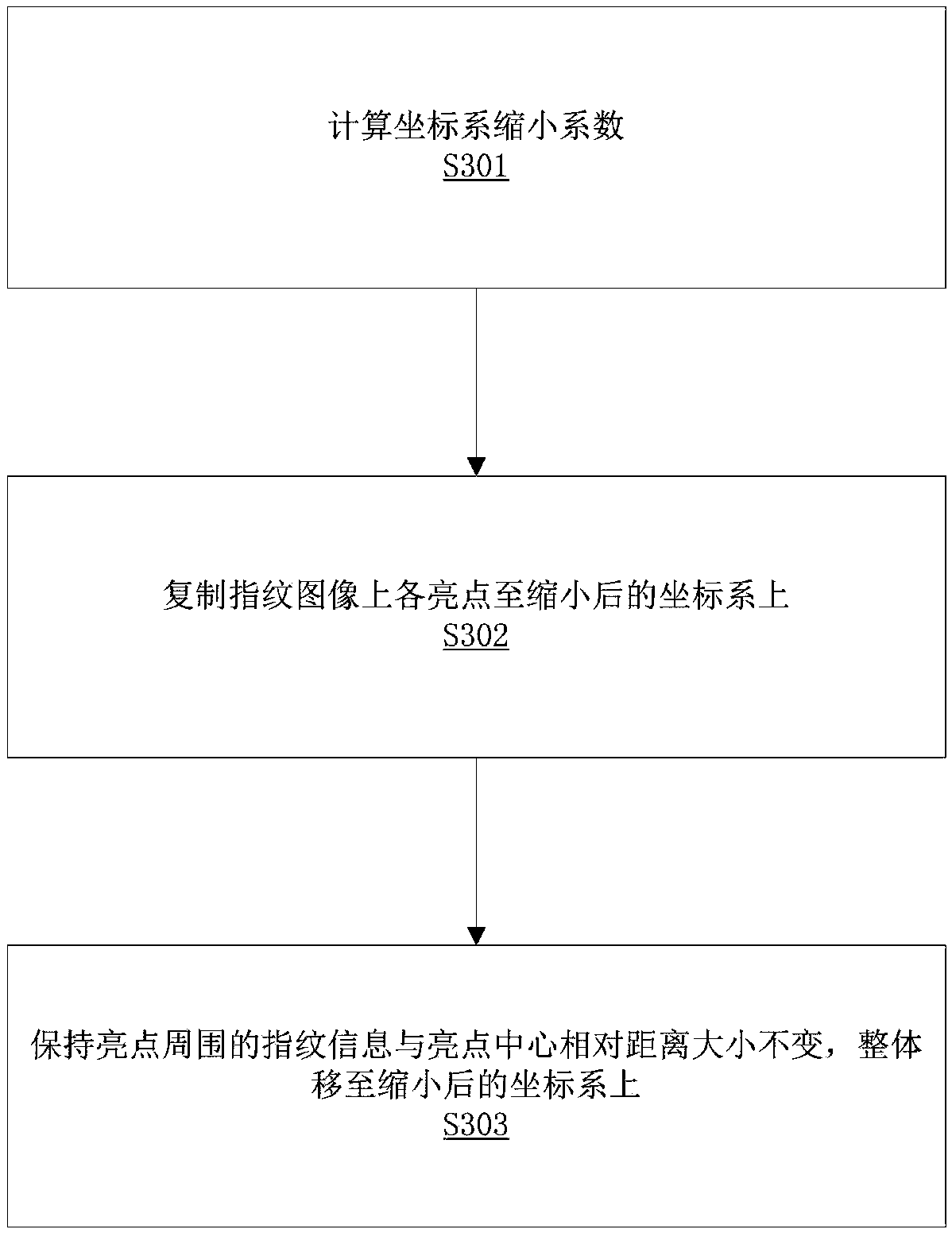

Coordinate transformation method for under-screen imaging, storage medium and electronic equipment

ActiveCN110895665AGuaranteed RestoreGuaranteed clarityImage enhancementImage analysisComputer graphics (images)Engineering

The invention relates to the technical field of optical fingerprint identification, in particular to a coordinate transformation method for under-screen imaging, a storage medium and electronic equipment. The coordinate transformation method for under-screen imaging comprises the following steps: calculating a coordinate system reduction coefficient; copying each bright spot on the fingerprint image to the reduced coordinate system; and keeping the relative distance between the fingerprint information around the bright spot and the center of the bright spot unchanged, and integrally moving thefingerprint information to the shrunk coordinate system. Through coordinate conversion, restoration of the fingerprint image is guaranteed, meanwhile, it is guaranteed that pixels cannot be lost, andthe definition of the restored fingerprint image is guaranteed. And the mode of restoring the fingerprint image is simple in calculation process, high in restoration speed and good in quality.

Owner:SHANGHAI HARVEST INTELLIGENCE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com