Production process of hafnium disilicide

A production process, a technology of disilicidation, applied in the direction of metal silicide, etc., can solve the problems of poor fluidity, low degree of alloying, and insufficient combination, etc., and achieve the effect of reasonable process, high purity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

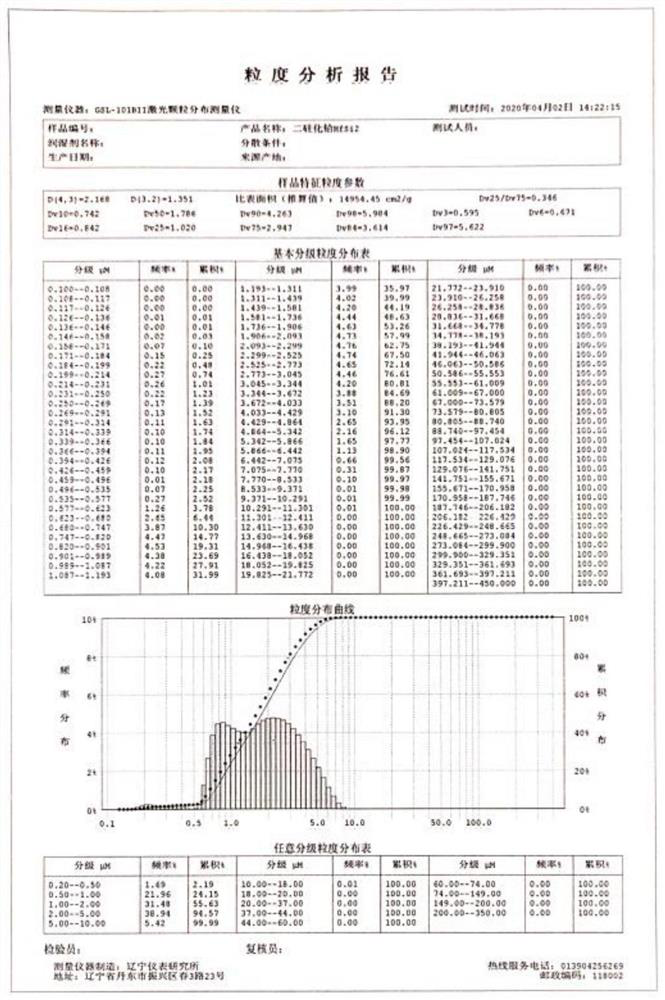

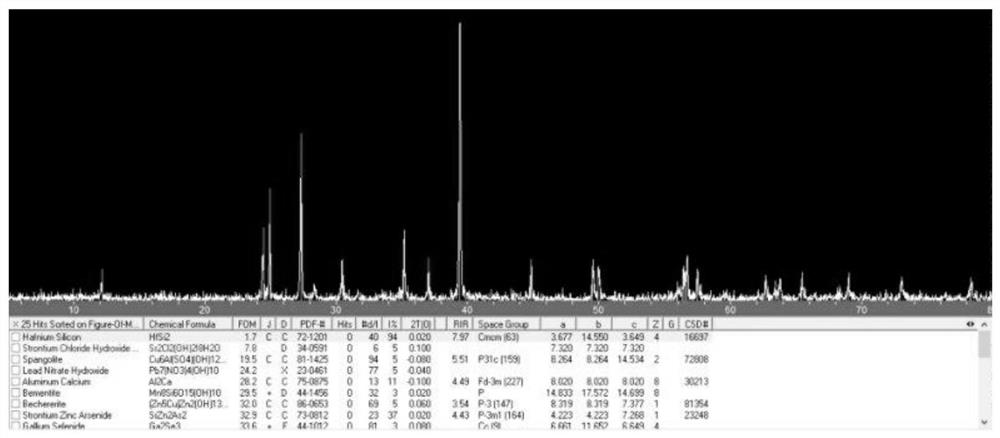

Image

Examples

Embodiment 1

[0027] (1) Mixing

[0028] a. Hafnium dioxide powder has a purity of 99.9% and a fineness of 200 mesh;

[0029] b. Silicon powder is 325 mesh silicon powder, and the purity of silicon powder is 99.99%;

[0030] c. Add 8.8kg of zirconia powder and 1.2kg of silicon powder to 100g of carboxymethyl cellulose as a binder, put it into a vacuum ball mill and fill it with argon protection, and mix the materials by ball milling. The ball milling speed is 120 rpm, ensuring 10 hours, mix well, obtain mixed material;

[0031] (2) Briquetting

[0032] After mixing the materials in step (1), according to 600 grams per block, use a three-beam four-column hydraulic press to press into a round cake-shaped block, the pressing pressure is 20MPa, and the size of the briquetting block is φ80mm×25mm;

[0033] (3) Sintering reduction

[0034] Put the block material pressed in step (2) into the quartz crucible of a 200kg vacuum sintering furnace. The input amount of raw materials is 51kg, vacuumi...

Embodiment 2

[0040] (1) Mixing

[0041] a. Hafnium dioxide powder has a purity of 99.9% and a fineness of 200 mesh;

[0042] b. Silicon powder is 325 mesh silicon powder, and the purity of silicon powder is 99.99%;

[0043] c. Add 8.78kg of zirconia powder and 1.22kg of silicon powder to 100g of carboxymethyl cellulose as a binder, put it into a vacuum ball mill and fill it with argon protection, and mix the materials by ball milling. The ball milling speed is 120 rpm, ensuring 10 hours, mix well, obtain mixed material;

[0044] (2) Briquetting

[0045] After mixing the materials in step (1), according to 600 grams per block, use a three-beam four-column hydraulic press to press into a round cake-shaped block, the pressing pressure is 20MPa, and the size of the briquetting block is φ80mm×25mm;

[0046] (3) Sintering reduction

[0047] Put the block material pressed in step (2) into the quartz crucible of a 200kg vacuum sintering furnace. The input amount of raw materials is 51kg, vacuu...

Embodiment 3

[0053] (1) Mixing

[0054] a. Hafnium dioxide powder has a purity of 99.9% and a fineness of 200 mesh;

[0055] b. Silicon powder is 325 mesh silicon powder, and the purity of silicon powder is 99.99%;

[0056] c. Add 8.79kg of zirconia powder and 1.21kg of silicon powder to 100g of carboxymethyl cellulose as a binder, put it into a vacuum ball mill and fill it with argon protection, and mix the materials by ball milling. The ball milling speed is 120 rpm, ensuring 10 hours, mix well, obtain mixed material;

[0057] (2) Briquetting

[0058] After mixing the materials in step (1), according to 600 grams per block, use a three-beam four-column hydraulic press to press into a round cake-shaped block, the pressing pressure is 20MPa, and the size of the briquetting block is φ80mm×25mm;

[0059] (3) Sintering reduction

[0060] Put the block material pressed in step (2) into the quartz crucible of a 200kg vacuum sintering furnace. The input amount of raw materials is 51kg, vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com