Technological method for extracting zinc by roasting blast furnace gas mud by virtue of rotary kiln

A technology of blast furnace gas mud and process method, which is applied in the field of metallurgical production, can solve the problems of waste of carbon resources in production costs, increase in production costs, and hazards to ironmaking equipment, and achieve the effects of shortening the production kiln period, saving production costs, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

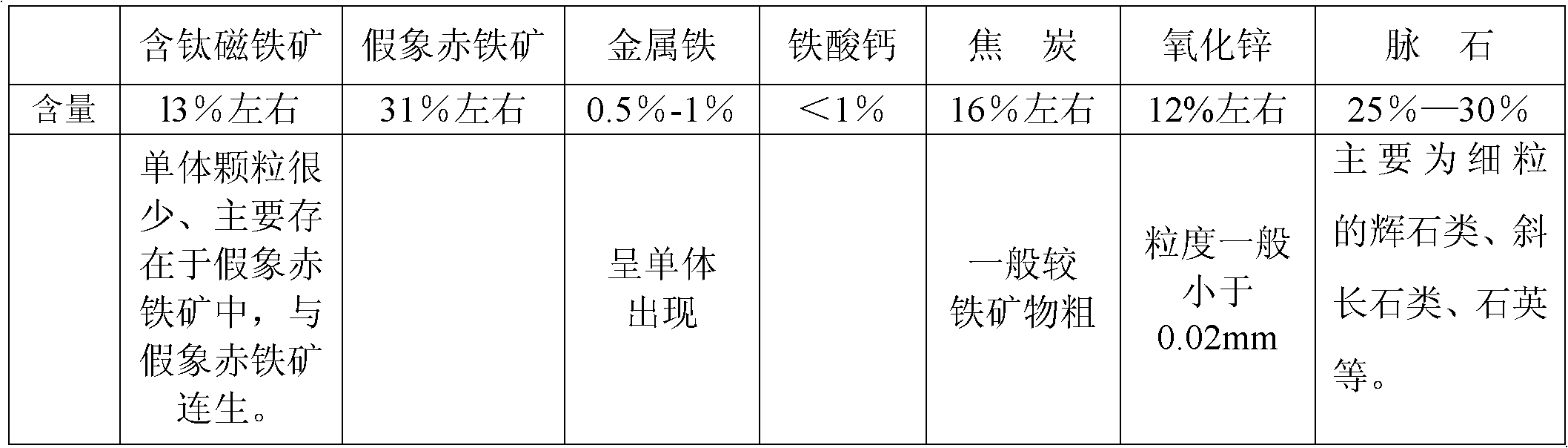

[0041] Taking the one-time treatment of 50 tons of gas mud in a steel plant as an example, the process of extracting zinc by roasting gas mud in a rotary kiln is described below:

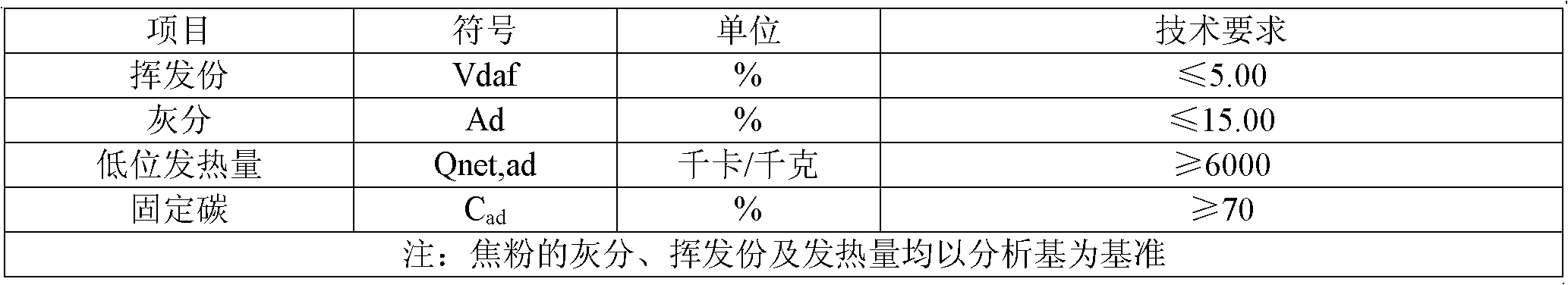

[0042] 1. Measure 50 tons of gas mud, and then add coke powder with a mass ratio of 18% to it, and then use a loader to mix evenly, and then carry out sampling inspection on the mixed material to ensure that the calorific value should remain At about 1800 kcal / kg.

[0043] 2. The gas mud coke powder mixture that meets the calorific value requirements is sent into the rotary kiln through the belt conveyor. After the mixture is dried in the drying section of the rotary kiln, preheated in the preheating section and fired and reduced in the reaction section , to generate secondary zinc oxide products and metallized slag, wherein the maximum temperature of the drying section is kept at about 400°C, the maximum temperature of the preheating section is kept at about 850°C, and the maximum temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com