Less slag decarbonization refining method used in top-bottom combined blowing converter

A technology of top-bottom double blowing and converter, applied in the direction of manufacturing converters, etc., can solve the problems of prolonged smelting cycle, lime consumption and slag reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

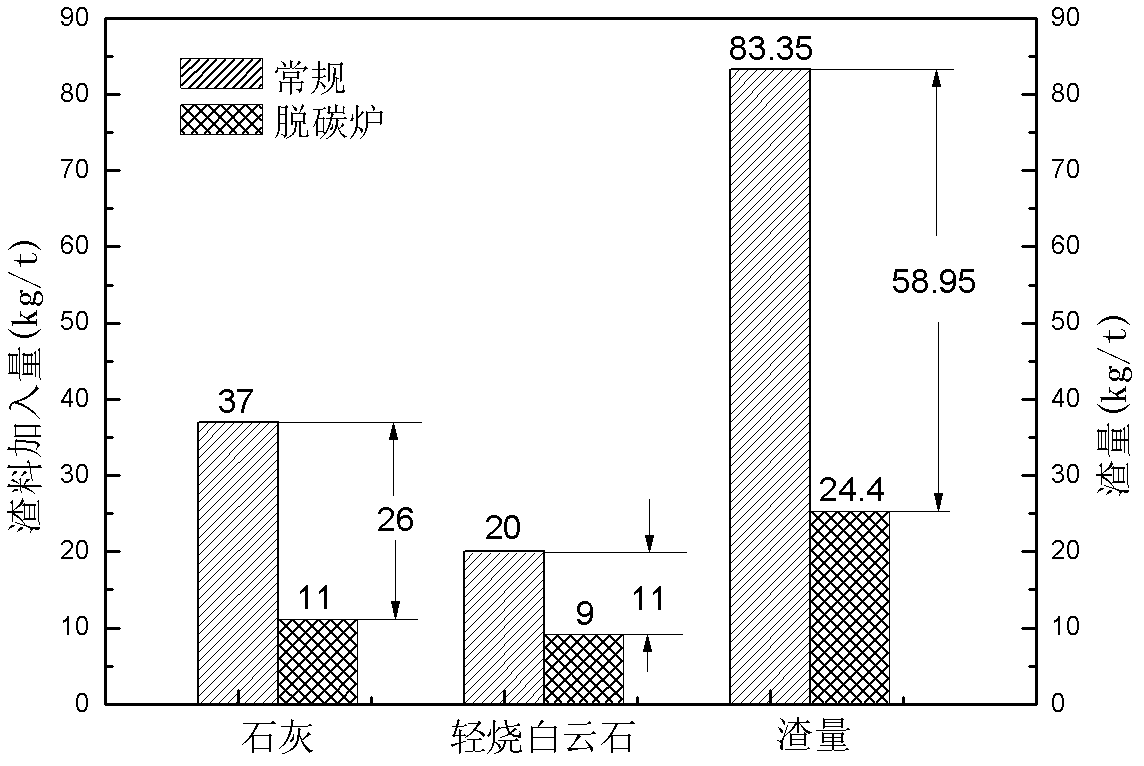

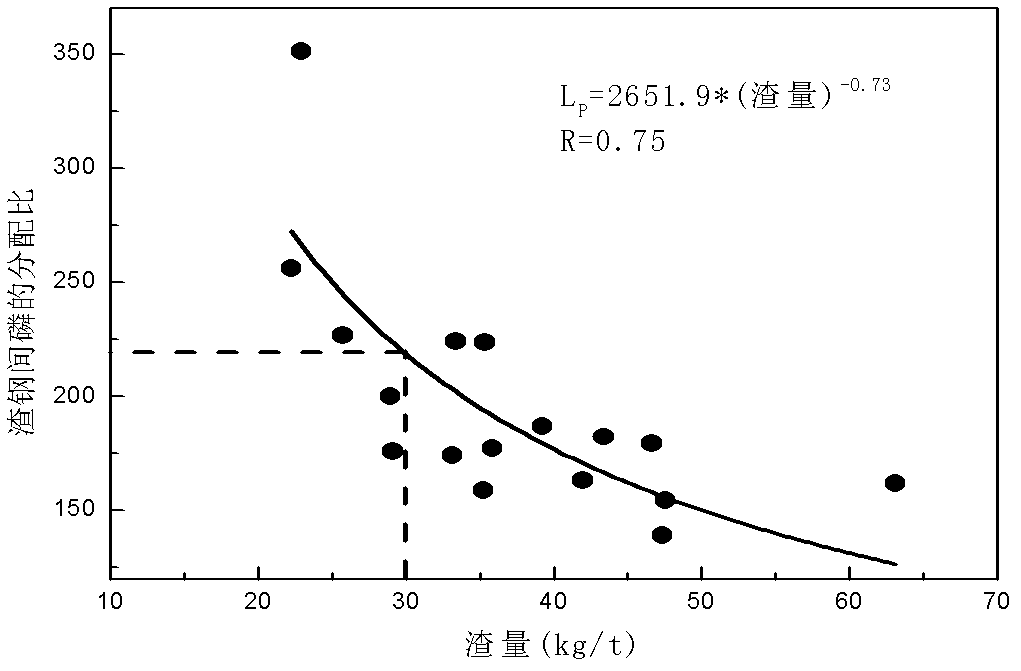

[0033] The semi-steel produced by the 300t dephosphorization converter (see Table 1 for composition and temperature details) is blended into the 300t decarburization converter and then ignited and blown. In the early stage, 11.68kg / t of lime is added, 9kg / t of light burning and 1.35kg / t of fluorite are used to make slag , the composition of slag is shown in Table 2. Oxygen blowing volume 35.24Nm 3 / t, the blowing time is 11min to reach the end point (see Table 1 for the end point composition and temperature). The amount of smelting slag is 24.56kg / t, and the phosphorus distribution ratio between slag and steel is L P Reached 314.

[0034] Table 1 Metal composition in the smelting process (%)

[0035] ingredients

C

Si

S

P

mn

temperature / ℃

semi-steel

3.392

0.022

0.052

0.011

0.023

1351

end point

0.063

/

0.010

0.005

0.031

1695

[0036] Table 2 Slag...

Embodiment 2

[0039] The semi-steel produced by the 300t dephosphorization converter (see Table 3 for composition and temperature details) is blended into the 300t decarburization converter and then ignited and blown. In the early stage, 13.35kg / t of lime is added, 8.91kg / t of light burning and 0.89kg / t of ore are used to make slag , the composition of slag is shown in Table 4. Oxygen blowing volume 33.56Nm 3 / t, the blowing time is 11min to reach the end point (see Table 3 for the end point composition and temperature). The amount of smelting slag is 26.42kg / t, and the phosphorus distribution ratio between slag and steel is L P Reach 200.

[0040] Table 3 Metal composition in the smelting process (%)

[0041] ingredients

C

Si

S

P

mn

temperature / ℃

semi-steel

3.292

0.024

0.017

0.012

0.027

1310

end point

0.024

/

0.008

0.007

0.022

1656

[0042] Table 4 Slag co...

Embodiment 3

[0045] The semi-steel produced by the 300t dephosphorization converter (see Table 5 for composition and temperature details) is blended into the 300t decarburization converter and then ignited and blown. In the early stage, 14.18kg / t of lime is added, 8.94kg / t of light burning and 2.29kg / t of ore are used to make slag , the composition of slag is shown in Table 6. Oxygen blowing volume 31.72Nm 3 / t, the blowing time is 11min to reach the end point (see Table 5 for the end point composition and temperature). The amount of smelting slag is 36.15kg / t, and the phosphorus distribution ratio between slag and steel is L P Reach 235.

[0046] Table 5 Metal composition in the smelting process (%)

[0047] ingredients

C

Si

S

P

mn

temperature / ℃

semi-steel

3.317

0.017

0.026

0.008

0.029

1344

end point

0.053

/

0.008

0.006

0.020

1639

[0048] Table 6 Slag co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com