Patents

Literature

63 results about "Spherical probe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

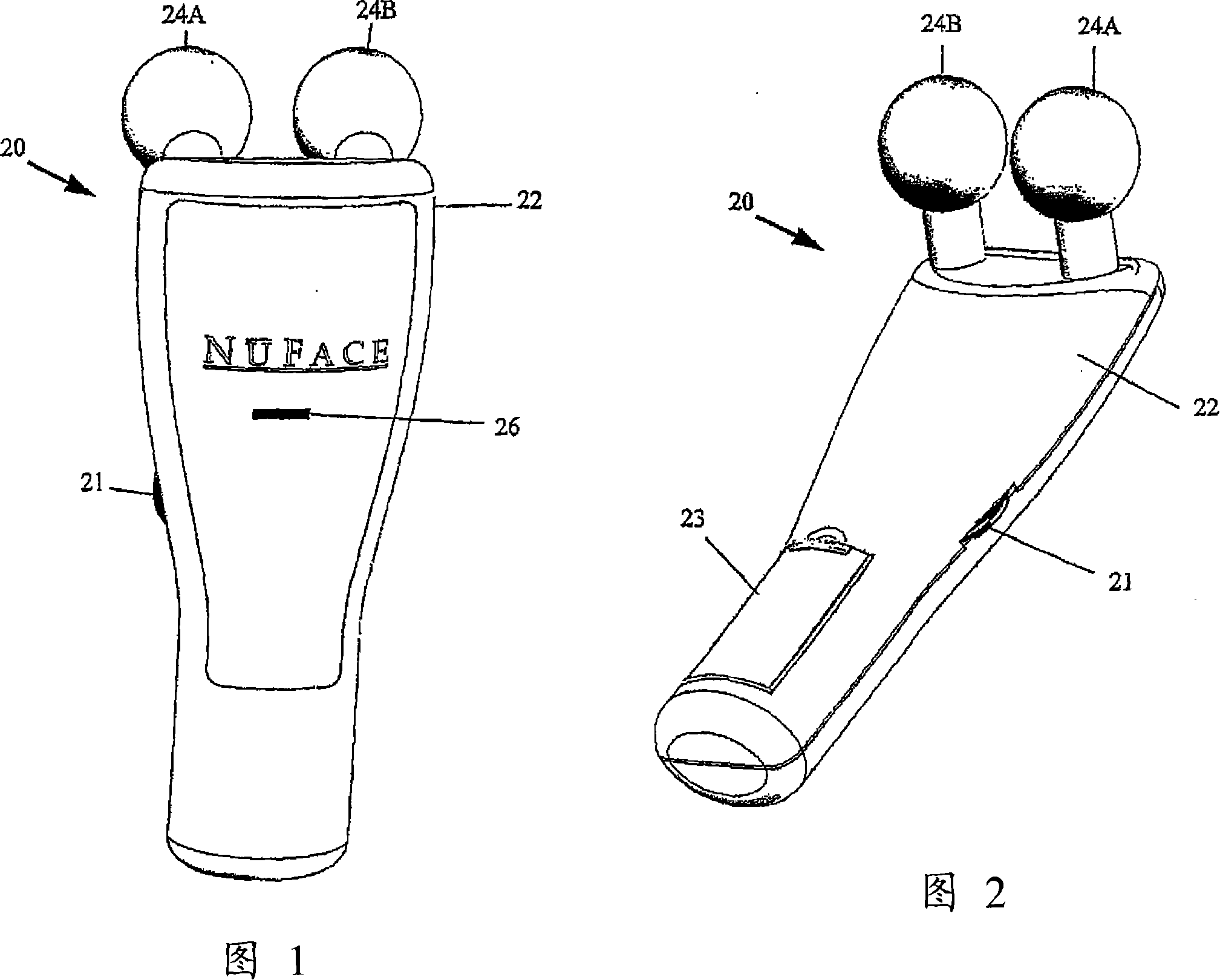

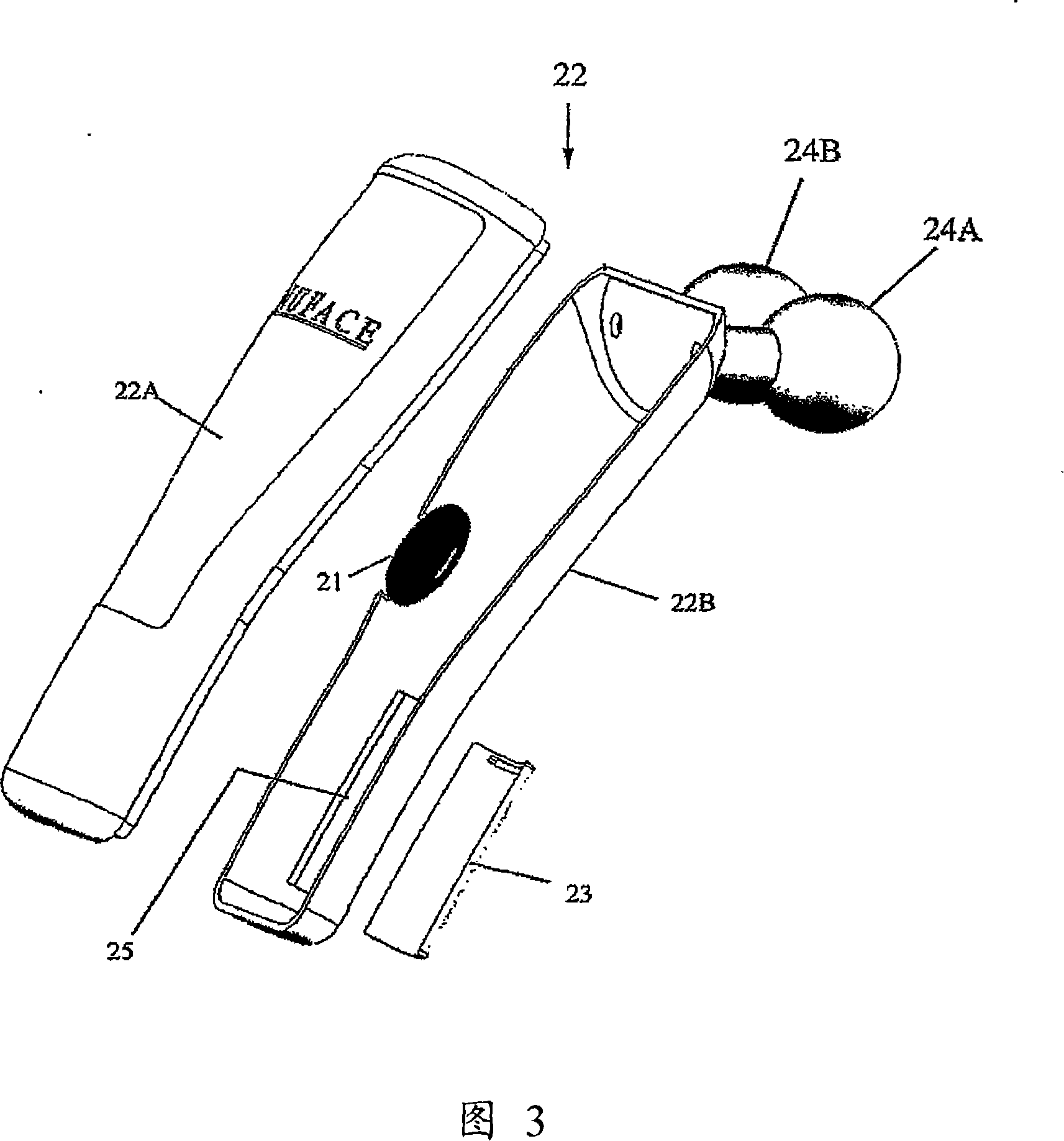

Micro-Dermal Tone Skin Stimulator

InactiveUS20080195181A1Increase contactMaximum efficacyElectrotherapyArtificial respirationLow voltageHand held

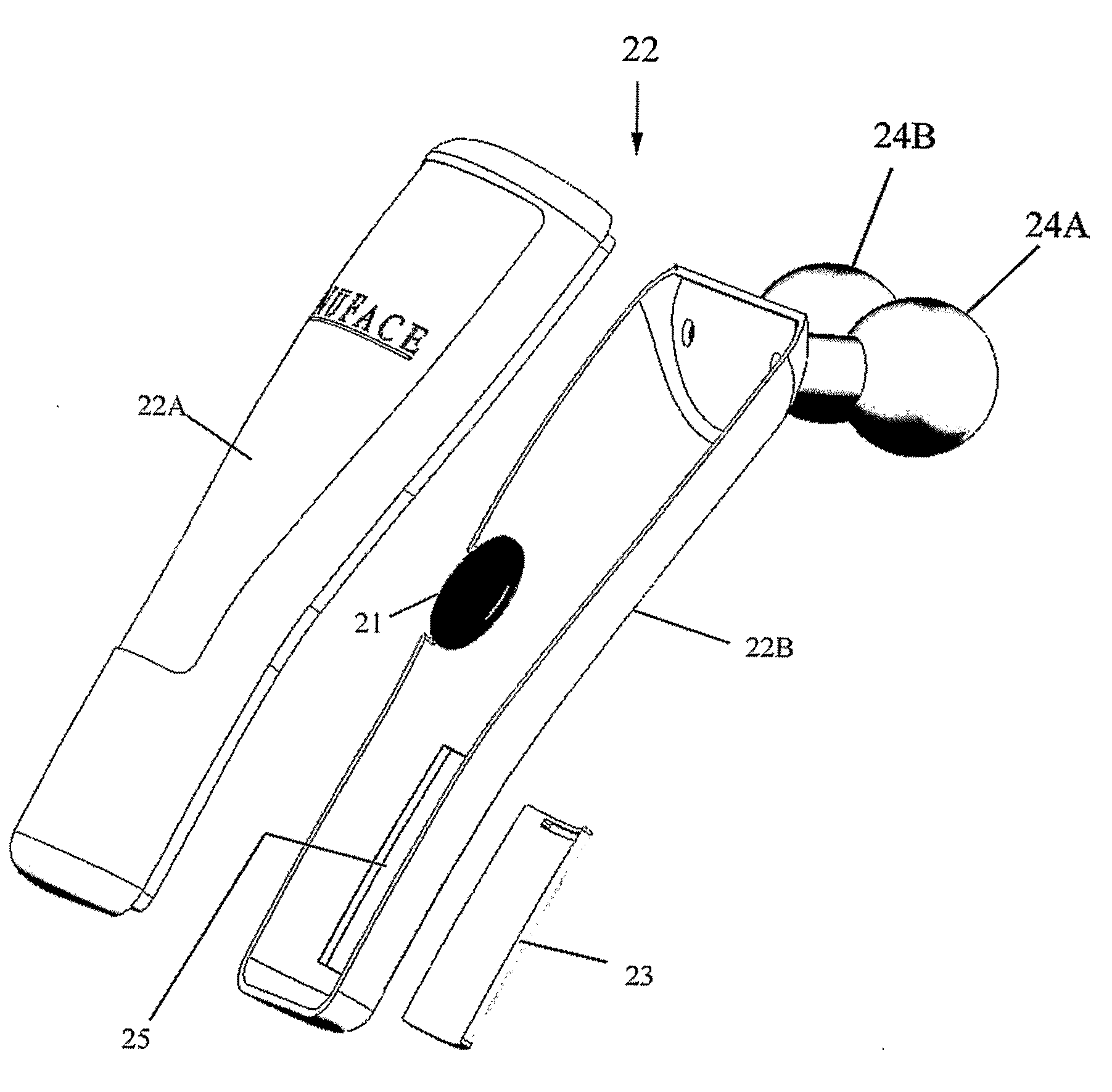

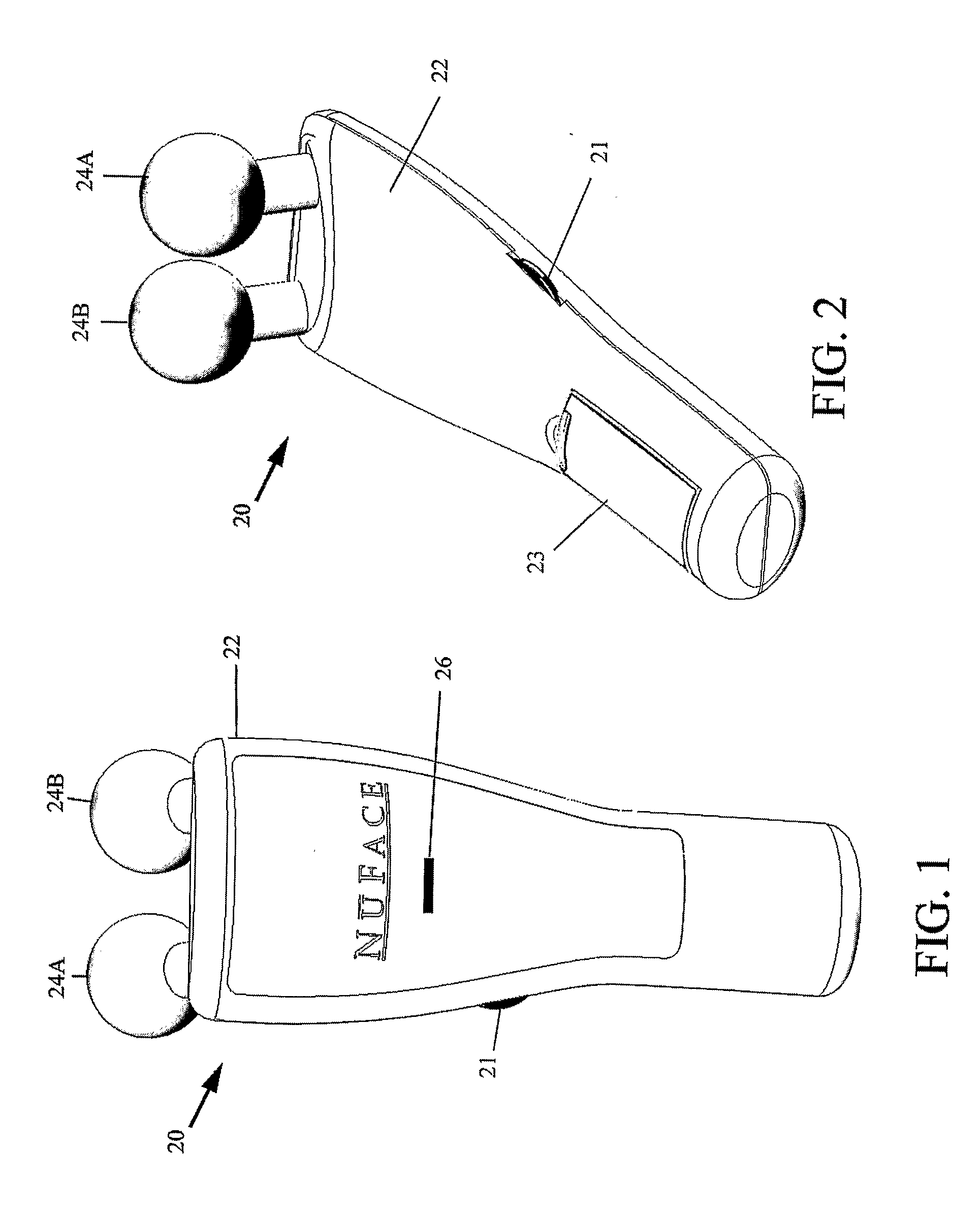

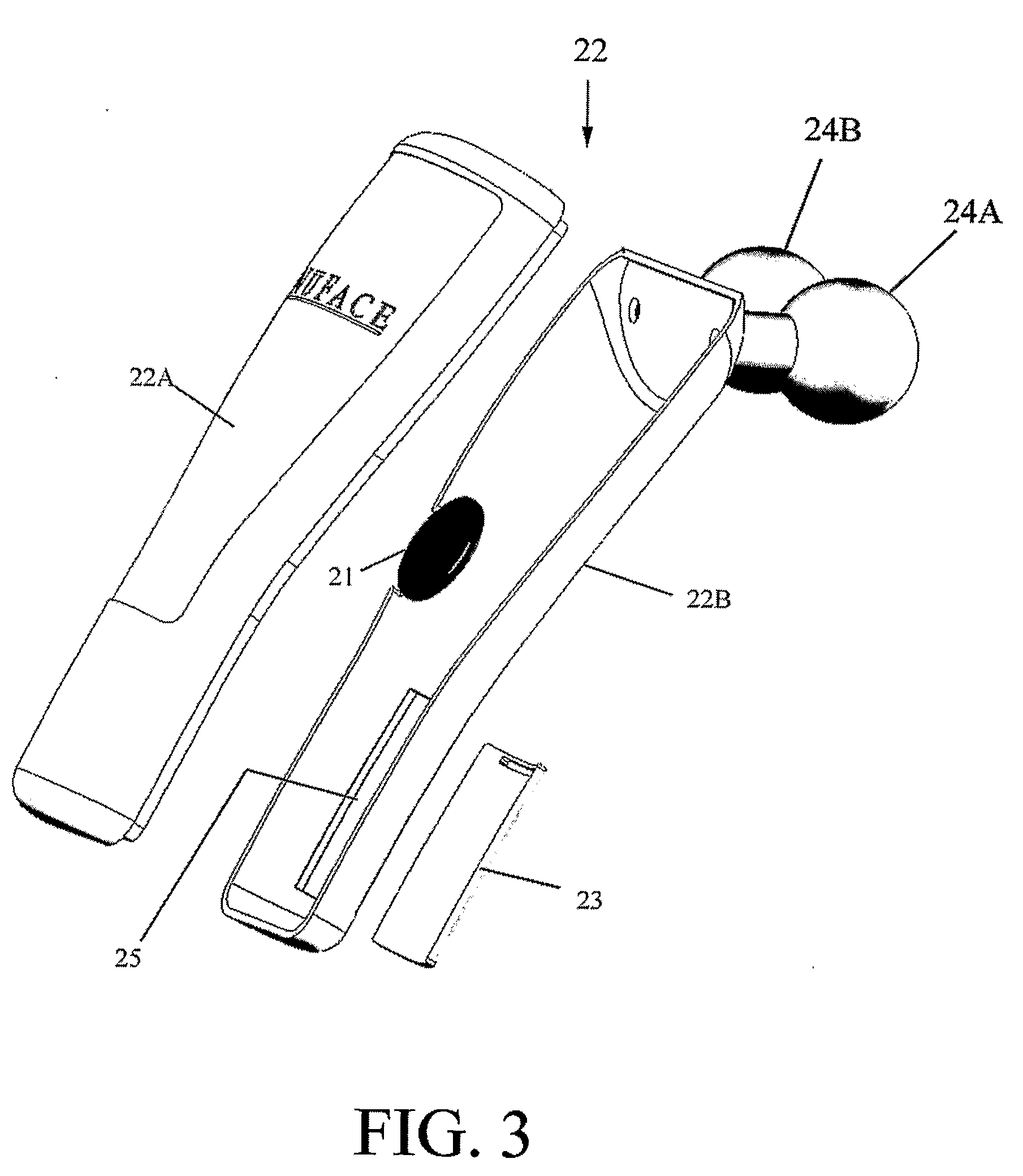

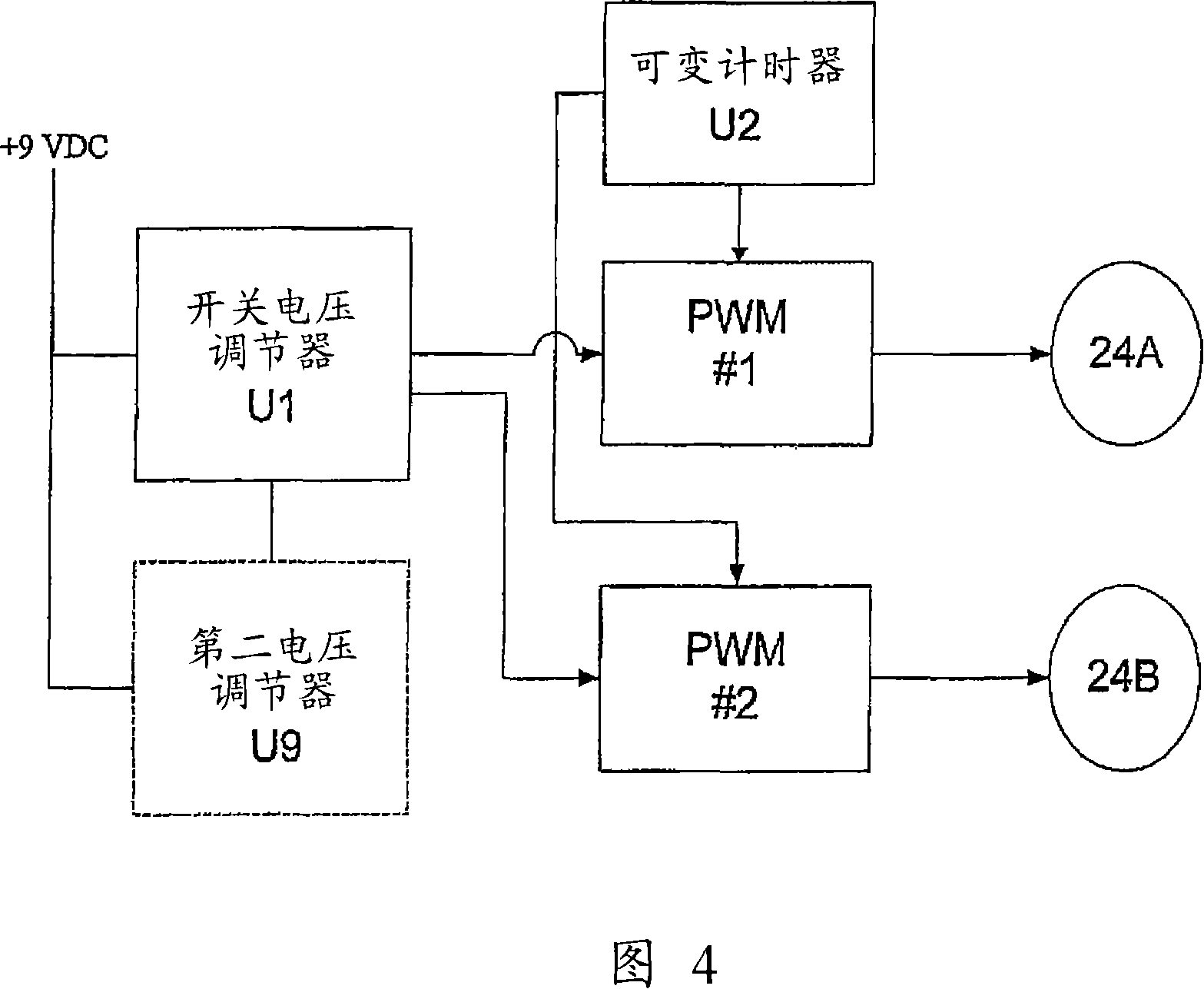

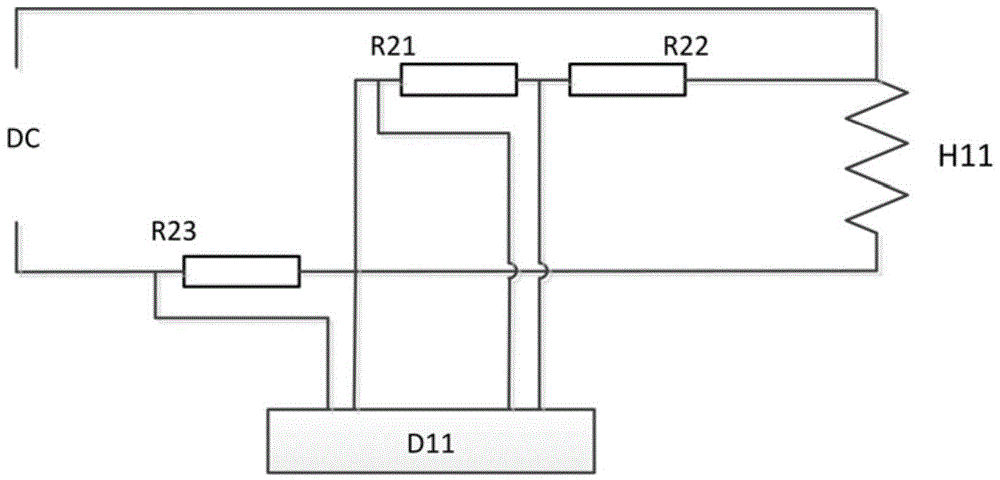

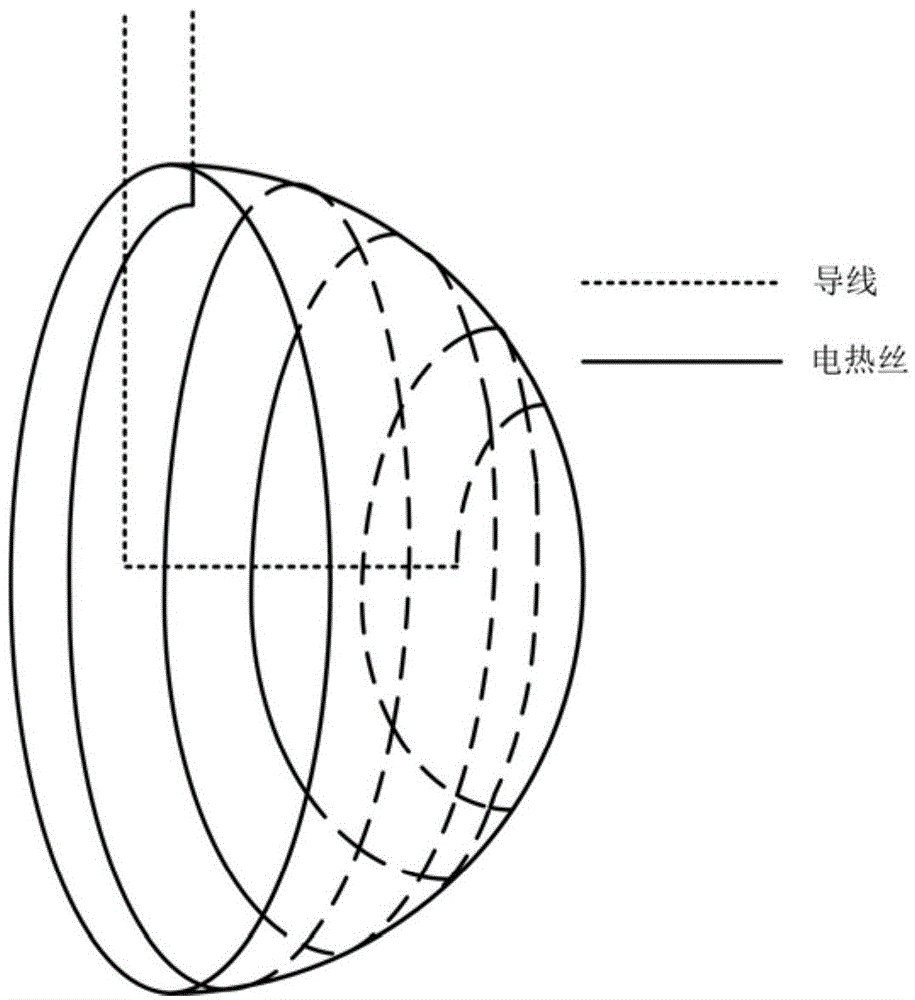

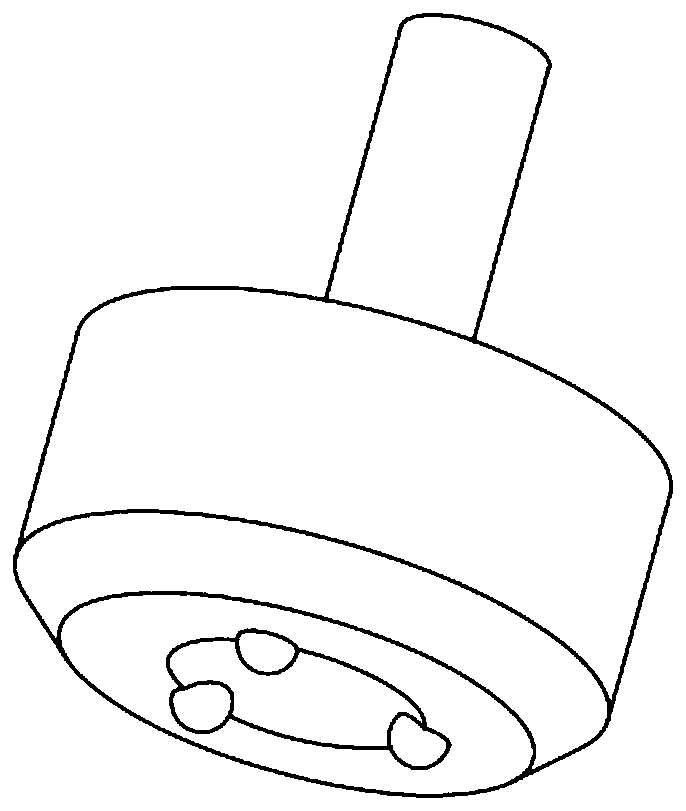

A micro dermal tone skin stimulator system (2) that uses sale, painless, low-level electrical impulses to “reprogram” muscles to assure nearly original muscle shape and to support skin tissues with healthier blood circulation and more youthful firmness. The system comprises a portable hand-held unit with fully-integrated components, including a housing (22), battery pack, an internal circuit board, and an integrated pair of spherical toning probes (24A &24B) for delivering stimulation to the skin. The circuit board generates a positive low-voltage square wave with 60 ms pulse duration for five cycles, then a negative square wave for five cycles, which repeats, delivering an adjustable 0 to 400 micro-amps output (adjustable by potentiometer). Delivering electrical impulses through the spherical probes (24A &24B) using a gliding technique rehabilitates the muscles, improves circulation, texture and tone almost immediately, and continued use provides lasting clarity and restores freshness to one's appearance.

Owner:CAROL COLE

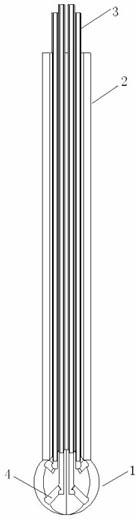

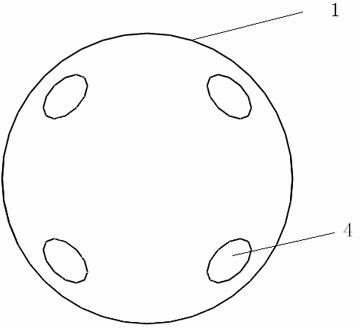

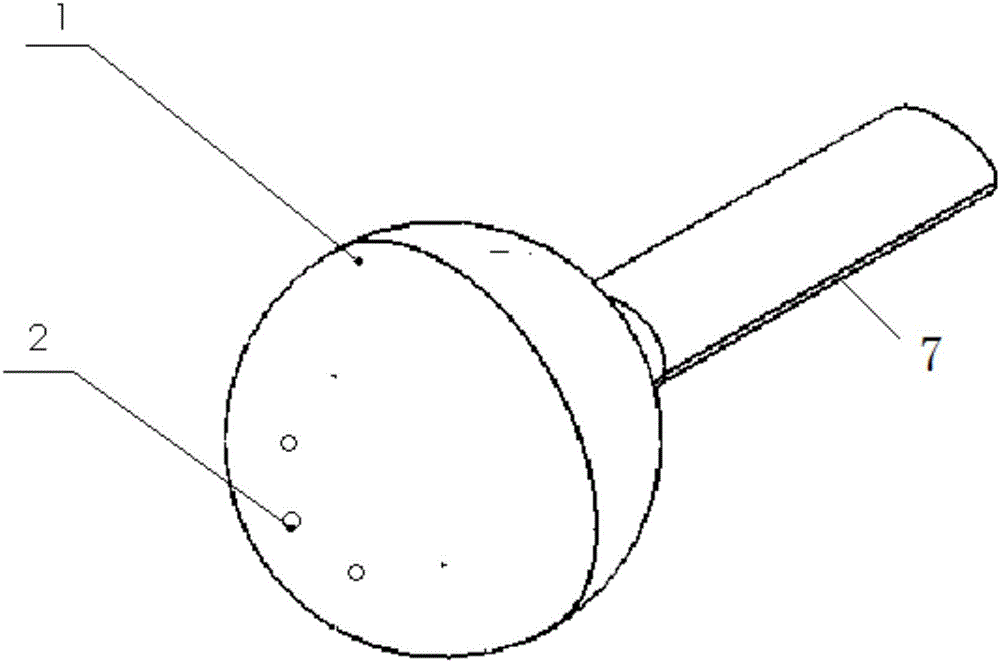

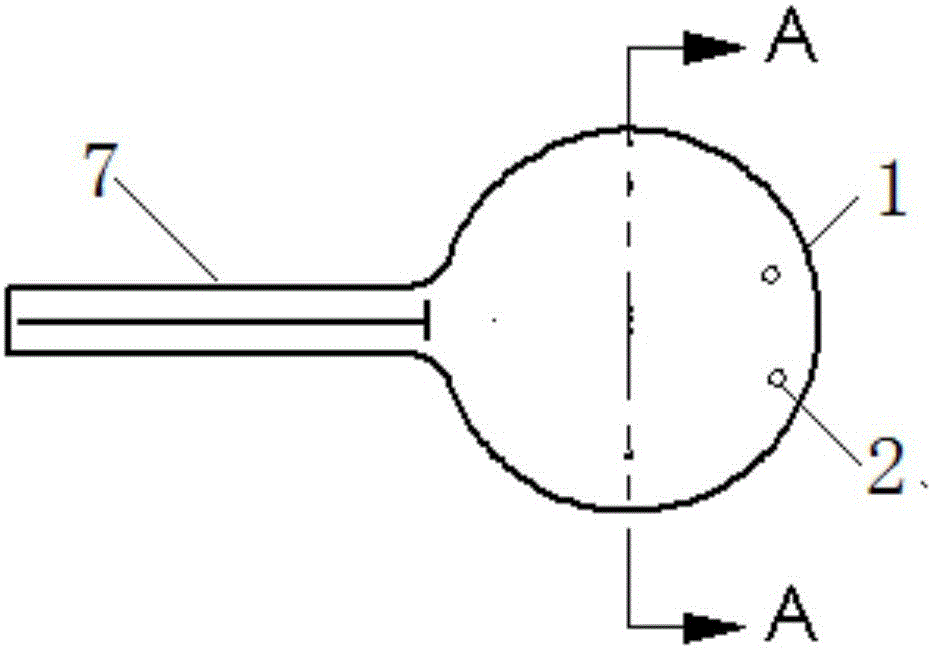

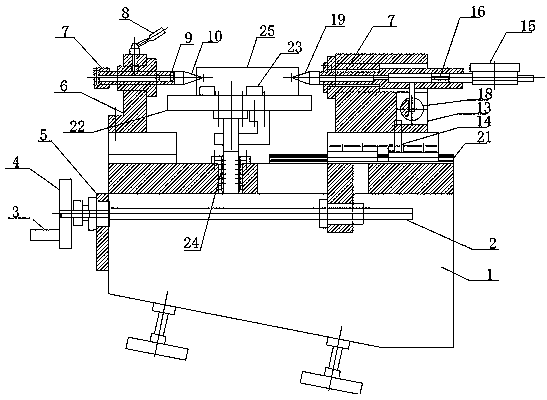

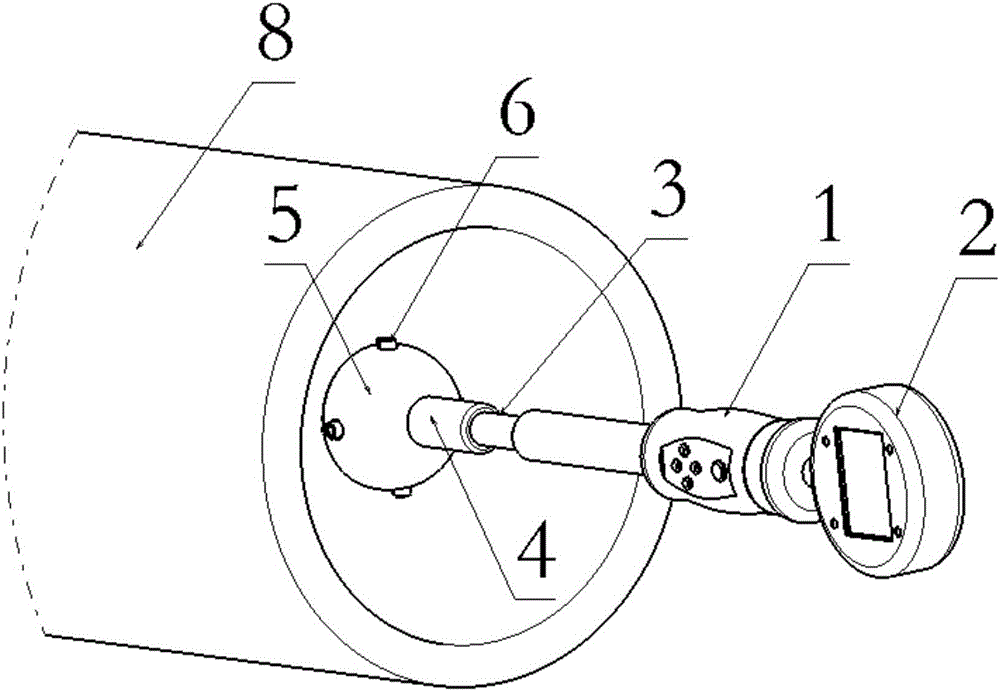

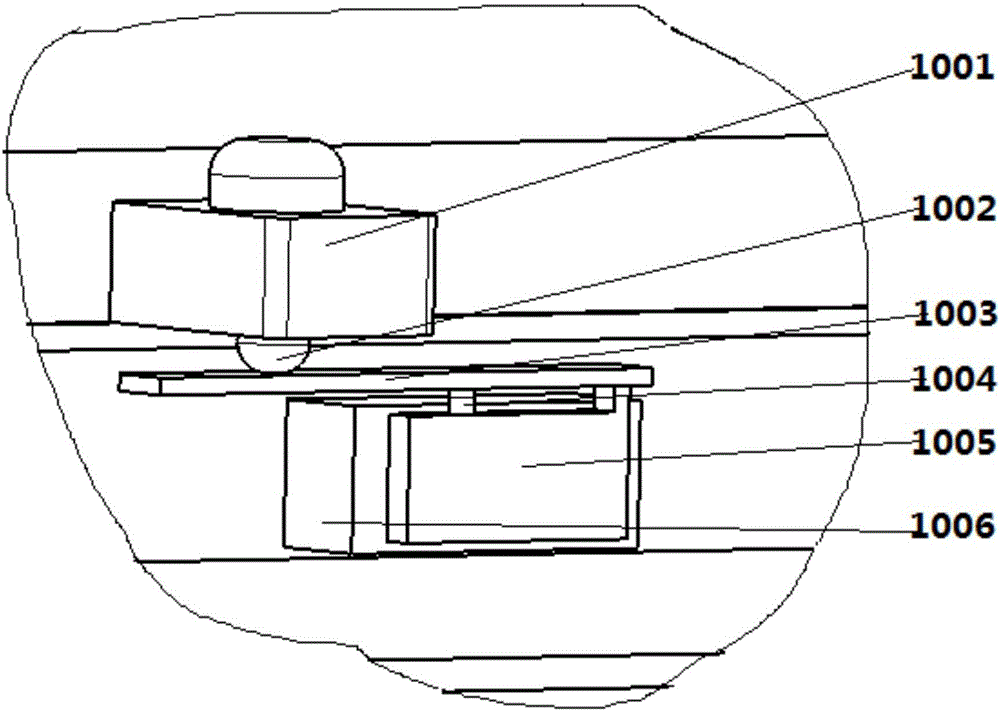

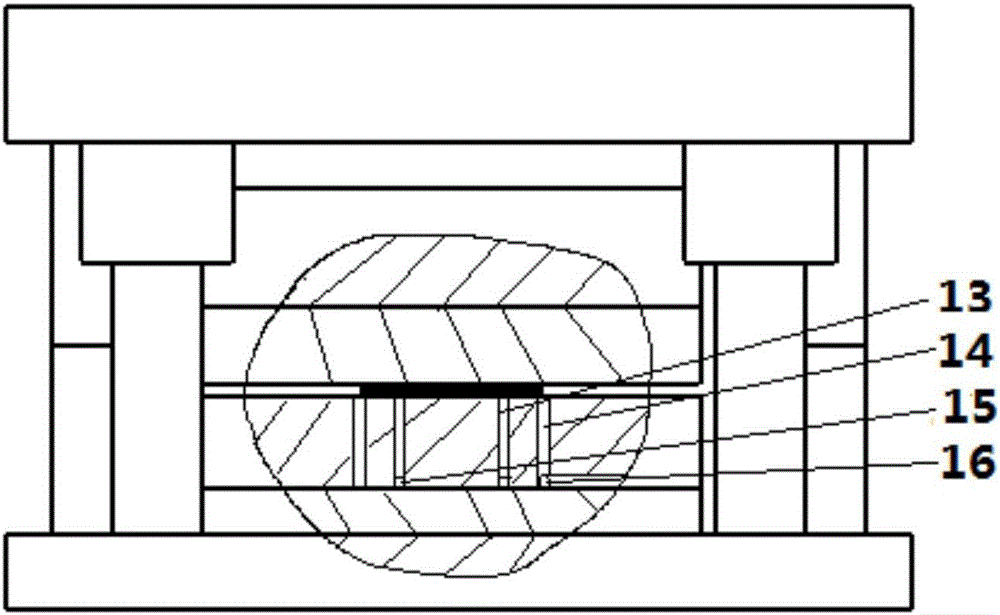

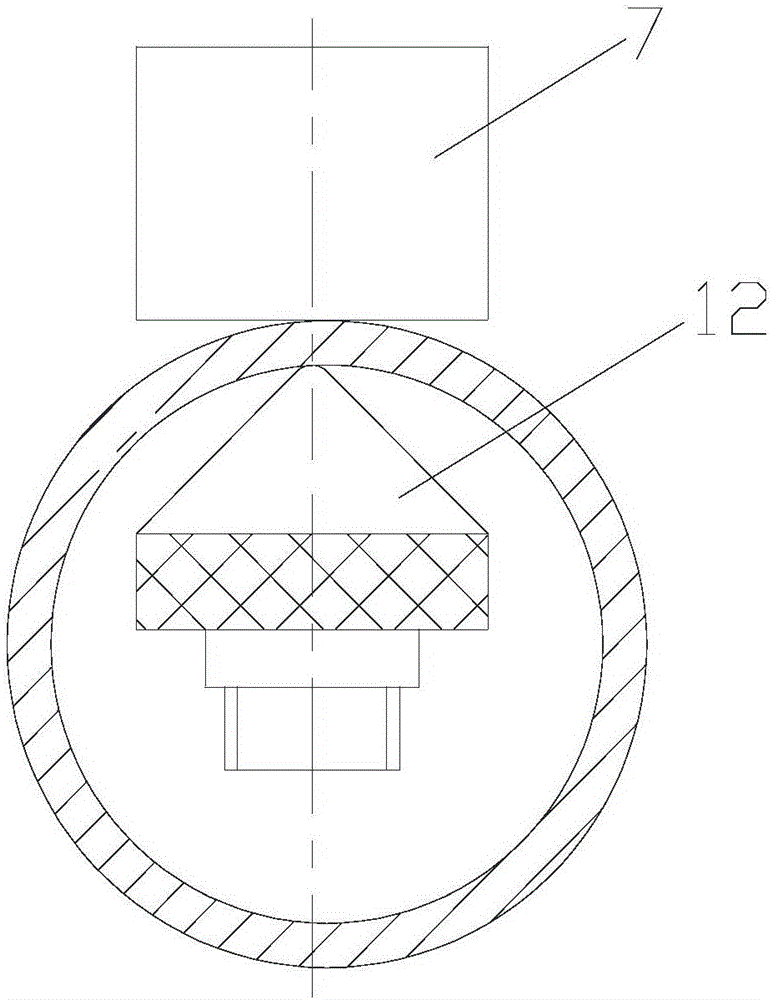

Spherical hole-pressure static cone penetration probe for detecting sludge

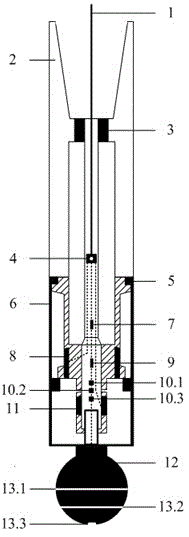

The invention declares a spherical hole-pressure static cone penetration probe for detecting sludge. The probe comprises a coaxial cable (1) used for signal and data transmission, a probe rod (2) and a waterproof ring (3) at the upper part, and an analog-digital converter (4) in the middle, wherein a seal ring (5) and a side wall friction tube (6) are arranged at the lower part of the probe rod (2); an inclinometer (7), a side wall friction resistance sensor (8) , a temperature sensor (9), three pore water pressure sensors (10.1, 10.2 and 10.3) and a round sphere-shaped resisting force sensor (11) are arranged in the side wall friction tube (6); the spherical probe (12) is connected with the lower part of the side wall friction tube (6); three hole-pressure filtering rings (13.1, 13.2 and 13.3) are arranged on the spherical probe (12) and are respectively connected with the three pore water pressure sensors (10.1, 10.2 and 10.3). The probe provided by the invention has the characteristics of being in-situ, direct, quick, accurate and economical, and provides a powerful detect tool for geotechnical engineering practice.

Owner:SOUTHEAST UNIV

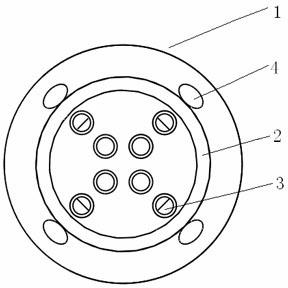

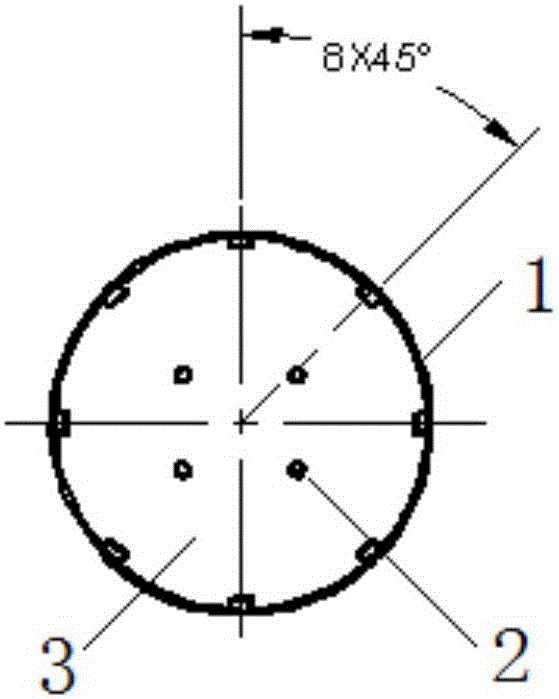

Full-flow direction flow velocity measurement probe and measurement method thereof

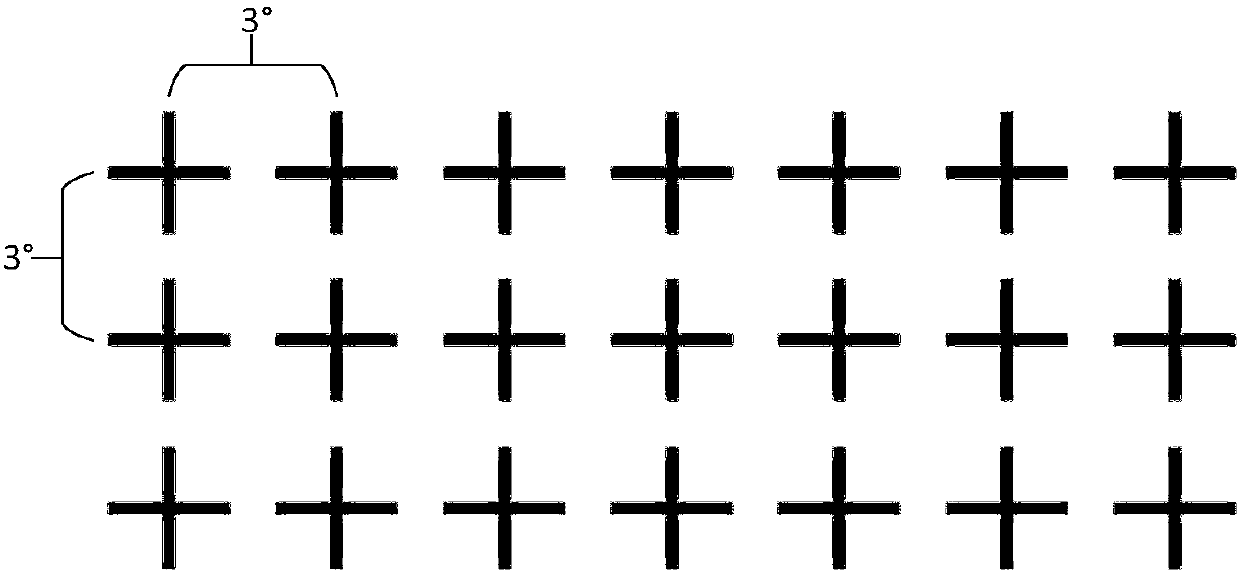

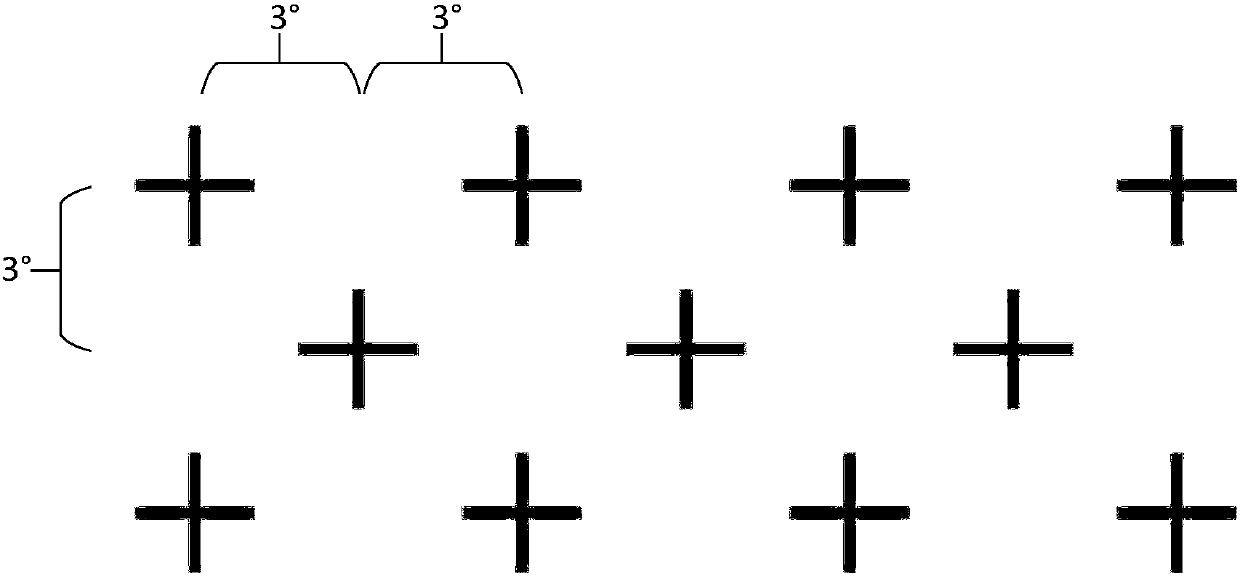

InactiveCN102636662ASimple structureLow costIndication/recording movementFluid speed measurementSpherical probeAngular degrees

The invention discloses a full-flow direction flow velocity measurement probe and a measurement method of the full-flow direction flow velocity measurement probe, and relates to the field of measurement of fluid velocity and direction. The probe comprises eight pressure measuring holes at the spherical probe head and eight pressure guide tubes led out from the tail of the probe and is characterized in that the probe head is spherical, the eight pressure measuring holes are uniformly distributed on the sphere, and thus when the pressure measuring holes are watched from the forward directions from the front and back, left and right and up and down, four pressure measuring holes are uniformly distributed in the six forward directions. In the measurement process, by taking the apparently maximum total pressure as reference, the zone of the incoming flow is judged, and in combination with the apparent total pressure of the zone, the pressures on the four holes of the zone, the flow velocity coefficient, the angle coefficient and the like, the flow velocity and flow direction are calculated; the flow velocity measurement probe has the advantages of simple structure, low cost, wide flow direction detection range and the like; and the flow velocity measurement probe can be widely applied to the three-dimensional flow field measurement of engineering and scientific research.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

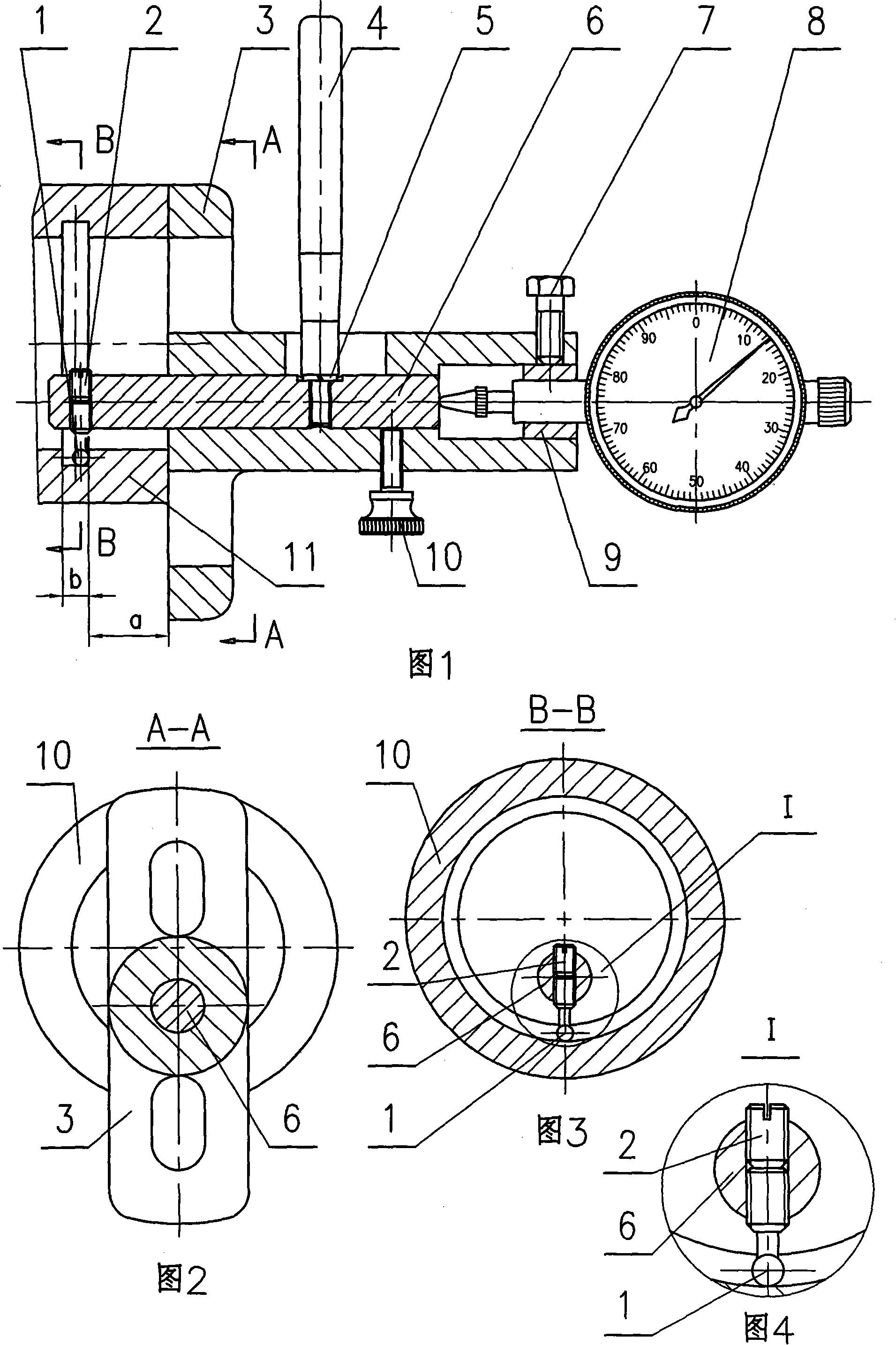

Inner hole fluted shaft direction dimension measuring implement

InactiveCN101140156AAccurate measurementMeasuring tool design is reasonableMechanical measuring arrangementsBiochemical engineeringSpherical probe

The invention relates to an axial dimensions measuring device for an inner hole groove; a spherical probe is arranged on one end of a slide measuring rod, the slide measuring rod is arranged in the inner hole of the measuring device body for clearance fit, a handle passes through an axial groove of the measuring device body and is arranged on the slide measuring rod with a stud bolt of the front end of the handle, a dial indicator is arranged on the small end of the measuring device body, the probe of the dial indicator props on one end without the spherical probe of the slide measuring rod, and a knurled thumb screw is arranged in a screw hole corresponding with the measuring device and can fix the slide measuring rod in the necessary position. The spherical probe is placed into a groove of the workpiece hole and the large end surface is close to the outer end of the inner hole of the measured workpiece, the slide measuring rod drives the spherical probe to axially move and be respectively close to the two sides of the groove in order to result in that the dial indicator shows two numerical values. Under the fit of a standard block or a measuring caliper, the width size of the groove in the inner hole of the workpiece and the axial position size from the groove to the inner hole end surface can be gained. The measuring device has the advantages of the reasonable design, the simple manufacture, the low cost, the convenient use and the fast and accurate measurement.

Owner:陈焕春

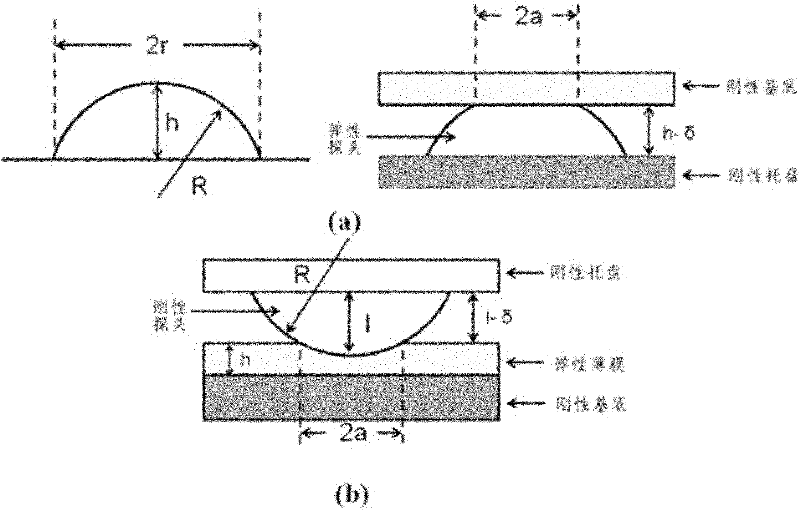

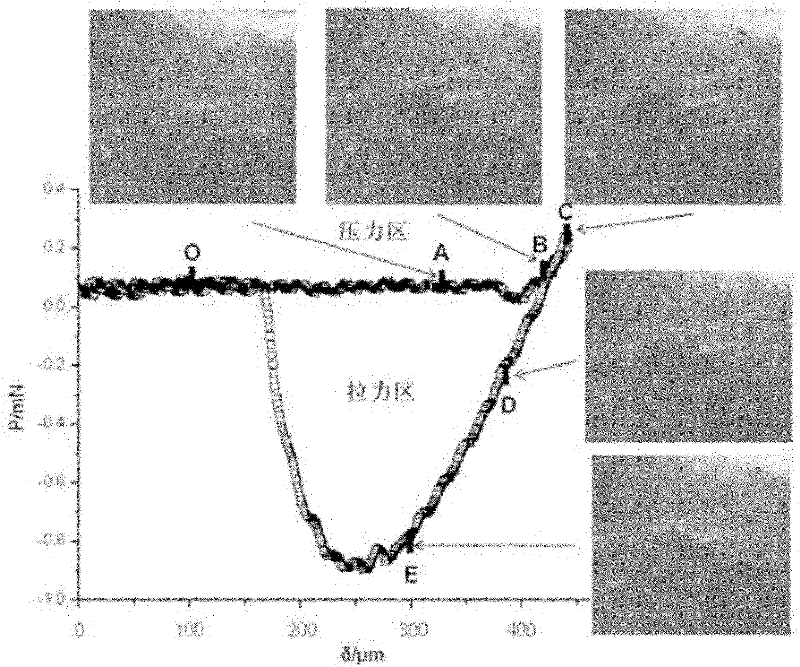

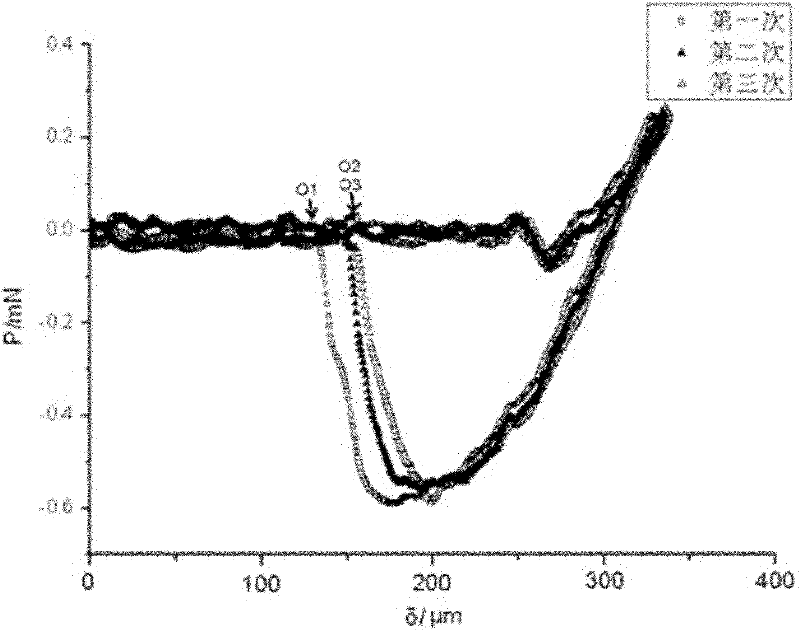

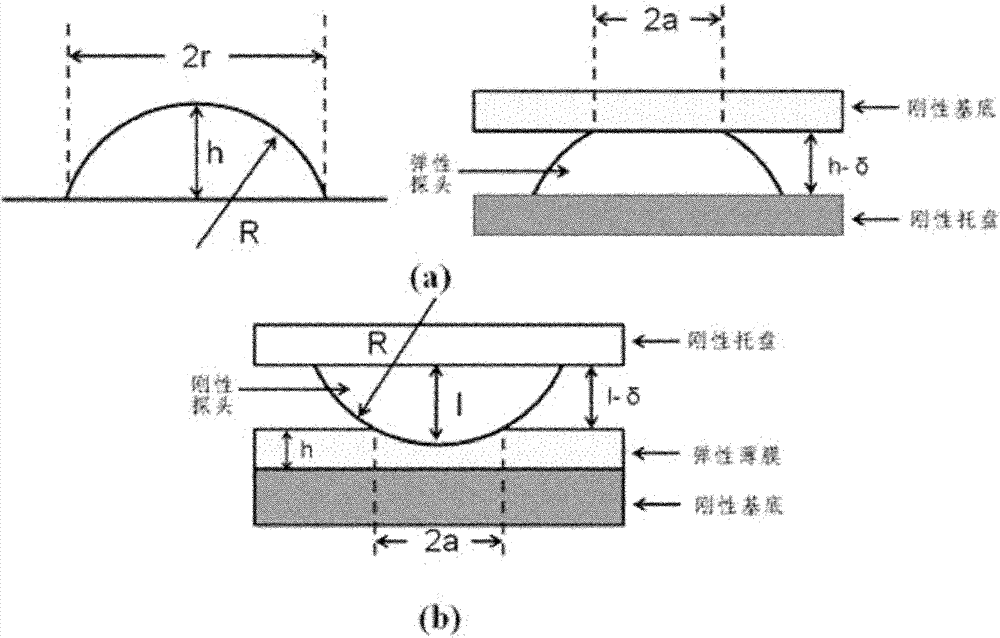

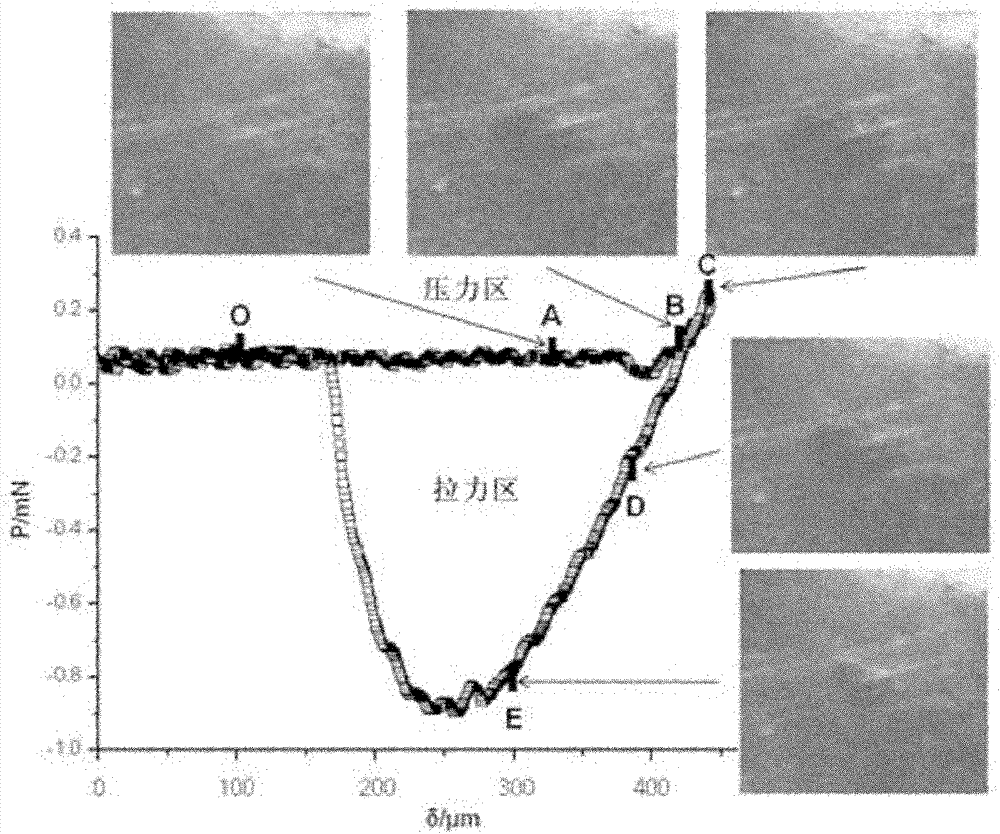

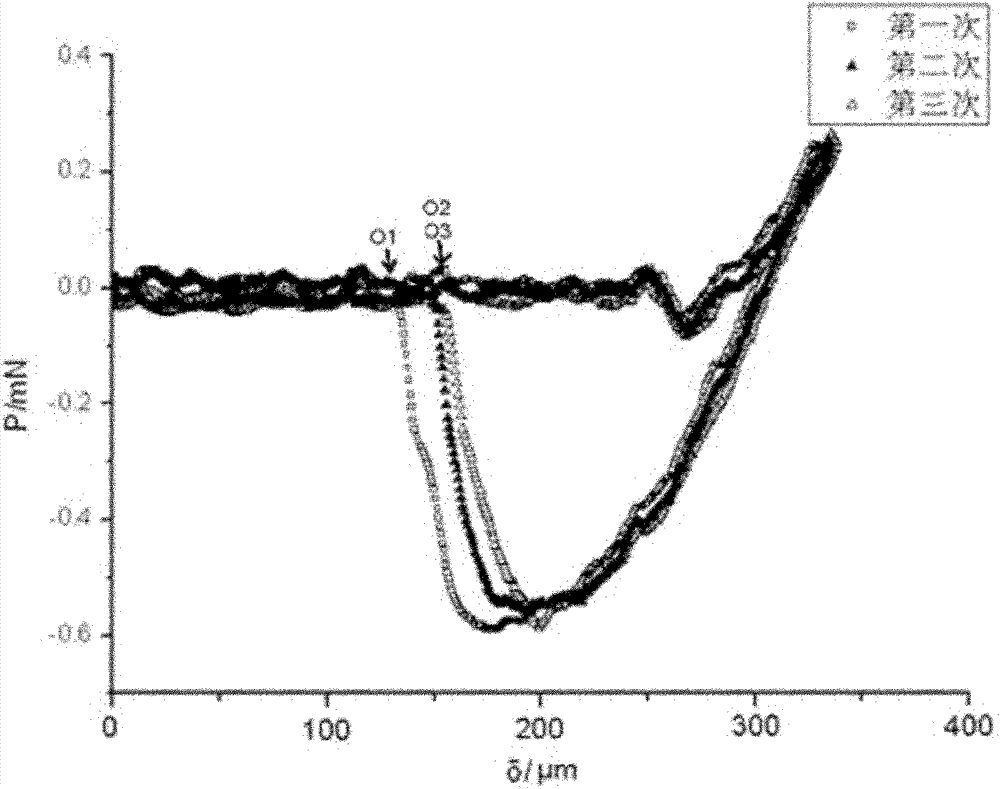

Method for measuring surface adhesive capacity and elastic modulus of soft material

InactiveCN102183441AReduce volumeWide range of test materialsSurface/boundary effectStrength propertiesElastomerSpherical probe

The invention discloses a method for measuring the surface adhesive capacity and an elastic modulus of a soft material, the method comprises the following specific steps of: (1) preparing a sample and selecting a probe according the physical property and the chemical property of a tested sample; (2) controlling a horizontal substrate and the spherical probe to move oppositely to be contacted and separated at a constant speed; (3) measuring an interaction force P, a relative displacement delta and a contact radius a respectively by using a pressure sensor, a displacement sensor and an optical microscope in the whole process of the step (2) when the substrate and the probe are contacted with each other; (4) frequently repeating the steps (2) and (3) under the control of software; and (5) quantitatively analyzing the adhesive capacity and the elastic performance of the tested material by using data obtained in the step (3) according to a jabatan kerja raya (JKR) theory. The measurement method has giant application potential in the aspects of scientific research on soft materials such as high-molecule elastic body, biogel and the like, product quality control in industrial manufacturing processes and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

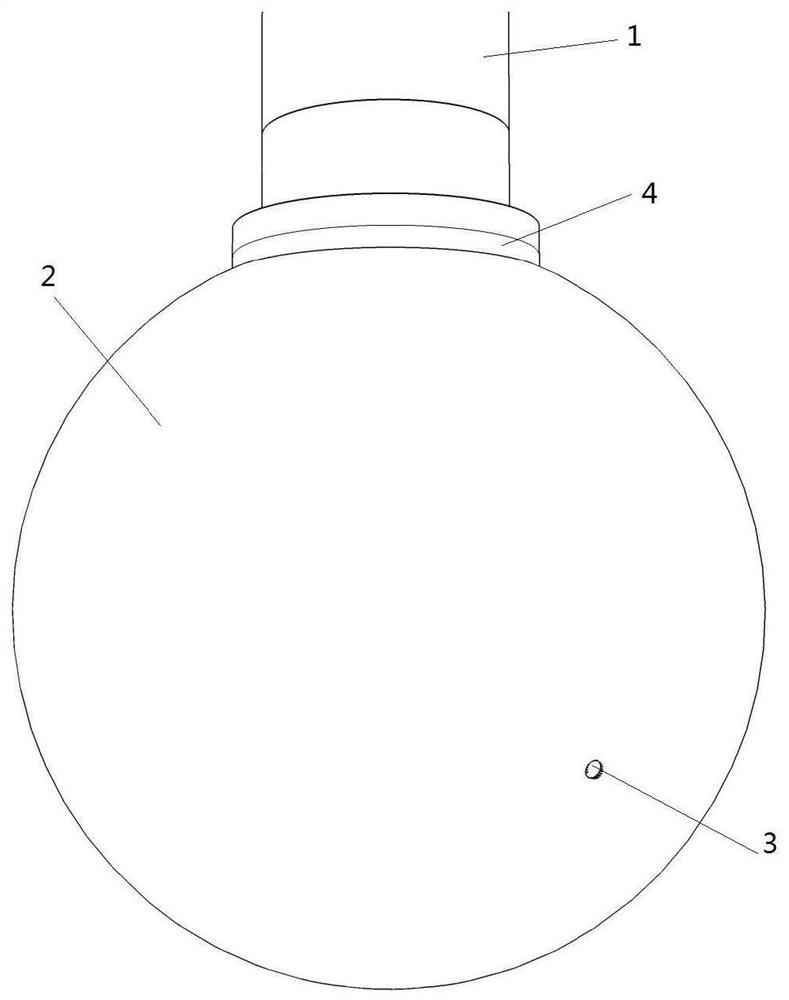

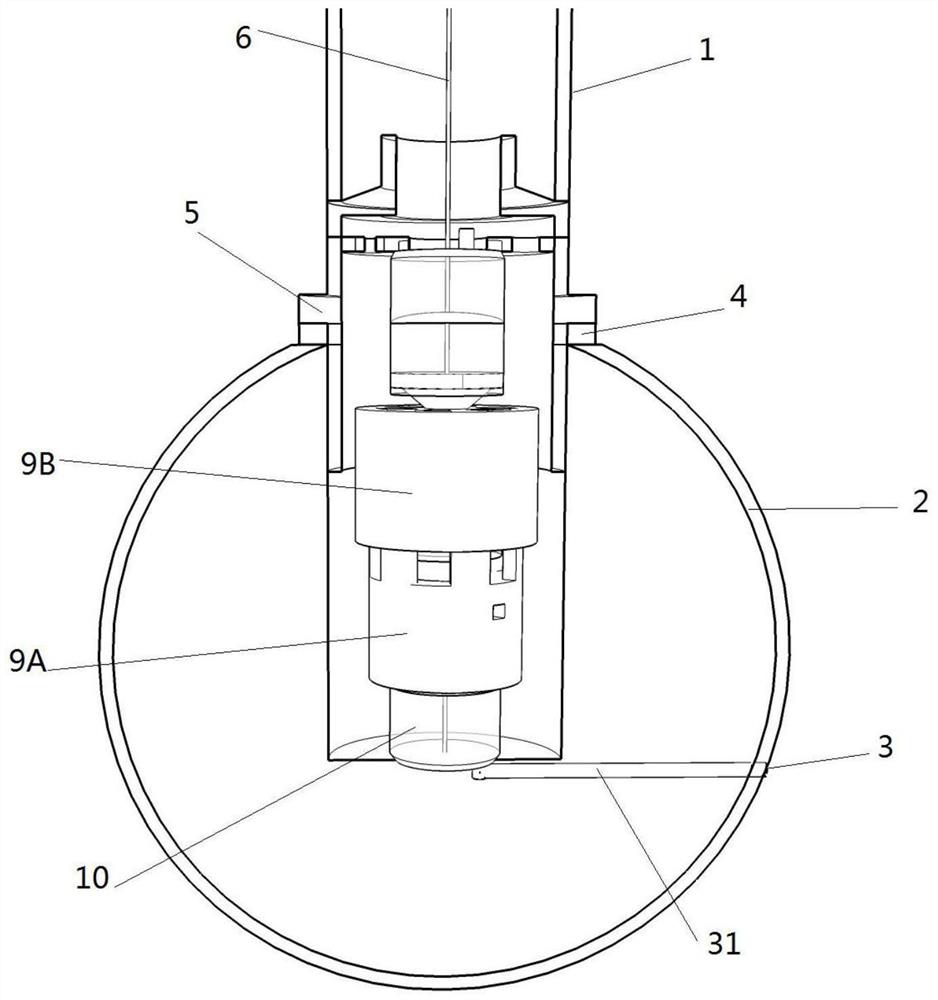

Omnidirectional atmospheric data measurement spherical probe

PendingCN106092205ASimple structureSolve the weight problemMeasurement devicesMeasurement devicePressure transmission

The invention provides an omnidirectional atmospheric data measurement spherical probe and provides an atmospheric data measurement instrument that is simple in structure, large in acquisition angle range, high in reliability, small in size and light in weight. According to the technical scheme of the invention, for different airflow angles, pressure measuring points on a spherical body are partitioned, and the partition areas of the pressure measuring points are positioned on the front, rear, left, right and top spherical surfaces of the hollow spherical body (1). The partitioned pressure measuring points are realized through a pressure cavity (3) in connection with the hollow spherical body and pressure measuring holes (2) uniformly distributed in the cross-shaped manner at intervals. The pressure measuring holes transmit the pressure to a pressure scanning valve (5) through a pressure measuring pipe (4). The pressure scanning valve converts a received pressure signal into a digital signal. Meanwhile, the pressure scanning valve transmits the digital signal to a calculation unit (6) arranged in the hollow spherical body, so that atmospheric parameters and the current atmospheric data information of an aircraft are calculated by the calculation unit. In this way, the simultaneous acquisition and the omnidirectional measurement of multi-point pressures at different airflow angles in different areas can be achieved.

Owner:CHENGDU KAITIAN ELECTRONICS

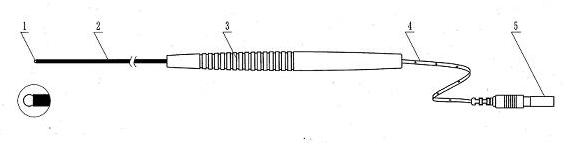

Electrode for nerve electrophysiology monitoring in high field intensity magnetic resonance compatible technology

ActiveCN102626309AEasy to operateSmall influence of high field strength magnetic fieldDiagnostic recording/measuringSensorsSpherical probeHigh field

The invention belongs to the field of medical instruments and auxiliary devices, and in particular relates to an electrode for nerve electrophysiology monitoring in high field intensity magnetic resonance compatible technology. The electrode comprises a probe electrode and a pin electrode, wherein the probe electrode is a spherical probe electrode, and the pin electrode is a pin-shaped electrode. The spherical probe electrode is composed of a head portion, an electrode rod, a handle, a wire and a plug. The pin type electrode is composed of a pin-shaped head portion, a handle, a wire and a plug. The wire penetrates through the handle to be welded with the head portion through silver, and the other end of the wire is rivet joint with the plug. A high field intensity magnetic field has small influence on the electrode for monitoring, and a heat effect and a displacement effect are small. The electrode for monitoring does not generate extra current and tissue burn, and can be safely applied in a high field intensity environment without interfering magnetic resonance imaging. A recording electrode does not need to be removed when nerve electrophysiology monitoring is performed, image analysis is not influenced, and operation is convenient, simple and standard.

Owner:XIAN FRIENDSHIP MEDICAL ELECTRONICS CO LTD +1

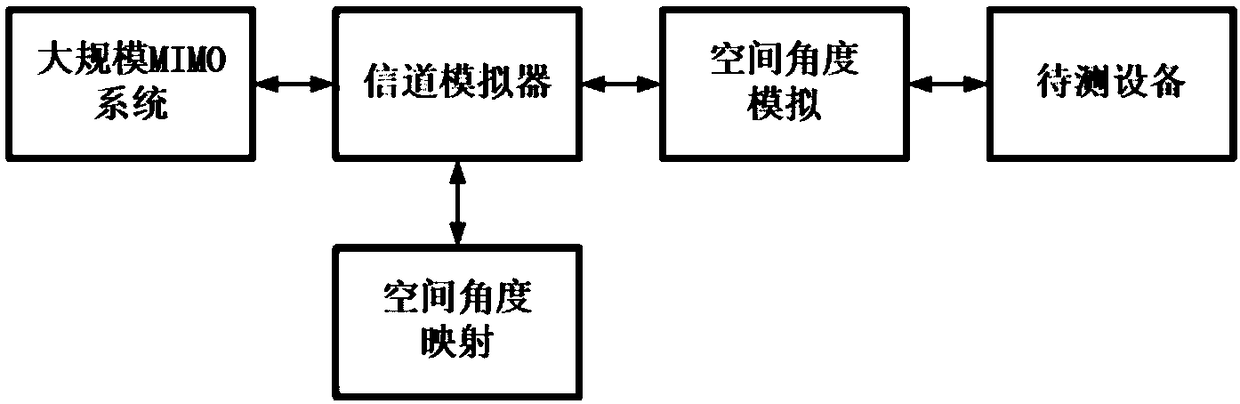

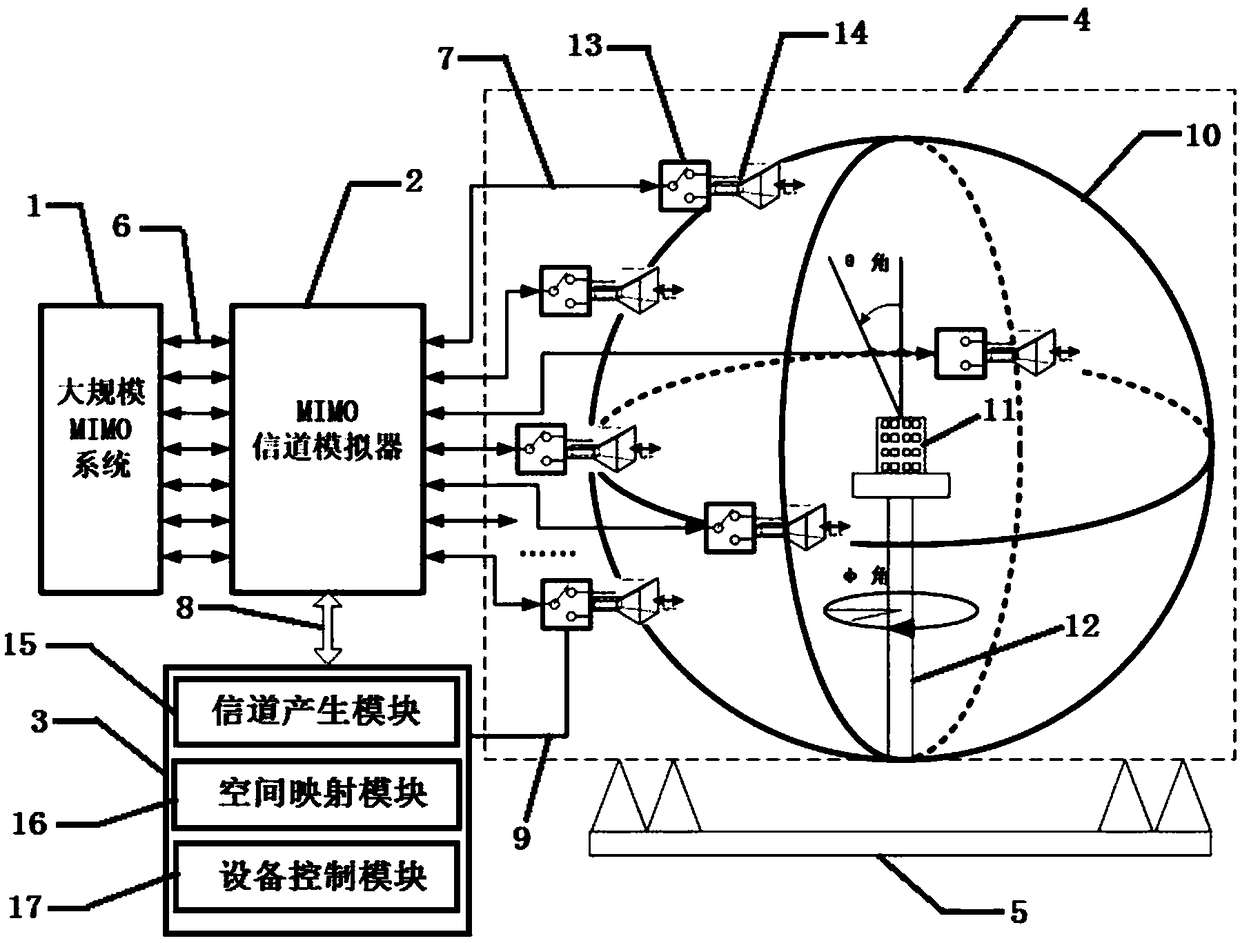

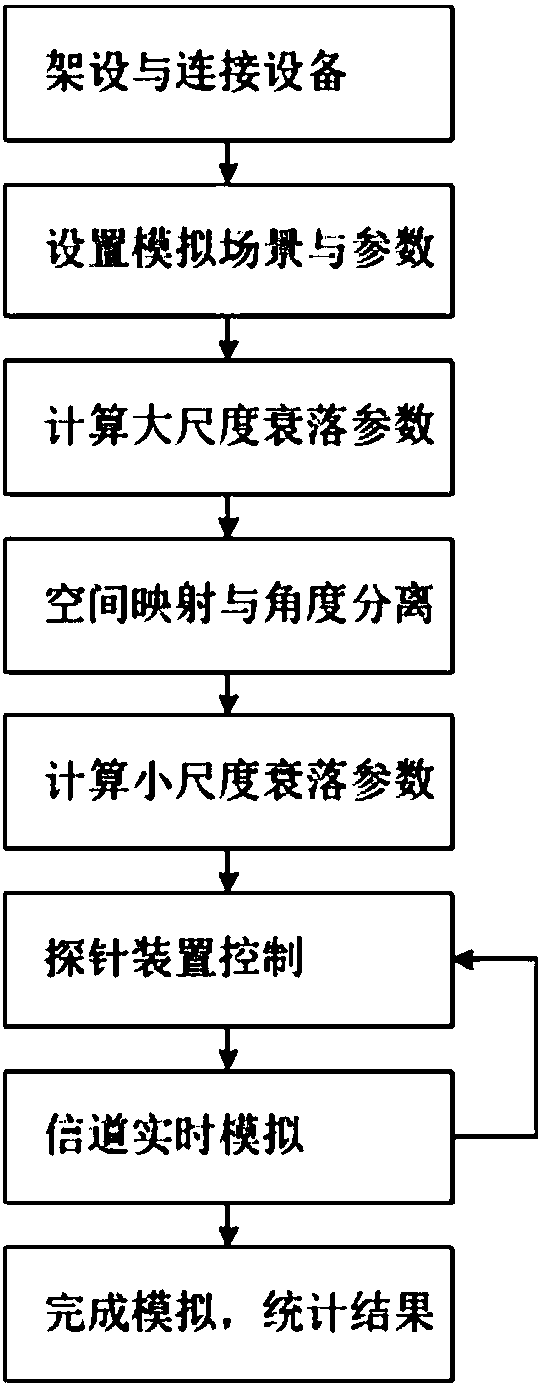

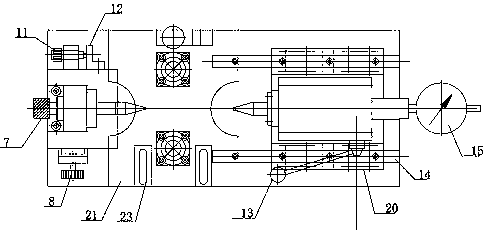

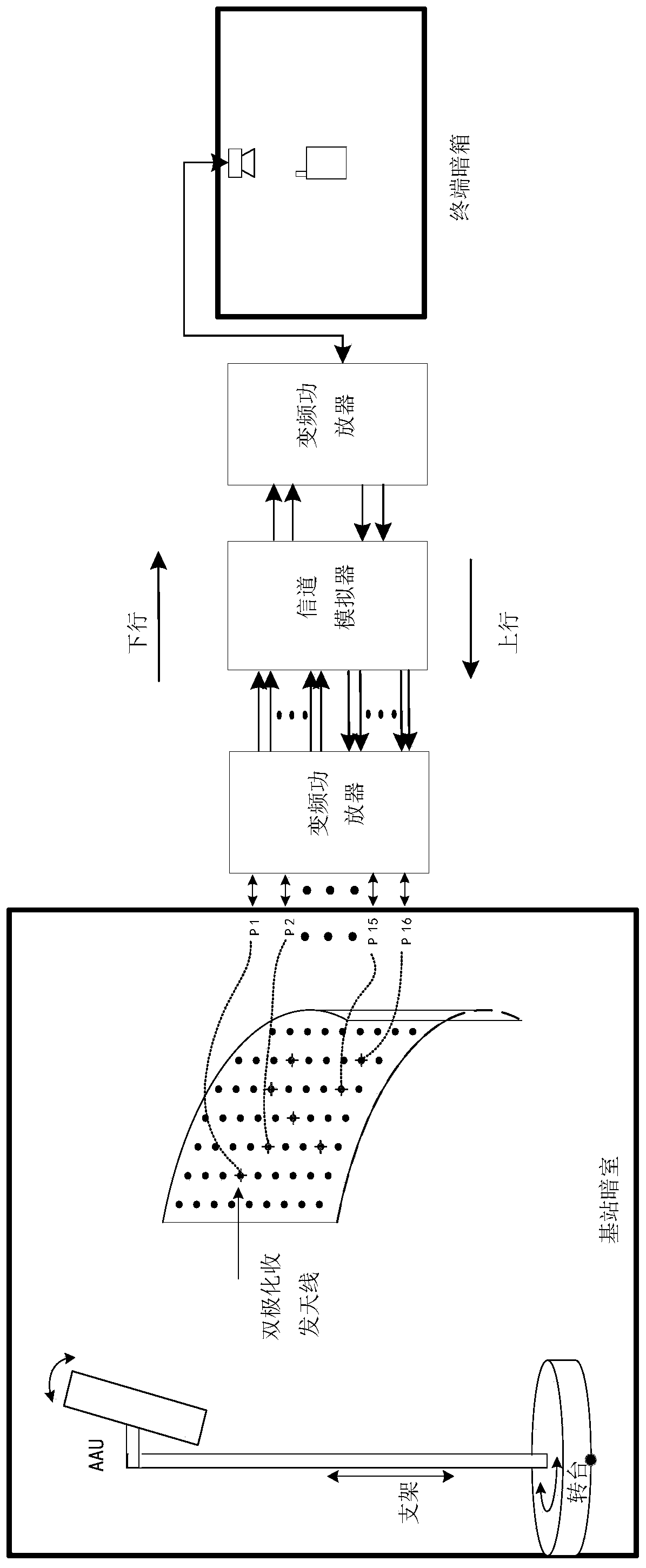

Millimeter wave large-scale MIMO (Multiple Input Multiple Output) channel simulation system and method

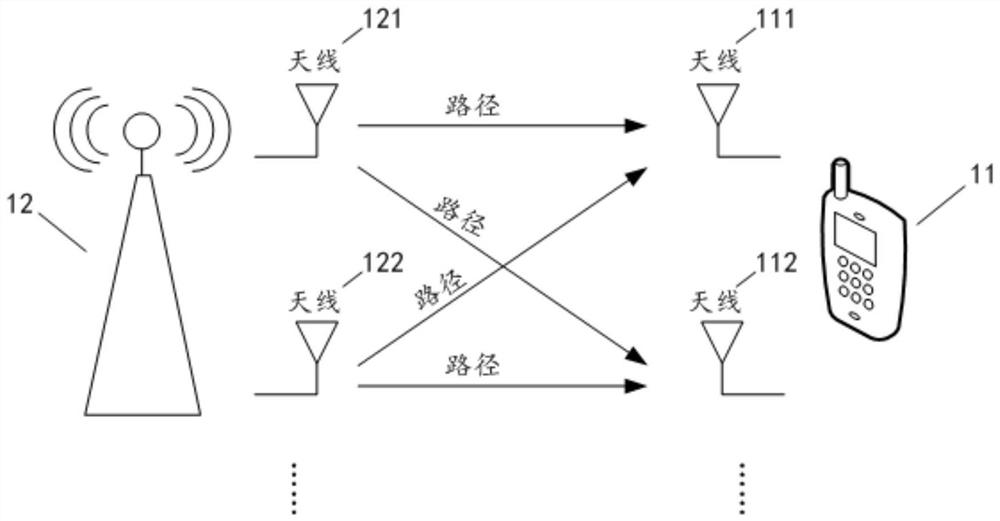

ActiveCN108494512AFlexible simulatorFlexible testingTransmission monitoringRadio transmissionSpherical probeMillimetre wave

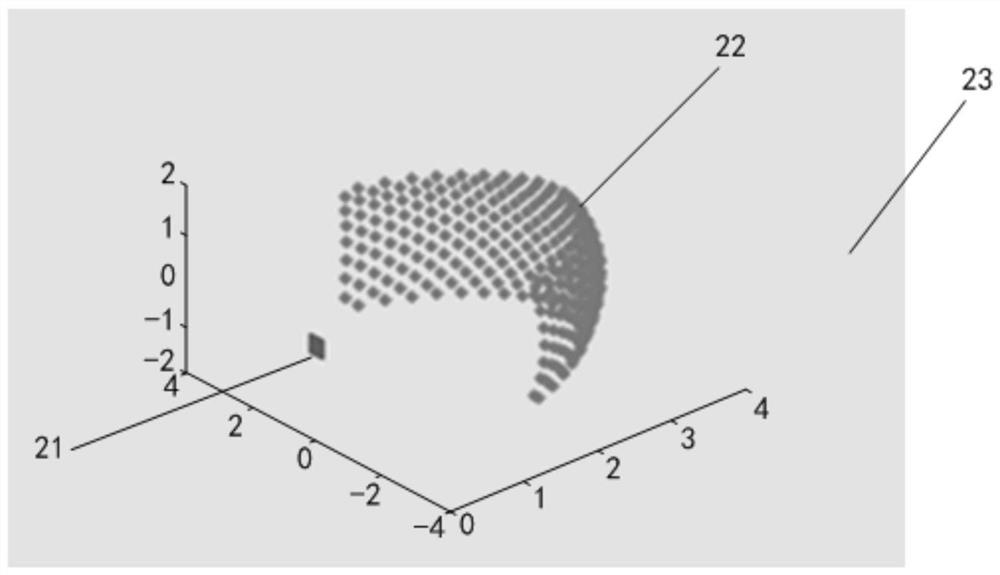

The invention discloses a millimeter wave large-scale MIMO (Multiple Input Multiple Output) channel simulation system. The system comprises a shielding device, wherein a large-scale MIMO system, a MIMO channel simulator and a channel and equipment control device are arranged outside the shielding device; a three-dimensional spherical probe device is arranged in the shielding device; the large-scale MIMO system is connected with the MIMO channel simulator; the MIMO channel simulator is connected with the three-dimensional spherical probe device; and the channel and equipment control device communicates with the three-dimensional spherical probe device and the MIMO channel simulator respectively. A channel space mapping method is adopted to realize space separation and mapping of beam signals, and an antenna-based subchannel is mapped into a space angle direction-based subchannel, thereby reducing the number of analog subchannels, simplify a channel generation method at the same time, effectively reducing simulator resources and lowering the cost.

Owner:SOUTHEAST UNIV

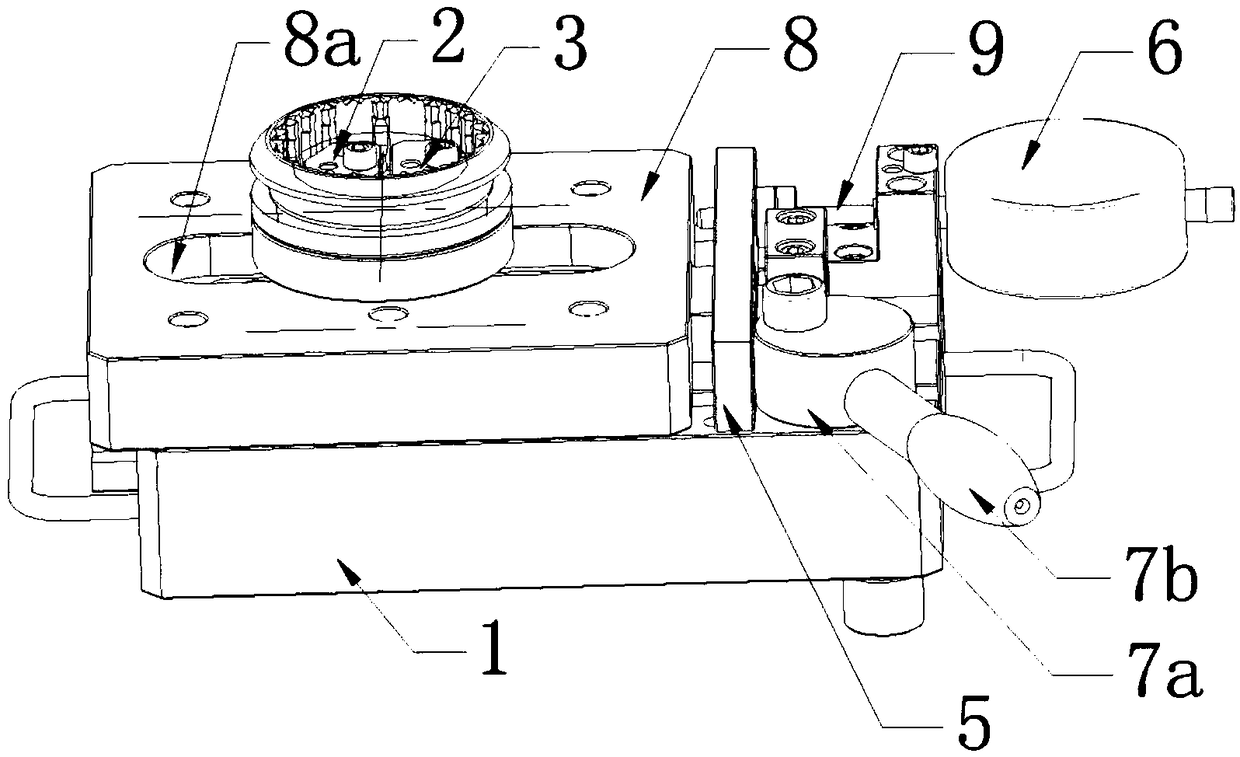

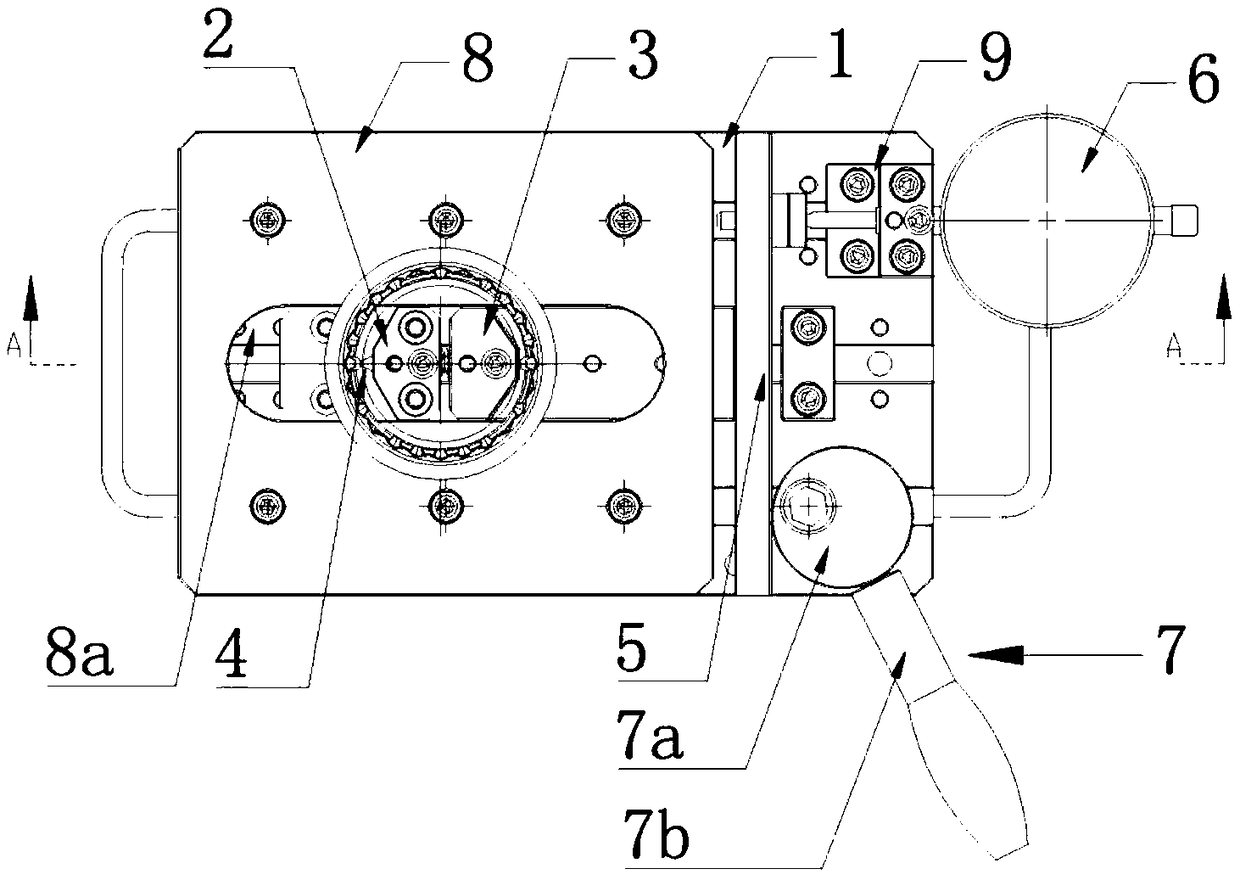

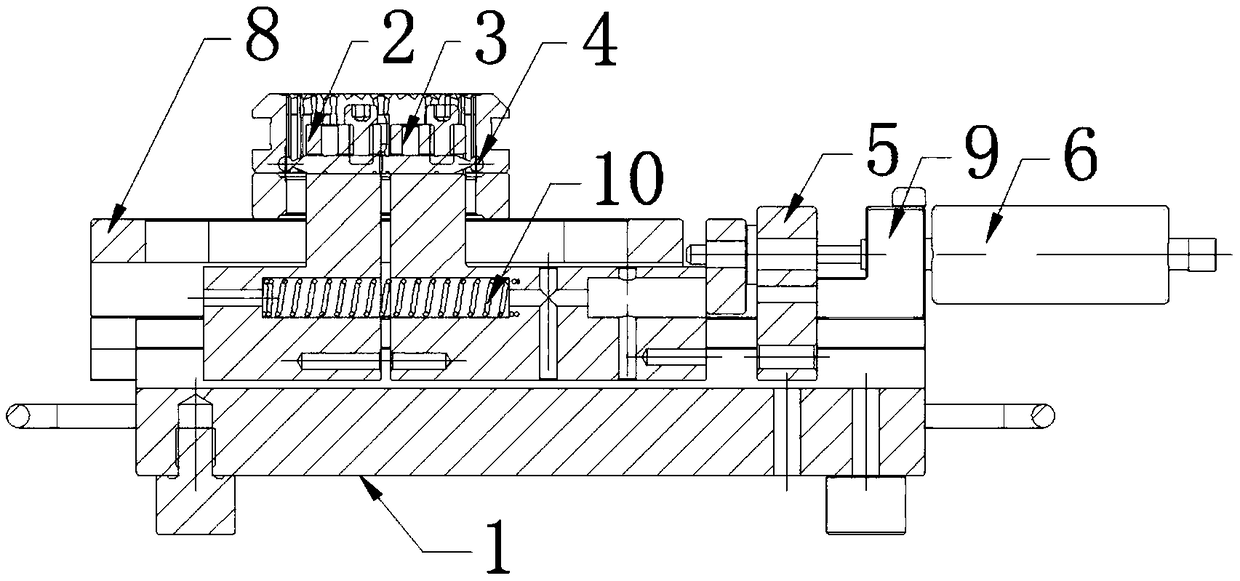

Universal disk type gear M value detecting device

PendingCN109443171AEasy to detectResolve detectionMechanical clearance measurementsObservational errorSpherical probe

Owner:GETRAG JIANGXI TRANSMISSION

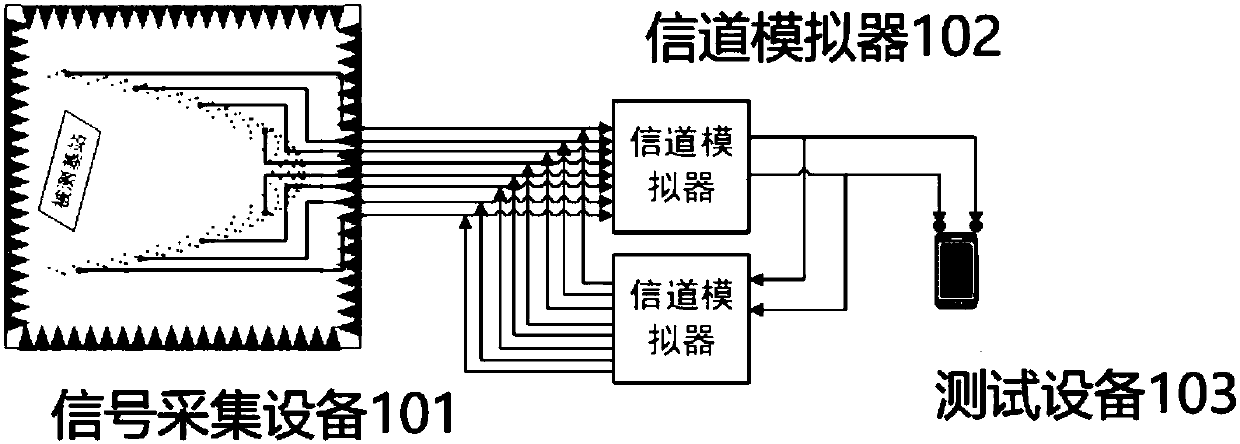

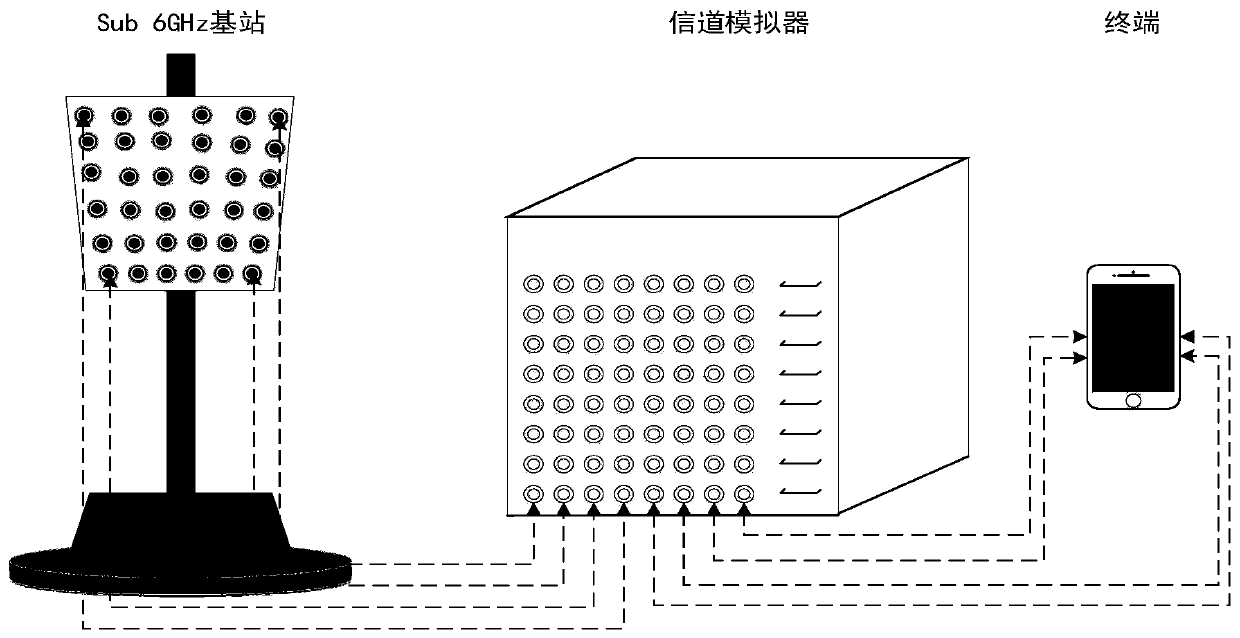

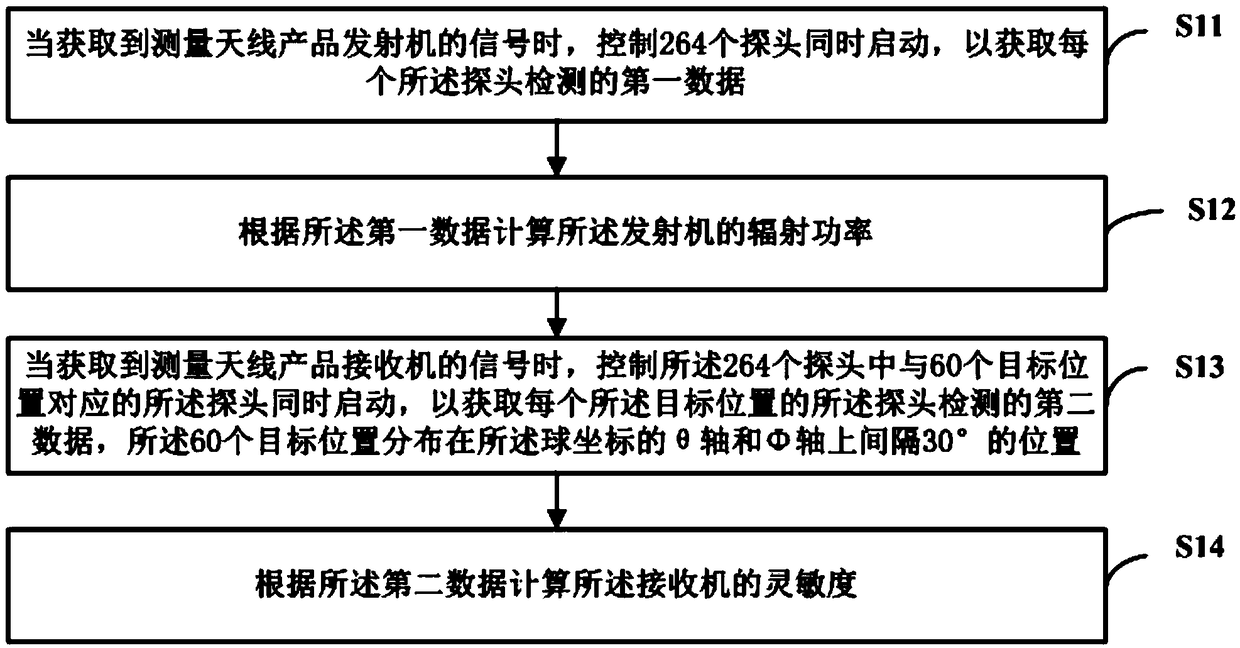

Base station performance test method, device and system

ActiveCN110166143AGuaranteed accuracyTransmission monitoringWireless communicationSpherical probeEngineering

The invention discloses a base station performance test method, device and system. The performance test system comprises a spherical probe wall, a channel simulator and test equipment; according to the channel model of the tested equipment, probes distributed in a spherical probe wall can be selected, the selected probes are used for collecting test signals emitted by the tested equipment, and then the channel simulator is used for simulating an actual propagation channel and processing the test signals, so that the performance of the tested equipment can be evaluated through a processing result received by the test equipment. Thus, for different tested devices with different antenna numbers, the test can be completed through the test system, and the accuracy of the channel simulation testis effectively ensured.

Owner:CHINA ACADEMY OF INFORMATION & COMM

Micro-dermal tone skin stimulator

Owner:CAROL COLE

Probe and method for measuring plasma space potential by aid of bias currents

InactiveCN106771675AHigh measurement accuracyAvoid launchElectrostatic field measurementsThermionic emissionSpherical probe

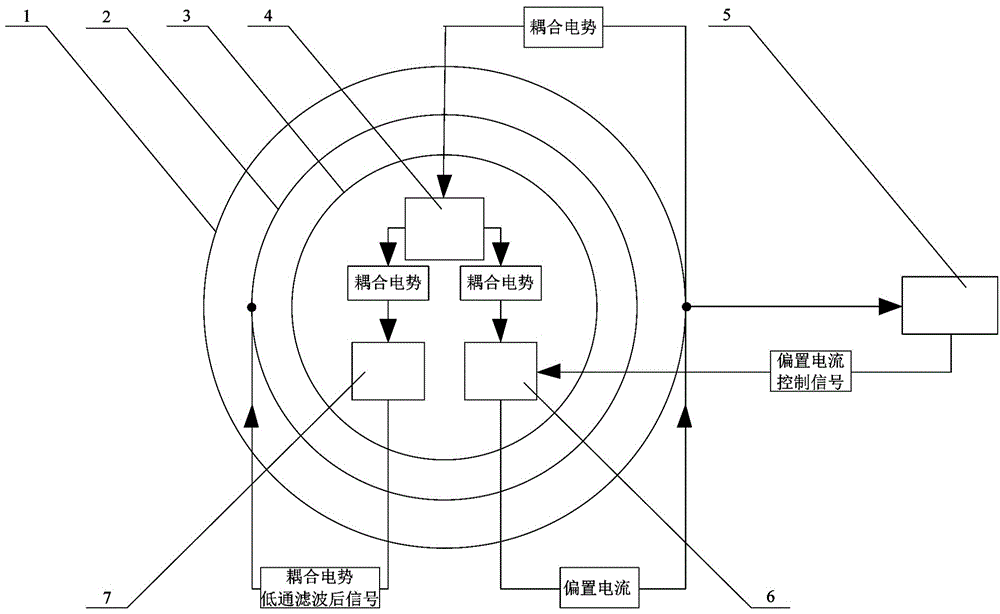

The invention discloses a probe and method for measuring plasma space potential by the aid of bias currents. The method includes: acquiring relative coupling potential by coupling the spherical probe with plasma around the spherical probe; allowing 'suspension type' constant-current source circuit to applying the bias current to the probe; internally installing a high-impedance coupling potential detection circuit and a bias current circuit in the spherical probe; allowing a signal processing unit to process coupling potential signals of the probes and provide control voltage signals to the bias current. The equivalent mode of application of the bias current is adopted for the probe, floating point potential of the probe is changed and approaches to plasma space potential around the floating point potential; plasma parameters are diagnosed according to the Langmuir probe, the initial value of the applied bias current is acquired from calculation, and rapid convergence of the bias current value is realized; the plasma space potential is finally acquired through final measurement with a continuous bias current increasing method; thermionic emission of the emission probe and space-charge effect thereof can be avoided, and measurement precision of the probe on the plasma space potential can be improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Multi-point laser internal diameter measuring instrument and measurement calculation method thereof

InactiveCN106441130AEliminate human errorHigh measurement accuracyUsing optical meansContinuous measurementSection plane

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

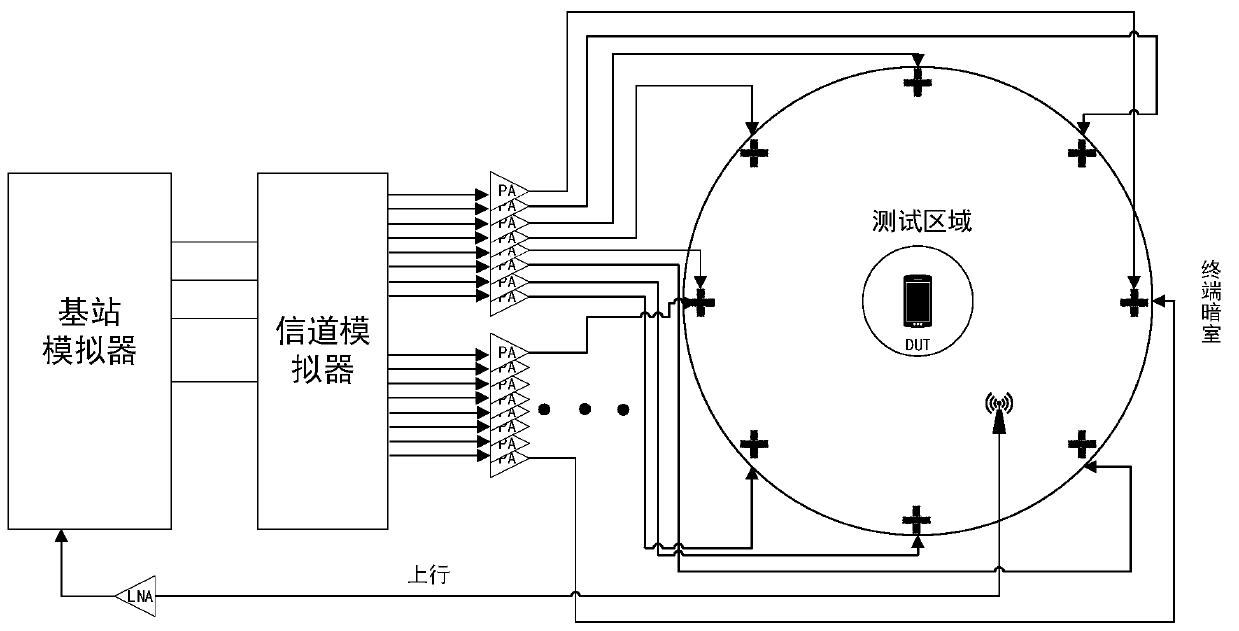

Base station oriented millimeter wave end-to-end performance test system and method

ActiveCN111555826AReduce testing costsSupport bi-directional testingPropogation channels monitoringSpherical probeChannel simulator

The invention discloses a base station oriented millimeter wave end-to-end performance test system and method. The system comprises a base station darkroom module, an intermediate hardware module anda terminal darkroom module. The base station darkroom module comprises a base station darkroom, a base station to be detected in the base station darkroom and a spherical probe wall, and the probe wall is provided with a probe supporting uplink and downlink bidirectional communication and used for transmitting bidirectional signals between the base station to be detected and the intermediate hardware module; the intermediate hardware module comprises variable frequency power amplifier equipment and a channel simulator, supports time slot synchronization with the base station to be tested, andperforms uplink and downlink switching; wherein the terminal camera obscura module comprises a shielding camera obscura, a probe and a millimeter wave terminal, and the millimeter wave terminal receives downlink data, sends uplink data and completes end-to-end connection with a base station to be tested. The method is applied to the system and comprises the steps of a probe selection algorithm anda white box test method based on a base station beam filtering signal.

Owner:CHINA ACADEMY OF INFORMATION & COMM

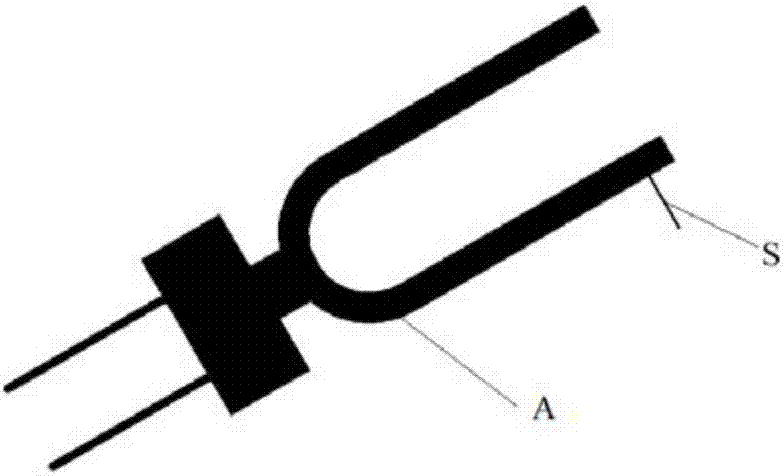

Synchronizer gear sleeve inner tooth M value gauge

PendingCN109141191ANovel ideaReasonable designMechanical clearance measurementsSpherical probeEngineering

The invention discloses a synchronizer gear sleeve inner tooth M value gauge. The gauge includes a bottom plate, wherein an upper surface of the bottom plate is provided with a fixed probe holder anda movable probe holder capable of moving forward and backward side by side, the fixed probe holder and the movable probe holder are respectively provided with a spherical probe, the two probes are placed on a straight line, the probes on the fixed probe holder and the movable probe holder respectively point to the front portion and the rear portion, the bottom plate is provided with a spring whichcan push the movable probe holder backward, the movable probe holder is connected with a detection block capable of moving forward and backward, the detection block is arranged behind the movable probe holder, a dial indicator is mounted on the bottom plate, and a detection head of the dial indicator points to the detection block. The gauge is advantaged in that the concept is novel, design is reasonable, the gauge is easy to use, the M value of an inner tooth of the gear sleeve is indirectly measured by a jaw structure formed by the fixed probe holder and the movable probe holder, compared with the prior art, operation is simpler, and overall efficiency is higher.

Owner:重庆市江汇机械有限责任公司

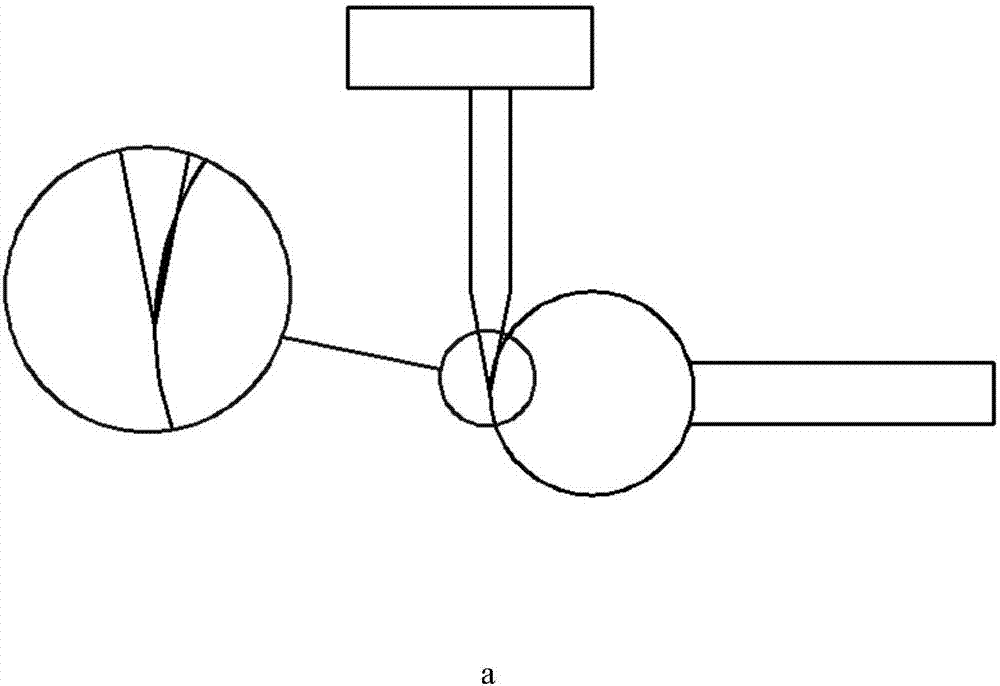

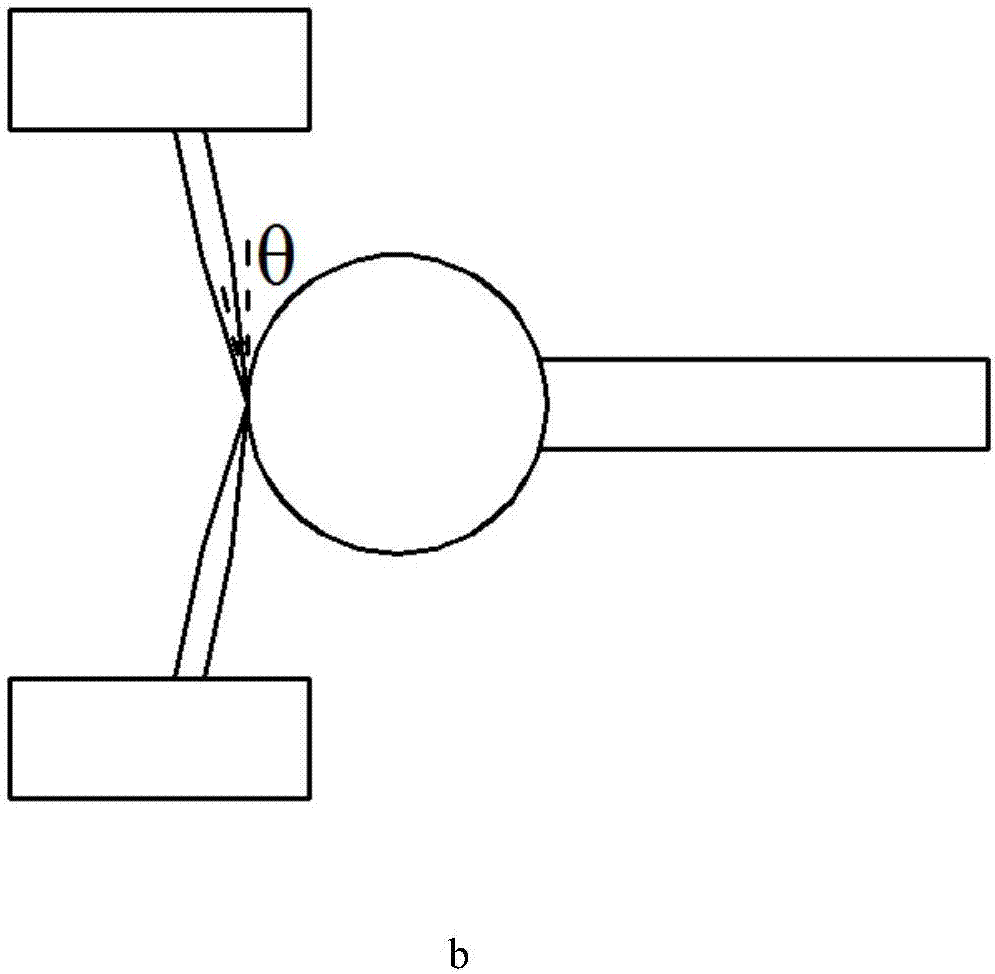

Method for high-precision measurement of sphericity of micro-spherical probe of nanometer three-coordinate measuring machine

InactiveCN107218879AEliminate radial errorsRealize high-precision measurementElectric/magnetic contours/curvatures measurementsPoint coordinate measurementsMicrosphereSpherical probe

The invention discloses a method for high-precision measurement of the sphericity of the micro-spherical probe of a nanometer three-coordinate measuring machine. A tungsten probe with large length-to-diameter ratio and a quartz tuning fork are combined. Scanning probe heads with nanometer-level resolution are constructed based on a precision micro stage. During measurement, the two scanning probe heads are driven by the micro stage to scan the large-section contour of a microsphere in the x-axis direction in a differential manner. Radial error generated in the scanning process can be automatically eliminated in a differential manner, and thus, accurate parameters of the large-section contour of the microsphere can be obtained. After the microsphere is rotated a certain angle, the measurement is repeated to acquire multiple sets of parameters of the large-section contour. A three-dimensional spatial contour of the microsphere is constructed through fitting according to feature points obtained. The geometric parameters of the microsphere are calculated based on the three-dimensional spatial contour. Thus, high-precision measurement of the sphericity of the microsphere is realized. The method has the characteristics of small measuring force, wide measuring range, and high measuring precision.

Owner:HEFEI UNIV OF TECH

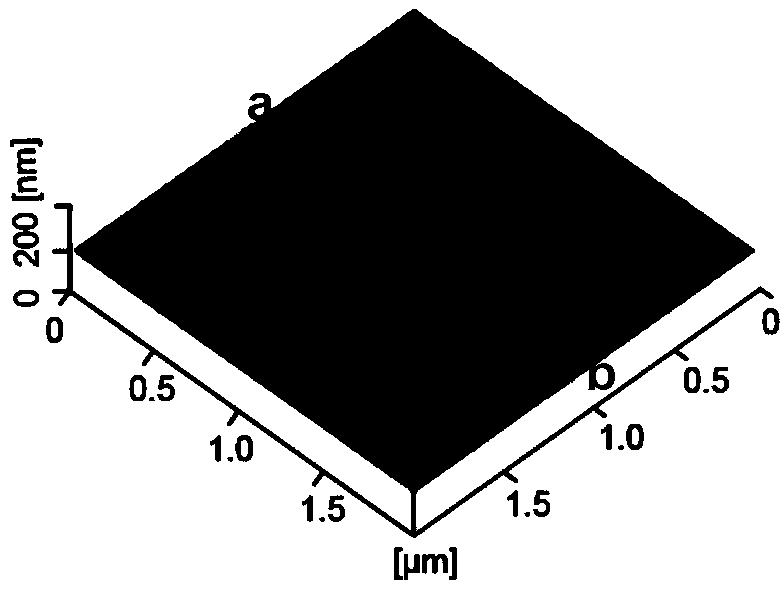

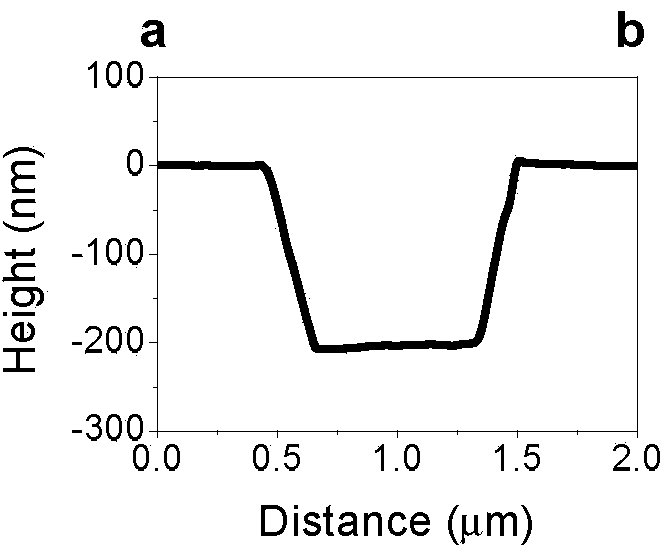

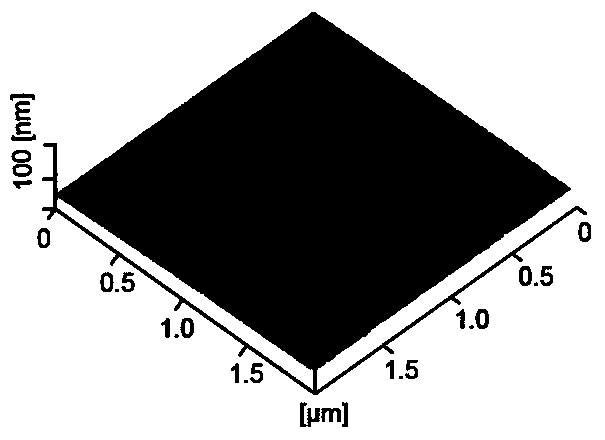

Monocrystalline silicon non-destructive surface nanometer machining method based on tribo-chemistry induction etching

ActiveCN103738912AYield won'tIncrease roughnessDecorative surface effectsChemical vapor deposition coatingContact pressureEtching

The invention provides a monocrystalline silicon non-destructive surface nanometer machining method based on tribo-chemistry induction etching, which is mainly applied to machining a monocrystalline silicon surface nanometer structure. The monocrystalline silicon non-destructive surface nanometer machining method has the special operation steps: generating a SiOx thin layer on a monocrystalline silicon surface through a wet oxidation method; taking the monocrystalline silicon with the SiOx thin layer growing out, and washing and fixing the SiOx thin layer on a sample table; mounting a silicon dioxide spherical probe on a scanning probe microscope or multiple-point contact micro-nanometer machining equipment; starting the equipment; controlling the probe to scan the surface of a sample according to set parameters; and arranging the sample into a mixed solution of a KOH solution and isopropanol, so as to finish a machining process. A SiOx mask used in the method has the advantages of simplicity and easiness of manufacturing and low cost; a contact pressure in a probe scanning process is very low, so that the yielding of a monocrystalline silicon substrate is avoided, and the machined monocrystalline silicon nanometer structure is long in service life; the SiOx thin-layer mask obtained by the wet oxidation method has a good effect and the machining depth can be increased.

Owner:SOUTHWEST JIAOTONG UNIV

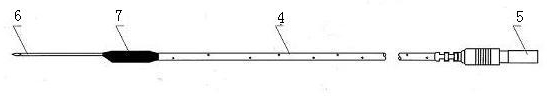

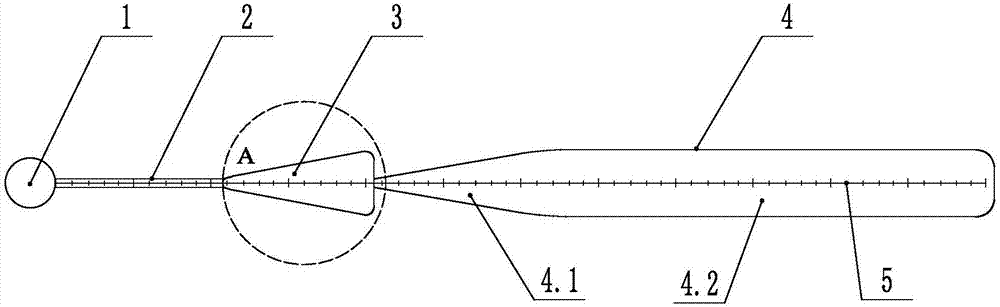

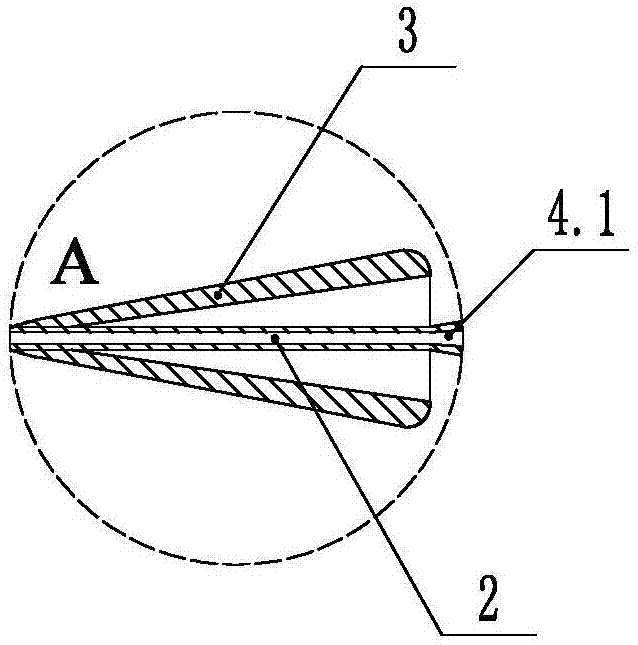

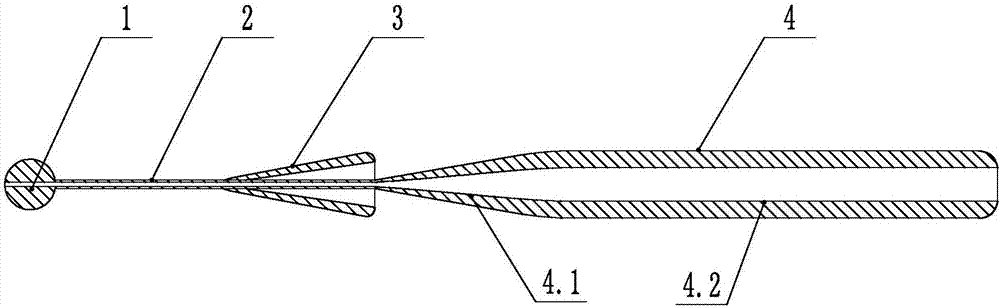

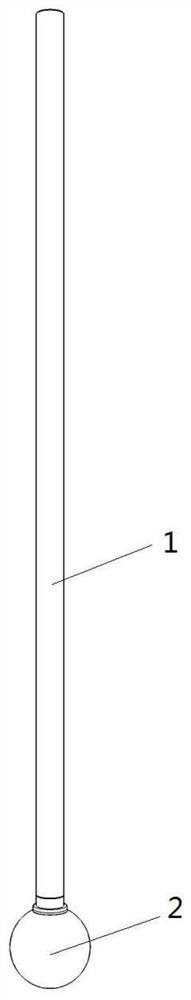

Urethral calibrator expander

ActiveCN106924865AEffective guidancePrevent abnormal channelSurgeryMedical devicesUrethral injuryUrethritis

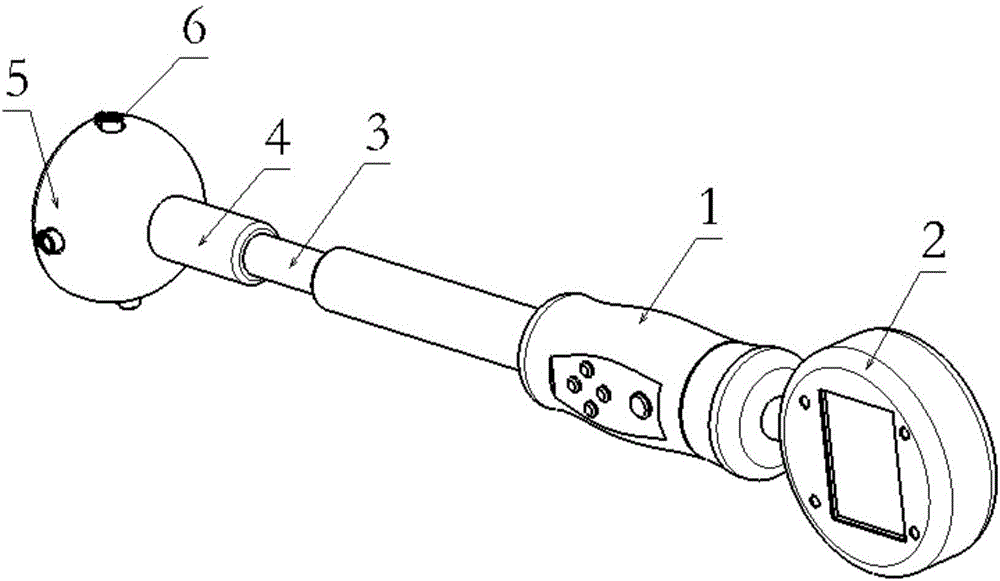

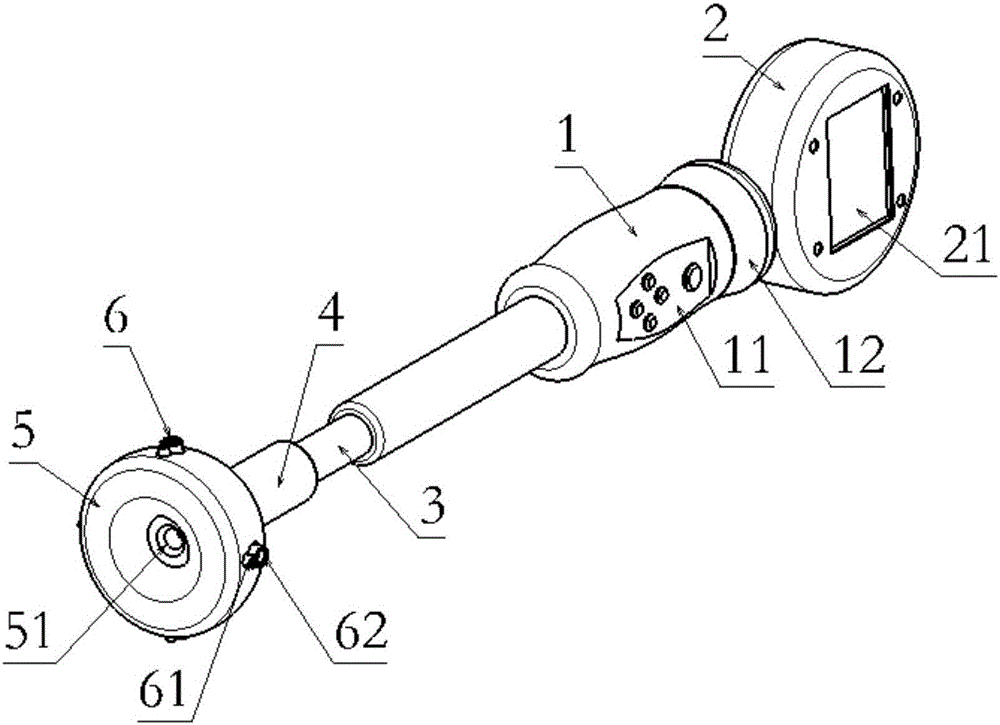

The invention discloses a urethral calibrator expander formed by a spherical probe (1), a connection rod (2) and an expansion tube (4) orderly connected from left to right. The right end of the connection rod (2) is covered with a tapered expanding device (3); the top of the tapered expanding device (3) faces the ball probe (1) and the bottom faces the expanding tube (4); the interior of the tapered expanding device (3) is in a hollow-bowl structure; the length of the tapered expanding device (3) is shorter than the connection rod (2); and the diameter of the bottom surface of the tapered expanding device (3) is greater than the diameter of a cross section of the connection rod (2). The narrow part of the urethral stricture can be effectively probed; the diameter and the length of the narrow part can be measured; relative reference information is provided for urethrostenosis surgery treatment and surgical method; meanwhile, pains of a patient and damage to the urethral stricture due to the exchange of various types of urethral calibrator expander can be reduced as possible as can; a material drawing performance for urethral stricture inflammatory excreta and stones can be met; and inspection and clinical treatment guide can be facilitated.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

Method for manufacturing high-frequency acoustic self-focusing spherical probe

InactiveCN102247164AFlat surfaceQuality improvementUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySpherical probeUltraviolet

The invention discloses a method for manufacturing a high-frequency acoustic self-focusing spherical probe, which comprises: (1) forming a silicon nitride layer on a substrate; (2) performing photoetching treatment on the silicon nitride layer and etching a hole, namely firstly performing the photoetching treatment on the silicon nitride layer, then exposing photoresist by using an exposure protection layer and an exposing apparatus in combination, later removing excessive photoresist by washing with developing solution, and finally etching the silicon nitride layer by using reactive ion etching (RIE) and forming a hole on the silicon nitride layer; and (3) placing the treated device in solution prepared from HF, HNO3, HAC in a volume ratio of 1:4:3, applying magneton stirring for corrosion, and thus obtaining the focusing spherical probe. The high-frequency acoustic self-focusing spherical probe prepared by the invention has smooth surface and reliable quality, and can reduce human factors influencing quality of probe in production process of the acoustic self-focusing spherical probe, greatly improve uniformity of quality and meet requirements for large-scale production.

Owner:HUAZHONG UNIV OF SCI & TECH

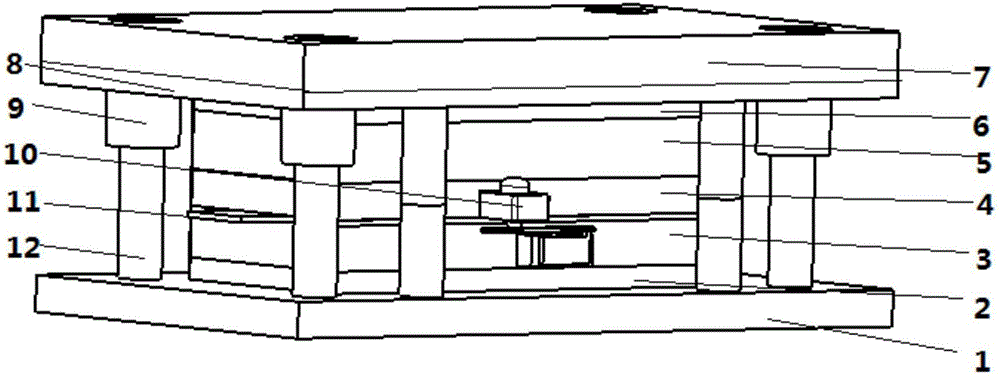

Progressive die with multiple detection functions

InactiveCN106140962AGuaranteed accuracyReduce manufacturing costShaping toolsShaping safety devicesInfraredSpherical probe

The invention provides a progressive die with multiple detection functions, including a closed height detection device, a strip position detection device, a feeding detection device, a lower die and an upper die, and the lower die includes a lower die base, a lower backing plate and a concave The formwork, the upper mold includes a stripping plate, a punch fixing plate, an upper backing plate and an upper mold base. The four corners of the lower mold base are provided with guide posts, and the four corners of the upper mold base are provided with guide sleeves. The closed height detection device includes a spherical probe, a spherical The top of the probe is lower than the bottom plane of the unloading plate by the thickness of a strip. Sensors are installed on the side wall of the concave formwork. The strip position detection device includes a light source emitter and an infrared receiving head. The light source emitter is fixed on the bottom of the unloading plate, and the infrared receiving head It is directly below the light source emitter and fixed on the concave mold, the feeding detection device includes an optical fiber sensor, and the optical fiber sensor is placed in the positioning pin hole of the concave mold. The progressive die with multiple detection functions described in the present invention further improves the detection function of the stamping die, reduces the scrap rate of workpieces, and saves production costs.

Owner:TIANJIN CITY JIUYUE TECH

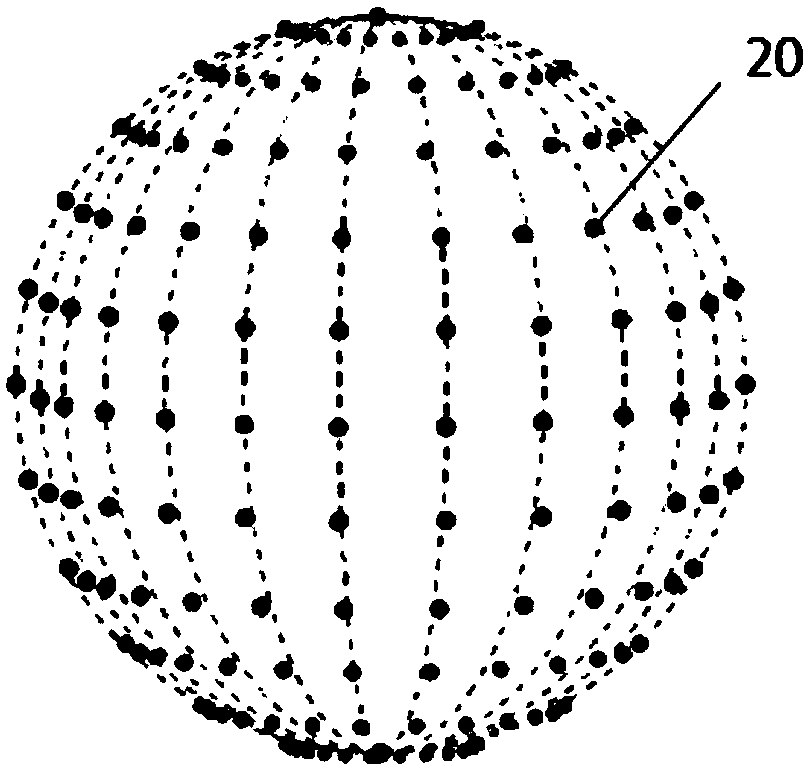

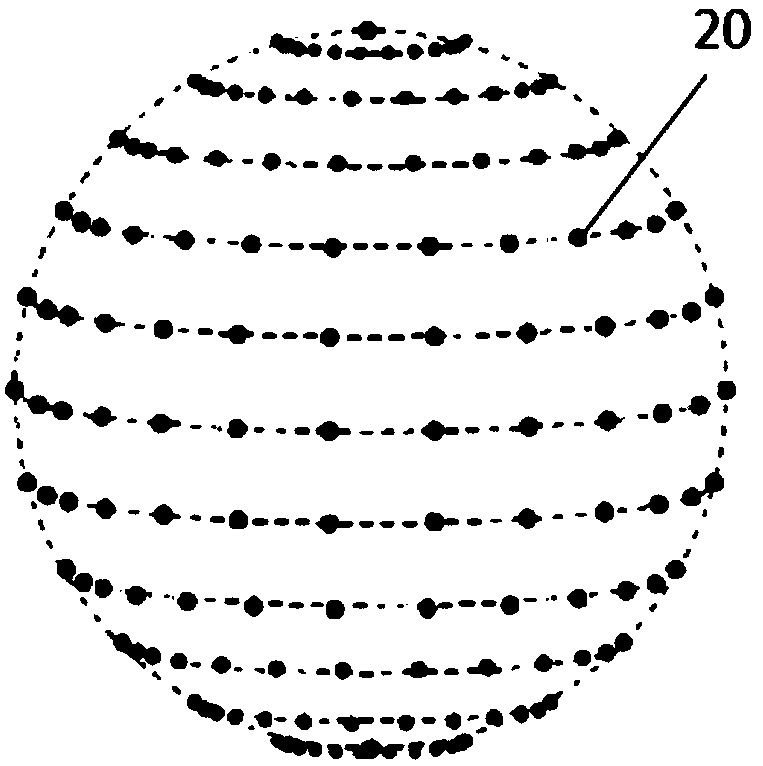

Antenna near-field test method and device

InactiveCN109104254ATransmitters monitoringElectromagentic field characteristicsSpherical probeField tests

An antenna near-field test method and device are provided, the antenna near-field test device comprises 264 spherical probes which are spherically distributed at positions with included angle of 15 degrees with the theta axis and the phi axis of the spherical coordinate, the test method comprises that: when a signal of a transmitter of a measurement antenna product is acquired, controlling 264 probes to start simultaneously to acquire first data detected by each probe; and when the signal of the transmitter of the measurement antenna product is acquired, controlling 264 probes to start simultaneously to acquire first data detected by each probe. Calculating radiated power of the transmitter according to the first data; when a signal of a receiver for measuring an antenna product is acquired, controlling a probe of 60 target positions distributed at positions spaced apart by 30 degrees on a theta axis and a phi axis of the spherical coordinates to simultaneously start to acquire seconddata detected by the probe of each of the target positions; calculating a sensitivity of the receiver from the second data. The embodiment of the invention eliminates the influence of the artificial placement position, the different binding method, the speed of the turntable and the like on the test result, so that the test speed is fast and the test result is accurate.

Owner:QIKU INTERNET TECH SHENZHEN CO LTD

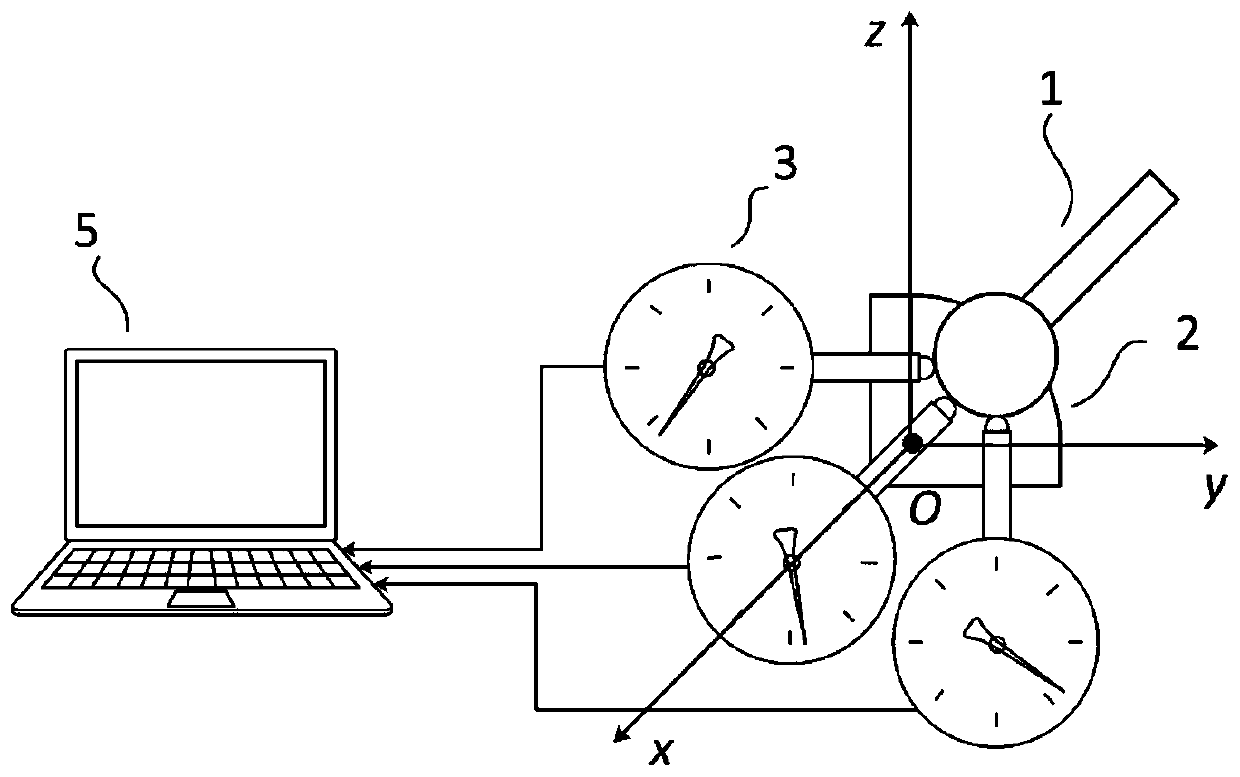

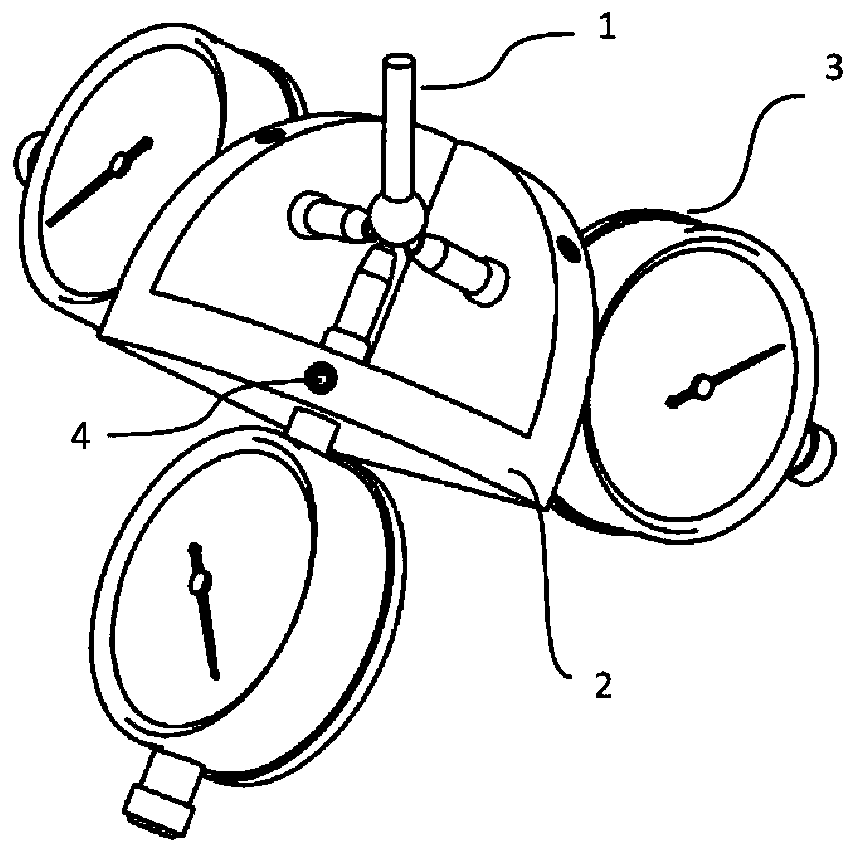

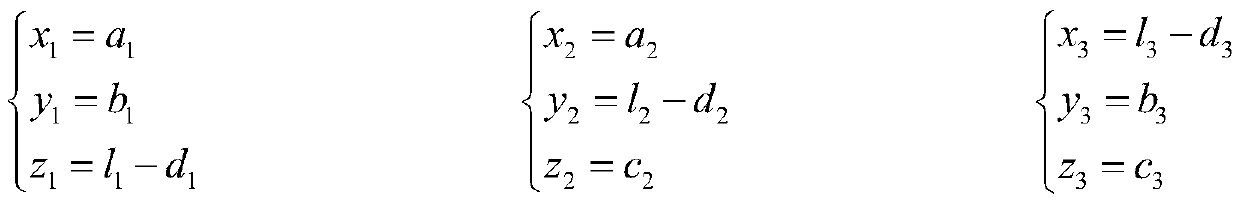

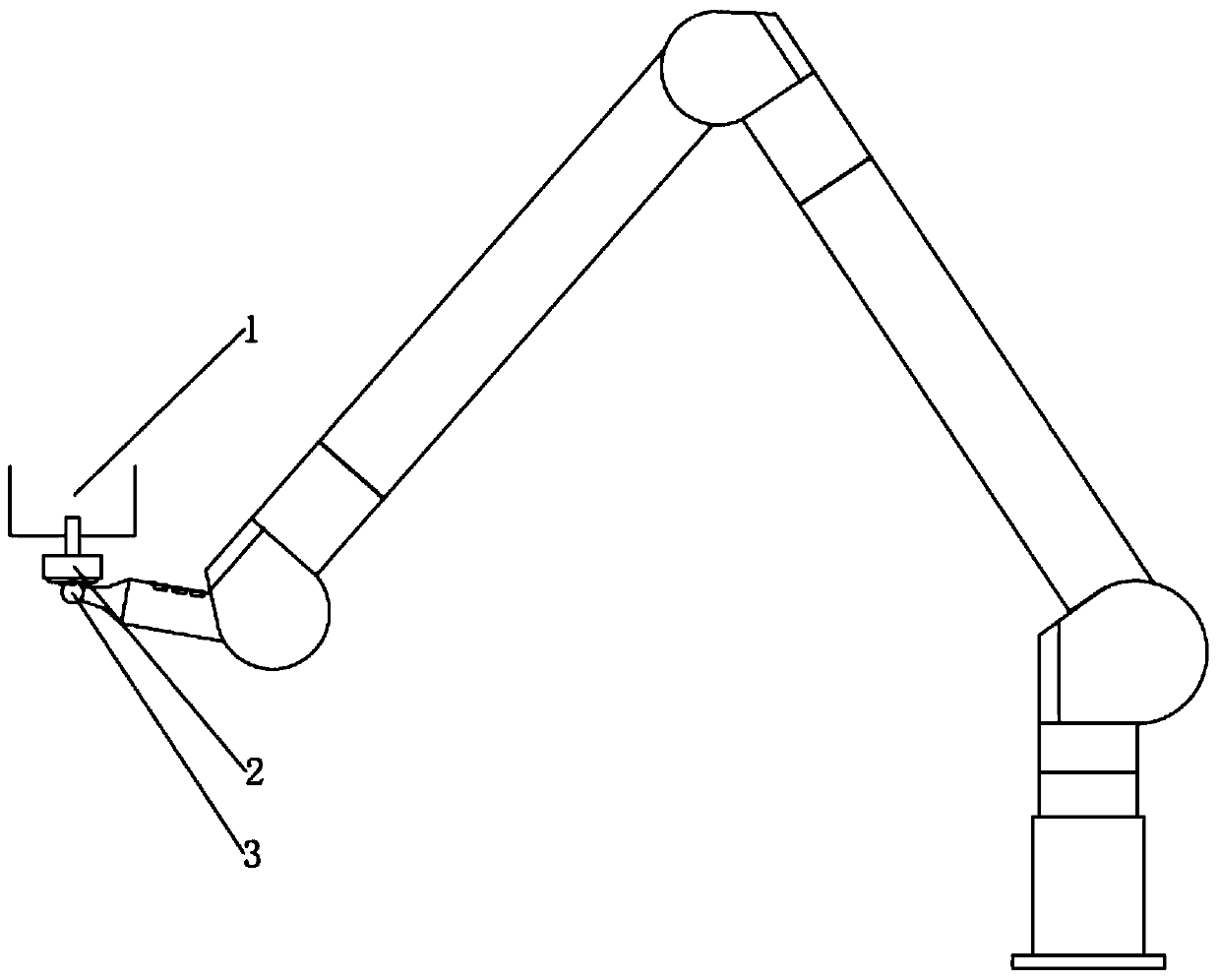

Device and method for measuring spatial repeated positioning accuracy at tail end of mechanical arm

The invention provides a device for measuring repeated positioning accuracy of an actuator at a tail end of a mechanical arm. The device comprises probe type measuring devices, a clamping device, a mechanical arm tail end probe ball and a computer; the clamping device is formed by connecting three mutually perpendicular structural plates, each plate comprises a through hole capable of fixing the probe type measuring devices, the clamping rod of each probe type measuring device passes through the through hole, and probes of the three probe type measuring devices are arranged in the clamping device; spherical probe balls are installed at the tail end of the mechanical arm, the mechanical arm is operated and the probe balls are moved to the inner side of the clamping device, and the probe balls at the tail end of the mechanical arm are tangent to the probes of the three probe type measuring devices at the same time. Correspondingly, the invention further provides a method for measuring the repeated positioning accuracy of an actuator at a tail end of a mechanical arm, the values of the three probe type measuring devices of the device are introduced into a computer, and the precise coordinates of the probe center of the mechanical arm can be obtained through numerical calculation. With a simple structure, convenient operation and low cost, the device and method can reduce labor andmanufacturing cost greatly.

Owner:TSINGHUA UNIV

Method for measuring surface adhesive capacity and elastic modulus of soft material

InactiveCN102183441BReduce volumeWide range of test materialsSurface/boundary effectStrength propertiesElastomerSpherical probe

The invention discloses a method for measuring the surface adhesive capacity and an elastic modulus of a soft material, the method comprises the following specific steps of: (1) preparing a sample and selecting a probe according the physical property and the chemical property of a tested sample; (2) controlling a horizontal substrate and the spherical probe to move oppositely to be contacted and separated at a constant speed; (3) measuring an interaction force P, a relative displacement delta and a contact radius a respectively by using a pressure sensor, a displacement sensor and an optical microscope in the whole process of the step (2) when the substrate and the probe are contacted with each other; (4) frequently repeating the steps (2) and (3) under the control of software; and (5) quantitatively analyzing the adhesive capacity and the elastic performance of the tested material by using data obtained in the step (3) according to a jabatan kerja raya (JKR) theory. The measurement method has giant application potential in the aspects of scientific research on soft materials such as high-molecule elastic body, biogel and the like, product quality control in industrial manufacturing processes and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

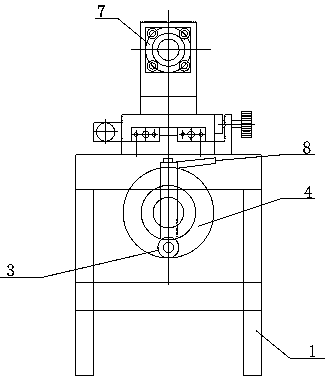

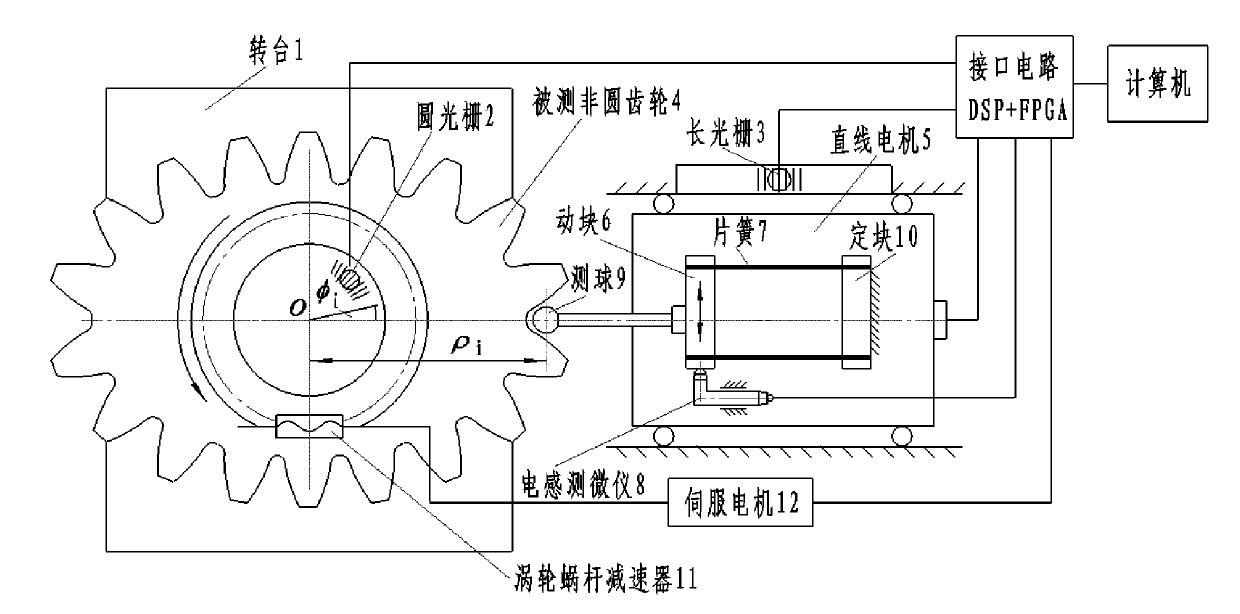

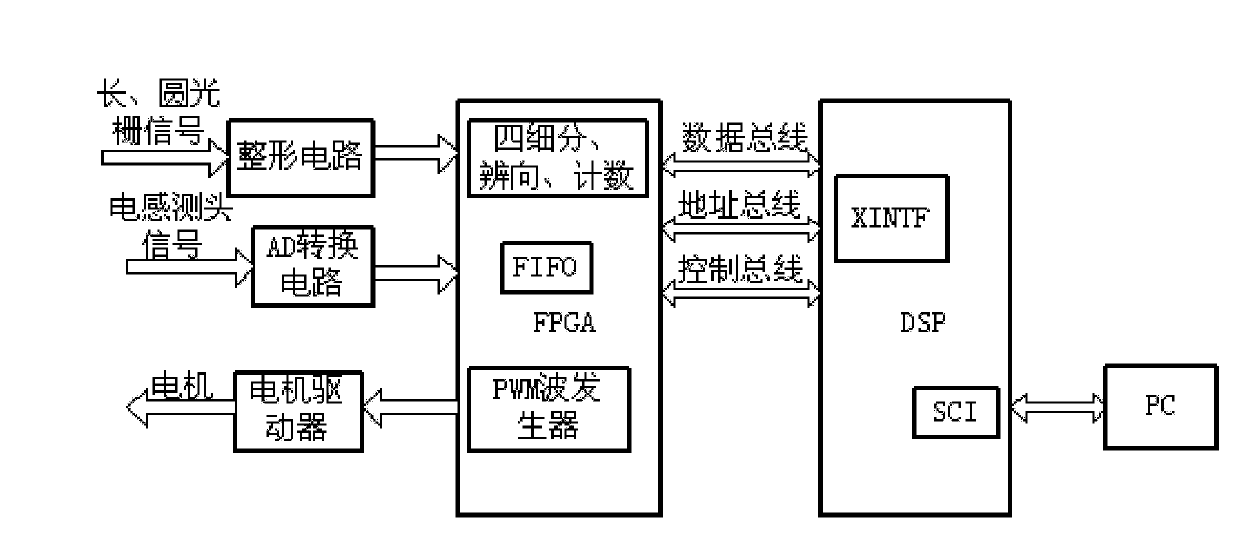

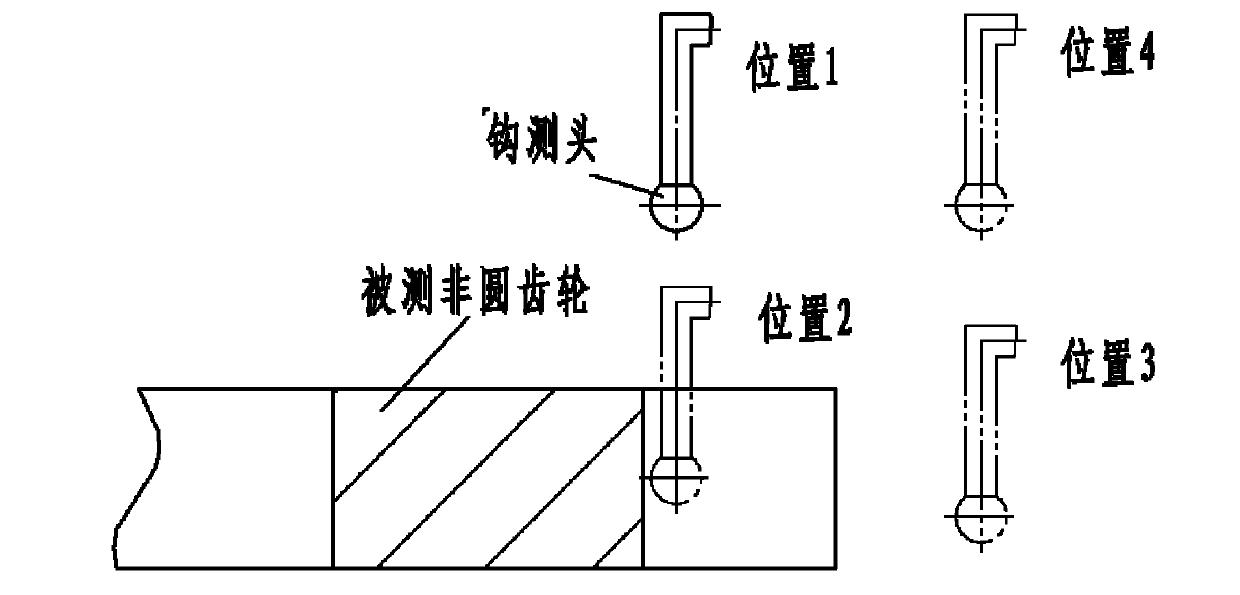

Measurement method and implementation device of non-circular gear tooth profile total deviation

InactiveCN102003934BSimple structureShort and high measurement accuracyElectric/magnetic contours/curvatures measurementsUsing electrical meansGratingMeasurement point

The invention belongs to the field of instrument meter and automatic detection, and discloses a measurement method and implementation device of non-circular gear tooth profile total deviation, and the invention adopts the technical proposal that the non-circular gear tooth profile total deviation is measured by adopting a polar coordinate measurement method, which comprises the following steps: calculating the PI values of a polar angle and a polar radius of each sampling point according to the polar coordinate measurement method on the basis of tooth profile curve line features and a sampling mode of the non-circular gear firstly before measurement; installing the measured non-circular gear on a precise rotary table with a circular grating, the rotary table is driven to rotate through a transmission mechanism by an alternating current servo motor, determining the actually rotated angle of the non-circular gear through the count of the circular grating, installing a spherical probe and a micrometering device on a mobile seat of a linear electric motor and controlling a measured ball to move to the position of the starting measurement point by the linear electric motor. In the measurement, the rotary table rotates continuously to control the spherical probe installed on the mobile seat of the linear electric motor to move toward the sampling point. The invention is mainly applicable to the measurement of the non-circular gear tooth profile total deviation.

Owner:TIANJIN UNIV

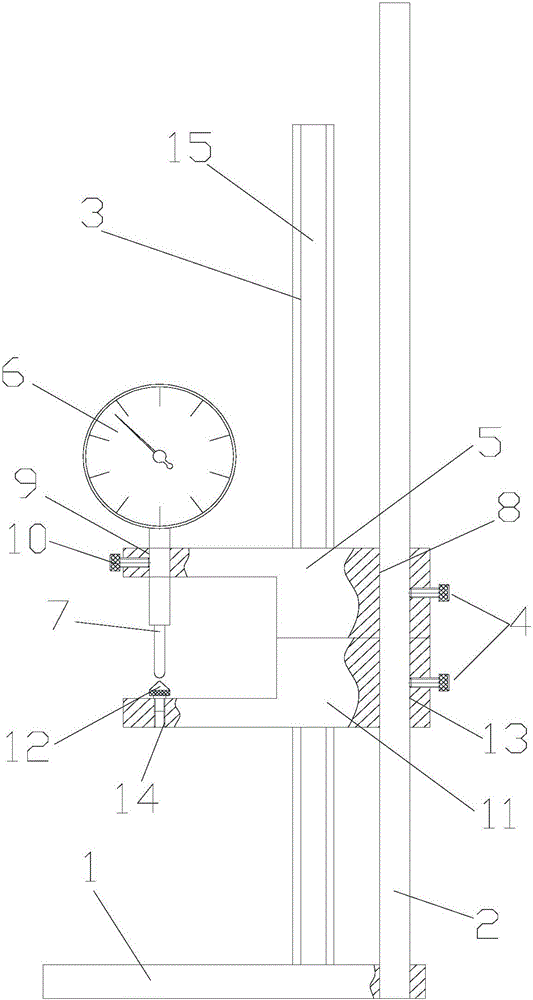

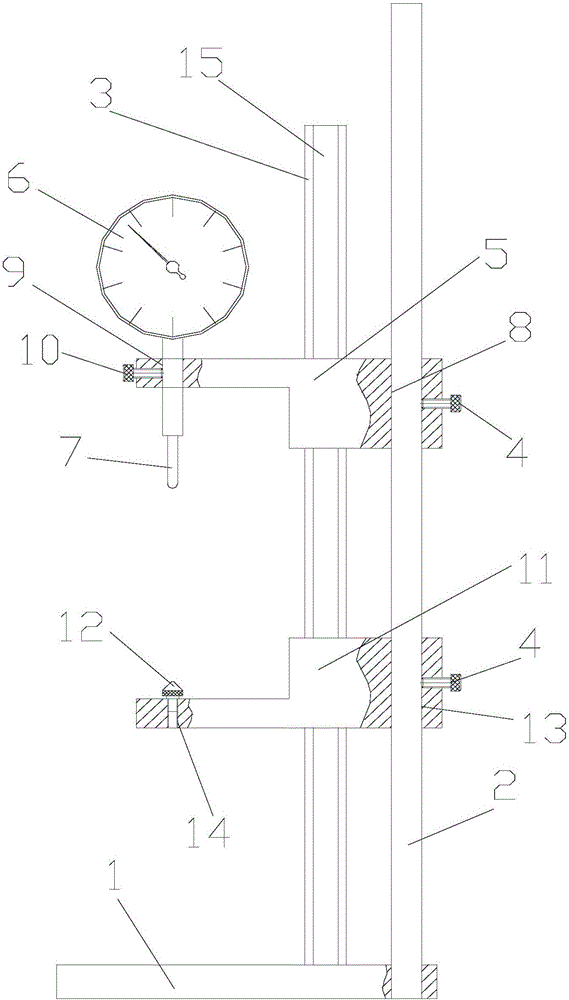

Cantilever-type indicator thickness gauge

InactiveCN106152905AIncrease contactGuaranteed measurement accuracyMechanical thickness measurementsSpherical probeCantilever

Provided is a cantilever-type indicator thickness gauge, which comprises a base and a stand column. The lower end of the stand column is fixedly arranged at one side portion of the base; the stand column is equipped with an indicator lifting device and a spherical probe lifting device, wherein the indicator lifting device is arranged above the spherical probe lifting device. The indicator lifting device and the spherical probe lifting device are fit to a guide post fixedly arranged on the base and then, moves up and down along the guide post to adjust working position thereof; the indicator lifting device and the spherical probe lifting device are fixedly arranged on the stand column through fixation screws on the indicator lifting device and the spherical probe lifting device; and after a workpiece arranged between the indicator lifting device and the spherical probe lifting device is measured, measurement value of the workpiece is determined by reading the numerical value of an indicator. The cantilever-type indicator thickness gauge can realize on-line or on-site measurement visually, accurately, economically and conveniently, is simple to operate and visual to read, and has the advantages of being wide in application range, easy for popularization and application and high in practicality.

Owner:SHAANXI BAOCHENG AVIATION INSTR

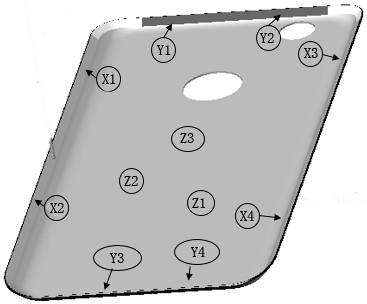

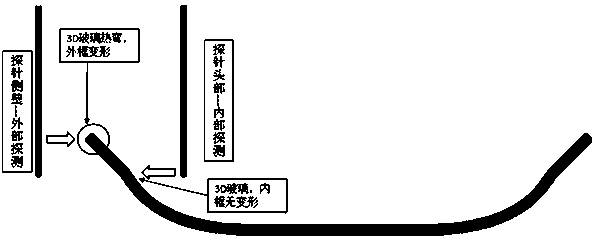

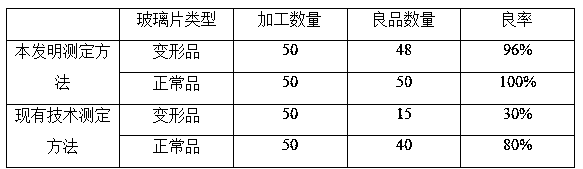

CNC machining center coordinate measuring method for 3D curved glass

ActiveCN109520389ASolve problems caused by deformationHigh dimensional accuracyGlass reforming apparatusMechanical measuring arrangementsSpherical probeEngineering

The invention relates to a CNC machining center coordinate measuring method for 3D curved glass. Processing center X / Y / Z coordinates of the inner arc surface of a piece of 3D curved glass are measuredby a spherical probe, so that a problem caused by outer glass frame deformation due to thermal bending of the product is solved. The dimensional accuracy of the processed product is improved; and especially for processing of a mobile phone 3D curved screen having four sides with unequal heights, the precision dimensions of the length, width, and height of the mobile phone 3D curved glass can be controlled well; and the production yield is improved substantially.

Owner:KORNERSTONE MATERIALS TECH

Test system

PendingCN114222325ASmall amount of calculationImprove test efficiencyTransmission monitoringWireless communicationTest efficiencySpherical probe

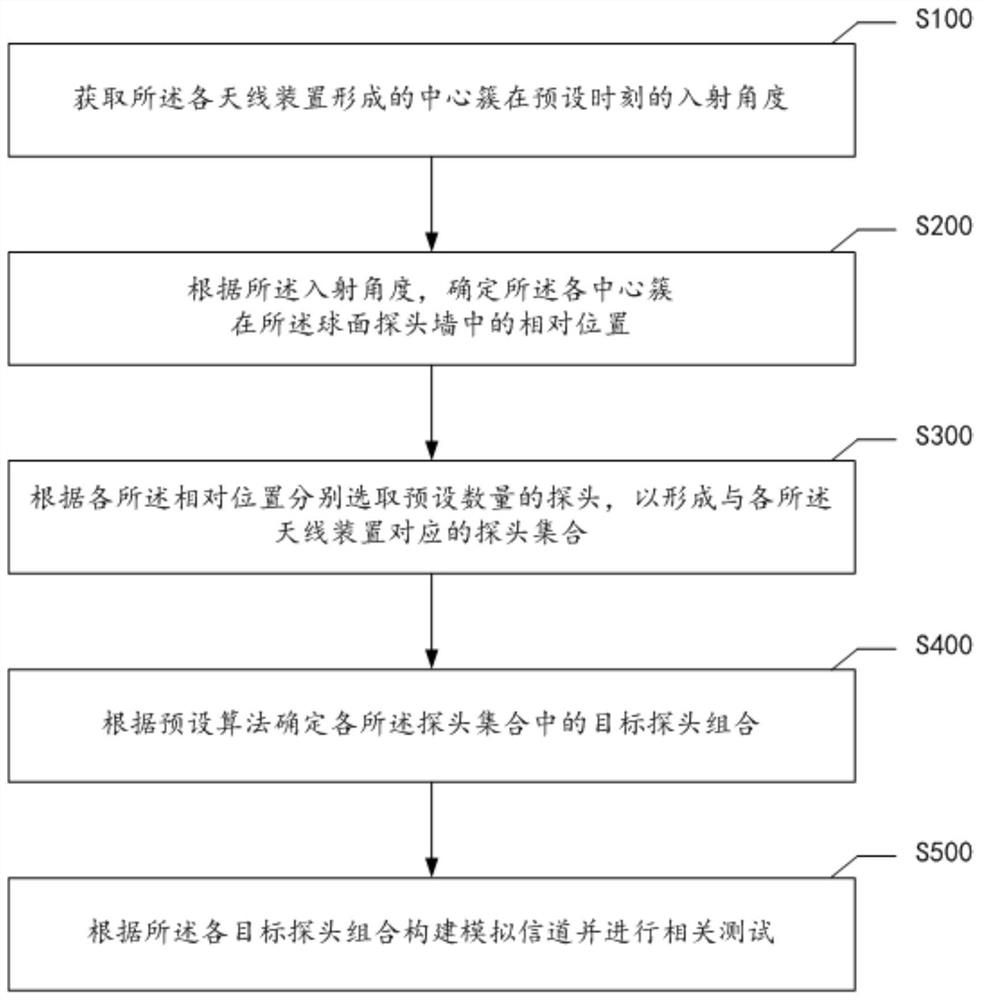

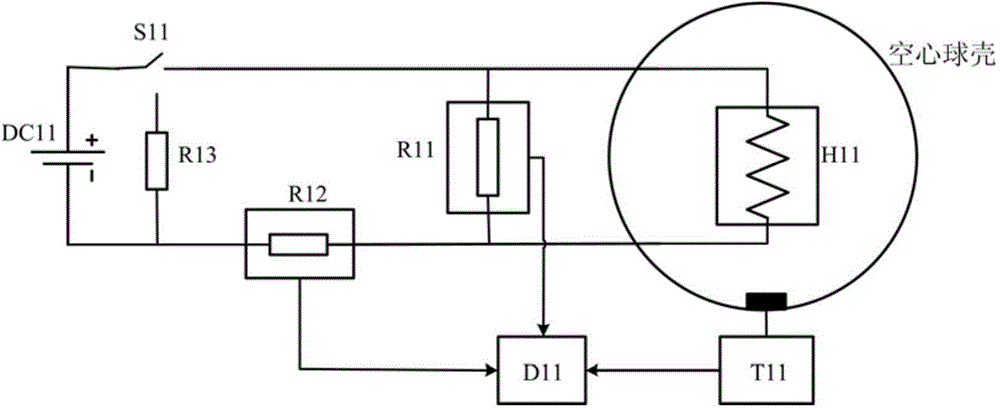

The embodiment of the invention discloses a test system. The test system comprises a terminal to be tested, a spherical probe wall and a control device, wherein the terminal to be tested is provided with an antenna device; the spherical probe wall is arranged around the terminal to be tested; wherein the control device is configured to acquire an incident angle of a center cluster formed by each antenna device at a preset moment, determine a relative position of each center cluster in the spherical probe wall according to the incident angle, and respectively select a preset number of probes according to each relative position to form a probe set corresponding to each antenna device, and determining a target probe combination in each probe set according to a preset algorithm, constructing an analog channel according to each target probe combination, and performing related tests. Wherein the preset algorithm is used for determining a better probe combination used for reconstructing an analog channel in the probe set. By means of the system, large-scale multiple-input-multiple-output air interface testing can be carried out, meanwhile, the calculation amount of the channel reconstruction process is reduced, and the testing efficiency is improved.

Owner:北京电信技术发展产业协会

Deep soil thermal parameter monitoring sensor and detection method

InactiveCN104897718AImprove measurement efficiencyHigh speedMaterial heat developmentSpherical probeZinc alloys

Owner:XI AN JIAOTONG UNIV +1

A Calibration Method for Joint Coordinate Measuring Machine Combined with CNC Machine Tool

ActiveCN108827210BImprove adaptabilityReduce calibration costsMeasurement devicesNumerical controlJoint coordinates

The invention discloses a calibration method for an articulated coordinate measuring machine combined with a numerical control machine tool. The existing measuring machine calibration method requires the use of high-precision measuring instruments or auxiliary calibration tools, and on-site calibration is difficult. In the present invention, a three-ball and cone-socket calibration tool is clamped on the spindle of a numerically controlled machine tool, and a virtual calibration rod is set in a defined measurement area; the virtual calibration rod is a sequence of t measuring points arranged equidistantly; the cone of the three-ball and cone-socket calibration tool The center of the hole is positioned to each measuring point in turn; after positioning to a certain measuring point, the spherical probe of the calibration machine is embedded in the taper hole of the three-ball cone-socket calibration tool for data sampling; Measure the cone hole center of the three-ball cone-socket calibration tool n times at different attitudes; process the probe coordinates obtained after data sampling to obtain the optimal solution for the structural parameter vector A of the calibration machine. The invention adopts the numerical control machine tool as the calibration instrument, which improves the site environment adaptability of the calibration method and reduces the cost.

Owner:HANGZHOU DIANZI UNIV

FBG-based full-depth adaptive high-precision full-flow penetration spherical probe

ActiveCN112461434BAccurate acquisition of mechanical propertiesImprove accuracyPressure difference measurement between multiple valvesFluid pressure measurement by optical meansDifferential pressureSpherical probe

The invention relates to an FBG-based full-sea depth self-adaptive high-precision full-flow penetration spherical probe, comprising a probe rod and a spherical CPT probe, the probe rod and the spherical CPT probe are connected through a probe rod connector, and the spherical CPT probe is provided with There are pore pressure measurement holes and permeable stones, and the pore pressure measurement holes are connected with the pore pressure passage of the lower chamber of the excess pore pressure sensor; the probe rod connector is sequentially provided with n differential pressure sensors with increasing ranges step by step from bottom to top (n≥2), the adjacent differential pressure sensors are connected by an interlocking device to form a multi-stage sensor nesting structure. Higher-order differential pressure sensors can protect the range of the sensor and obtain the best accuracy in the case of effective measurement, realize the self-adjustment of the range and accuracy, and can accurately obtain the mechanical properties of deep seabed sediments in the whole sea. For deep sea science Research, resource and energy development engineering activities and marine security and national defense engineering are of great significance.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com