A Calibration Method for Joint Coordinate Measuring Machine Combined with CNC Machine Tool

A technology of coordinate measuring machines and numerical control machine tools, which is applied to measuring devices and instruments, can solve the problems of complex implementation process, lack of consideration of single-point repeatability accuracy index, and difficult calibration, so as to achieve simple manufacturing, reduce calibration costs, and reduce The effect of calibration difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

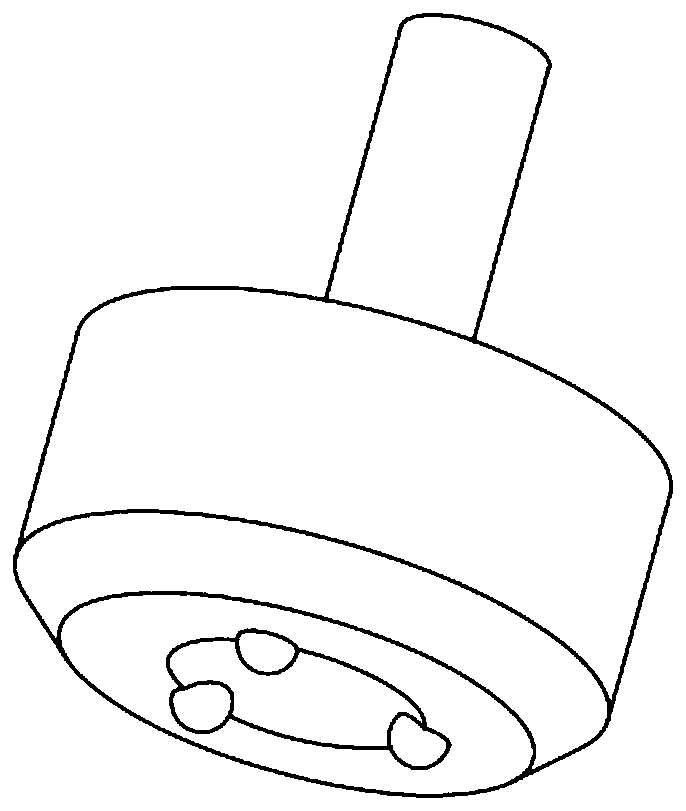

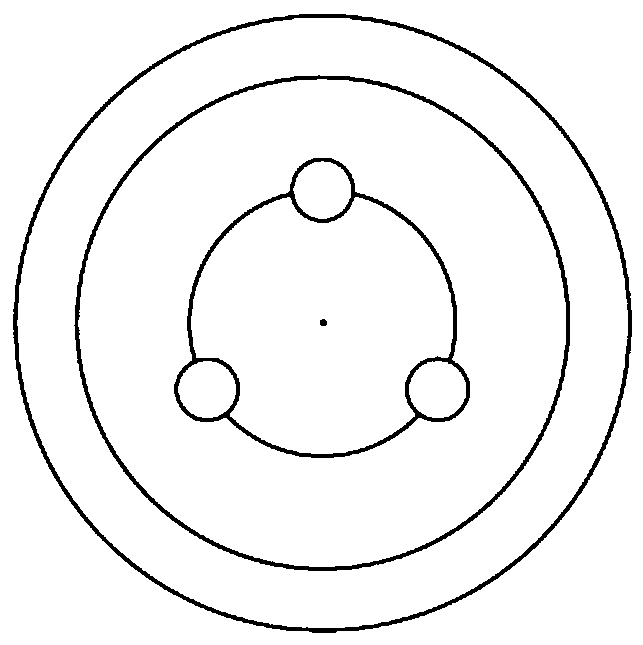

[0036] Such as figure 1 and2 As shown in Fig. 1, a method for calibrating an articulated coordinate measuring machine combined with a CNC machine tool, the three-ball and cone-socket calibration tool used is a special shaft part, including an integrally formed small shaft section and a large shaft section; the small shaft section is clamped on the CNC On the main shaft 1 of the machine tool; the end face of the large shaft section is provided with a tapered hole, and the tapered hole is located on the circumference of the end face of the large shaft section, and three spheres uniformly distributed along the circumferential direction are fixed on the tapered hole. The three-ball cone-socket calibration tool uses magnetic materials.

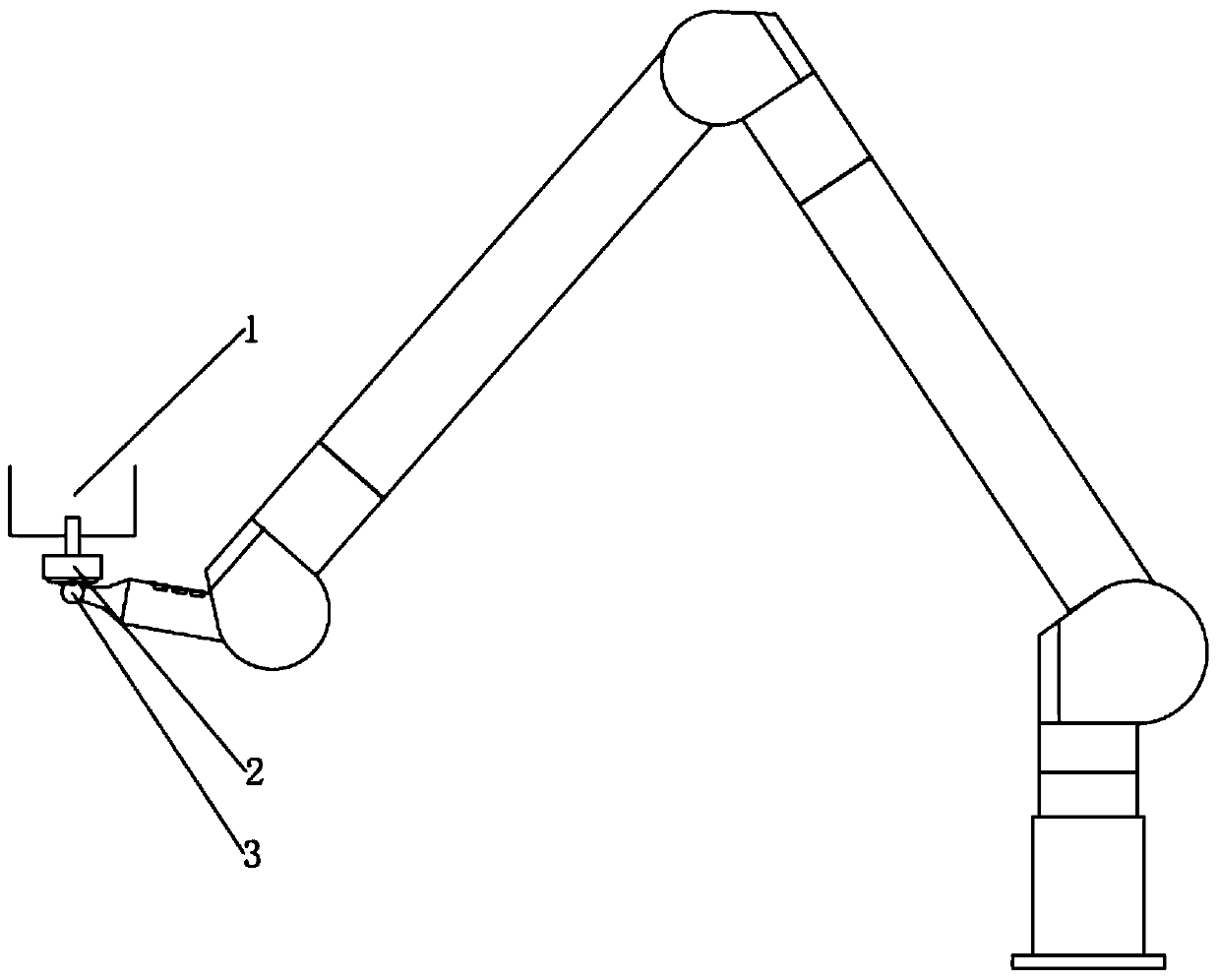

[0037] Such as image 3 As shown, during the data acquisition process, when the spherical probe 3 of the measuring mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com