Patents

Literature

451results about How to "Reduce calibration costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calibration method of correlation between single line laser radar and CCD (Charge Coupled Device) camera

InactiveCN101882313AEasy to makeEasy to buyImage analysisElectromagnetic wave reradiationLaser scanningIntersection of a polyhedron with a line

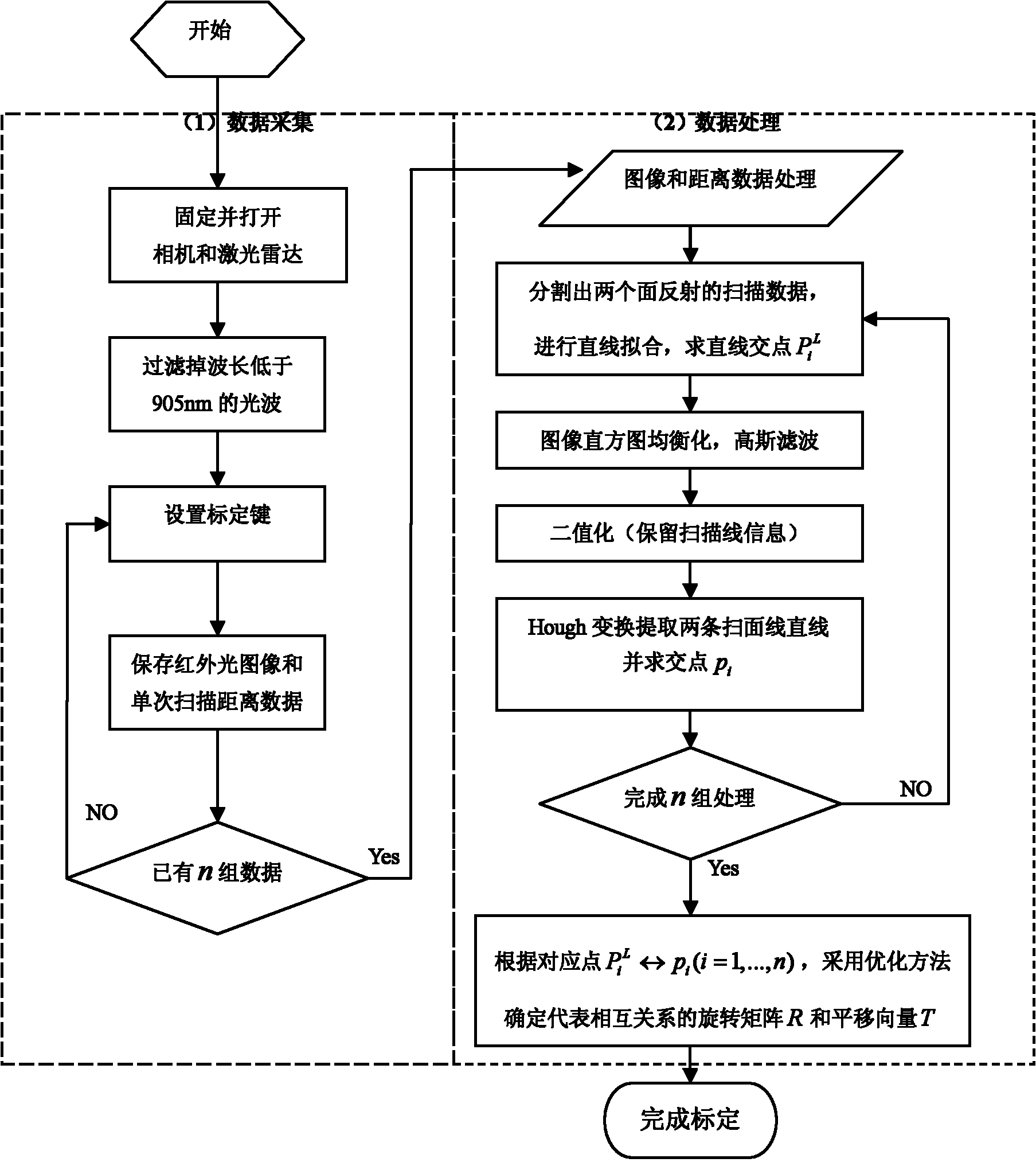

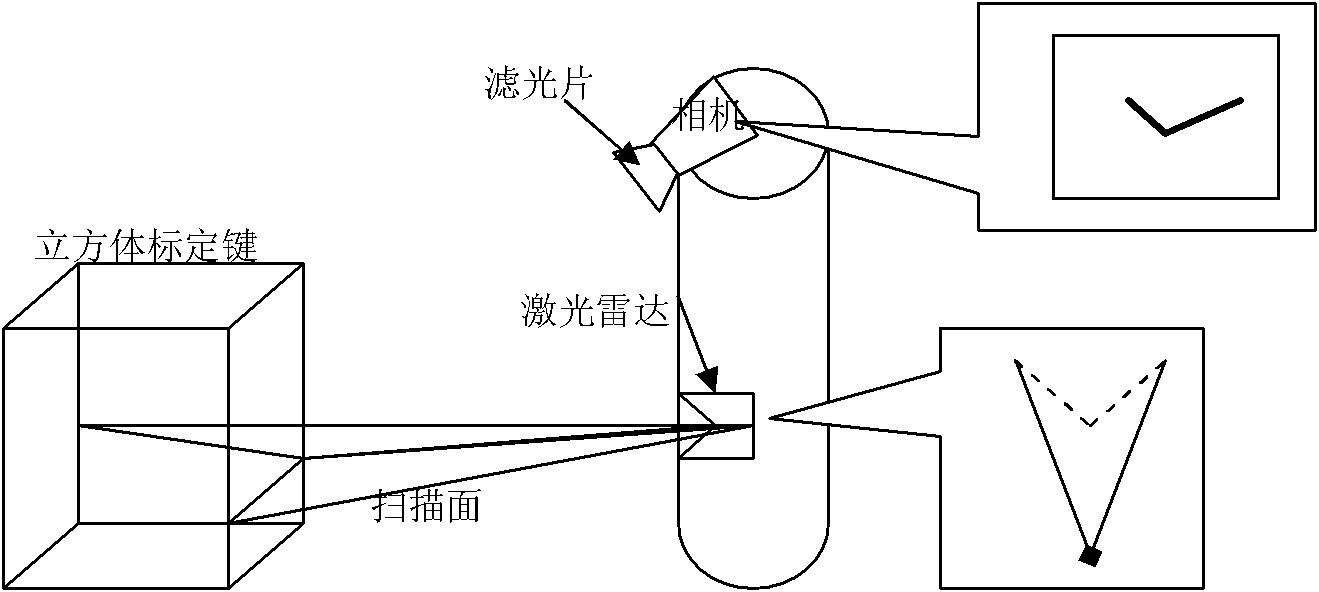

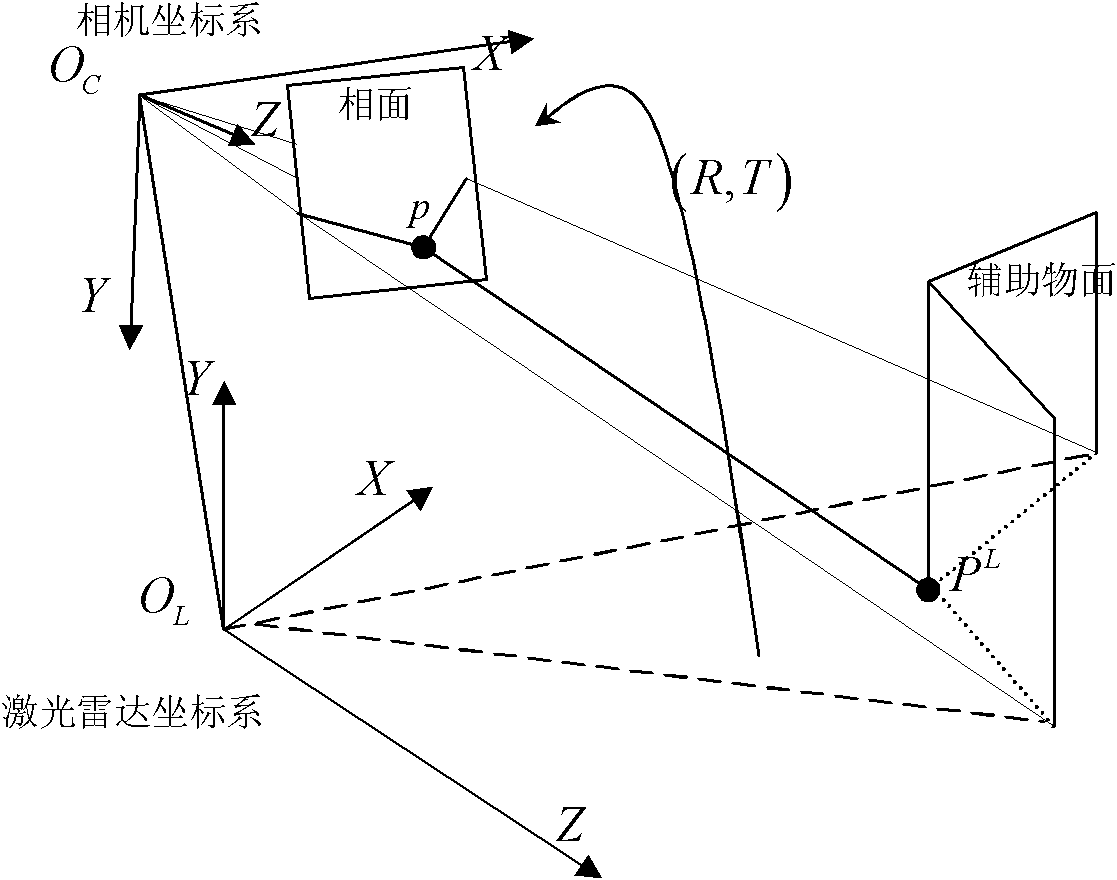

The invention discloses a calibration method of correlation between a single line laser radar and a CCD (Charge Coupled Device) camera, which is based on the condition that the CCD camera can carry out weak imaging on an infrared light source used by the single line laser radar. The calibration method comprises the steps of: firstly, extracting a virtual control point in a scanning plane under the assistance of a cubic calibration key; and then filtering visible light by using an infrared filter to image infrared light only, carrying out enhancement, binarization treatment and Hough transformation on an infrared image with scanning line information, and extracting two laser scanning lines, wherein the intersection point of the two scanning lines is the image coordinate of the virtual control point in the image. After acquiring multiple groups of corresponding points through the steps, a correlation parameter between the laser radar and the camera can be solved by adopting an optimization method for minimizing a reprojection error. Because the invention acquires the information of the corresponding points directly, the calibration process becomes simpler and the precision is greatly improved with a calibrated angle error smaller than 0.3 degree and a position error smaller than 0.5cm.

Owner:NAT UNIV OF DEFENSE TECH

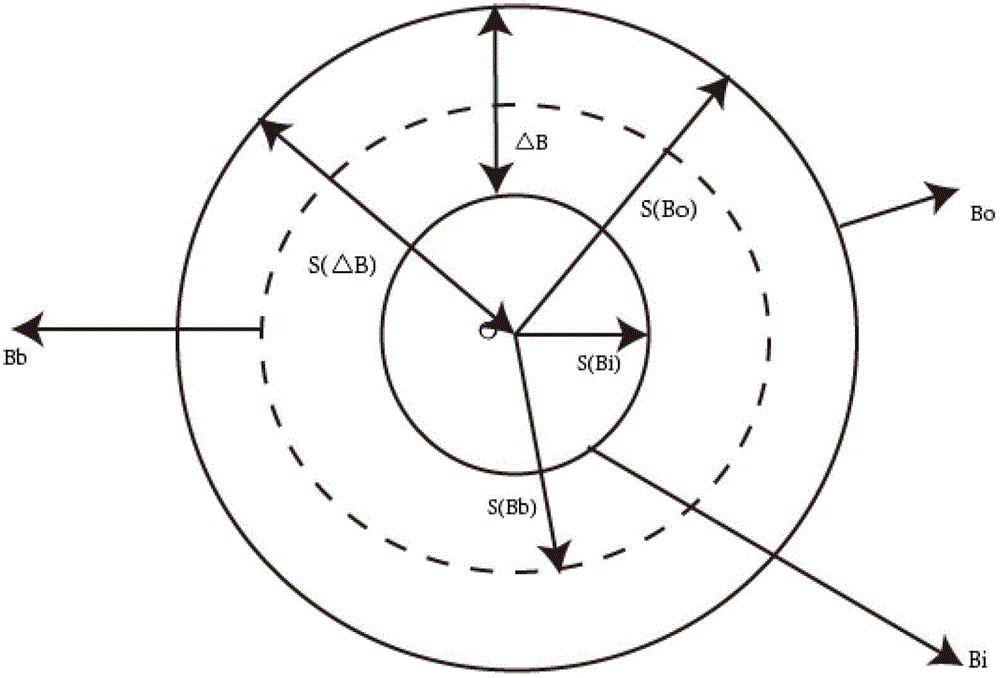

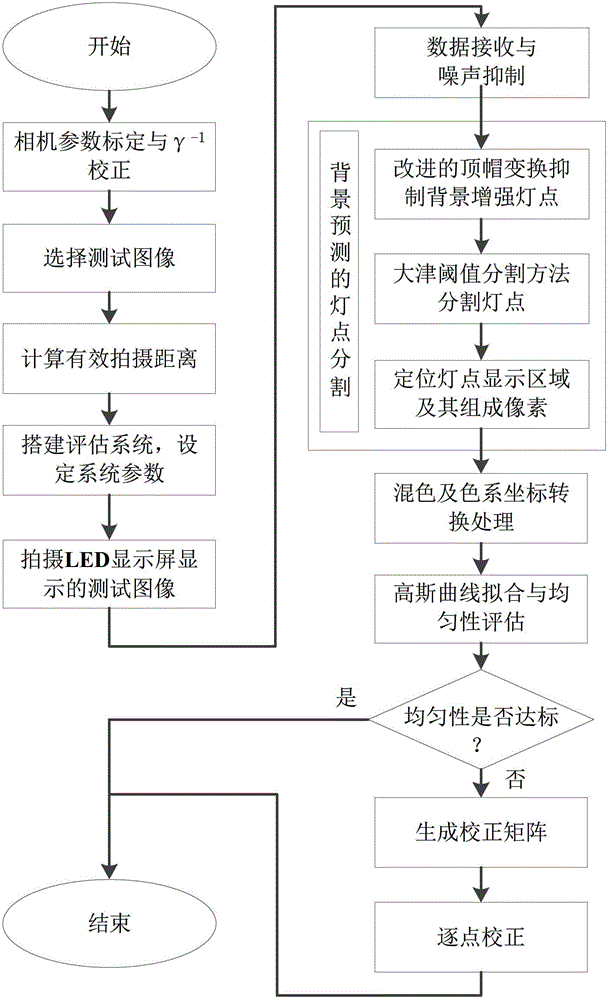

Online calibration system and online calibration method for ununiformity of LED (light-emitting diode) display screen

InactiveCN102723054AAccurately assess severityAccurate evaluation of luminance distortionStatic indicating devicesLED displayLED lamp

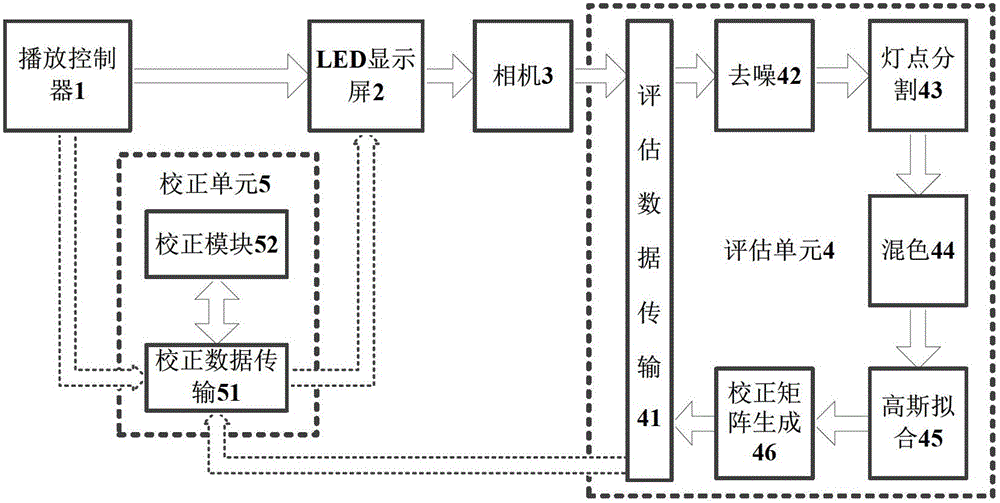

The invention discloses an online calibration system and an online calibration method for ununiformity of an LED (light-emitting diode) display screen. The online calibration system and the online calibration method mainly solve problems that an existing test method is only used for testing brightness uniformity, tested brightness uniformity index cannot reflect an overall performance of an LED display screen, and ununiformity calibration cannot be carried out according to tested data. The online calibration method includes steps of acquiring test images displayed by the LED display screen by a camera, and dividing LED lamp points by a method based on background prediction after noise is eliminated; repositioning luminous zones of the lamp points and component pixels of the luminous zones; and then mixing the lamp points to form colors of the pixels, and fitting acquired chromaticity coordinates of the lamp points to form a Gaussian curve after gross errors are eliminated, and solving a mean value of the chromaticity coordinates; substituting the mean value of the chromaticity coordinates into a uniformity evaluation formula to evaluate the uniformity; and finally generating a calibration matrix and performing online real-time online ununiformity calibration point by point. The online calibration method for the ununiformity of the LED display screen is high in precision and efficiency and good in stability, is simple, convenient and feasible, and is capable of being used for testing a uniformity display performance and ununiformity calibration for the LED display screen.

Owner:XIDIAN UNIV

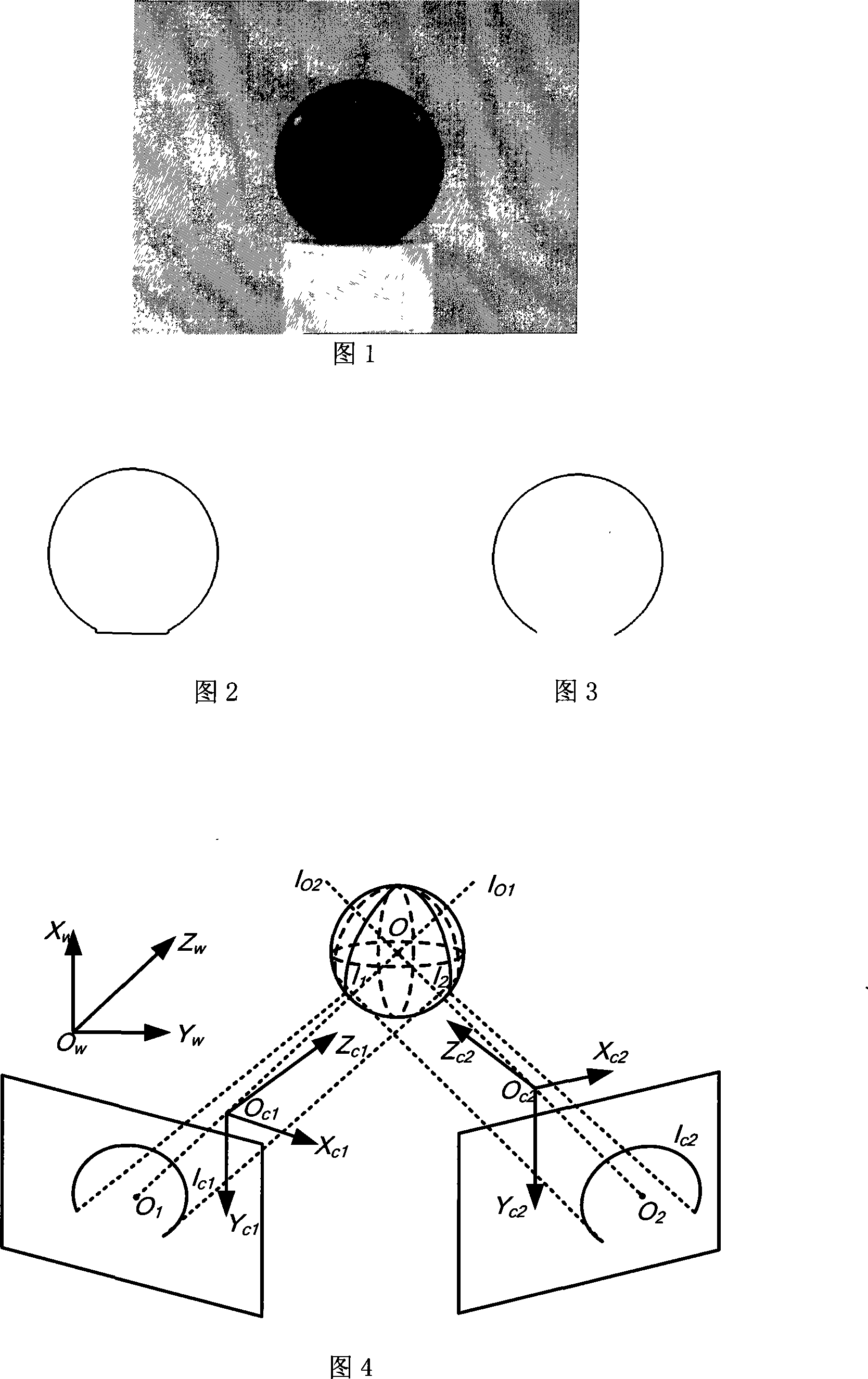

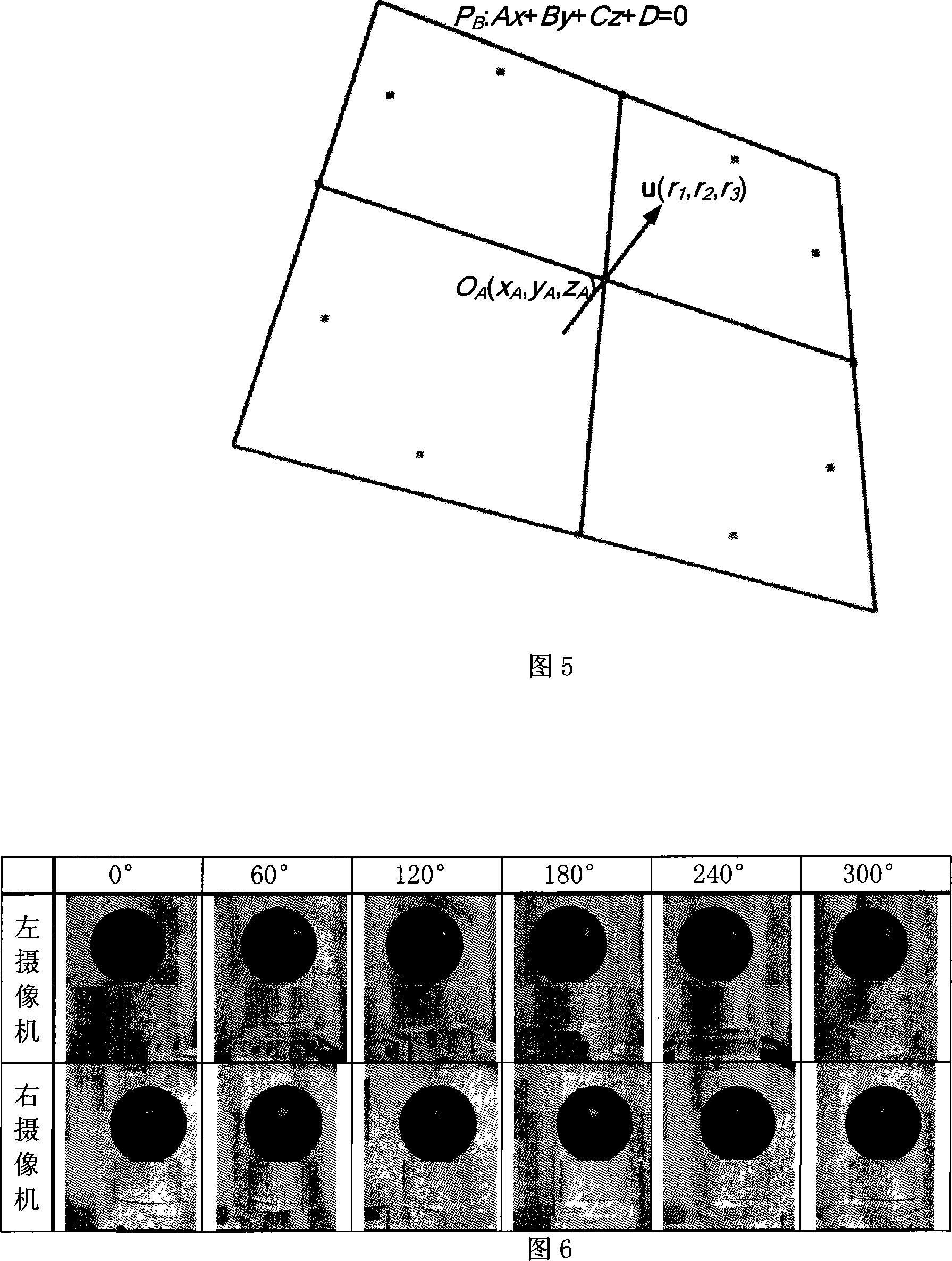

Binocular vision rotating axis calibration method

InactiveCN101216296ANo precision requiredEasy to operateImage analysisUsing optical meansVisual perceptionHuman eye

The invention belongs to detection techniques with visual principle, particularly relates to a method for calibrating rotating shaft by binocular vision with convenient operation and simple calibration process. The technical proposal of the invention includes that the method for calibrating rotating shaft by binocular vision comprises the following steps of: (1) obtaining edge of a spherical target; (2) calculating the coordinates of the spatial spherical center; and (3) calibrating and calculating parameters of the rotating shaft. The invention measures the spatial characteristic points mainly by using two cameras to simulate the structure of human eyes.

Owner:TIANJIN UNIV

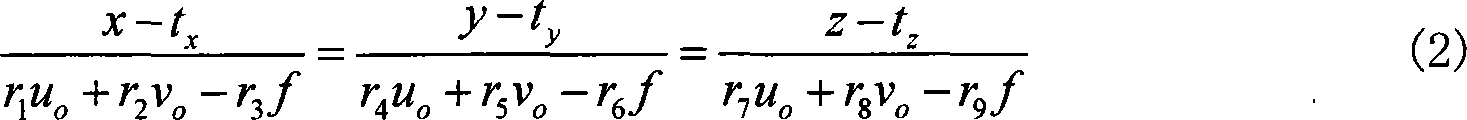

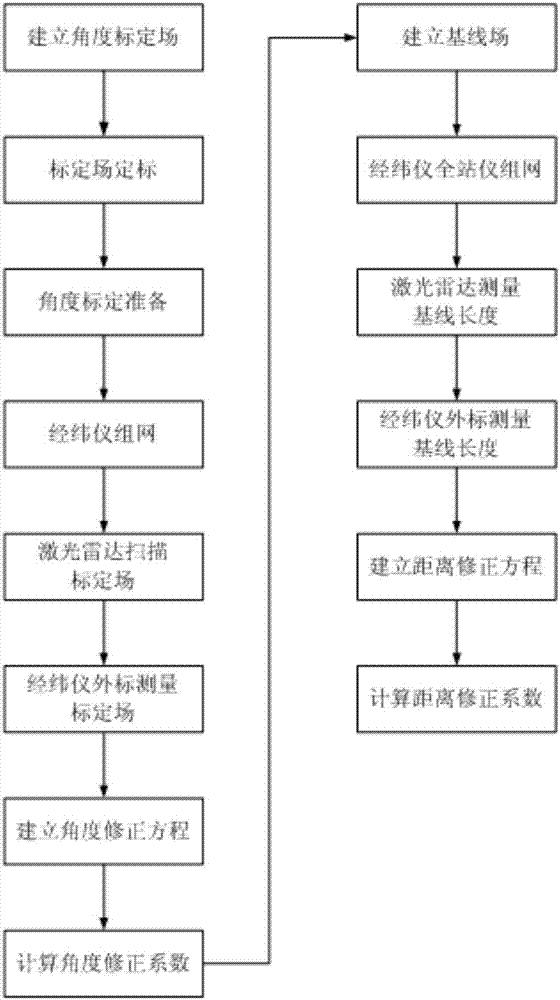

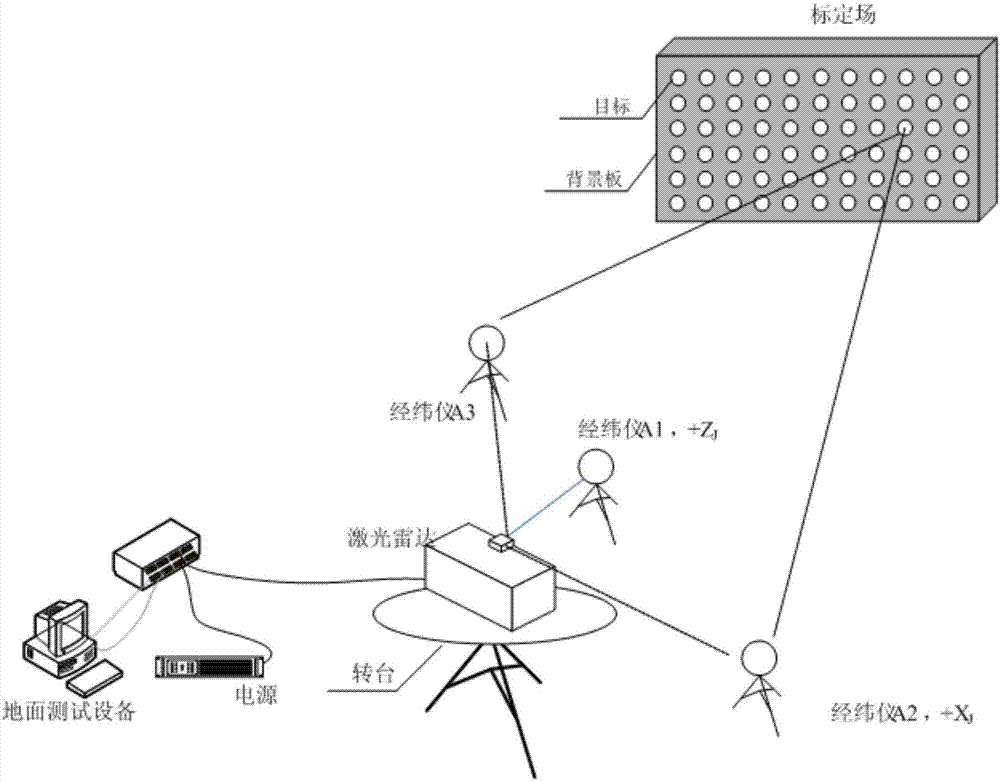

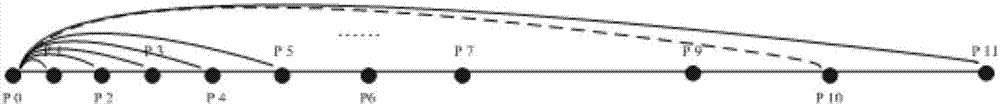

Laser radar two-step calibration method based on calibration field

ActiveCN107167790ABreaking high flatness requirementsBreak flatness requirementsWave based measurement systemsDistance correctionTheodolite

The invention discloses a laser radar two-step calibration method based on a calibration field. The method comprises steps of establishing a calibration field; carrying out calibration; preparing angle calibration; networking a theodolite; scanning a laser radar; measuring the theodolite; establishing an angle correction equation; calculating an angle correction coefficient; establishing a base line field; measuring the laser radar; measuring the theodolite; establishing a distance correction equation; and calculating a distance correction coefficient. According to the invention, rapid calibration of the laser radar is achieved without taking a precisely designed and processed calibration device as a calibration standard; a problem of too high requirements on a test place, the calibration field and the calibration device in the normal method is solved; through cooperation of a rotation bench, the whole test process is achieved, the test difficulty level is reduced and a difficulty in ensuring precision of full field-of-view angle correction in the normal method is solved; and through the test of the calibration field and the base line field step by step, effects of correcting separation distances in a calibration model are achieved and disadvantages in mutual coupling of distance parameters and angle parameters in the normal method are overcome.

Owner:BEIJING INST OF CONTROL ENG

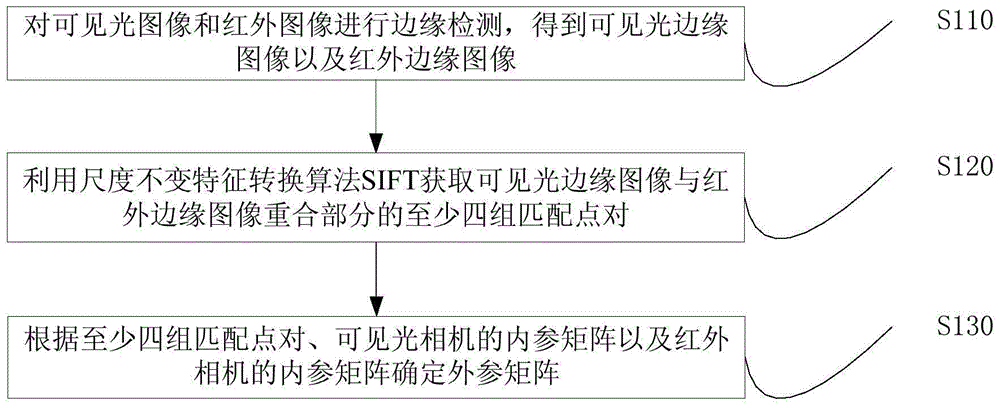

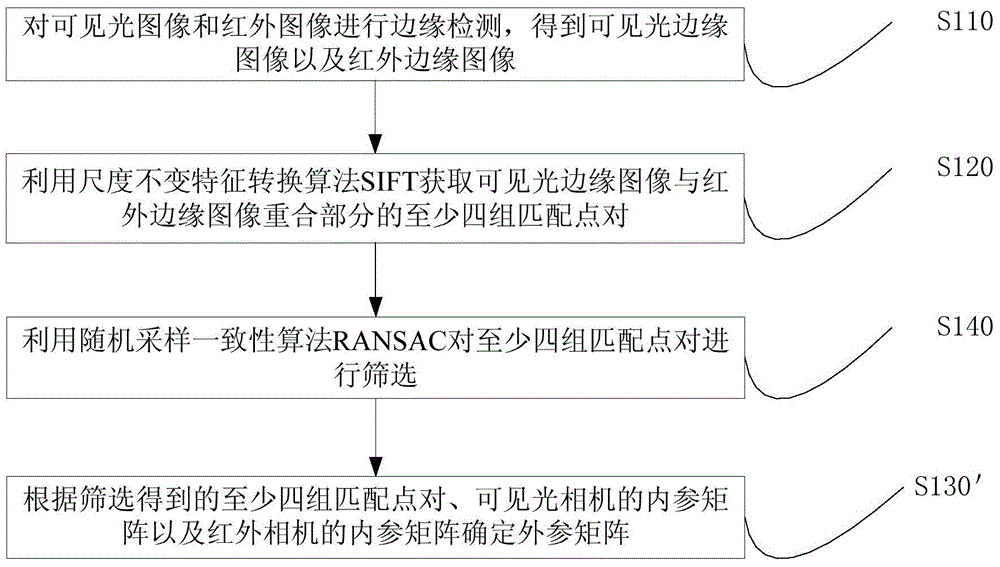

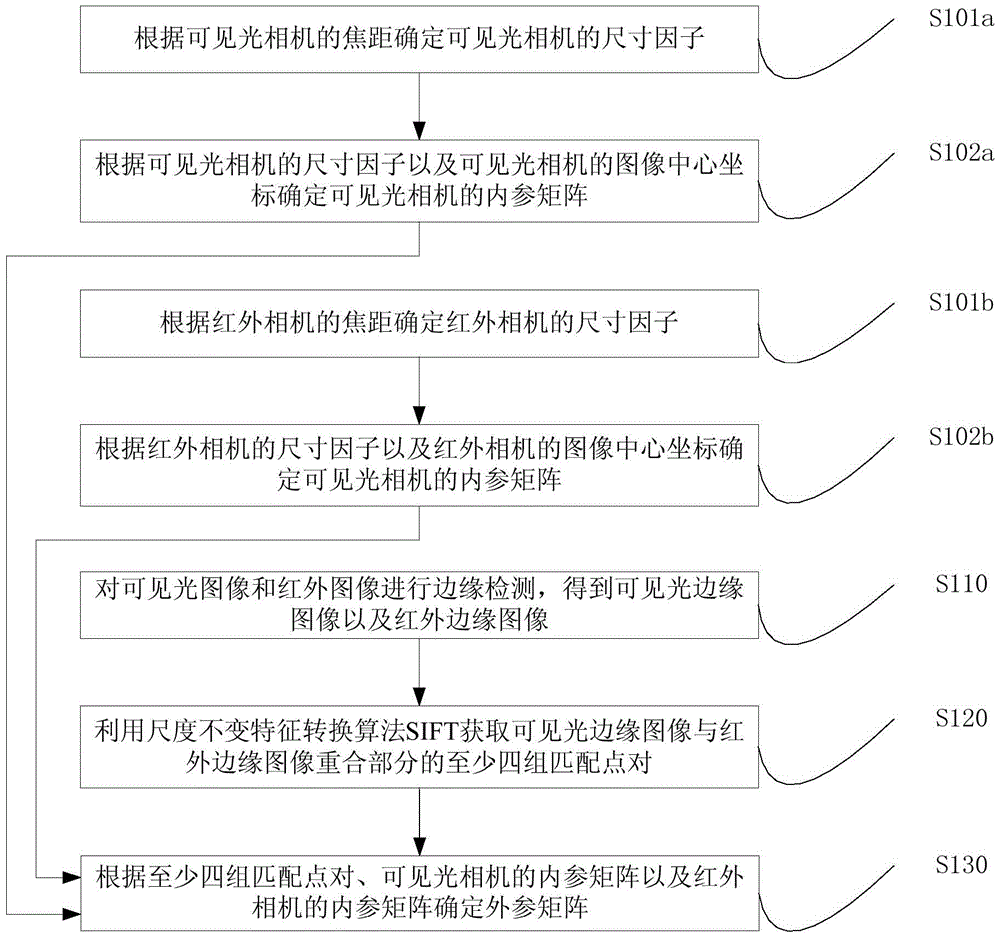

Method and device for jointly calibrating parameters of visible light camera and infrared camera

ActiveCN105701827AReduce calibration costsImprove calibration efficiencyImage enhancementImage analysisScale-invariant feature transformIntrinsics

The invention discloses a method and device for jointly calibrating the parameters of a visible light camera and an infrared camera. The method comprises steps of: detecting the edges of a visible light image and an infrared image to obtain a visible light edge image and an infrared edge image; acquiring at least four groups of matched point pairs of the visible light edge image and the infrared edge image by using a scale invariant feature transform (SIFT) algorithm; and determining an extrinsic parameter matrix according to the at least four groups of matched point pairs, the intrinsic parameter matrix of the visible light camera, and the intrinsic parameter matrix of the infrared camera. The method and the device may acquire the matched point pairs in the visible light edge image and the infrared edge image without a calibration board and determine the extrinsic parameter matrix without the calibration board so as to reduce the calibration cost of camera parameters. Further, when a focal length of the camera is changed, the extrinsic parameter matrix can be determined without camera position adjustment so that parameter calibration efficiency is increased.

Owner:CHINA FORESTRY STAR BEIJING TECH INFORMATION CO LTD

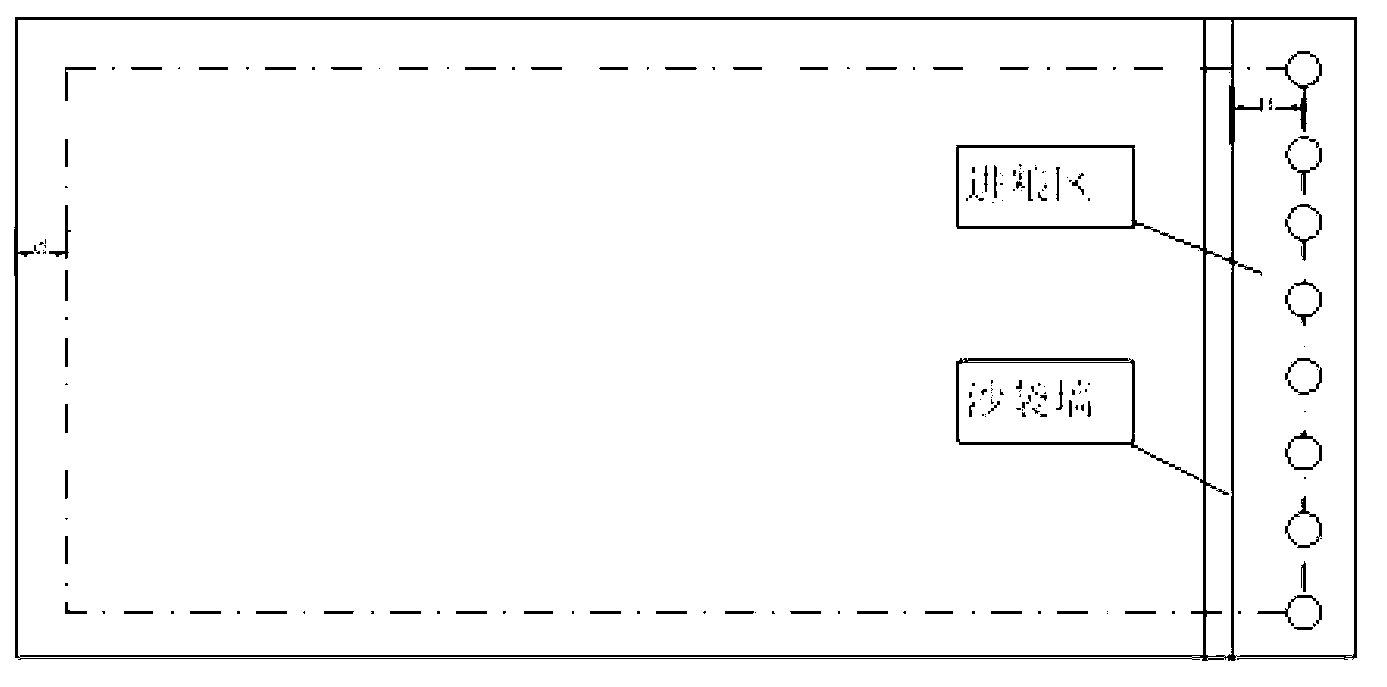

Grain storage quantity detection method for horizontal warehouse and shallow silo

InactiveCN102706417ALow costReduce workloadWeighing apparatus for materials with special property/formGrain storageSurface pressure

The invention relates to a grain storage quantity detection method for horizontal warehouses and shallow silos. The grain storage quantity detection method comprises the following steps of: firstly selecting specific pressure sensors to lay a grain warehouse pressure sensor detection network; distributing the pressure sensors along the side wall of the grain warehouse in the mode that all the pressure sensors are evenly-spaced laid at d meter distance from the side wall; and determining whether a grain warehouse is calibrated or not so as to obtain a calibration parameter and a grain warehouse weight prediction model, spreading the top surface of a grain pile in the grain warehouse after the grain warehouse is fully filled with the grain, detecting the average output valve of the pressure sensor at the bottom of the grain warehouse, and detecting the grain storage quantity of the grain warehouse according to an actually-tested bottom surface area of the grain warehouse, a bottom surface area of the calibrated grain warehouse and calibrated parameters by using a model so as to obtain an estimated value of the weight of the grain warehouse. According to the grain storage quantity detection method provided by the invention, the pressure sensors are required to be arranged on the bottom surface of the grain warehouse, and a compensating item of a side grain warehouse friction action is added into a bottom surface pressure estimating model in order to avoid using the side pressure sensor and accurately obtain the estimated value of the pressure of the bottom surface of the grain warehouse, so that the quantity of the sensors is obviously reduced, and the device detection cost and the installation and maintenance cost are reduced.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

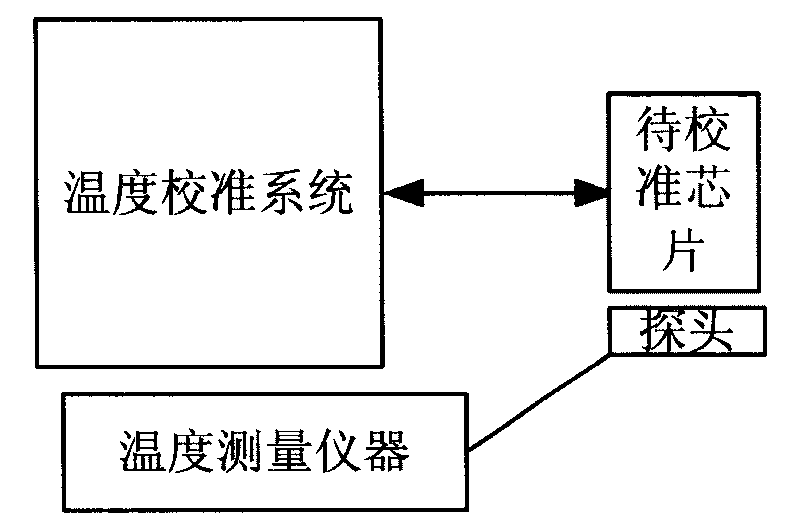

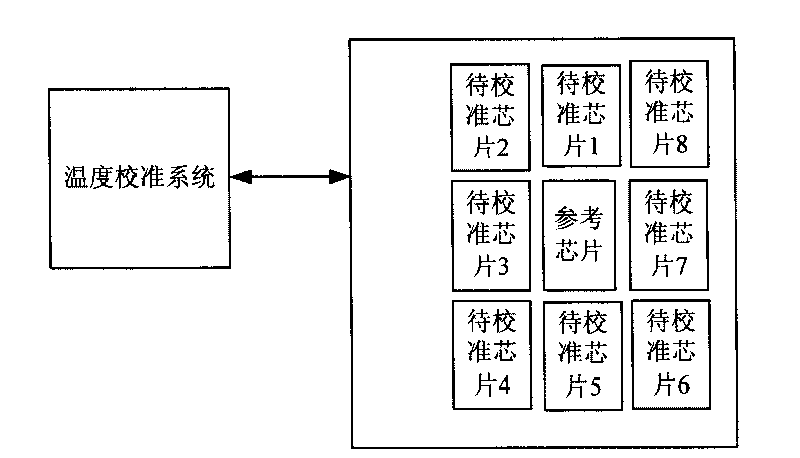

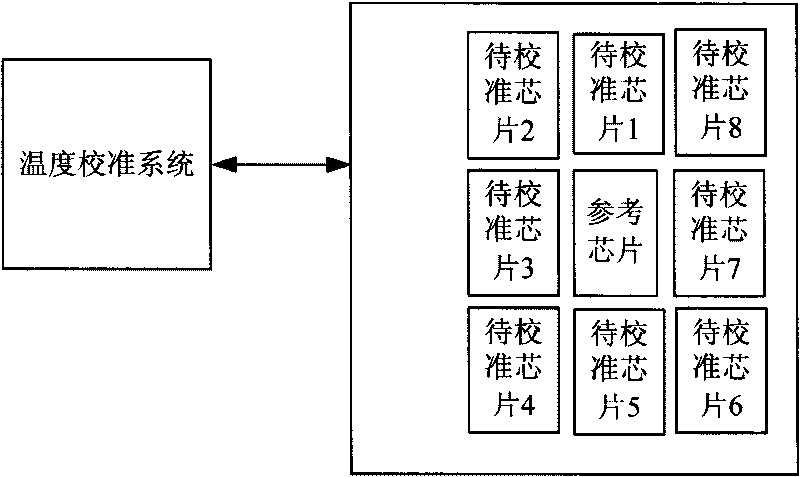

Calibration system and calibration method of temperature sensor chip

ActiveCN101750170ASimple structureEasy to buildThermometer testing/calibrationDigital interfaceEngineering

The invention discloses a calibration system of a temperature sensor chip, which comprises a test board and a temperature calibration system, wherein the test panel is provided with a temperature sensor reference chip and a chip to be calibrated; and each chip is connected and communicates with the temperature calibration system through a unified digital interface. The temperature calibration system reads the temperature values of various calibration chips and reference chips through the unified digital interface; and various chips to be calibrated simultaneously acquire the data, thereby realizing synchronous acquisition and calibration of multichip data, greatly improving the acquisition efficiency of the data and reducing the test and calibration time of the chips and calibration cost. The invention has the advantages of simple structure, easy building, short calibration time, high calibration efficiency, low cost, high degree of automation and the like. The invention also discloses a calibration method of the temperature sensor chip.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

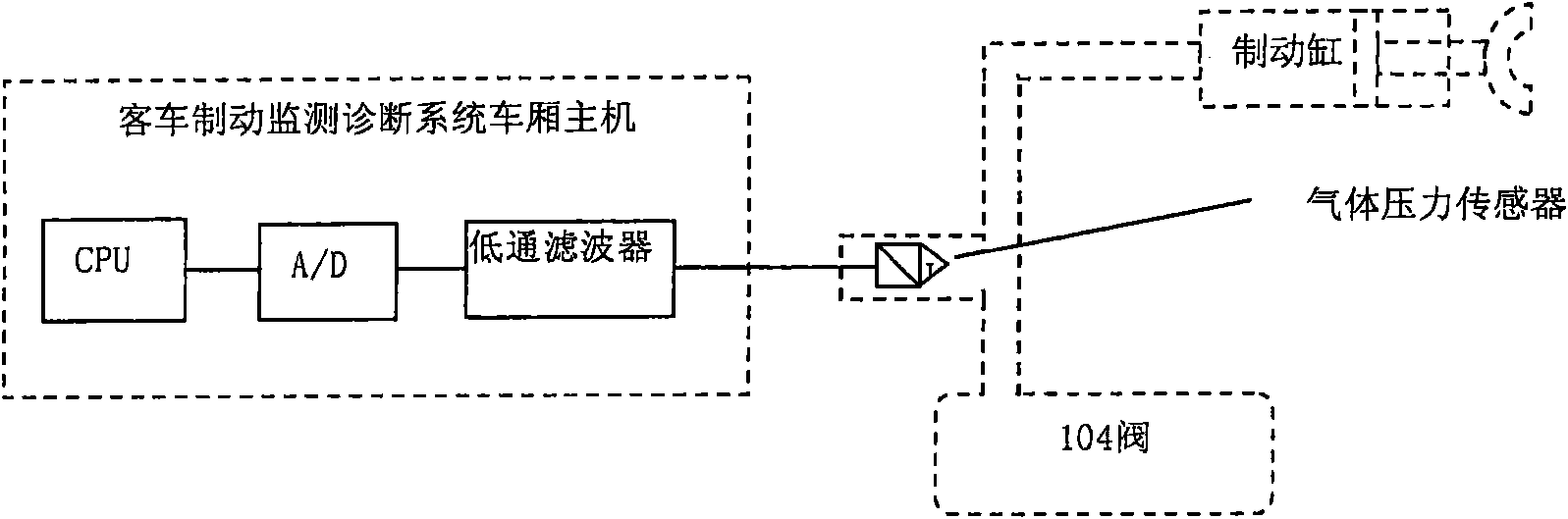

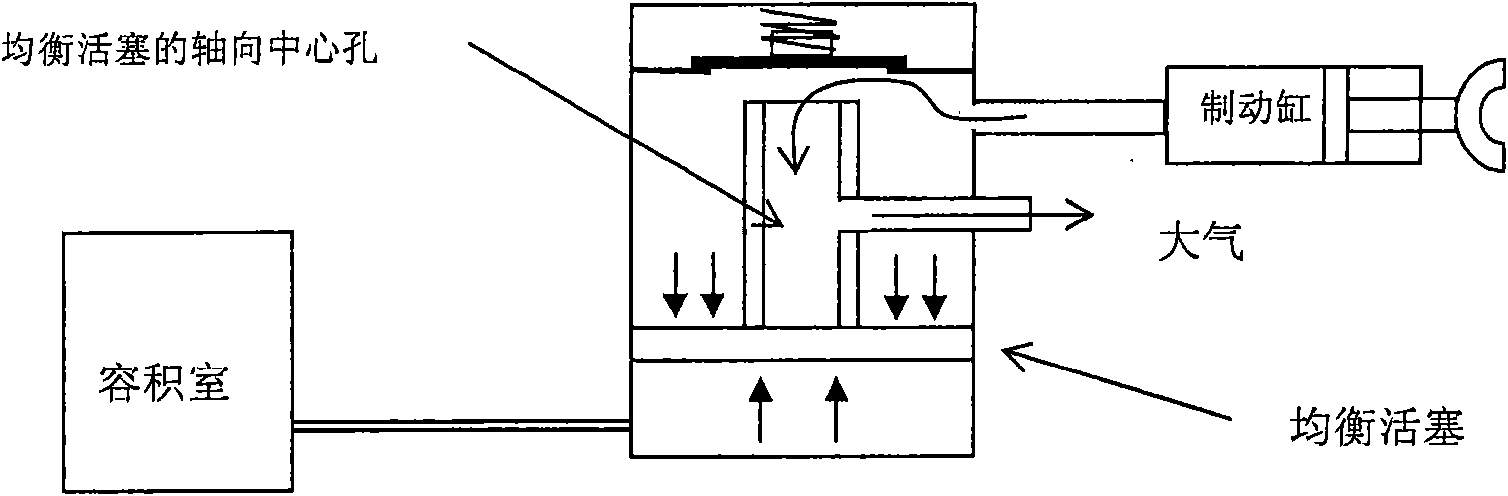

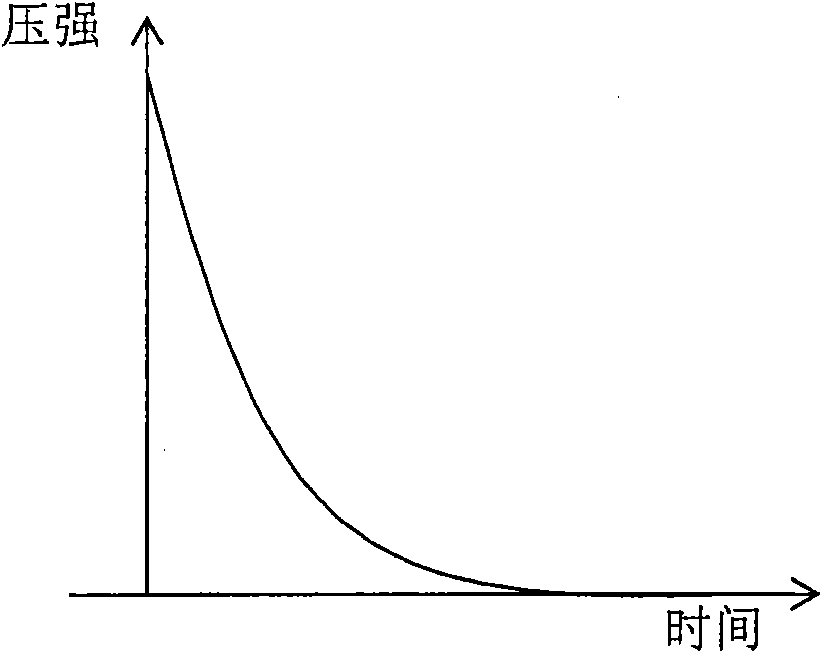

Method and device for zero point calibration of gas pressure sensor

InactiveCN101655406AEasy to operateReduce workloadFluid pressure measurementOffset calibrationWorkload

The invention provides a method and a dehvice for the zero point calibration of a gas pressure sensor, which comprises the steps that: when a brake cylinder is released, the pressure value of the brake cylinder is obtained; the releasing process is judged to be normal or abnormal according to the time the pressure value is obtained and according to the pressure value; when the releasing process isnormal, the pressure value of the brake value is judged to whether reach zero or not; when the pressure value of the brake reaches zero, the pressure value obtained currently is compared with a pre-stored composite error nominal value; when the pressure value obtained currently is smaller than or equal to the composite error nominal value, the pressure value obtained currently is regarded as a zero point correct value; and the zero point of the gas pressure sensor is calibrated according to the zero point correct value. The method and the device can solve the problem of zero point drift and have simple operation and lowered workload and calibration cost.

Owner:LOCOMOTIVE & CAR RES INST OF CHINA ACAD OF RAILWAY SCI

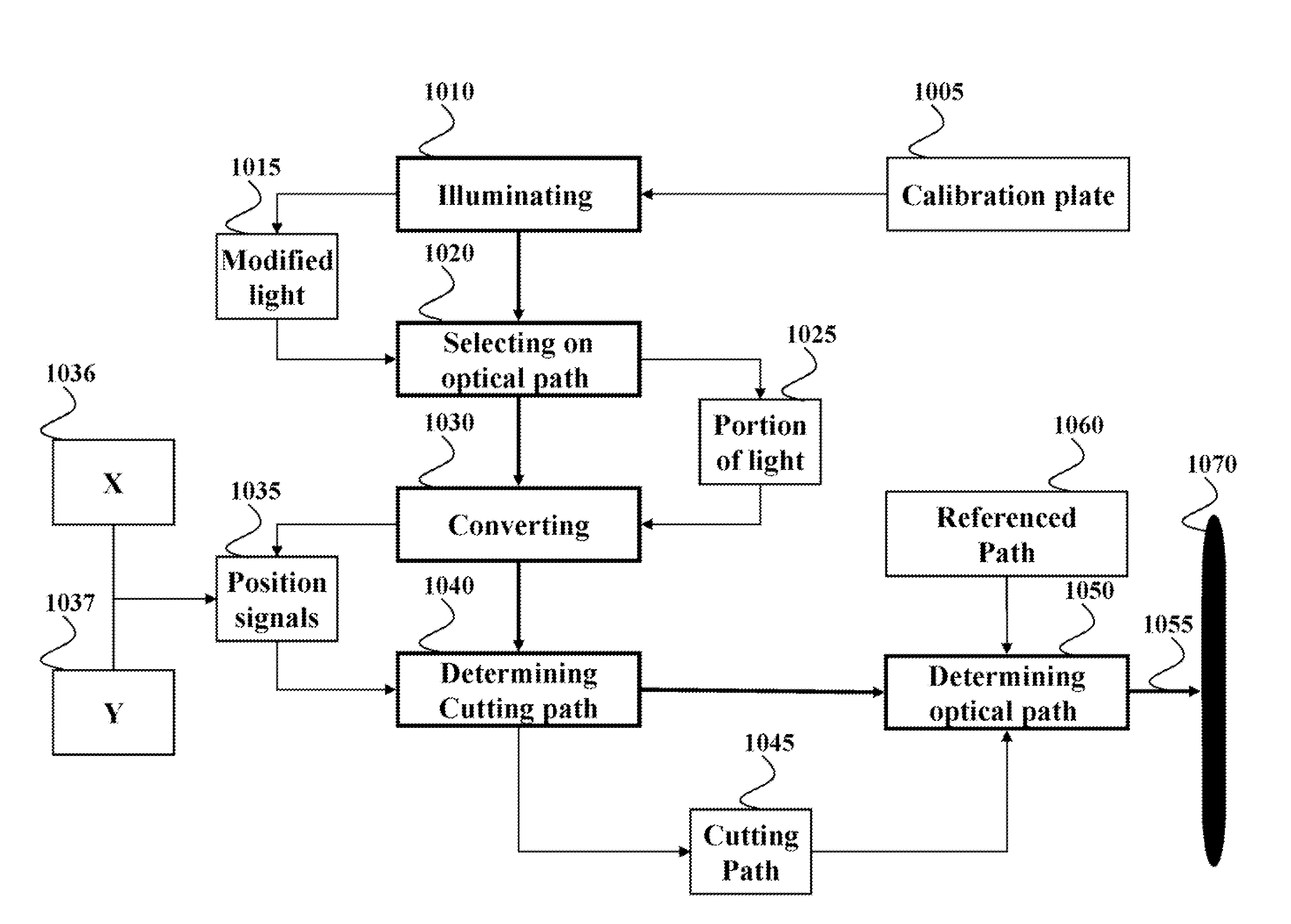

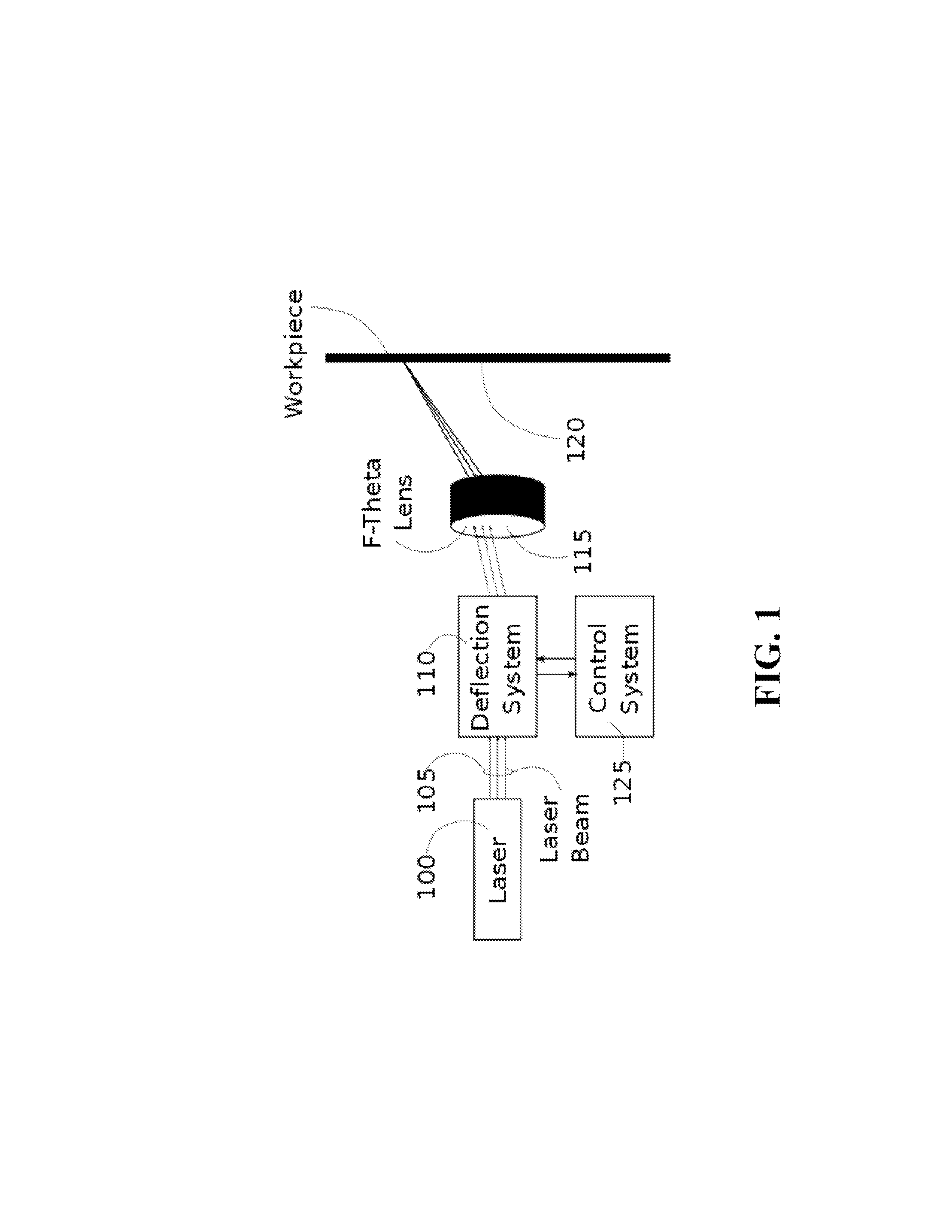

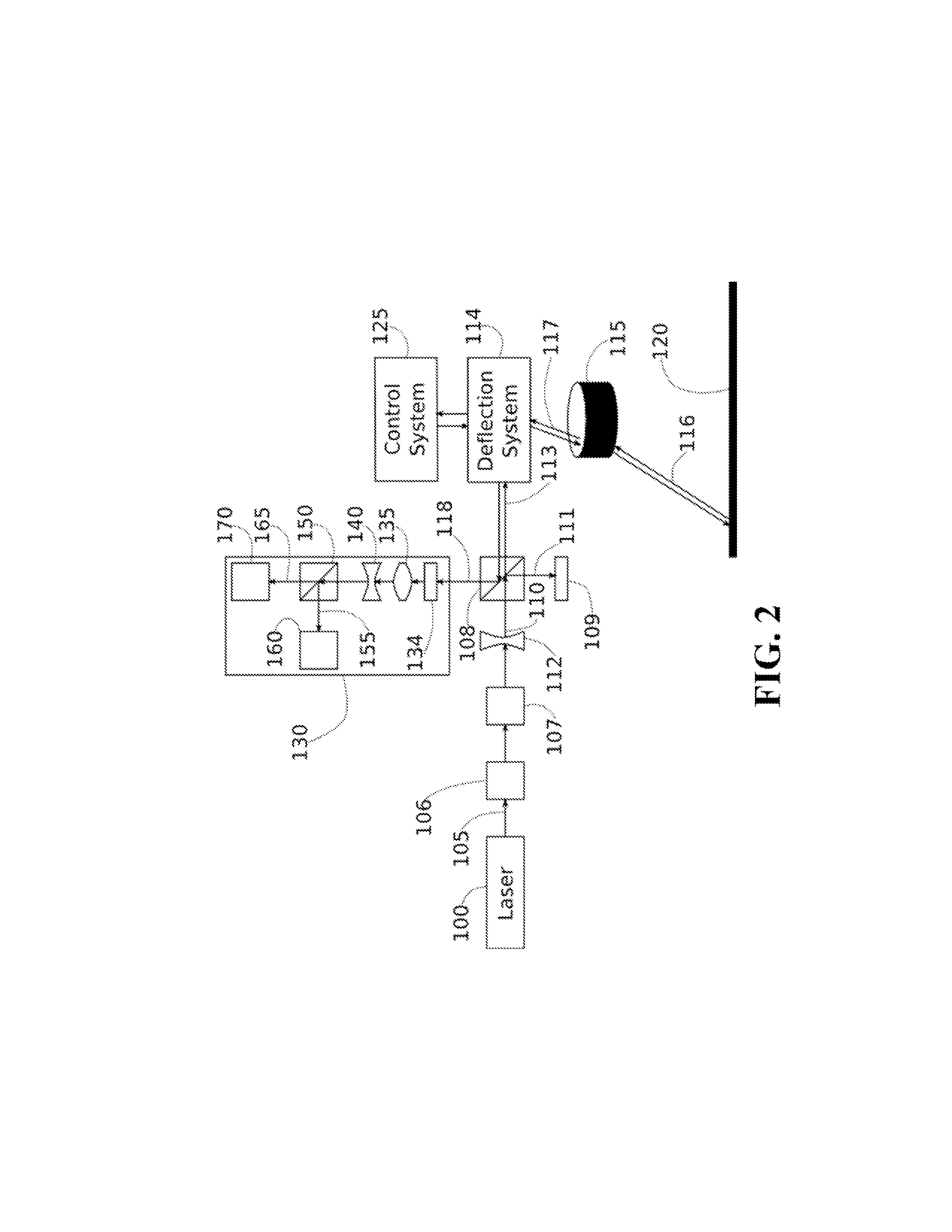

System and Method for Calibrating Laser Cutting Machines

InactiveUS20130178972A1Reduce calibration costsLow costProgramme controlComputer controlControl systemLaser cutting

A system for calibrating a laser cutting machine includes a calibration plate arranged to simulate a workpiece; a first quad photodiode (QPD) and a second QPD for converting light including an image of a portion of a surface of the calibration plate into a plurality of electrical signals, wherein the first and the second QPDs are positioned to receive the light propagated from the surface of the calibration plate through the optical path of the laser beam; and a control system for calibrating the laser cutting machine based on the plurality electrical signals.

Owner:MITSUBISHI ELECTRIC RES LAB INC

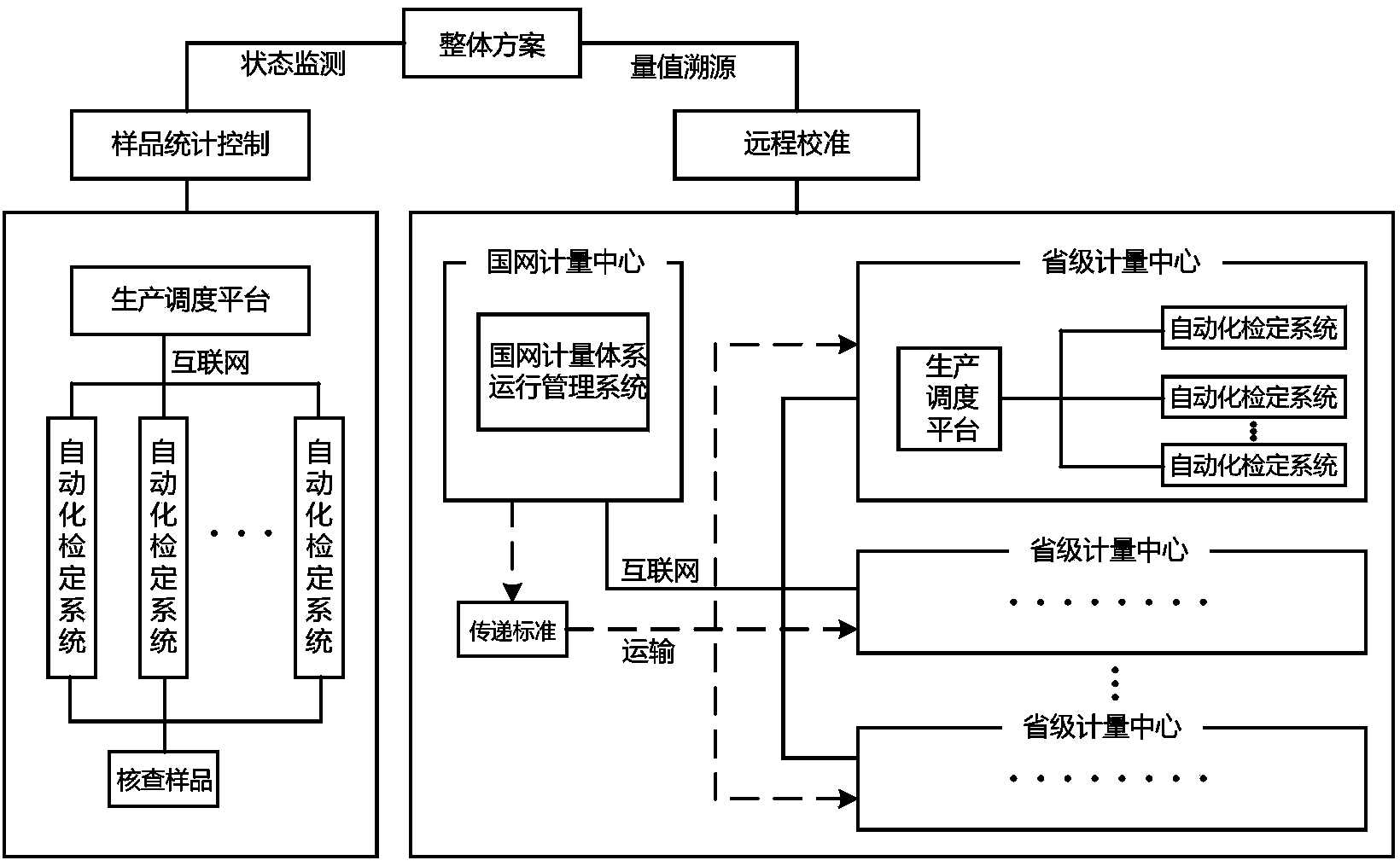

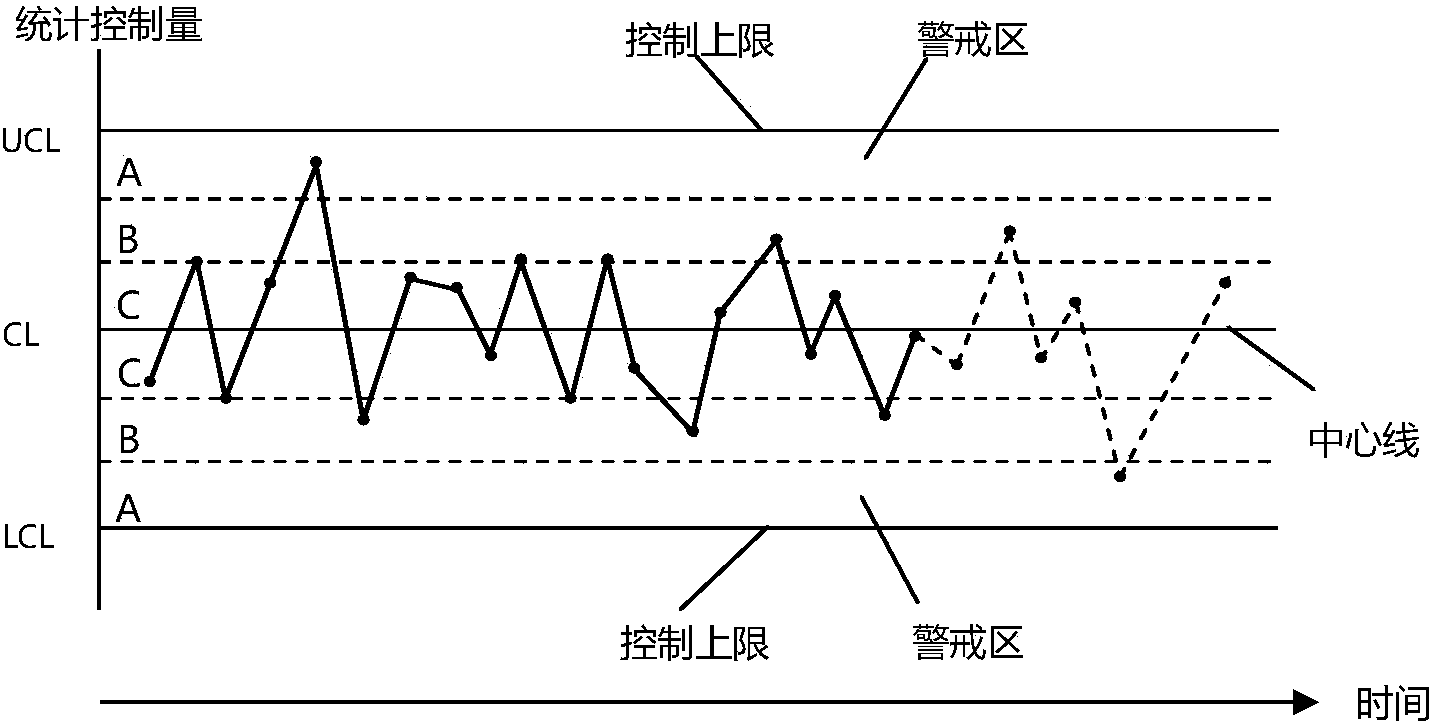

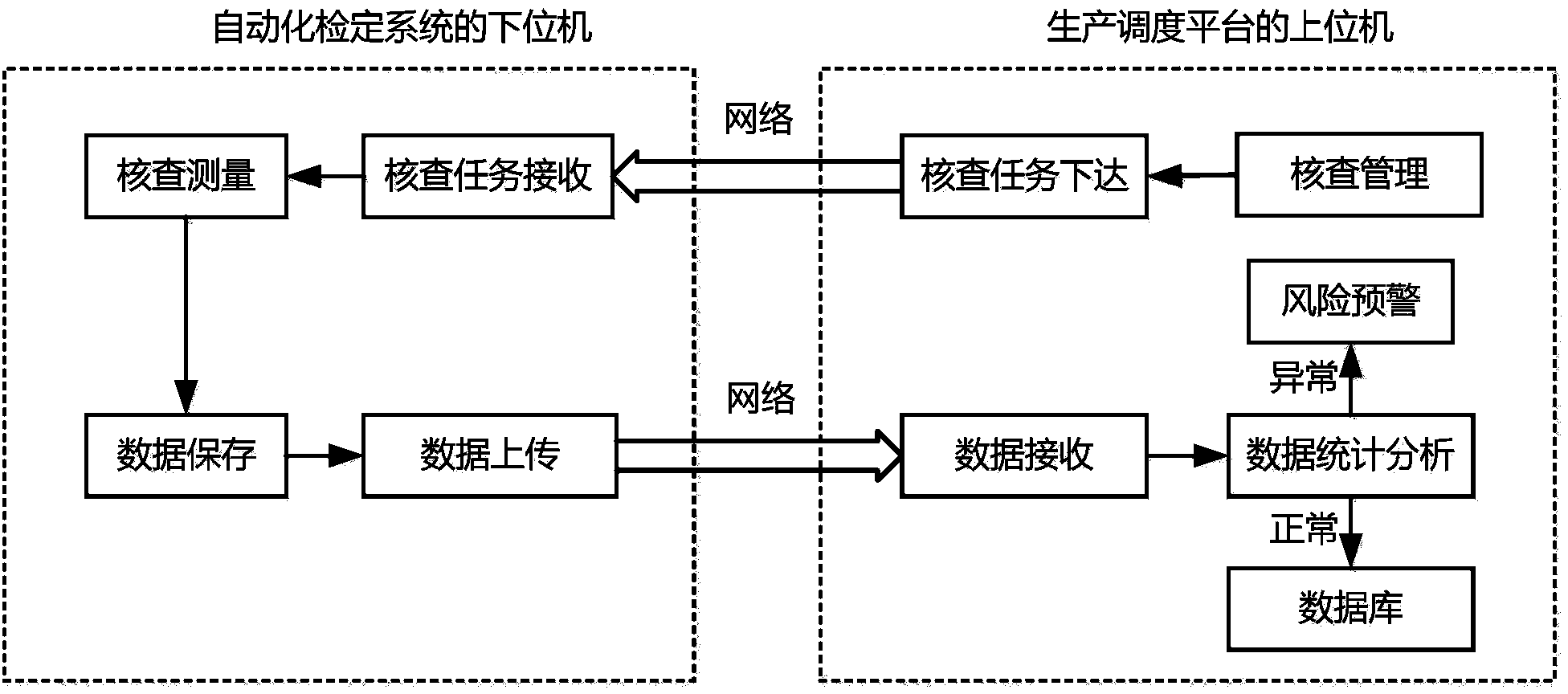

Value traceability and monitoring method for low-voltage current transformer automation verification system

ActiveCN104330759AReduce lost timeImprove reliabilityElectrical measurementsLow voltageDependability

The invention provides a value traceability and monitoring method for a low-voltage current transformer automation verification system. Value traceability is performed on the low-voltage current transformer automation verification system based on a network remote correction method. The method comprises monitoring test data of low-voltage current transformer inspection samples output by the verification system through a statistical method and performing risk early warning on the low-voltage current transformer. Comparing with the prior art, time required by correction is shortened, correction costs are reduced, and the metering center work delaying time of a measuring center is reduced; results can be re-inspected on line before verification, so that the correction quality is improved; sample testing and verification data statistical processing are completed automatically through a computer, the monitoring amount of the automation verification system state is reduced, and the reliability and the timeliness of state monitoring of the automation verification system are improved.

Owner:STATE GRID CORP OF CHINA +2

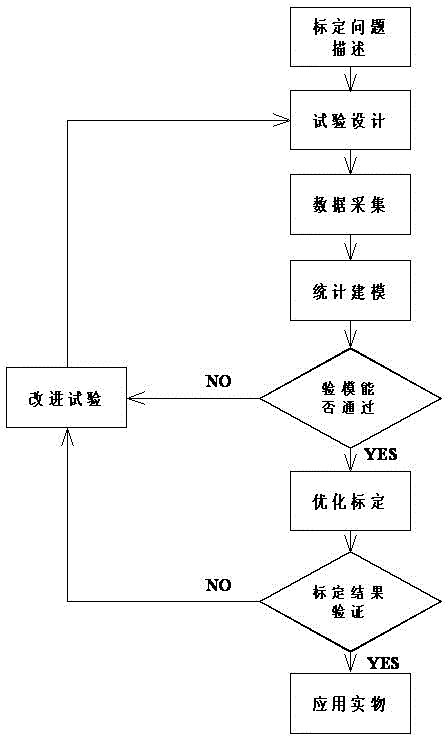

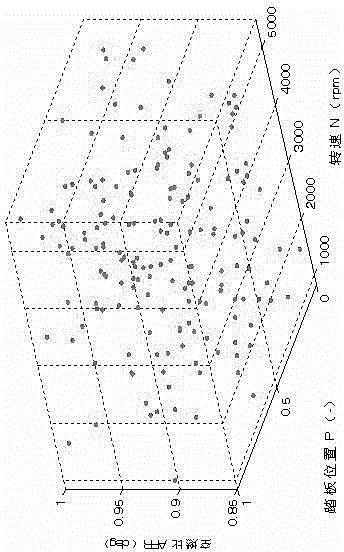

Model-based gasoline engine calibration method

ActiveCN104408271AIncreased calibration workloadDelayed production cycleSpecial data processing applicationsTest designOperating point

The invention provides a model-based gasoline engine calibration method, belongs to the technical field of gasoline engines, and designs and develops a statistical model based gasoline engine calibration method mainly for a dynamic property optimized calibration process of a gasoline engine. The model-based gasoline engine calibration method comprises the following steps: (1), design of test operating points, (2) establishment of a mathematical statistics model and (3), optimization of calibrating procedure design, wherein firstly, relatively fewer test points can be selected in a test design phase so as to reduce workload; then an engine statistical model is established with a mathematical statistics method after related data are acquired; and finally, optimized calibration is performed on the basis of the statistical model. Under the premise that the performance of the gasoline engine is improved without loss of calibration accuracy, the model-based gasoline engine calibration method has the advantages as follows: time is saved, the cost is reduced, the output torque is increased, and the problems that the traditional manual calibration method is time-consuming, labor-consuming and low in efficiency and the conventional automatic optimized calibration equipment is complicated in technology and expensive are solved.

Owner:JILIN UNIV

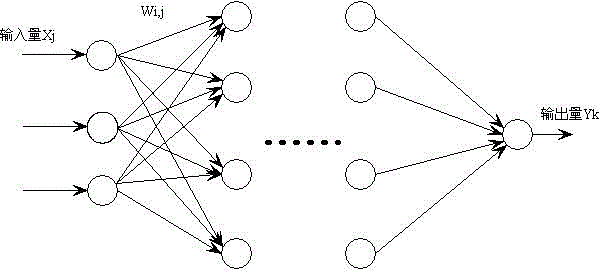

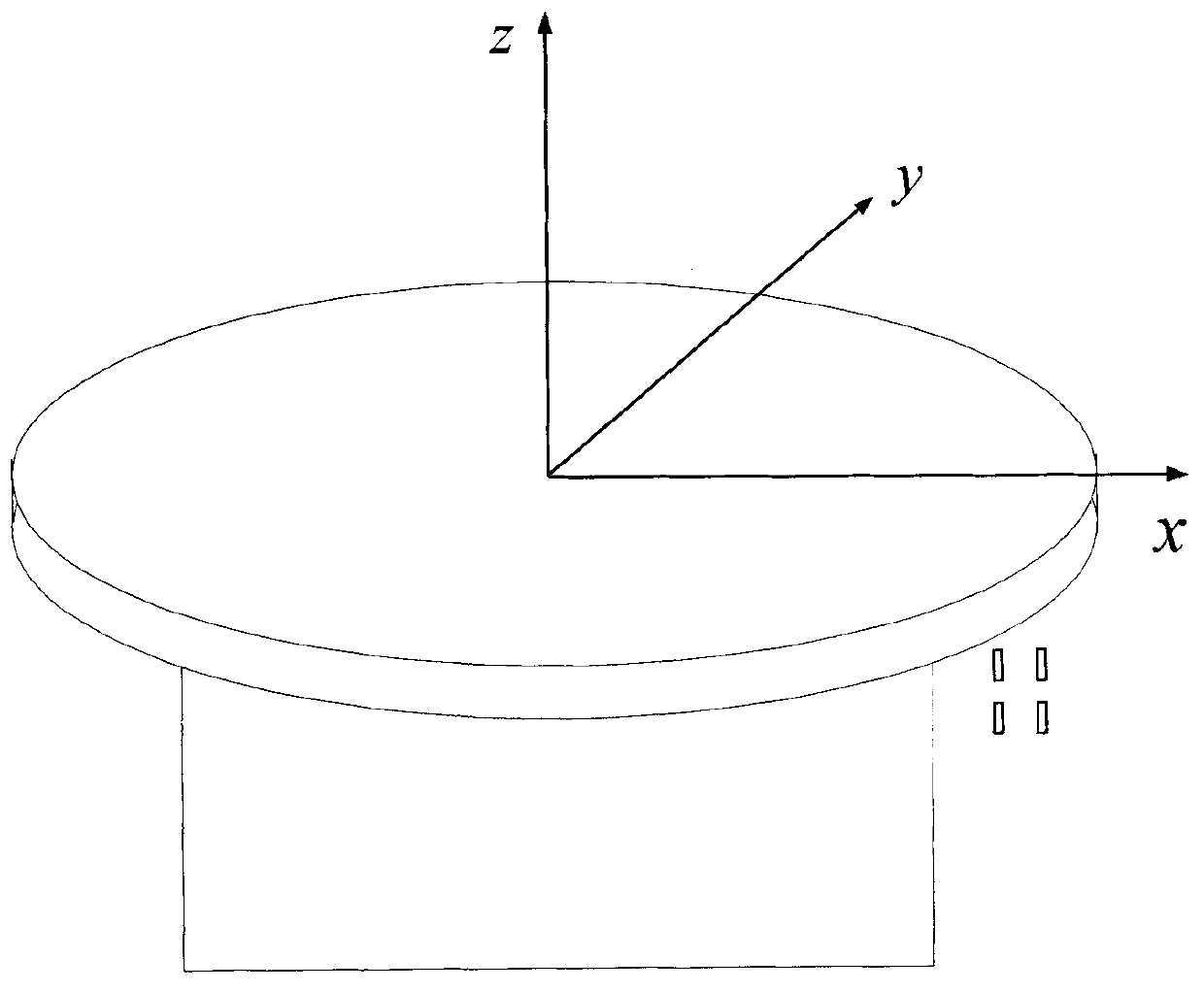

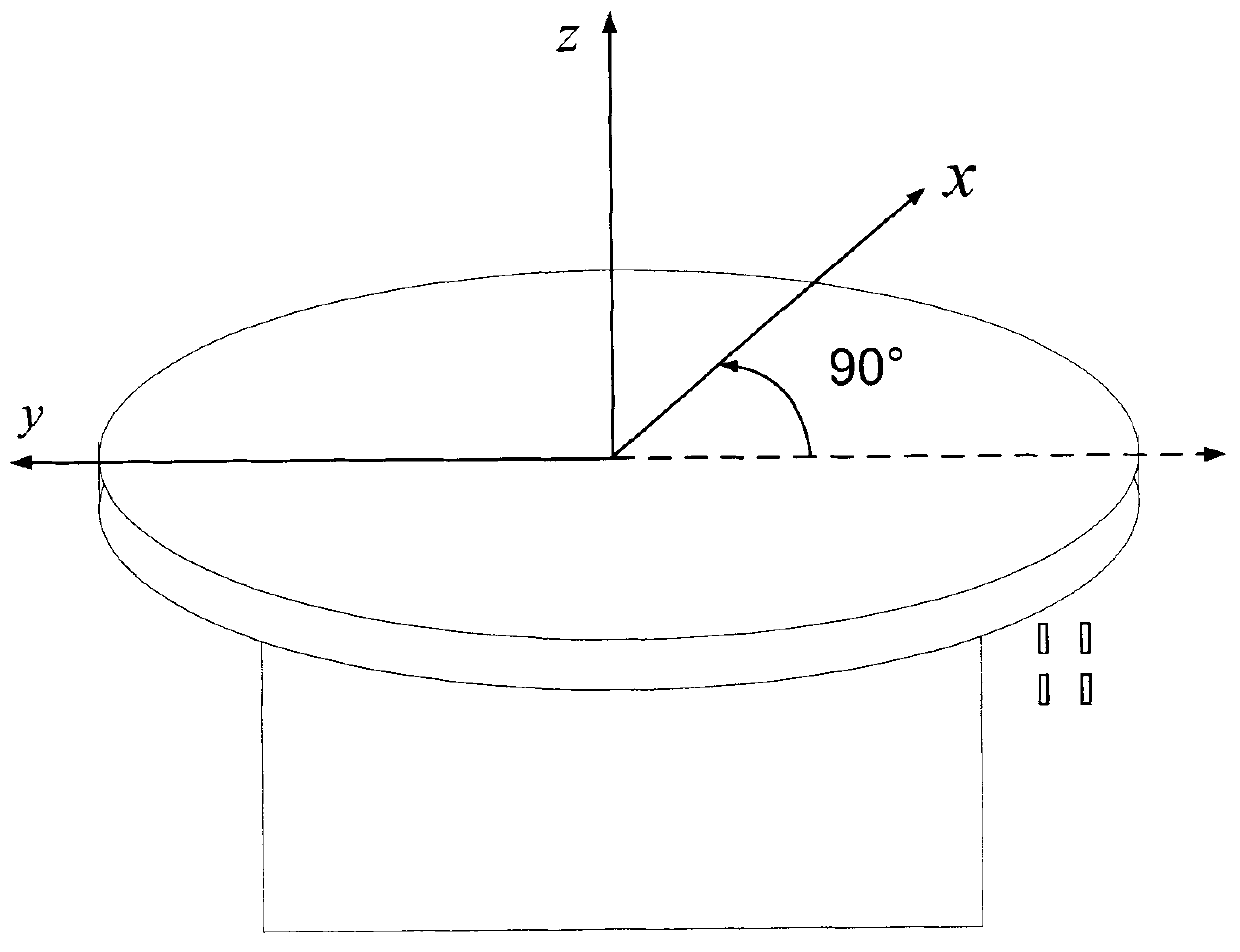

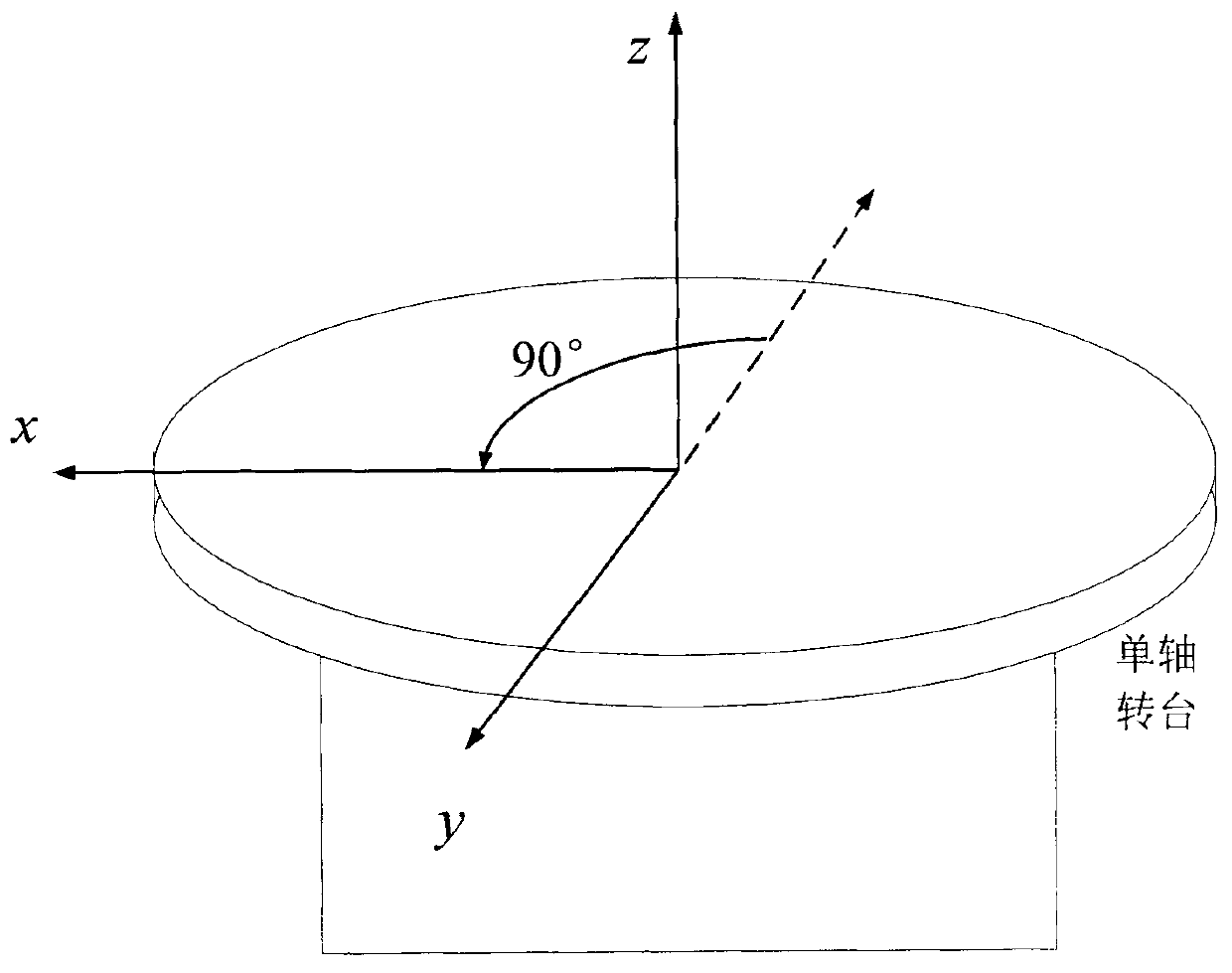

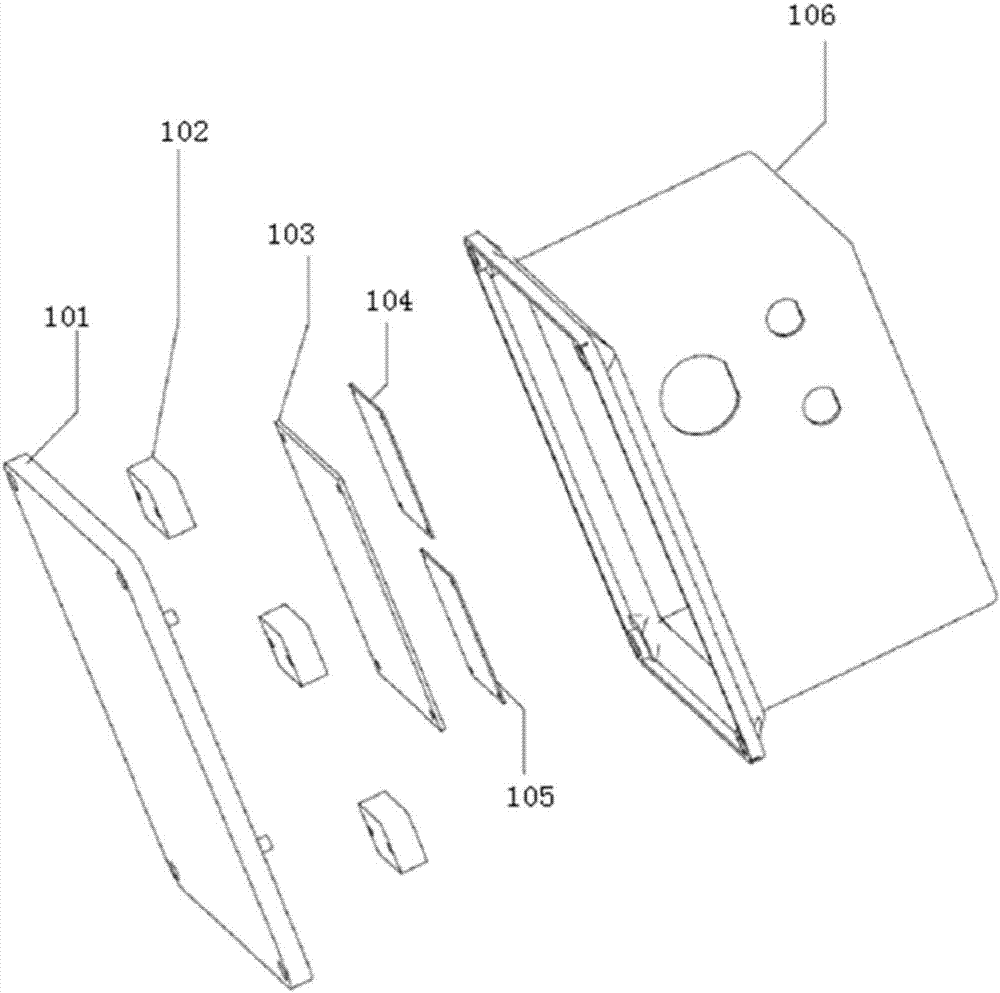

Single-axle table calibration method for fiber optic gyro strapdown inertial navigation system

InactiveCN102003968AReduce calibration costsSimple stepsNavigation by speed/acceleration measurementsFiberAccelerometer

The invention aims at providing a single-axle table calibration method for a fiber optic gyro strapdown inertial navigation system. The fiber optic gyro strapdown inertial navigation system is placed on a single-axle table, the fiber optic gyro strapdown inertial navigation system is electrified for preheating, the angular velocity outputted by a fiber optic gyro and the specific force outputted by a quartz flexible accelerometer are collected, then the single-axle table is controlled to rotate at 90 degrees counter-clockwise around a rotating shaft three times, the angular velocity outputted by the fiber optic gyro and the specific force outputted by the quartz flexible accelerometer at each time are respectively collected, and the drift of the fiber optic gyro in an x, y and z-axis coordinate system of an inertia device and the zero bias value of the quartz flexible accelerometer in the x, y and z-axis coordinate system of the inertia device are further obtained. The method can measure the drift of the fiber optic gyro and the zero bias value of the quartz flexible accelerometer by utilizing the single-axle table to rotate into different angular positions; furthermore, the calibration cost of the single-axle table is low, the steps are simple, and the single-axle table only needs to be placed on the ground during the calibration without a laboratory.

Owner:HARBIN ENG UNIV

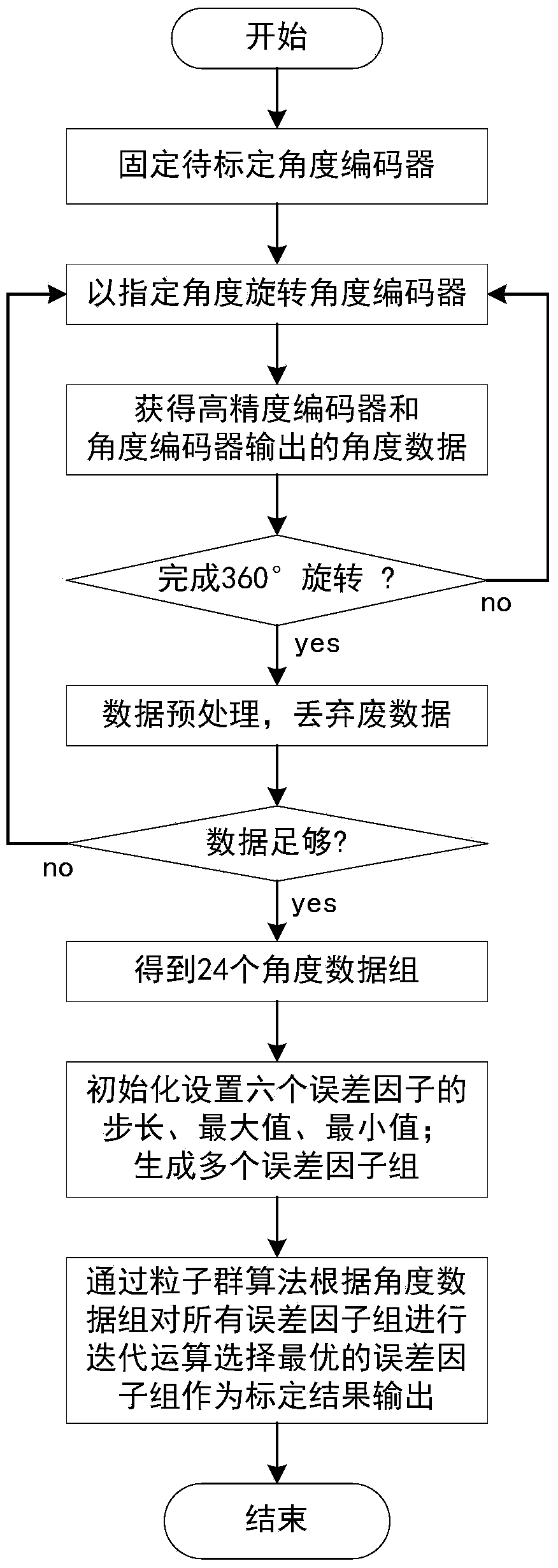

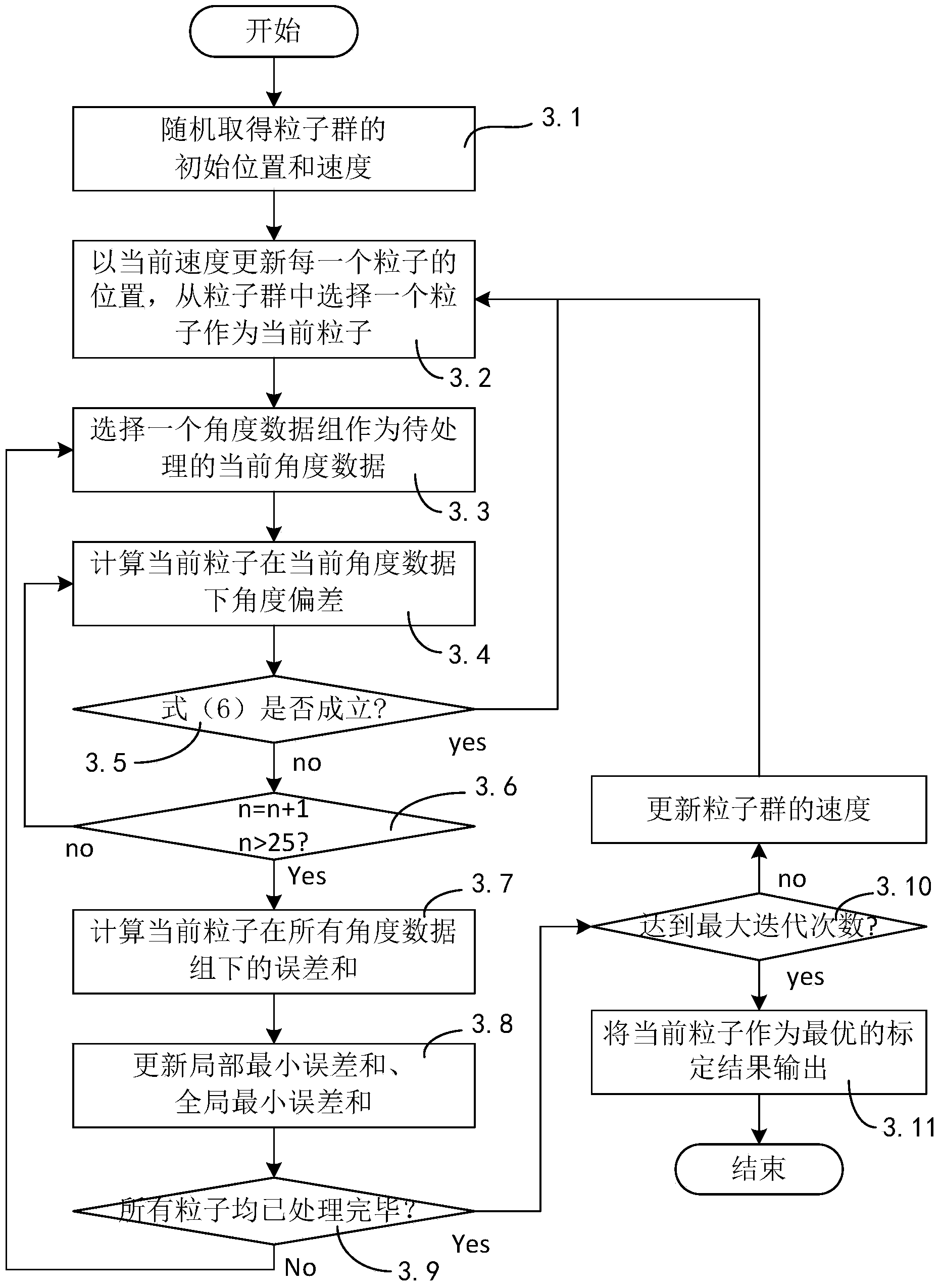

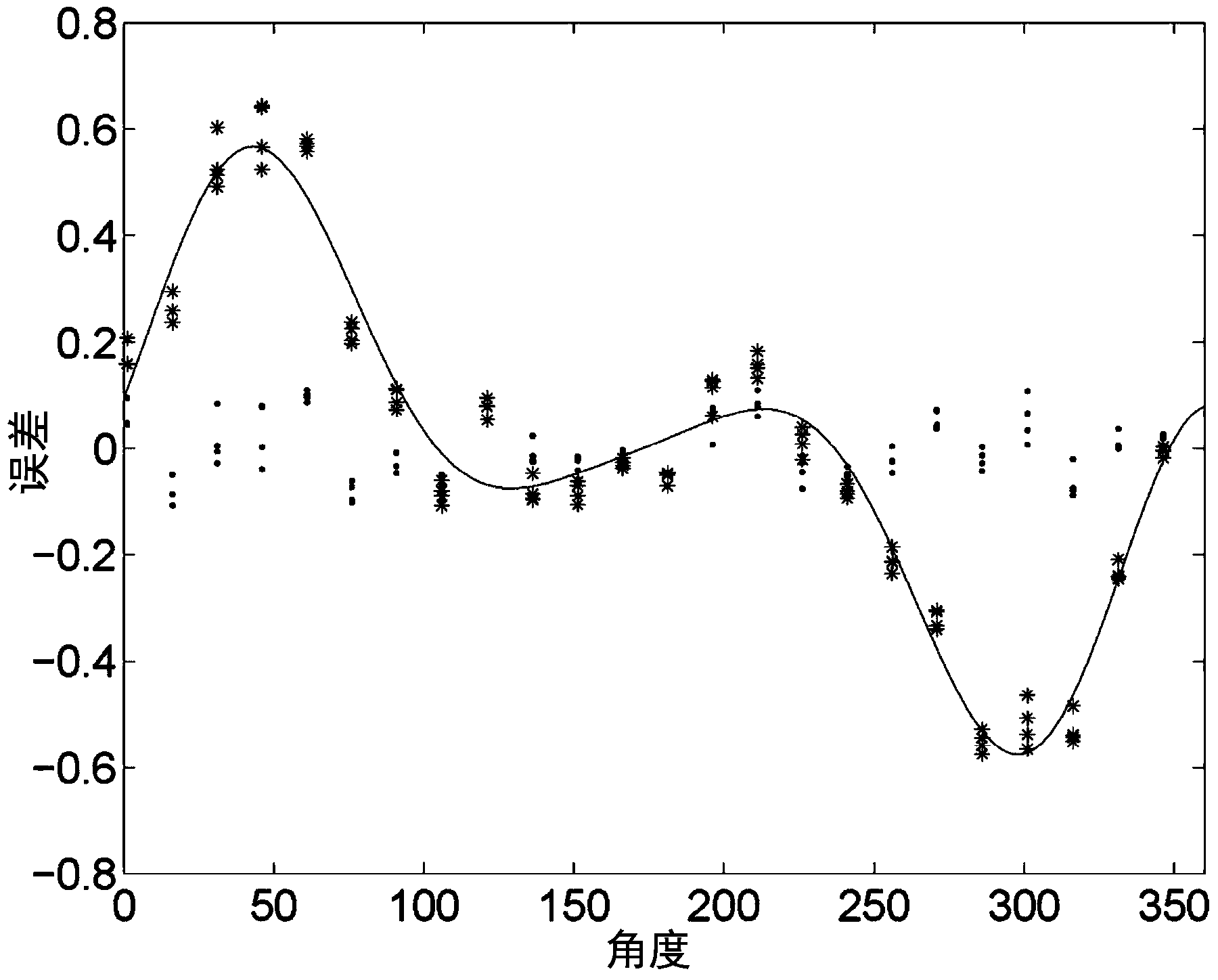

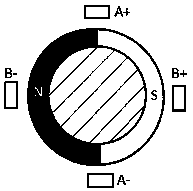

Calibration method and device for angle encoder

The invention discloses a calibration method and device for an angle encoder. The method comprises the steps that a stepping motor is controlled to rotate by at least 360 degrees step by step, the angle data of the stepping motor after the stepping motor rotates by the appointed angle are collected step by step through a high-precision encoder and the angle encoder to be calibrated so as to obtain a plurality of angle data sets, error factors are initialized, a plurality of error factor sets are generated and serve as particles, and an optimal error factor set is selected as a calibration result to be output according to the particle swarm optimization and the angle data set. The device comprises a host, a stepping motor controller and a base support. The base support is provided with the stepping motor and the high-precision encoder. An output shaft of the stepping motor is respectively connected with the angle encoder and the high-precision encoder. The high-precision encoder and the angle encoder are respectively connected with the host. The stepping motor controller is connected with the stepping motor. The device has the advantages of being high in calibration precision, low in calibration cost, small in needed calibration data size and high in calibration speed.

Owner:HUNAN UNIV

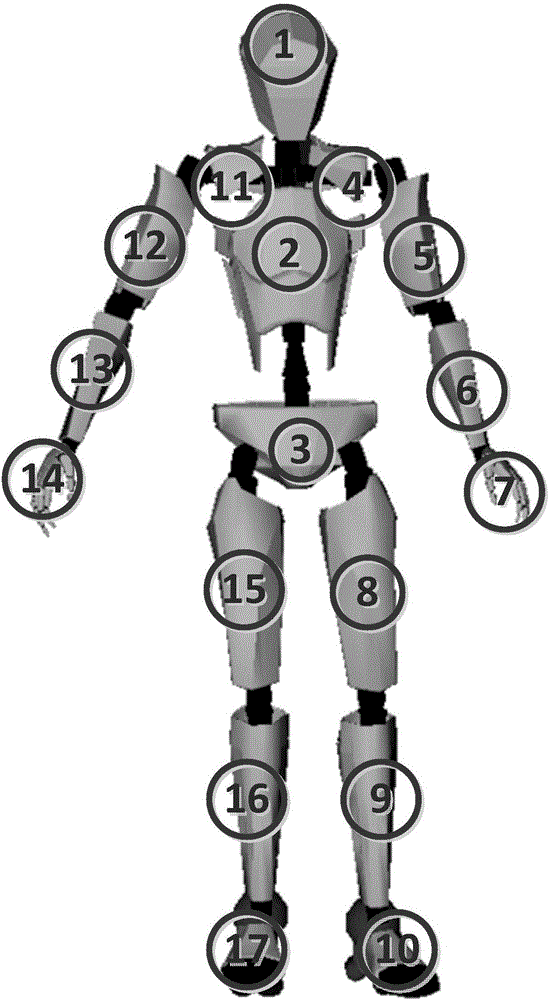

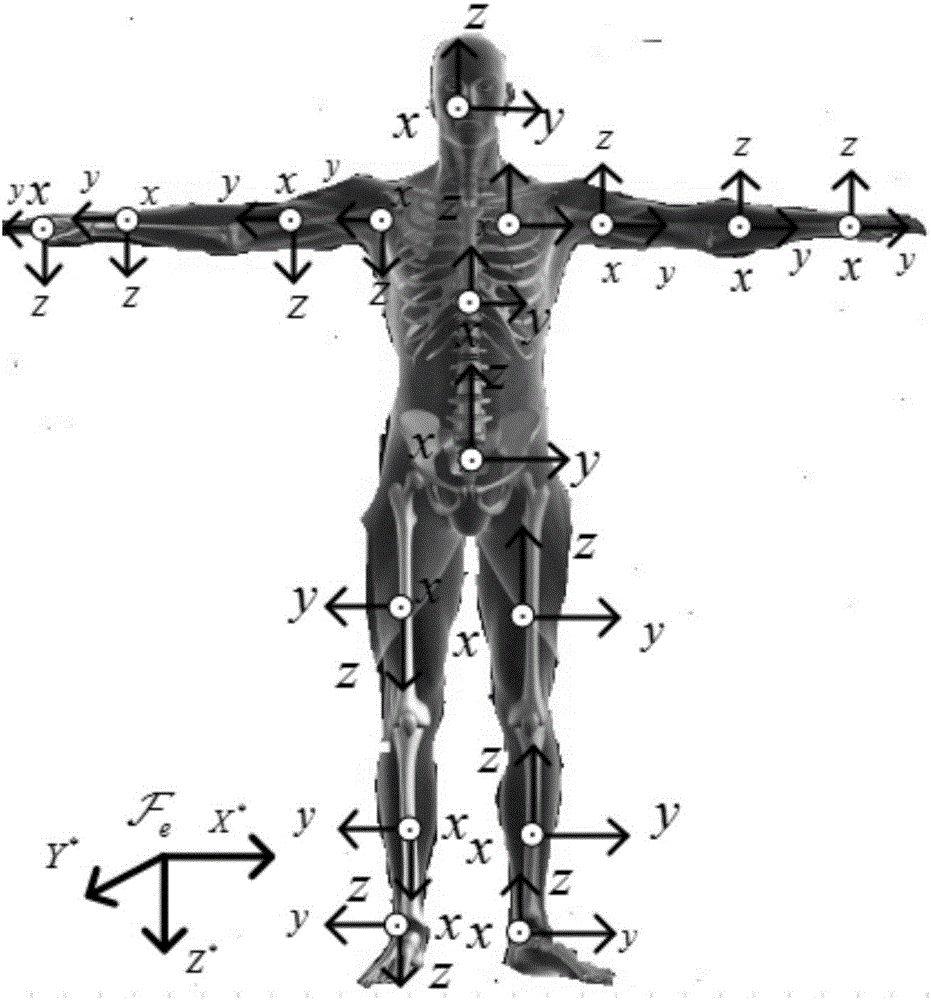

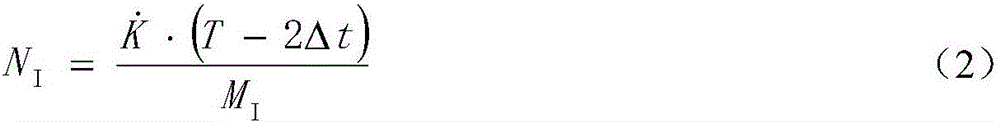

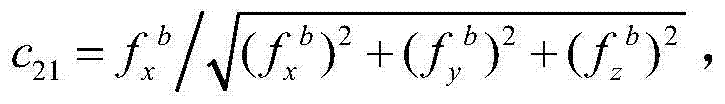

Initialization calibrating method for M-IMU human motion capture system

ActiveCN106153077AReduce mistakesEasy to calibrateMeasurement devicesDiagnostic recording/measuringHuman motionPostural orientation

The invention provides an initialization calibrating method for an M-IMU human motion capture system and relates to an initialization calibrating method for a human motion capture system. According to the initialization calibrating method, the problems of complex operation, low precision and the like in the prior art are solved. The initialization calibrating method comprises the following steps: (1) dividing human limbs into 17 parts, marking serial numbers, and defining a coordinate system; (2) fixing M-IMU sensors on 17 parts; (4) setting three calibrating gestures; (4) carrying out implication averaging on obtained data, so as to obtain average measuration of the M-IMU sensors under the three calibrating gestures; (5) acquiring a relative rotation matrix RS2B2 of a trunk sensor coordinate system and a human coordinate system; (6) acquiring a rotation matrix ReB2 of the trunk sensor coordinate system relative to the human coordinate system; (7) calculating to obtain formula (show in the description); and (8) acquiring a relative rotation matrix RSiBi<o> of a sensor coordinate system of each limb relative to the human coordinate system. The initialization calibrating method is applied to the limb gesture measurement field.

Owner:苏州康莲医疗技术有限公司

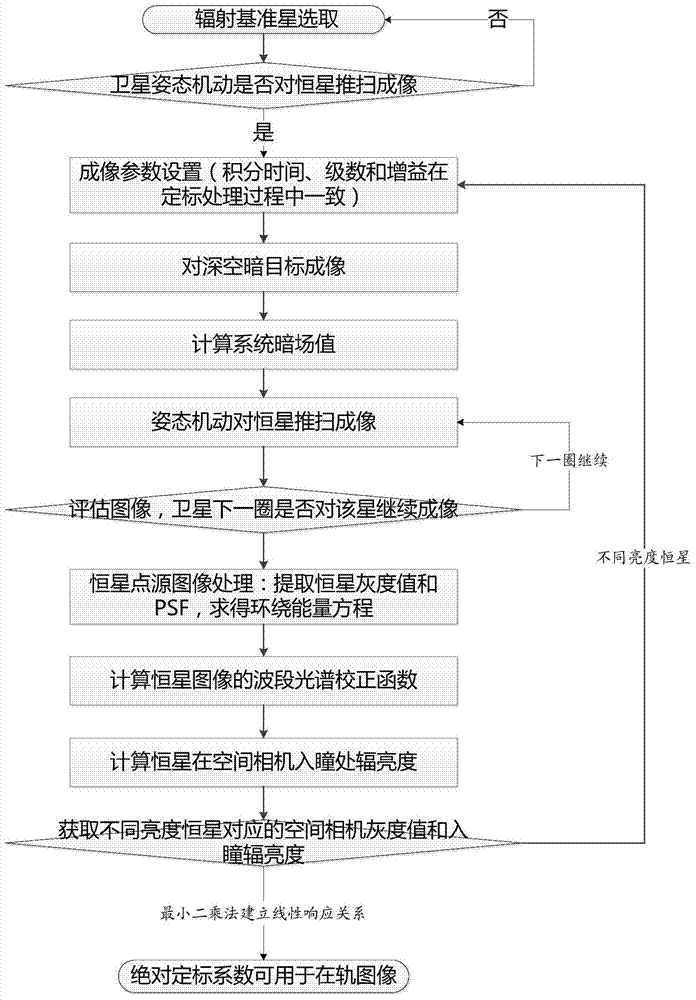

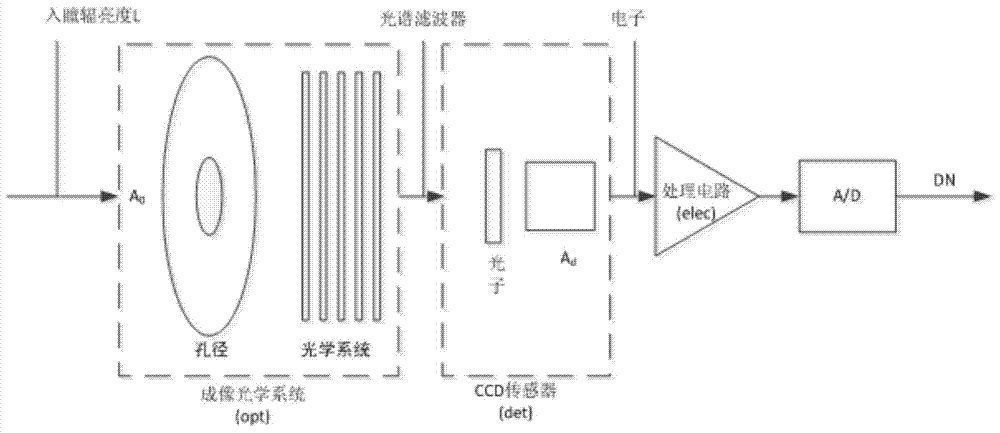

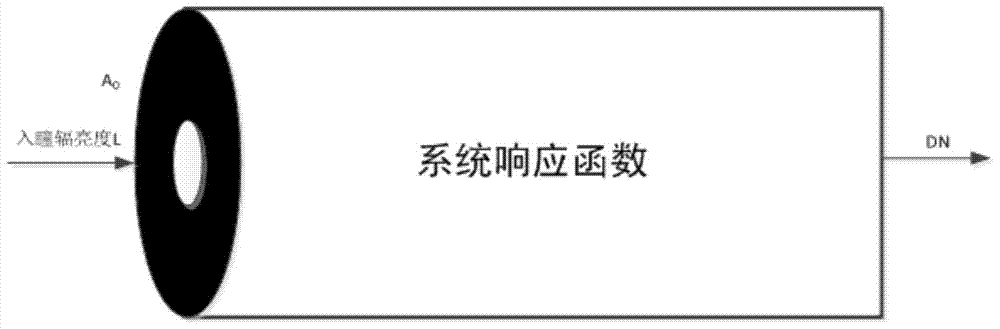

Space camera in-orbit absolute calibration method based on fixed star

ActiveCN104729535ACalibration environment requirements are lowReduce calibration costsImage analysisMeasurement devicesRadiationFixed stars

The invention relates to a space camera in-orbit absolute calibration method based on a fixed star. According to the method, the dynamic adjusting capability of a satellite platform attitude machine is adequately utilized, a corresponding relation between a fixed-star source with stable target radiation characteristic and a gray value output by a space camera is established, and the space camera in-orbit absolute radiation calibration is realized according to the advantages of the fixed star imaging and the optimized absolute calibration algorithm. An imaging mode adjusted by satellite attitude is adopted, the requirement for a calibration environment is low, an additional calibration device is not needed, and the in-orbit absolute calibration does not depend on the special calibration field, so that the calibration cost is remarkably reduced, and the calibration time is saved.

Owner:AEROSPACE DONGFANGHONG SATELLITE

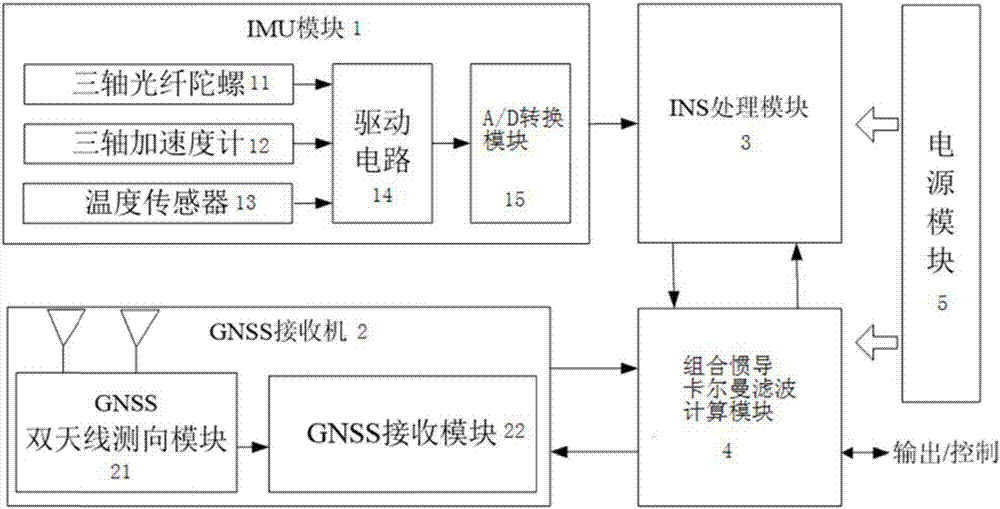

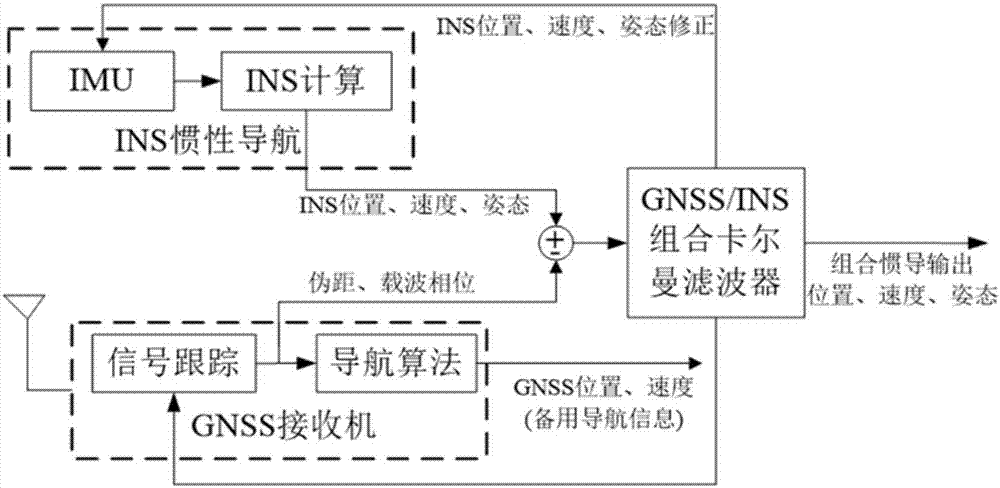

Double antenna combination inertial navigation device based on self calibration of installation parameters

InactiveCN107037469AHigh precisionImprove efficiencySatellite radio beaconingEphemerisElectrical and Electronics engineering

The invention provides a double antenna combination inertial navigation device based on self calibration of installation parameters. The double antenna combination inertial navigation device based on self calibration of installation parameters includes an IMU inertia measuring module, an INS processing module, a GNSS receiver, a combination inertial navigation Kalman filtering calculating module and a power supply module, wherein the combination inertial navigation Kalman filtering calculating module calculates the coordinates of the antenna in the inertial navigation coordinate system according to the following formula, according to the navigation state parameter, the navigation measuring information, the available ephemeris data and the satellite health state. The double antenna combination inertial navigation device based on self calibration of installation parameters can realize on-line calculation of the coordinates of each antenna in the inertial navigation coordinate system when double antenna combination inertial navigation is aligned precisely and dynamically, and has no requirement for special optical equipment as each installation relationship can realize self-calibration, thus improving the efficiency and saving the calibration cost.

Owner:BEIJING SDI SCI & TECH

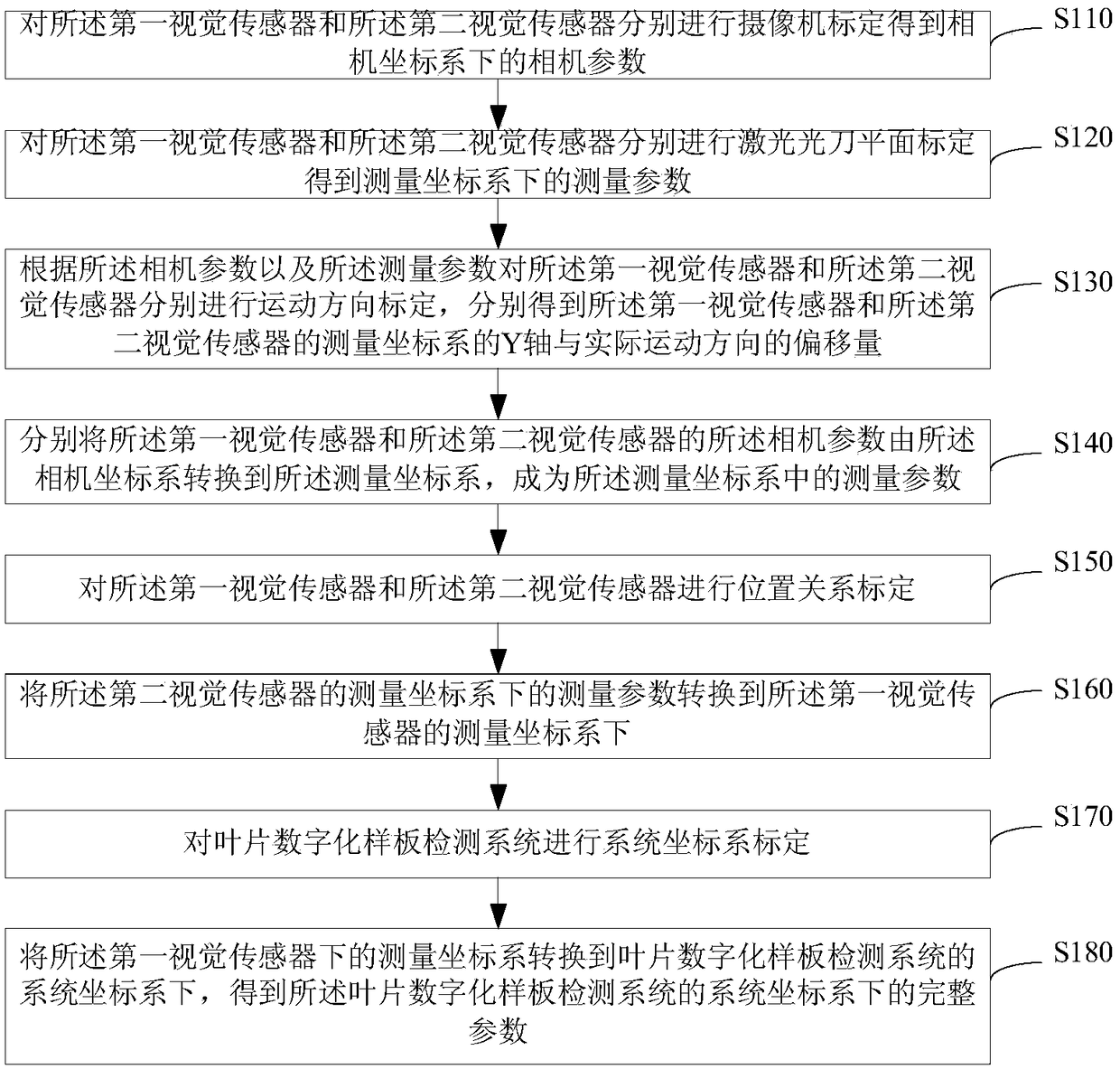

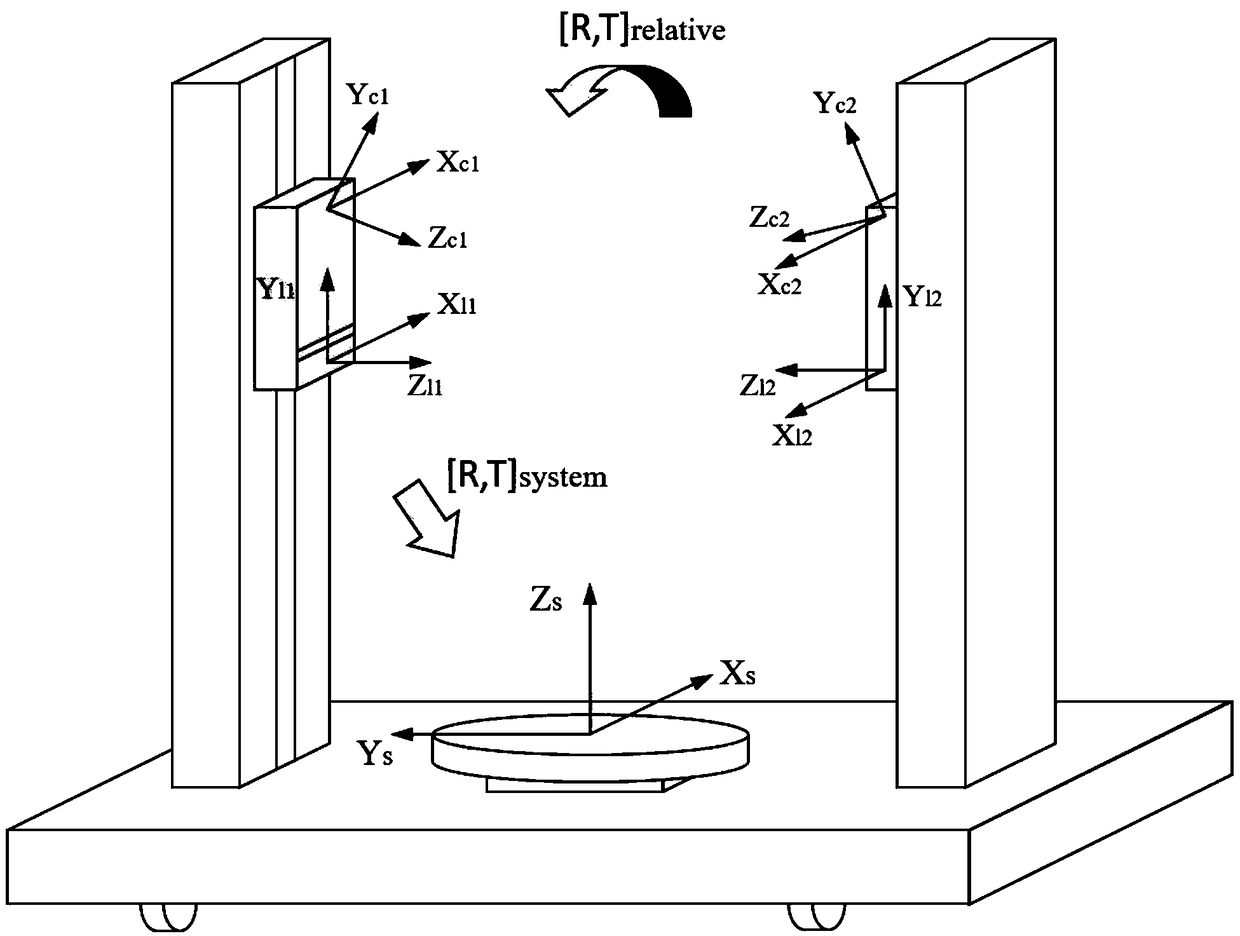

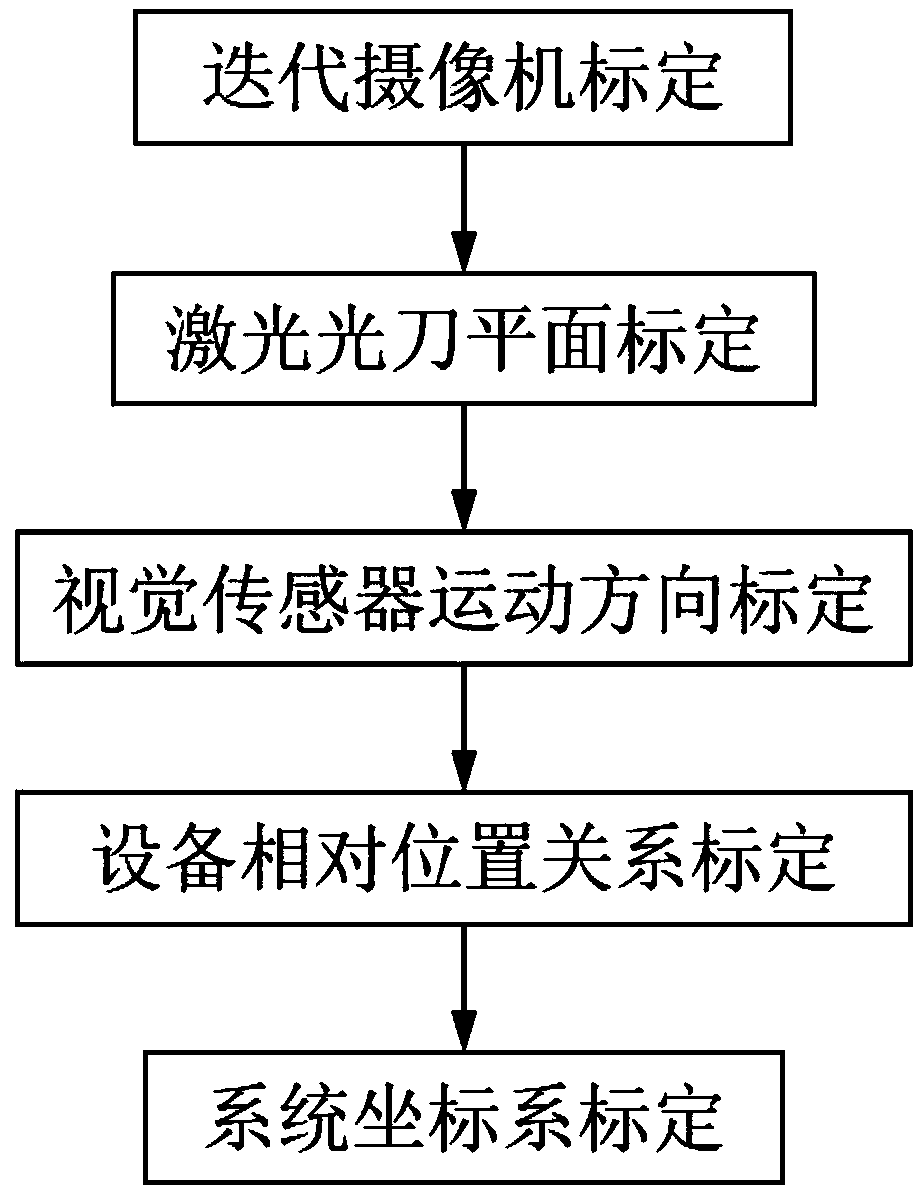

Calibration method and device of blade digitalized templet detection system

ActiveCN108844459AImprove applicabilityAccurately obtain the mutual conversion relationshipUsing optical meansLaser KnivesVision sensor

The invention discloses a calibration method and device of a blade digitalized templet detection system, and relates to the technical field of visual measurement. The method comprises that camera calibration is carried out on first and second visual sensors; laser knife planar calibration is carried out on the two visual sensors; motion direction calibration is carried out on the two visual sensors according to camera and measurement parameters; the camera parameters of the two visual sensors are converted into a measurement coordinate system; the position relation of the two visual sensors iscalibrated; the measurement parameter in the measurement coordinate system of the second visual sensor is converted to the measurement coordinate system of the first visual sensor; the system coordinate system is calibrated; and the measurement coordinate system of the first visual sensor is converted to the system coordinate system. The calibration method is complete.

Owner:JIANGSU JITRI HUST INTELLIGENT EQUIP TECH CO LTD

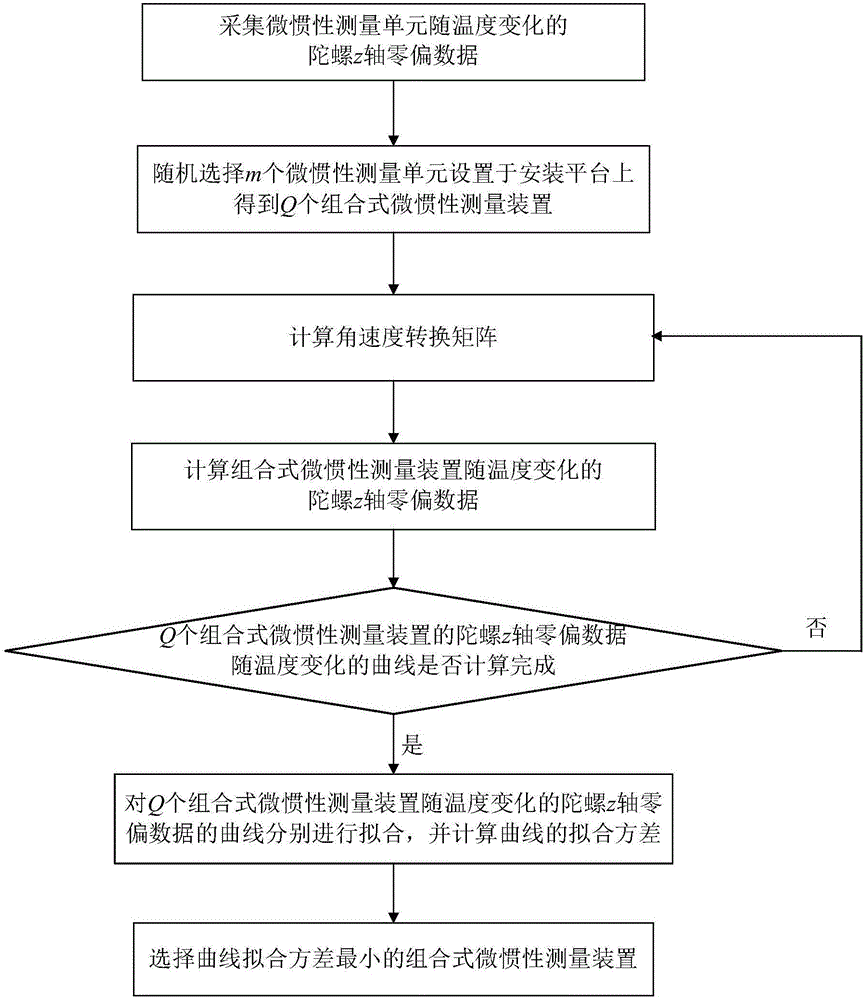

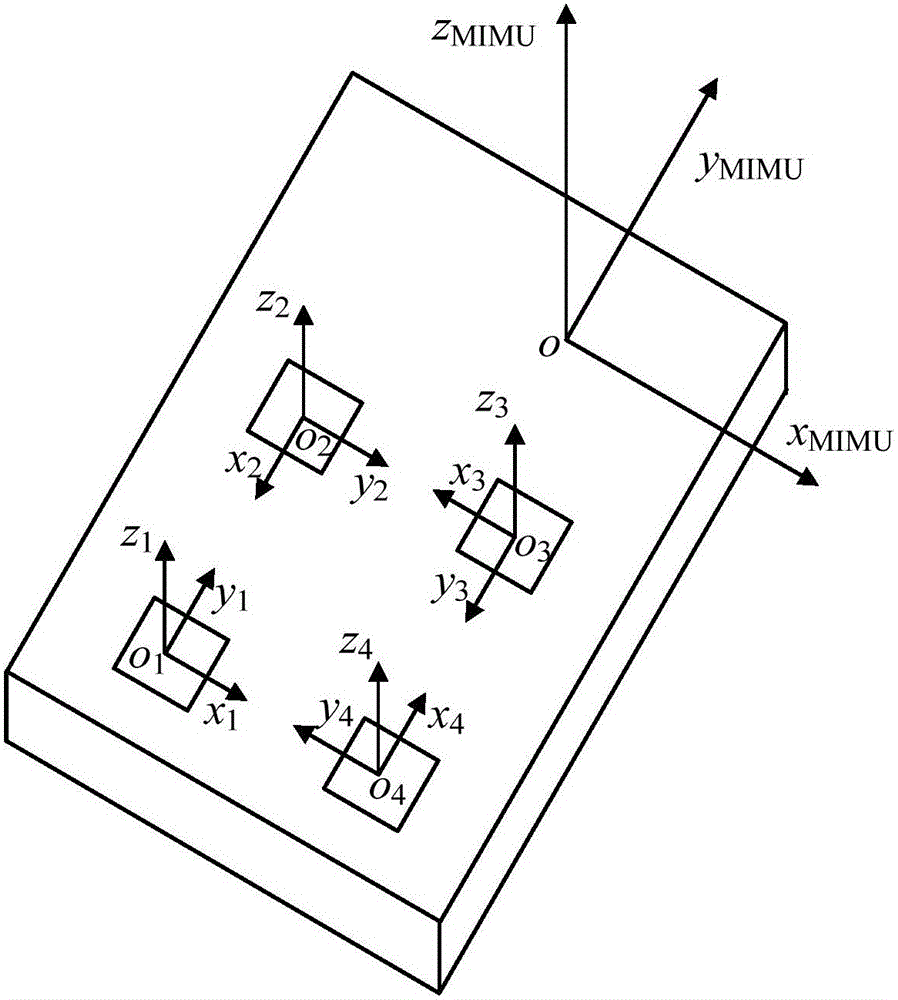

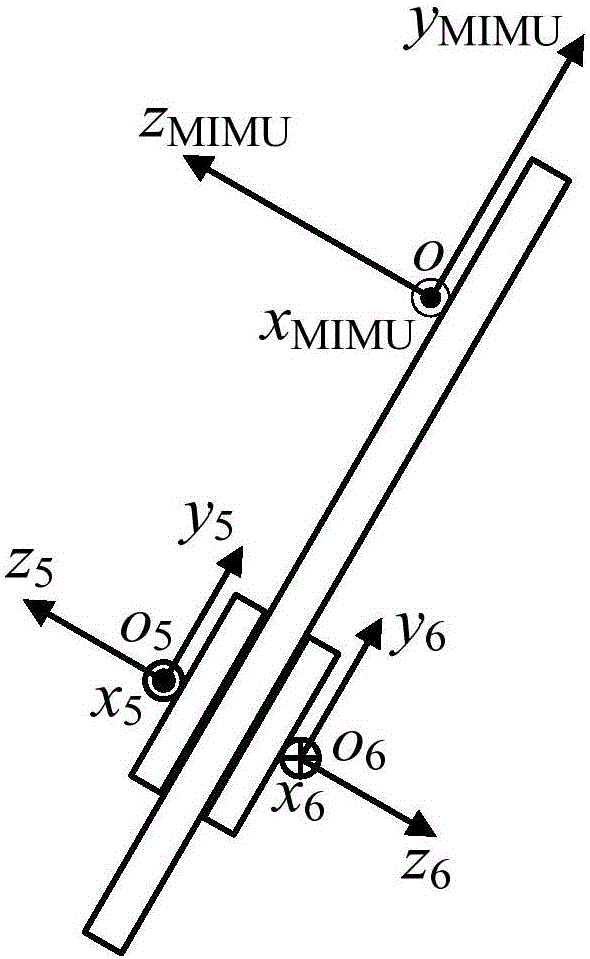

Micro inertial measurement unit screening method and combined type micro inertial measurement device

ActiveCN106017470AImprove performanceImprove reliabilityNavigation by speed/acceleration measurementsMeasurement deviceCurve fitting

The invention provides a micro inertial measurement unit screening method and a combined type micro inertial measurement device. In the screening method, according to a multi-position method, an angular speed conversion matrix is calculated, the spinning top z-axis zero-offset data, changing along with temperature, of the combined type micro inertial measurement device is calculated, and micro inertial measurement units are screened with the minimum curve fitting residual error, changing along with temperature, of spinning top x-axis / y-axis / z-axis zero-offset data of the combined type micro inertial measurement device as the standard; the combined type micro inertial measurement device comprises at least two micro inertial measurement units capable of measuring angular speeds of three axes. The micro inertial measurement units are arranged on an installation platform. The combined type micro inertial measurement device has the advantages that the micro inertial measurement units low in price can be combined to establish an inertial measurement system high in performance, cost is saved, higher reliability is achieved, the influences of temperature changes on spinning top zero-offset are reduced, and effective error compensation of the inertial measurement device is achieved.

Owner:湖南云箭格纳微信息科技有限公司

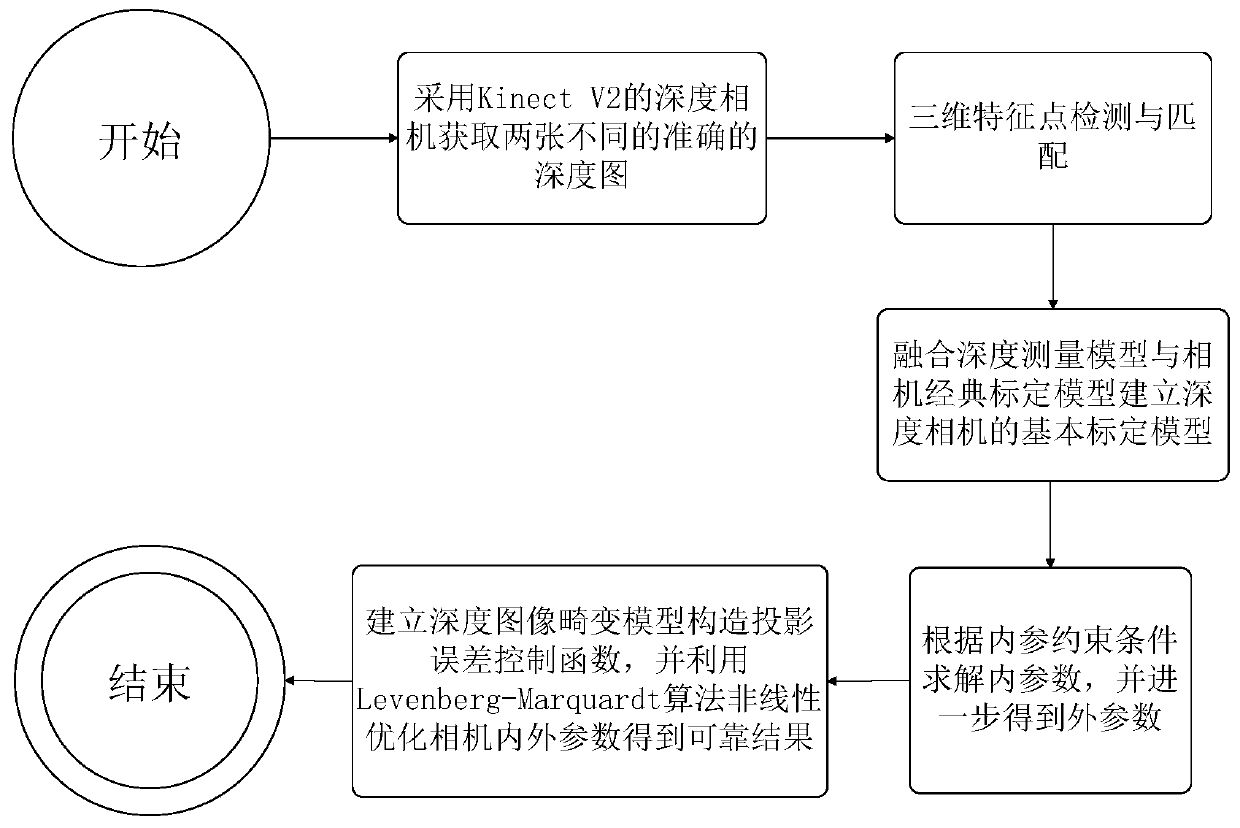

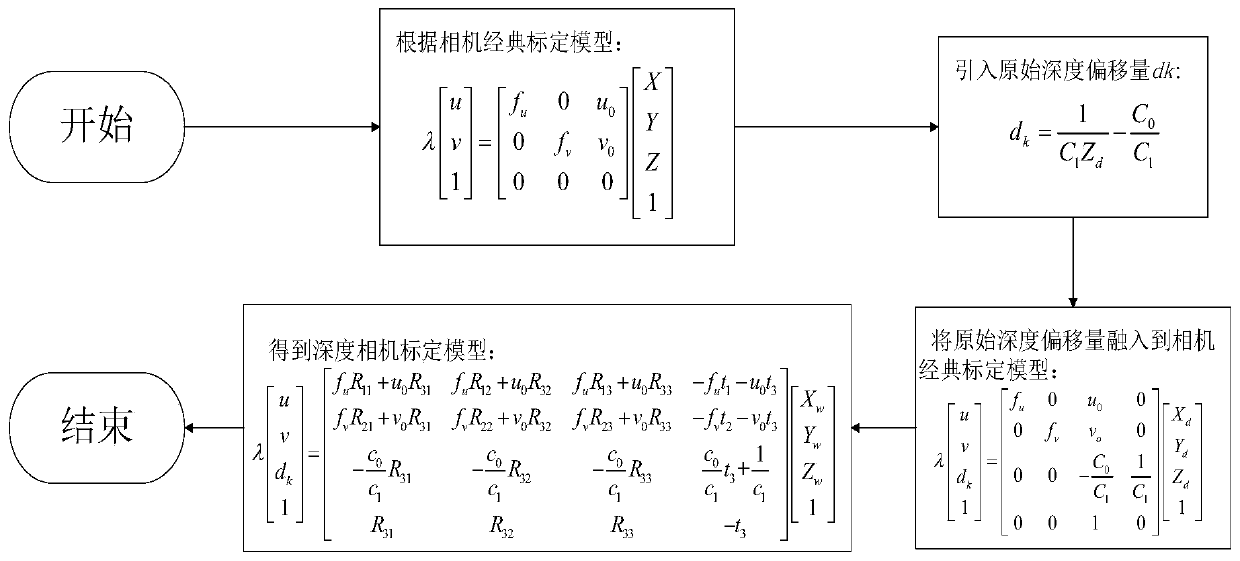

Depth camera automatic calibration algorithm based on three-dimensional feature points

PendingCN110209997ALow costEasy to operateImage analysisComplex mathematical operationsThree-dimensional spaceColatitude

The invention provides a depth camera automatic calibration algorithm based on three-dimensional feature points. According to the calibration algorithm, calibration work of a depth camera can be completed at a time by using two depth images and corresponding three-dimensional feature pixel points. The method comprises the following steps: firstly, combining a depth camera measurement model and a classical camera calibration model according to known coordinates of characteristic pixel points in a three-dimensional space, coordinates of corresponding points in a depth image and an original erroroffset to obtain a basic calibration model of a depth camera; secondly, obtaining an initial value of an internal parameter of the camera through an internal parameter constraint condition of the depth camera, and obtaining an external parameter according to the initial value of the internal parameter; and finally, optimizing the established depth image error control function to obtain an optimalparameter of the depth camera. According to the calibration algorithm, a traditional calibration model of the depth camera is simplified, the defect that classic calibration is affected by illumination conditions, scene uncertainty and the like is overcome, internal and external parameters of the camera are accurately obtained, a good restoration effect on edge distortion of the depth image is achieved, and the calibration algorithm has the advantages of being easy to operate, high in calibration precision, good in practicability and robustness and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

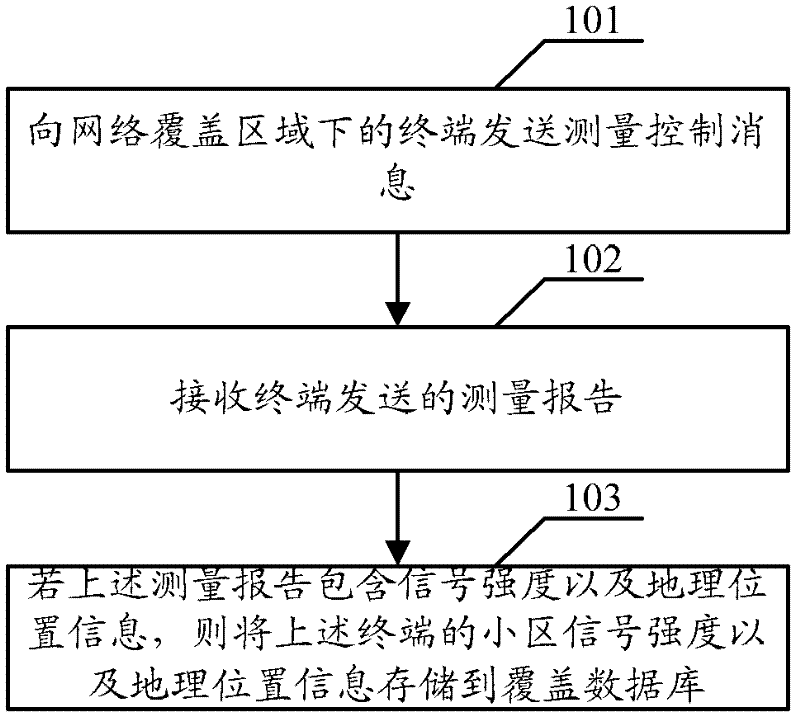

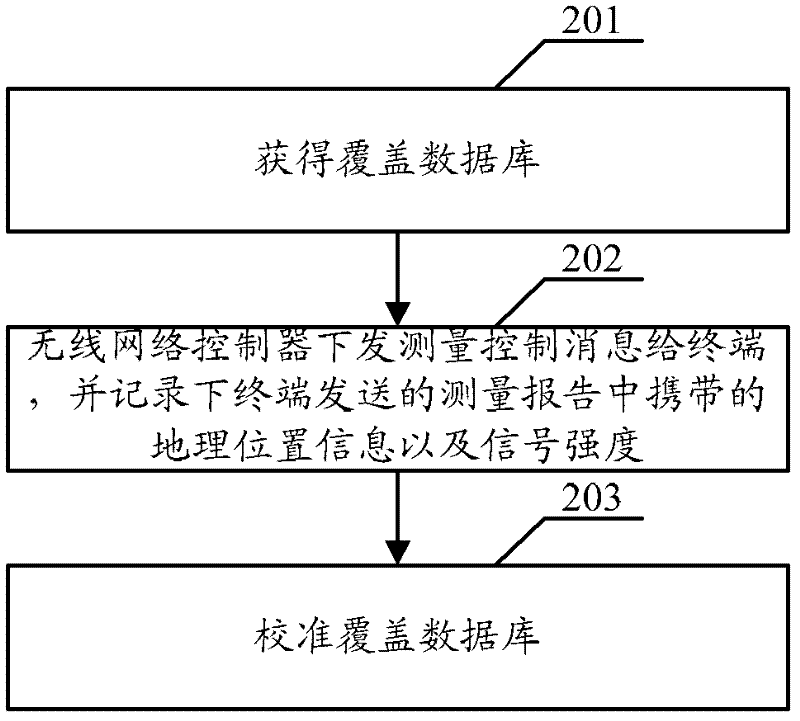

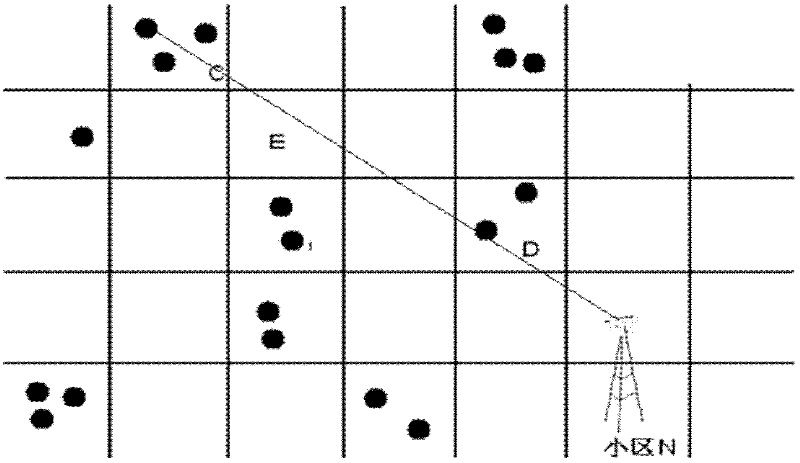

Calibration method and device of coverage database

ActiveCN102333339AAchieve calibrationHigh speedPosition fixationNetwork planningGeographic siteGeolocation

The embodiment of the invention discloses a calibration method and device of a coverage database. The method of the embodiment of the invention comprises the following steps: a measurement control message is sent to a terminal in a network coverage area, and the measurement control message is the information indicating the geographic position of the terminal which is carried by the terminal supporting a global positioning system (GPS) in a reported measurement report; the measurement report sent by the terminal is received; and if the measurement report contains signal strength and the geographic position information, the district signal strength and the geographic position information of the terminal are stored in the coverage database. With the scheme disclosed by the invention, the calibration time and the calibration cost are reduced, and the positioning technology is convenient to apply and popularize.

Owner:HUAWEI TECH CO LTD

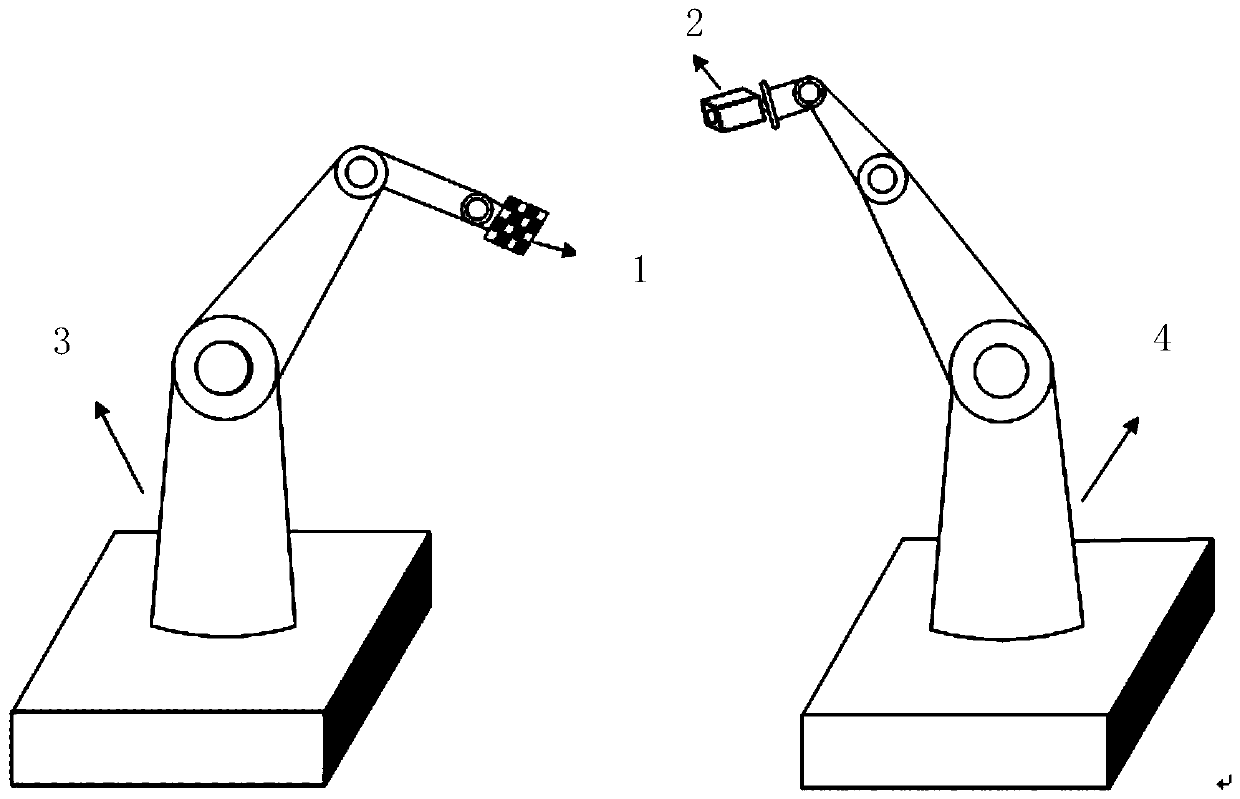

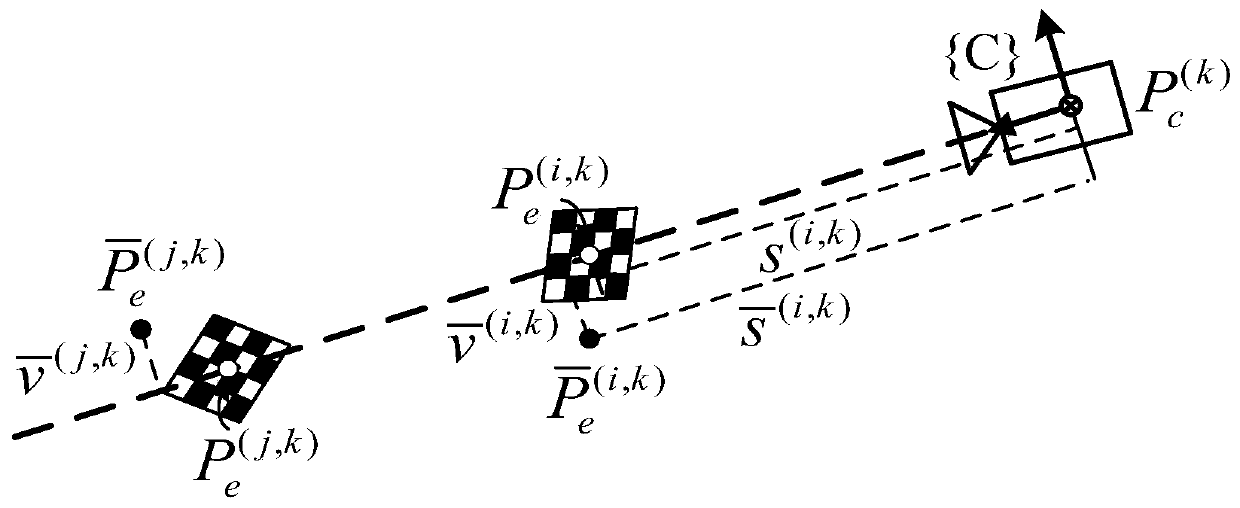

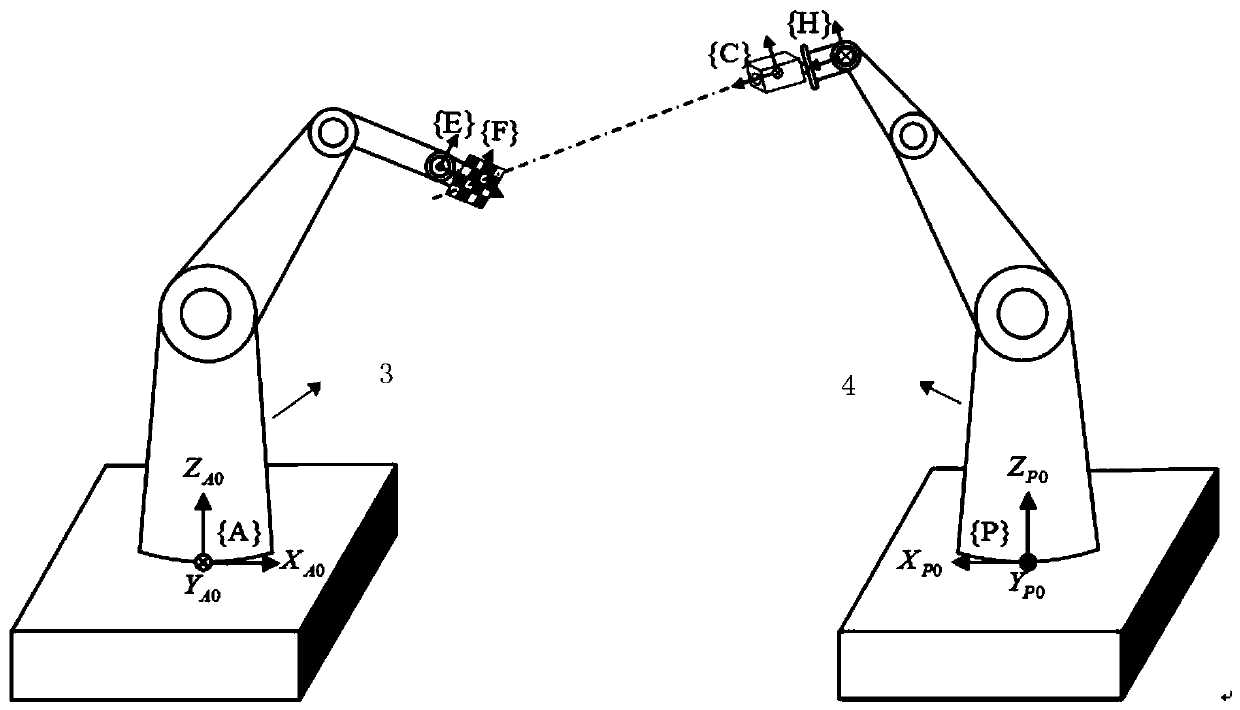

Double-mechanical arm calibration method based on camera optical axis constraint

ActiveCN109877840AImprove calibration accuracyEasy to operateProgramme-controlled manipulatorOptical axisVision based

The invention relates to a double-mechanical arm calibration method based on camera optical axis constraint. The double-mechanical arm calibration method comprises the following steps that firstly, adouble-mechanical arm calibration system is established; secondly, a parameter calibration equation based on an error model is established; thirdly, feature point alignment and position data based onvisual control is acquired; and fourthly, the calibration equation is solved. According to the double-mechanical arm calibration method, the double-mechanical arm calibration system is established only through a camera and a checkerboard calibration plate, operation is easy and convenient, an expensive high-precision instrument and an elaborate calibration tool are not needed, and the calibrationcost is reduced; the calibration precision is higher, the number of the calibration steps is smaller, and the operation is more convenient; a visual control method based on images is used for controlling movement of a drive mechanical arm, feature points are automatically aligned to a camera optical axis, professional operation is not needed in the calibration process, and only an operator is needed to carry out simple supervision; and the double-mechanical arm calibration method is suitable for various double-arm cooperative systems and high in calibration precision, and a calibration resultcan meet requirements of most double-arm cooperative tasks.

Owner:HARBIN ENG UNIV

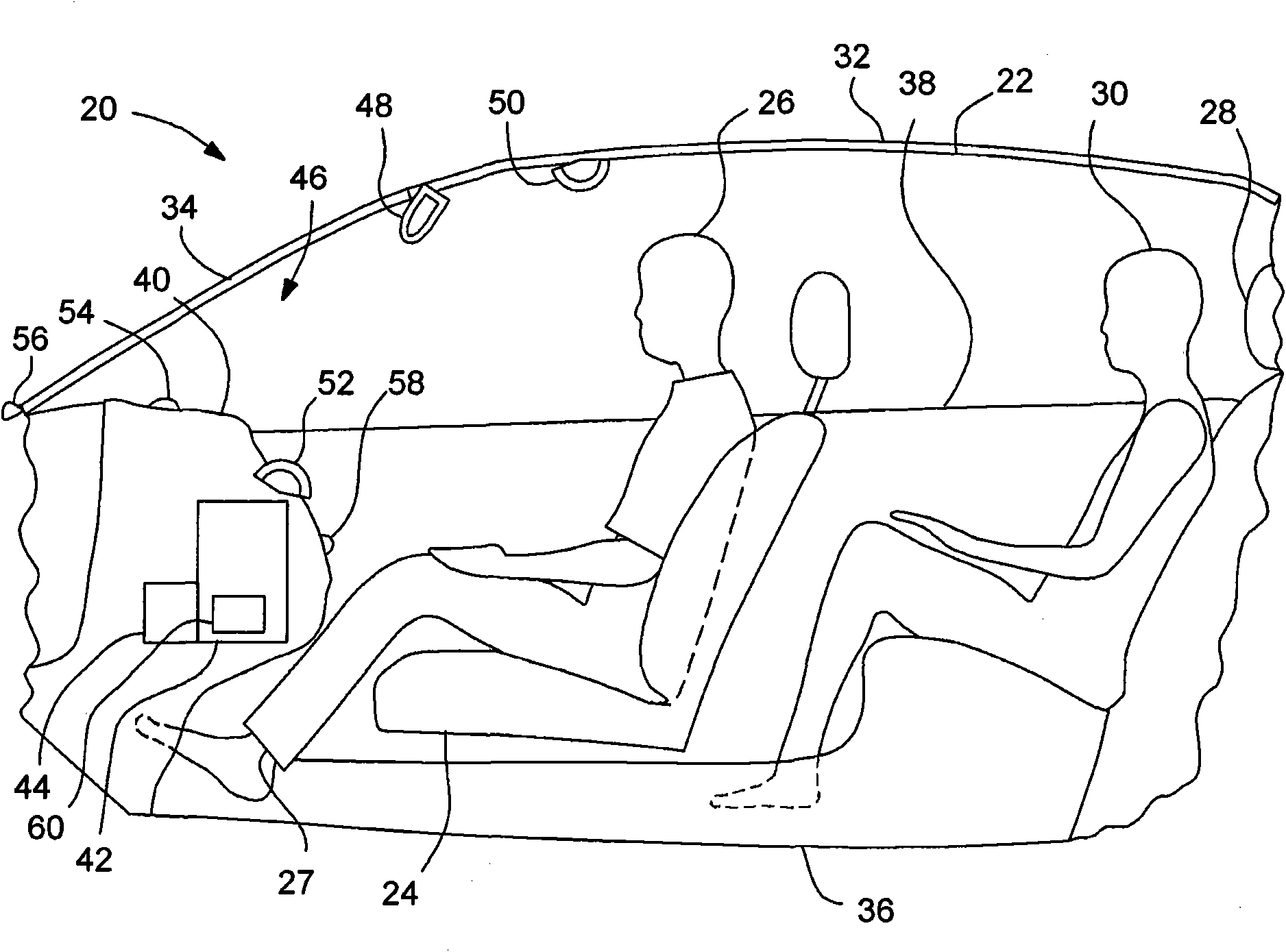

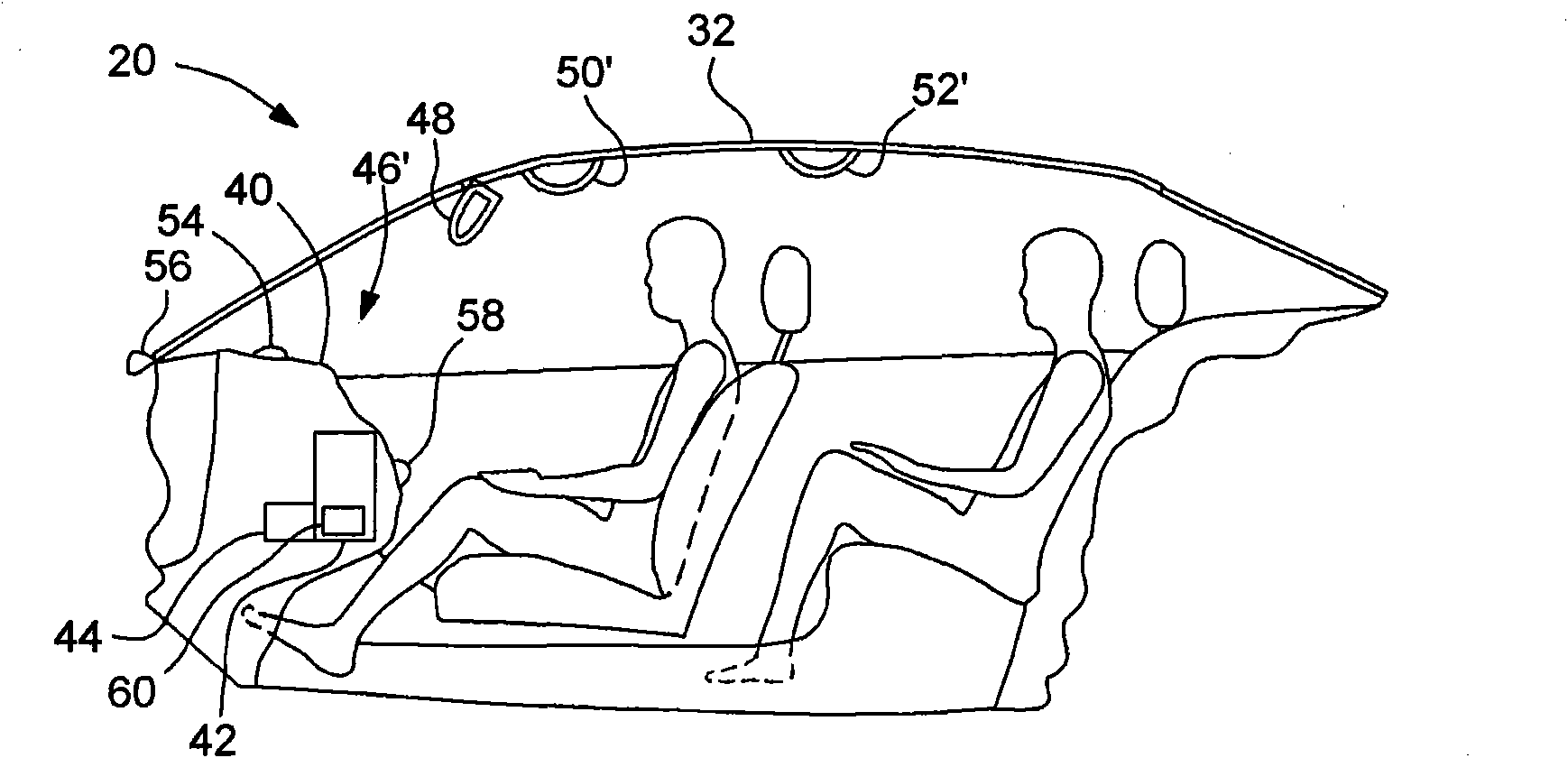

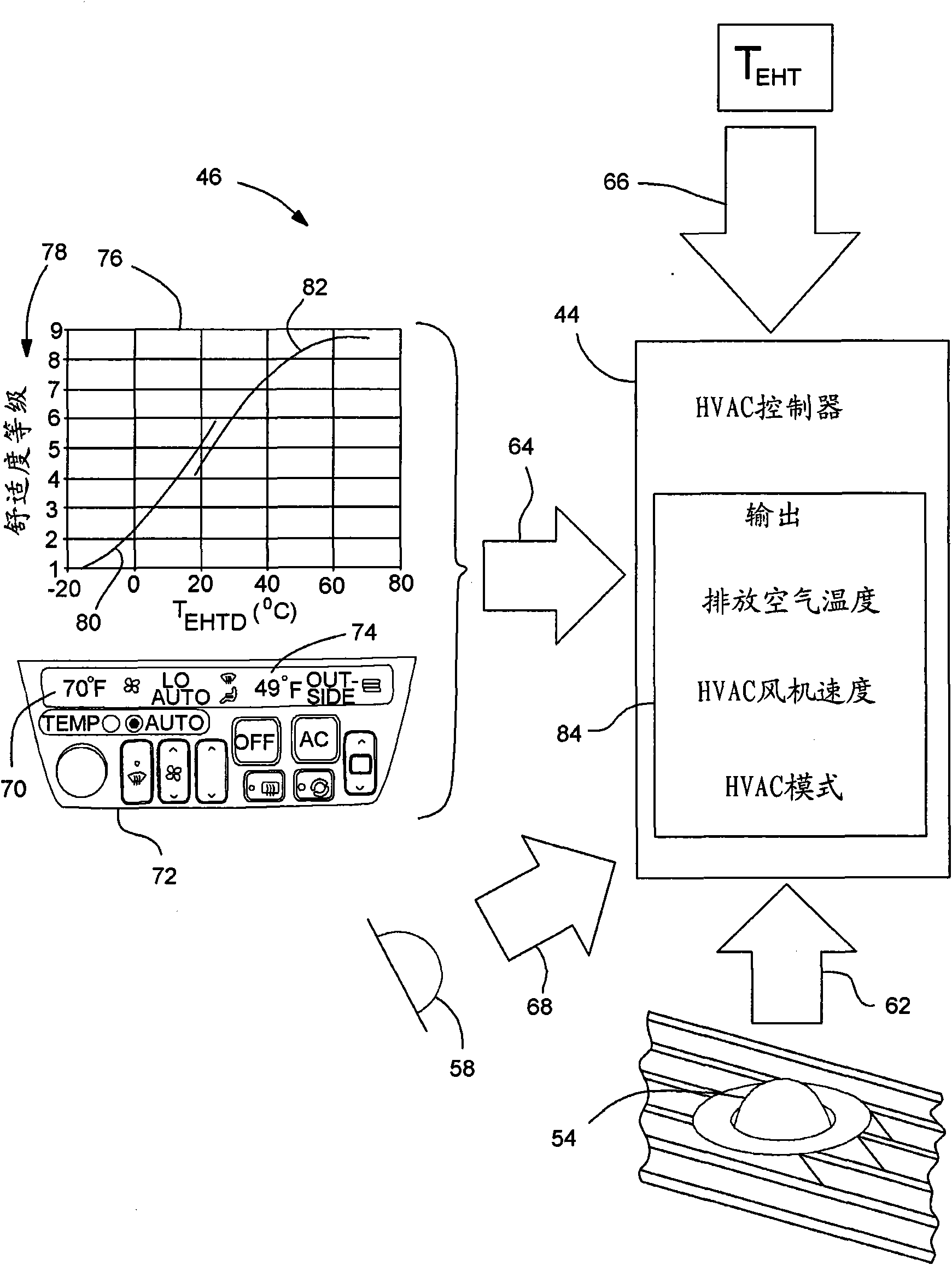

Automatic climate control for a vehicle

InactiveCN101633302AGood thermal comfortImprove comfortAir-treating devicesSpace heating and ventilation safety systemsAutomatic controlAir velocity

A system and method of operating an automatic climate control system for a vehicle is disclosed. The method may include determining a breath level air temperature in a passenger compartment of the vehicle; determining a mean radiant temperature in the passenger compartment; determining an average air velocity in the passenger compartment; determining a clothing level factor, and calculating an equivalent homogeneous temperature based on the breath level air temperature, the mean radiant temperature, the average air velocity and the clothing level factor; comparing the calculated equivalent homogeneous temperature to a desired equivalent homogeneous temperature; and adjusting an output of the automatic climate control system based on the comparison of the calculated equivalent homogeneous temperature to the desired equivalent homogeneous temperature.

Owner:GM GLOBAL TECH OPERATIONS LLC

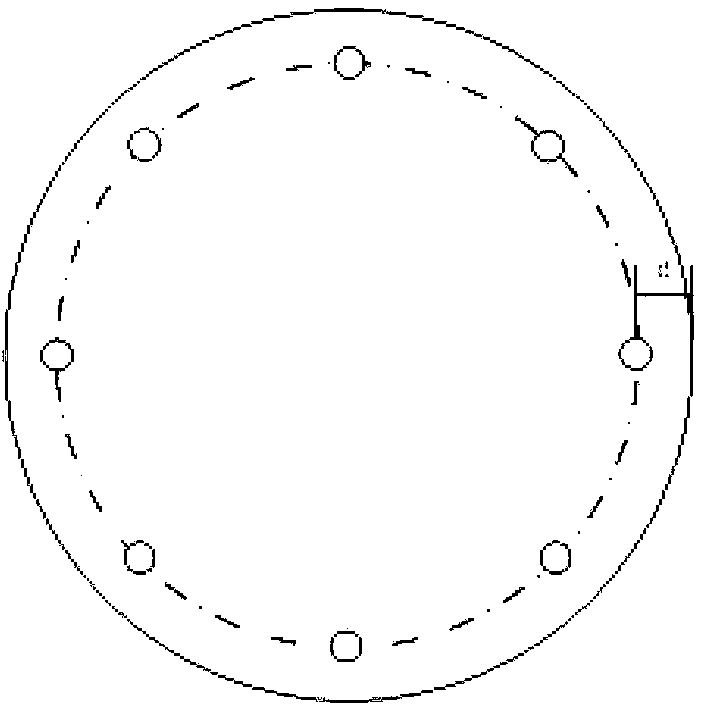

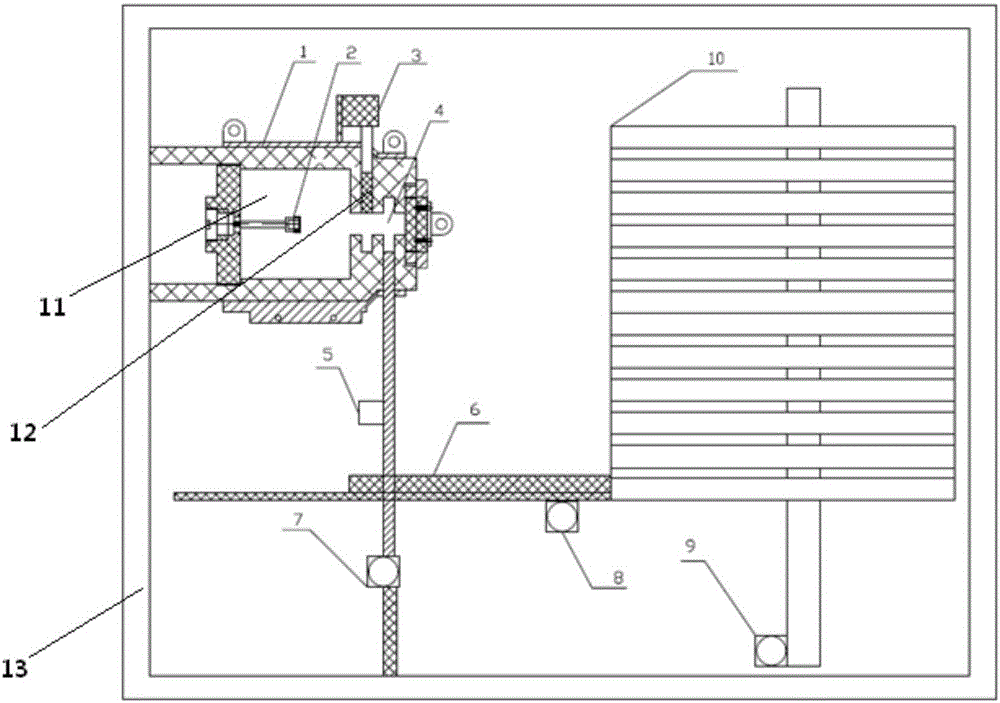

Gamma ray irradiation device used for thermoluminescence personal dosimeter calibration

PendingCN106443759AReduce area requirementsImprove calibration efficiencyRadiation measurementThermoluminescenceControl system

The invention belongs to the dosimeter calibration technology field, and discloses a gamma ray irradiation device used for thermoluminescence personal dosimeter calibration. The irradiation device comprises an irradiation system, a positioning system, a transmission system, and a control system. The irradiation system, the positioning system, and the transmission system are disposed in the same housing. The irradiation system is disposed on the upper part of the transmission system, and the positioning system is disposed on one side of the transmission system. The control system comprises a computer, a PLC special controller, a positioning sensor, and an irradiation controller. The computer and the PLC special controller are used to independently realize the control over the gamma ray irradiation device, and the positioning, the transmission, and the irradiation of the thermoluminescence personal dosimeter are realized automatically. The gamma ray irradiation device has advantages of high calibration efficiency, low calibration place requirement, good automatic shielding effect, and ability of realizing automatic calibration.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

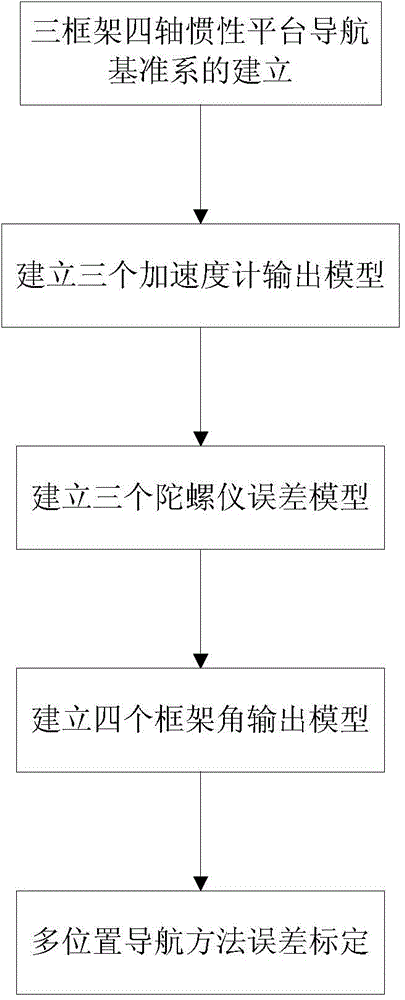

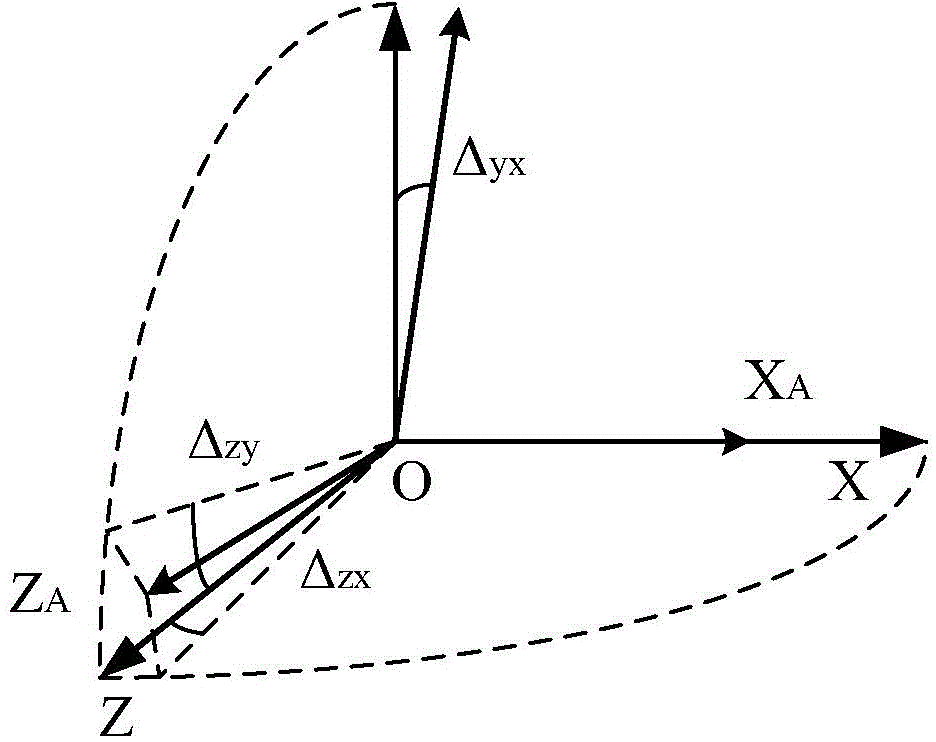

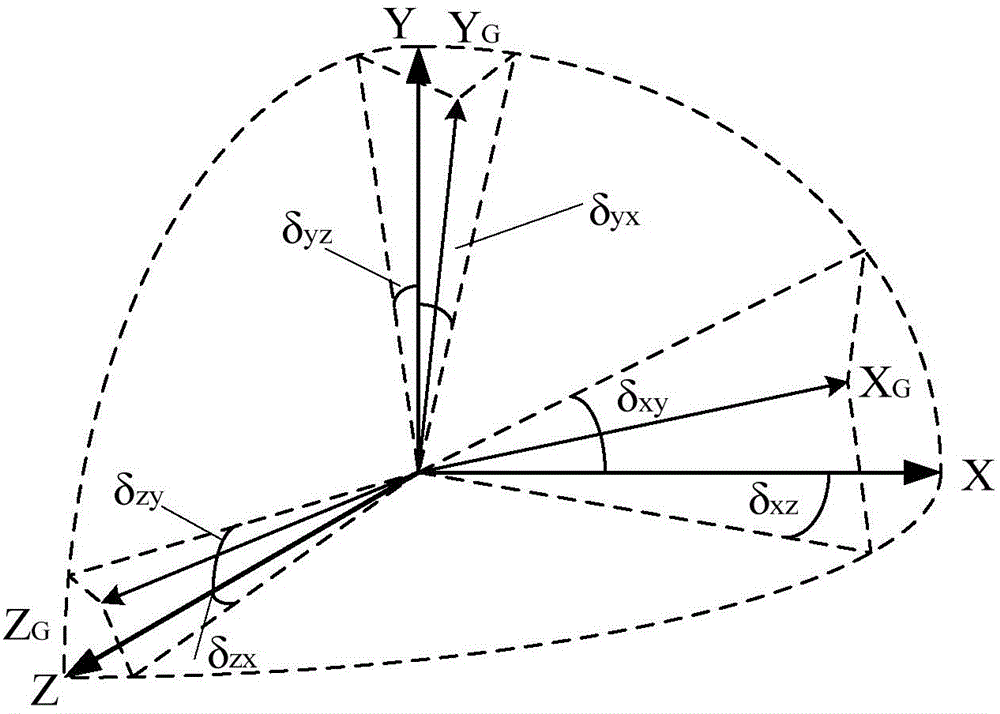

Three-frame four-axis inertial platform error calibration method based on navigation datum system

ActiveCN103983276AImprove the accuracy of useAccurate CalibrationNavigation by speed/acceleration measurementsGyroscopeAccelerometer

A three-frame four-axis inertial platform error calibration method based on a navigation datum system comprises the following steps: with an X accelerometer input shaft as a datum axis, establishing a datum coordinate system OXYZ calibrated by a platform system; based on the datum coordinate system, establishing a platform system accelerometer output error model including an accelerometer installation error, a gyroscope drift error model and a frame angle output error model; and then according to the above three models, completing a calibration work of a three-frame four-axis inertial platform. Relying on a high-precision accelerometer on the platform, the navigation method is adopted to achieve self-calibration, and thus the calibration method is greatly simplified, the calibration cost is reduced, and the calibration accuracy is improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

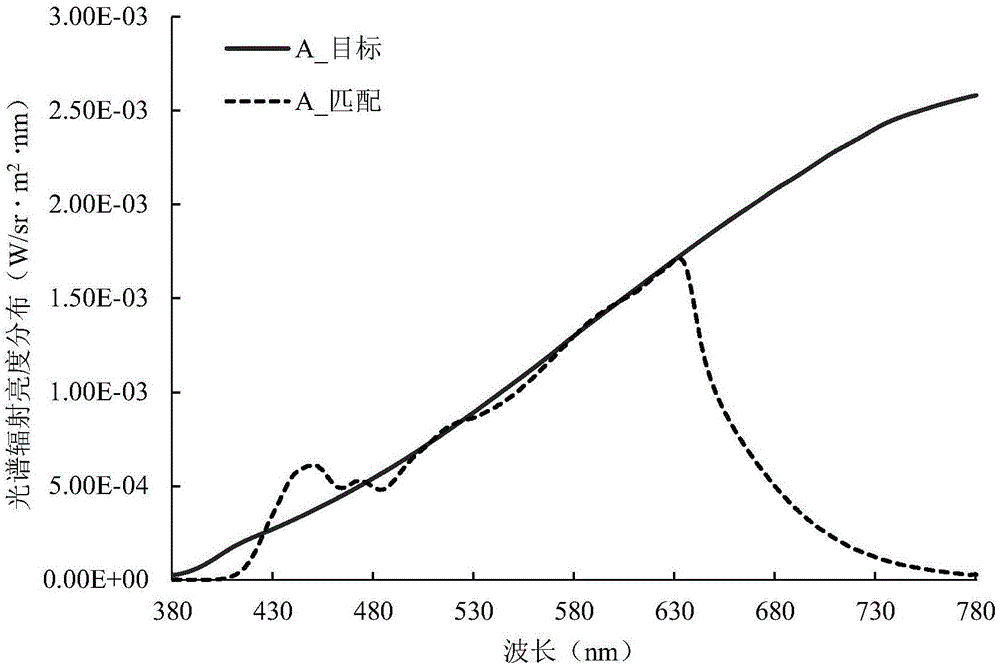

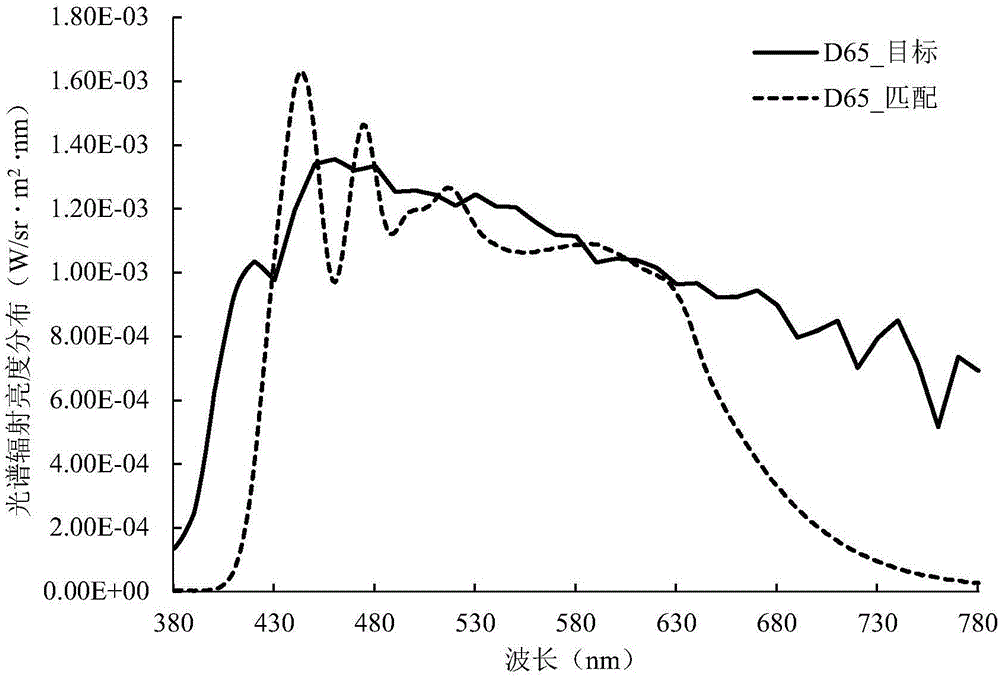

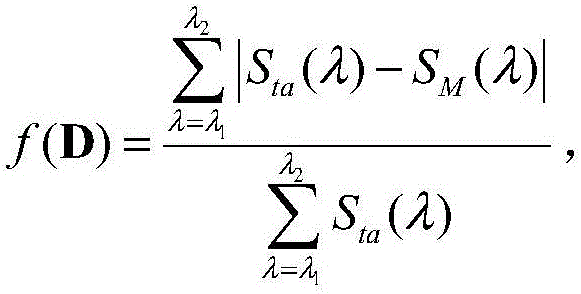

Multi-color LED spectrum and illumination matching method

InactiveCN105934020AReduce calibration costsSimple and fast operationElectrical apparatusElectroluminescent light sourcesIlluminanceRadiance

The invention discloses a multi-color LED spectrum and illumination matching method. The method is characterized by, to begin with, obtaining spectrum sample data of a single LED in each color through sampling and measuring; then, carrying out transition on spectrum and illumination to be matched to obtain corresponding target spectrum radiance distribution; and finally, carrying out iterative matching through a differential evolution algorithm to obtain a driving value of each LED. The invention also provides corresponding spectrum and illumination matching evaluation indexes for evaluating the matching results. The method solves the defects of an existing spectrum matching method, can realize illumination matching while carrying out spectrum matching, can obviously reduce calibration cost due to LED mixed light source maintenance and updating, and is simple to operate and easy to implement. Besides, the problem of spectrum change due to heat of an LED light source is solved in the matching process, and the method can meet requirement for spectrum and illumination simultaneous matching in the practical application.

Owner:ZHEJIANG UNIV

Method for calibrating digital oscilloscope

InactiveCN101655542AGuaranteed firmnessReduce calibration costsElectrical measurementsCalibration resultInstrumentation

The invention relates to a method for calibrating a digital oscilloscope, comprising the following steps: S1: inputting a standard signal; S2: judging whether calibration is required, if so, performing S3, otherwise, performing S4; S3: adjusting corresponding parameters and performing S2; and S4: terminating. The above method for calibrating digital oscilloscopes needs no special calibrating instruments, and can finish various calibration processes only by inputting a standard signal and adjusting corresponding parameters, thus lowering calibration cost greatly. A user can use the above calibrating method for calibrating digital oscilloscopes at any time, therefore, the stable degree of the calibration results can be ensured.

Owner:秦轲 +2

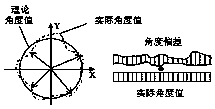

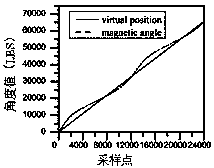

Magnetoelectric encoder self correction method based on permanent magnet synchronous motor sensorless speed control

ActiveCN108180933AStrong practical applicationStrong commercial application valueInstrumentsPermanent magnet synchronous motorCalculation error

The invention discloses a magnetoelectric encoder self correction method based on permanent magnet synchronous motor sensorless speed control, which relates to the field of magnetoelectric encoder error correction. In order to eliminate angle calculation errors of the magnetoelectric encoder, an angle error compensation method based on permanent magnet synchronous motor sensorless control is put forward. In order to acquire a high-precision virtual angle value, a sensorless speed control method for the permanent magnet synchronous motor is used. According to the deviation between the high-precision virtual angle value and a magnetoelectric encoder angle value, angle compensation is carried out. In order to eliminate noise signals in an angle compensation table and ensure the precision of the compensation table, an oversampling linear interpolation method is put forward. The method is technically characterized by comprising acquisition of a magnetoelectric encoder output angle value, making of the angle compensation table and table making by oversampling linear interpolation.

Owner:HARBIN UNIV OF SCI & TECH

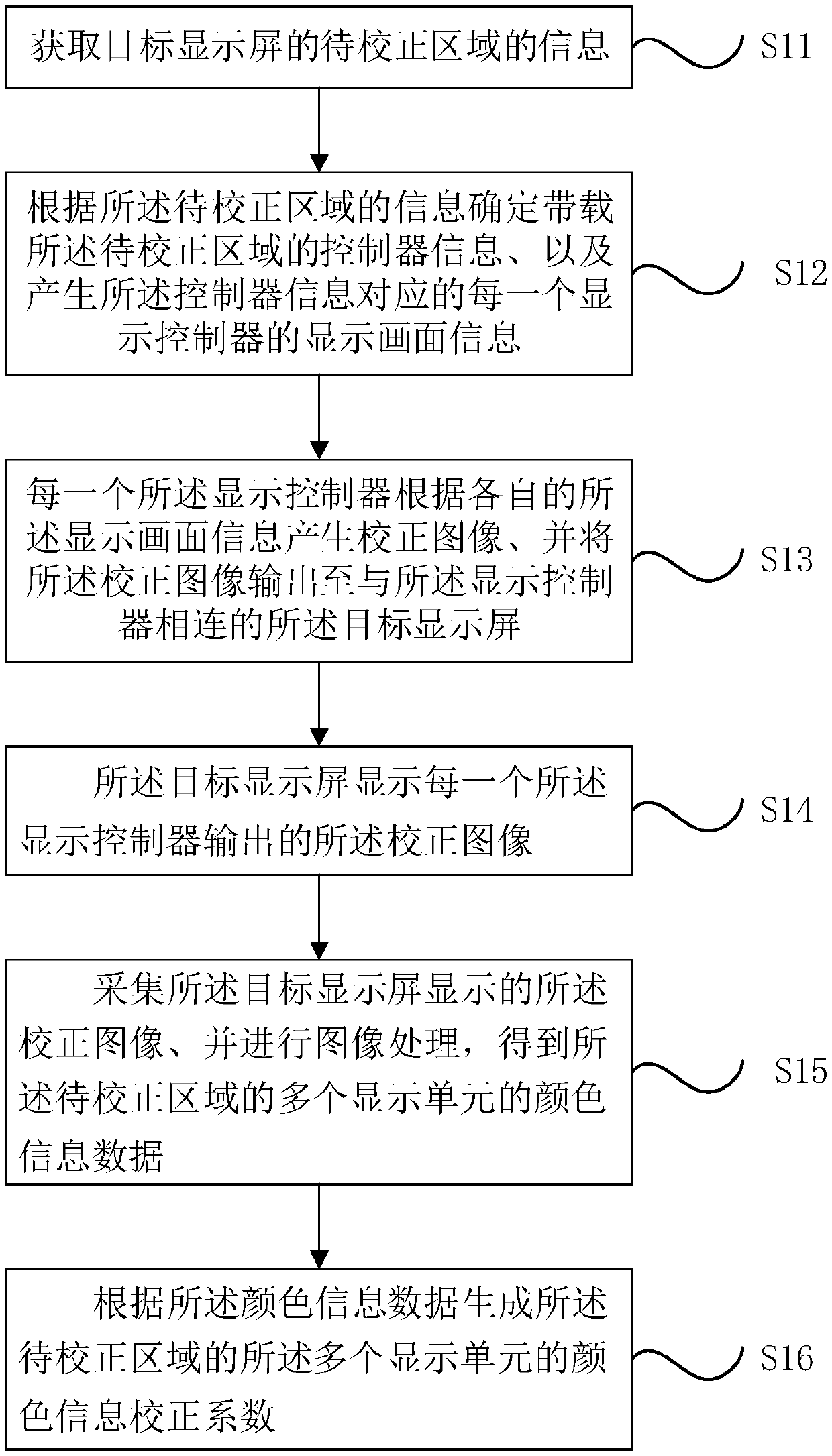

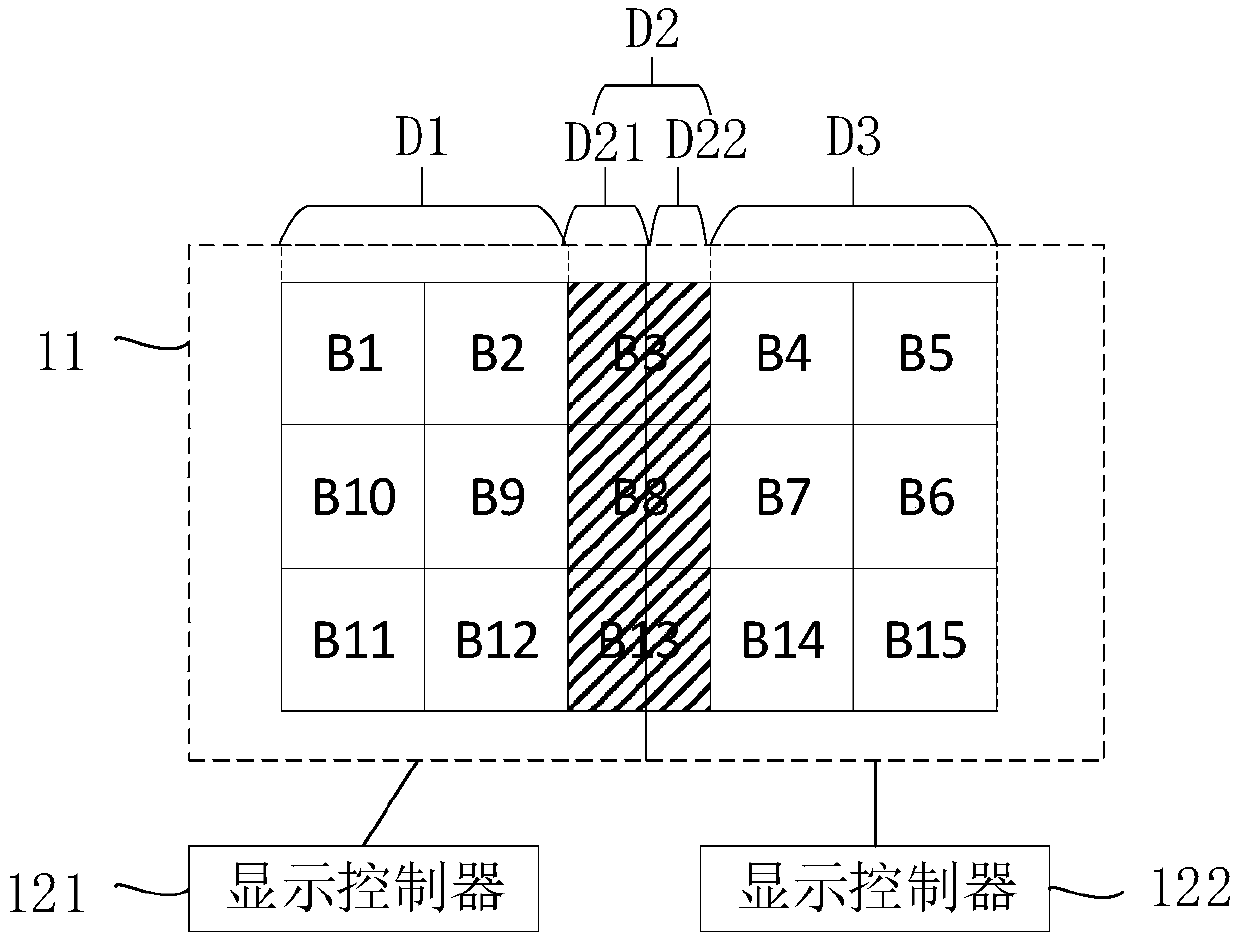

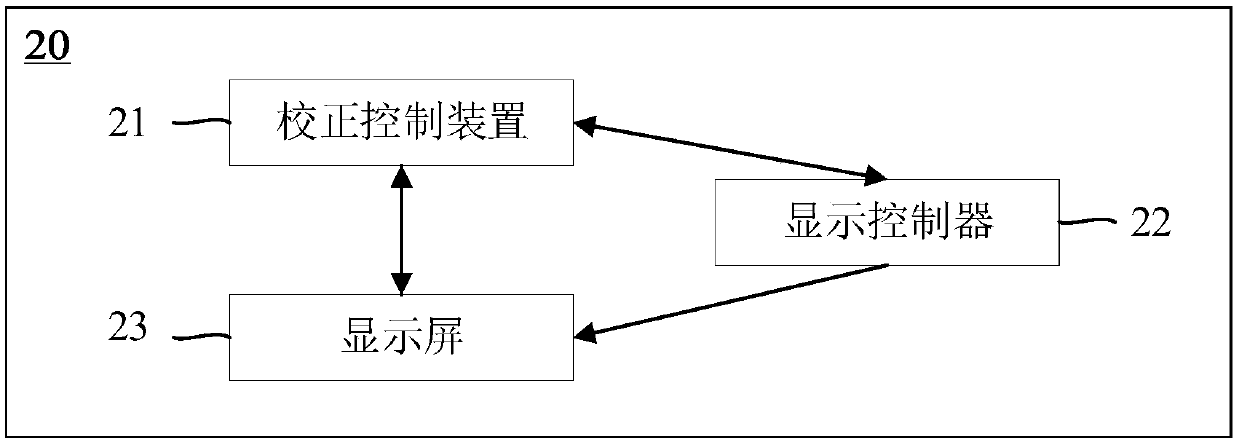

Display screen correction method and display screen correction system

PendingCN110930917AAvoid intractable phenomenaReduce calibration costsStatic indicating devicesImaging processingComputer graphics (images)

The invention relates to a display screen correction method and system. The method comprises: obtaining information of a to-be-corrected area of a target display screen; determining controller information carrying the to-be-corrected area according to the information of the to-be-corrected area, and generating display picture information of each display controller corresponding to the controller information; generating a correction image by each display controller according to the respective display image information, and outputting the correction image to the target display screen by each display controller; displaying the corrected image by the target display screen; collecting the corrected image displayed by the target display screen, and performing image processing to obtain color information data of a plurality of display units of the to-be-corrected area; and generating color information correction coefficients of the plurality of display units of the to-be-corrected area according to the color information data. One-time loading and one-time correction of the display screen exceeding the output resolution of the display card of the upper computer can be realized.

Owner:XIAN NOVASTAR TECH

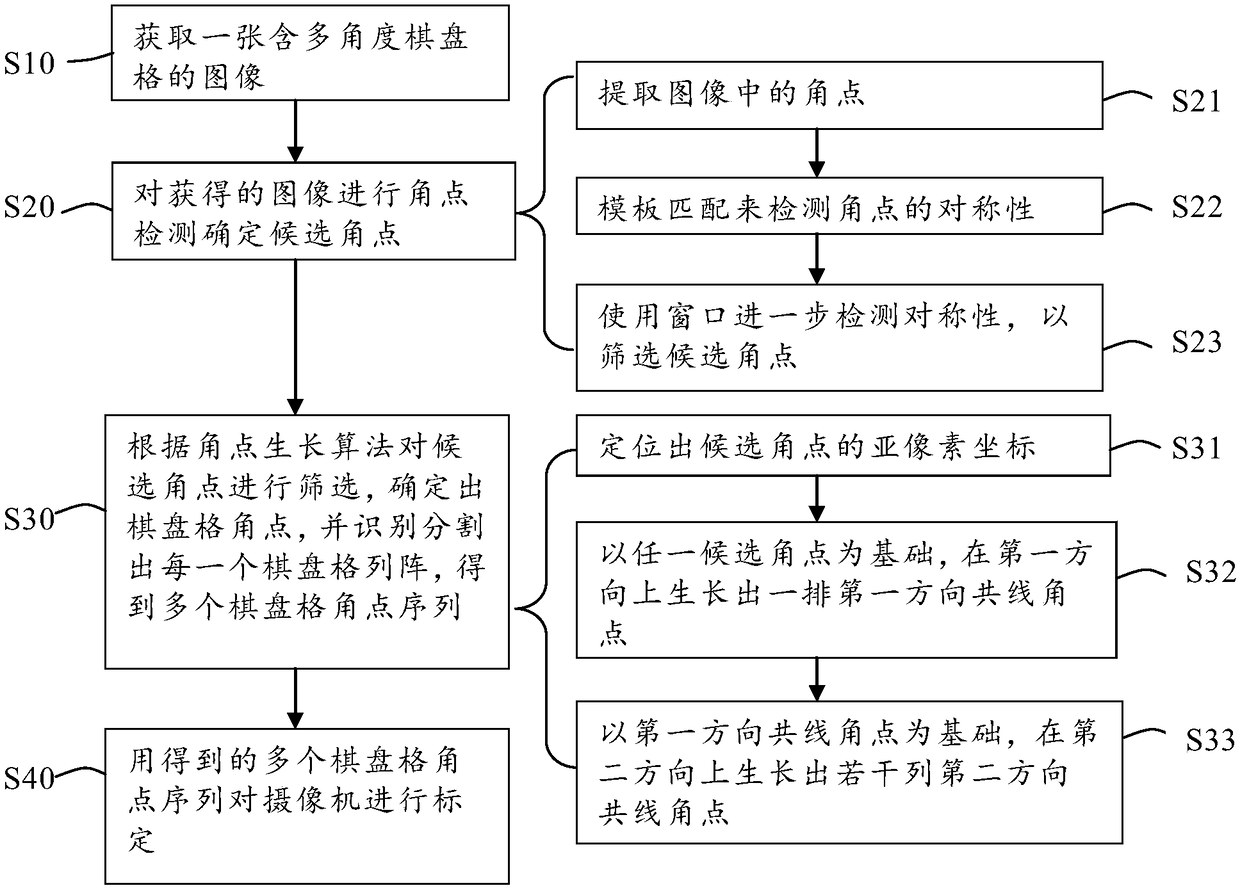

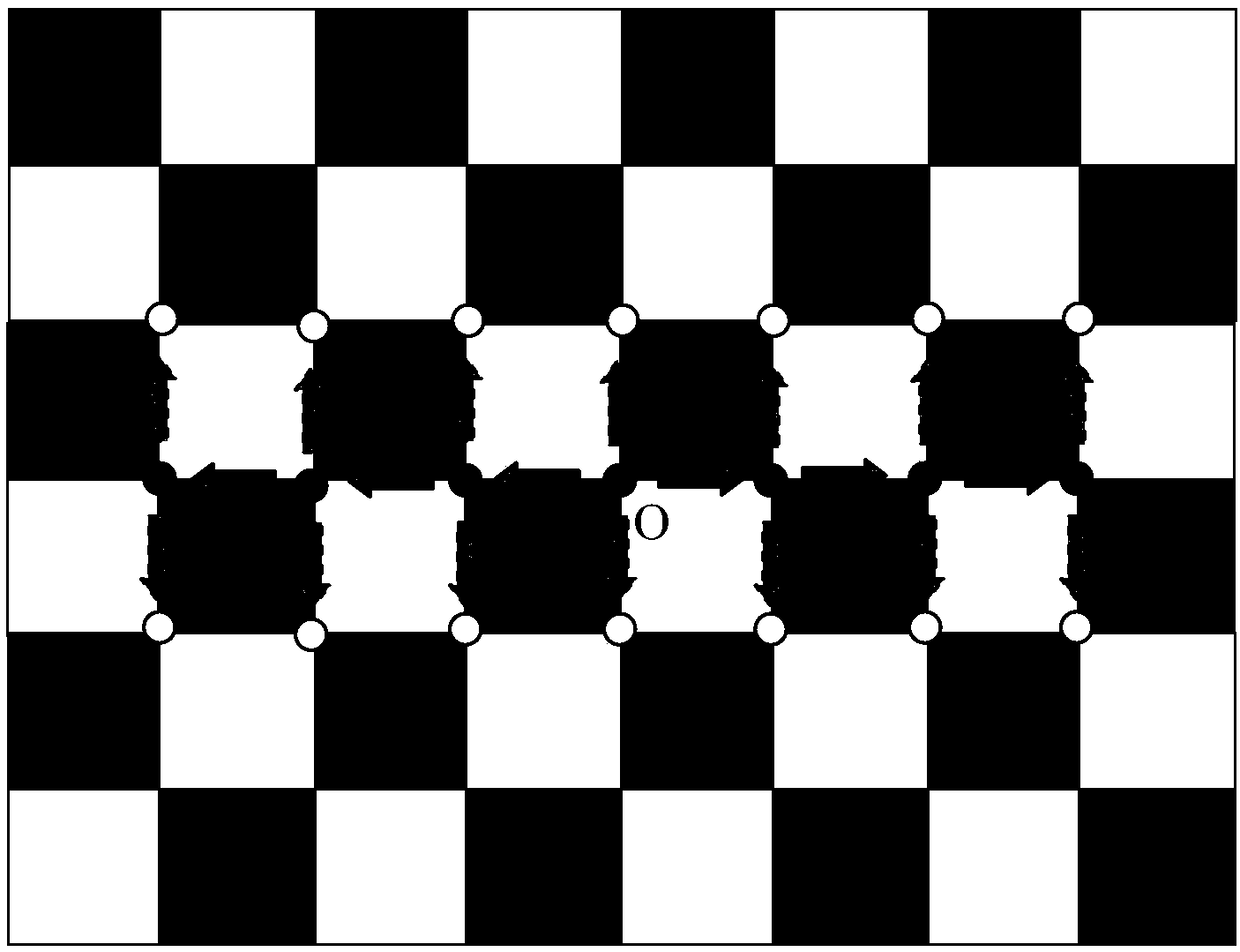

Multi-checkerboard corner detection method and camera calibration method

InactiveCN108257185ASimplify the calibration procedureReduce calibration costsImage analysisAngular pointCheckerboard

The invention discloses a multi-checkerboard corner detection method and a camera calibration method. The multi-checkerboard corner detection method comprises the following steps: an image containingcheckerboards at multiple different angles is acquired; the acquired image is subjected to corner detection to determine candidate corners; and the candidate corners are screened according to a cornergrowth algorithm, checkerboard corners are determined, each checkerboard array is recognized and segmented, and multiple checkerboard corner sequences are obtained. According to the technical scheme,the calibration procedure is thus greatly simplified, the calibration cost is reduced, and the calibration time is saved.

Owner:X CHIP MICROELECTRONICS TECH CO LTD

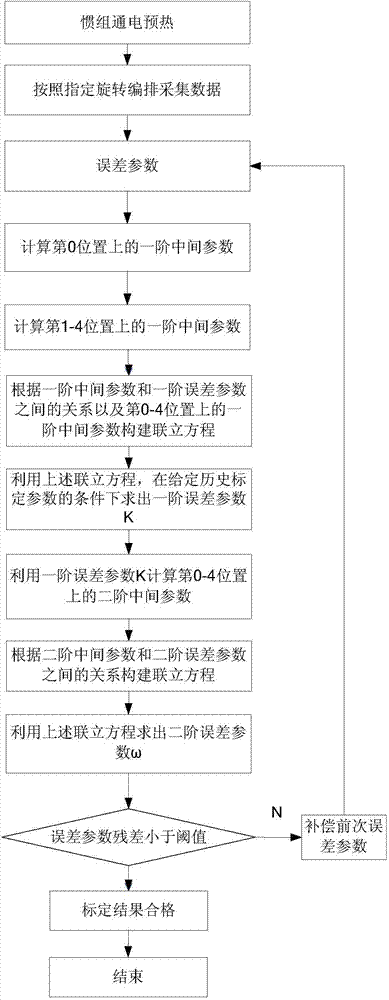

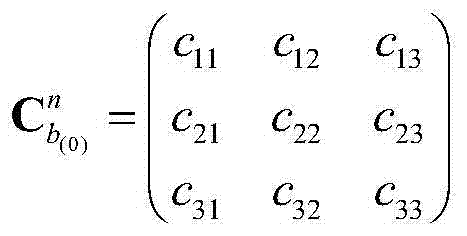

Method for calibrating inertial measurement unit applicable to low-precision single-shaft transposition device with azimuth reference

ActiveCN104121928AImprove long-term stabilityInertial navigation accuracy has little impactMeasurement devicesErrors and residualsComputer science

The invention discloses a method for calibrating an inertial measurement unit applicable to a low-precision single-shaft transposition device with azimuth reference, belonging to the technical field of inertia. The method is characterized by comprising the following steps: rotating the low-precision single-shaft transposition device to arrange five positions, fitting out a first-order intermediate parameter delta g and a second-order intermediate parameter shown in the specification by utilizing a speed error and an upward attitude error, calculating error parameters of each device through a least square method according to the relation between the intermediate parameter and the error parameter as well as the latest historical calibration parameters, substituting the iterated error parameter of the previous time and the original output data of the inertial measurement unit into a navigation equation in order to effectively eliminate the positioning error caused by a turntable, then re-calculating the observed quantity, the intermediate parameter and the error parameter residual error, then compensating the residual error of the error parameter, and deducing the rest by analog until the error parameter residual error obtained through the iteration calculation is smaller than a threshold value. By adopting the method, the calibration cost and the dependence of the calibration on the precision of the turntable can be greatly reduced, the calibration time is shortened, and the engineering practicability can be achieved.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com