Double-mechanical arm calibration method based on camera optical axis constraint

A dual manipulator and calibration method technology, applied in the field of robot calibration, can solve the problems of lower absolute positioning accuracy of the end of the manipulator, kinematic parameter error, complex calibration process, etc., and achieves reduced calibration costs, fewer calibration steps, and calibration accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

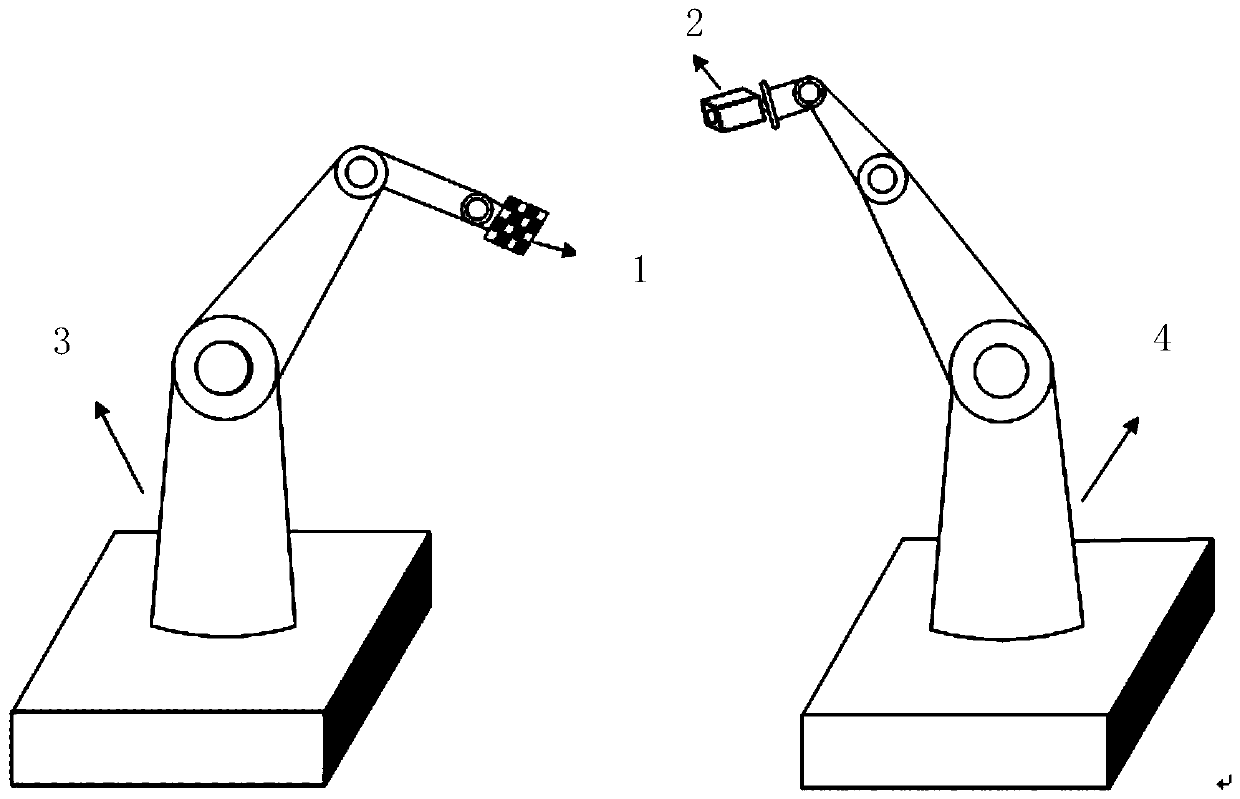

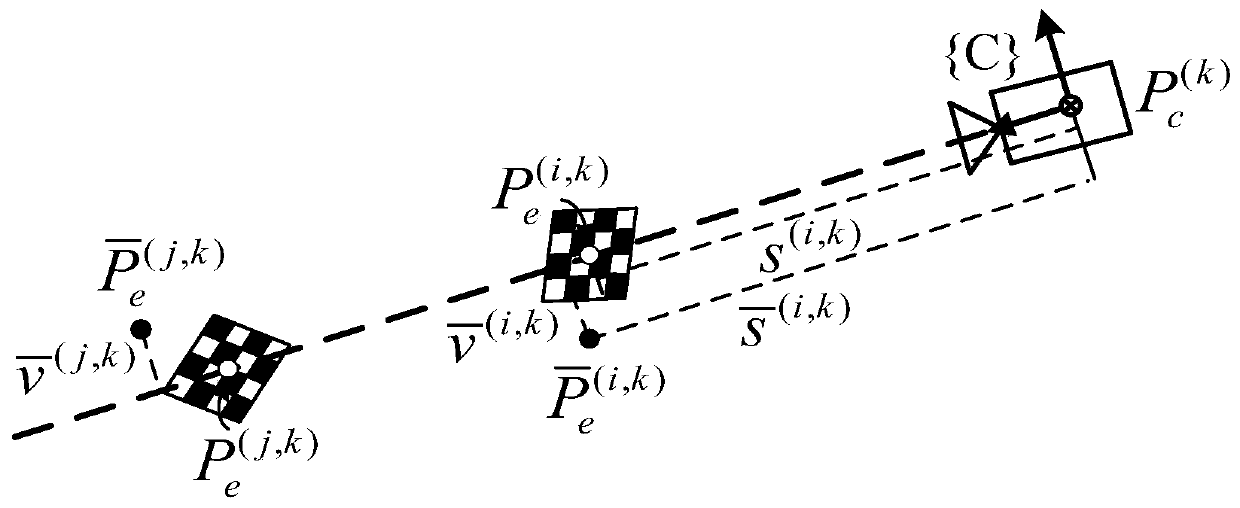

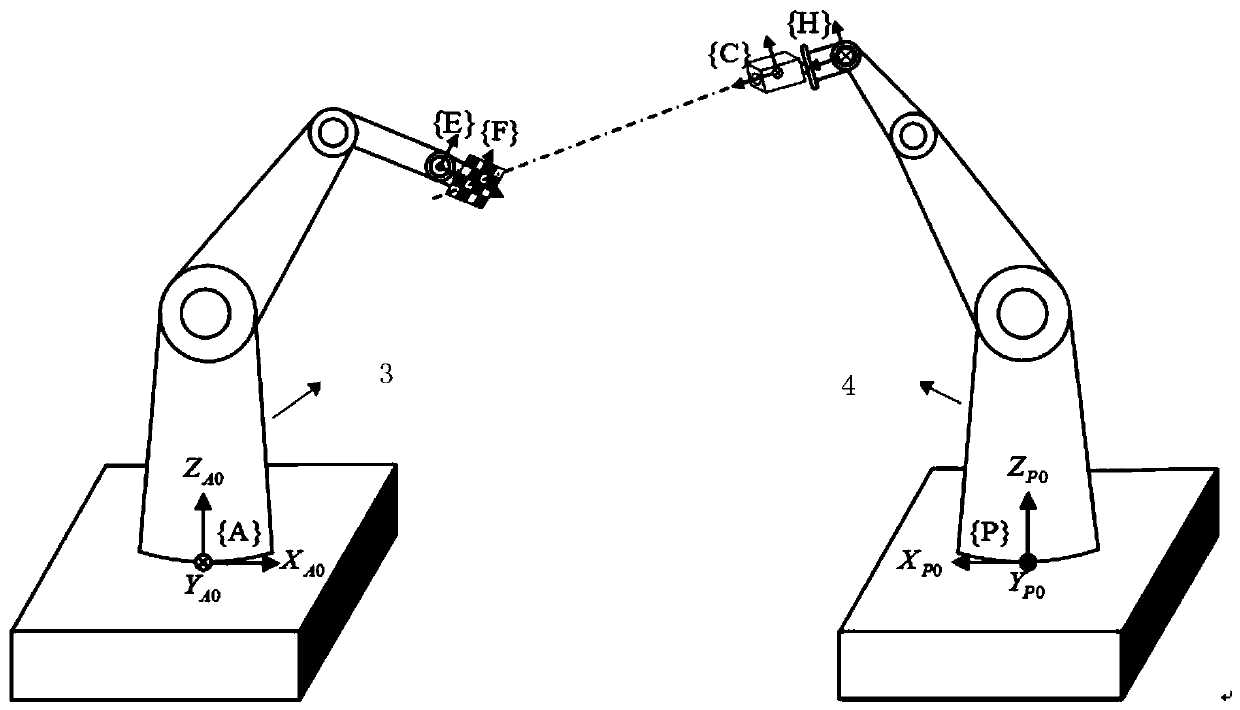

[0038] The invention provides a method for calibrating dual mechanical arms based on camera optical axis constraints. At present, robots are developing rapidly, and more and more fields require dual-arm collaborative robots. In order to successfully complete the operation tasks, the dual-arm system must be calibrated. In view of the low positioning accuracy of the current dual-arm collaborative robot, the present invention simultaneously completes the calibration of kinematic parameters and base coordinates of the two robotic arms, providing technical support for the dual-arm system to complete high-precision tasks. The basic idea of the present invention is to make the optical axis of the camera installed at the end of one manipulator serve as a virtual linear constraint, and the pose of the other end of the manipulator satisfy the virtual constraint of the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com