Method for calibrating inertial measurement unit applicable to low-precision single-shaft transposition device with azimuth reference

A technology of inertial measurement unit and calibration method, which is applied in measurement devices, instruments, etc., can solve the problem of undiscovered single-axis system-level calibration algorithm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

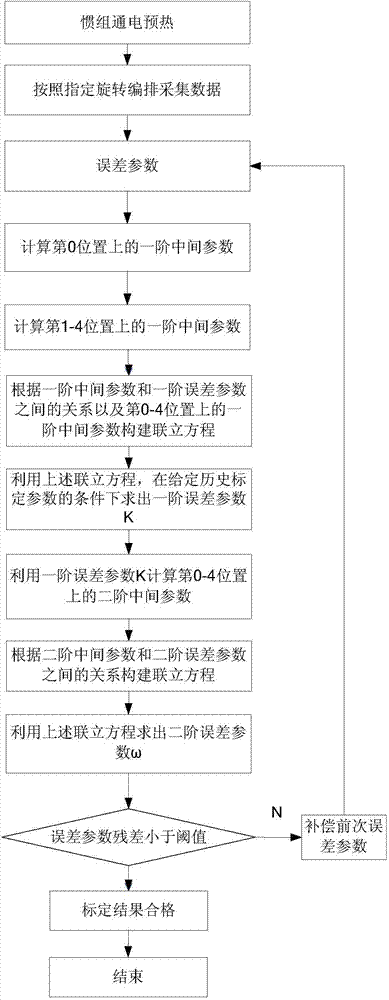

[0111] The present invention provides an inertial measurement unit calibration method suitable for low-precision azimuth reference single-axis indexing equipment. The specific calibration steps are as follows:

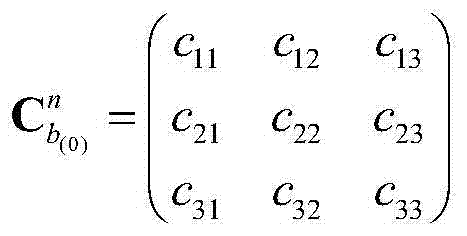

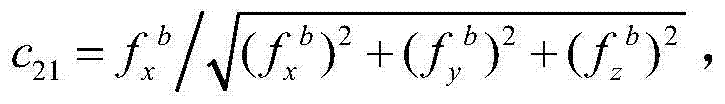

[0112] Step 1: Install the inertial measurement unit on the single-axis indexing device, the initial position of the inertial measurement unit is oriented down-east-south, the navigation coordinate system is selected as the North-Up-East (N-U-E, North-Up-East) coordinate system, and the inertial measurement After the unit is powered on for 30 minutes to warm up, it starts to collect the output raw data. The arrangement of the calibration positions is shown in Table 1: the inertial measurement unit first stops at the 0th position for 3-5 minutes, and then rotates to the first position for 3- 5 minutes, then turn to the second position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com