Calibration method and device for angle encoder

A technology for angle encoders and calibration methods, which is applied in the field of calibration methods and devices for angle encoders, and can solve problems affecting the measurement accuracy of angle encoders, inaccurate working errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

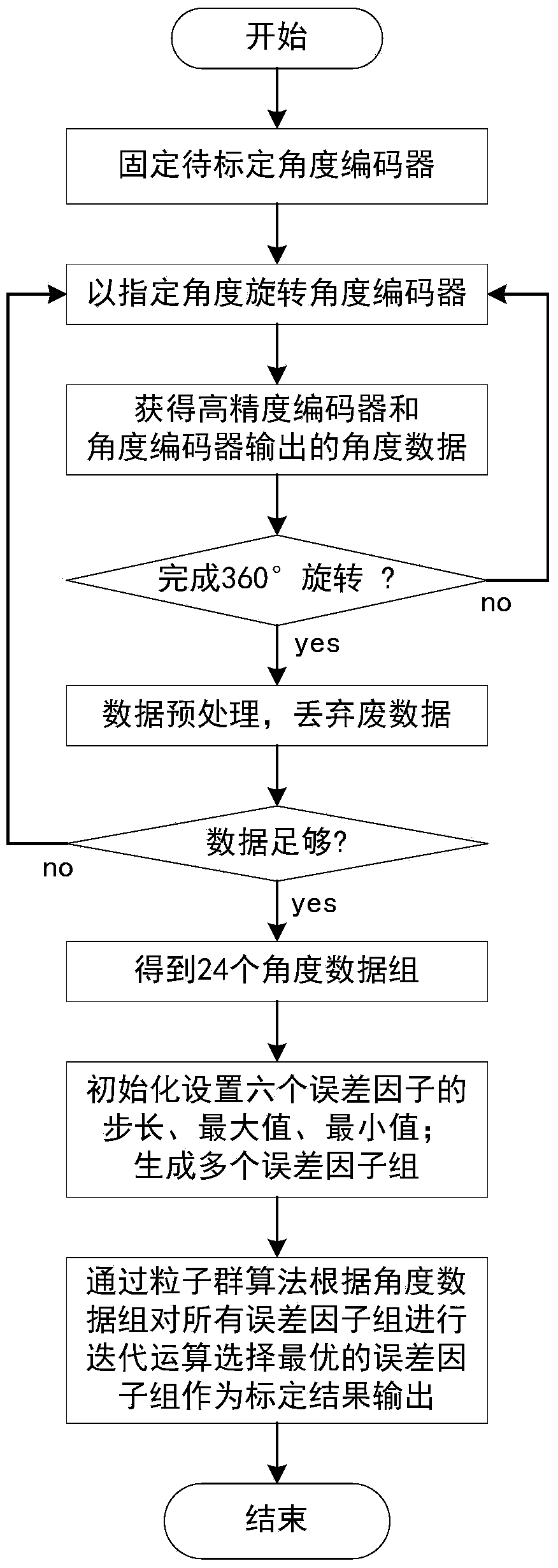

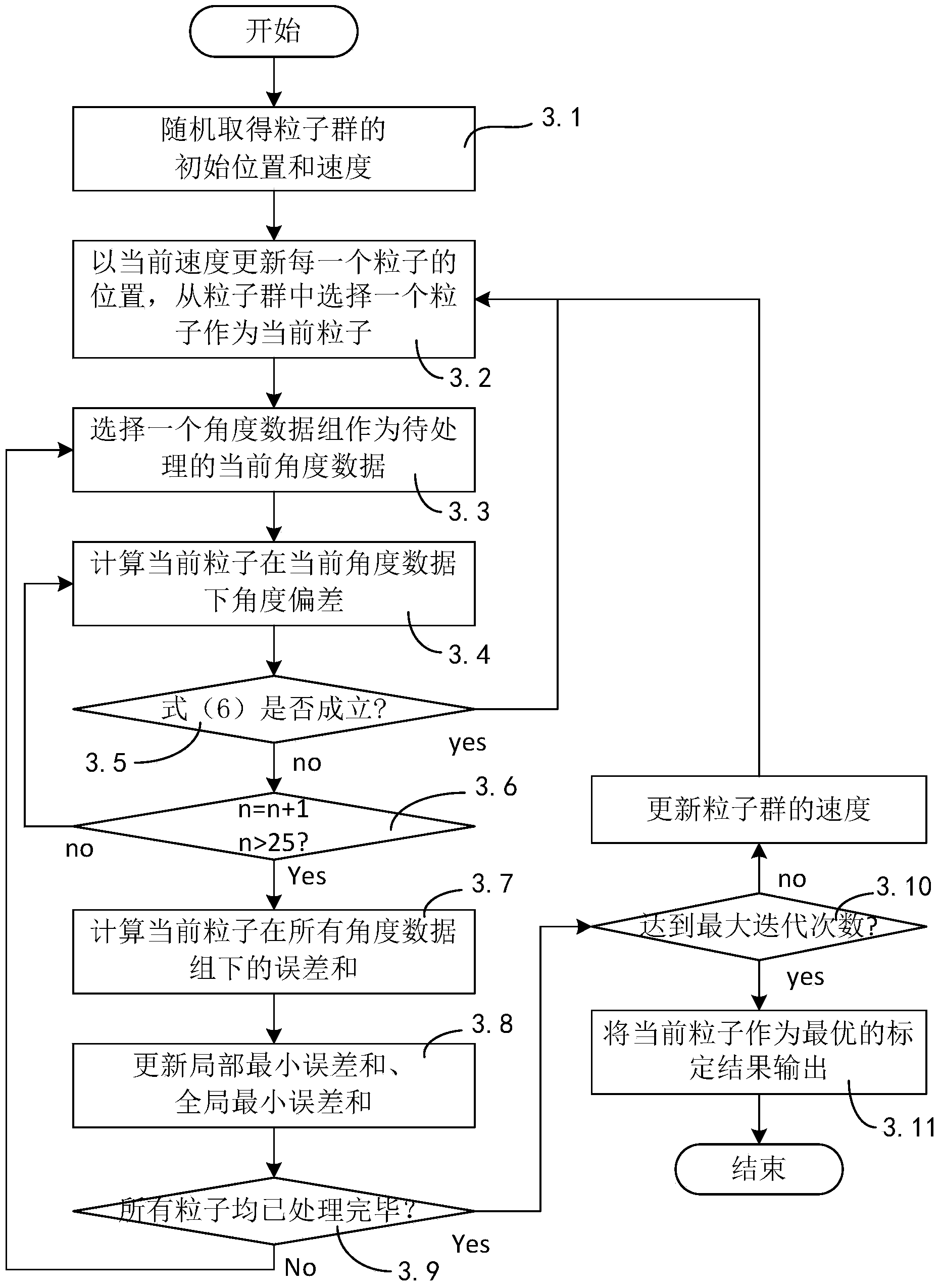

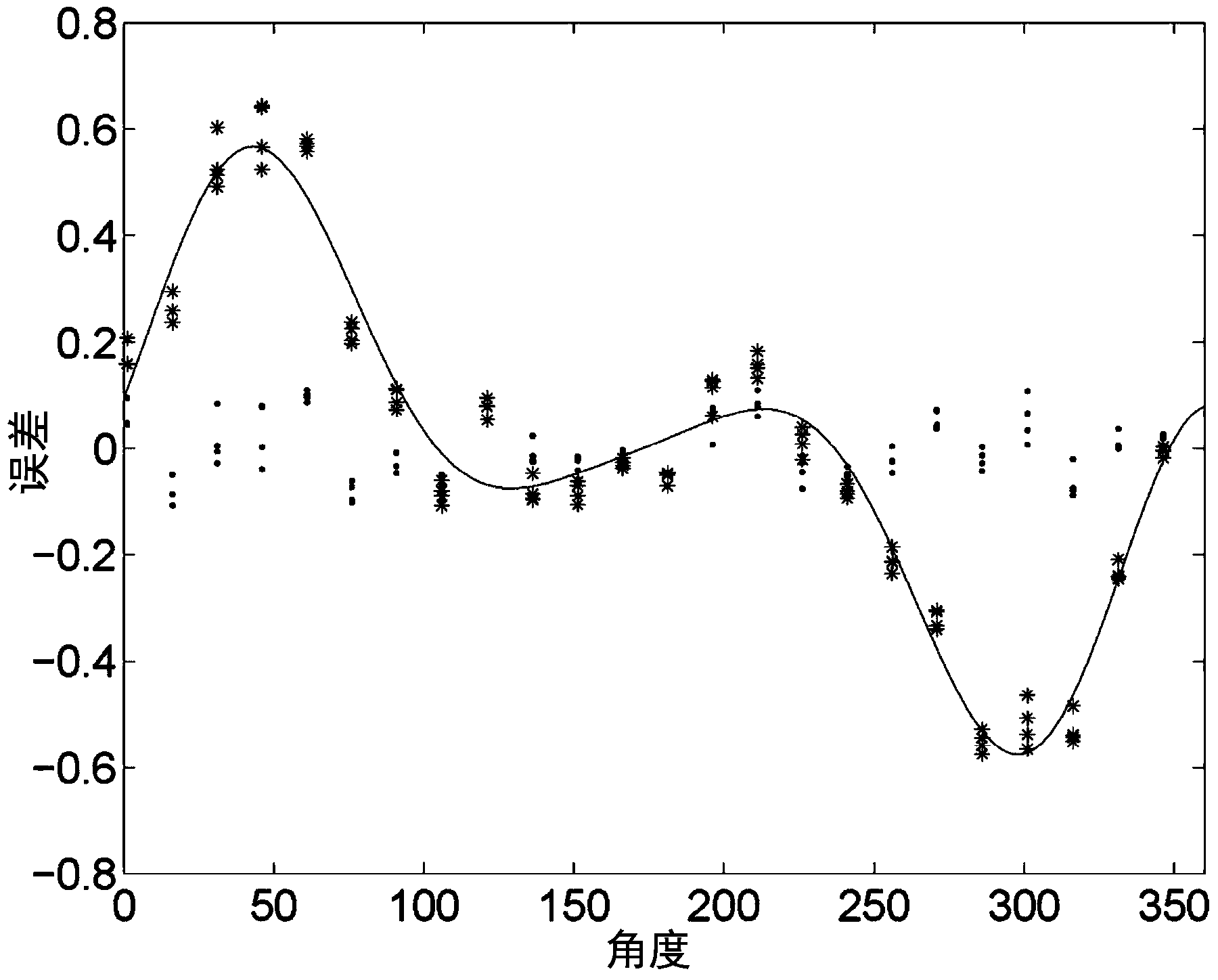

[0089] Such as figure 1 As shown, the implementation steps of the calibration method of the angle encoder in this embodiment are as follows:

[0090] 1) The angle encoder to be calibrated is driven by a stepping motor to gradually rotate at a specified angle to complete a rotation of no less than 360 degrees, and the angle encoder to be calibrated is obtained through a high-precision encoder connected to the output shaft of the stepping motor in each The plurality of angle data output from the position of the specified angle is associated with the corresponding position of the specified angle as an angle data group, and finally a plurality of angle data groups respectively corresponding to each position of the specified angle are obtained.

[0091] In the present embodiment, the specific steps of step 1) are as follows:

[0092] 1.1) Regularly collect the angle data output by the angle encoder to be calibrated; at the same time, rotate the angle encoder to be calibrated at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com