Multi-checkerboard corner detection method and camera calibration method

A camera calibration and corner detection technology, used in image analysis, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

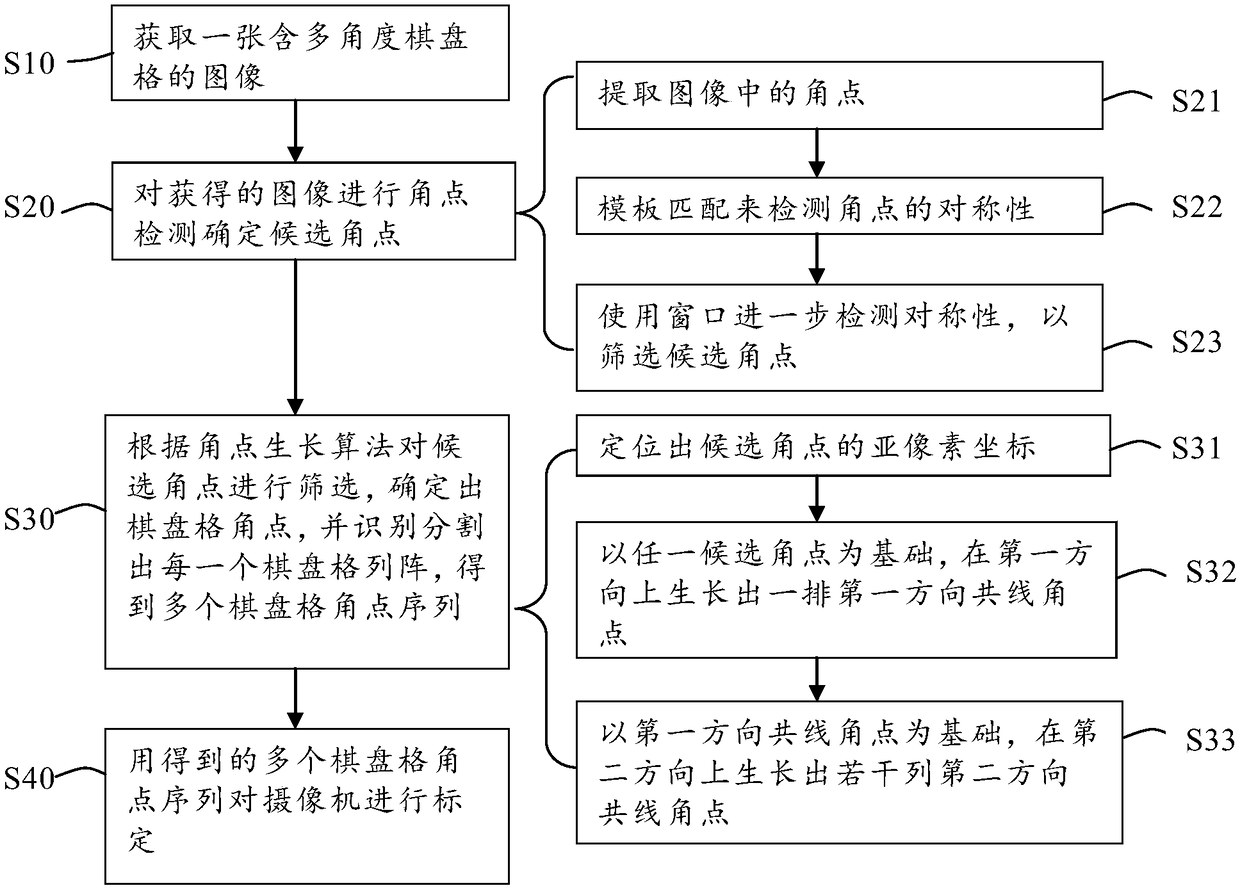

[0070] Such as figure 1 What is shown is a schematic flowchart of a camera calibration method in an embodiment of the present invention. refer to figure 1 , the camera calibration method includes the following steps:

[0071] Including the following steps:

[0072] Step S10, obtain an image containing multi-angle checkerboard:

[0073] According to the requirements, build a multi-checkerboard calibration environment, and place multiple checkerboard calibration boards on the fixture according to a certain pose relationship. Each calibration plate is placed at a different angle, and there is no obstruction between each other, and the calibration plate fills the entire field of view as much as possible.

[0074] Select a shooting pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com