A fast and high-precision calibration device for line-scan cameras in high-speed rail detection systems

A detection system and line array camera technology, applied in measuring devices, line-of-sight measurement, measuring distance, etc., can solve the problems of slow calibration speed and low calibration accuracy, achieve convenient installation and adjustment, simplify calibration procedures, and save calibration time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

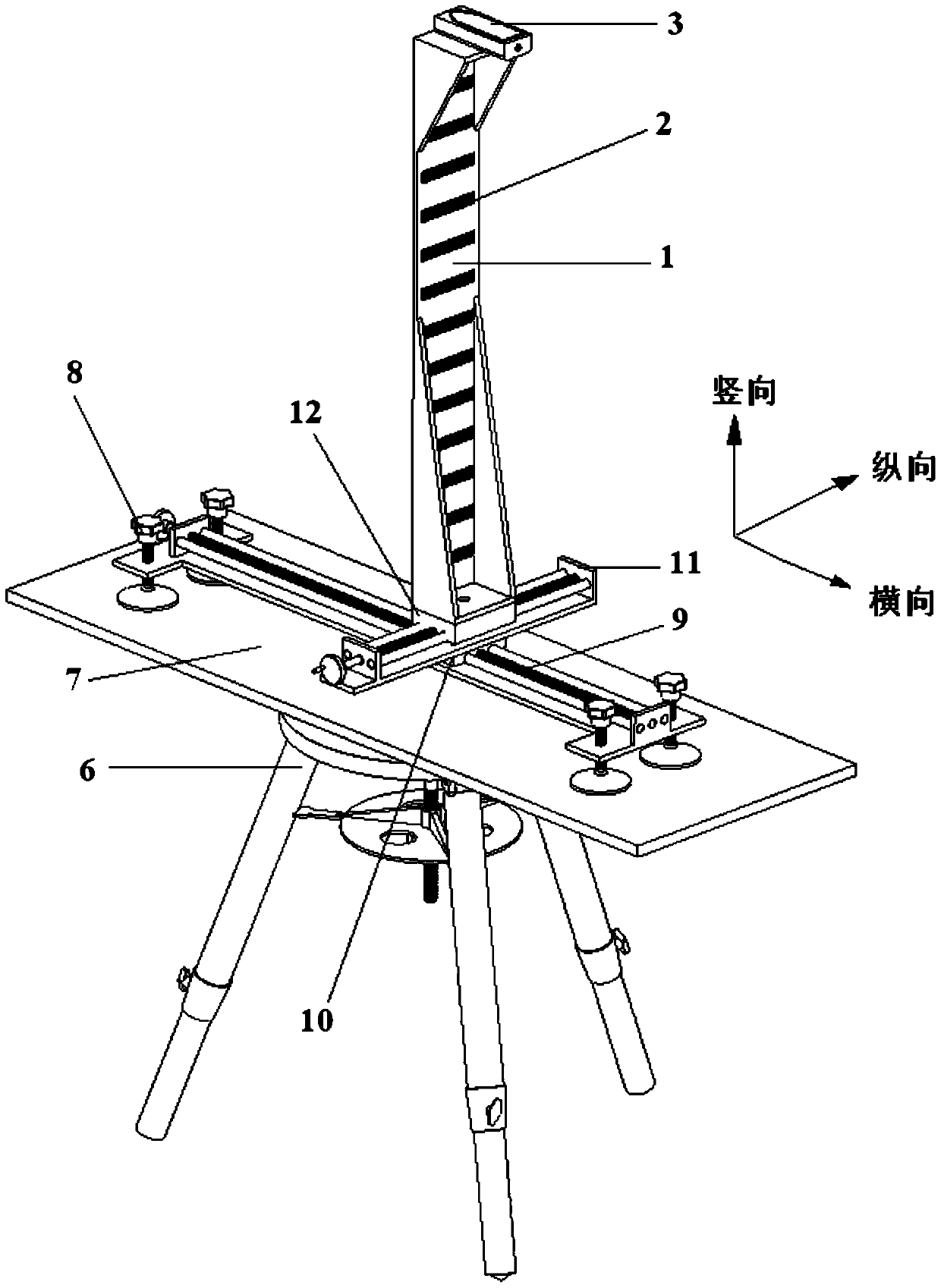

[0039] This embodiment provides a fast and high-precision calibration device for a line-scan camera of a high-speed rail detection system, such as Figure 1 to Figure 4 As shown, it includes a calibration plate 1 arranged vertically, and a plurality of black calibration stripes 2 are arranged on the calibration plate 1. A laser range finder 3 is installed on the top surface of the calibration plate 1, and the laser range finder 3 emits a laser that hits the Installed on the positioning mark 5 on the rail inspection car 4;

[0040] The laser rangefinder 3 can rotate relative to the calibration plate 1;

[0041] The tail of the laser range finder 3 is aligned with the face with the black calibration stripe 2 on the calibration plate 1, and the reference point of the laser range finder 3 is the tail of the laser range finder 3;

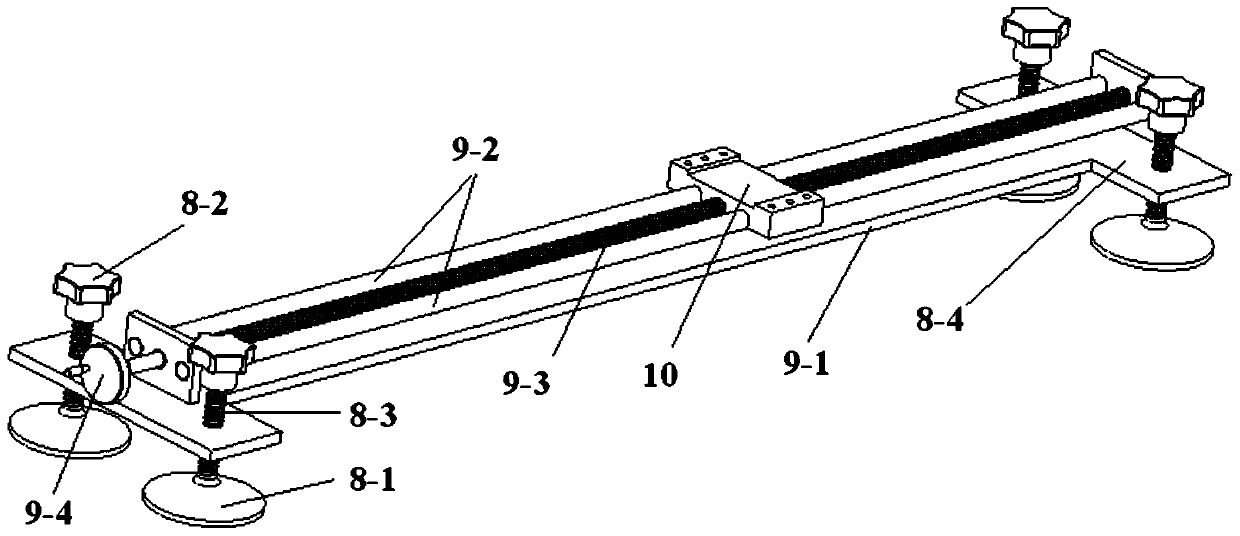

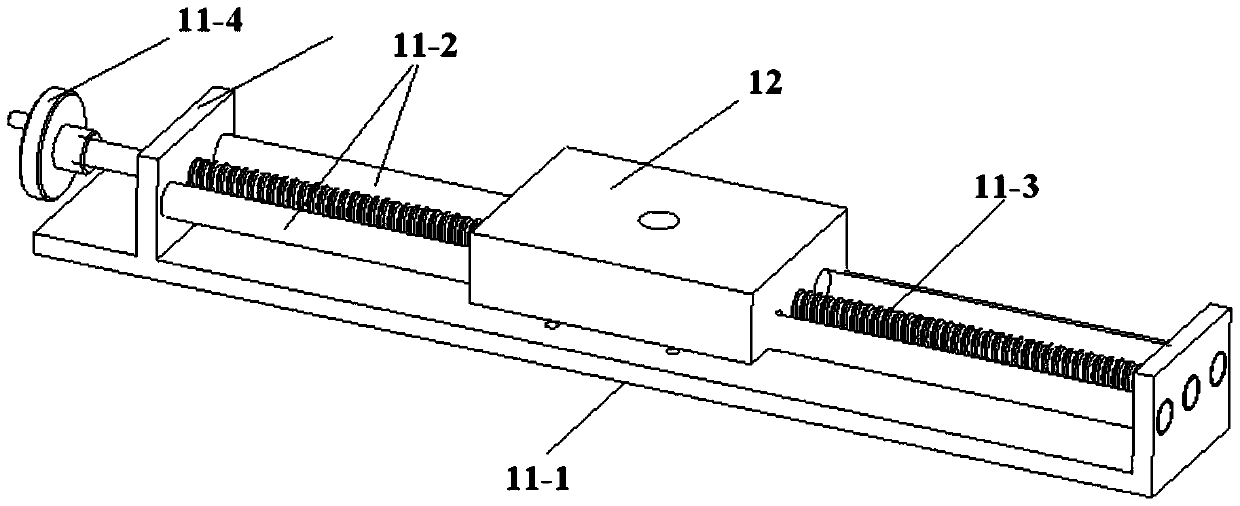

[0042] It also includes a support platform 7 installed on the tripod 6, on the support platform 7, a lateral movement guide rail 9 is installed through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com