Distribution machine used in concrete component production system

A technology of production system and distribution machine, which is applied in the field of distribution machine, can solve the problems of ineffective control of concrete supply, increase the opening degree of the discharge door, and inability to weigh concrete, so as to improve the distribution efficiency and prevent concrete from sticking , easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

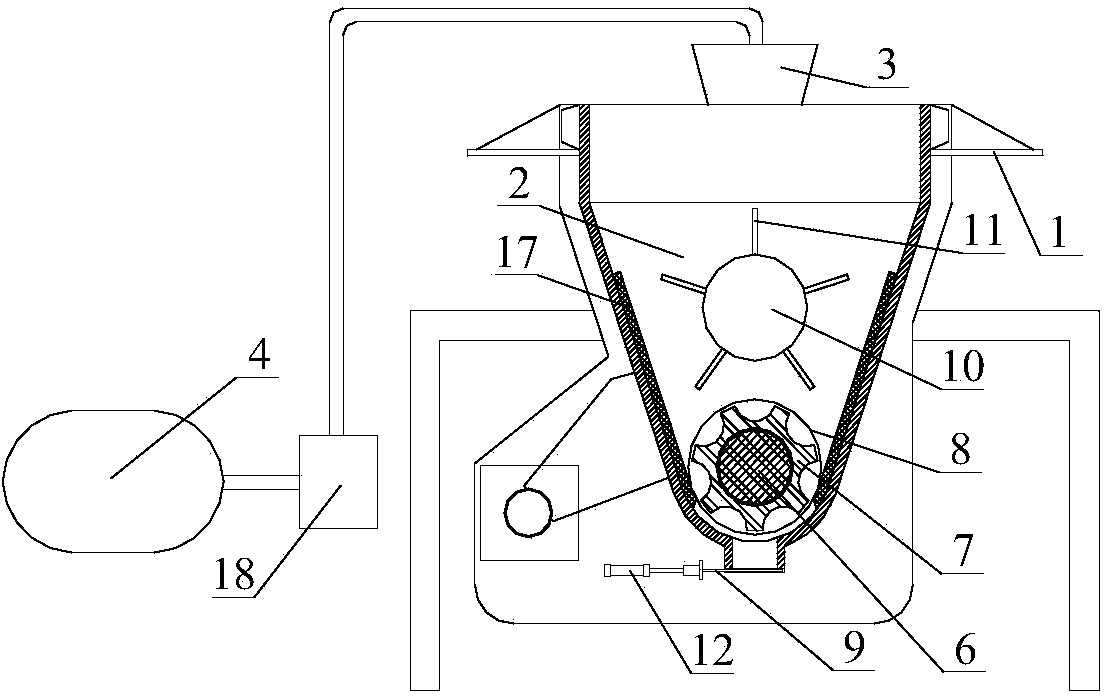

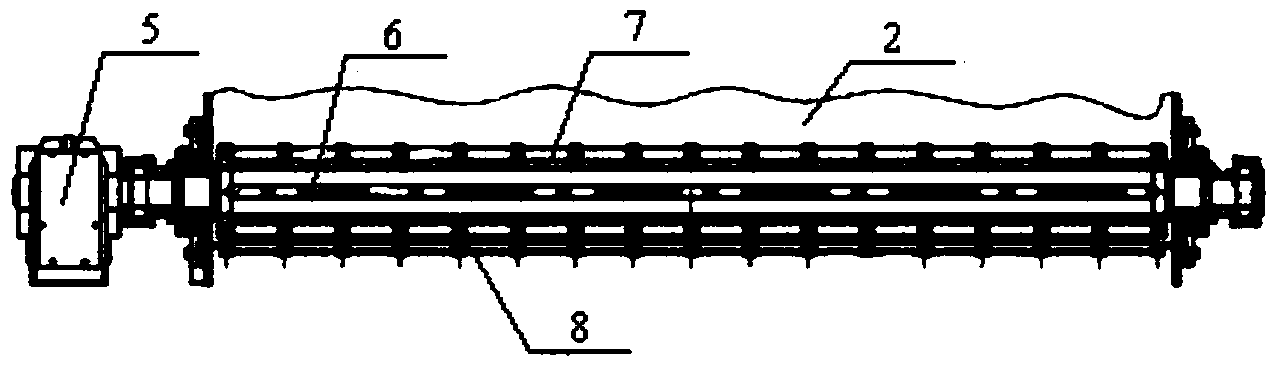

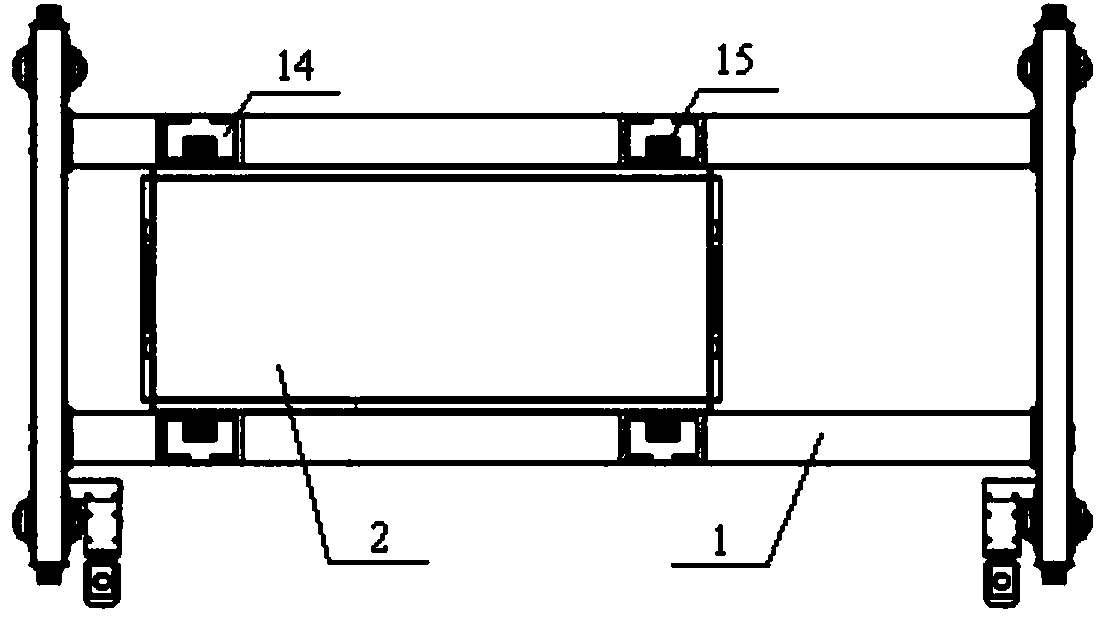

[0029] The distribution machine used in the concrete member production system, the key is: the distribution machine includes a frame 1, a distribution box 2 arranged on the frame 1, a feed hopper 3 communicated with the distribution box 2, and a feed hopper 3 Connected storage tank 4, a weighing mechanism and a feeding mechanism arranged on the frame 1, the feeding mechanism includes a first driving device 5, an axle 6 arranged in the distribution box 2 and connected with the first driving device 5, etc. The star wheel 7 that is arranged on the wheel shaft 6 at intervals, the spacer 8 that is arranged between adjacent star wheels 7, the position corresponding to the star wheel 7 at the bottom of the distribution box 2 is provided with a discharge port, and the discharge port A discharge ram 9 is provided, and the discharge ram 9 forms a sliding fit with the distribution box 2 .

[0030] The distribution machine also includes a stirring mechanism, the structure includes a stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com