Method and device for jointly calibrating parameters of visible light camera and infrared camera

An infrared camera and joint calibration technology, which is applied in image data processing, instruments, calculations, etc., can solve the problems of increasing manpower and material costs for obtaining camera parameters, and achieve the effect of reducing calibration costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

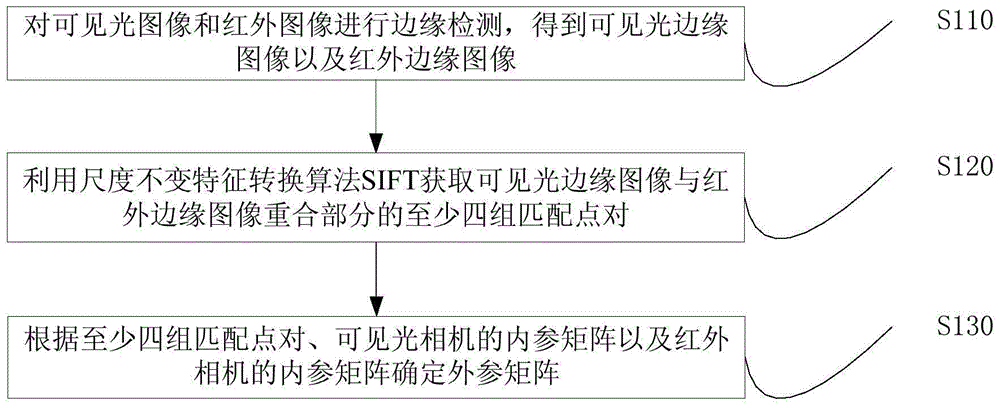

[0022] figure 1 It is a flow chart of a joint calibration method for parameters of a visible light camera and an infrared camera provided by Embodiment 1 of the present invention. This embodiment is applicable to the case of calibrating the parameters of a visible light camera and an infrared camera. Capability of the terminal to execute, such as a personal computer (PersonalComputer, PC), notebook computer, tablet computer, etc., the method specifically includes the following steps:

[0023] S110. Perform edge detection on the visible light image and the infrared image to obtain a visible light edge image and an infrared edge image.

[0024] When performing edge detection on visible light images, edge detection based on search or edge detection based on zero crossing can be used. The search-based edge detection method detects the boundary by finding the maximum and minimum values in the first derivative of the image, usually locating the boundary in the direction of the la...

Embodiment 2

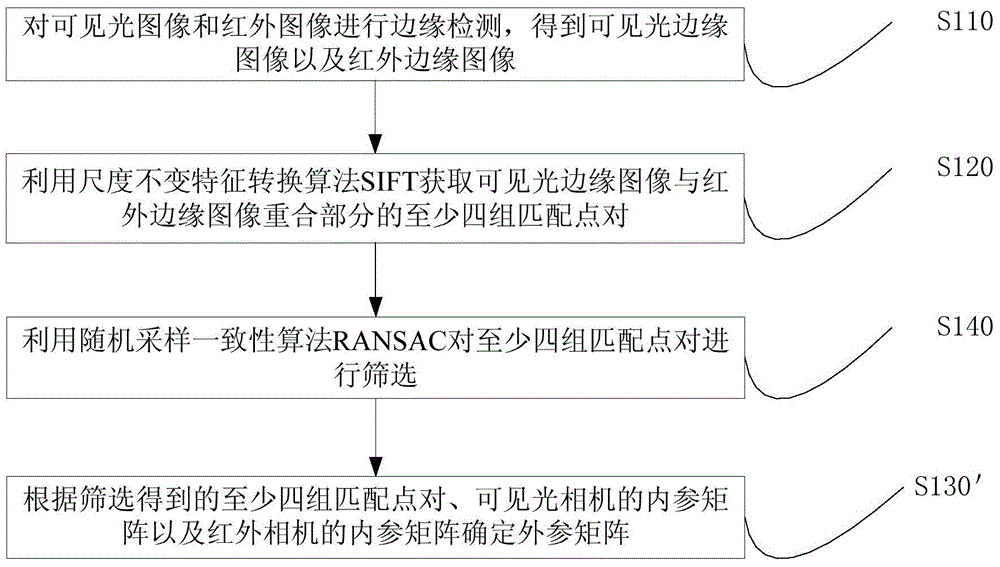

[0054] figure 2 It is a flow chart of a method for joint calibration of parameters of a visible light camera and an infrared camera provided in Embodiment 2 of the present invention. Preferably, at S120, use the scale-invariant feature transformation algorithm SIFT to obtain at least the overlapping portion of the visible light edge image and the infrared edge image After four sets of matching point pairs, also include:

[0055] S140. Use the random sampling consensus algorithm RANSAC to screen at least four sets of matching point pairs.

[0056] The Random Sampling Consensus (RANdomSAmpleConsensus, RANSAC) algorithm achieves the goal by repeatedly selecting a set of random subsets in the data. The selected subsets are assumed to be interior points and verified by the following method:

[0057] S1. Construct a prediction model, and the prediction model is adapted to a hypothetical interior point. The prediction model can be generated according to at least four sets of matc...

Embodiment 3

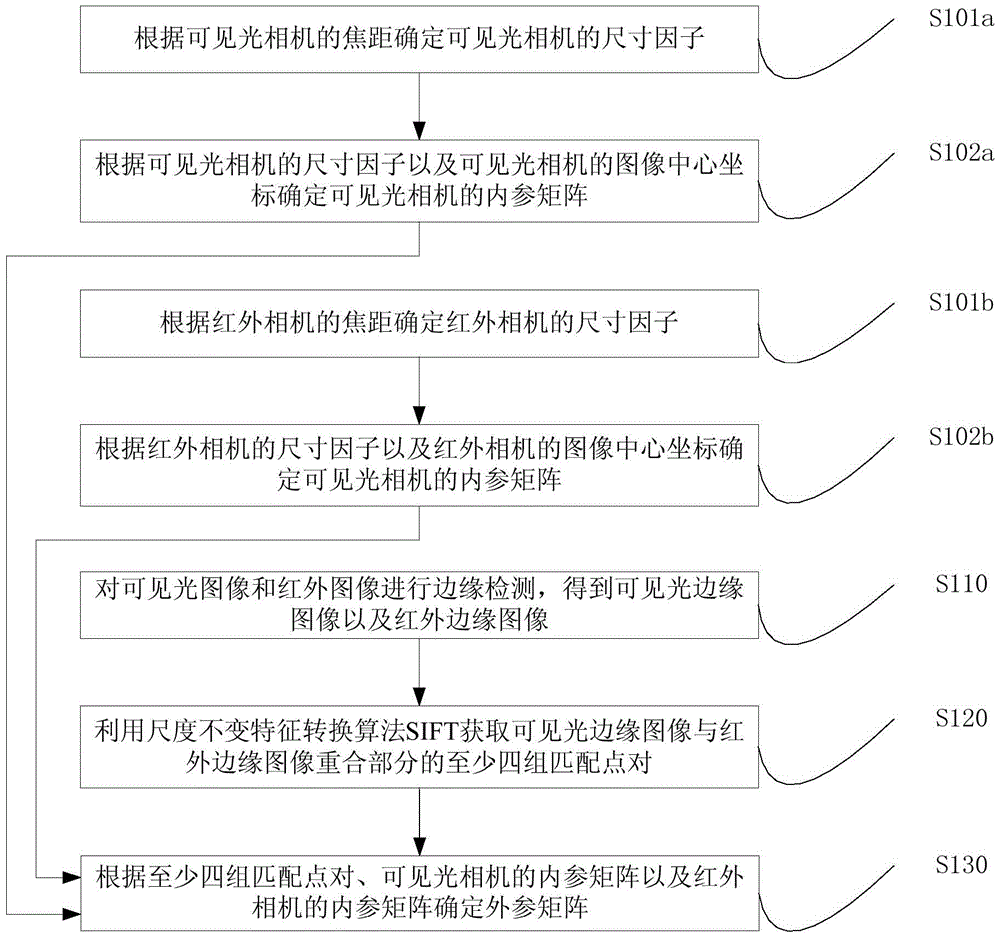

[0067] image 3 It is a flowchart of a joint calibration method for parameters of a visible light camera and an infrared camera provided in Embodiment 3 of the present invention. Optionally, at S130, according to the at least four sets of matching point pairs, the internal reference matrix of the visible light camera, and the Before the internal reference matrix of the infrared camera determines the external reference matrix, the method also includes:

[0068] S101a. Determine the size factor of the visible light camera according to the focal length of the visible light camera.

[0069] The size factors for visible light cameras include the u-axis size factor c x2 and v-axis size factor c y2 . u-axis size factor c x2 is the u-axis focal length f cx2 Divide by the v-axis focal length f cy2 . v-axis size factor c y2 is the v-axis focal length f cy2 divided by the u-axis focal length f cx2 .

[0070] S102a. Determine an internal reference matrix of the visible light ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com