Depth camera automatic calibration algorithm based on three-dimensional feature points

A depth camera and three-dimensional feature technology, applied in computing, complex mathematical operations, image data processing, etc., can solve the problems of being easily affected by the environment, complex solution process, and high calibration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

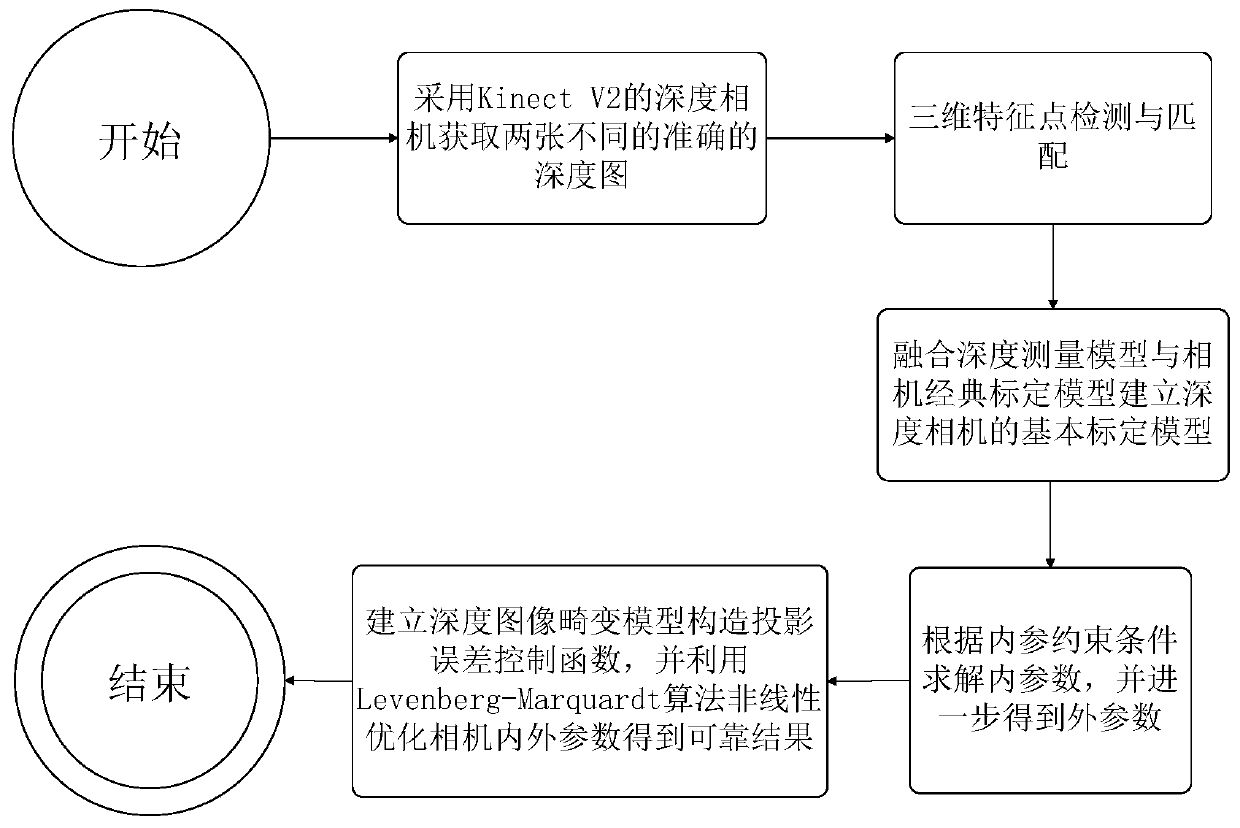

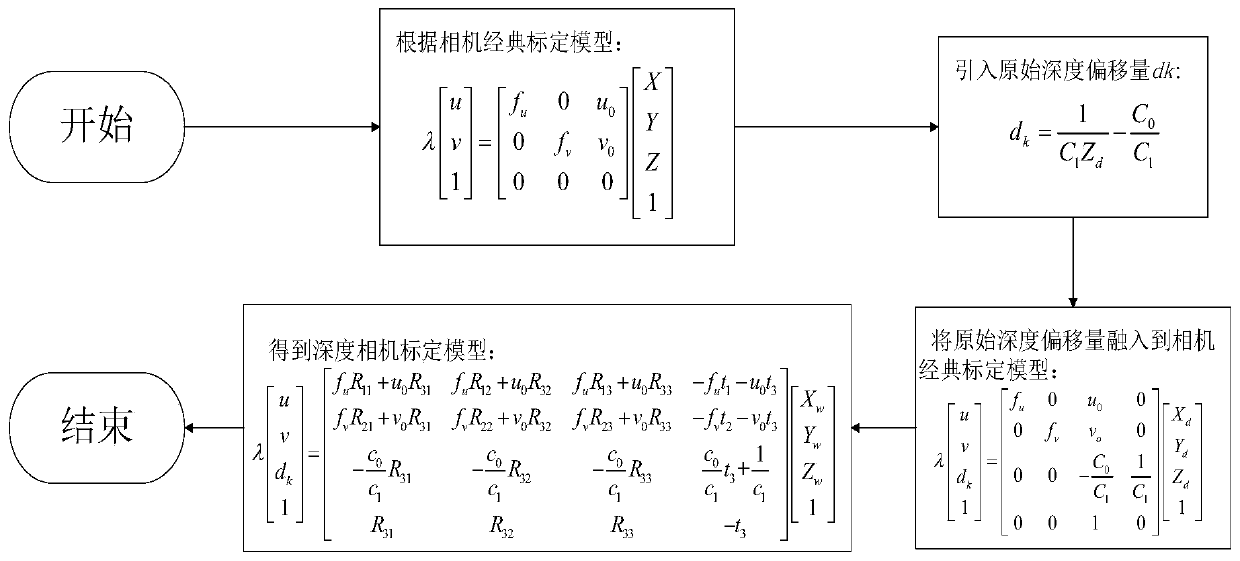

[0069] Attached below figure 1 to attach Figure 4 , the present invention will be described in further detail.

[0070] Reference attached image 3 , the depth camera calibration model mentioned in the present invention is firstly based on the classic camera calibration model, as follows:

[0071]

[0072] Then introduce an original depth offset d on the basis of the classic camera calibration model k , as follows:

[0073]

[0074] And, with [u v d k 1] T form a projective space coordinate. Projective space coordinates and space point coordinates [X w Y w Z w 1] T The relationship of conforms to the homography relationship between images, thus obtaining the matrix transformation from the depth camera coordinate system to the pixel coordinate system:

[0075]

[0076] Among them, λ=Z d ,Z d Indicates the coordinate component of the Z direction in the depth camera coordinate system, and the internal reference is A':

[0077] Finally, by combining the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com