Model-based gasoline engine calibration method

A calibration method and gasoline engine technology, applied in the field of gasoline engines, can solve the problems of complex calibration technology and expensive automatic calibration equipment, and achieve the effect of reducing calibration cost and calibration workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

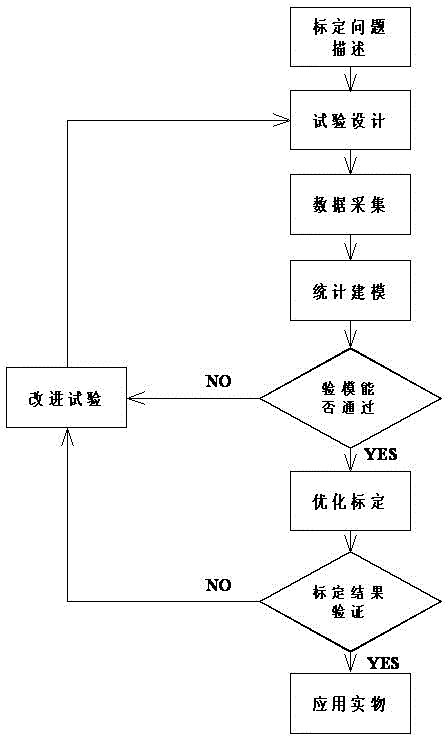

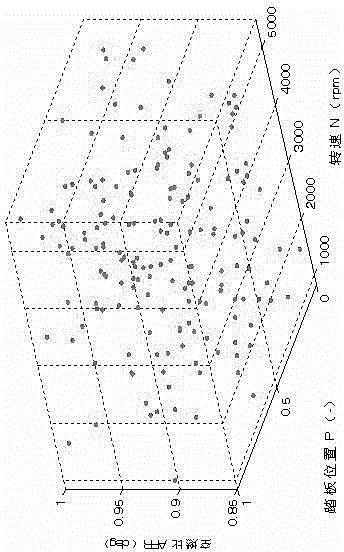

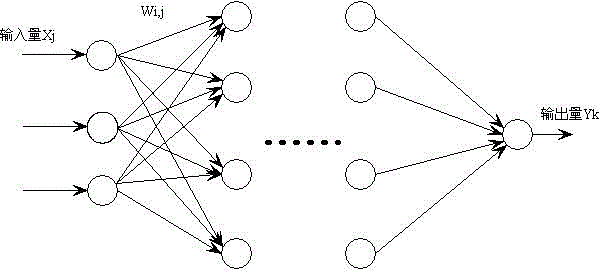

Method used

Image

Examples

Embodiment

[0117] Example: Optimizing and Calibrating the Ignition Advance Angle to Improve Engine Dynamics Experiment

[0118] The optimized optimal ignition advance angle replaces the original ignition advance angle to control the engine, and then compares the output torque before and after the optimized calibration to observe the degree of torque influence. Figure 12 Shown is the effect comparison structure diagram before and after optimization calibration. Among them, TESIS enDYNA is a high-fidelity virtual engine, and it is also the object of the optimization and calibration function of the present invention. The same working condition means that the input conditions are the same as the accelerator pedal position and the engine speed. The calibrated ignition advance angle and the ignition advance angle controller that comes with enDYDA are used to control the virtual engine respectively, and the output torque is compared.

[0119] Set the enDYNA engine in driving mode, given the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com