A self-inspection method based on electrode automatic production system

A production system and electrode technology, applied in the field of self-inspection based on an automated production system for electrodes, can solve problems such as equipment safety hazards, production stagnation, manual inspection, etc., to prevent failures or accidents, lower operating thresholds, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

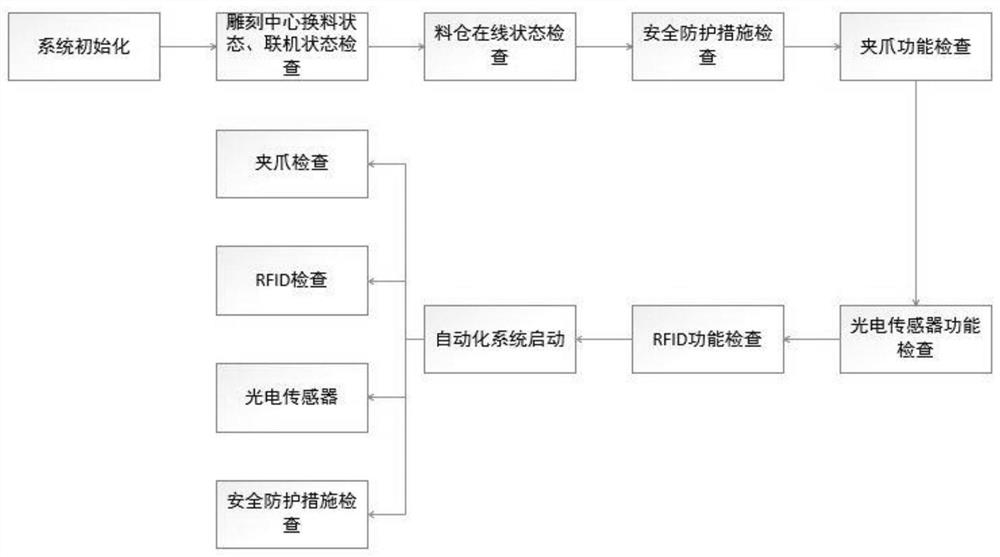

[0045] see figure 1 , a kind of self-inspection method based on electrode automatic production system of the present invention, comprises the following steps:

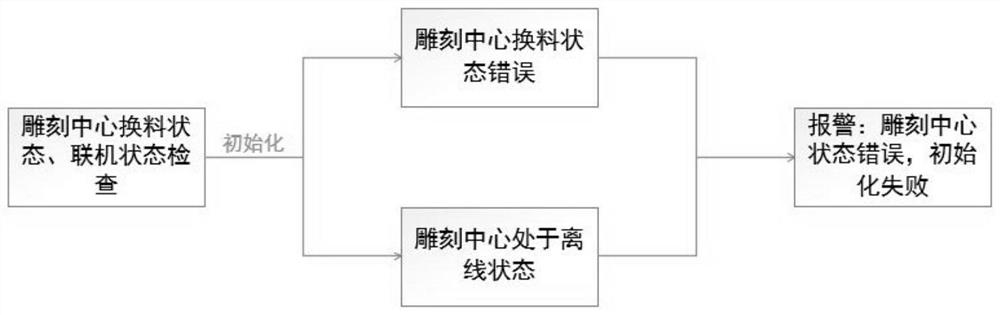

[0046] S1, engraving center refueling status, online status check

[0047]First check whether each engraving center is online, whether the XYZ three-axis is in the safe position for refueling when online, whether the automatic door is opened in place, whether the ITS chuck is opened in place, whether the air blowing on the positioning surface of the electrode chuck is turned on, and whether the engraving center Whether it is in standby state, whether the spindle is locked, and when the engraving center refueling state is wrong or offline, it will give an alarm, such as figure 2 shown;

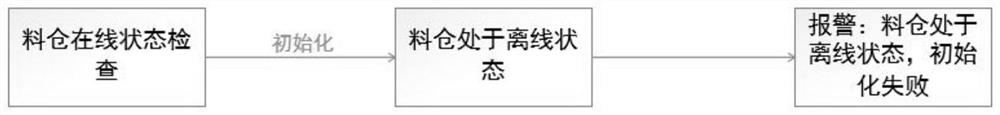

[0048] S2. Online status check of silo

[0049] Check whether the silo is online. The silo must be online during initialization. When the silo is offline, it cannot be initialized and an alarm will be given, such as image 3 shown;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com