Single-axle table calibration method for fiber optic gyro strapdown inertial navigation system

A strapdown inertial navigation and fiber optic gyroscope technology, applied in the field of navigation, can solve the problems of high price, inability to guarantee accuracy, troublesome installation (requires a foundation of three to five meters, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention is described in more detail below in conjunction with accompanying drawing example:

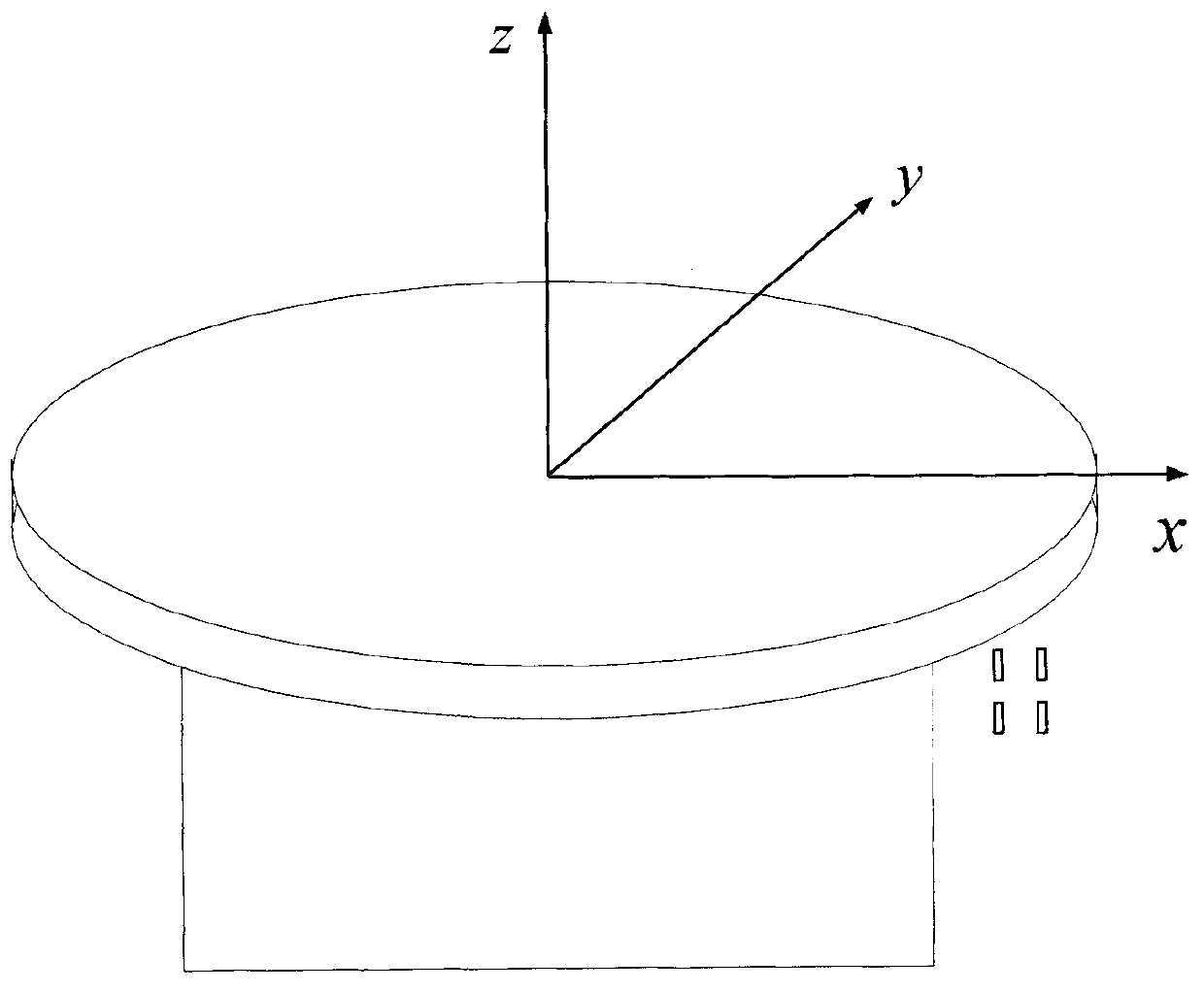

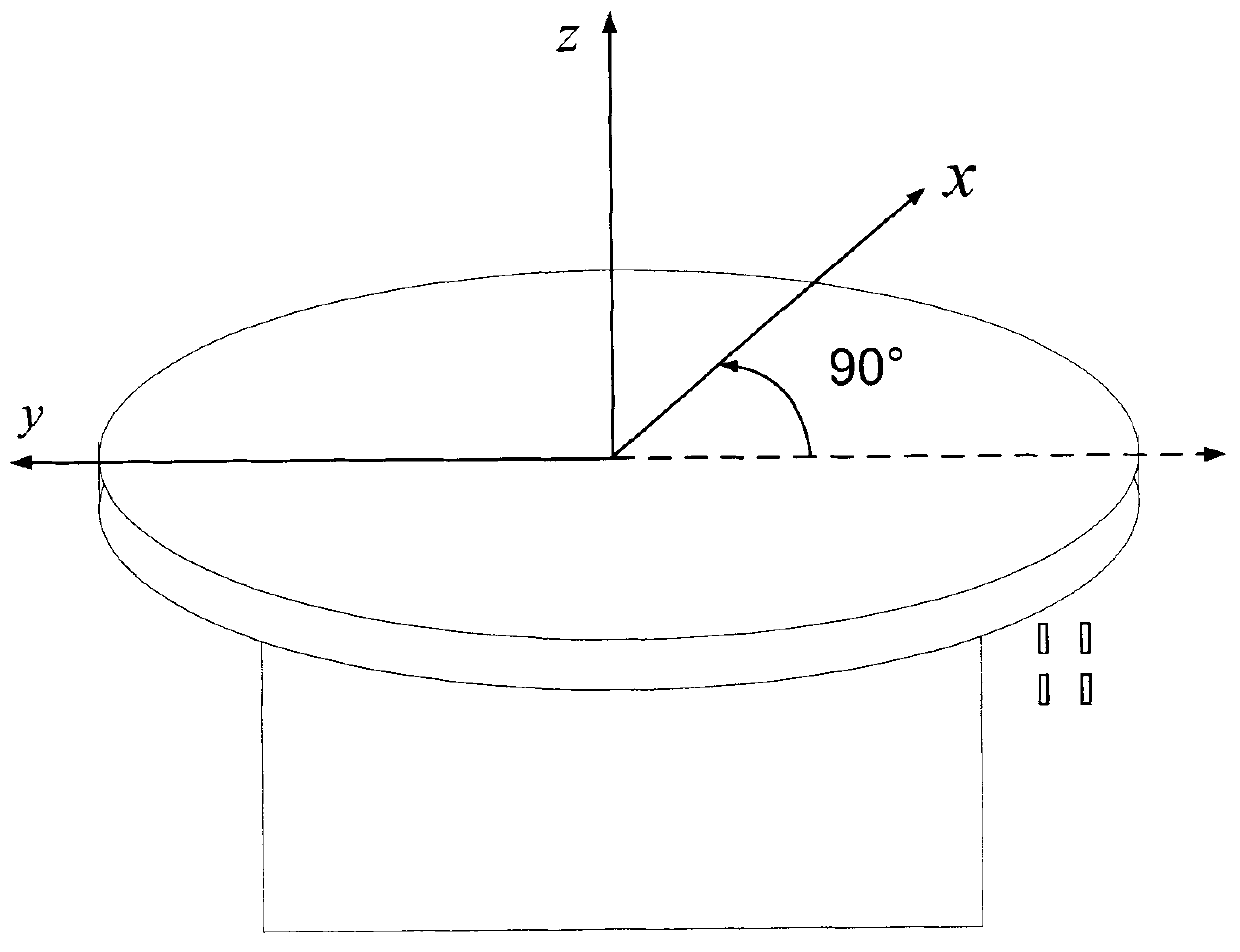

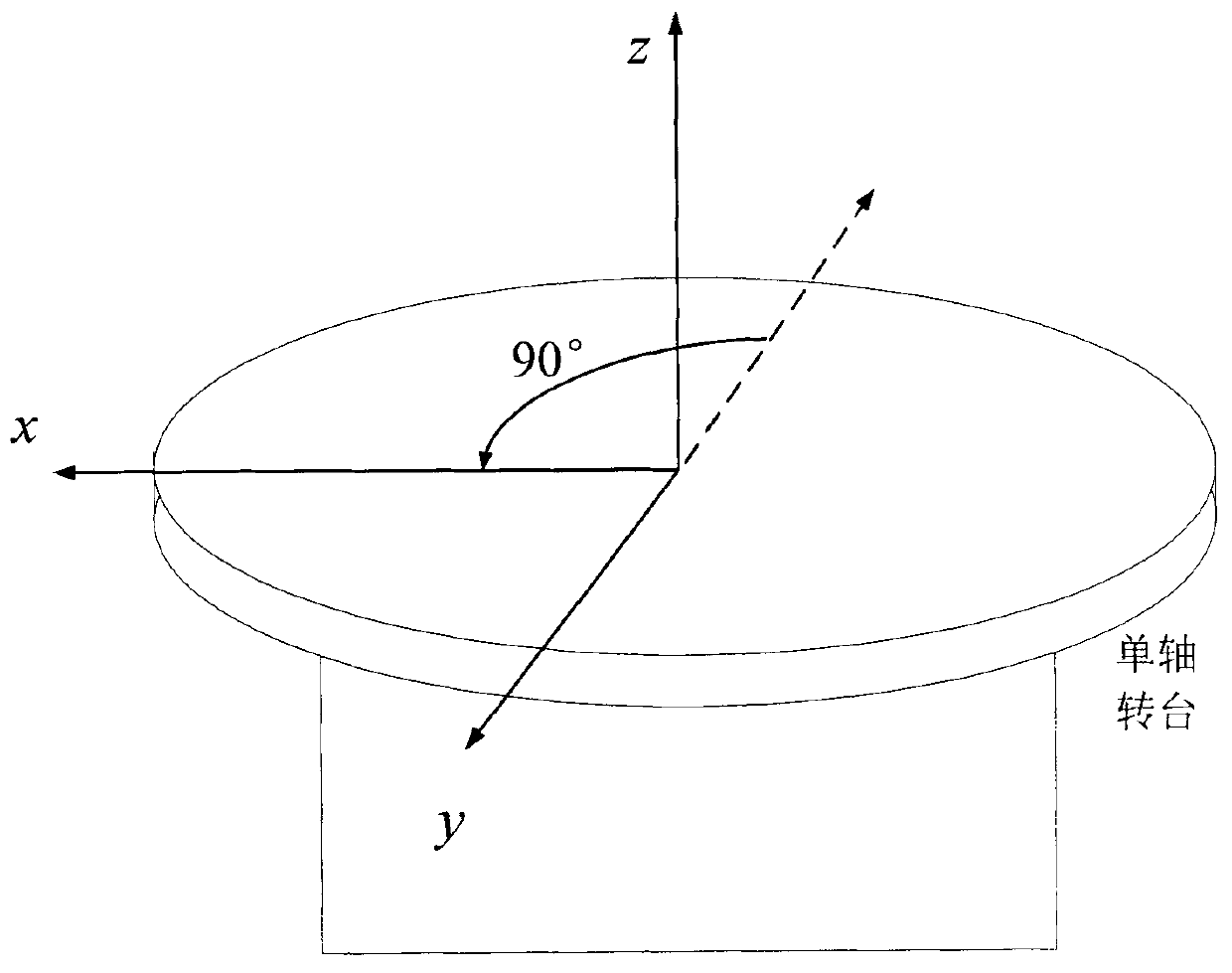

[0089] combine Figure 1~4 , a single-axis turntable calibration method for a fiber optic gyro strapdown inertial navigation system, which is characterized by:

[0090] (1) Place the fiber optic gyroscope strapdown inertial navigation system on a single-axis turntable, power on the fiber optic gyroscope strapdown inertial navigation system to preheat, and then collect the data output by the gyroscope and accelerometer;

[0091] (2) Record the position of the fiber optic gyro strapdown inertial navigation system at the initial moment as position a, such as figure 1 As shown, the angular velocity output by the fiber optic gyroscope within 300 seconds is collected at position a

[0092] ω a (1), ω a (2),... ω a (N)

[0093] Compared with the output of the quartz flexible accelerometer

[0094] f a (1), f a (2),... f a (N),

[0095] in h is the sampling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com