Universal disk type gear M value detecting device

A detection device and gear technology, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of disk gears being unable to detect M values, etc., and achieve the effect of reducing measurement errors, avoiding errors, and convenient and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

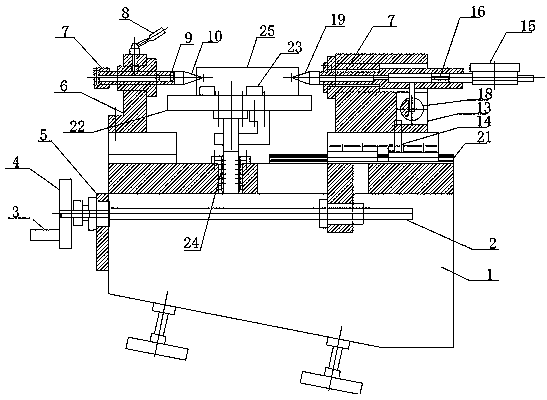

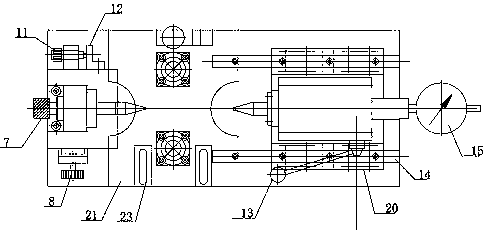

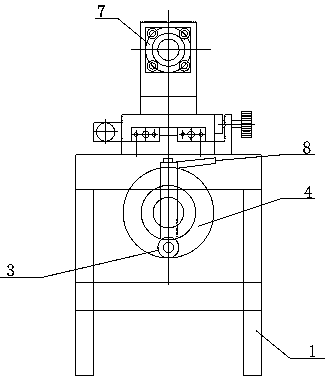

[0018] Such as Figures 1 to 3 As shown, the present invention proposes a general-purpose disc gear M value detection device, including a checker seat 1, and three modules of a fixed seat 6, a sliding seat 13, and a measuring platform 22 are installed on the upper end of the tester seat 1, and the fixed seat 6 passes through the Bolts are fixed on the upper left side of the inspection tool base 1, the sliding seat 13 is set on the upper right side of the inspection tool base 1 through the slide rail 21, the measuring platform 22 is installed on the upper end of the middle section of the inspection tool base 1 through the lifting screw 24, and the inspection tool base 1 is provided with Screw mandrel 2, the other end of the sliding seat 13 connected to one end of the screw mandrel 2 is provided with a hand wheel handle 3, a hand wheel disc 4, and a screw locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com