Patents

Literature

34results about How to "Avoid Human Measurement Errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

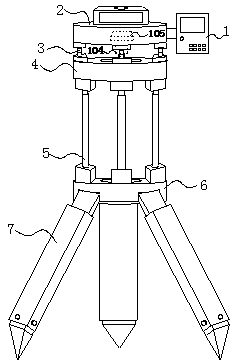

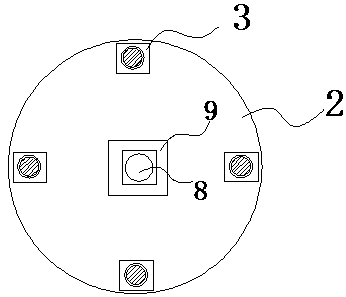

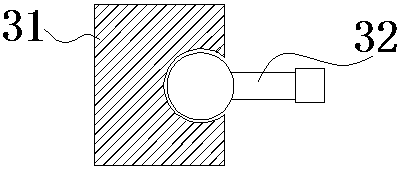

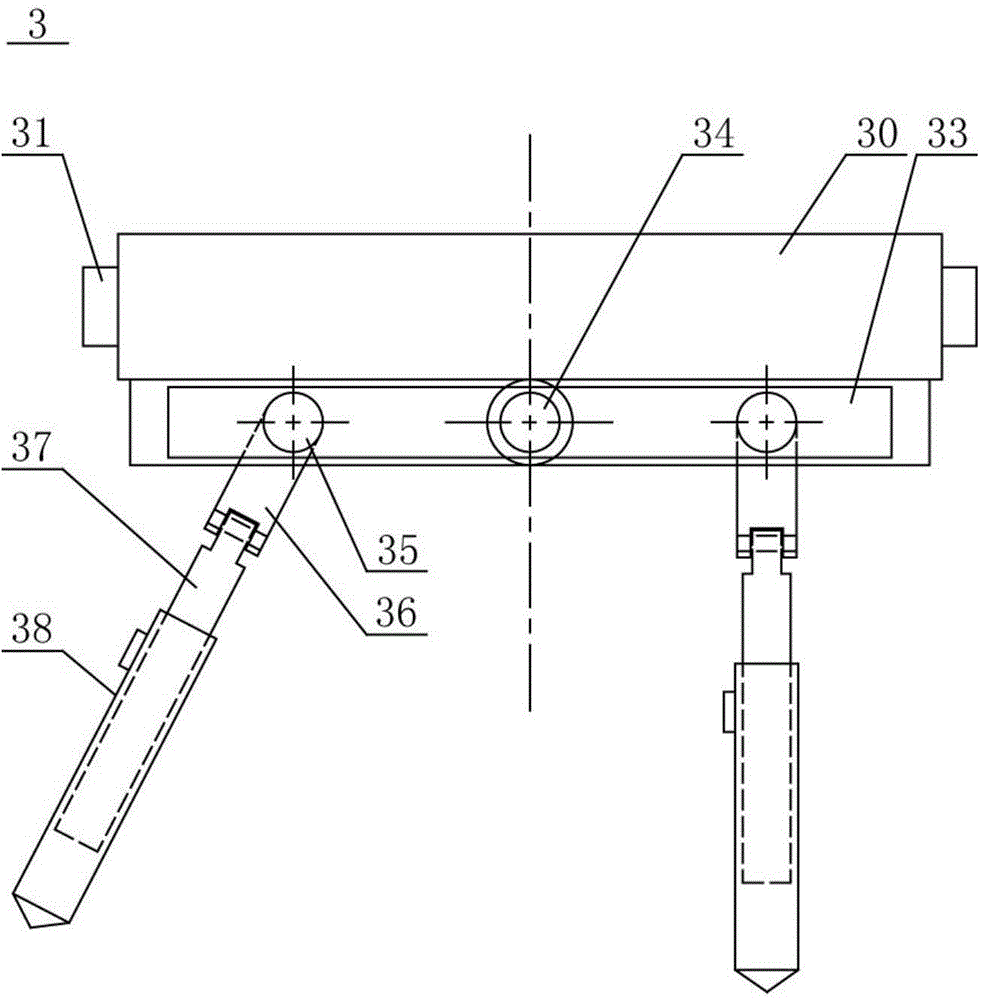

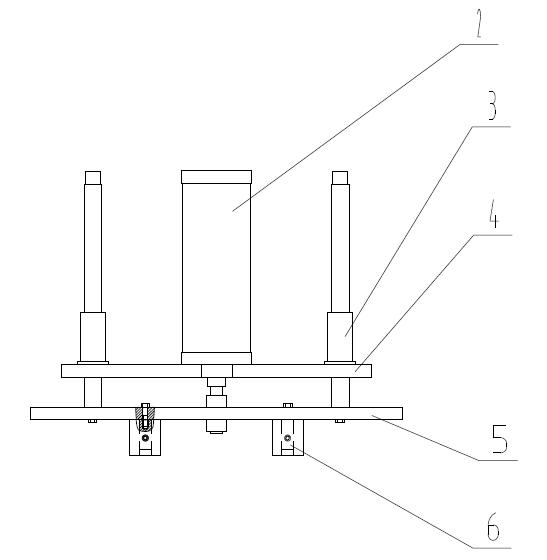

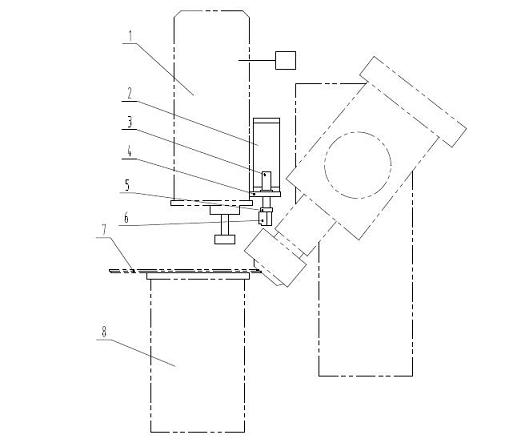

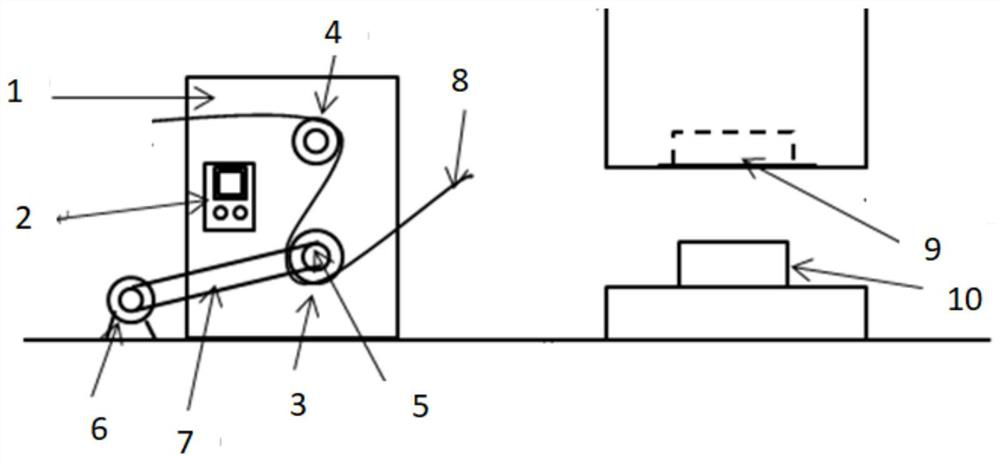

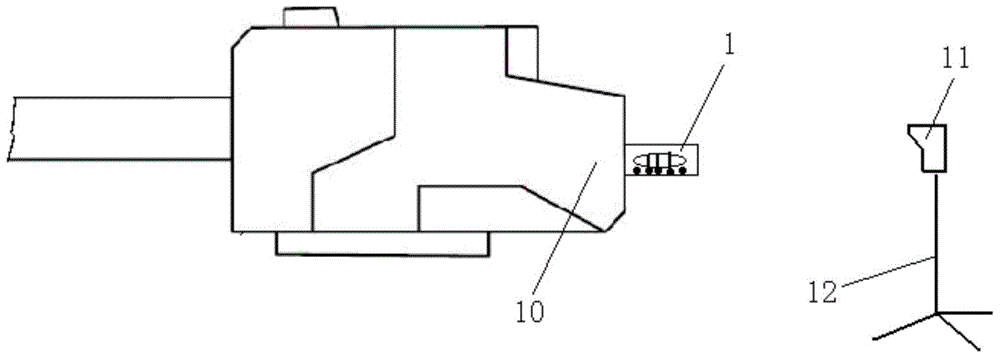

Foot stand for automatic leveling and instrument height measuring

PendingCN109555955AEasy to use and accurate measurementAvoid Human Measurement ErrorsStands/trestlesControl using feedbackLaser rangingAutomatic control

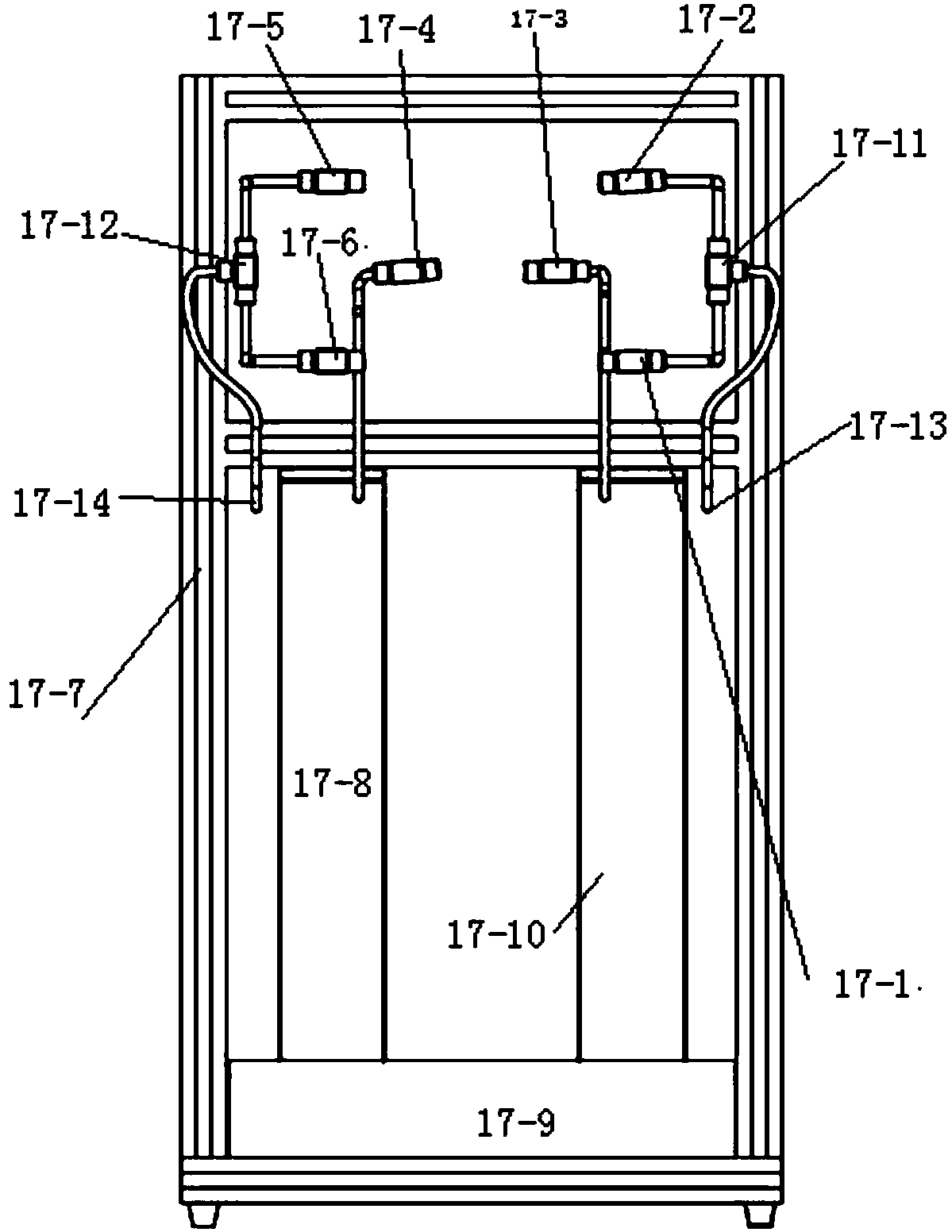

The invention discloses a foot stand for automatic leveling and instrument height measuring. The foot stand comprises a control terminal, a fixed base, a short electric telescopic rod, an upper support, a long electric telescopic rod, a lower support, supporting legs, a laser ranging module, a horizontal inclination angle sensor, a control unit, a lithium battery and a power supply module. The horizontal inclination angle sensor and the laser ranging module are used for measuring the levelness and height of a supporting frame, and the heights and levelness of a plurality of electric telescopicrods can be automatically controlled, so that system errors caused by manual instrument height measurement and levelness adjustment in the prior art is reduced.

Owner:青海煤炭地质勘查院

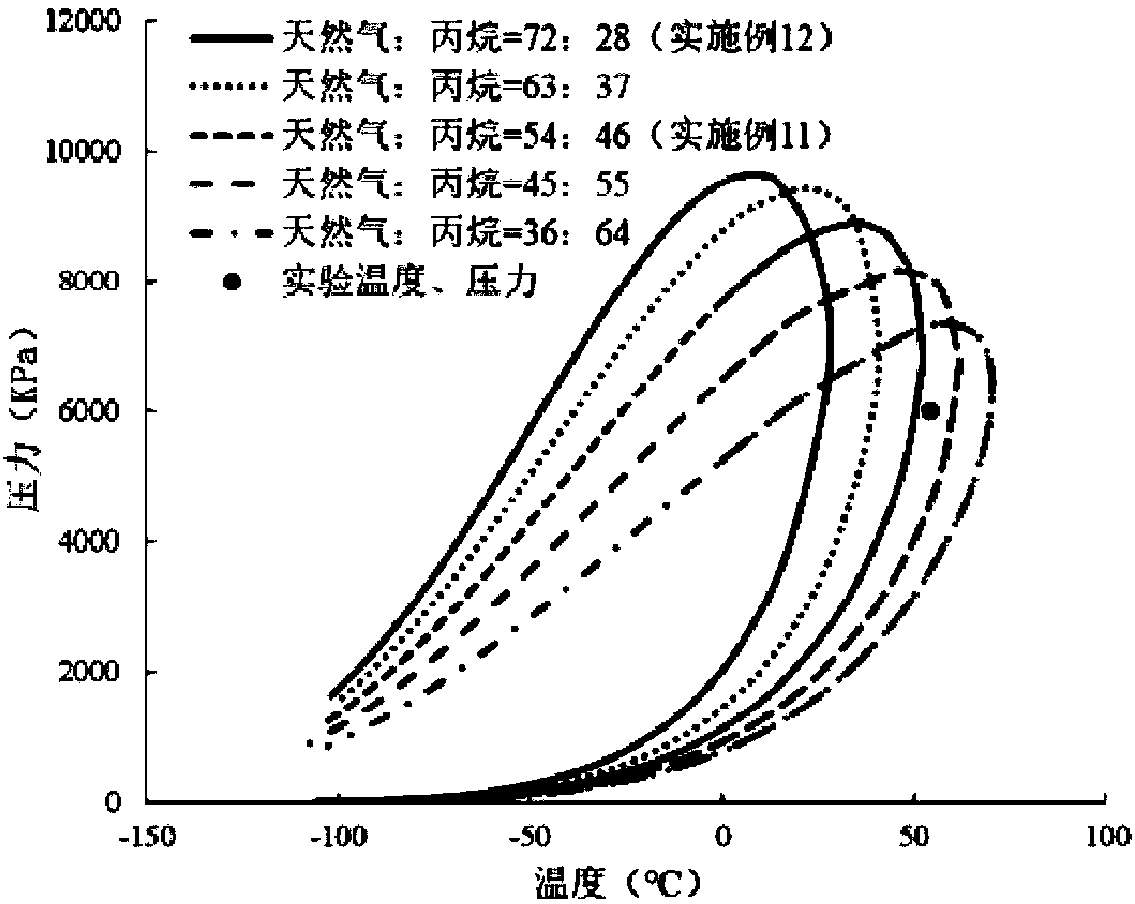

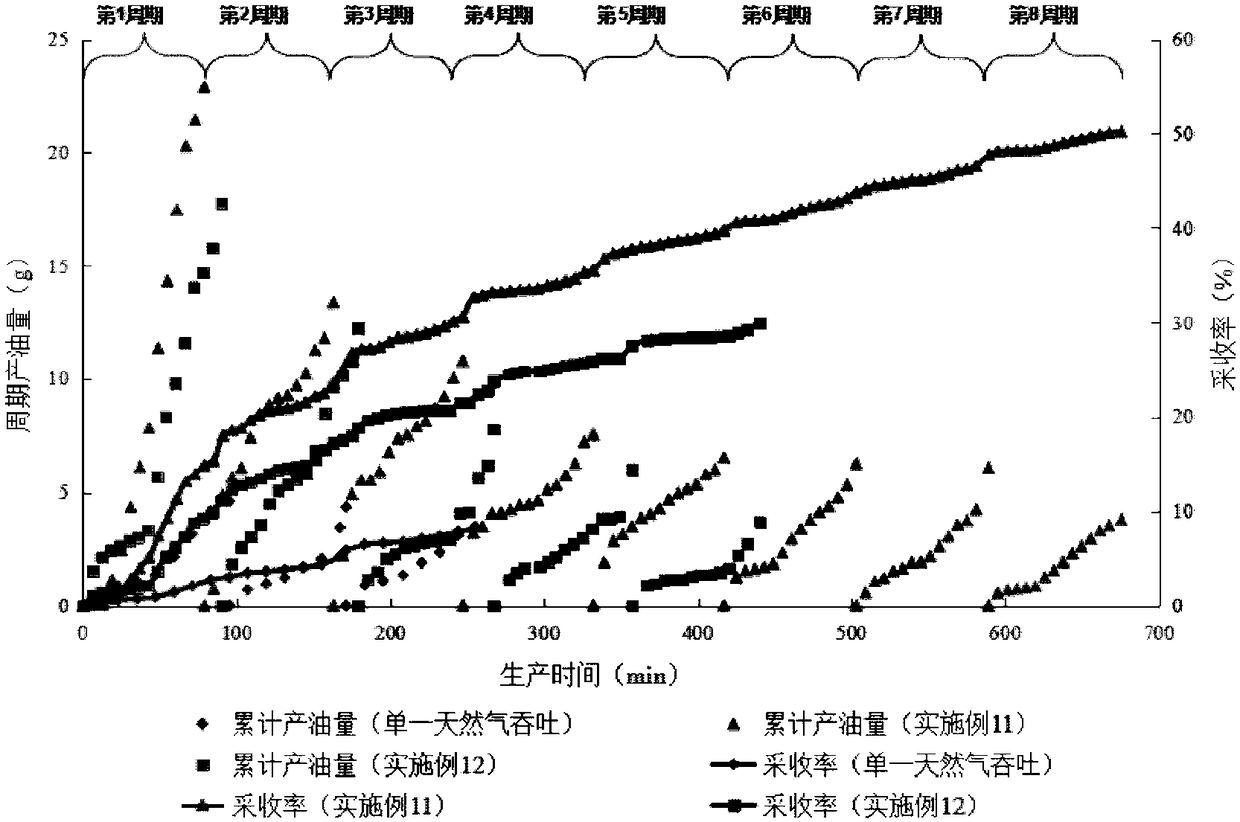

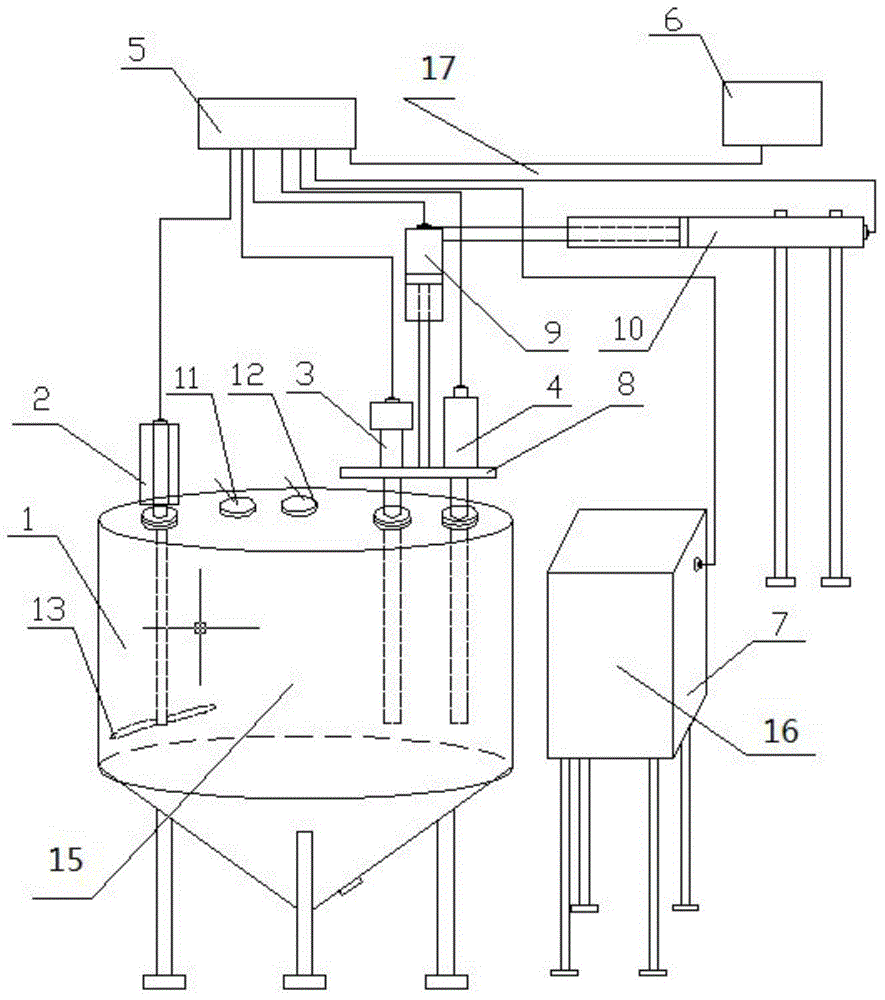

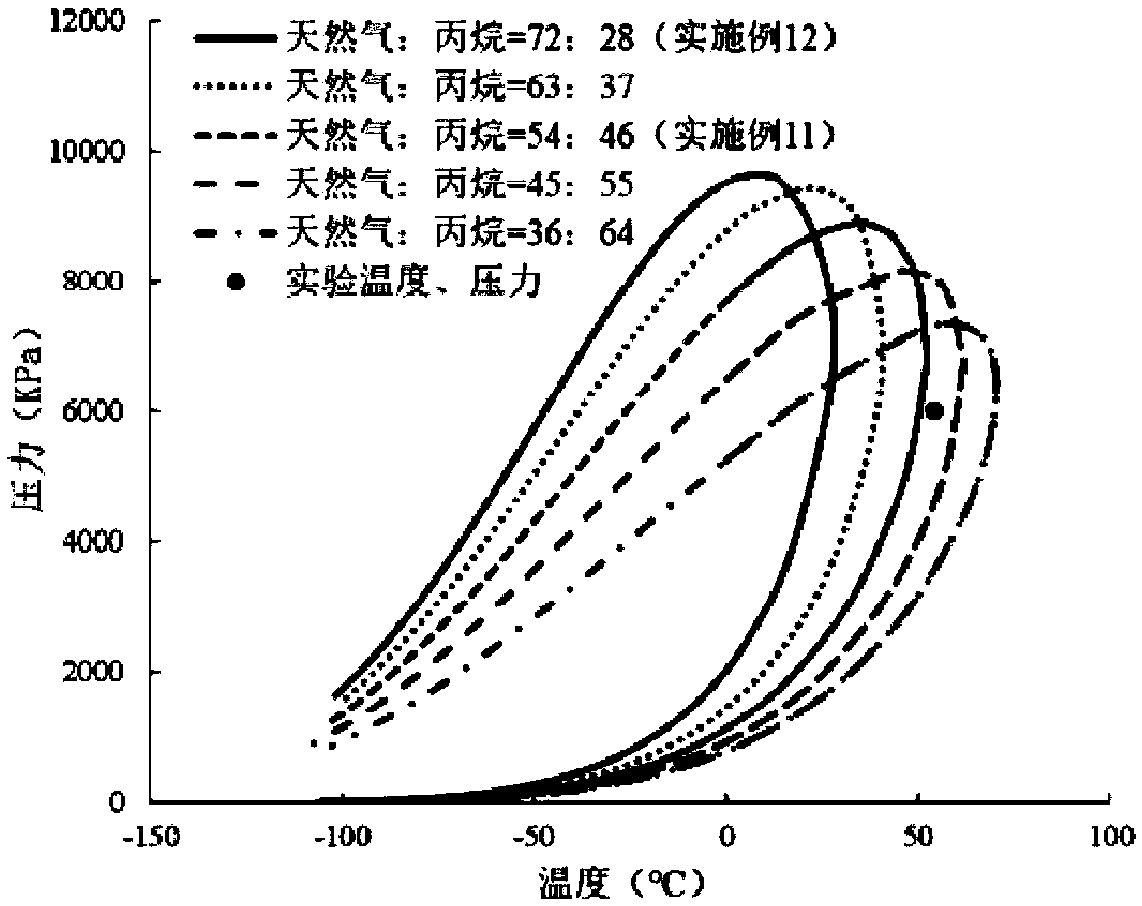

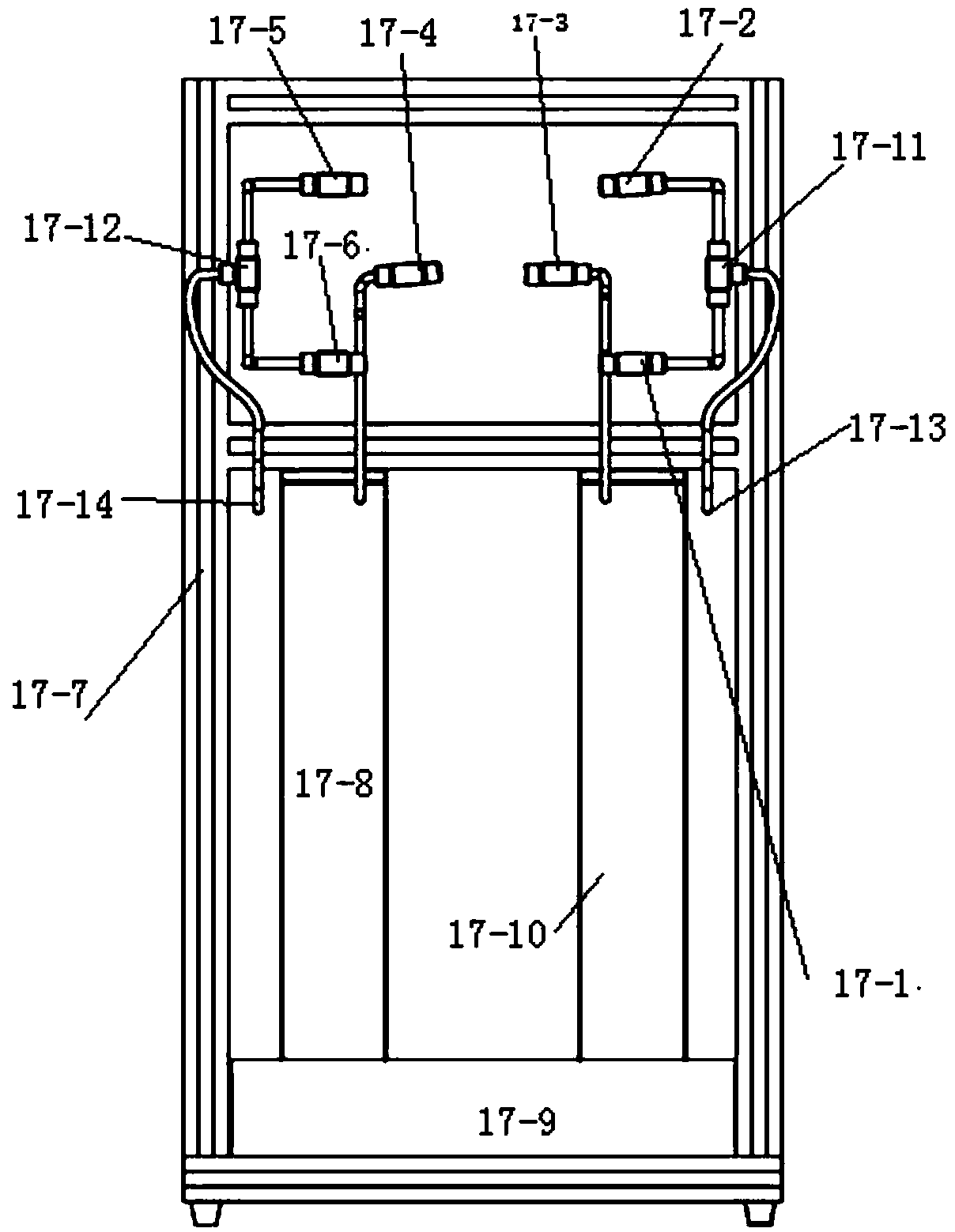

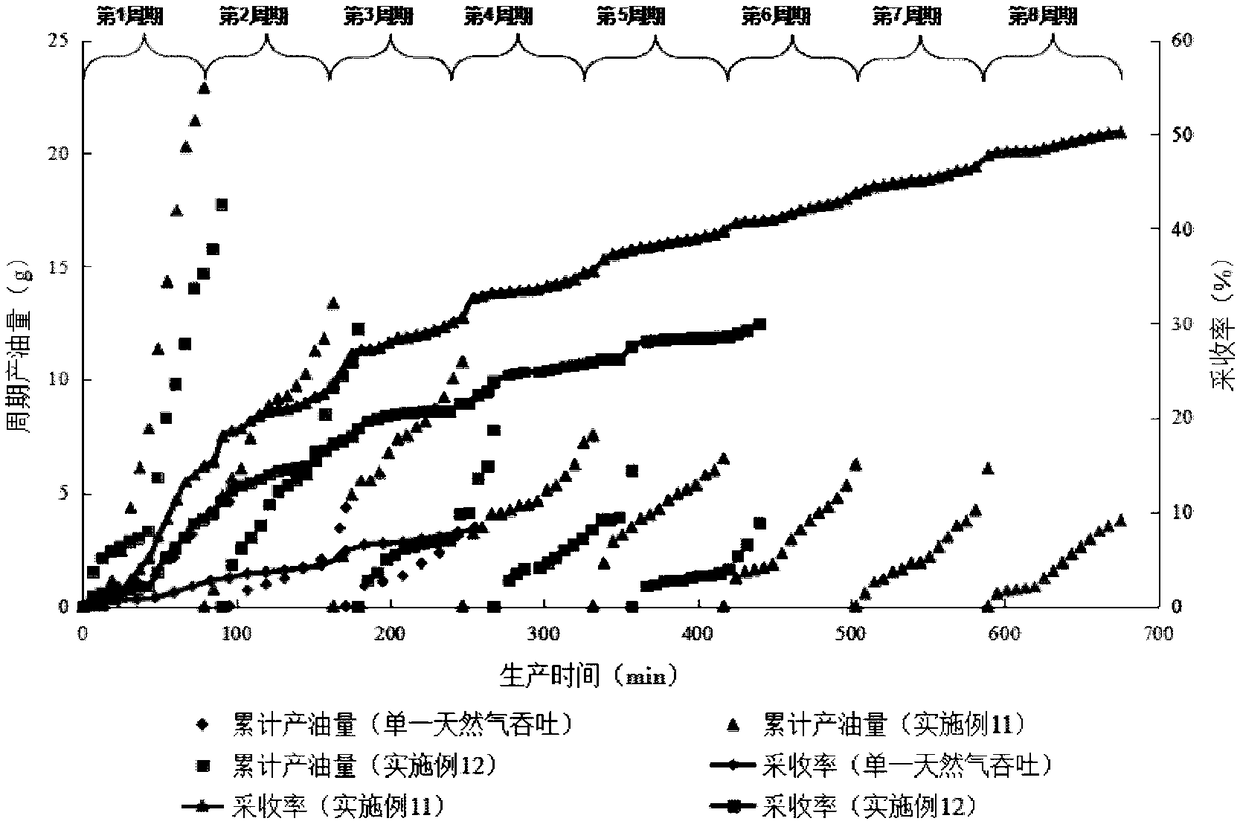

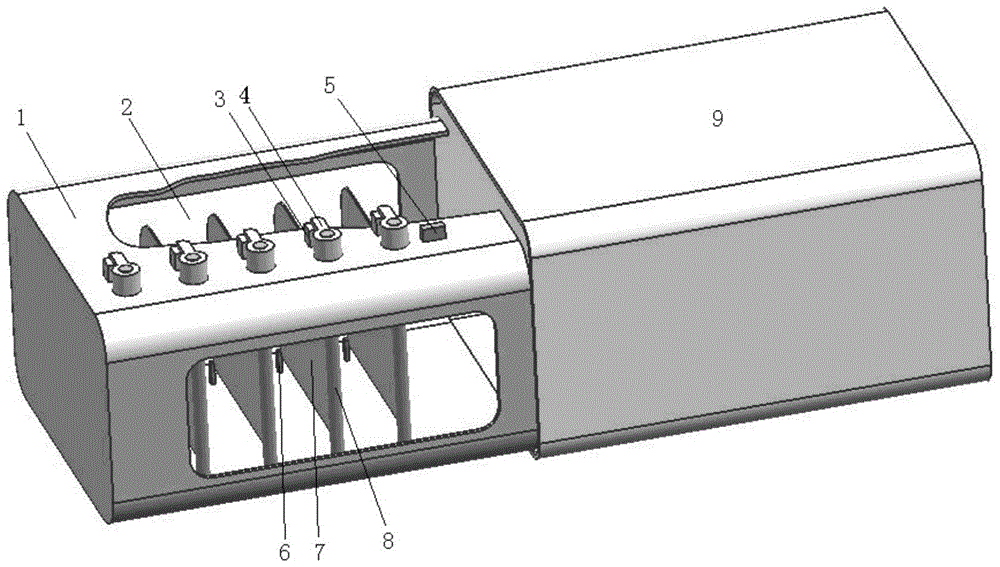

Complex heavy oil reservoir oil solubility foaming agent intensified mixed gas huff-puff experimental equipment and application method thereof

ActiveCN108071390AEnhanced Oil RecoveryEnhanced overall recoverySurveyFluid removalSolubilityFoaming agent

The invention discloses complex heavy oil reservoir oil solubility foaming agent intensified mixed gas huff-puff experimental equipment. The mixed gas is natural gas and propane which have better dissolution and viscosity-breaking effects compared with the natural gas, CO2 or CH4 and other single light component gas, the propane gas can be effectively prevented from liquefaction, so that the propane gas consumption can be reduced, and the propane gas use cost is reduced. In addition, an oil solubility foaming agent is matched with the mixed gas to generate artificial foam oil to reduce the speed of gas output during the huff-puff period, and the heavy oil viscosity can be reduced, so that the problem that the recovery efficiency of existing complex heavy oil reservoir is not high can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

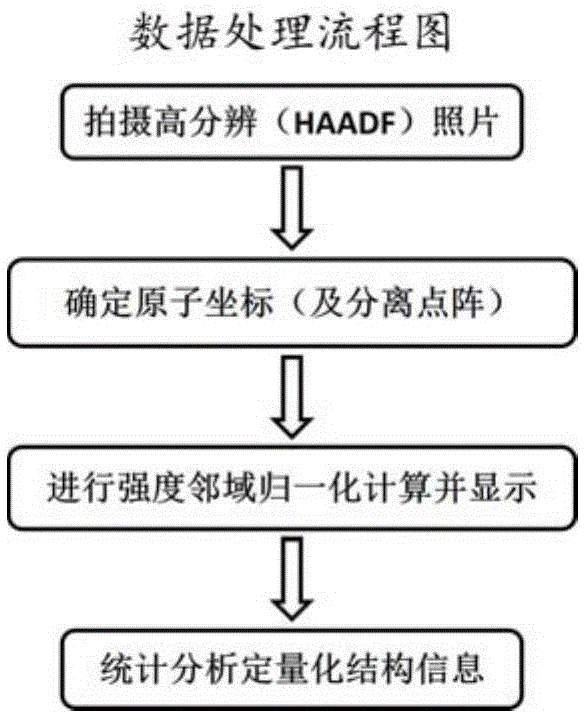

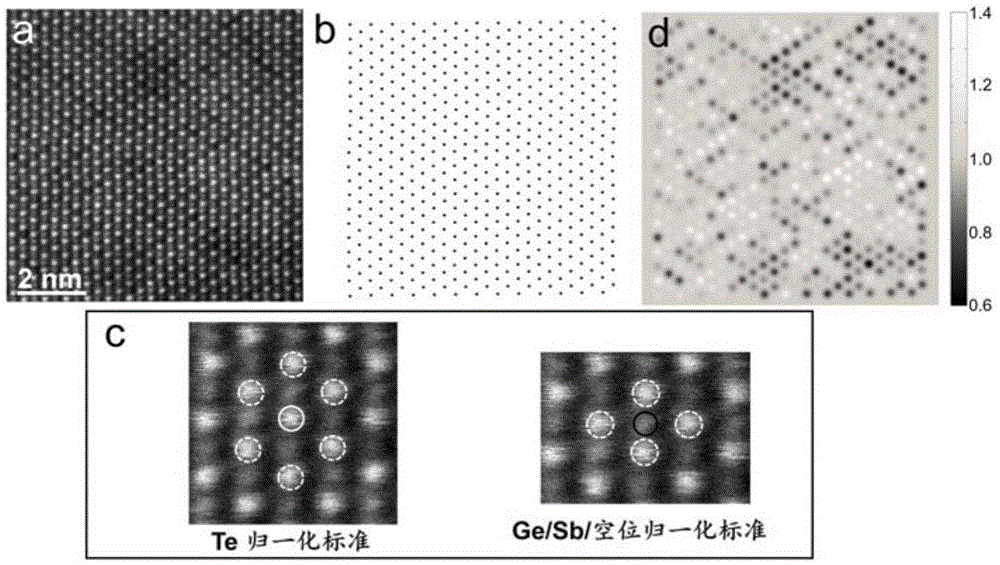

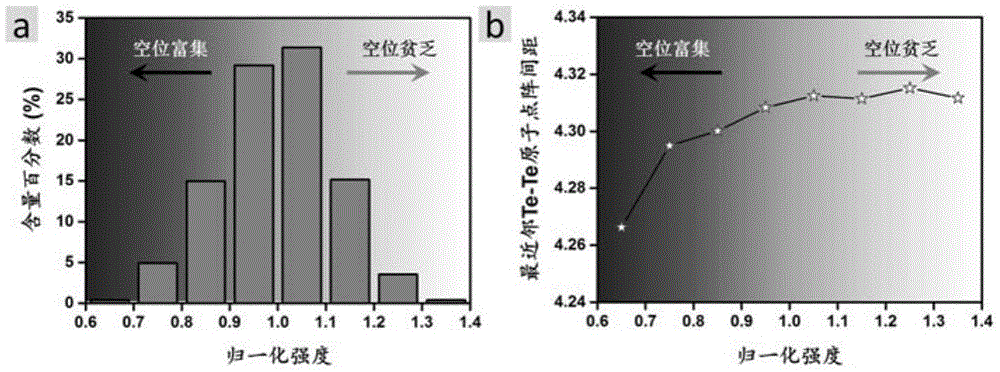

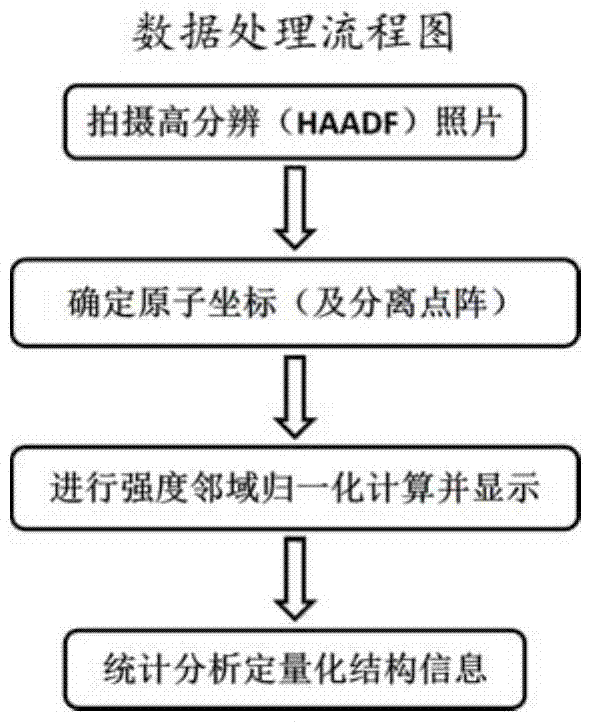

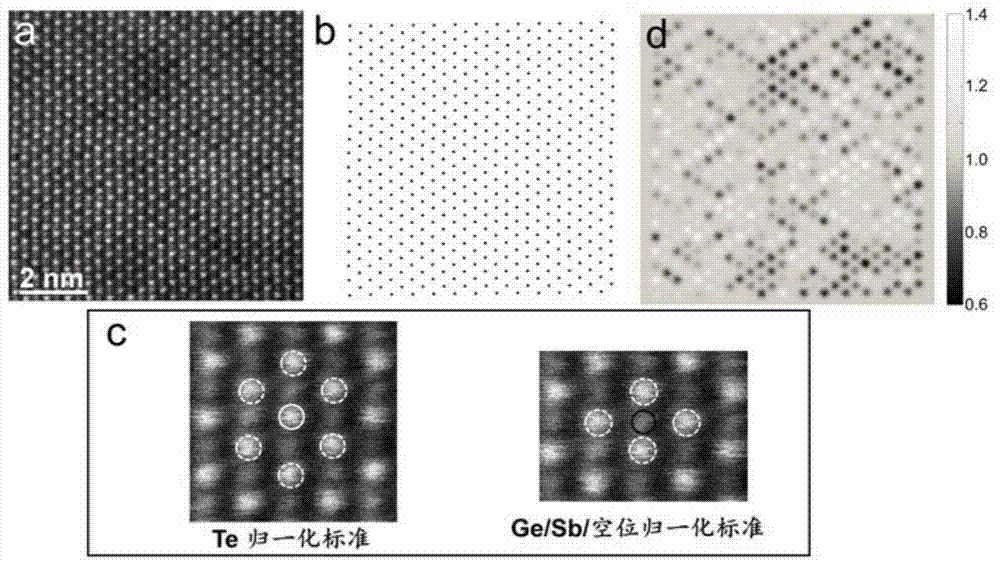

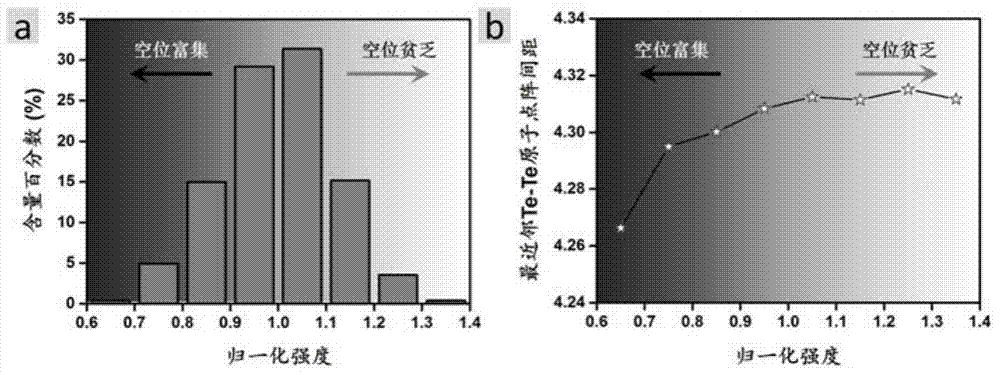

Material structure quantitative analysis method based on transmission electron microscope HAADF image

InactiveCN105527461AAvoid workloadAvoid errorsScanning probe techniquesStatistical analysisOperability

The invention provides a material structure quantitative analysis method based on a transmission electron microscope HAADF image. The method is characterized by obtaining the coordinate position of each atom lattice in a transmission electron microscope high-resolution image through the image processing technique to obtain integral intensity of each atom and neighbourhood normalized intensity; and by fully combining the relation between HAADF imaging principle and intensity information, obtaining some quantitative information on the basis of qualitative research of the HAADF image. Through the data of the atomic lattice coordinates and normalized intensity and the like, a plurality of quantitative structure information can be obtained through analysis. In the method, the determination of the atom lattice coordinates and integral intensity is scientific and reasonable; application of the neighbourhood normalized intensity avoids the influence due to the case that the material (especially the polycrystal nanometer material) has larger range of structure fluctuation and defects; and the structure information can be summarized and analyzed quickly, and enormous workloads and errors due to manual measurement are prevented. The method has the advantages of accurate result, wide application range and high operability and the like.

Owner:BEIJING UNIV OF TECH

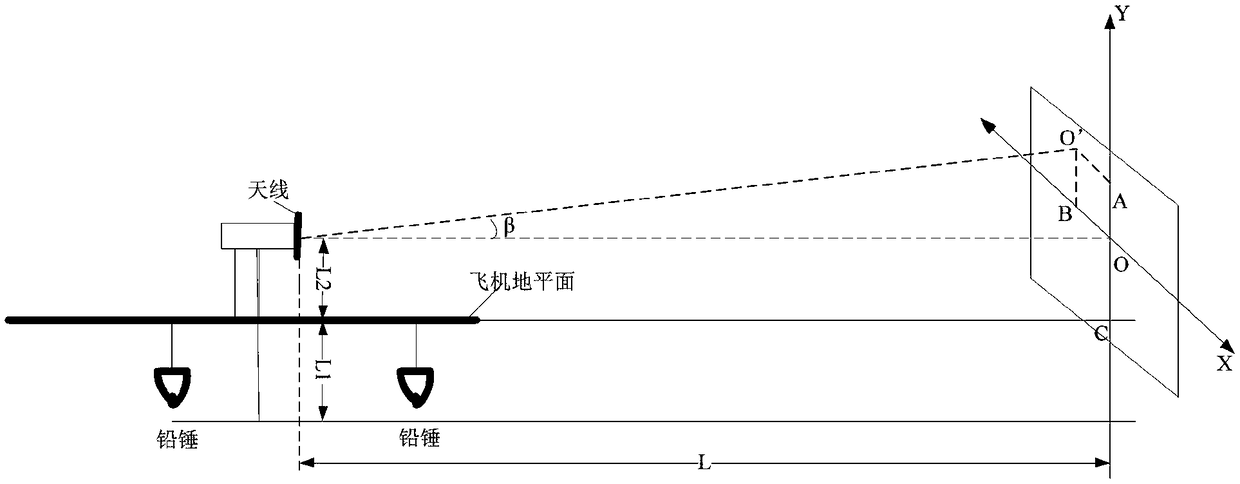

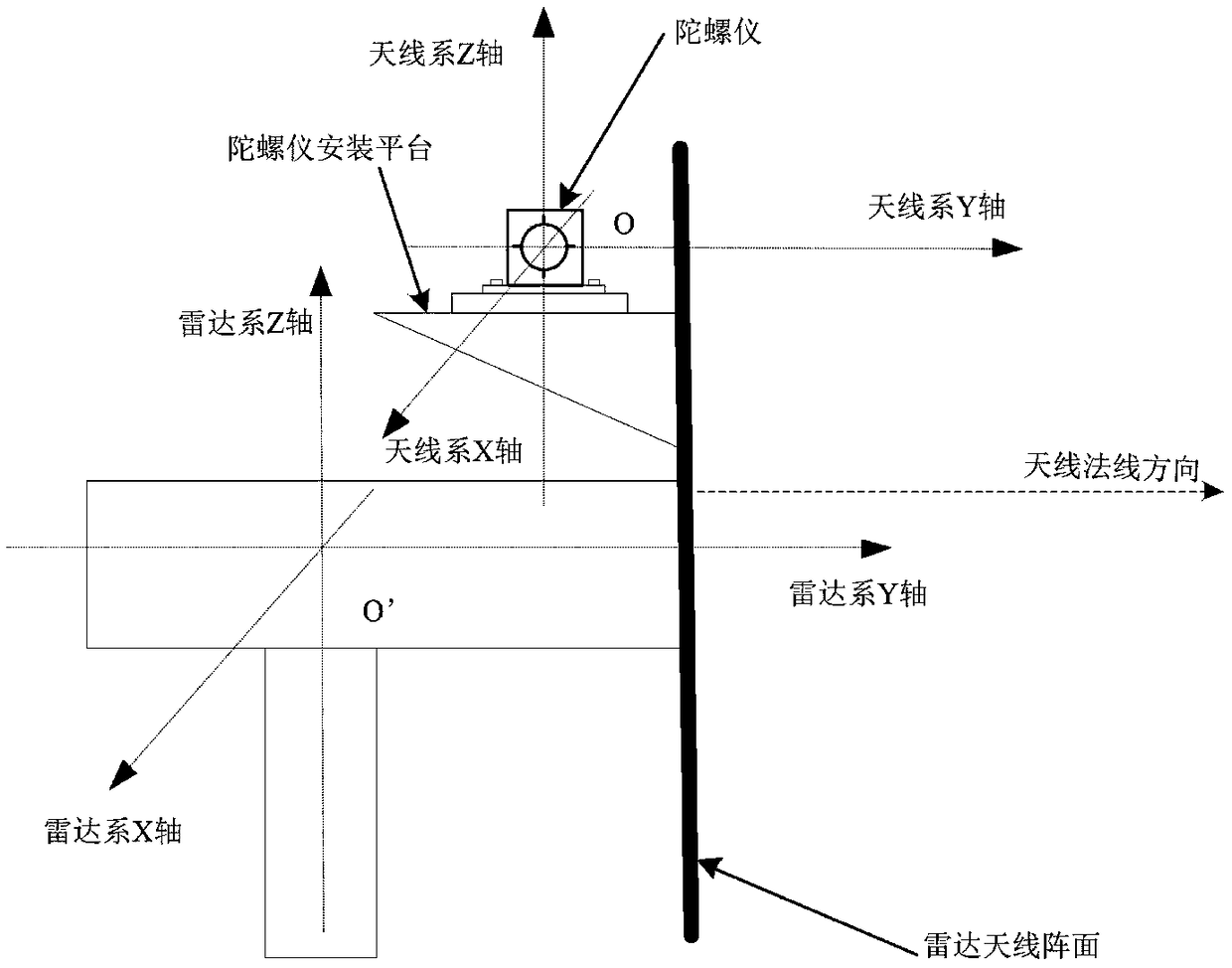

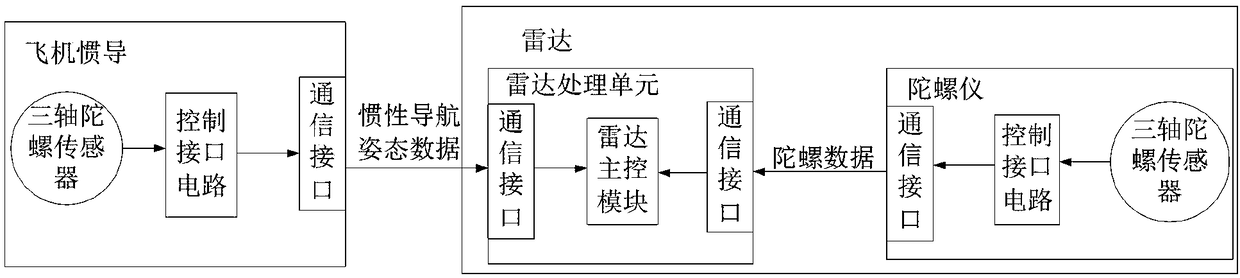

Automatic radar boresighting method based on gyroscope

ActiveCN109212495AReduce cost of measurementImprove production and assembly efficiencyWave based measurement systemsNavigation by speed/acceleration measurementsGyroscopeRadar

The invention relates to an automatic radar boresighting method based on a gyroscope. The method comprises the following steps of obtaining attitude information of the gyroscope, wherein the attitudeinformation of the gyroscope comprises a roll angle, a pitching angle and a course angle of a radar antenna; obtaining attitude information of aircraft inertial navigation, wherein the attitude information of the aircraft inertial navigation comprises a roll angle, a pitching angle and a course angle of an aircraft; comparing difference values of the attitude information of the gyroscope and the attitude information of the aircraft inertial navigation by taking the attitude information of the aircraft inertial navigation as a reference; and calculating boresighting data of a radar according tothe difference values, wherein the boresighting data comprises an azimuth error and a pitching error of the radar. According to the automatic radar boresighting method, the automatic boresighting function of the radar can be achieved, and the boresighting precision is high, so that the measurement precision of the radar is improved.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

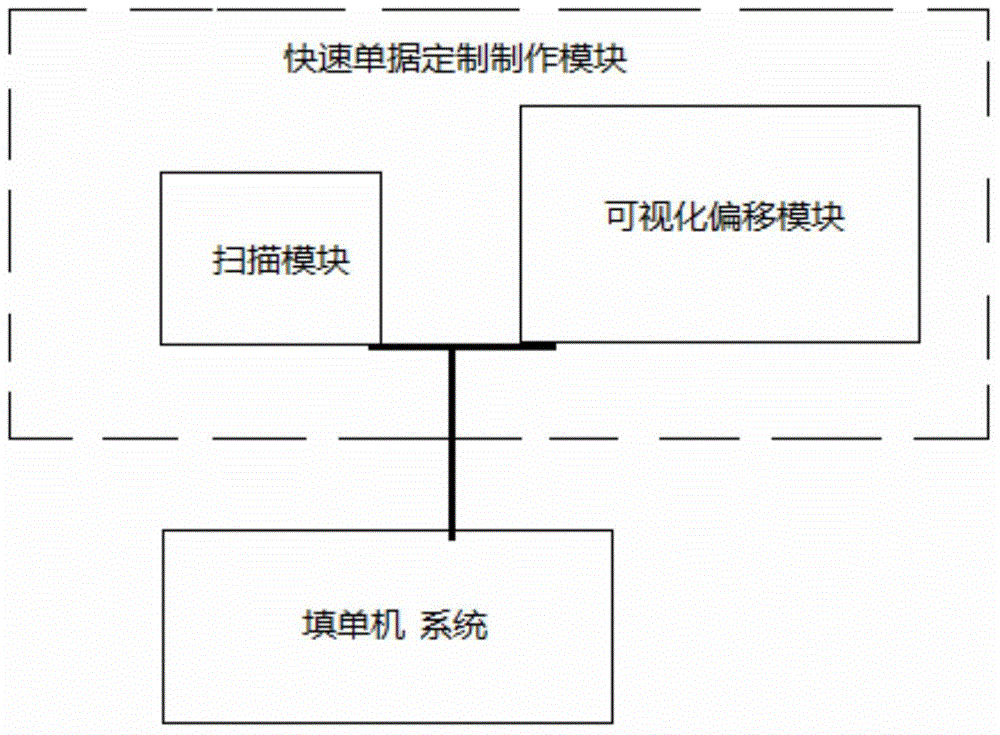

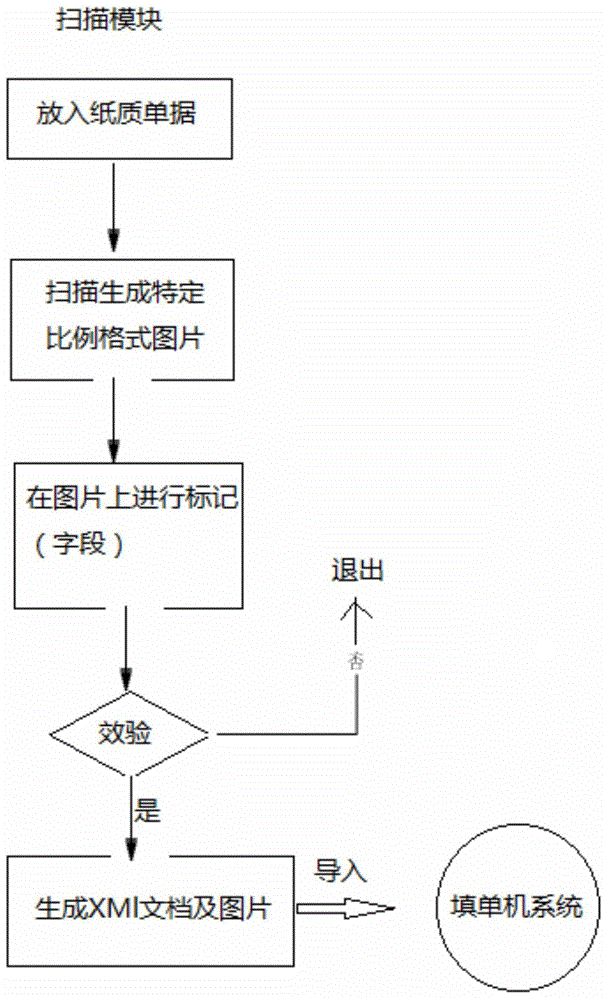

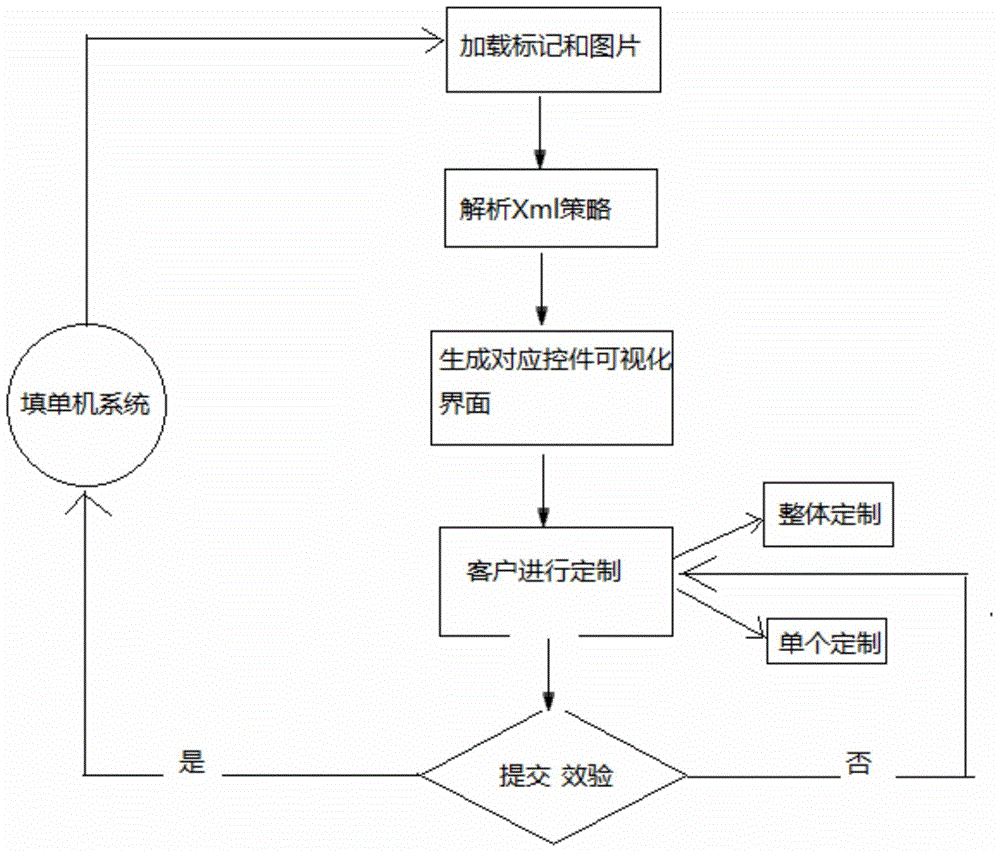

Self-service form filling machine capable of quickly customizing receipts on site and self-service form filling method

ActiveCN104484318ARealize visualizationAutomatically generate data to test printing effectSpecial data processing applicationsComputer moduleSelf-service

The invention relates to a self-service form filling machine capable of quickly customizing receipts on site and a self-service form filling method. A receipt customizing module is embedded in a system of the form filling machine and comprises a scanning module and a visual skewing module; the scanning module is used for scanning a picture of a receipt required to be customized; printing fields which are required to be configured are marked on corresponding positions of the scanned picture; the scanned picture is loaded in the system of the form filling machine; the ratio of the scanned picture to a material object is 1:1; the visual skewing module is used for receiving and loading the scanned picture and mark data in the system of the form filling machine; corresponding dynamic widgets are generated according to the mark data; the positions of the dynamic widgets are adjustable; the positions of the adjusted dynamic widgets can be recorded and stored; and the data of the adjusted scanned picture and the data of the adjusted dynamic widgets are transmitted to the system of the form filling machine. By the self-service form filling machine capable of quickly customizing the receipts on site and the self-service form filling method, a method of calculating coordinates manually by using a scale is omitted, and the coordinates can be automatically calculated on an interface automatically in a dragging manner.

Owner:NANJING AOTO ELECTRONICS CO LTD

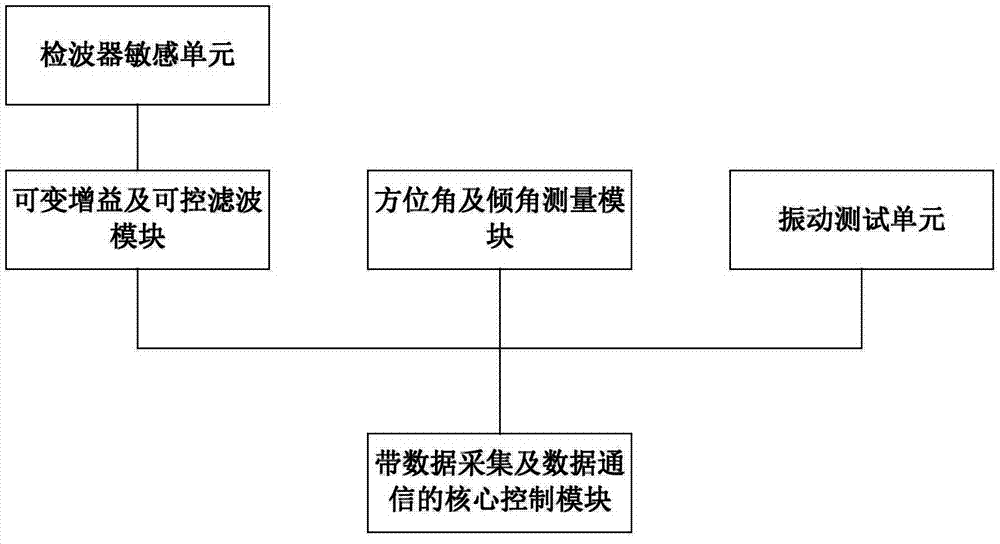

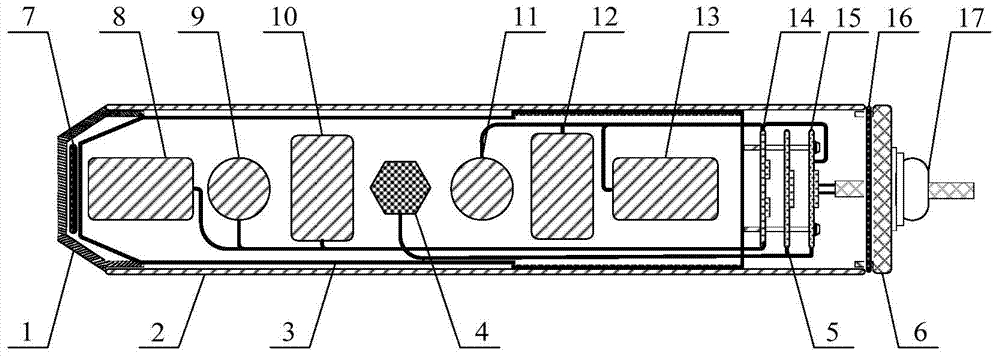

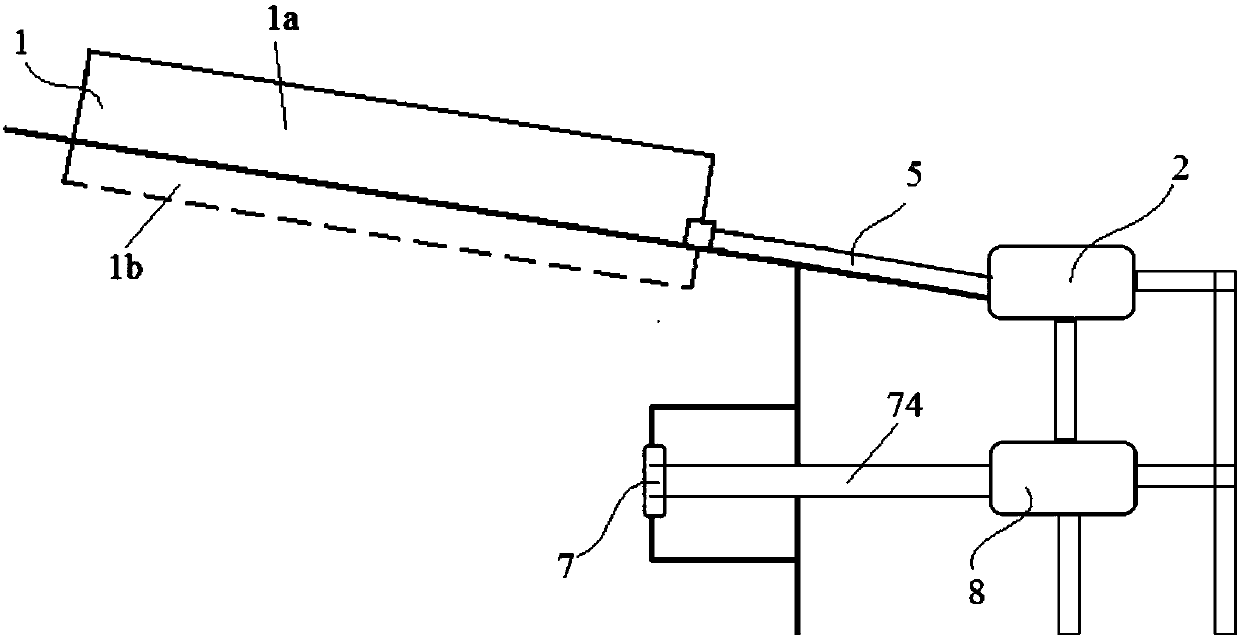

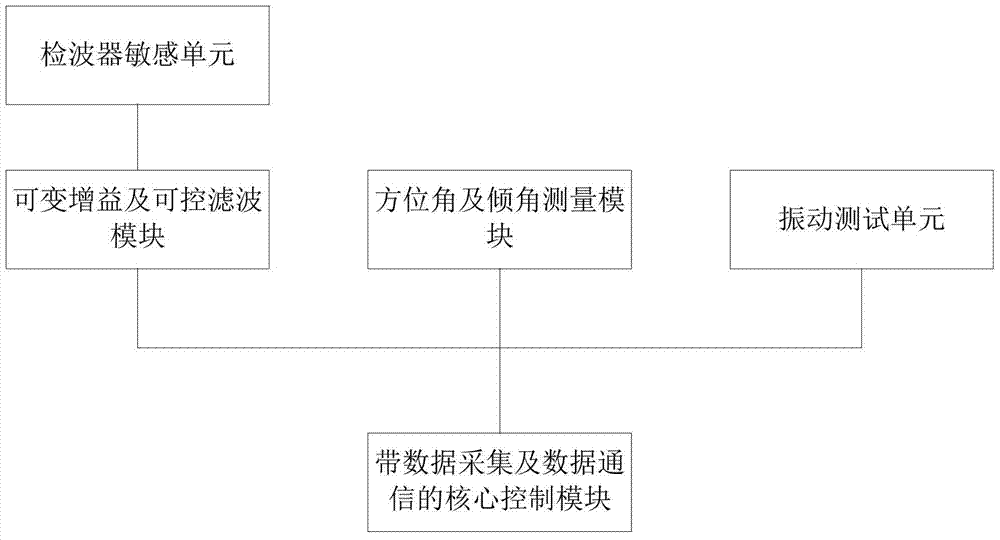

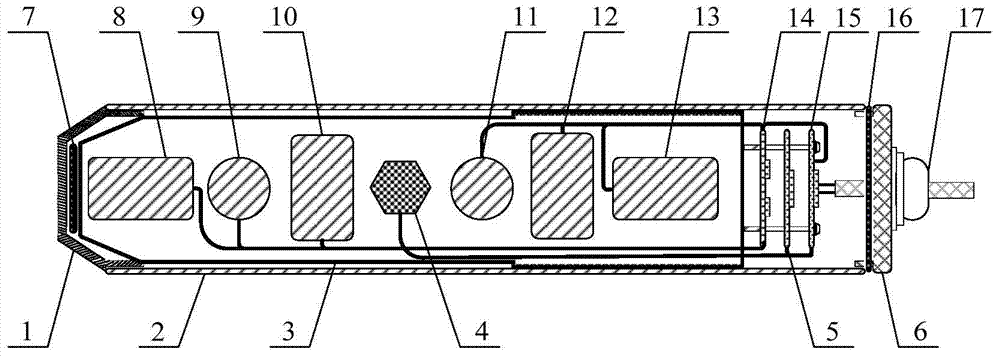

Mine microseism wave detector installed in deep hole

ActiveCN103941283AReduce the difficulty of punchingProvide punching efficiencySeismic signal receiversPhysicsSignal-to-noise ratio (imaging)

The invention discloses a mine microseism wave detector installed in a deep hole. The mine microseism wave detector installed in the deep hole comprises a wave detector sensing unit, a vibration testing unit, a variable gain and controllable filtering module, an azimuthal angle and dip angle measurement module and a core control module with data collection and communication functions. The wave detector can achieve automatic recording of related information, lowers the complexity of artificial operation, avoids introducing more artificial measurement errors, achieves self-measurement of the azimuthal angle and the dip angle, reduces the amount of the related information recorded manually, lightens the workload of manual recording and the probability of wrong recording, and guarantees normal work. A work state self-detection function of the wave detector is added, maintenance difficulty and complexity are lowered, the utilization rate is improved, variable gains and controllable filtering are increased, the grain range and the filtering frequency band are adjustable, the signal-to-noise ratio and the anti-attenuation capacity of a single source are improved, and the wave detector sensing unit is favorable for improving the signal-to-noise ratio of the wave detector array.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

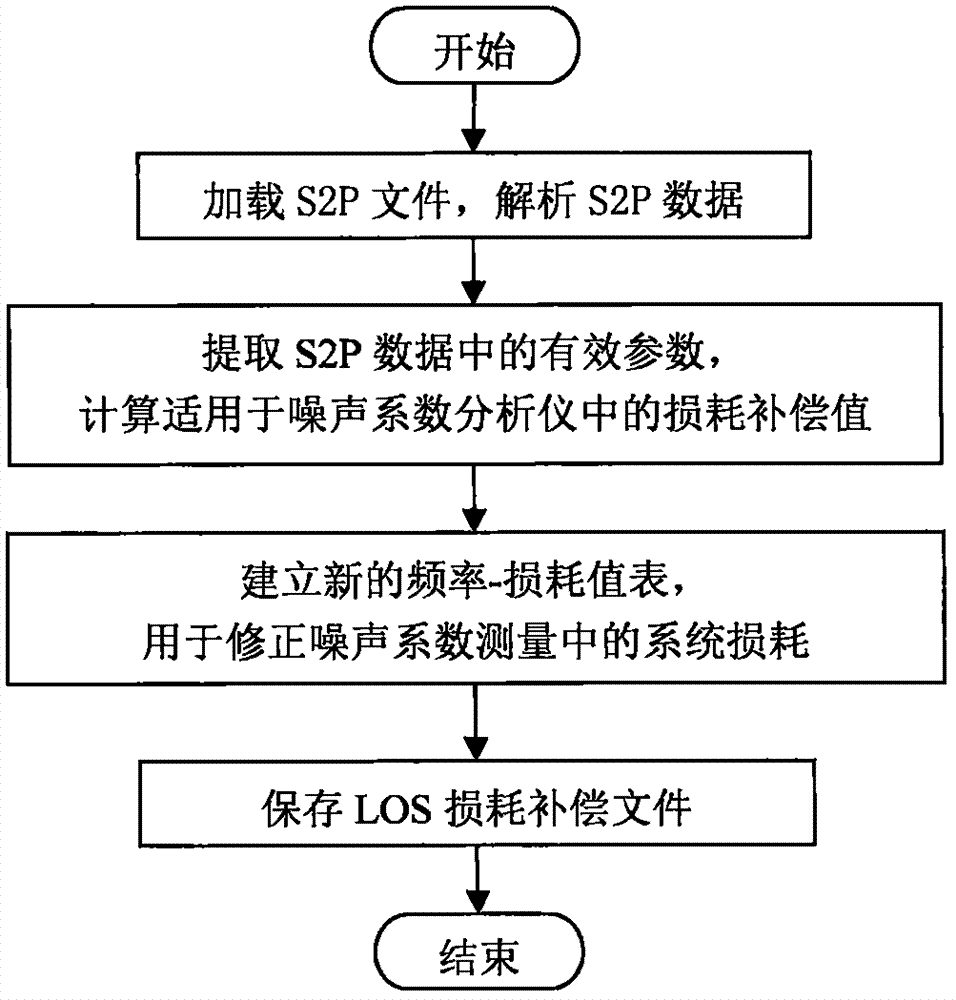

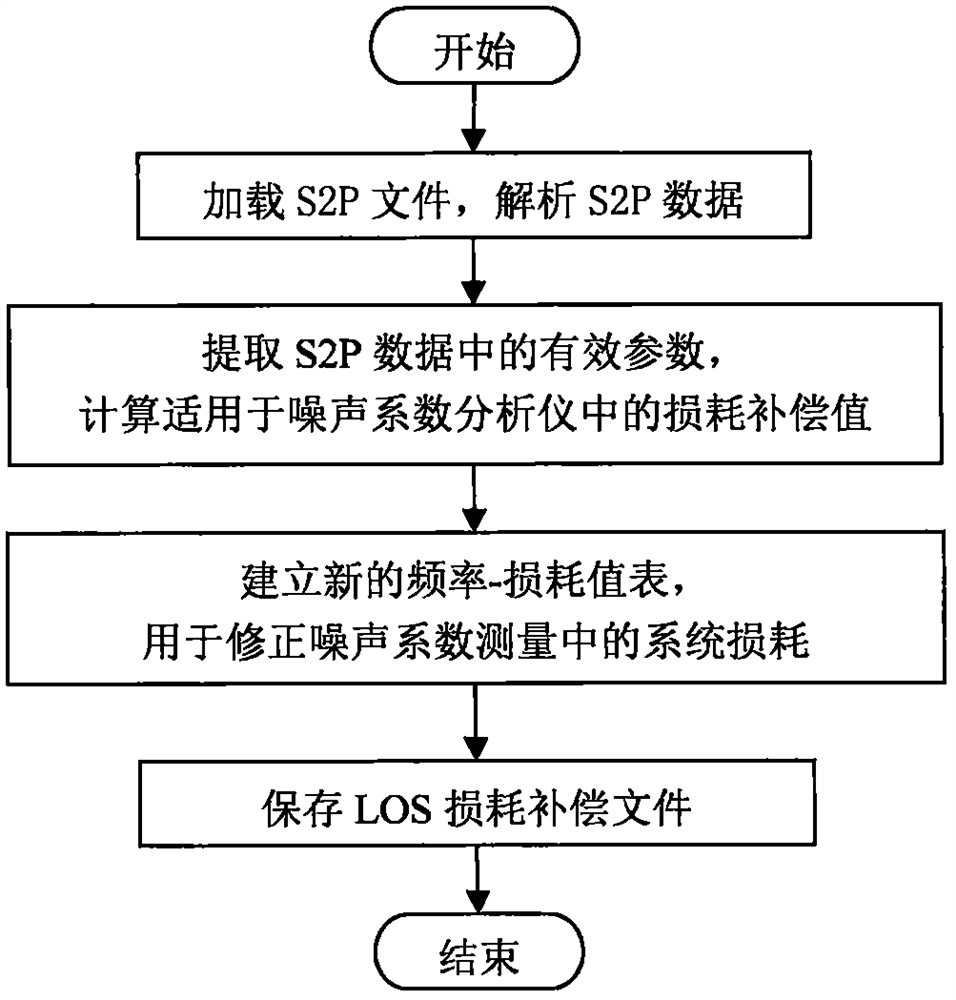

Method for acquiring loss compensation data by calling S2P document in noise coefficient analyzer

ActiveCN107247696ASimplifies manual entryAvoid Human Measurement ErrorsNatural language data processingTransmission monitoringComputer scienceNoise figure

The invention presents a method for acquiring loss compensation data by calling S2P document in a noise coefficient analyzer, which includes steps of, step one, loading a S2P document originated from a network analyzer, and analyzing the S2P format document data; step two, extracting effective parameter in S2P data, and calculating the loss compensation value in the noise coefficient analyzer; step three, building up a new frequency-loss value list for modifying the system loss in the noise coefficient measurement; step four, storing the LOS format loss compensation document, and generating the LOS format document with the same name as the S2P document; or naming the file by the user in LOS format. The method is simple to operate; the whole algorithm can be embedded in host machine software of the noise coefficient analyzer, and can be automatically completed through one-button operation of the menu or a programming method at the outer part of an instrument; the method provides a new rapid and effective input way for the building of the loss compensation table in the noise coefficient measurement.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

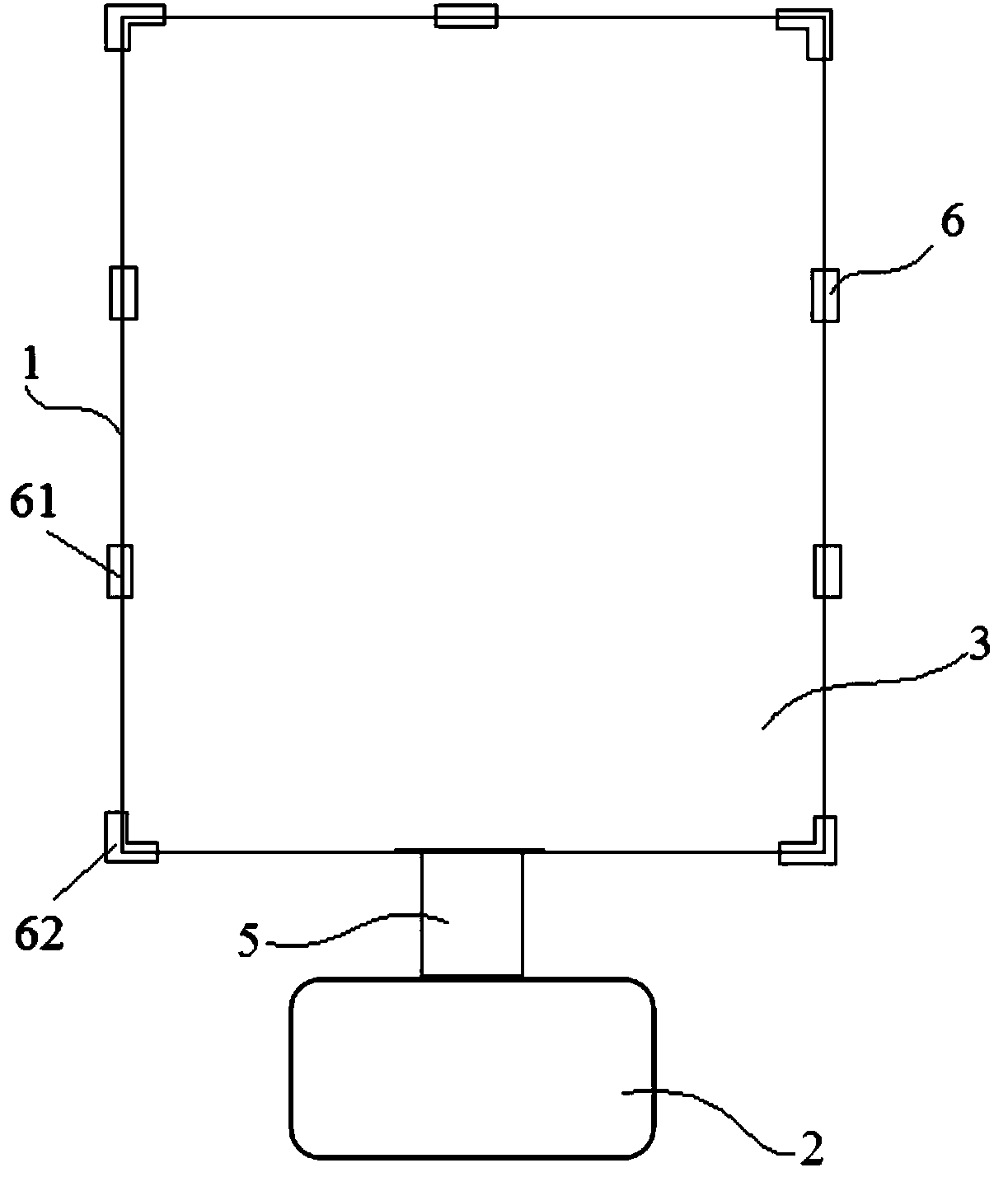

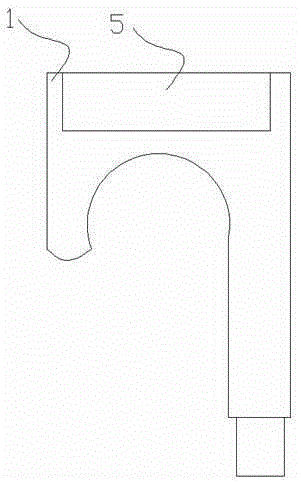

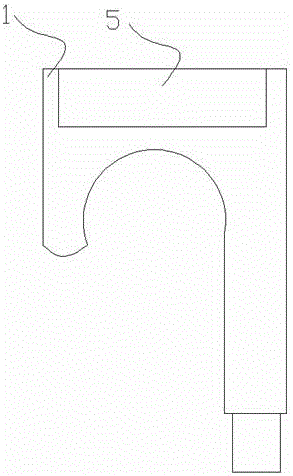

Leveling device and measurement method thereof

InactiveCN104567811AGuaranteed accuracyAccurately reflectIncline measurementLevel staffMechanical engineering

The invention discloses a leveling device and a measurement method thereof, relates to the technical field of leveling instruments and aims to solve the problems that during the measurement of an existing leveling rod, the leveling rod needs to be held manually, the work efficiency is low, and the data cannot be measured accurately because of shake of a worker who holds the leveling rod. The leveling device comprises a ruler which stands on a ruler pad, a leveling air bubble which is mounted on the side surface of the ruler, a slide way which is arranged along the longitudinal direction of the ruler and a fixing bracket which can slide relatively along the slide way, wherein the fixing bracket comprises a slider matched with the slide way, and bracket legs which are connected with the slider by bolts. The measurement method comprises the following steps: (1) vertically arranging the ruler on the ruler pad; (2) moving the slider to enable the fixing bracket to reach suitable height, and tightening and fixing the slider on the slide way; (3) regulating the bracket legs so that the bracket legs can form a stable structure with the ruler, tightening, regulating the length of the bracket legs and fixedly locking so that the leveling air bubble is in the middle and leveling can be realized.

Owner:SHANGHAI CONSTRUCTION GROUP

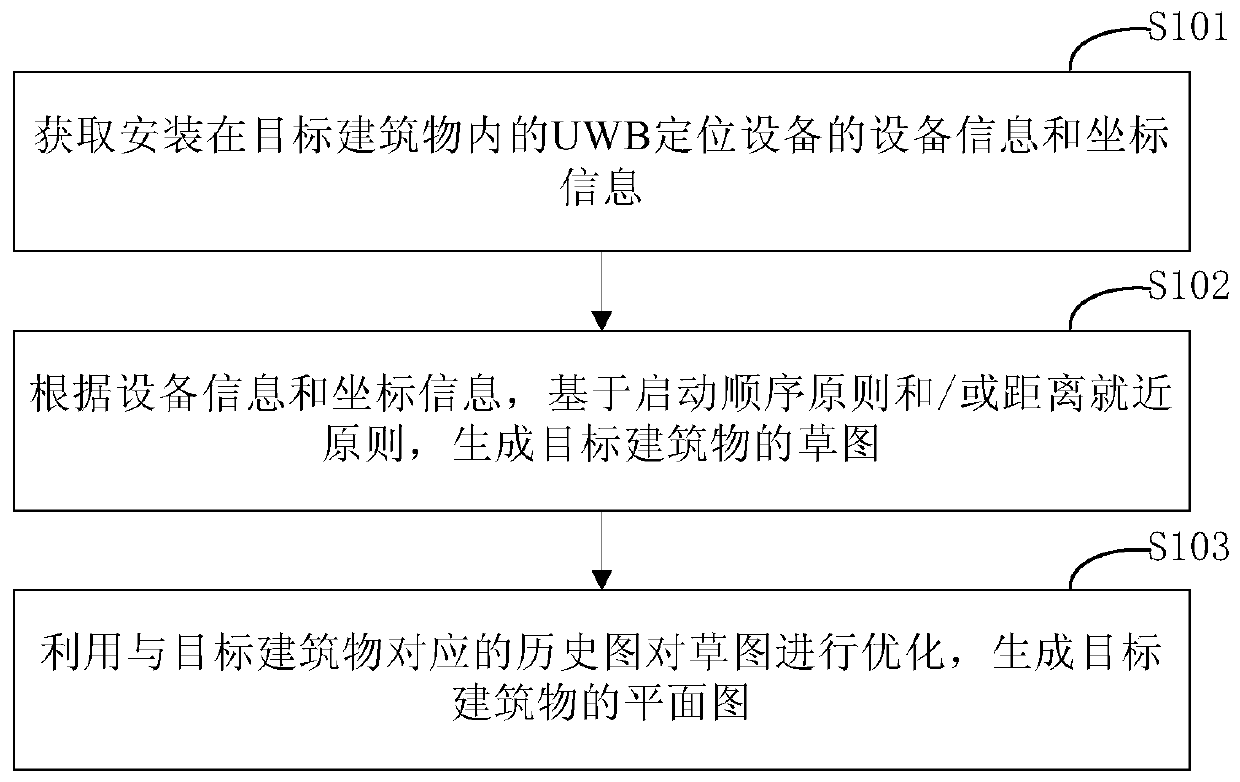

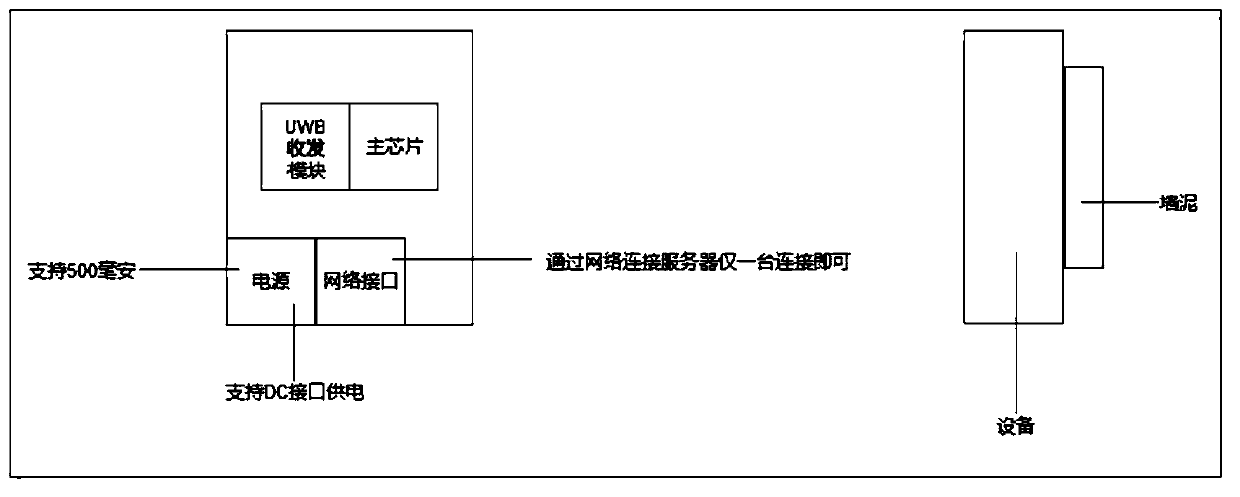

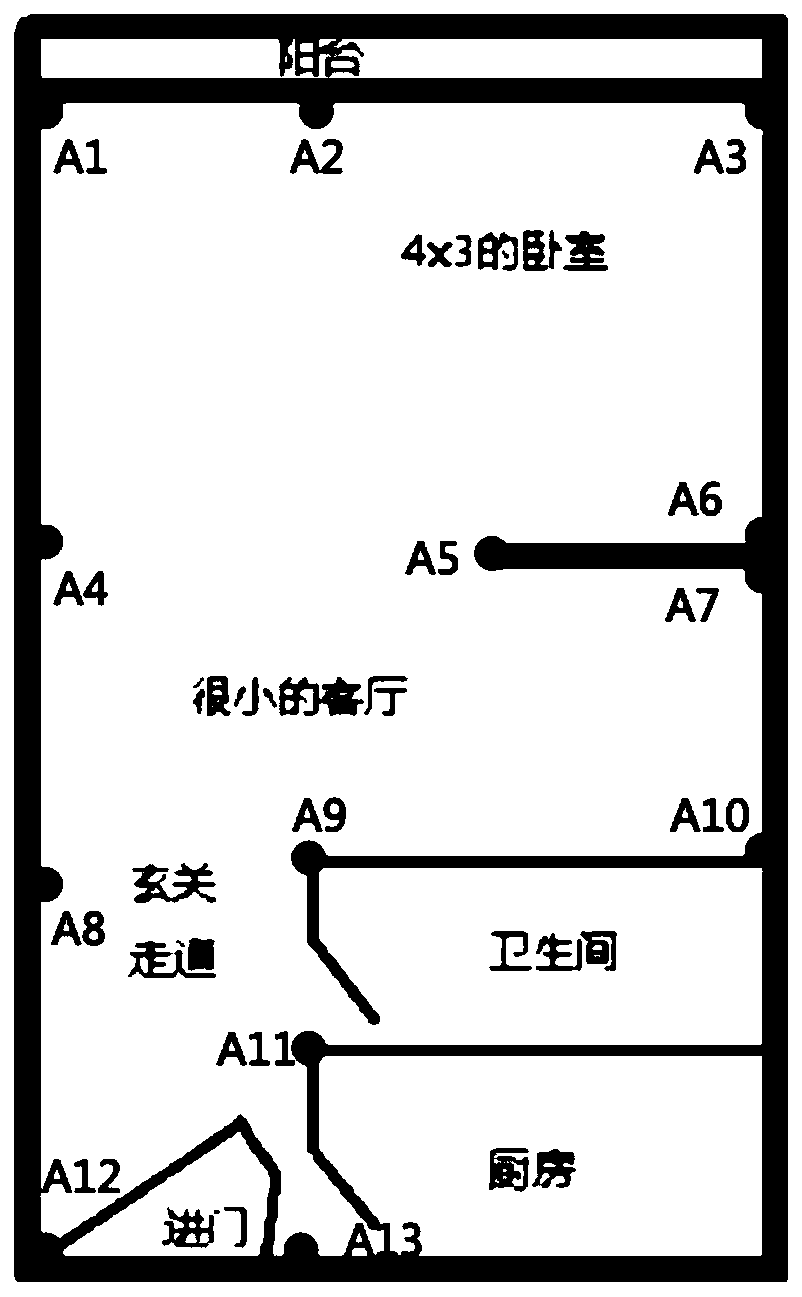

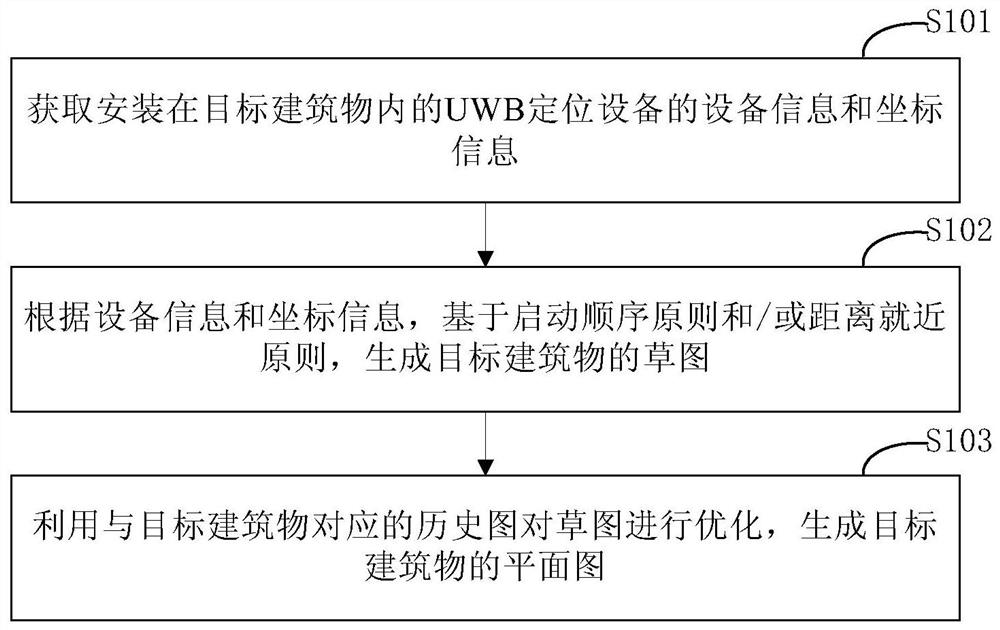

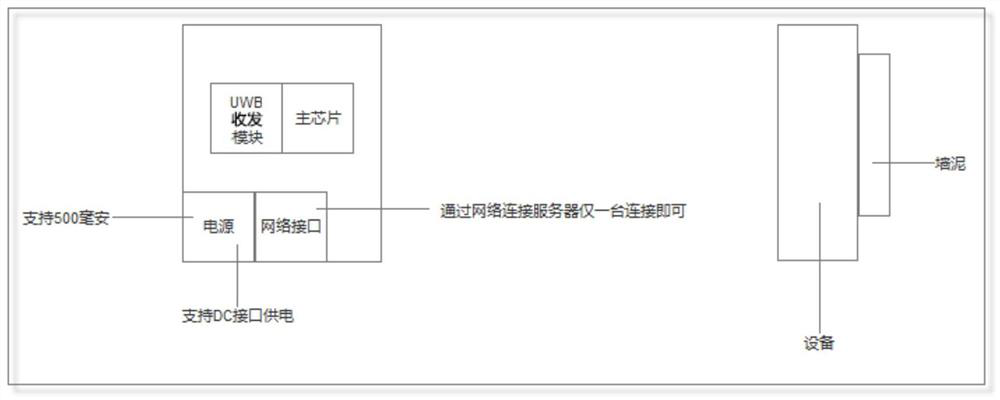

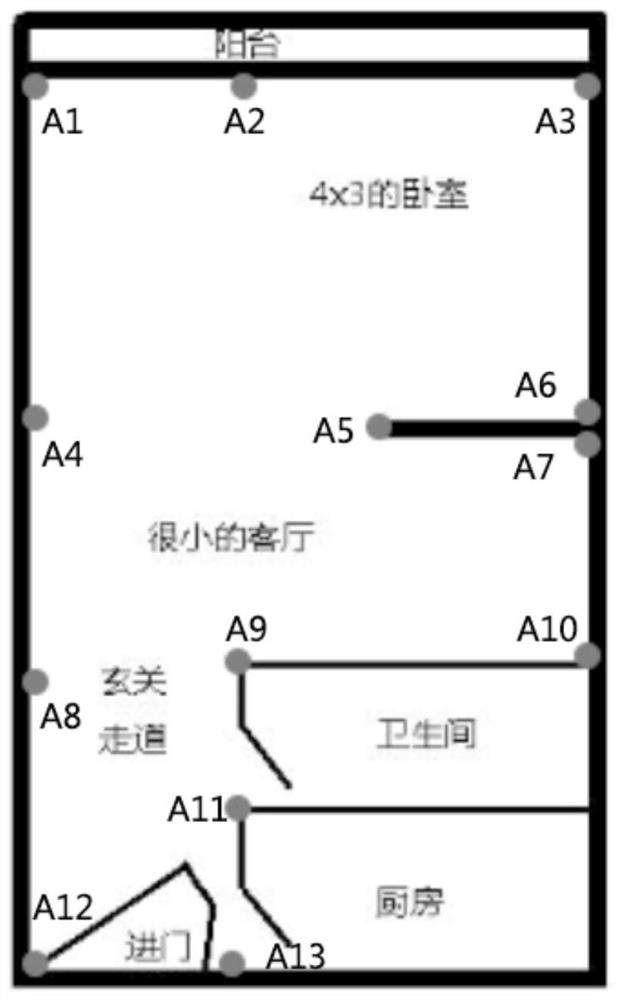

A method and device for constructing a planar graph based on a UWB technology

ActiveCN109902409AOvercoming human error in measurement dataGet Over Professional DraftsmenPosition fixationSpecial data processing applicationsMeasurement cost1-planar graph

The invention discloses a method and device for constructing a plane graph based on a UWB technology, and relates to the technical field of computers. A specific embodiment of the method comprises thesteps of obtaining device information and coordinate information of a UWB positioning device installed in a target building; Generating a sketch of the target building based on a starting sequence principle and / or a distance proximity principle according to the equipment information and the coordinate information; And optimizing the sketch by using the historical map corresponding to the target building to generate a planar graph of the target building. According to the implementation mode, the planar graph can be rapidly constructed based on the UWB technology, manual measurement errors areavoided, the measurement cost is reduced, and the user experience is improved.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

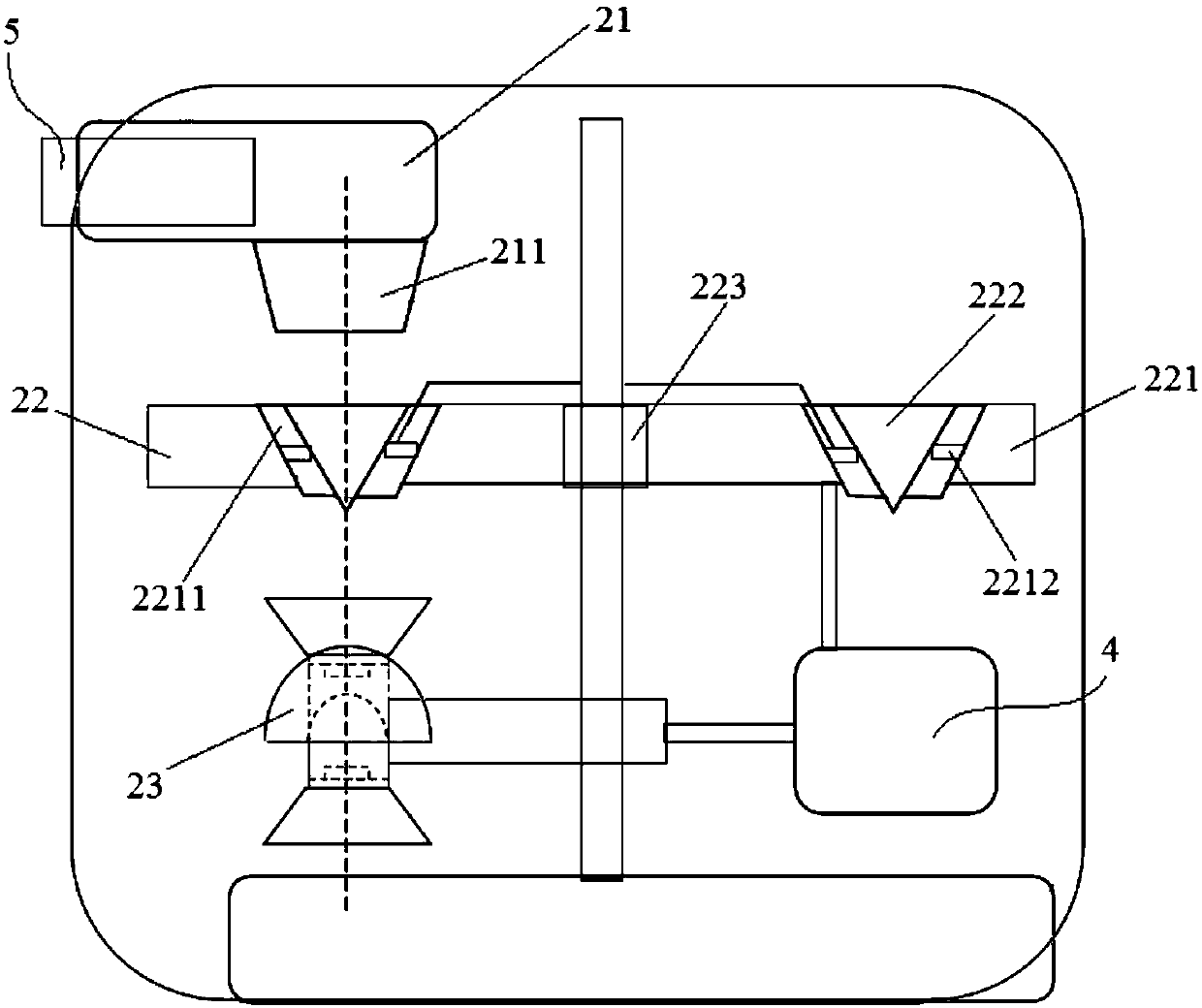

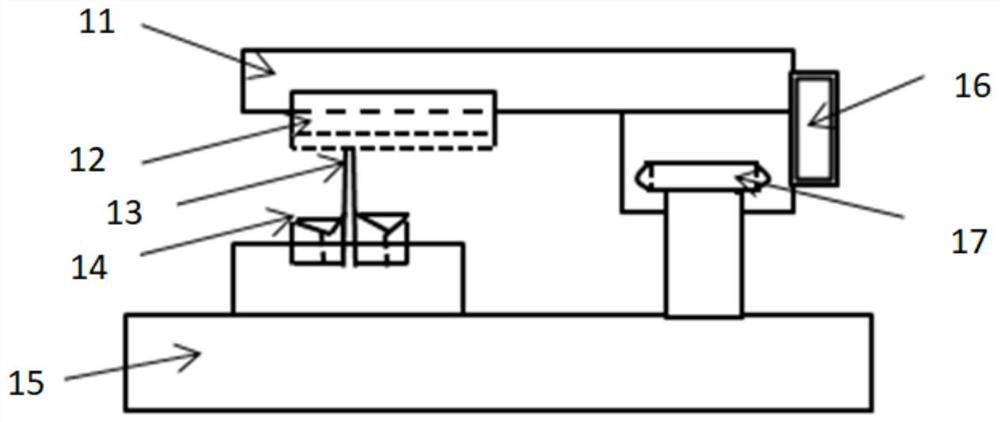

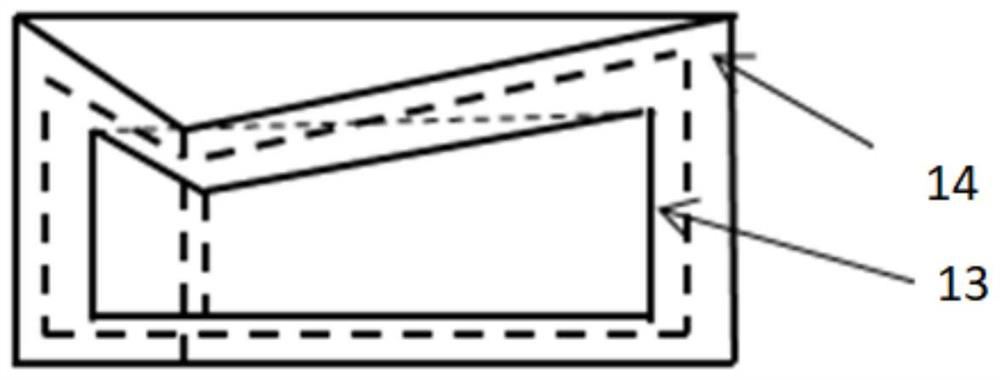

Device for measuring density and viscosity of coating for casting

InactiveCN104406886AReduce laborMonitor operationFlow propertiesSpecific gravity measurementViscosityBiomedical engineering

The invention relates to a device suitable for detecting and controlling the density and the viscosity of a coating for casting, in particular to a device for measuring the density and the viscosity of coating for casting. The device is characterized by comprising a measuring device, a washing device and a control device connected with the measuring device and the washing device. The device has the advantages that the structure is special, a viscosity value and a density value can be monitored in real time, the measurement accuracy is ensured, the use and the operation are convenient and simple, and the production efficiency is greatly improved.

Owner:KOCEL STEEL

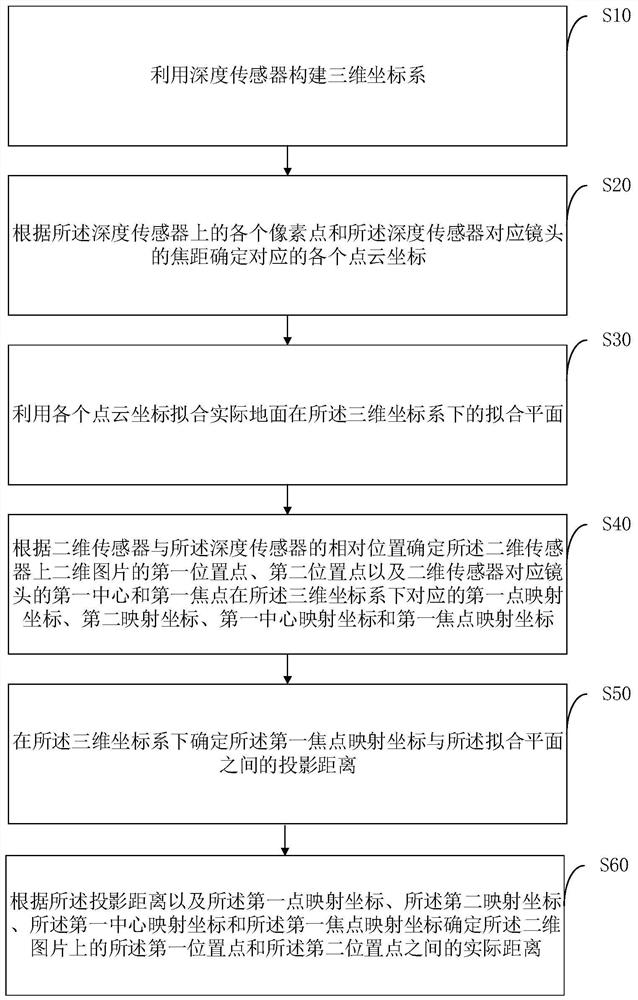

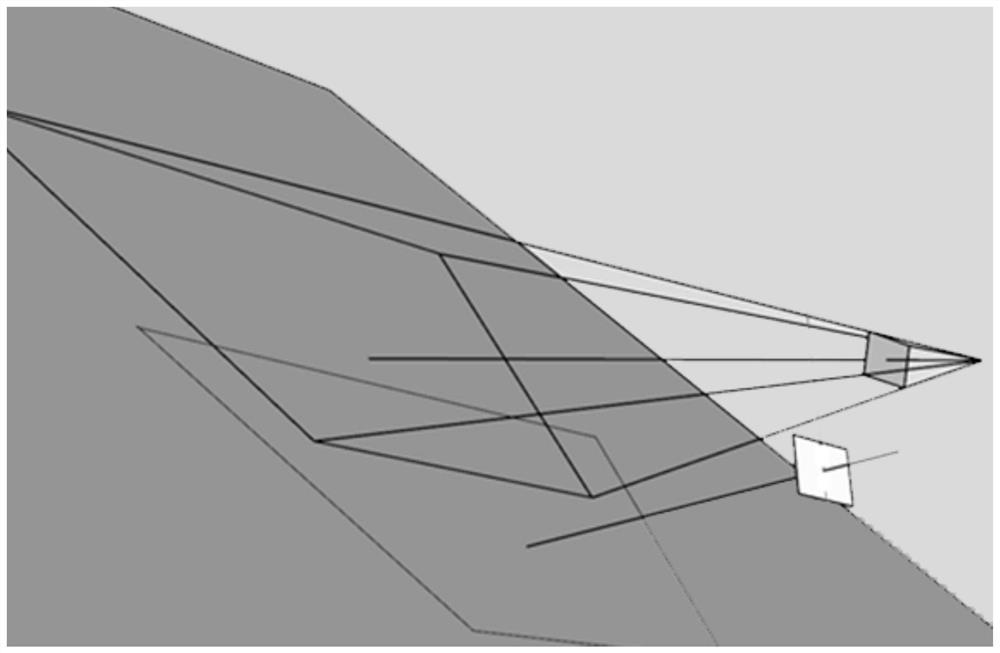

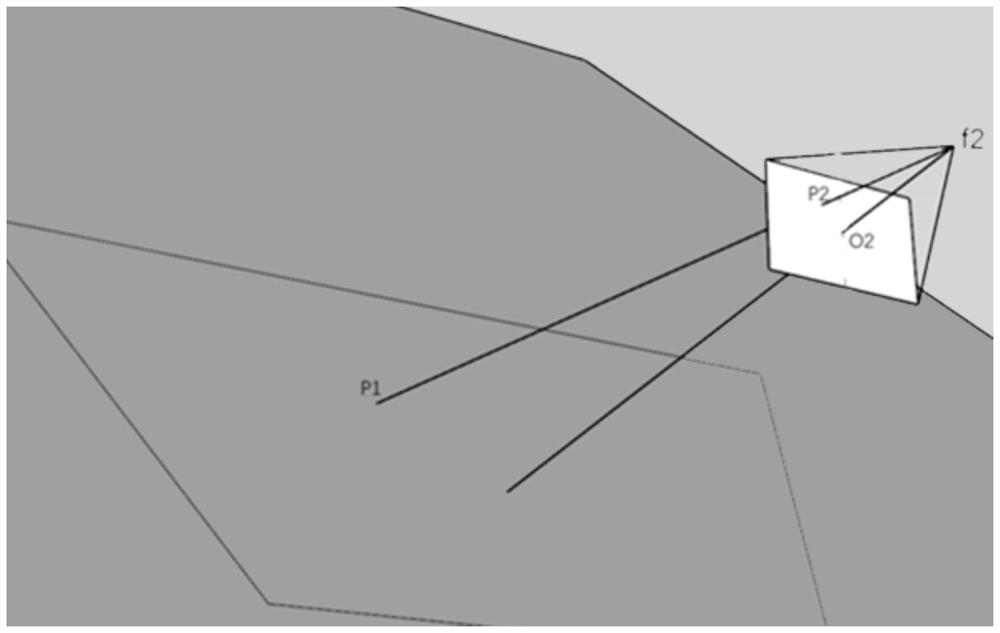

Image distance measurement method and device, distance measurement equipment and readable storage medium

PendingCN112816967AAvoid Human Measurement ErrorsUsing reradiationPoint cloudComputer graphics (images)

The embodiment of the invention discloses an image distance measurement method and device, distance measurement equipment and a readable storage medium. The method comprises the following steps of: constructing a three-dimensional coordinate system by using a depth sensor; according to each pixel point on the depth sensor and the focal length of a lens corresponding to the depth sensor, determining each corresponding point cloud coordinate so as to determine a fitting plane by using the point cloud coordinates; according to the relative positions of a two-dimensional sensor and the depth sensor, determining a first position point and a second position point of a two-dimensional picture on the two-dimensional sensor and a first point mapping coordinate, a second mapping coordinate, a first center mapping coordinate and a first focus mapping coordinate corresponding to a first center and a first focus of a lens corresponding to the two-dimensional sensor in a three-dimensional coordinate system; and determining the actual distance between the first position point and the second position point on the two-dimensional picture according to the first point mapping coordinate, the second mapping coordinate, the first center mapping coordinate and the first focus mapping coordinate. According to the technical scheme, errors caused by manual measurement can be effectively avoided.

Owner:CHENGDU KANGYE TECH CO LTD

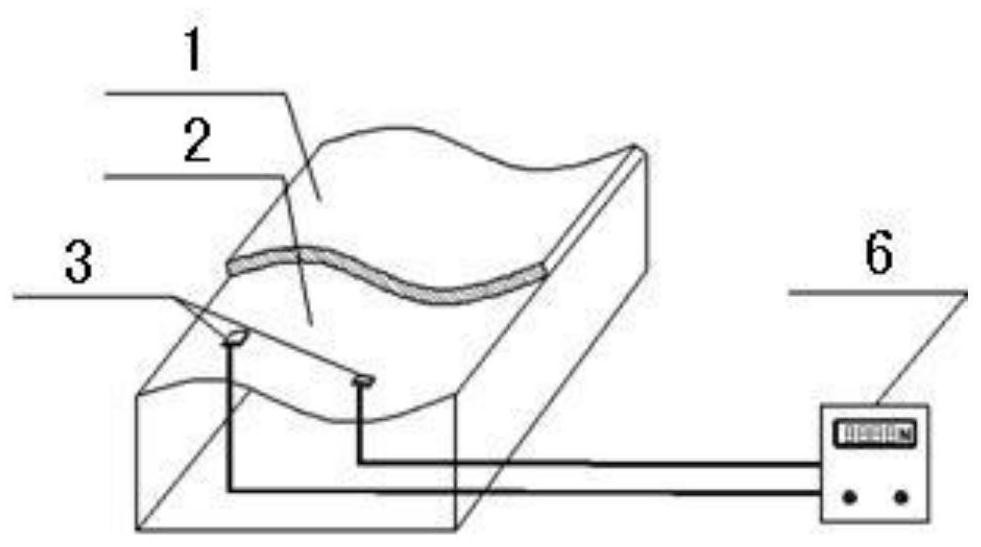

System for measuring runoff sediment and interflow and building method thereof

PendingCN107907663AReduce damageShorten recovery timeEarth material testingPermeability/surface area analysisSoil scienceEnvironmental engineering

The invention relates to a system for measuring runoff sediment and interflow and a building method thereof. The system comprises a runoff sediment automatic measuring device, an interflow automatic measuring device and a recording device, wherein the runoff sediment automatic measuring device comprises building plates and a first measuring assembly; the building plates are vertically inserted into ground; the inserted part, under the ground, of each building plate is an underground plate section, and the reserved part, above the ground, of each building plate is a ground plate section; the ground plate sections are sequentially connected by connecting parts to form a runoff plot; the first measuring assembly comprises a sample outlet, a sediment measuring device and a runoff measuring device arranged sequentially from top to bottom; each building plate is connected with the sample outlet through a sample through pipe; the runoff water and sediment mixed sample in the runoff pot entersthe sediment measuring device through the sample outlet; the filtered sediment sample is measured by the sediment measuring device; the runoff measuring device is used for measuring the runoff watersample which flows through the sediment measuring device and then flows into the runoff measuring device; the recording device is used for recording the measuring results of the runoff sediment automatic measuring device and the interflow automatic measuring device.

Owner:BEIJING FORESTRY UNIVERSITY

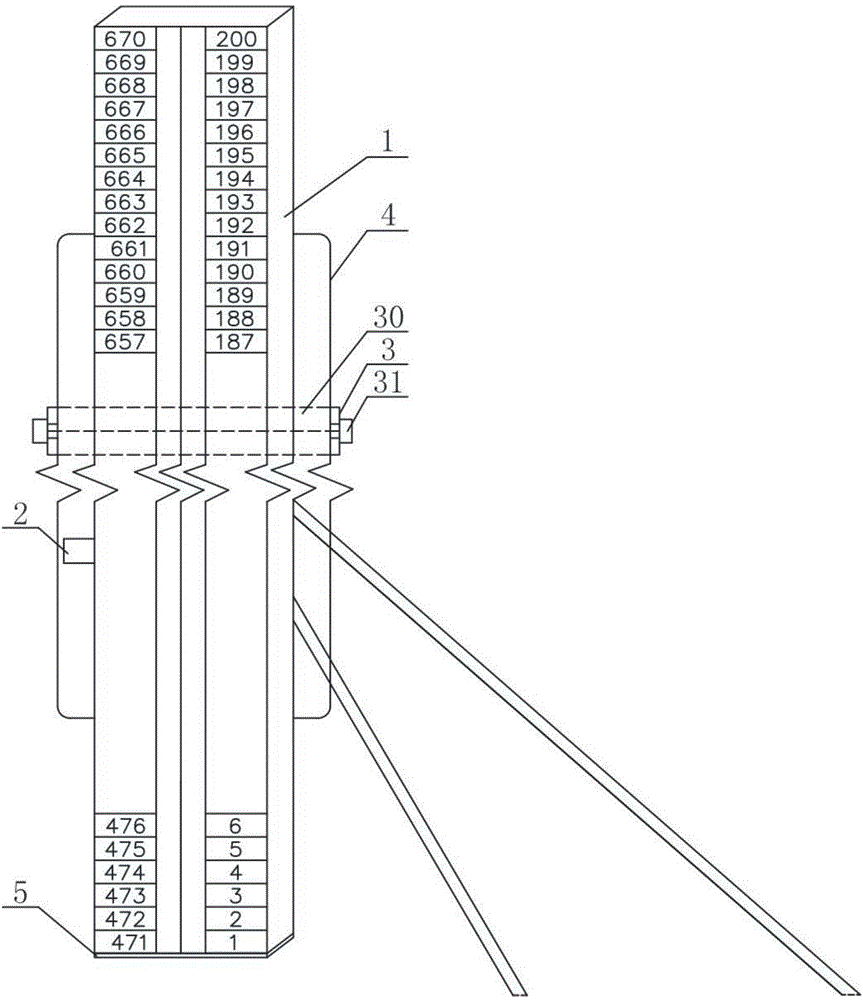

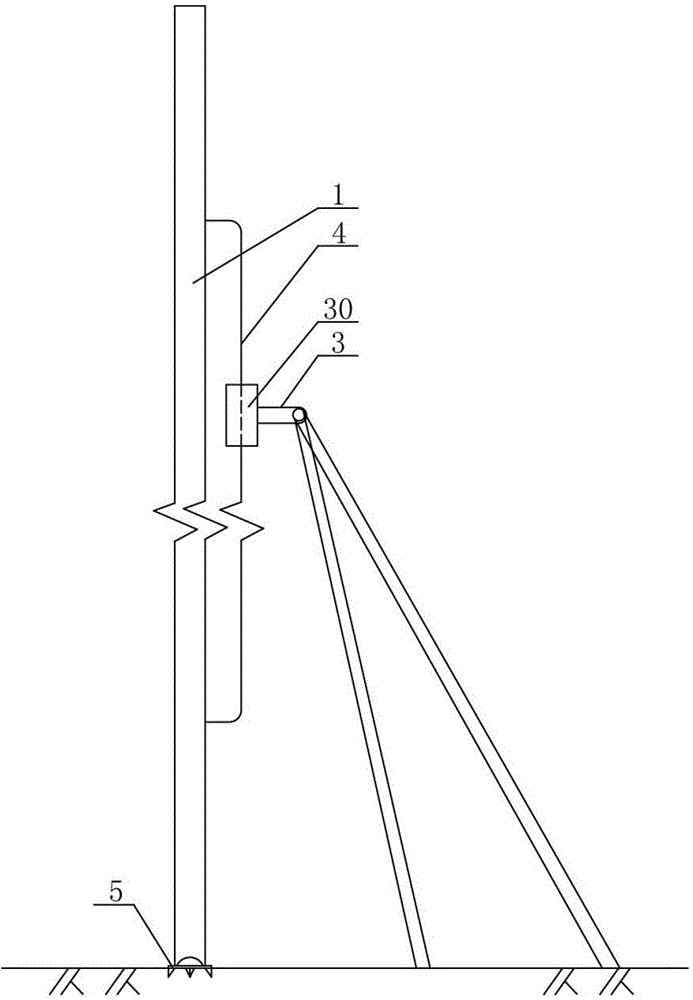

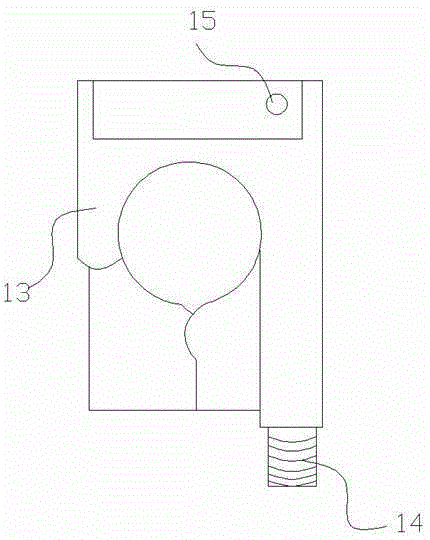

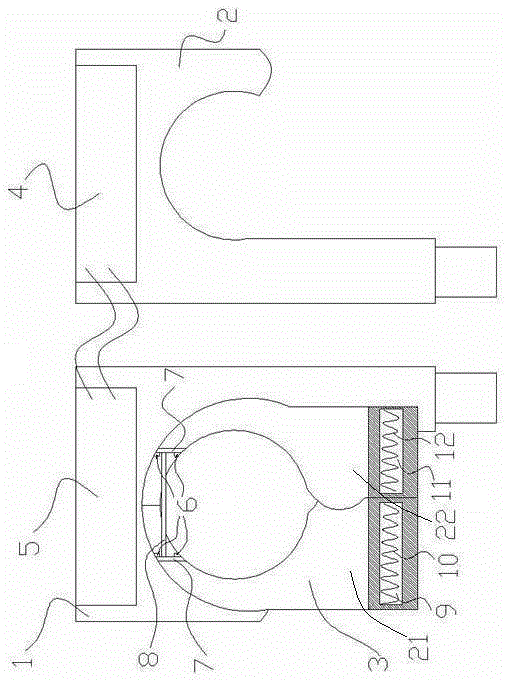

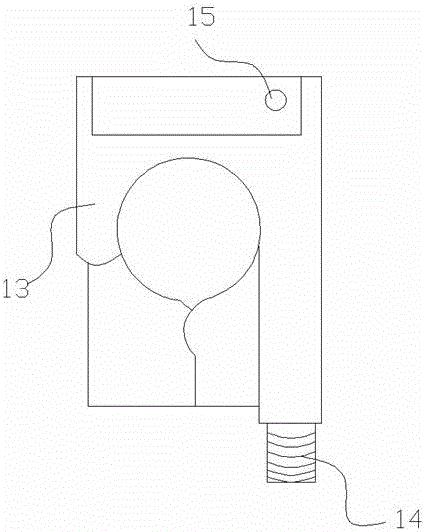

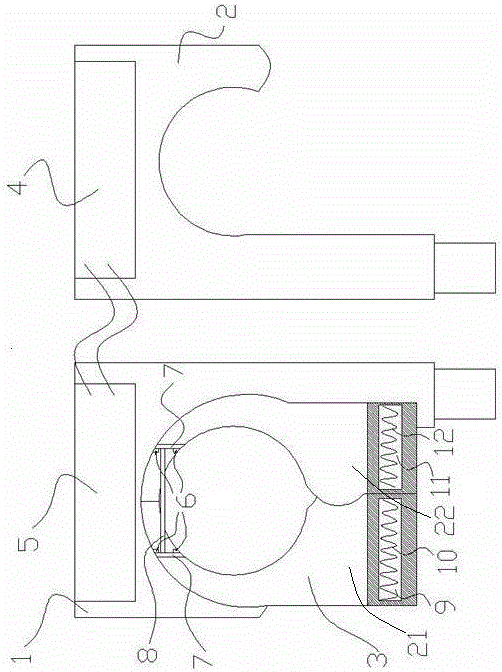

High-voltage power transmission cable earth current automatic detection device

InactiveCN105301346AAvoid zero touchSolve the safety problem of climbing tower to detect ground currentMeasurement using digital techniquesPower flowHigh pressure

The invention discloses a high-voltage power transmission cable earth current automatic detection device. The device comprises a sampler (13) and a receiver (16). The sampler (13) comprises an upper shell (2), a middle shell (3) and a lower shell (1). A PCB panel (4) is arranged on the upper shell (2). A first induction coil (10) is arranged in a first chamber (9) of the left part (21) of the middle shell. A second induction coil (12) is arranged in a second chamber (11) of the right part (22) of the middle shell. The first induction coil (10) and the second induction coil (12) are connected with a control circuit of the PCB panel (4). A supporting bar (7) is arranged between two bulges (6) on the left part (21) of the middle shell and a supporting bar (7) is arranged between two bulges (6) on the right part (22) of the middle shell. The two supporting bars (7) are connected by a spring (8). The device is simple in structure and convenient for installation, has strong environmental endurance, is low in safe risk, and can do monitoring in real time.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

A Quantitative Analysis Method of Material Structure Based on TEM Haadf Image

InactiveCN105527461BAvoid workloadAvoid errorsScanning probe techniquesImaging processingOperability

Owner:BEIJING UNIV OF TECH

A kind of mine microseismic detector installed in deep hole

ActiveCN103941283BReduce automatic loggingRealize automatic recordingSeismic signal receiversObservational errorData acquisition

The invention discloses a mine microseism wave detector installed in a deep hole. The mine microseism wave detector installed in the deep hole comprises a wave detector sensing unit, a vibration testing unit, a variable gain and controllable filtering module, an azimuthal angle and dip angle measurement module and a core control module with data collection and communication functions. The wave detector can achieve automatic recording of related information, lowers the complexity of artificial operation, avoids introducing more artificial measurement errors, achieves self-measurement of the azimuthal angle and the dip angle, reduces the amount of the related information recorded manually, lightens the workload of manual recording and the probability of wrong recording, and guarantees normal work. A work state self-detection function of the wave detector is added, maintenance difficulty and complexity are lowered, the utilization rate is improved, variable gains and controllable filtering are increased, the grain range and the filtering frequency band are adjustable, the signal-to-noise ratio and the anti-attenuation capacity of a single source are improved, and the wave detector sensing unit is favorable for improving the signal-to-noise ratio of the wave detector array.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

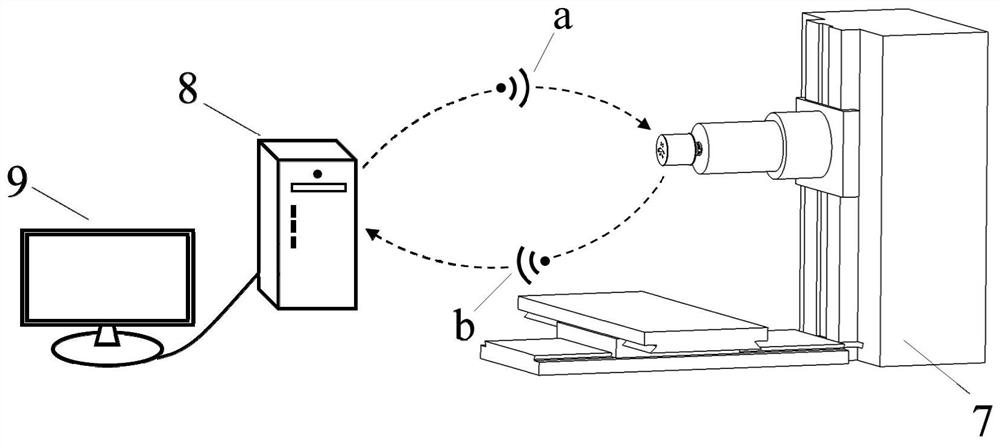

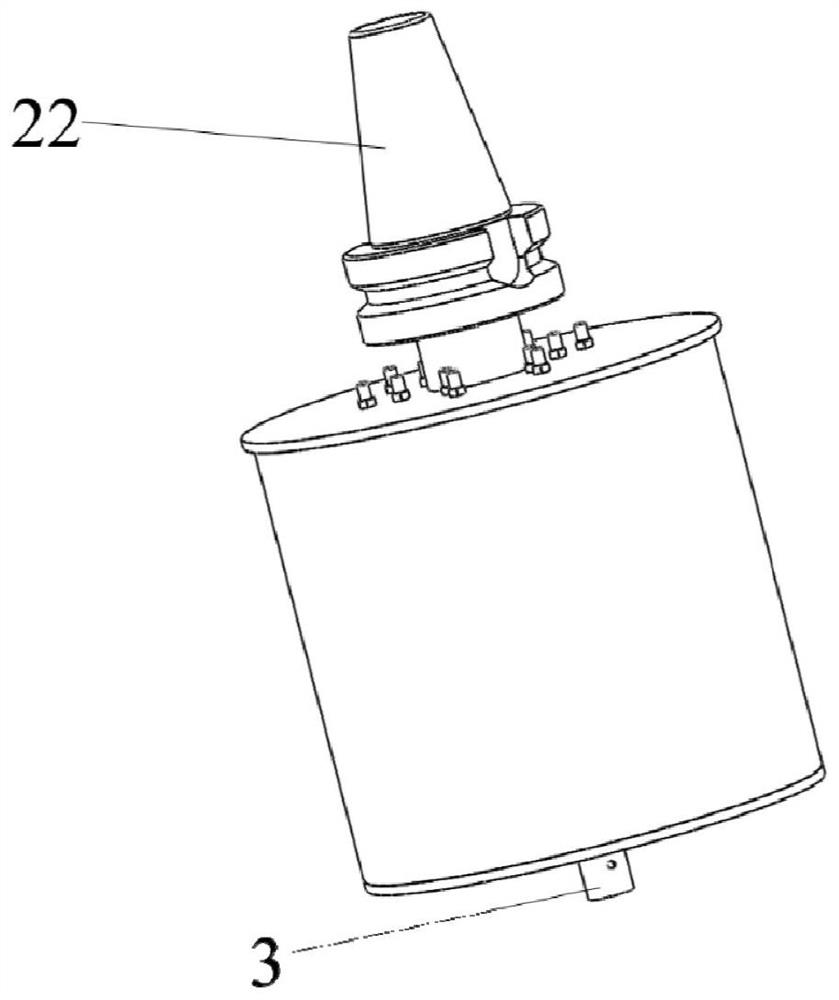

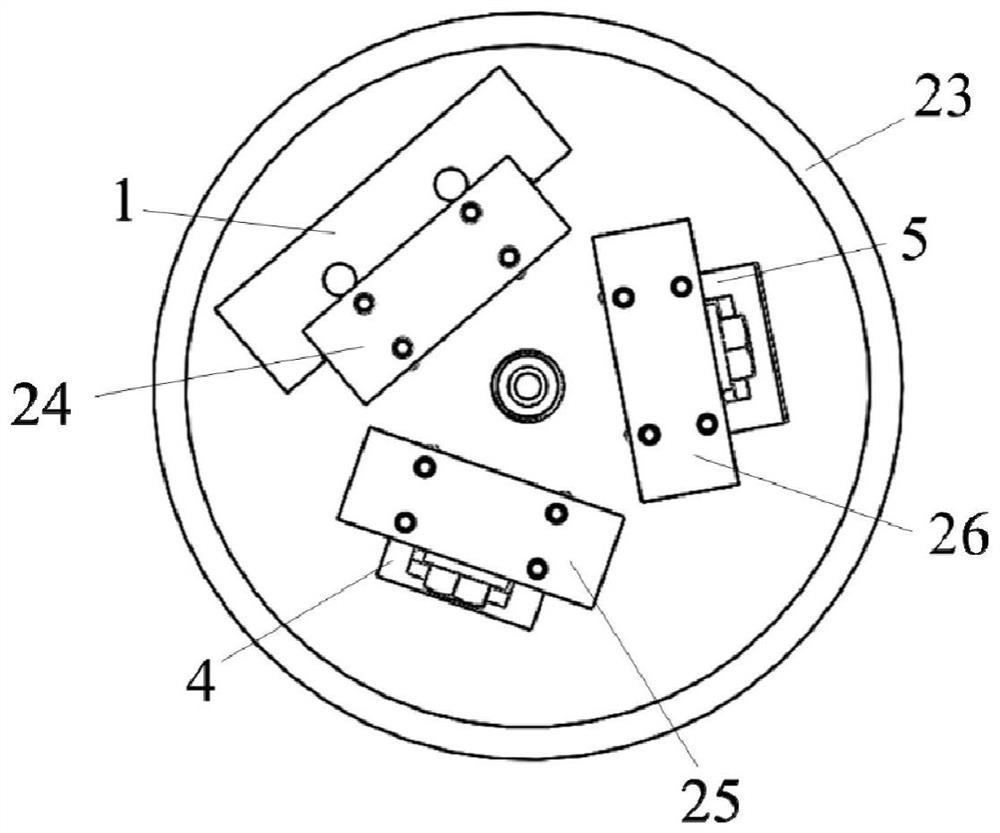

Knife handle type ultrasonic thickness measuring device and measuring method based on wireless communication

ActiveCN114111658AGuaranteed stabilityMiniaturizationAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansUltrasonic thickness measurementNumerical control

The invention discloses a knife handle type ultrasonic thickness measuring device and method based on wireless communication, and belongs to the technical field of ultrasonic thickness measurement. According to the device, an ultrasonic sensor, a wireless communication unit, an excitation / receiving unit, a power supply and other modules are organically integrated with a cutter handle structure and can be conveniently integrated on a conventional numerical control machine tool; in the ultrasonic thickness measurement process, the industrial personal computer transmits an ultrasonic excitation signal to the ultrasonic device in a wireless communication mode and completes automatic receiving of an ultrasonic echo signal, interference of a signal cable on ultrasonic scanning motion in a conventional mode of wired communication is effectively avoided, and reliable guarantee is provided for complex feature multi-axis linkage ultrasonic on-machine thickness measurement. And the ultrasonic echo signal is subjected to compression processing and wavelet filtering processing, so that the quality of the ultrasonic echo signal is effectively ensured. The defects of an ultrasonic thickness measuring device and method based on wired communication are overcome, and the ultrasonic on-machine automatic thickness measuring capacity and efficiency are improved.

Owner:DALIAN UNIV OF TECH

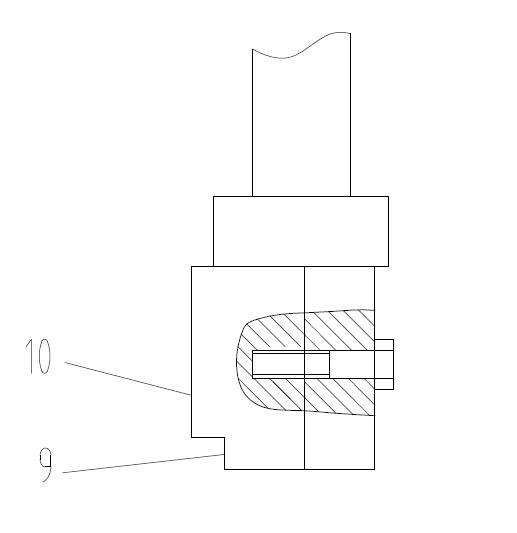

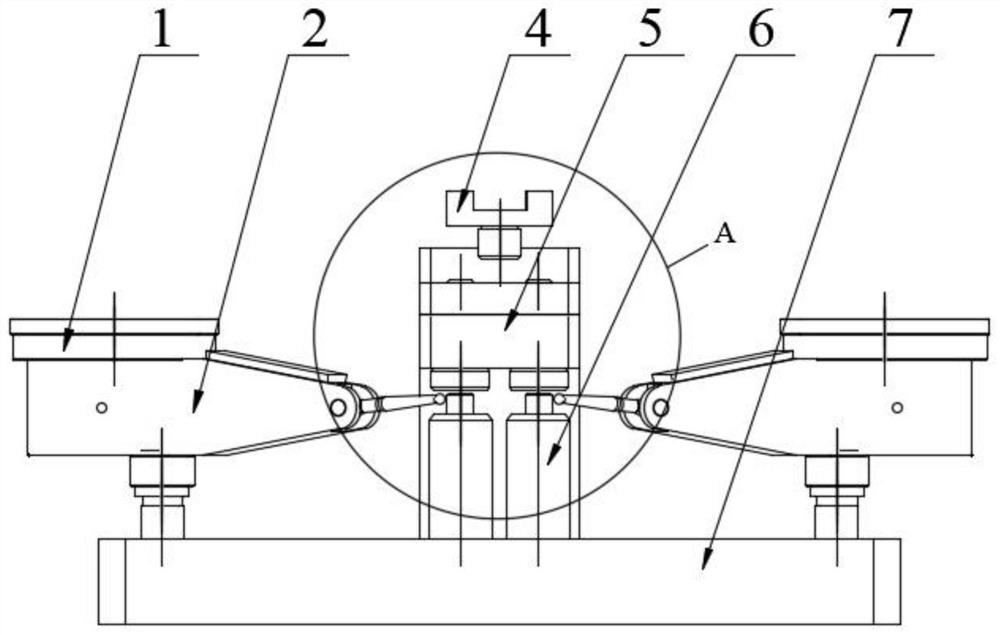

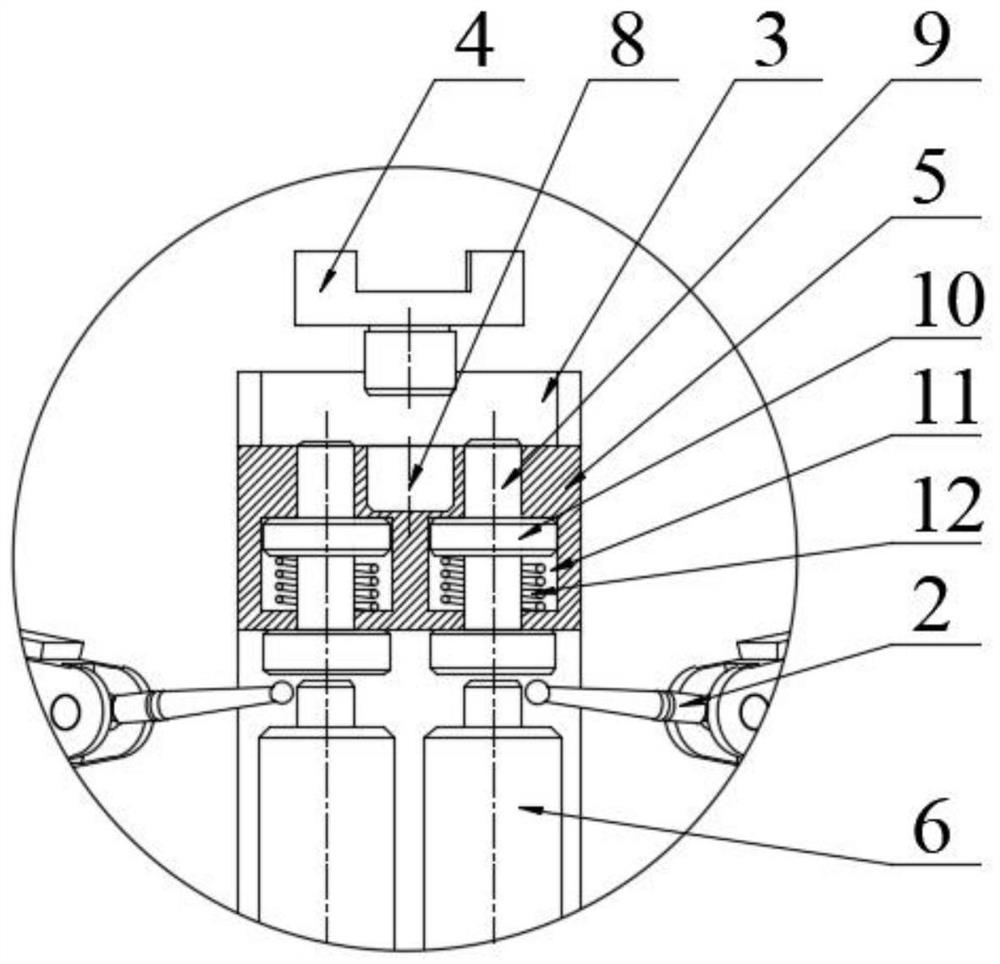

Multilayered workpiece machining positioning mechanism of edge milling machine

InactiveCN102554674ALow costSimple structureMilling equipment detailsPositioning apparatusMechanical engineeringPiston rod

The invention discloses a multilayered workpiece machining positioning mechanism of an edge milling machine, which comprises a piston type actuating mechanism, a saddle, guide column guiding sleeves, a connecting plate and positioning blocks. The piston type actuating mechanism is fixedly connected with the edge milling machine, the saddle is vertically and fixedly connected with one end of a cylinder, the connecting plate is parallel to the saddle and is connected with a piston rod of the piston type actuating mechanism, the positioning blocks are connected with the connecting plate, and the guide column guiding sleeves are connected between the saddle and the connecting plate. The multilayered workpiece machining positioning mechanism has the advantages that the multilayered workpiece machining positioning mechanism is reliable in operation, labor intensity of workers is reduced, labor efficiency is improved, the quality of products is guaranteed, and the like.

Owner:CRRC SHIJIAZHUANG CO LTD

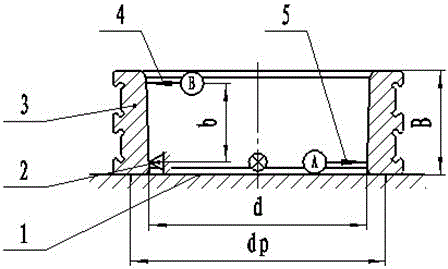

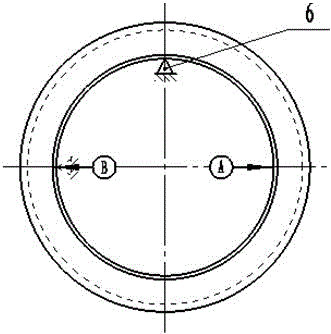

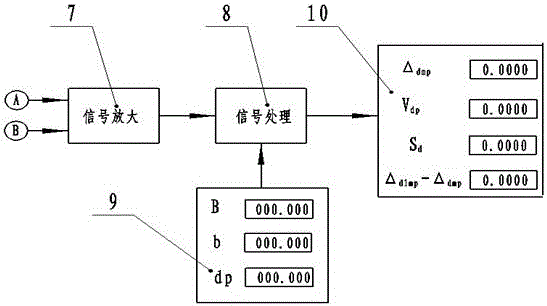

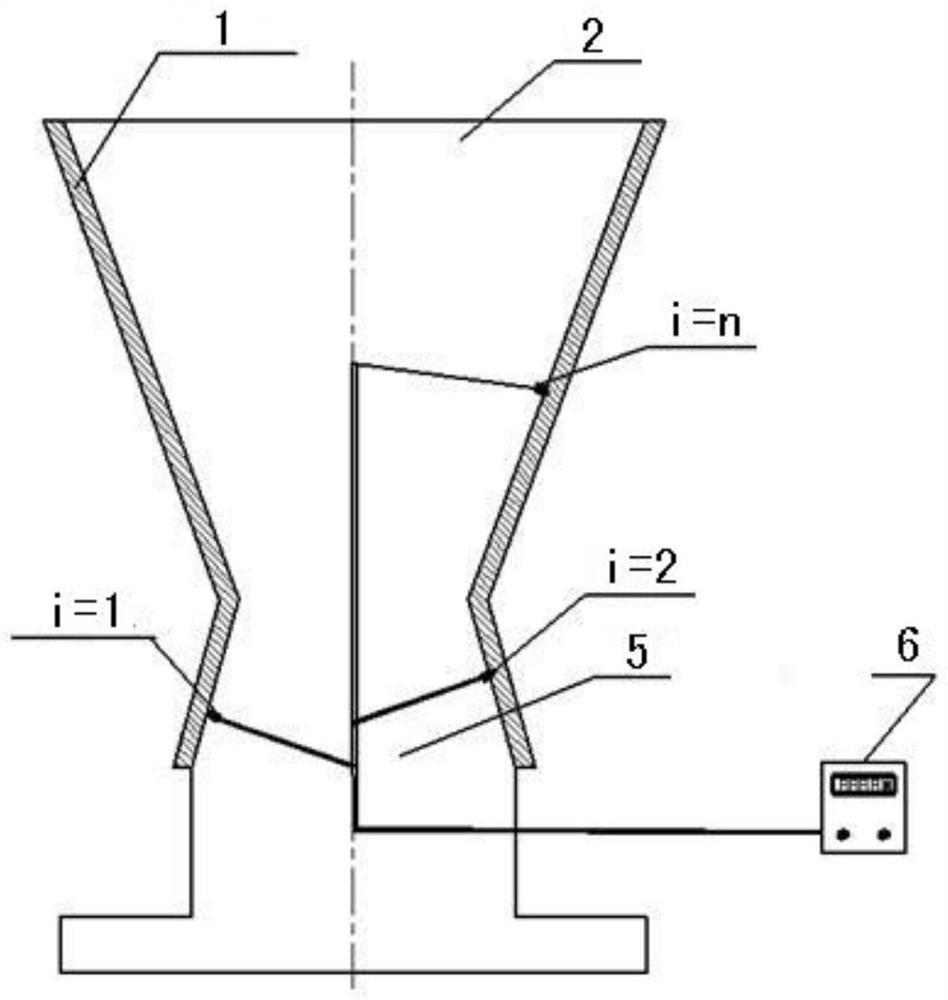

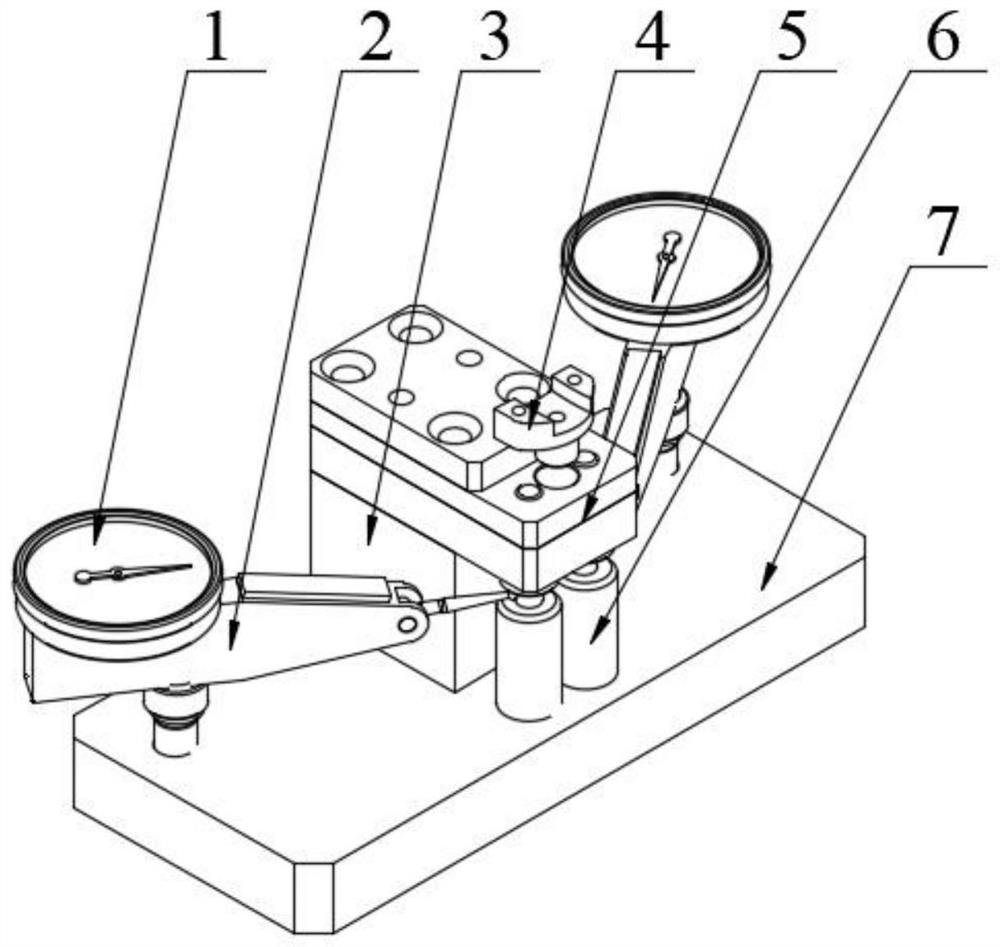

Full-parameter measuring system and method for inner bore of bearing ring with tapered bore

InactiveCN102818545BEasy to adjustAvoid Human Measurement ErrorsMeasurement devicesObservational errorMeasurement cost

The invention relates to an all-parameter measuring system with a bearing ring inner hole as a conical bore and a measuring method for the all-parameter measuring system. The system comprises a measuring fulcrum, an auxiliary fulcrum and two measuring heads, wherein the measuring fulcrum, the auxiliary fulcrum and the measuring heads are arranged on a measuring platform; the measuring heads are provided with displacement sensors; output signals of the two sensor measuring heads are transmitted into a signal amplifying module, a signal processing module and a display module which are connected in sequence; and the signal processing module is further connected with an input device in an input manner. The measuring device is simple to adjust, and belongs to common bearing instruments; measurement requirements on a volume production field can be met; measurement cost is greatly reduced; measurement on whole technical parameters of a conical bore can be accomplished at a single working position; working efficiency is greatly improved; a simple circuit control part is adopted to accomplish relatively complex calculation processes; artificial measurement errors caused by operating personnel is avoided; and meanwhile, labor intensity of the operating personnel is lightened; storage and process to measurement data can also be realized through the circuit control part, thereby being convenient for a quality engineer to monitor and control quality of a working procedure product in real time.

Owner:LUOYANG BEARING RES INST CO LTD

Aluminum-plastic film corner aluminum layer thickness testing method and cutting device thereof

PendingCN114459314AGuaranteed accuracyImprove accuracyMechanical thickness measurementsLarge fixed membersTest samplePlastic film

The invention provides an aluminum-plastic film corner aluminum layer thickness testing method and a cutting device thereof, and the aluminum-plastic film corner aluminum layer thickness testing method comprises the following steps: (1) marking a corner detection point of a to-be-tested aluminum-plastic film and a center line passing through the corner detection point, and shearing the corner of the to-be-tested aluminum-plastic film as a test sample; (2) fixing and cutting the test sample to obtain a cut sample; (3) testing the aluminum layer thickness of an angular position detection point of the cutting sample, comparing the aluminum layer thickness with the theoretical angular position aluminum layer thickness, and if the aluminum layer thickness of the angular position detection point is greater than the theoretical angular position aluminum layer thickness, returning the cutting sample as a test sample to the step (2) until the aluminum layer thickness of the angular position detection point is less than or equal to the theoretical angular position aluminum layer thickness; and (4) testing the thickness of the corner aluminum layer at a point near the corner detection point of the cutting sample in the step (3), and determining the thinnest point of the corner of the aluminum plastic film and the thickness of the corner aluminum layer of the aluminum plastic film. According to the test method provided by the invention, the accuracy of aluminum layer thickness measurement at the corner of the aluminum plastic film is further improved.

Owner:TIANJIN ENERGIES

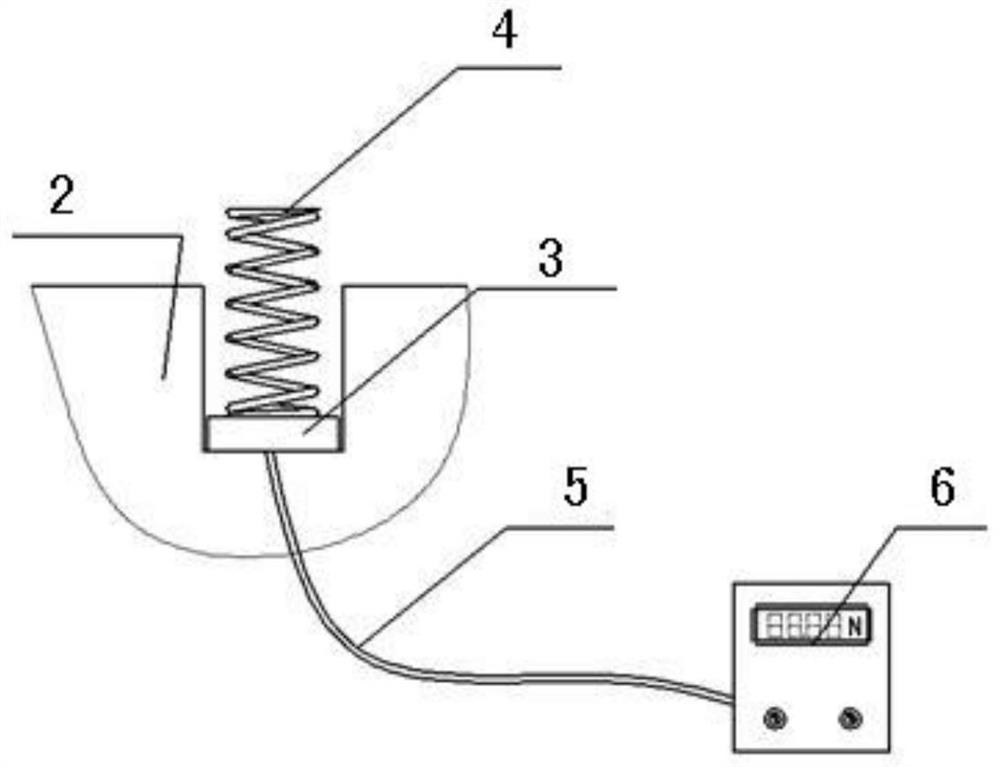

A Measuring Method of Prefabricated Body Conformity

ActiveCN110823801BWon't breakFast test processMechanical measuring arrangementsMaterial analysisContact pressureDestructive testing

The invention discloses a method for measuring mold-fitting properties of a prefabricated body, which comprises step 1) preparing a mold according to the shape of the prefabricated body, and setting reserved positions on the mold; step 2) installing contact pressure sensors on the reserved positions; and step 3) prefabricating Body-fitting mold assembly; step 4) record the pressure value F of all measurement points on the prefabricated body i ; Step 5) set the standard pressure value to be F when sticking the mold, then the deviation value D is 0, analyze the relationship between the pressure value Fi and the deviation value Di, Di=(F-Fi) / k, wherein k is the spring coefficient; 6) According to the deviation range requirements of the product surface requirements, evaluate the moldability of the prefabricated body. This method, by arranging a contact sensing device on the mold, can sense the contact condition of the prefabricated body when it is molded, and feed back its moldability and deviation value in the form of force. It is a non-destructive testing method that will not damage the prefabricated body. .

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

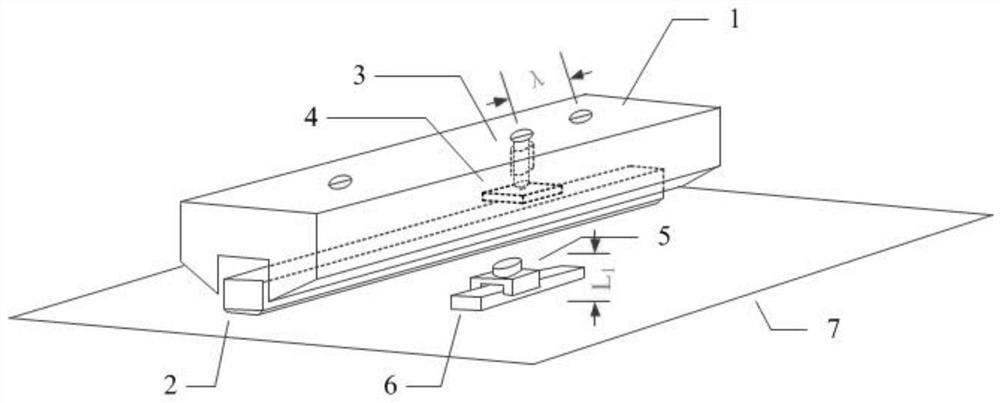

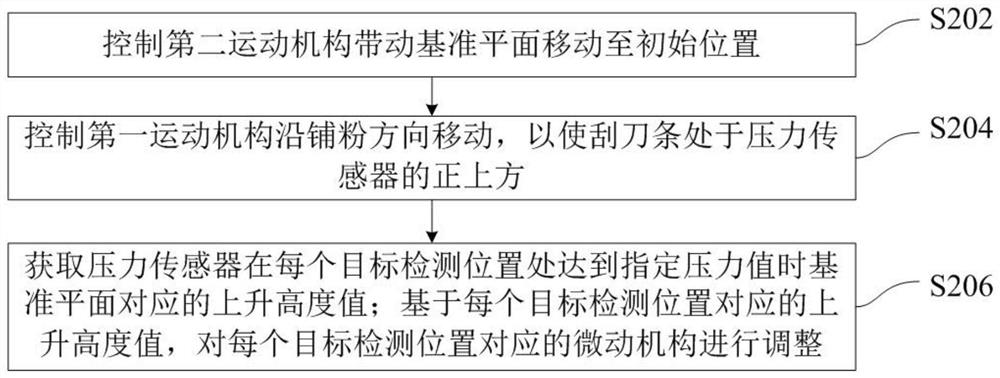

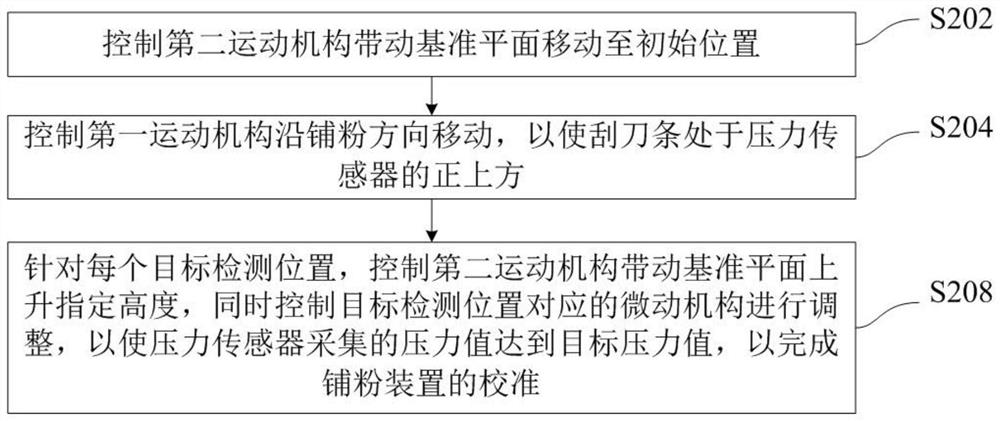

Calibration method, device and system for powder spreading device

PendingCN114289739AHigh precisionEasy to operateAdditive manufacturing apparatusIncreasing energy efficiencyControl systemReciprocating motion

The invention provides a calibration method, device and system for a powder spreading device. The method is applied to a control system. The control system is connected with a first movement mechanism arranged in a powder spreading device in an equipment forming area, a micro-motion mechanism arranged in an adjusting hole of the first movement mechanism, a second movement mechanism arranged below the powder spreading device and corresponding to a reference plane, and a pressure sensor arranged on a guide rail on the reference plane. The powder spreading device further comprises a scraper strip embedded and fixed in the first movement mechanism; the first movement mechanism drives the scraper strip to do reciprocating motion in the equipment forming area in the powder laying direction; a plurality of adjusting holes are formed in the first movement mechanism; a micro-motion mechanism is arranged in each adjusting hole, and a movable pressing block is arranged below each micro-motion mechanism; the inching mechanism adjusts the embedding height of the scraper strip in the first movement mechanism by applying pressure to the movable pressing block. Calibration based on the structure can improve the calibration precision of the powder spreading device.

Owner:HUNAN FARSOON HIGH TECH CO LTD

An experimental device for enhancing mixed gas huff and puff with oil-soluble foaming agent in complex heavy oil reservoirs and its application method

ActiveCN108071390BEnhanced Oil RecoveryEnhanced overall recoverySurveyFluid removalFoaming agentOil viscosity

The invention discloses complex heavy oil reservoir oil solubility foaming agent intensified mixed gas huff-puff experimental equipment. The mixed gas is natural gas and propane which have better dissolution and viscosity-breaking effects compared with the natural gas, CO2 or CH4 and other single light component gas, the propane gas can be effectively prevented from liquefaction, so that the propane gas consumption can be reduced, and the propane gas use cost is reduced. In addition, an oil solubility foaming agent is matched with the mixed gas to generate artificial foam oil to reduce the speed of gas output during the huff-puff period, and the heavy oil viscosity can be reduced, so that the problem that the recovery efficiency of existing complex heavy oil reservoir is not high can be solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

CNC Machine Tool with High Precision Positioning Function

ActiveCN109015048BGuarantee processing qualityReduce laborMeasurement/indication equipmentsLarge fixed membersNumerical controlSoftware engineering

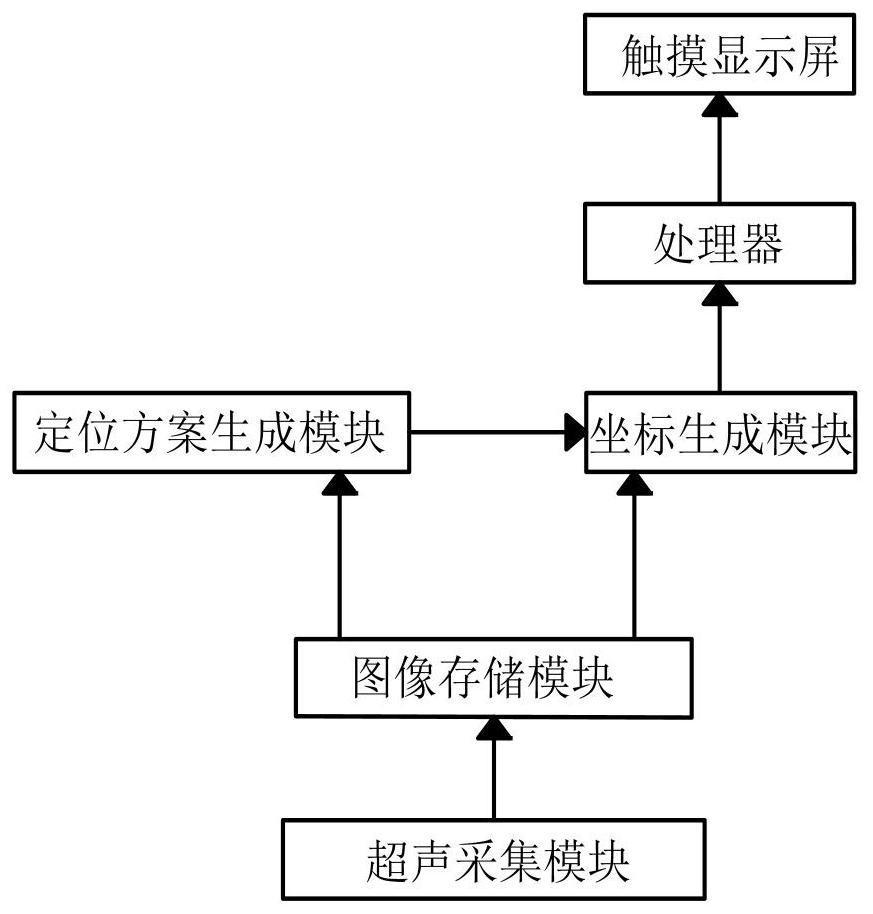

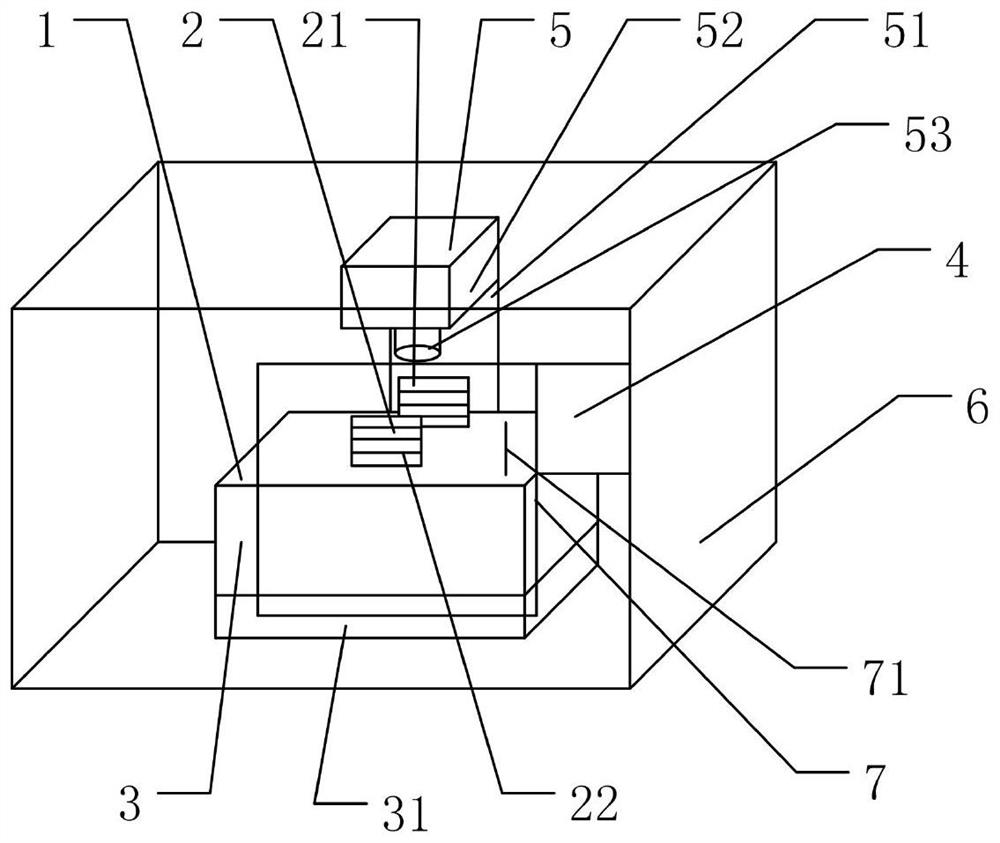

The invention discloses a numerically controlled machine tool with a high-precision positioning function, comprising: a workbench, a positioning fixture is arranged at the top; a lifting device is arranged at the bottom of the workbench; a human-computer interaction interface includes a virtual setting module; a virtual setting module Including: an ultrasonic acquisition module, which collects the size information of the workpiece to be processed through real scene scanning, generates 3D model information, transmits and stores it to the image storage module; a positioning scheme generation module, which generates multiple positioning schemes of the workpiece to be processed; and a coordinate generation module , its coordinate generation module generates the NC program information of the workpiece to be processed according to the 3D model information and the positioning scheme and transmits it to the processor; the present invention provides different positioning schemes according to the different positioning surfaces through the human-computer interaction interface, avoiding artificial selection of positioning The problem of unsatisfactory machining accuracy caused by the surface, and the 3D model information is obtained through the physical object, and the NC program is automatically generated, which not only ensures the machining quality of the workpiece, but also ensures the processing time.

Owner:东莞市硕凯机械有限公司

Carding cashmere length detection method and device based on pixel calculation

ActiveCN111489336AReduce the impactReduce mistakesImage enhancementImage analysisAlgorithmEngineering

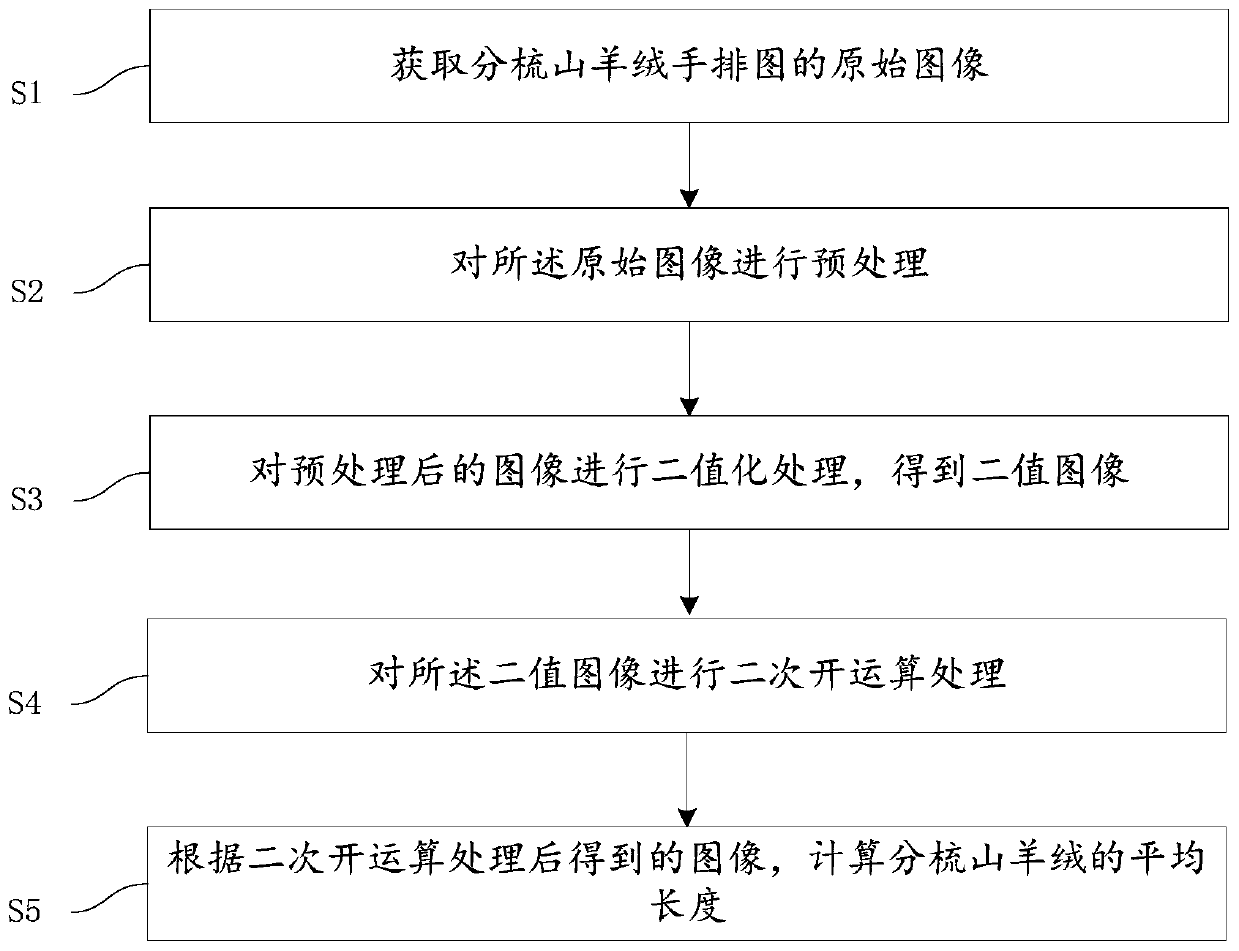

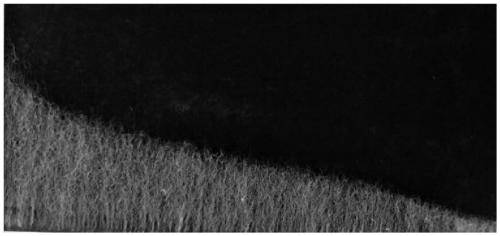

The invention relates to a carded cashmere length detection method and device based on pixel calculation. The carded cashmere length detection method based on pixel calculation comprises the steps ofacquiring an original image of a carded cashmere hand layout drawing; preprocessing an original image; performing binarization processing on a preprocessed image to obtain a binary image; carrying outsecondary opening operation processing on the binary image; and calculating the average length of the carded cashmere according to the image obtained after secondary opening operation processing. Onthe basis of a carding cashmere binary image, calculation of the average length of carding cashmere is completed through calculation of pixel points. The invention has the advantages that a small number of noisy points are allowed to exist in the binarized image, and the influence on the final measurement result is small; besides, manual point tracing, drawing and calculation are avoided, so thatmanual measurement errors are avoided, and the method is high in detection speed, small in error and high in efficiency.

Owner:INNER MONGOLIA UNIV OF TECH

A method of calling s2p file to obtain loss compensation data in noise figure analyzer

ActiveCN107247696BSimplifies manual entryAvoid Human Measurement ErrorsNatural language data processingTransmission monitoringEngineeringNoise figure

The present invention provides a method for calling S2P files in a noise figure analyzer to obtain loss compensation data, which includes the following steps: step 1, load the S2P file from the network analyzer, and parse the S2P format file data; step 2, extract Valid parameters in the S2P data, calculate the loss compensation value suitable for the noise figure analyzer; step 3, create a new frequency-loss value list to correct the system loss in the noise figure measurement; step 4, save the loss in LOS format Compensation file, generate a LOS format file with the same name as the S2P file, or save it as a LOS file with the user's own name. The invention is easy to operate, the whole algorithm can be embedded in the host software of the noise coefficient analyzer, and can be automatically completed by one-key operation in the menu, and can also be realized by program control outside the instrument; it provides a method for establishing a loss compensation table in noise coefficient measurement. A new fast and efficient input method.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

A laser displacement sensor calibration device

InactiveCN103852014BQuick check operationImprove work efficiencyUsing optical meansAdhesiveOptoelectronics

The invention relates to a laser displacement sensor verifying device which comprises a body, light-transmitting ports, a magnet, switching buttons, a positioning magnet, a positioning stop block, laser reflecting plates, rotating shafts and a box body, wherein the body is made of a stainless steel sheet with low deformation coefficient into a cuboid shape, and the upper surface and lower surface of the body are respectively provided with rectangular light-transmitting ports; the switching buttons are attracted through the magnet or the positioning magnet; the laser reflecting plates are made of white stainless steel sheets, and the surfaces of the laser reflecting plates are designed into non-specular surfaces and connected with the laser rays of the rotating shafts in a welding way; one ends of the rotating shafts are adhered to and fixedly connected with the switching buttons by using adhesives, and the other ends of the rotating shafts are inserted into holes inside the rotating shafts by using screw rods and tightly adhered to the rotating shafts by using the adhesives. According to the laser displacement sensor verifying device, the laser beams of the verified laser displacement sensor are emitted to the central positions of the laser reflecting plates, the switching buttons are respectively pulled from front to back or from back to front according to that the laser beams of the verified laser displacement sensor are emitted to the central position of the laser reflecting plates, a sensor system acquisition system acquires the position data of a plurality of the laser reflecting plates, so that the verification of the laser displacement sensor is completed. The laser displacement sensor verifying device disclosed by the invention is loaded into the box body when being not in use.

Owner:中国兵器工业第二0二研究所

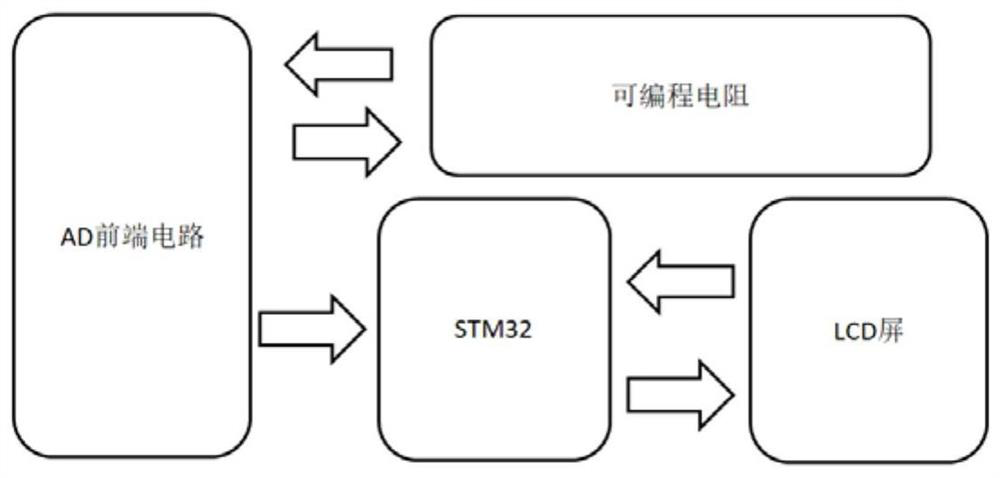

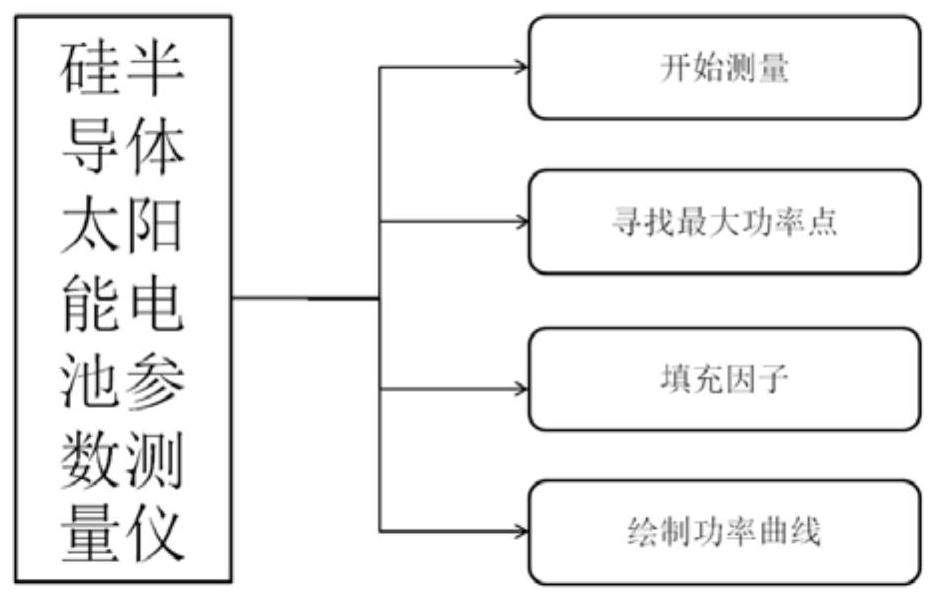

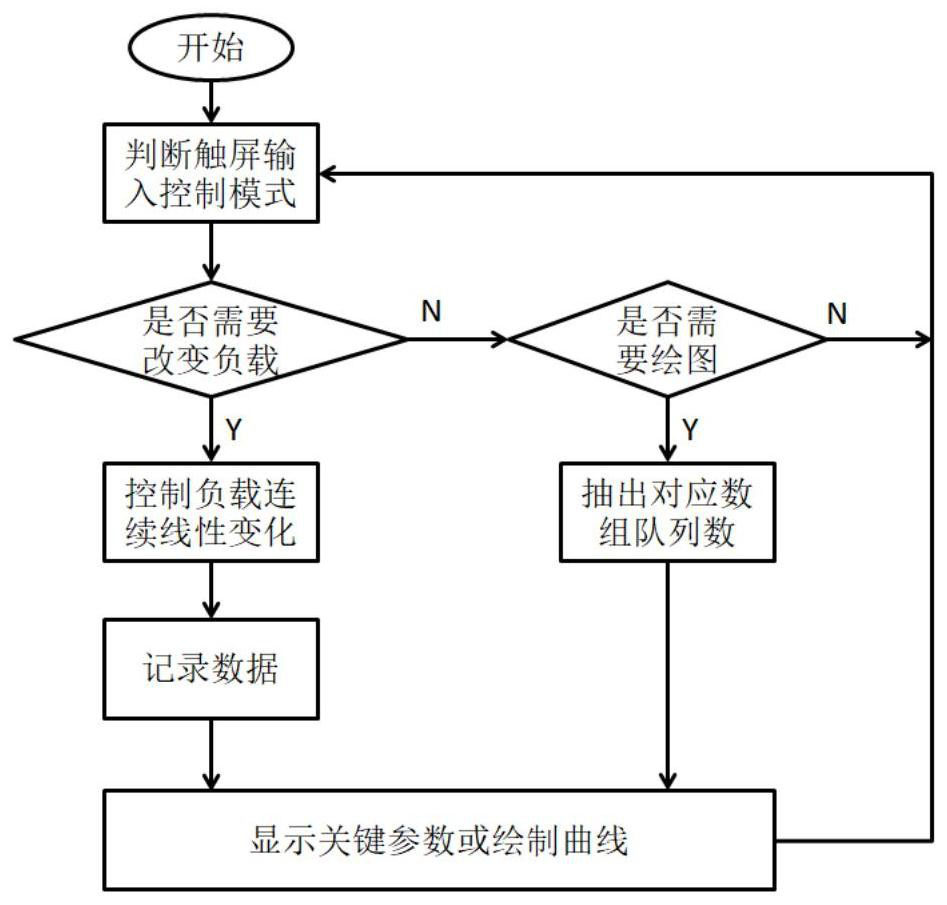

Silicon semiconductor solar cell parameter measuring instrument

PendingCN112821867AHigh measurement accuracyImprove experimental efficiencyPhotovoltaic monitoringPhotovoltaic energy generationPhysicsFill factor

The invention discloses a silicon semiconductor solar cell parameter measuring instrument. An A / D front-end circuit made of LM358 is used for controlling an input signal to be within a detection range of an A / D module; a programmable resistor manufactured by a relay module is used as a load of an A / D front-end circuit, and parameters are accurately measured through continuous linear change; an LCD screen displays the parameters of the solar cell and the working mode of the single-chip microcomputer is controlled by a screen touching mode. Measurement of voltage and current is completed in an STM32F407 chip, the output power of the battery under different load conditions is calculated in real time, a current-voltage curve and a power-voltage curve are drawn, and a fill factor is calculated while the maximum power point is obtained. The measuring instrument utilizes the modern electronic technology and the advanced single-chip microcomputer technology to realize the intelligent calculation of the output power of the solar cell and the automatic search of the maximum power point, and has the advantages of high measurement precision, fast speed measurement, visual result, low cost, high experiment efficiency and the like.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

Inspection device for inspecting height difference of bottom surface of workpiece

PendingCN113124729AAvoid Radial WobbleIt is convenient to measure the downward displacement of the inspection unitMechanical measuring arrangementsMicrometerEngineering

The invention relates to an inspection device for inspecting the height difference of the bottom surface of a workpiece. The device comprises a bottom plate, the middle part of the bottom plate is vertically and fixedly provided with a fixed block, and the two sides of the bottom plate are movably provided with dial indicators. An inspection bench extends out of one side of the fixing block, a plurality of limiting cavities which are symmetrical in a midspan mode are formed in the inspection bench, and inspection units are axially and slidably connected into the limiting cavities; the two ends of each inspection unit axially penetrate through the inspection bench, the bottom of each inspection unit abuts against the detection end of the dial indicator, and the tops of the multiple inspection units elastically support a workpiece to be inspected. The inspection device can conveniently and quickly inspect the height difference between the reference plane of the workpiece and the protruding part of the workpiece, the inspection precision is high, and the inspection efficiency is obviously improved compared with manual inspection by adopting a vernier caliper or a micrometer.

Owner:天津市臣涛精密机械设备有限公司

Method and device for constructing floor plan based on uwb technology

ActiveCN109902409BQuick buildImprove experienceGeometric CADPosition fixationMeasurement costFloor plan

The invention discloses a method and a device for constructing a plane map based on UWB technology, and relates to the field of computer technology. A specific implementation of the method includes: acquiring the device information and coordinate information of the UWB positioning device installed in the target building; Sketch; the sketch is optimized using the historical graph corresponding to the target building to generate a floor plan of the target building. This embodiment can quickly construct a plan based on UWB technology, avoid artificial measurement errors, reduce measurement costs, and improve user experience.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

A high-voltage transmission cable grounding current automatic detection device

InactiveCN105301346BAvoid contactSolve the safety problem of climbing tower to detect ground currentMeasurement using digital techniquesHigh pressureControl circuit

The invention discloses a high-voltage power transmission cable earth current automatic detection device. The device comprises a sampler (13) and a receiver (16). The sampler (13) comprises an upper shell (2), a middle shell (3) and a lower shell (1). A PCB panel (4) is arranged on the upper shell (2). A first induction coil (10) is arranged in a first chamber (9) of the left part (21) of the middle shell. A second induction coil (12) is arranged in a second chamber (11) of the right part (22) of the middle shell. The first induction coil (10) and the second induction coil (12) are connected with a control circuit of the PCB panel (4). A supporting bar (7) is arranged between two bulges (6) on the left part (21) of the middle shell and a supporting bar (7) is arranged between two bulges (6) on the right part (22) of the middle shell. The two supporting bars (7) are connected by a spring (8). The device is simple in structure and convenient for installation, has strong environmental endurance, is low in safe risk, and can do monitoring in real time.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com