Full-parameter measuring system and method for inner bore of bearing ring with tapered bore

A bearing ring and measuring method technology, applied in measuring devices, instruments, etc., can solve the problem of low accuracy, achieve the effects of simple adjustment, eliminate human measurement errors, and facilitate real-time monitoring and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

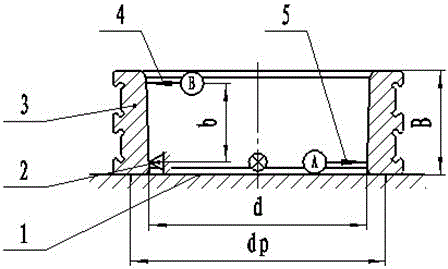

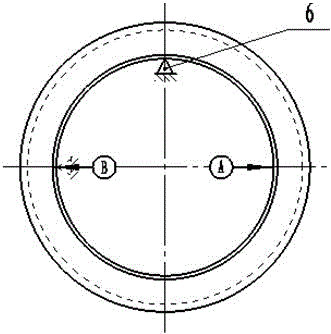

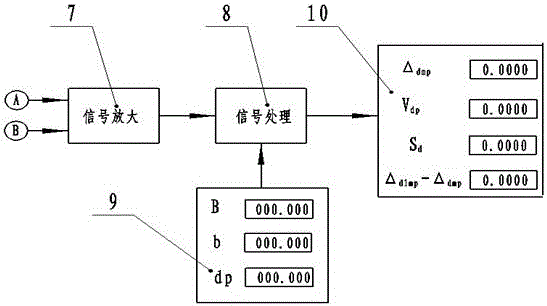

[0042] The full-parameter measurement system with the inner hole of the bearing ring as a tapered hole is as follows: figure 1 , 2 , 3, the mechanical part consists of a measuring platform 1, a measuring fulcrum 2, a radial auxiliary fulcrum 6, and two measuring heads 4, 5 with displacement sensors. When measuring, the small end surface of the inner hole of the bearing ring 3 is in close contact with the measuring platform 1, and the three points of the measuring fulcrum 2, the auxiliary fulcrum 6 and the probe 5 are distributed at 90° in the same radial plane at the small end of the inner hole, and the fulcrum 2 and the The probe 5 should be on the same straight line along the diameter, and the three points of the measuring point and the fulcrum should deviate from the chamfer at the small end of the inner hole; the other probe 4 should be placed directly above the measuring fulcrum 2, and the two points should be located on the same generatrix on the surface of the inner hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com