Self-service form filling machine capable of quickly customizing receipts on site and self-service form filling method

A form-filling machine and receipt technology, which is applied in the field of form-filling machines and form customization, can solve the problems of time-consuming, error-prone, and low efficiency, and achieve the effect of improving efficiency and avoiding human measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

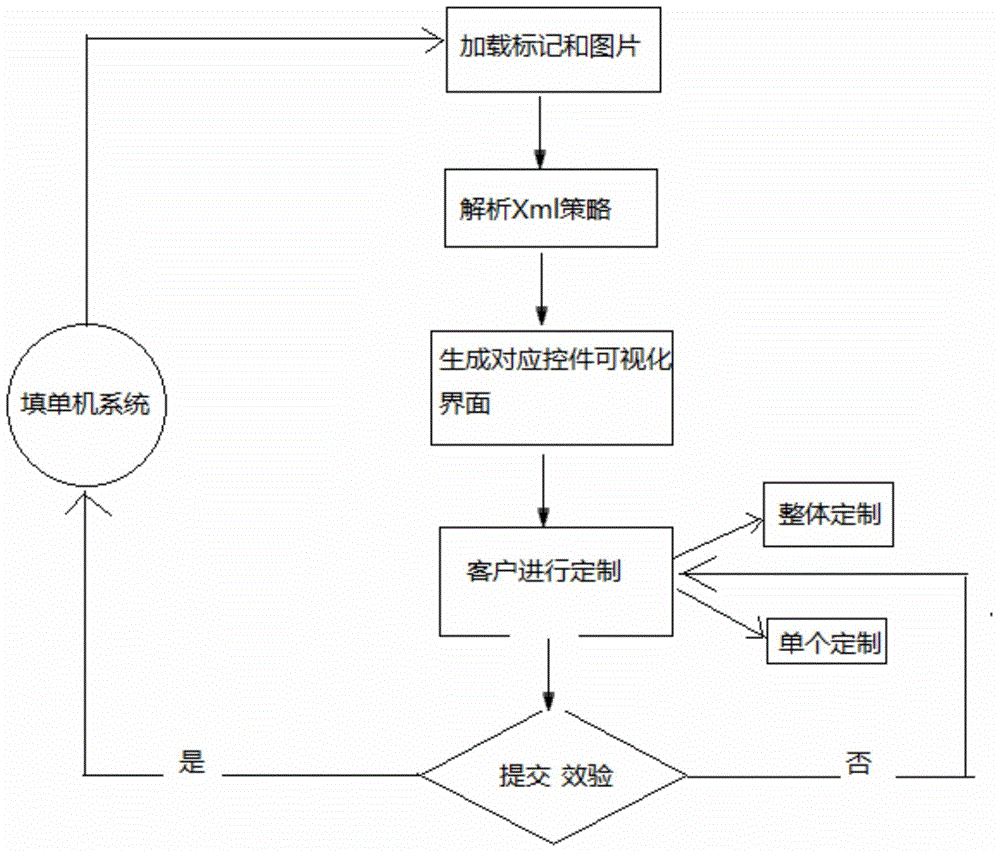

[0023] Below in conjunction with specific embodiment and Figure 1-3 The self-service form-filling machine and method for rapidly making documents on the spot of the present invention are described.

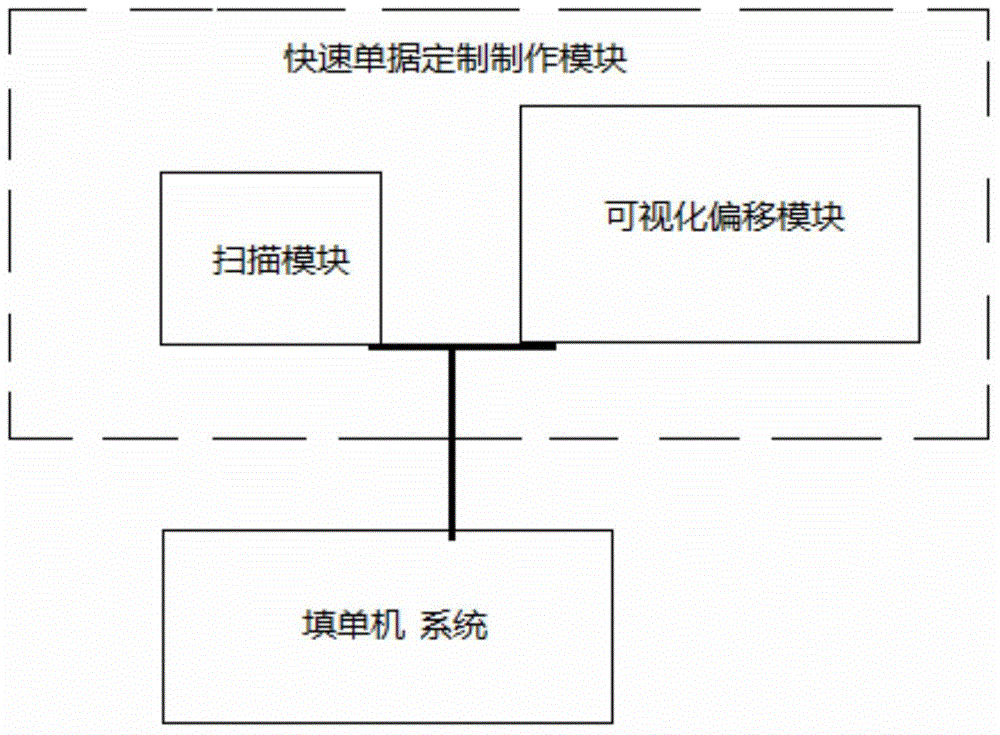

[0024] figure 1 It is a structural schematic diagram of a self-service form-filling machine for rapid on-site order customization of the present invention. It can be seen that the self-service form-filling machine for rapid on-site formulation of documents in the present invention includes a form-filling machine system, and the customized document module is embedded in the form-filling machine system. The customized document module includes a scanning module and a visual offset module.

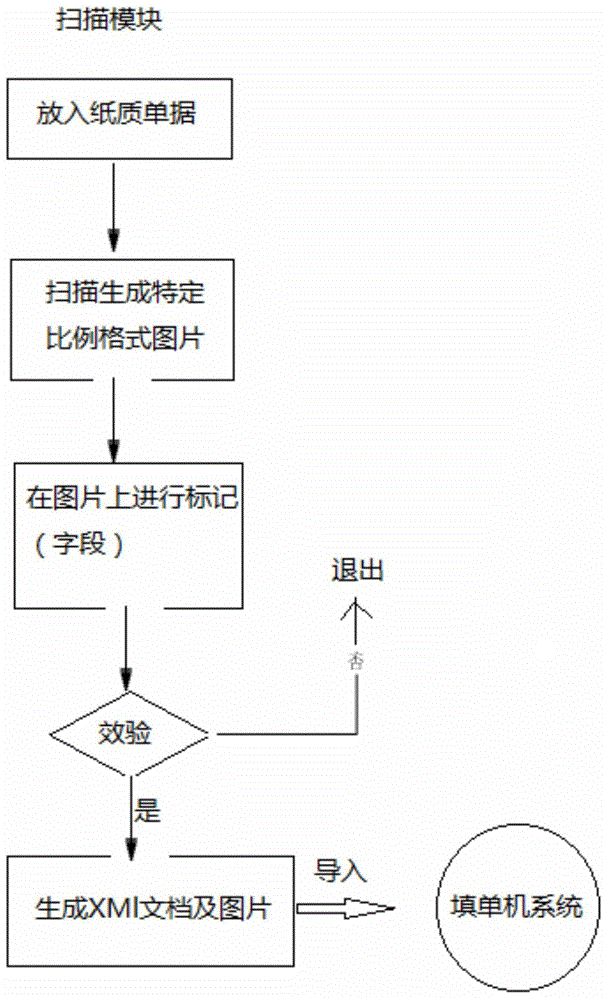

[0025] figure 2 Workflow diagram for the scanning module. It can be seen that the scanning module is used to scan the picture of the document that needs to be formulated, mark the printing field that needs to be configured at the corresponding position on the scanned picture, and load the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com