An experimental device for enhancing mixed gas huff and puff with oil-soluble foaming agent in complex heavy oil reservoirs and its application method

A technology for mixed gas and heavy oil reservoirs, which is applied in the fields of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of crude oil viscosity increase, formation pressure decrease, and poor solubility, so as to reduce viscosity, Reduce the dosage and avoid the effect of liquefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

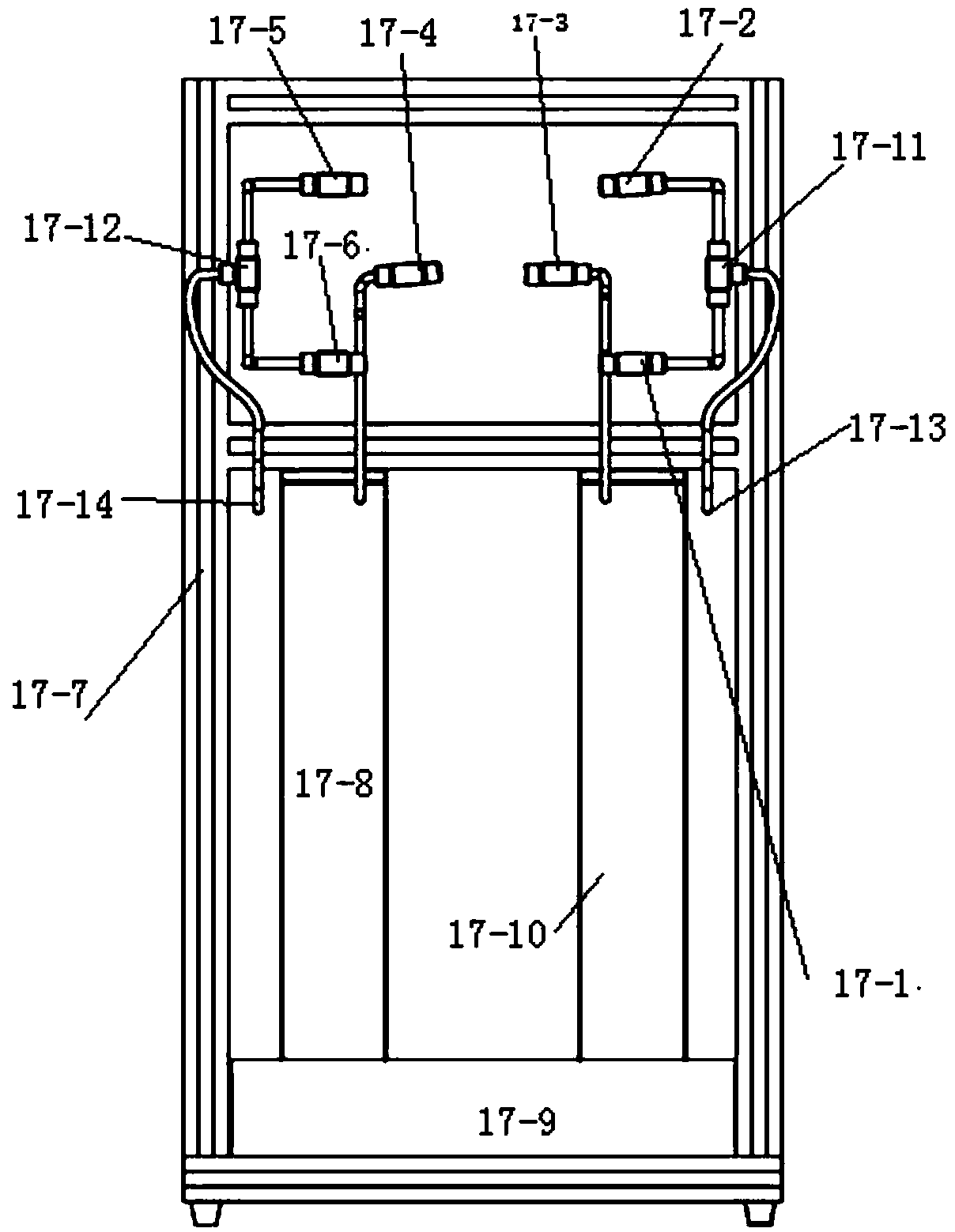

[0101] An oil-soluble foaming agent-enhanced mixed gas huff and puff experimental device for complex heavy oil reservoirs, comprising: a core holder, a formation water container and an active oil container are connected in parallel at the entrance of the core holder, The outlet of the holder is connected in parallel with an oil-soluble foaming agent container and a mixed gas container; the outlet of the core holder is also sequentially connected with an artificial foam oil generation observation window, a back pressure valve and a gas-liquid separation device.

[0102] The gas-liquid separation device includes: a separator, a high-precision electronic balance, a gas measurement system and a vacuum pump.

[0103] The core holder is an internal pressure measuring core holder; preferably, the pressure measuring points of the core holder are distributed on the core rubber sleeve of the core holder.

Embodiment 2

[0105] A complex heavy oil reservoir oil-soluble foaming agent enhanced mixed gas huff and puff experimental device as described in Example 1, the difference is that the length of the core holder is 1m-2m, and the inner diameter is 0.025m-0.075m .

Embodiment 3

[0107] A complex heavy oil reservoir oil-soluble foaming agent enhanced mixed gas huff and puff experimental device as described in Example 1, the difference is that the artificial foam oil generation observation window includes an outer body of the visible window, inside the visible window The two pieces of thickened glass are provided, and the flow passage provided in the middle of the thickened glass is provided with a visible window inlet at one end of the flow passage, and a visible window outlet is provided at the other end of the flow passage. The outer body of the window is connected with the thickened glass through a hollowed out window. In practical application, the artificial foam oil generation observation window can withstand a pressure greater than 10MPa and a temperature greater than 50°C. The visible window generated by the artificial foam oil is a cube, and the size range of the outer body of the visible window is 60-100mm in width, 140-180mm in length, and 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com