Oil extraction method utilizing circulated heating cavity gases

A gas circulation and cavity technology, which is applied in the development of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of high cost of polluted wastewater treatment, large boiler space, and difficult technical implementation, etc. Effective production period, reduced processing costs, and the effect of reducing oil production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention can be applied to oil recovery of throughput type, and can also be applied to oil recovery of oil displacement type. For ease of description, this embodiment takes the oil flooding type as an example for illustration.

[0034] The collection well pipe and injection well pipe of cavity gas, the oil production well pipe and the flue gas injection well pipe can share one or several well pipes by using the casing, or use independent well pipes respectively. In this embodiment, an independent well pipe is taken as an example for illustration.

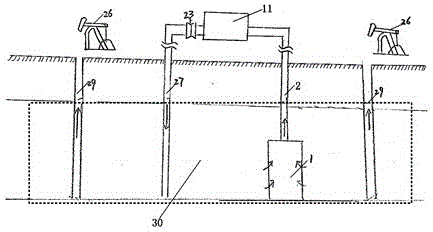

[0035] from figure 1 It can be seen from the figure that an oil recovery method using cavity gas circulation heating uses pressure difference to separate the cavity gas in the oil layer 30 through the separator 1 for gas-liquid separation, and then enters the heating device 11 through the pumping well pipe 2 . The pressure difference can be the difference between reservoir pressure and atmospheric pressure, or ...

Embodiment 2

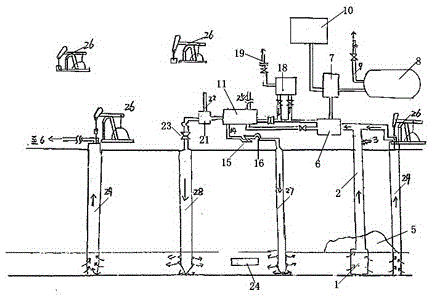

[0037] This embodiment also takes the oil flooding type as an example for illustration. refer to figure 2 , the cavity gas in the reservoir 4 enters the gas-liquid separator 6 through the pumping well pipe 2 by using the pressure difference. After the extraction, use the sampling device 3 to sample the cavity gas to grasp the oxygen content to ensure production safety. The above-mentioned pressure difference may be the difference between reservoir pressure and atmospheric pressure, or a pressure difference created by external force.

[0038] If the water content in the separated liquid is not high, it can directly enter the oil collector 8. If the water content in the separated liquid is high, it will first enter the oil-water separator 7 for oil-water separation, and the separated oil will enter the oil collector 8. The separated water can be concentrated to the water storage device 10, and the separated water can be injected into the downhole, or discharged after purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com