A Measuring Method of Prefabricated Body Conformity

A measurement method and prefabricated body technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of large mold size, heavy weight, difficult to apply to X-ray, CT scanning, etc., to achieve accurate results and avoid measurement The effect of error and quick test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

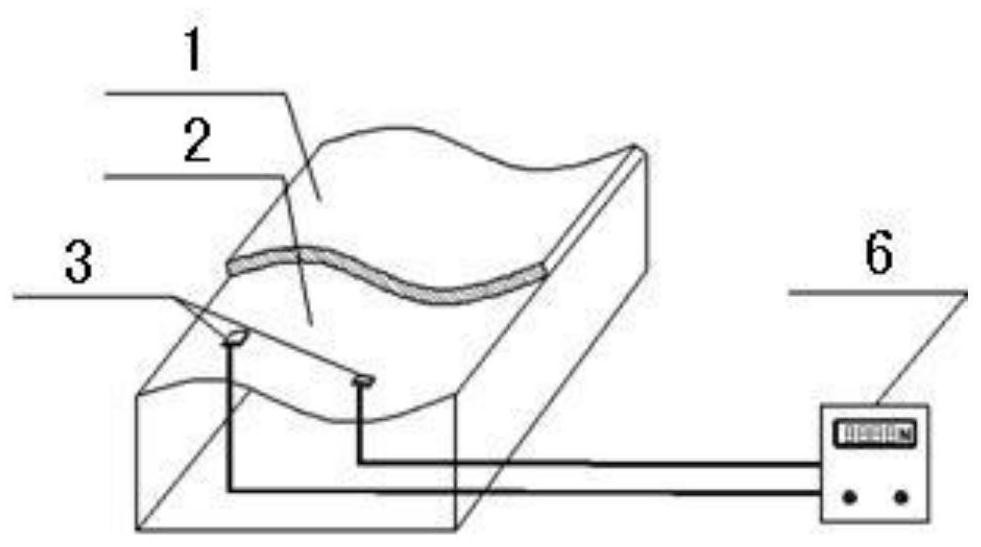

[0041] Such as image 3 As shown, embodiment 1: measurement of curved surface prefabricated body

[0042] The preform 1 has a length of 500 mm, positive and negative curvatures, and a preform thickness of 20 mm. According to the requirements of the prefabricated body 1, 8 measuring points are selected, and the measuring points are respectively located at the inflection points of the positive and negative curvatures of the prefabricated body 1.

[0043] The measurement method of prefabricated body-fitting moldability includes the following steps:

[0044] (1) Prepare the mold 2 according to the measurement requirements of the prefabricated body; during the mold processing, according to the 8 measurement points of the prefabricated body 1 on the mold 2, mark 8 reserved positions every 100mm from the end face of the mold 100mm (corresponding to the prefabricated 8 measurement points of body 1);

[0045] (2) Install sheet-type pressure sensors at each reserved position, and mak...

Embodiment 2

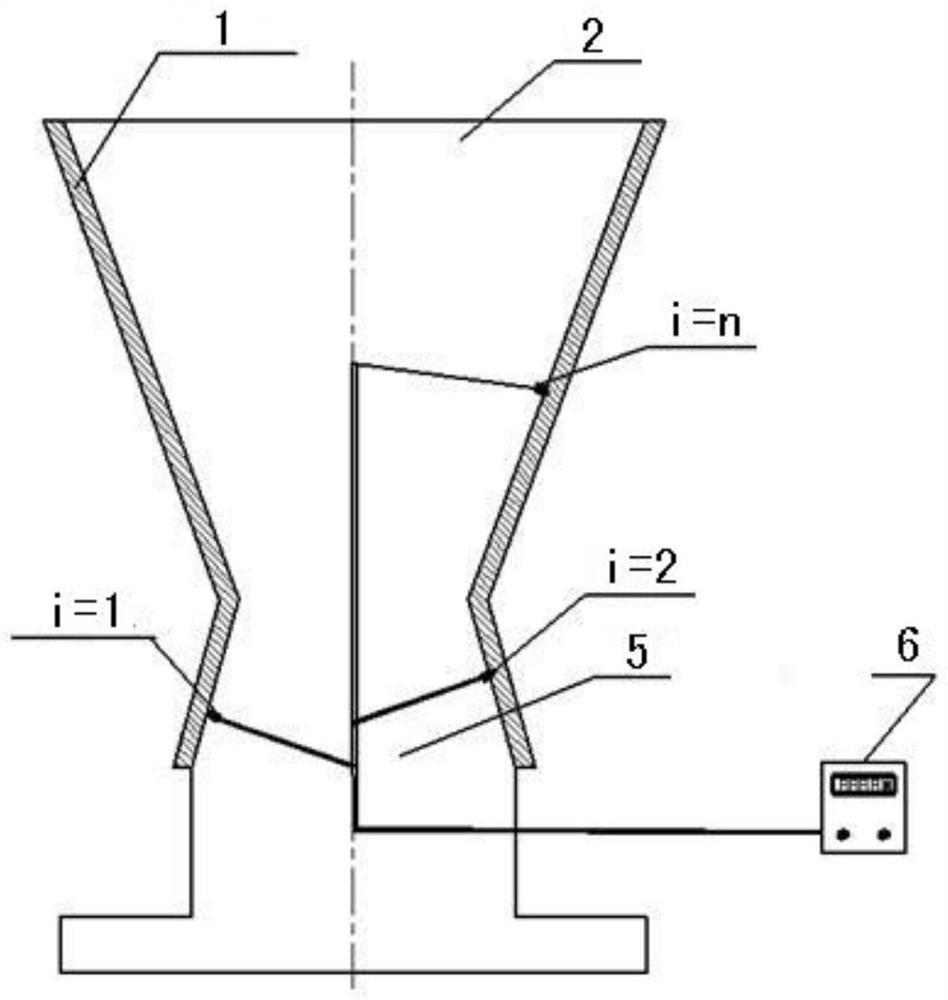

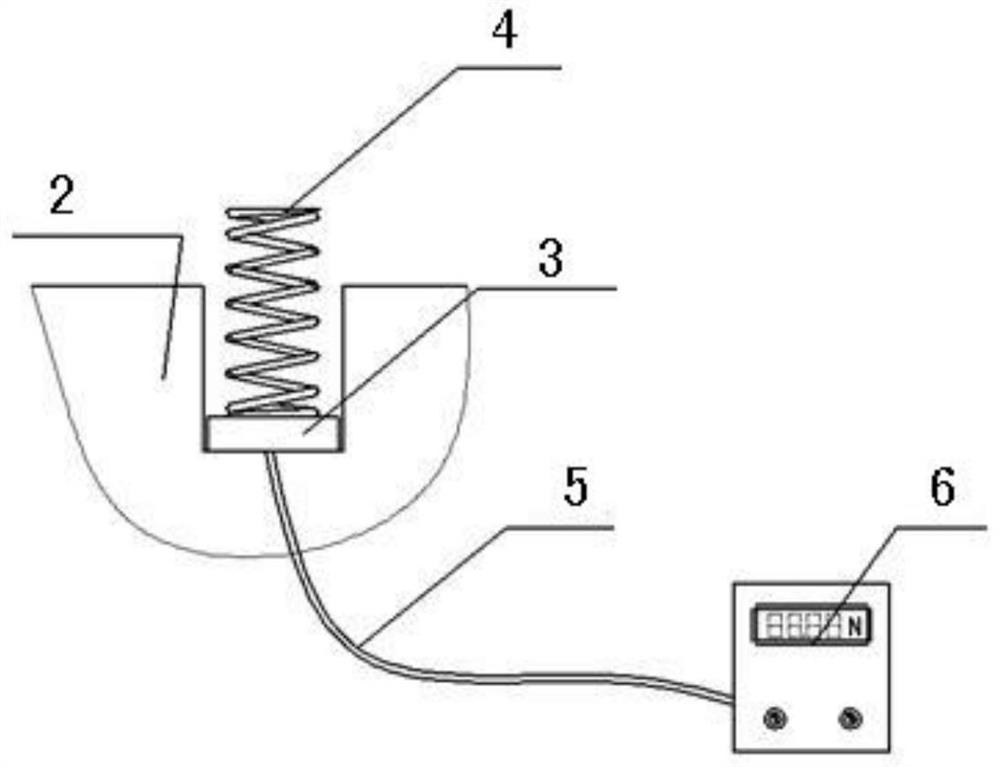

[0048] Such as Figure 4 As shown, embodiment 2: measurement of prefabricated body of rotary body

[0049] The height of the prefabricated part is 428mm, the diameter of the large end is 320mm, the diameter of the small end is 220mm, and the thickness of the prefabricated part is 18mm. According to the requirements of the prefabricated body, 10 measurement points are selected, and the 10 measurement points are located on the same circle. The measurement points are 36° apart.

[0050] Including the following steps:

[0051] (1) According to the measurement requirements of the prefabricated part, prepare the mold 2; when the mold is processed, mark 10 reserved positions on average (corresponding to 10 measurement points of the prefabricated body) at a height of 220 mm from the large end face of the mold;

[0052] (2) Install a sheet pressure sensor at each reserved position, and mark the position as i=1, 2, 3...10; the signal end cables 5 of the sheet pressure sensor are all c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com