Device for measuring density and viscosity of coating for casting

A measuring device and density technology, which is applied in the field of viscosity device and density, can solve the problems of inability to guarantee the metal erosion resistance and anti-sand sticking property of the coating, the inability to accurately control the coating properties, and the lack of equipment for coating viscosity, etc., to achieve reduction The effect of worker labor, improvement of surface quality, and guarantee of coating hangability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

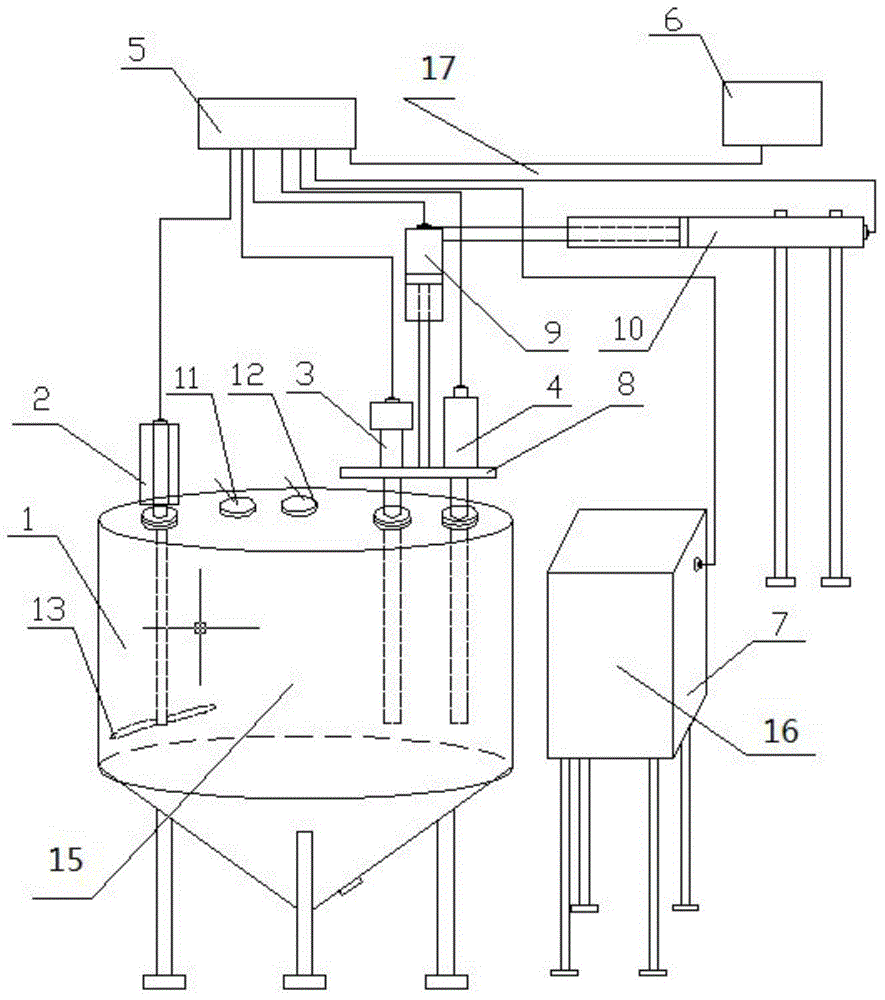

[0021] A device for measuring the density and viscosity of coatings for casting, such as figure 1 Shown: it is assembled by measuring device 15, cleaning device 16 and the control device 17 that is connected with both.

[0022] Described measuring device 15 comprises a stirring tank 1, and stirring tank 1 is connected with stirring motor 2, viscometer 3 and density meter 4 successively from left to right, and viscometer 3 and density meter 4 are connected with above-mentioned stirring tank by a supporting device 8. 1 are connected, and the supporting device 8 is connected with the vertical cylinder 9 and the horizontal cylinder 10 that drive it to move in sequence. The cleaning device 16 includes a cleaning machine 7, and the cleaning machine 7 is connected with the PLC controller 5.

[0023] The control device 17 includes a PLC controller 5 and a touch screen 6. The longitudinal cylinder 9, the horizontal cylinder 10, the corresponding lines at one end of the viscometer 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com