A kind of mine microseismic detector installed in deep hole

A geophone, mining technology, applied in seismic signal receivers and other directions, can solve the problems of increasing the difficulty and complexity of manual maintenance, the failure of the microseismic monitoring system to work normally, and the inability to realize long-distance transmission, etc., to increase the self-checking function, Provides the effect of punching efficiency, increasing variable gain and controllable filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

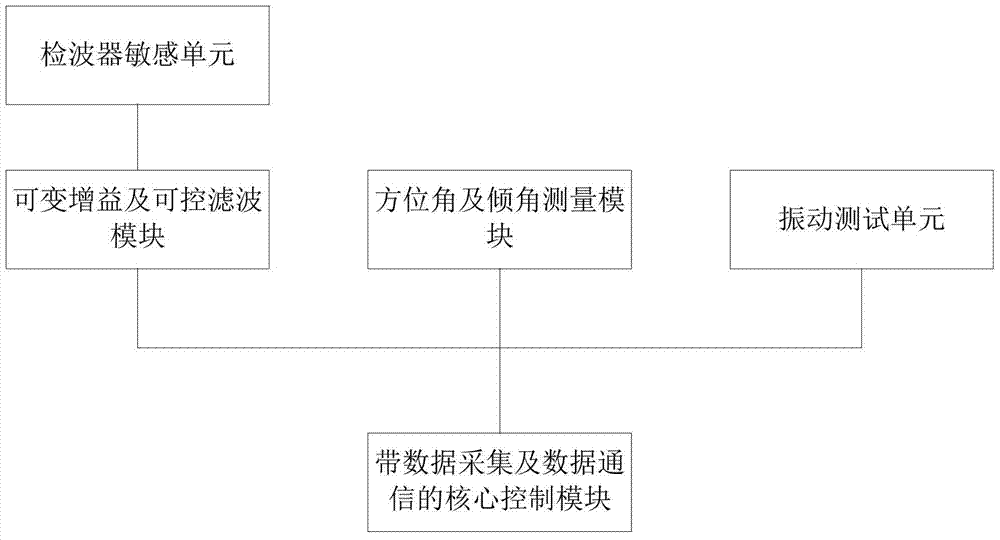

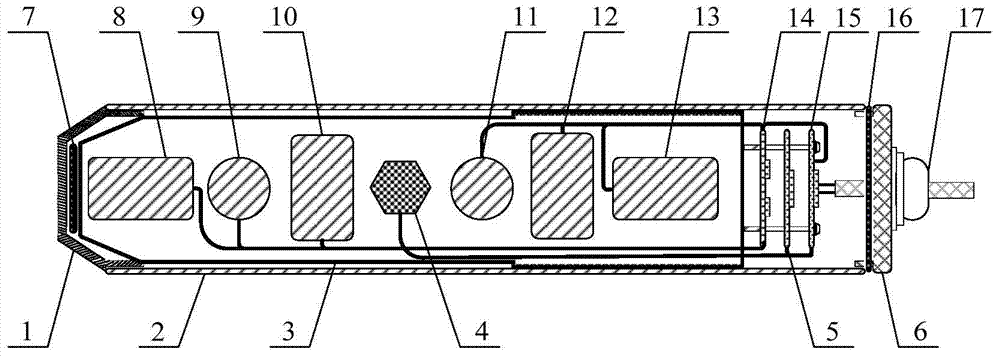

[0042] figure 1 It is a structural schematic diagram of a multi-parameter coupling mining geophone provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the geophone includes: a geophone sensitive unit, a vibration test unit, a variable gain and controllable filter module, an azimuth and inclination measurement module, and a core control module with data acquisition and data communication;

[0043] Wherein, the sensitive unit of the detector is used for sensing external mechanical vibration and converting the mechanical vibration into an analog electrical signal;

[0044] The vibration test unit is used to generate mechanical vibration under the control of the core control module of the data acquisition and data communication;

[0045] The variable gain and controllable filtering module is used to amplify and filter the analog electrical signal output by the sensitive unit of the detector;

[0046] The azimuth and inclination measurement module is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com