Patents

Literature

42results about How to "Reduce the difficulty of punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

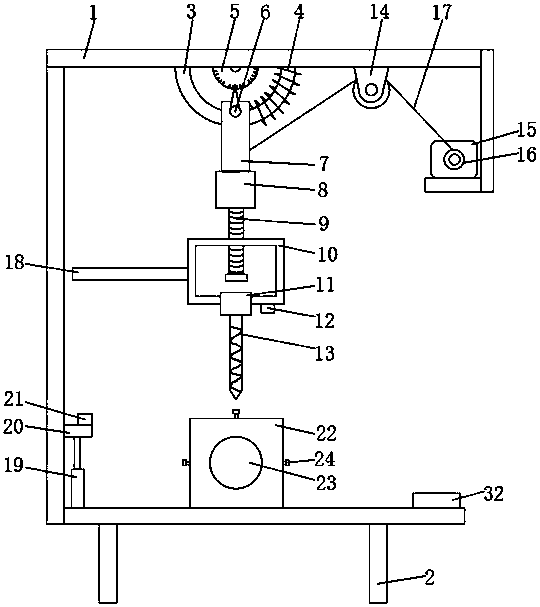

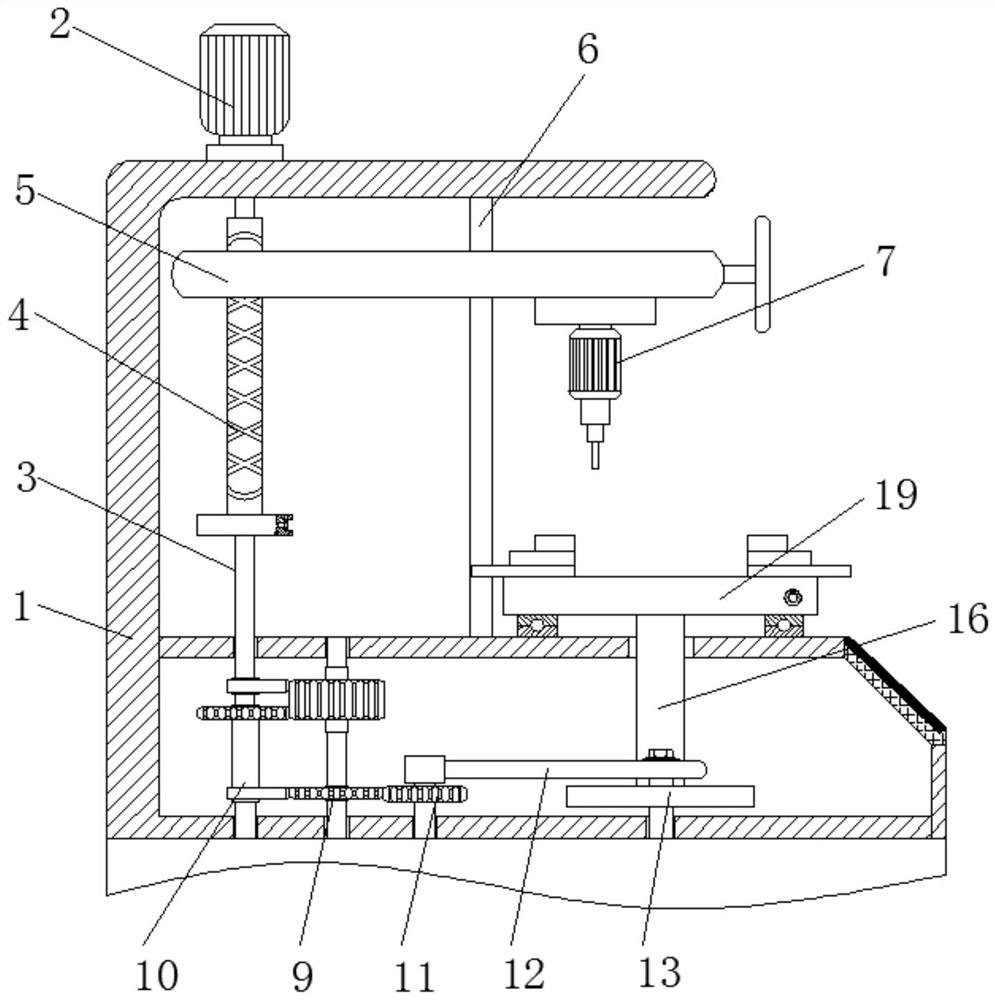

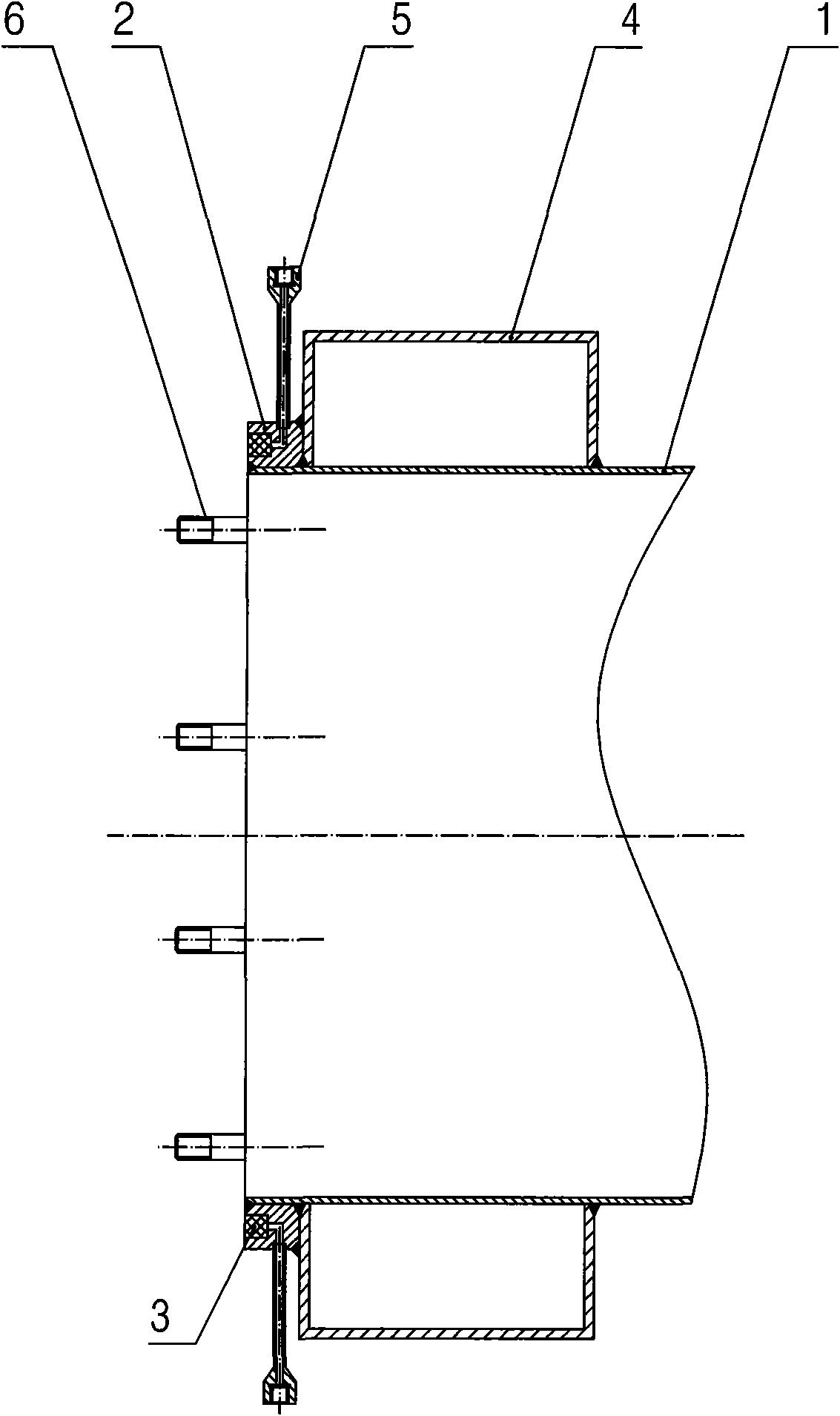

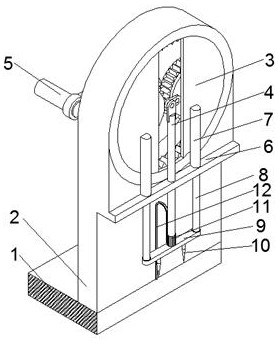

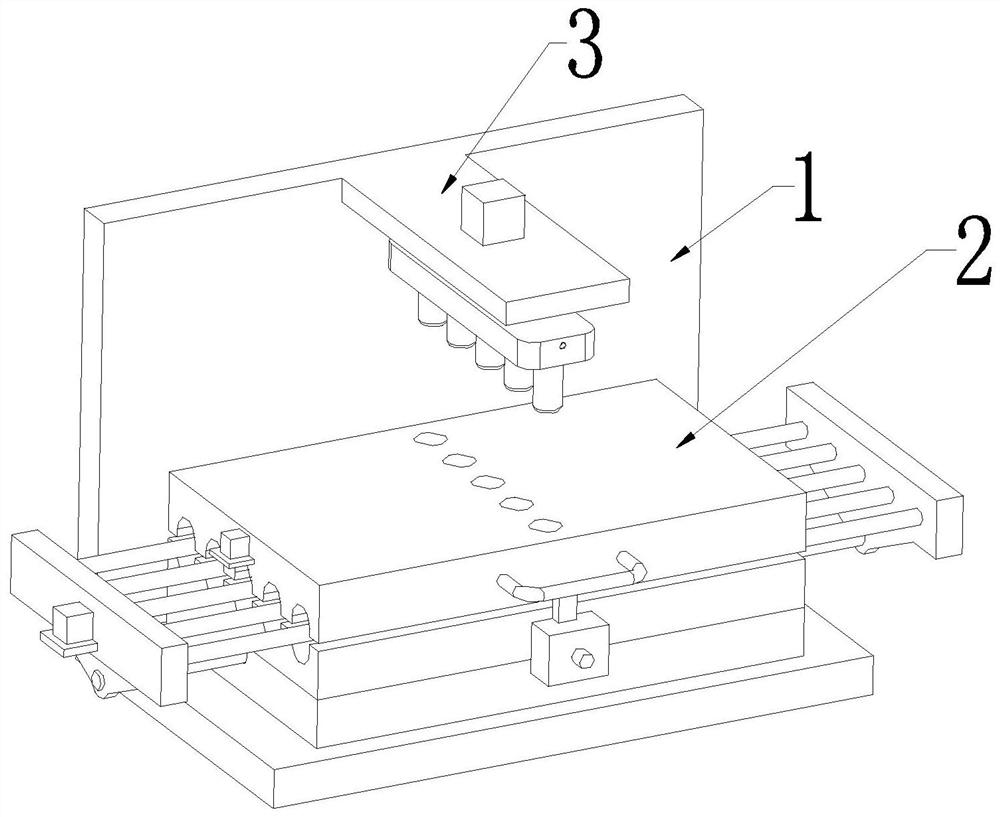

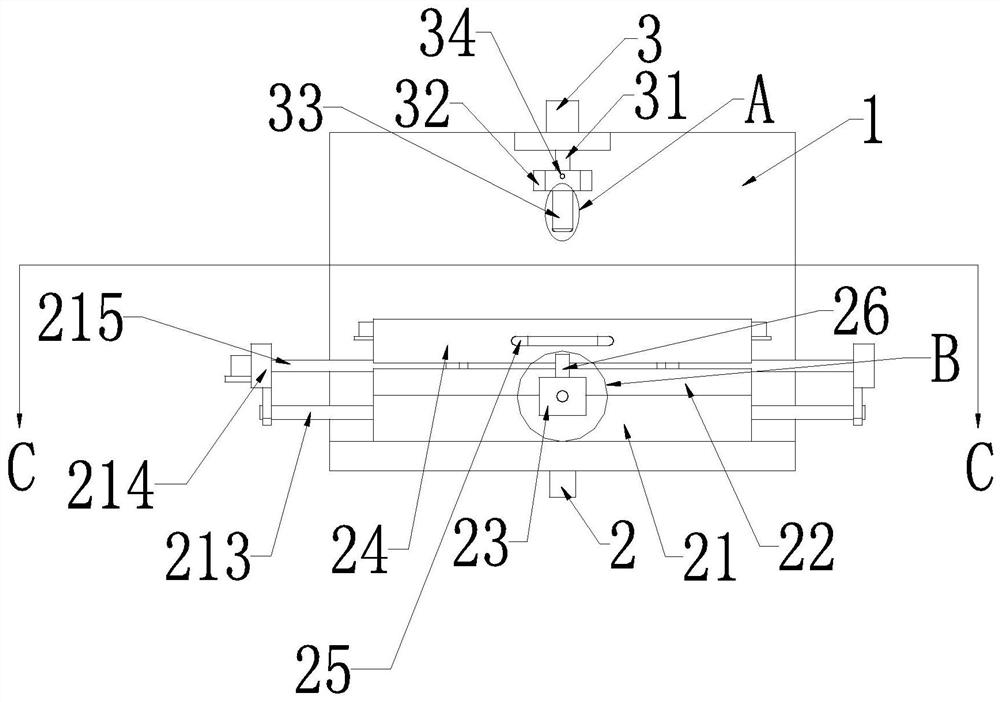

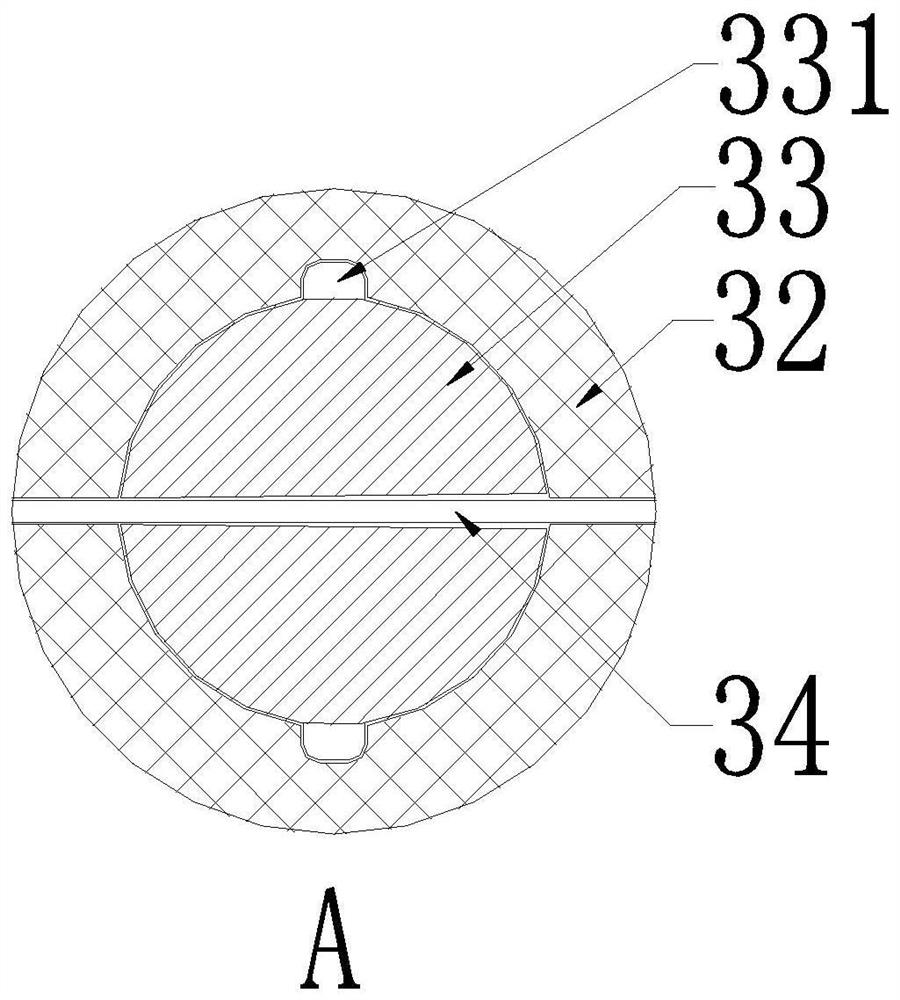

Punching device with bidirectional punching function

InactiveCN107008935AEasy to moveConvenient and stable positioningBoring/drilling machinesPunchingEngineering

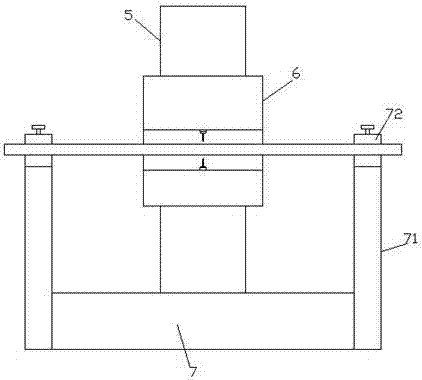

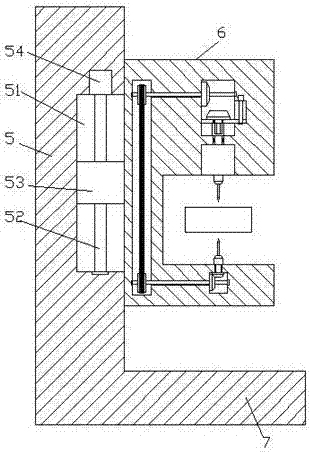

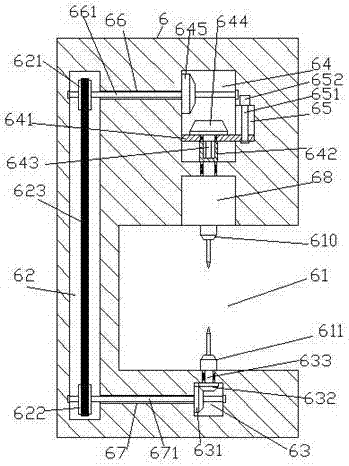

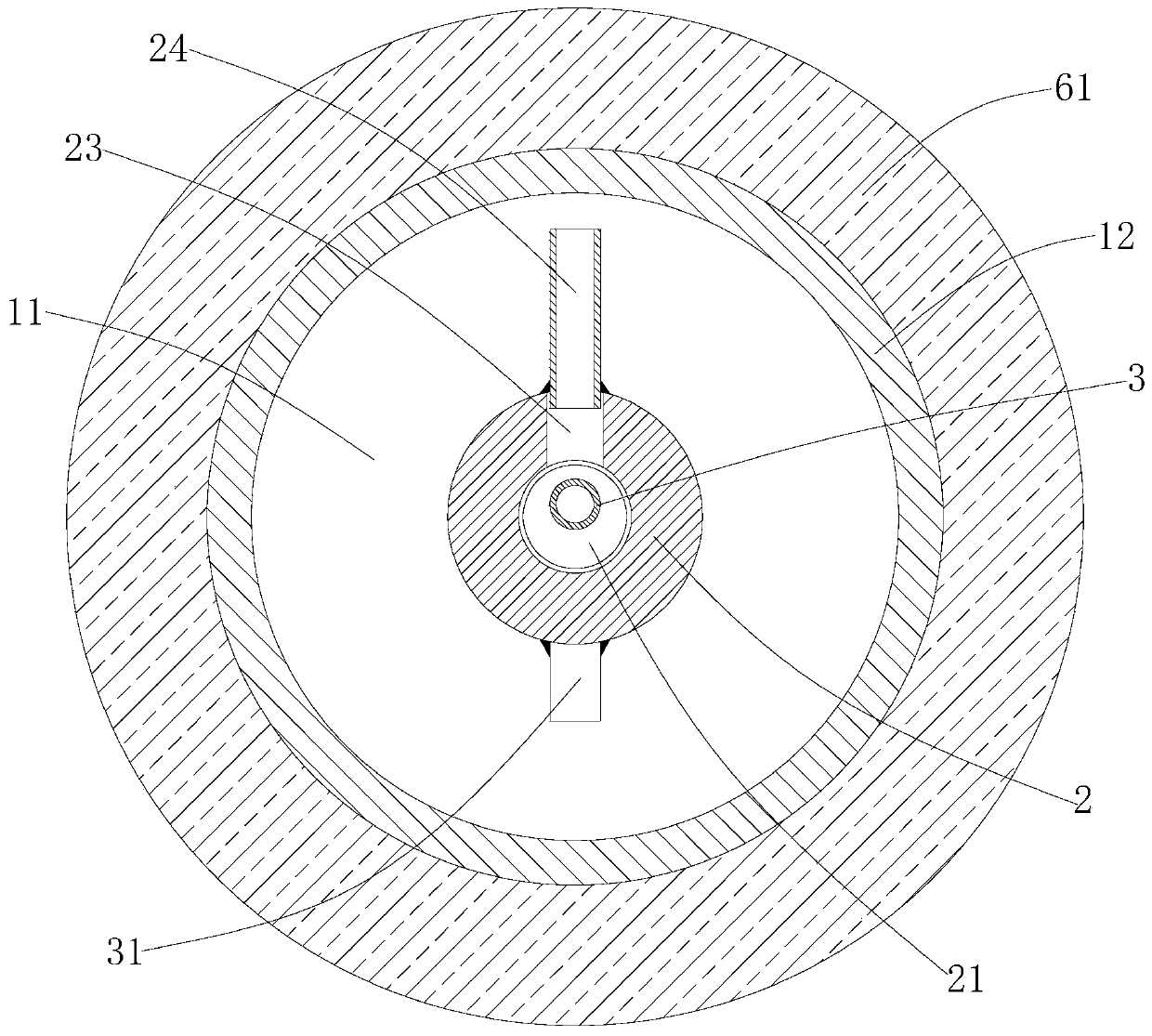

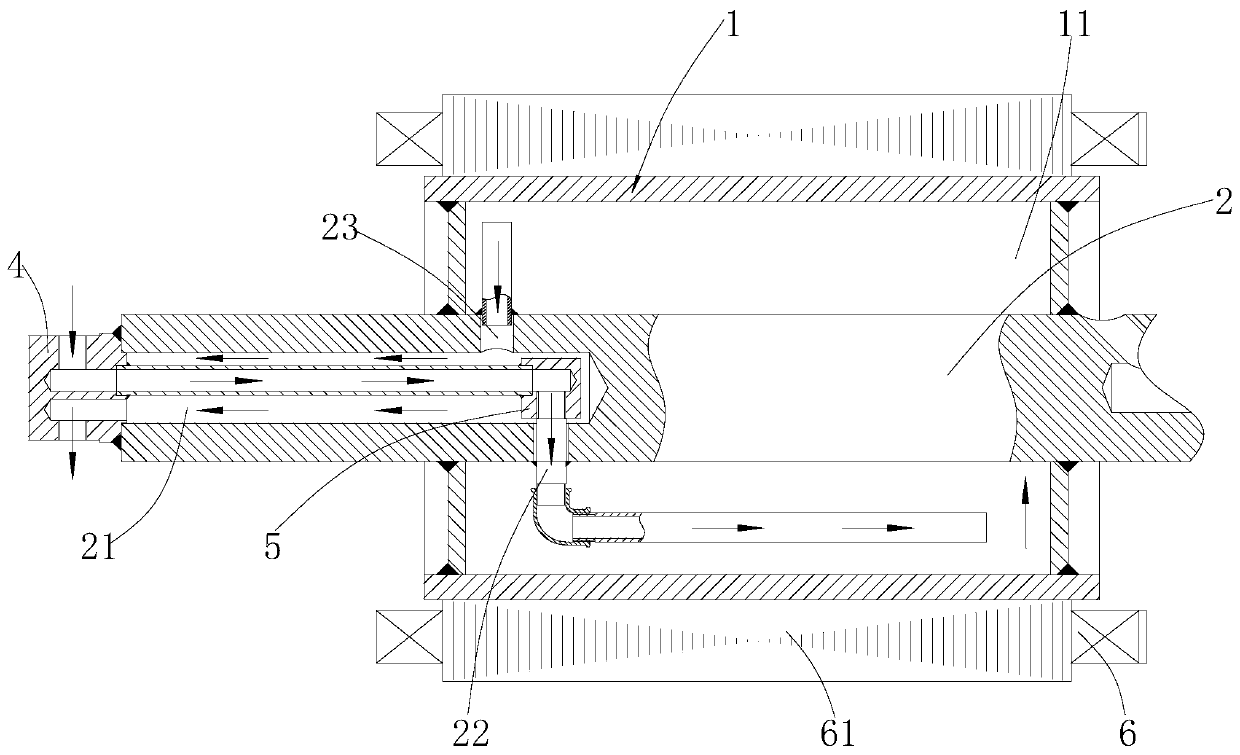

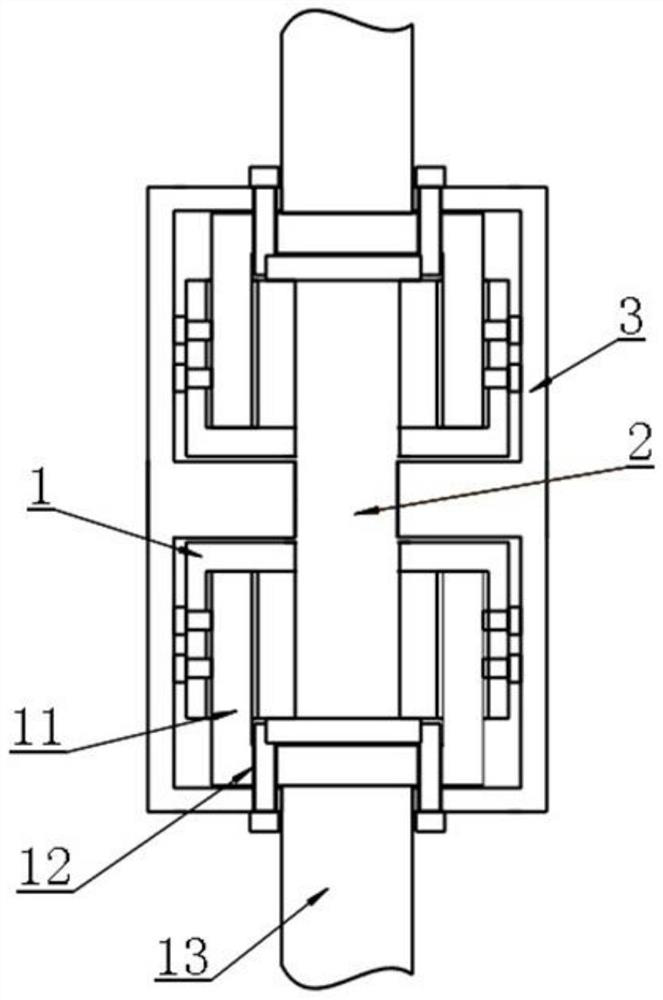

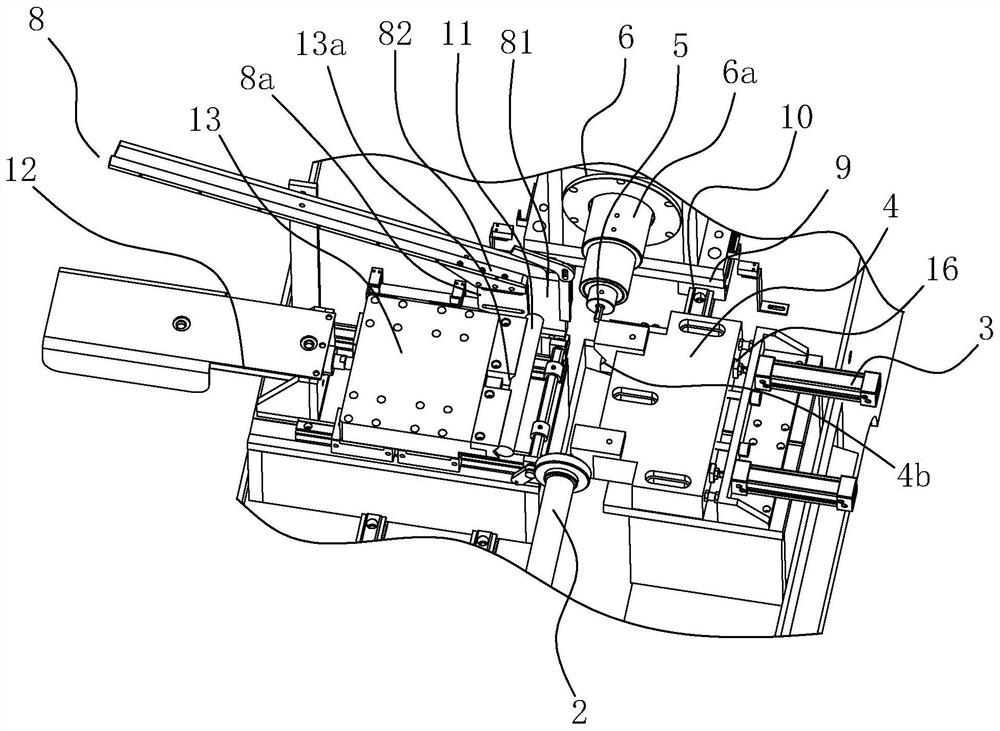

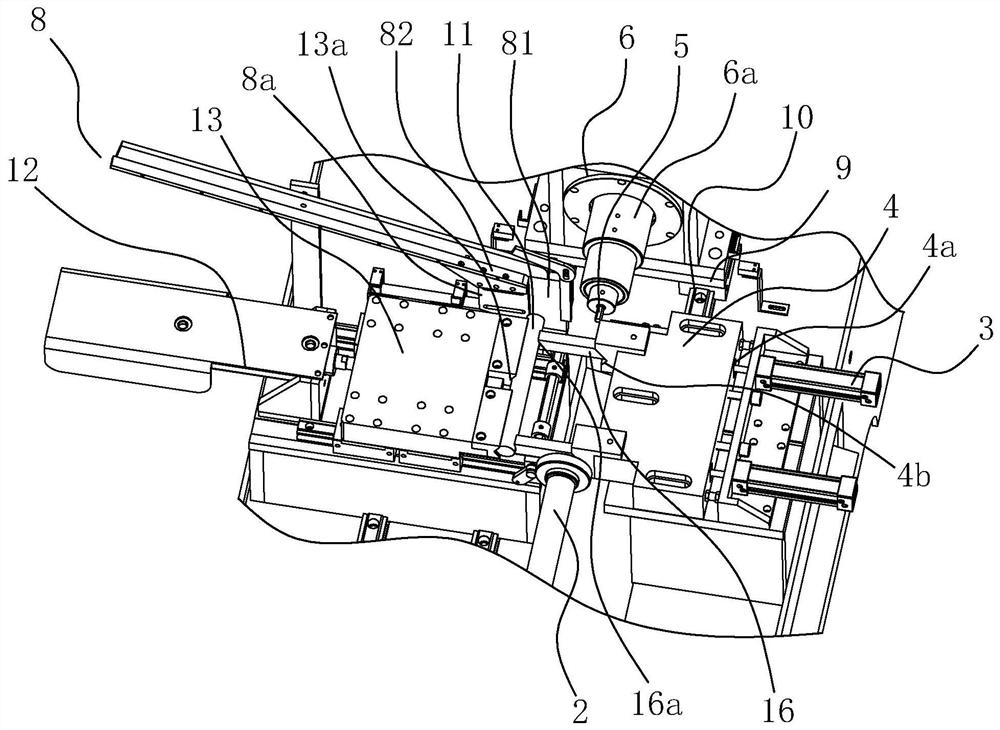

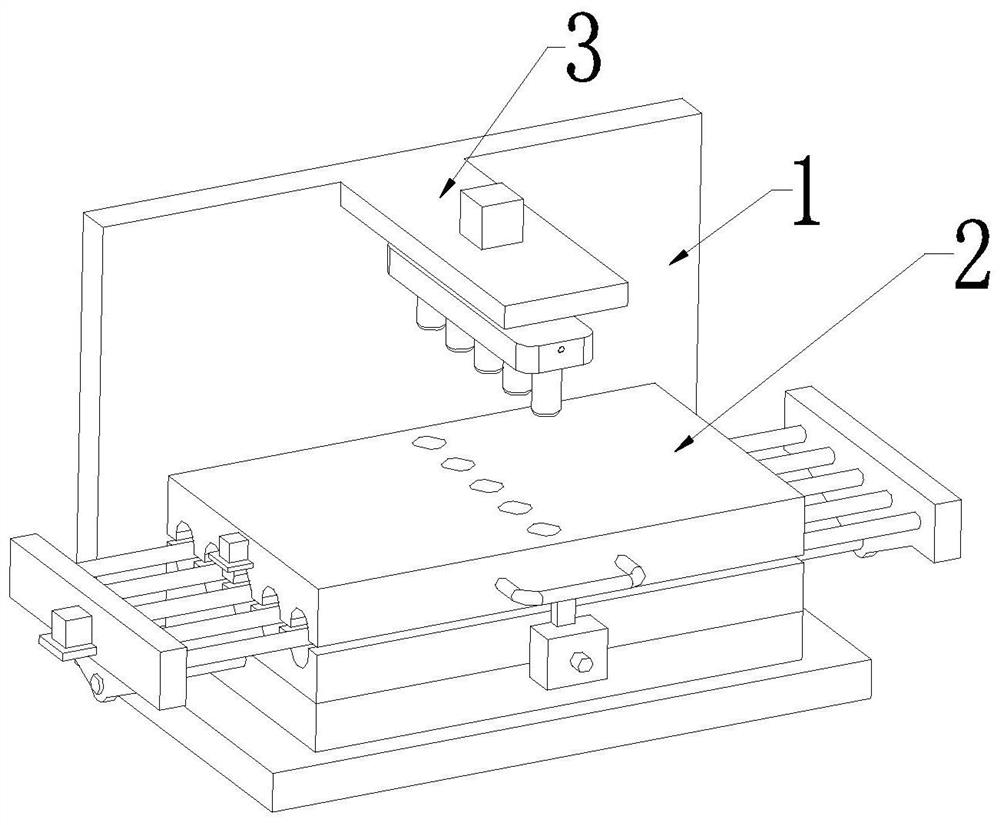

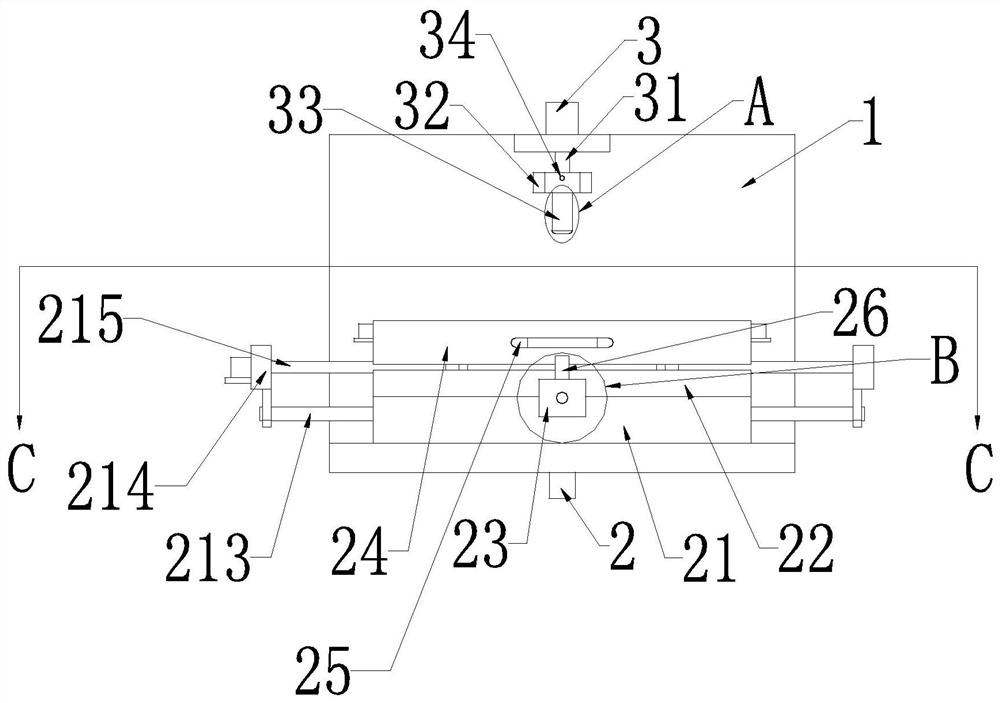

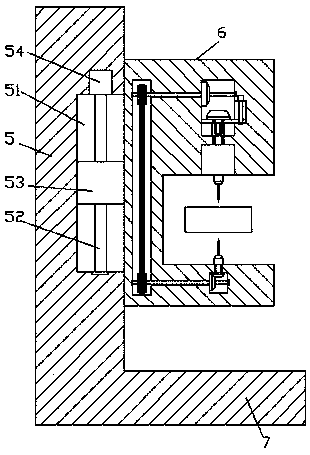

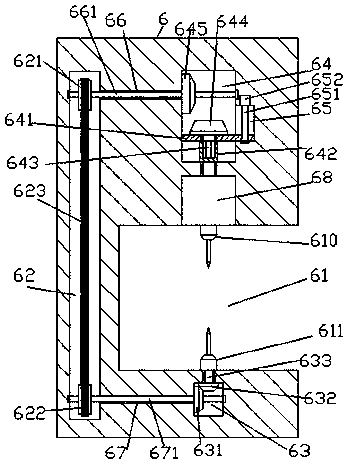

The invention discloses a punching device with a bidirectional punching function. The punching device comprises a base, a stand column fixed to the end face of the rear side of the base, and a punching mechanism arranged on the front end side of the stand column. A punching executing groove is formed in the end face of the front side of the punching mechanism, and a punching motor is fixedly arranged in the top wall in the punching executing groove. The bottom of the punching motor is cooperatively connected with an upper drill bit, and a lower drill bit is arranged at the position, corresponding to the upper drill bit, in the punching executing groove. A switching cavity is formed in the position, above the punching motor, in the punching mechanism. A first transmission cavity is formed in the position, below the upper drill bit, in the punching mechanism, and a second transmission cavity extending vertically is formed in the position, behind the punching executing groove, in the punching mechanism. A guide groove is formed in the inner wall of the front side of the switching cavity, and a switching driving threaded rod extending in the longitudinal direction is arranged in the guide groove. An inner spline shaft bush with the bottom end rotationally and cooperatively connected with the top end of the punching motor is arranged at the inner bottom of the switching cavity. The punching device is simple in structure, bidirectional punching can be achieved, the punching difficulty is lowered, the punching precision is improved, time and labor are saved, and the rejection rate is reduced.

Owner:南京苏宁锻造有限公司

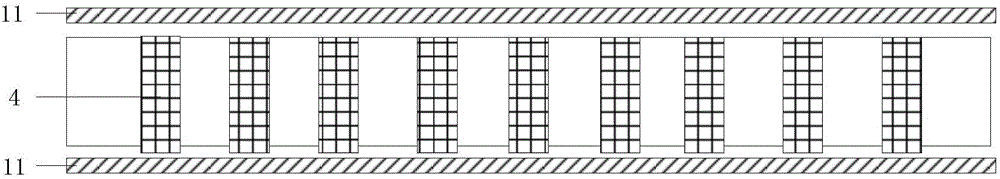

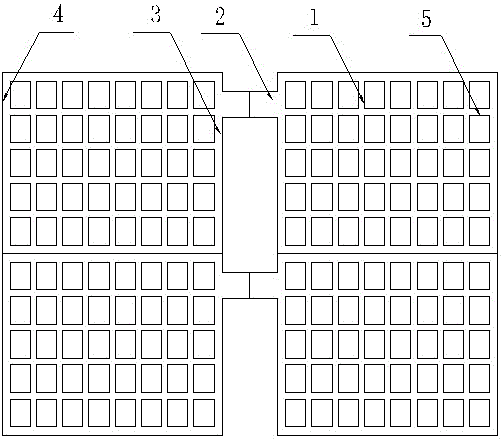

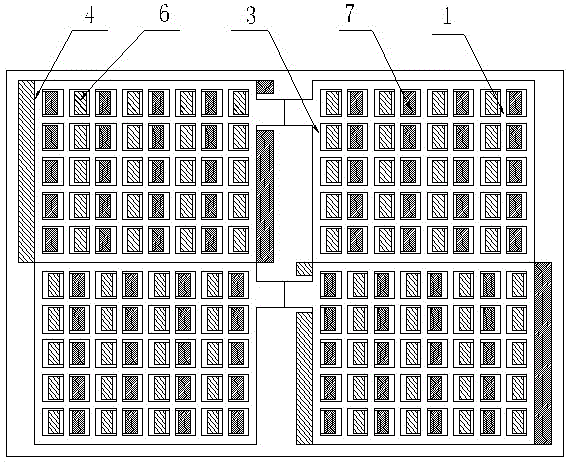

Array substrate and preparation method thereof, display panel, and display device

ActiveCN106057820ADoes not affect the display effectReduce widthStatic indicating devicesSolid-state devicesPunchingDisplay device

The present invention discloses an array substrate and a preparation method thereof, a display panel, and a display device. A grid fan-out line is arranged on one side of a substrate departing from the grid line, goes line along a black matrix projection area and extends to a driving binding area so as to allow the grid fan-out line not to go the side of the array substrate and reduce the width of the grid driving side frame, and because the grid fan-out line goes line on the projection area on the array substrate along the black matrix, the display effect of the array substrate cannot be influenced. Compared to the punching area of the punching technical scheme in a driving binding area in the prior art, the punching area of the technical scheme of punching in the display area and leading out the grid fan-out line from the back surface of the substrate is increased, and the array substrate and the preparation method thereof, the display panel, and the display device can punch fewer holes in a certain range compared to the technical scheme in the prior art, and therefore the difficulty of punching is reduced, the complexity of the preparation technology is reduced, and the preparation efficiency is improved.

Owner:BOE TECH GRP CO LTD +1

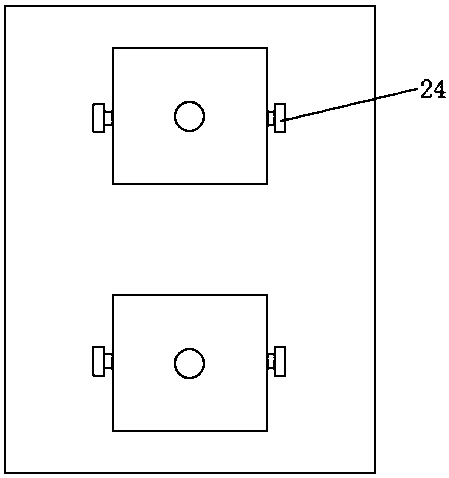

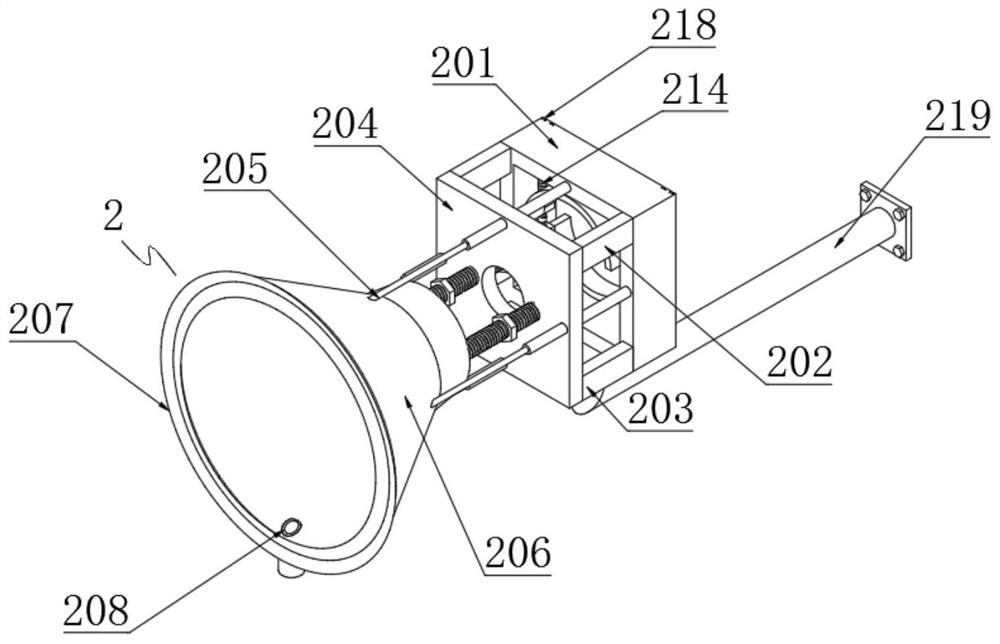

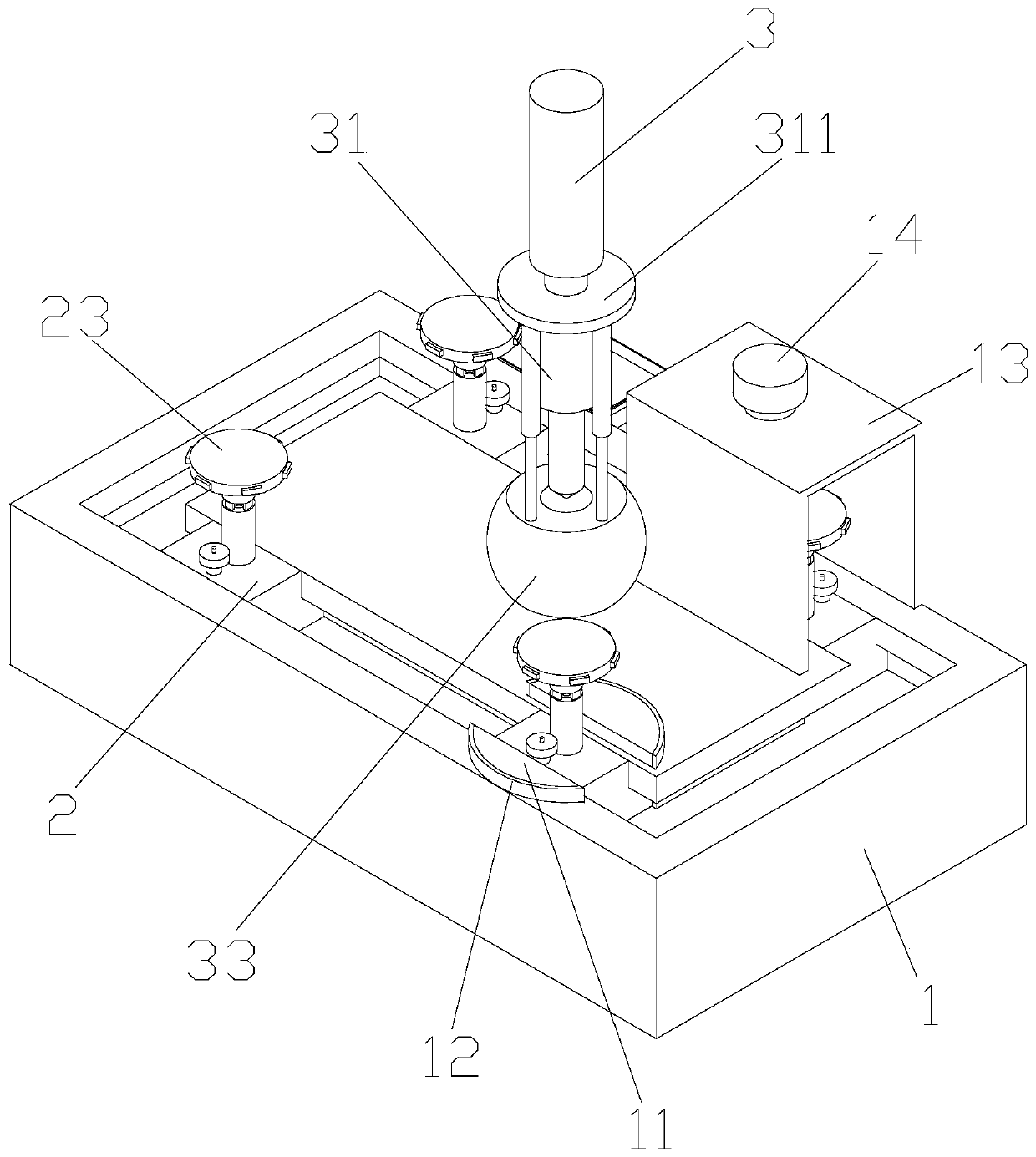

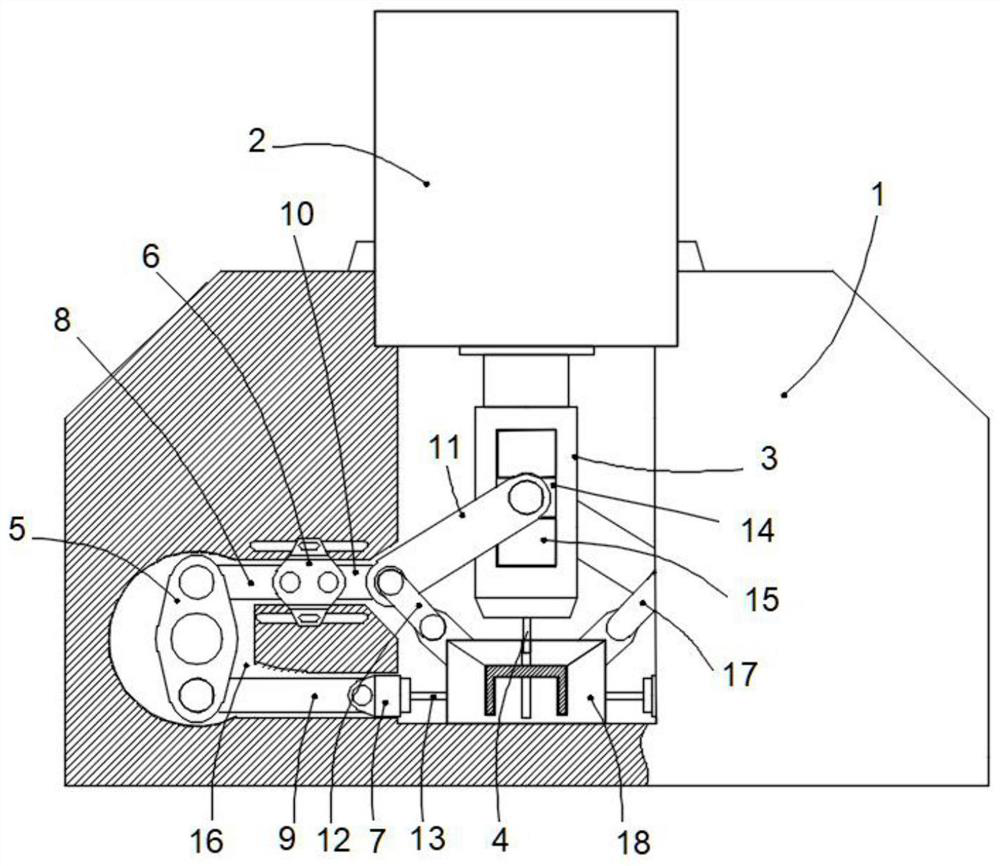

Orthopedics department positioning and punching device

InactiveCN108420502AAids in post-recoveryPrevent tamperingInstruments for stereotaxic surgeryBone drill guidesTemperature controlPunching

The invention discloses an orthopedics department positioning and punching device, comprising a body, wherein the inner top wall of the body is fixedly connected with an arc-shaped slide bar, one sideof the arc-shaped slide bar is provided with a rotation device, the middle of the arc-shaped slide bar is connected with a rotary block, a first spring sleeves the arc-shaped slide bar located between one side wall of the rotary block and the inner top wall of the body, and the inner top wall of the body is further fixedly connected with an angle scale. The orthopedics department positioning andpunching device has the advantage that an infrared sighting device is arranged to sight and punch an affected part, thus realizing accurate punching; the device can incline by a certain angle throughthe rotation device to punch the affected part, thus solving the problem that sometimes two or three holes are needed to meet the treatment need, reducing the workload, and facilitating later restoration of a patient; a fixing device is arranged to avoid involuntary movement of the patient due to pain or nervousness caused by punching, thus reducing punching difficulty; the temperature of a fixedpart is controlled to create a good hospital environment for the patient.

Owner:赵训明

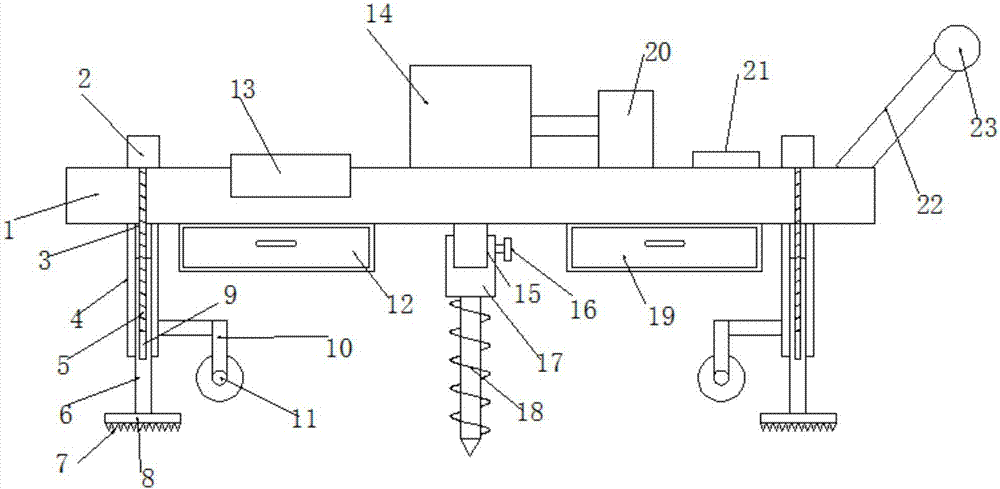

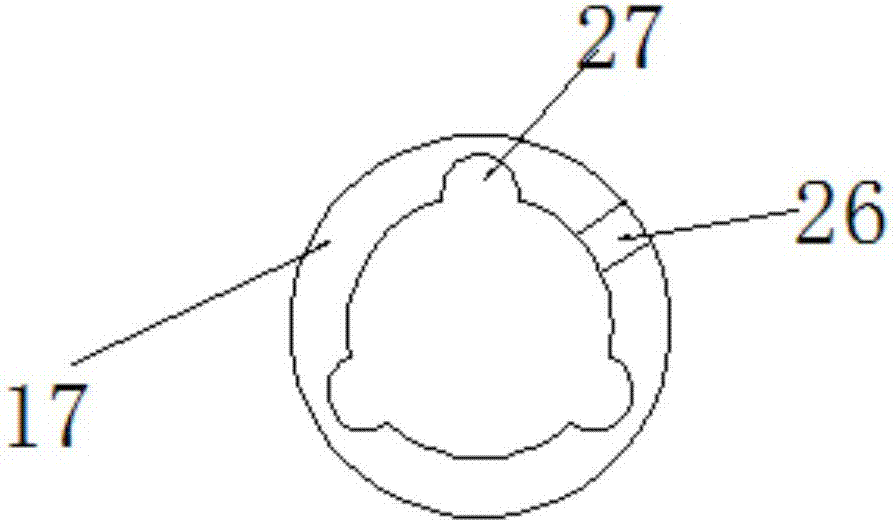

Perforating machine for gardens

InactiveCN107306523AReduce the difficulty of punchingRealize detachable connectionLawn machinesReduction driveDrive motor

The invention discloses a garden punching machine, which comprises a fixed plate, a speed reducer is fixed at the upper middle of the fixed plate, the input end of the speed reducer is connected with the output end of a drive motor, and the output end of the speed reducer is provided with a rotating shaft. The lower end of the rotating shaft is provided with a drilling rod, and the drilling rod is connected with the rotating shaft through a connecting sleeve. The connecting sleeve is provided with a mounting hole matched with the rotating shaft, and the inner wall of the mounting hole is distributed with three limiting grooves. The structure of the invention is simple. , Reasonable, reduces the difficulty of drilling for the staff, improves the drilling efficiency, can realize the switch between the fixed and mobile states of the device, facilitates the adjustment of the drilling position, improves the practicability of the device, and realizes drilling through the connecting sleeve The detachable connection of the drilling rod facilitates the replacement of the drilling rod, thereby facilitating the drilling of holes with different diameters, and also facilitates the protection of the storage box for different drilling rods, and also facilitates the temporary maintenance of the device, with strong practicability.

Owner:苏天平

Aluminum alloy for electrolytic capacitor outer shell and preparation method of aluminum alloy

InactiveCN107502788AReduce usageReduce manufacturing costCapacitor housing/encapsulationElectrolysisPunching

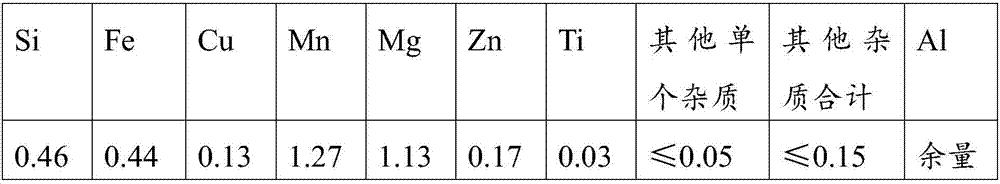

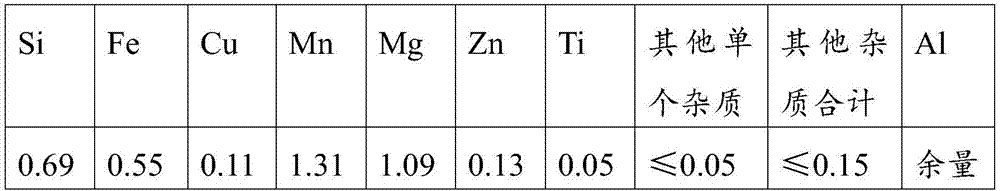

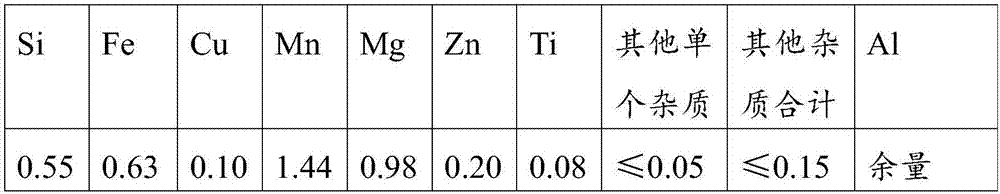

The invention relates to an aluminum alloy for an electrolytic capacitor outer shell and a preparation method of the aluminum alloy. The aluminum alloy comprises the following components of, by mass, 0.4-0.7% of Si, 0.2-0.7% of Fe, 0.05-0.25% of Cu, 1.0-1.5% of Mn, 0.8-1.3% of Mg, 0.1-0.25% of Zn, 0.01-0.08% of Ti, no larger than 0.15% of all other impurities and the balance Al, wherein the content of each of the other impurities is no larger than 0.05%. When the aluminum alloy for the electrolytic capacitor outer shell is smelted and cast, the using ratio of waste is 70% or more, the using quantity of original electrolytic aluminum ingots is decreased to the utmost extent, and the production cost is reduced. By adjusting the techniques in the production process, in performance, the aluminum alloy for the electrolytic capacitor outer shell has the advantages that the anti-explosion performance is excellent, and the punching difficulty is lowered.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

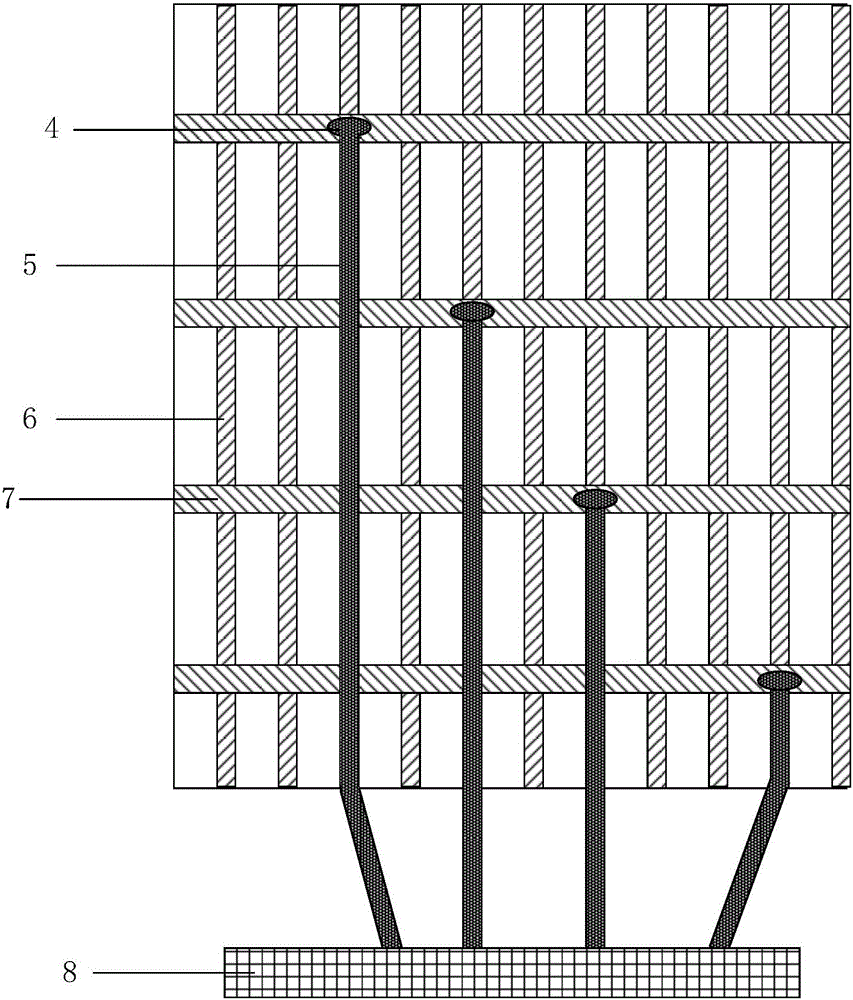

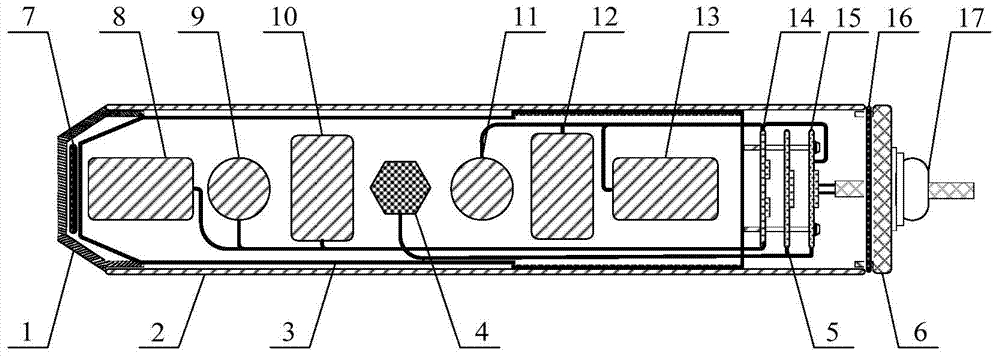

Mine microseism wave detector installed in deep hole

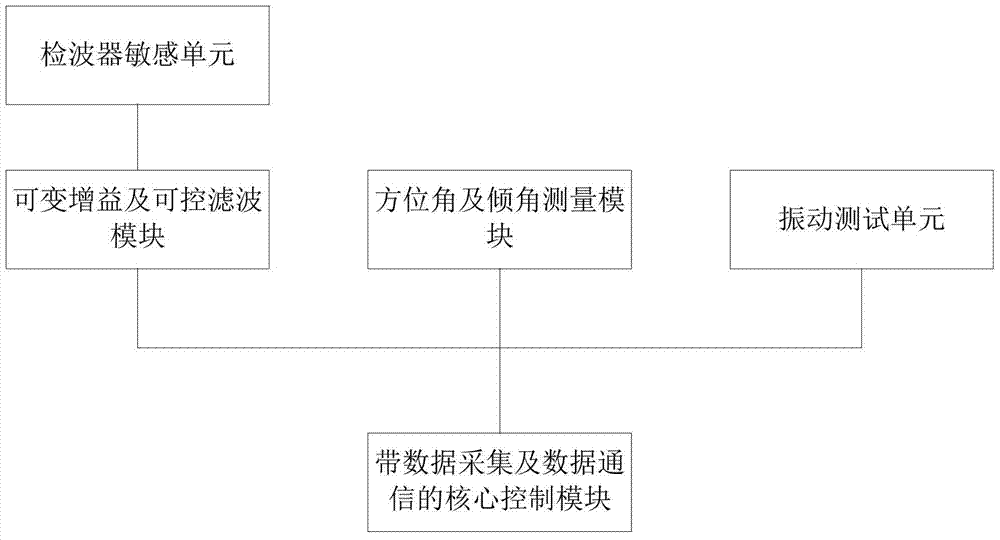

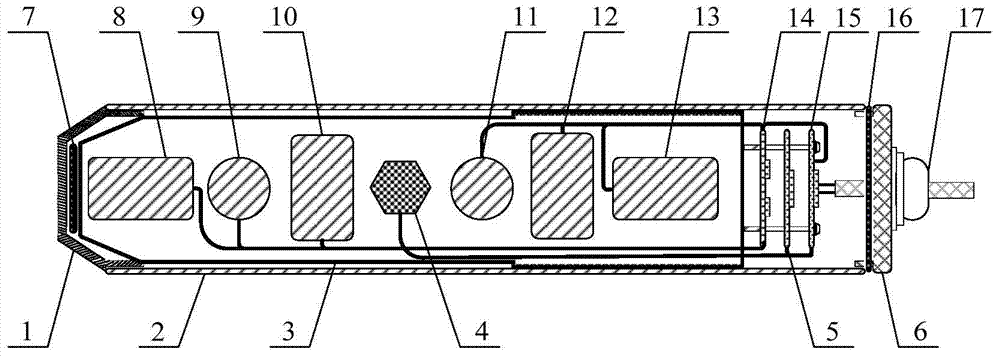

ActiveCN103941283AReduce the difficulty of punchingProvide punching efficiencySeismic signal receiversPhysicsSignal-to-noise ratio (imaging)

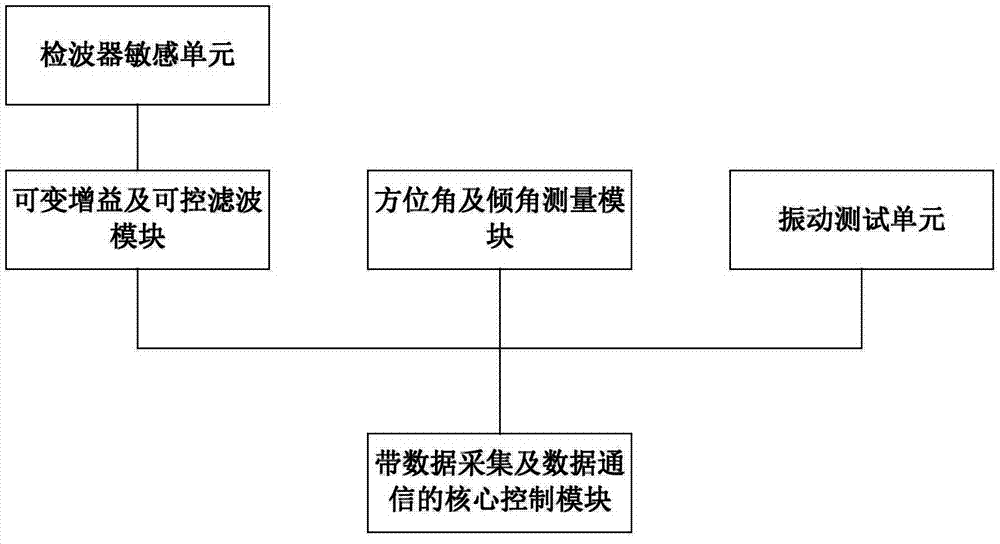

The invention discloses a mine microseism wave detector installed in a deep hole. The mine microseism wave detector installed in the deep hole comprises a wave detector sensing unit, a vibration testing unit, a variable gain and controllable filtering module, an azimuthal angle and dip angle measurement module and a core control module with data collection and communication functions. The wave detector can achieve automatic recording of related information, lowers the complexity of artificial operation, avoids introducing more artificial measurement errors, achieves self-measurement of the azimuthal angle and the dip angle, reduces the amount of the related information recorded manually, lightens the workload of manual recording and the probability of wrong recording, and guarantees normal work. A work state self-detection function of the wave detector is added, maintenance difficulty and complexity are lowered, the utilization rate is improved, variable gains and controllable filtering are increased, the grain range and the filtering frequency band are adjustable, the signal-to-noise ratio and the anti-attenuation capacity of a single source are improved, and the wave detector sensing unit is favorable for improving the signal-to-noise ratio of the wave detector array.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Automotive upholstery production device

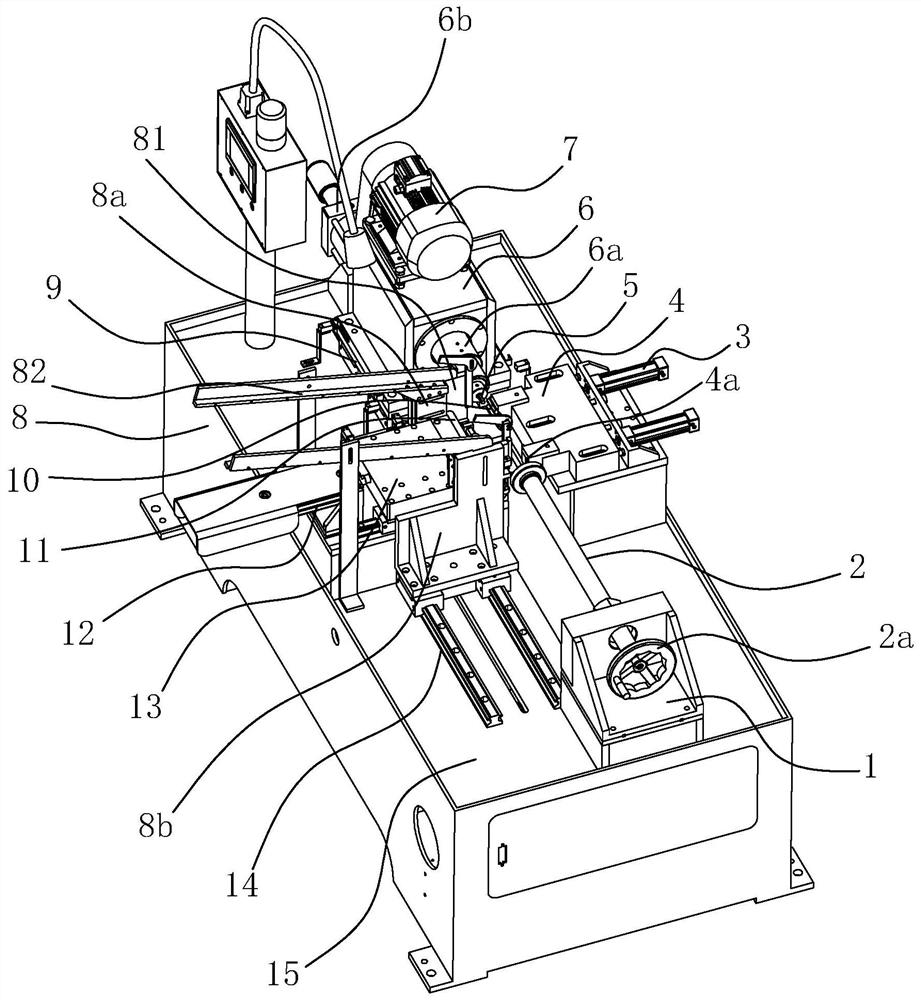

ActiveCN103753641AIncrease flexibilityIncrease punching frequencyMetal working apparatusPunchingEngineering

The invention discloses an automotive upholstery production device. The device is characterized by comprising a rack and a punching unit which is arranged on the rack movably. According to the device, a punching guide rail is added on the rack, so that offset of a device head on the rack during moving is prevented, the device head can fall in the preset hole position on a to-be-punched upholstery support accurately, the punching stability and the punching accuracy are improved, the punching quality is improved, and the punching efficiency is enhanced.

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

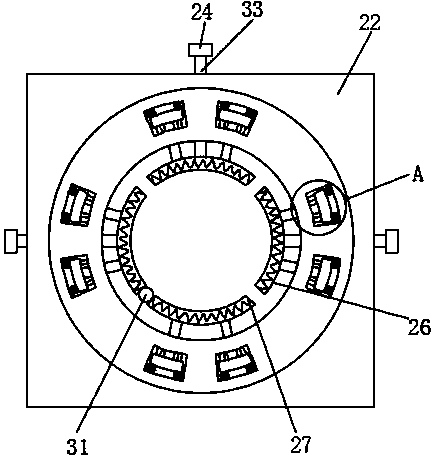

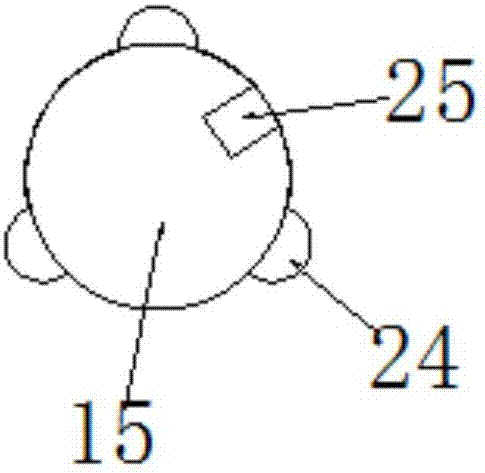

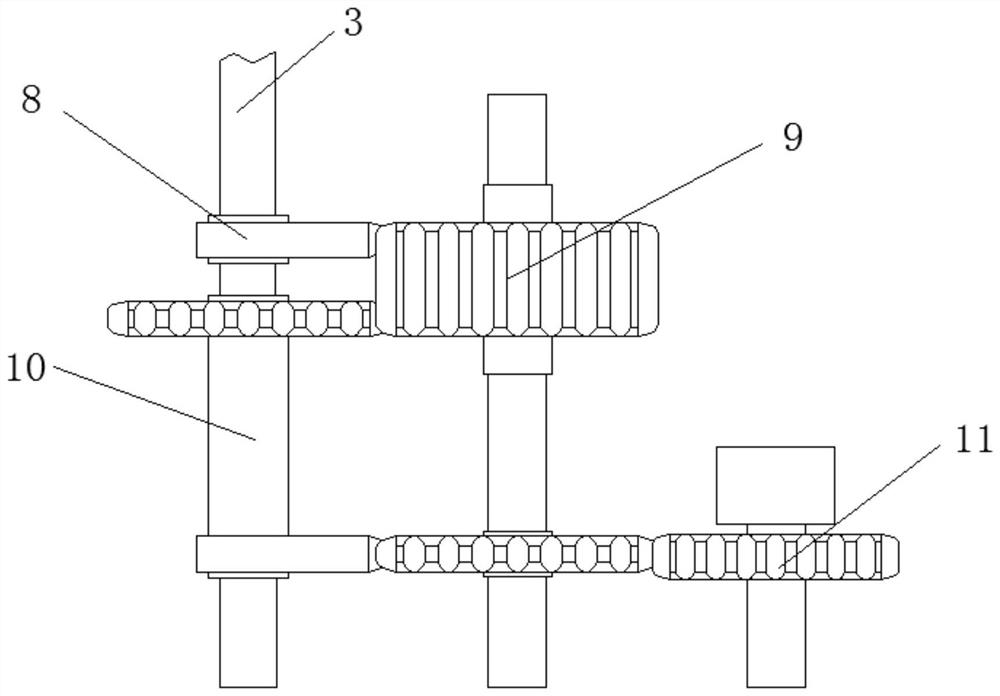

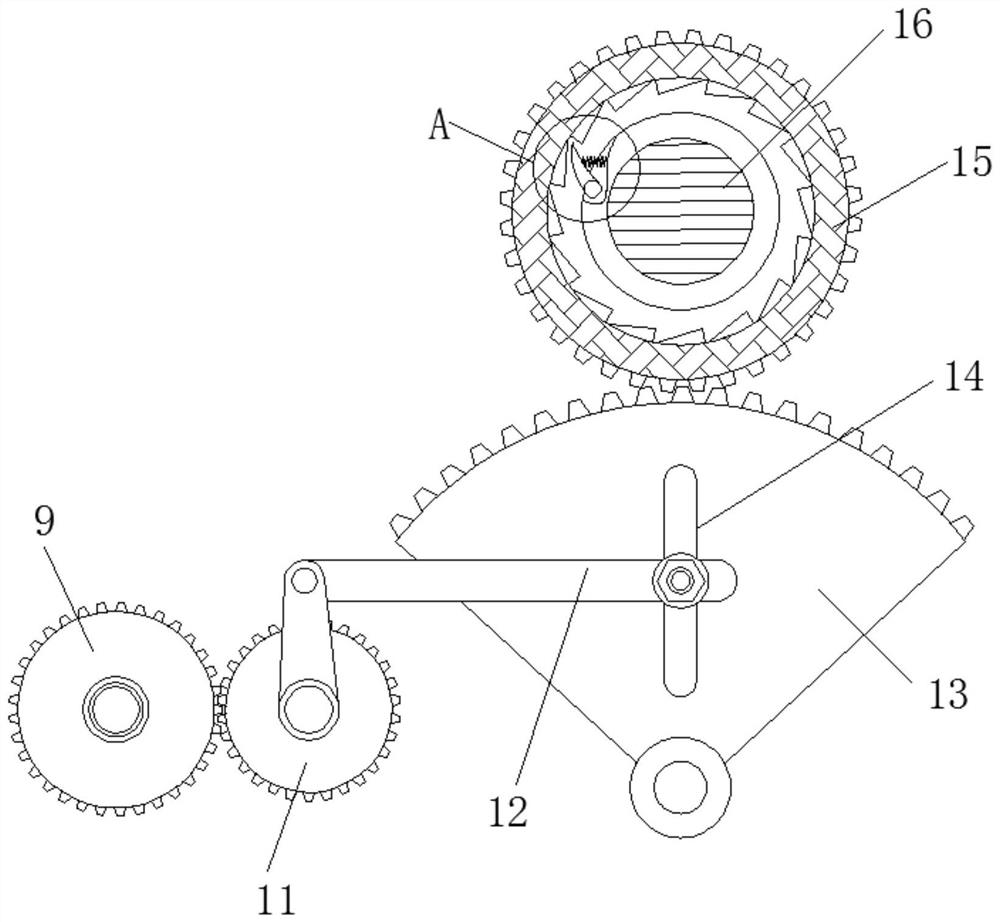

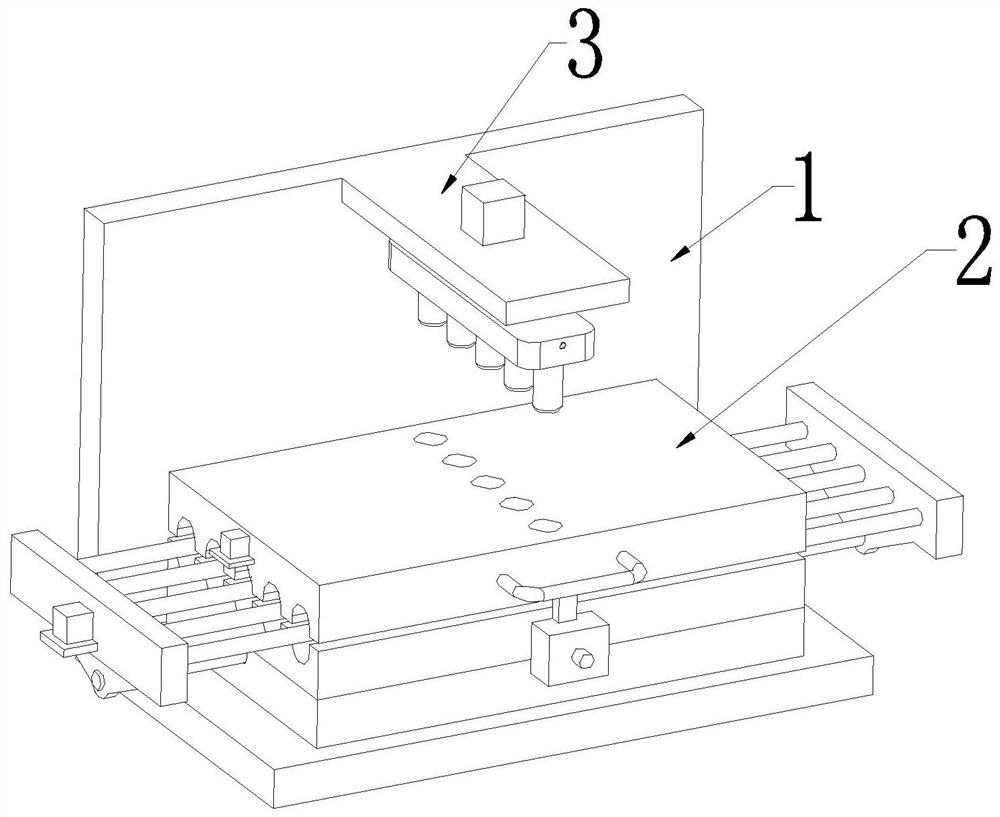

Intelligent continuous equidistant punching device for new material circular plate

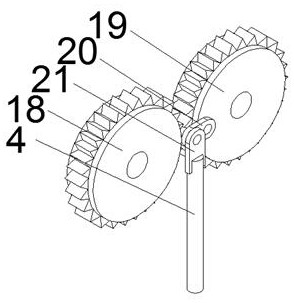

InactiveCN112453462AAvoid measuringAvoid punctuationBoring/drilling componentsBoring/drilling machinesRatchetPunching

The invention relates to the technical field of new material punching, and discloses an intelligent continuous equidistant punching device for a new material circular plate. The punching device comprises a support, wherein an adjusting motor is fixedly connected to the top of the support; a rotating shaft is fixedly connected to the bottom of the adjusting motor, and the rotating shaft is sleevedwith a sleeve shaft; a lifting plate is movably connected to the exterior of the sleeve shaft; a guide rod is movably connected to the interior of the lifting plate; a drilling motor is movably connected to the bottom of the lifting plate; a sector gear is fixedly connected to the exterior of the rotating shaft; and a connecting gear is connected to the exterior of the sector gear in an engaged manner. Through cooperative use of the sleeve shaft, the lifting plate, a guide rod, a transmission gear, a connecting rod, a reciprocating gear, a ratchet wheel, a support shaft, a pawl and a limitingspring, the continuous equidistant punching effect is achieved, the troubles of early-stage measurement, point marking and point alignment are avoided, the punching difficulty is effectively reduced,and the punching speed is increased, therefore, the working efficiency and the working quality of punching are effectively guaranteed.

Owner:戚金香

Sealing structure of vertical lift quick opening door

InactiveCN101644131AReduce widthReduce distortionSealing arrangementsWing arrangementsPunchingEngineering

The invention discloses a sealing structure of a vertical lift quick opening door, which can reduce the cost, the welding difficulty and the punching difficulty and improve the planeness of a sealingsurface. The sealing structure comprises a door baffle, a cylinder body as well as a door sealing flange and a reinforcing groove strip which are fixed on the outer surface of the cylinder body; wherein a loop-locked sealing groove is arranged at the side where the front of the door sealing flange faces to the door; a sealing strip is embedded inside the sealing groove; the door baffle is fixed onthe reinforcing groove strip by a fixing bolt; the wall thickness of the door sealing flange is less than or equal to 30mm, and the width thereof is less than or equal to 33mm; and the door sealing flange is also internally provided with a vent pipe communicated with the sealing groove. The sealing structure can be widely applied to medium-small sterilization equipment.

Owner:张家港华菱医疗设备股份公司

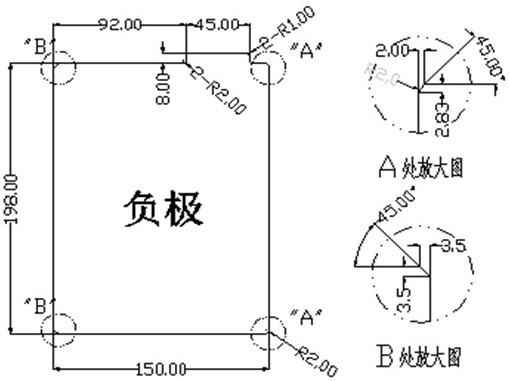

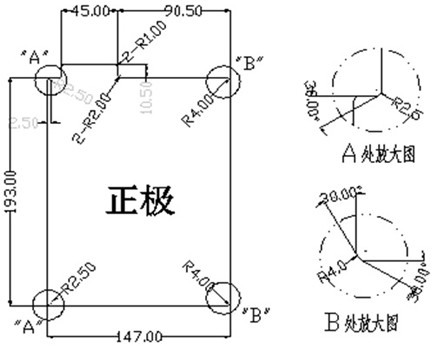

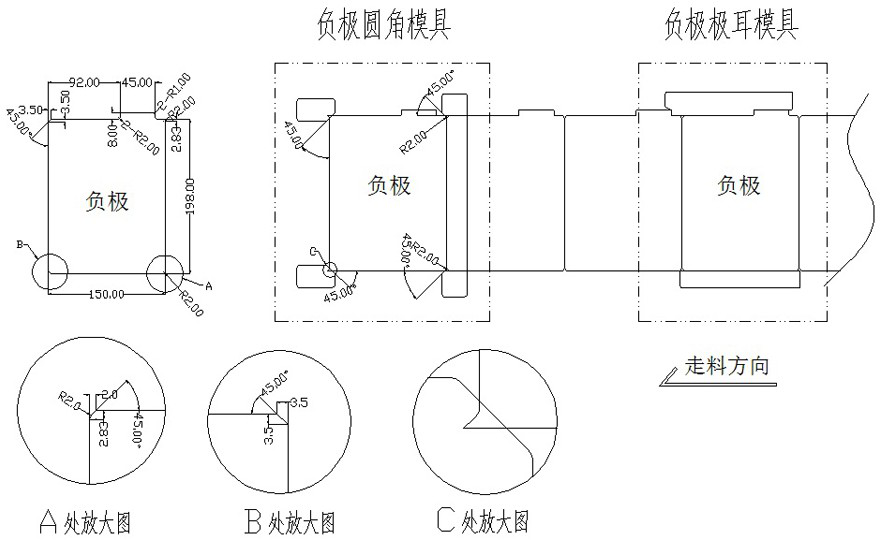

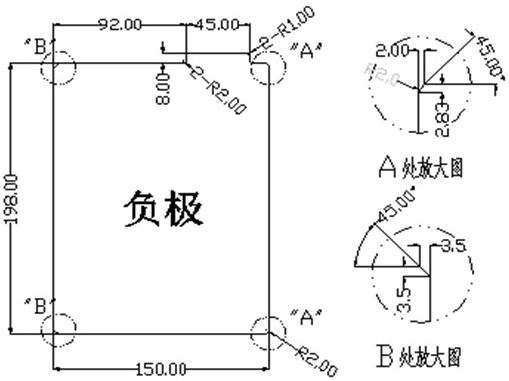

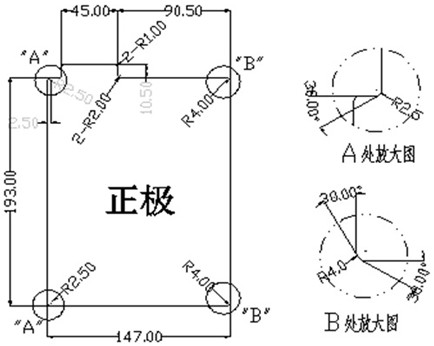

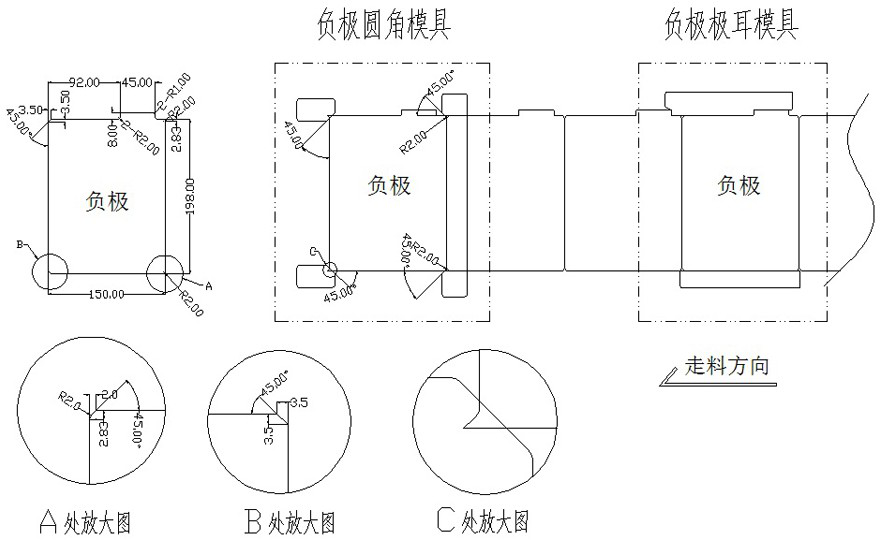

Pole piece cutting manufacturing process of lithium-ion soft-packed battery

ActiveCN111760958AAvoid short circuit problemsQuality improvementCell electrodesSecondary cellsCell fabricationPole piece

The invention relates to a pole piece cutting manufacturing process of a lithium-ion soft-packed battery, and belongs to the technical field of manufacturing of lithium-ion soft-packed batteries. Thepole piece cutting manufacturing process is mainly used for solving problems of sharp points and burrs generated during edge cutting of existing lithium-ion soft-packed battery pole pieces. The process is main characterized by comprising a die-cutting machine, a positive pole fillet angle mold, a negative pole bevel angle mold, a positive pole lead mold and a negative pole lead mold. After being cut at a station of the front positive pole lead mold to form a positive pole lead, a positive pole piece is then cut at a station of the rear positive pole fillet angle mold, so that fillet angles areformed at the four right angles; the fillet angles at the two sides of the positive pole piece are of an asymmetric structure; after being cut at a station of the front negative pole lead mold to form a positive pole lead, a negative pole piece is then cut at a station of the rear negative pole billet angle mold, so that bevel angles which are obtuse are formed at the four right angles; the bevelangles at the two sides of the negative pole piece are of an asymmetric structure. By means of the pole piece cutting manufacturing process, the punching difficulty of a pole piece cutting mold is lowered while the quality and stability of a battery are improved, and thus the service life of the pole piece cutting mold is greatly prolonged.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

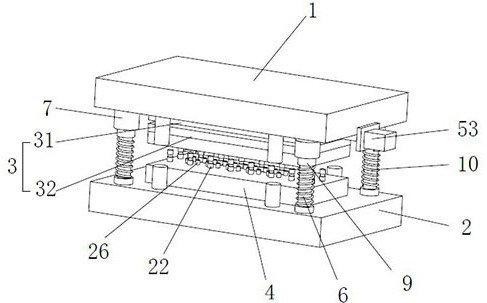

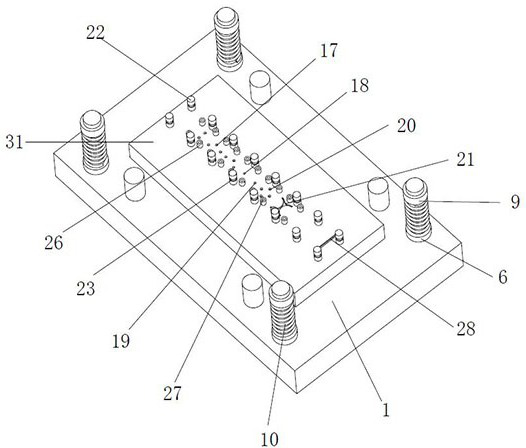

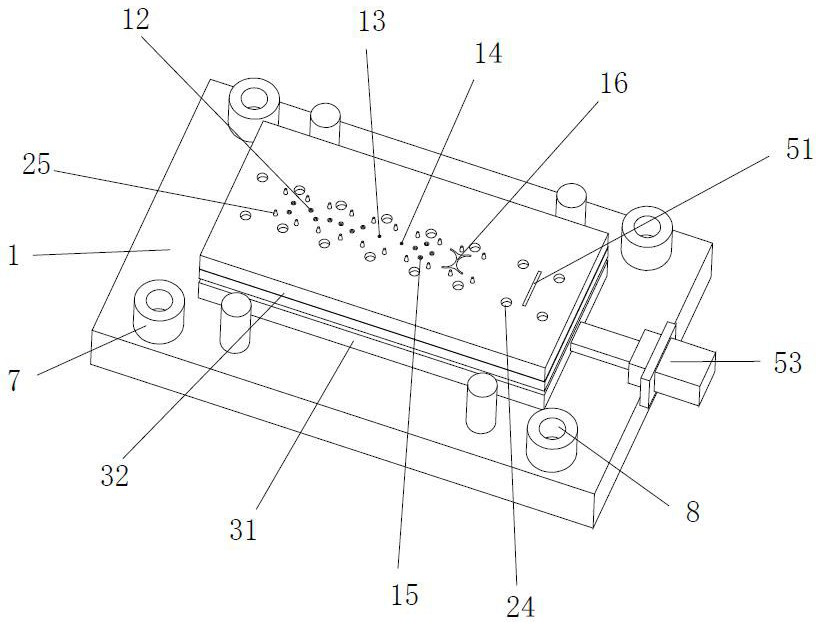

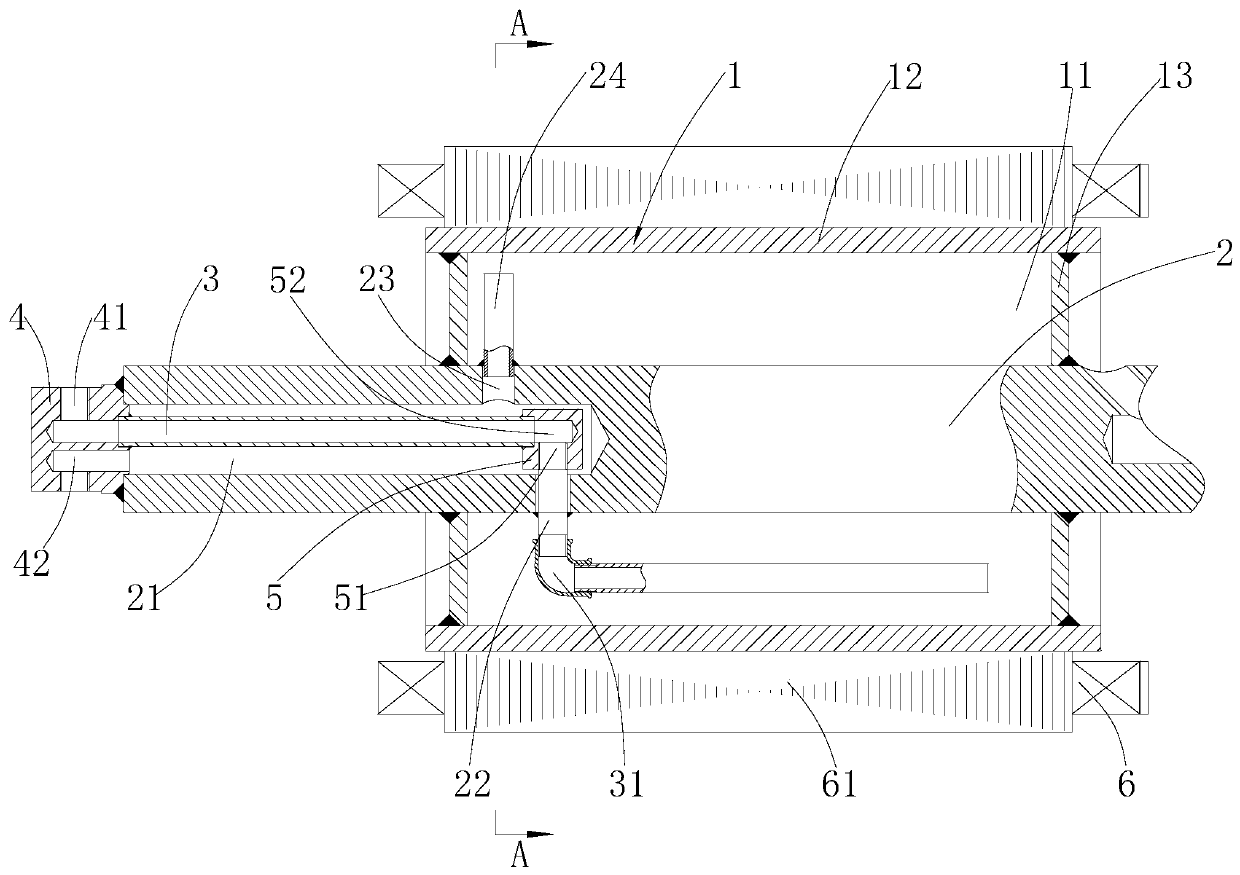

Stainless steel precision small hole burr-free punching die and forming method thereof

InactiveCN111604411AReduce the difficulty of productionHigh porosityShaping toolsPerforating toolsSheet steelPunching

The invention provides a stainless steel precision small hole burr-free punching die, and relates to the technical field of stamping equipment. The stainless steel precision small hole burr-free punching die comprises an upper backing plate, a lower backing plate, an upper template and a lower template, wherein the upper backing plate and the lower backing plate are arranged spaced, the upper template comprises a fixed plate and a movable plate that are arranged spaced, the movable plate is close to and slidably connected to the fixed plate, the side, facing the movable plate, of the fixed plate is sequentially and fixedly provided with a first stage punching needle, a second stage pre-punching needle, a second stage punching needle, a third stage punching needle and a trimming punch in the feeding direction of sheet steel, the first stage punching needle, the second stage pre-punching needle, the second stage punching needle, the third stage punching needle and the trimming punch penetrate through the movable plate and are in sliding connection with the movable plate, the lower template is provided with a first stage groove, a second stage pre-groove, a second stage groove, a third stage groove and a trimming groove corresponding to the first stage punching needle, the second stage pre-punching needle, the second stage punching needle, the third stage punching needle and the trimming punch respectively. The die has the advantages of high production efficiency, high product precision and high economic benefit.

Owner:厦门加新精密金属有限公司

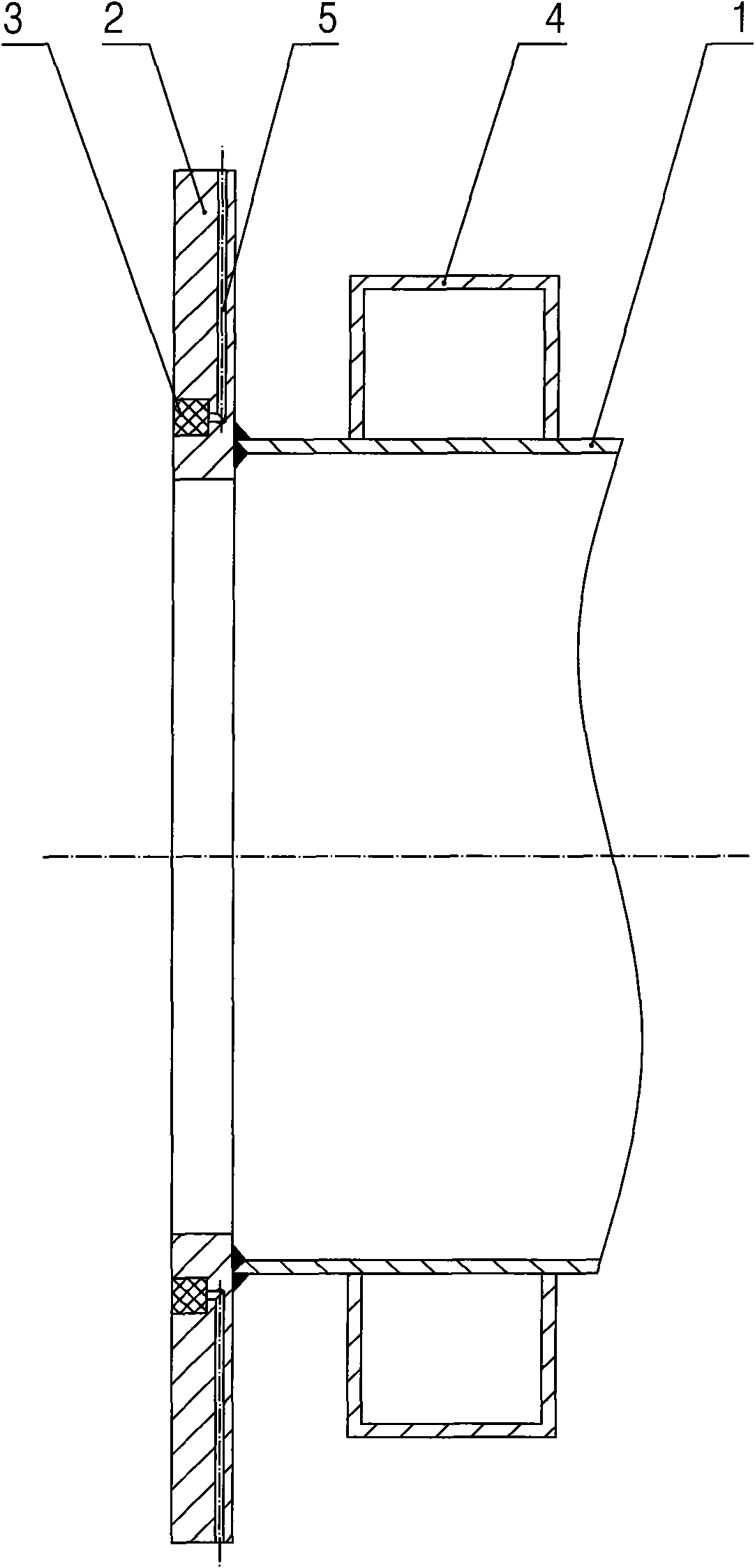

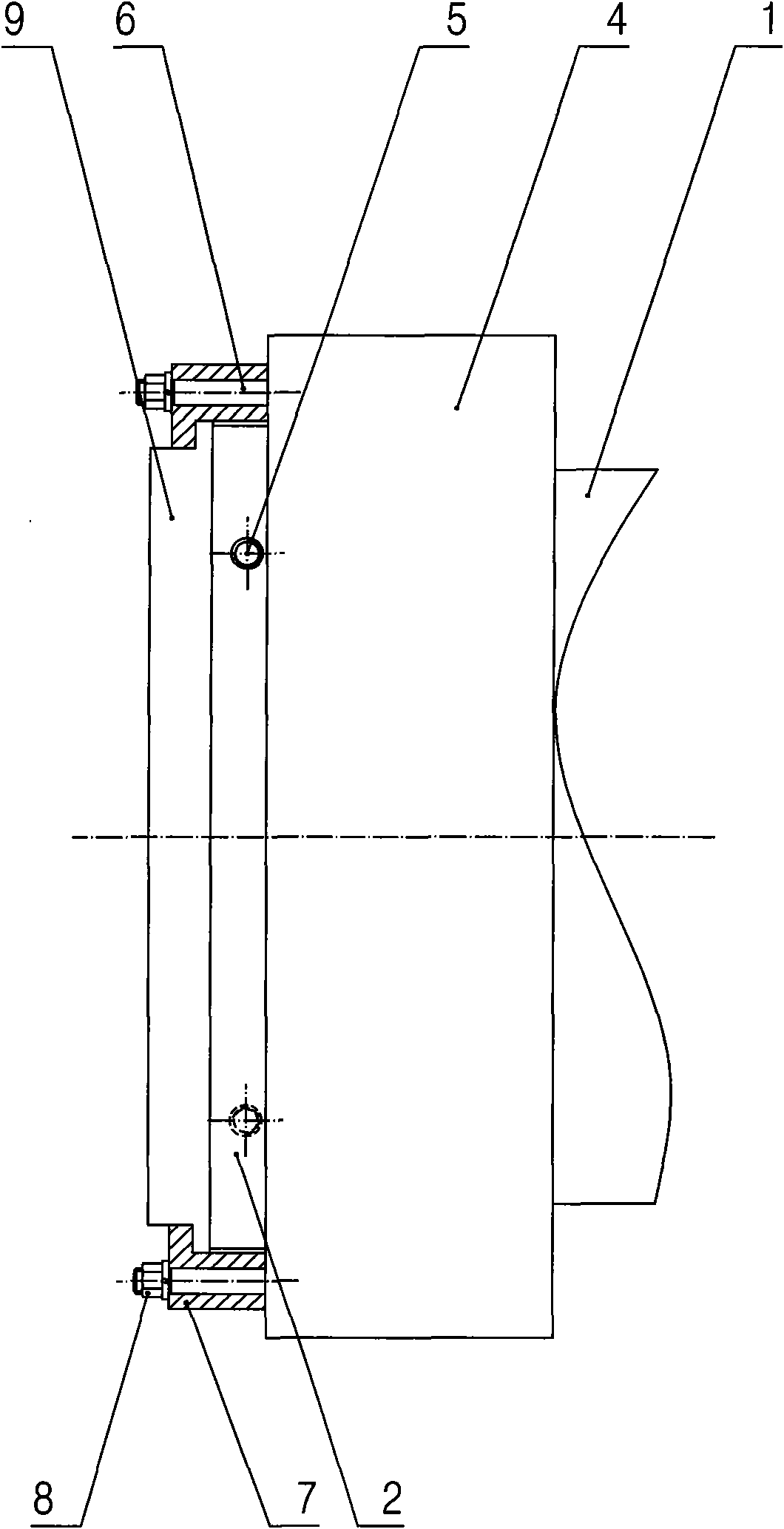

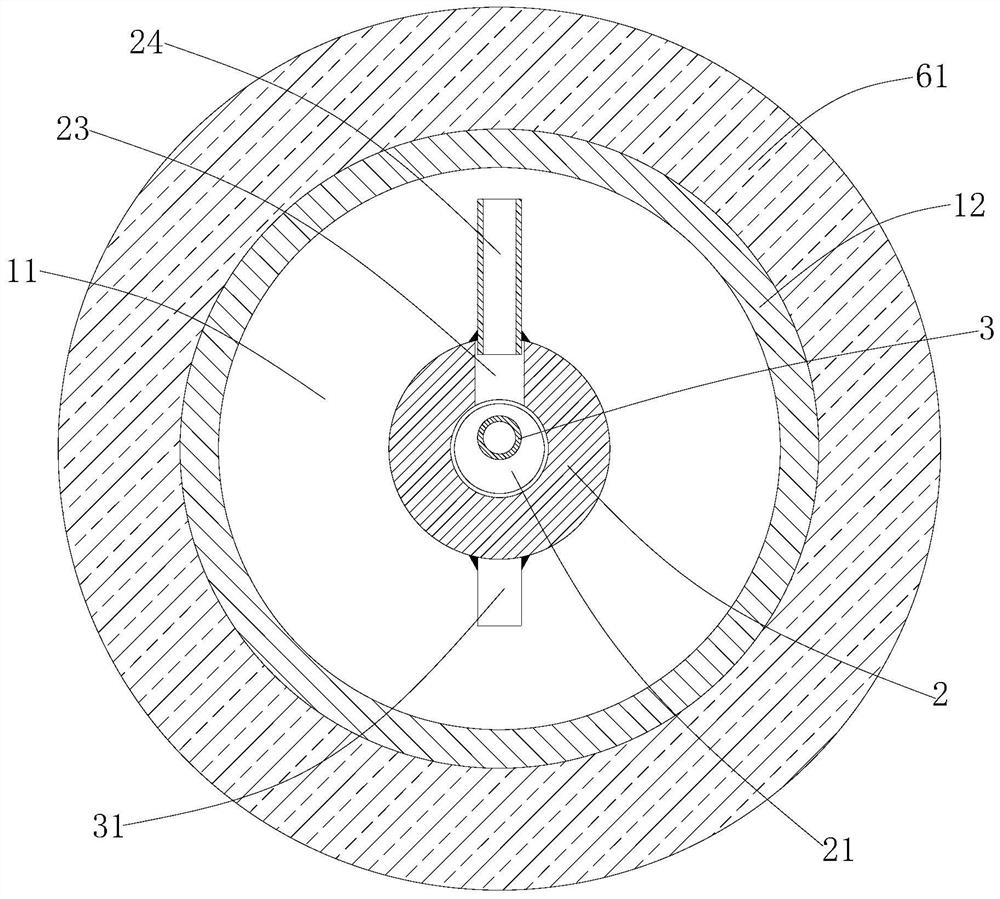

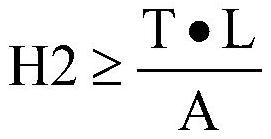

Inner stator motor cooling device, motor and inner stator motor cooling method

ActiveCN109842243AAvoid the dangerous situation of burning the coilReduce the difficulty of punchingCooling/ventillation arrangementPunchingControl theory

The invention provides an inner stator motor cooling device, a motor and an inner stator motor cooling method, which belong to the technical field of motor heat dissipation. The inner stator motor cooling device comprises a mounting seat, a connecting shaft and a liquid inlet pipe. The motor uses the inner stator motor cooling device. The inner stator motor cooling method employs the inner statormotor cooling device. According to the inner stator motor cooling device provided by the invention, a coolant enters from the liquid inlet pipe and flows into a sealing cavity on the mounting seat through a liquid inlet hole, and the heat generated by the stator exchanges heat with the coolant in the sealing cavity to reach the purpose of cooling the stator; after the coolant reaches a certain amount in the sealing cavity, the coolant enters a liquid outlet hole and flows out through the gap between a first blind hole and the liquid inlet pipe to form a stable coolant circulation system. The cooling method is low in punching difficulty and is easy to process. At the same time, the danger that cooling water is likely to enter the motor to burn down the coil when two eccentric holes are opened can also be avoided.

Owner:HEBEI NEWSTAR ELECTRIC MOTOR CO LTD

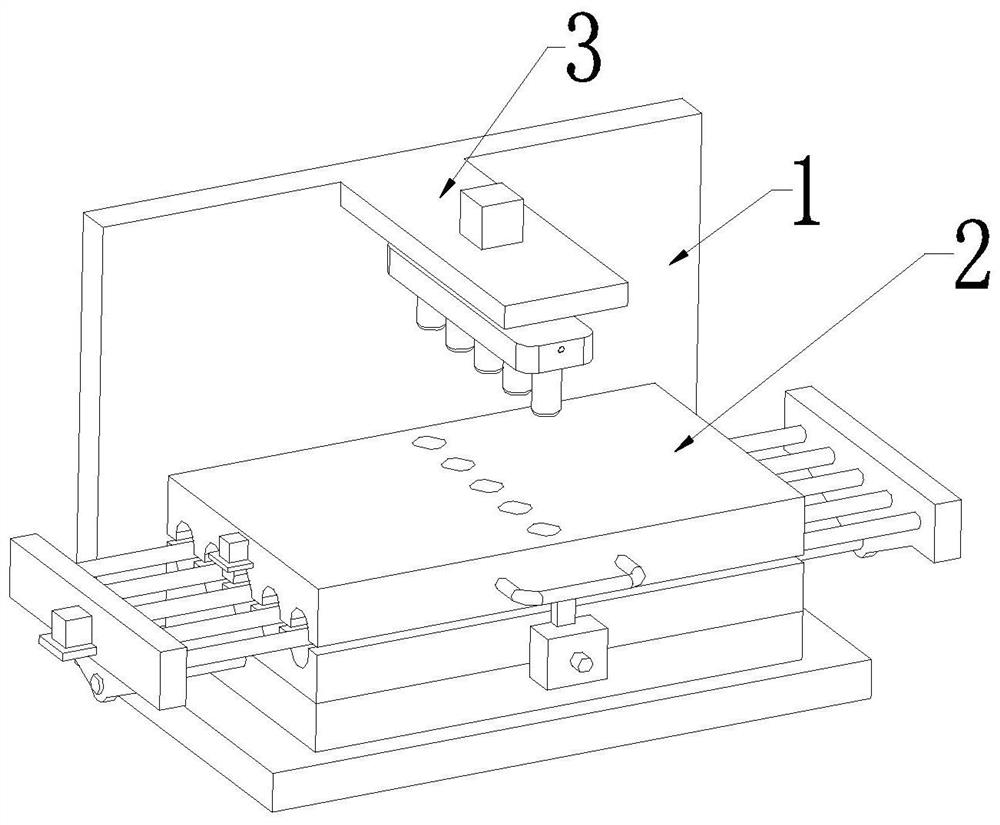

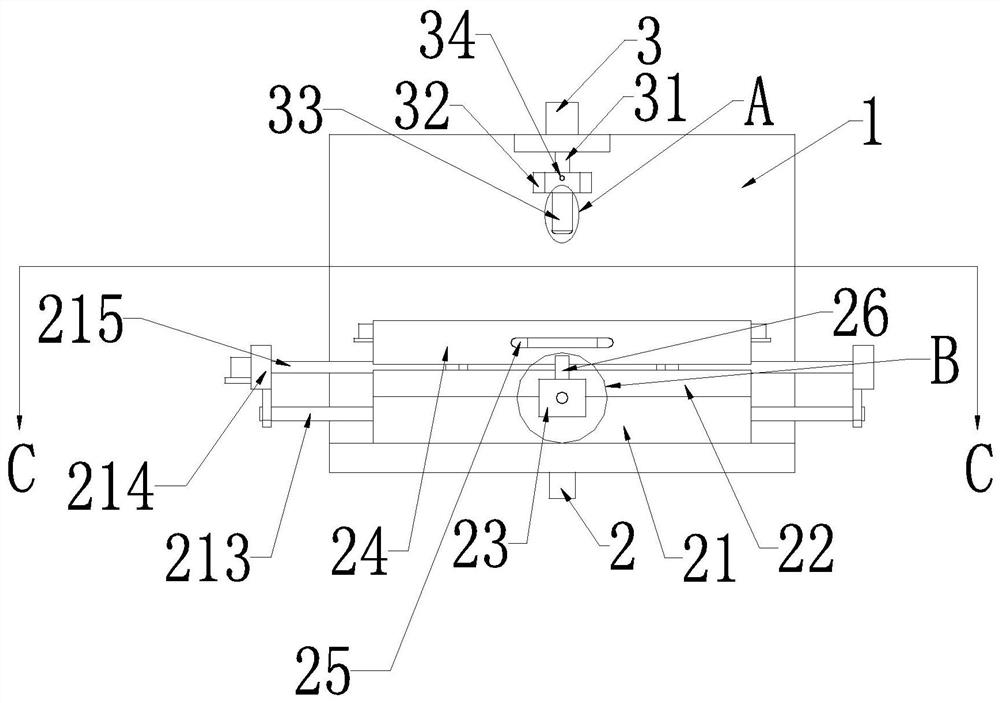

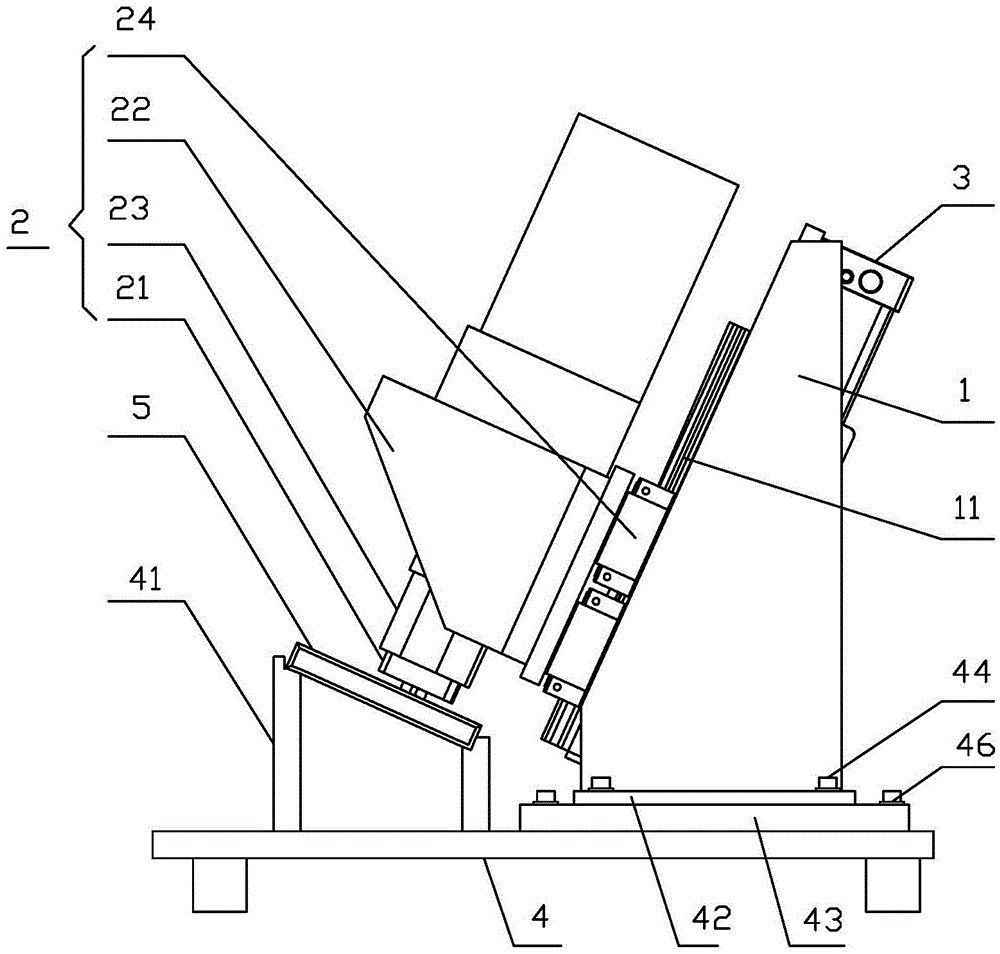

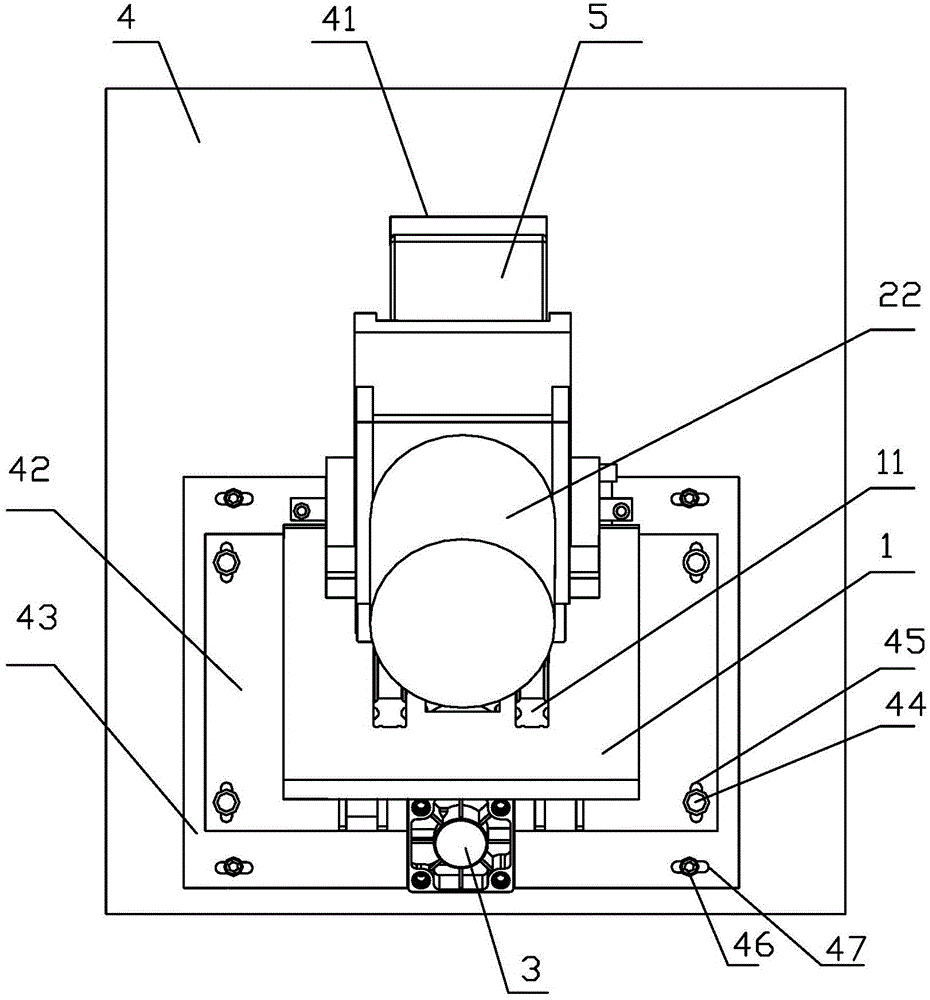

Intelligent cutting equipment for steel structure bridge pipe fittings

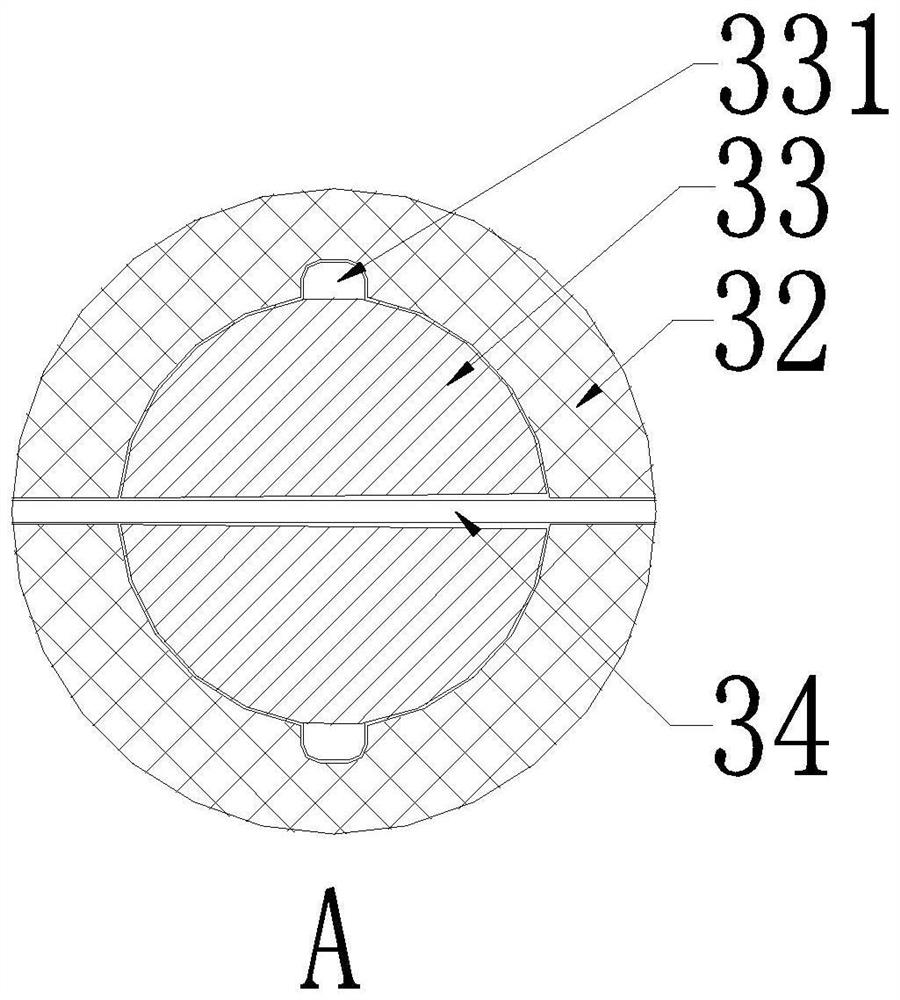

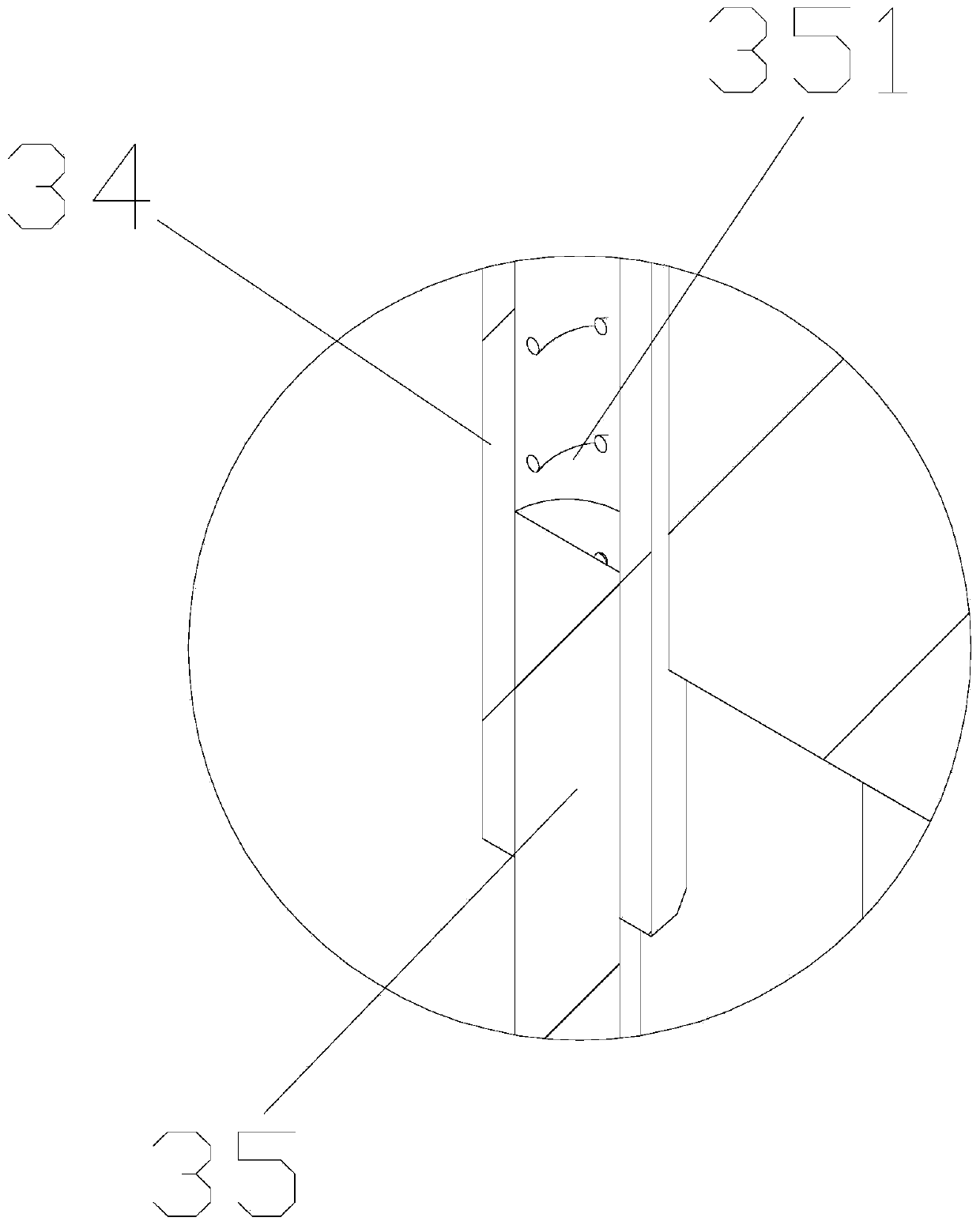

ActiveCN111958256AIncrease workloadEfficient removalOther manufacturing equipments/toolsPunchingPipe fitting

The invention relates to intelligent cutting equipment for steel structure bridge pipe fittings. The intelligent cutting equipment comprises an installation frame, a pre-cutting assembly and a punching assembly, wherein the pre-cutting assembly and the punching assembly are sequentially arranged on the installation frame from bottom to top. The intelligent cutting equipment can solve the followingproblems caused when existing steel structure pipe fittings are cut: a, when an existing steel pipe is cut, the circumference of the cut surface is prone to deforming, burrs are generated on the cutsurface, and then the cut steel pipe is often required to be subjected to secondary processing in order to meet the use requirement, so that the workload of workers is greatly increased; and b, when the existing steel pipe is vertically cut, incomplete cutting often occurs, repeated cutting is needed afterwards, the production progress is greatly slowed down, and time is wasted.

Owner:山东省华东重工有限公司

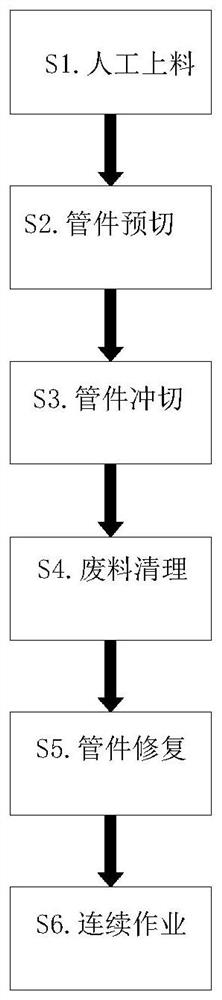

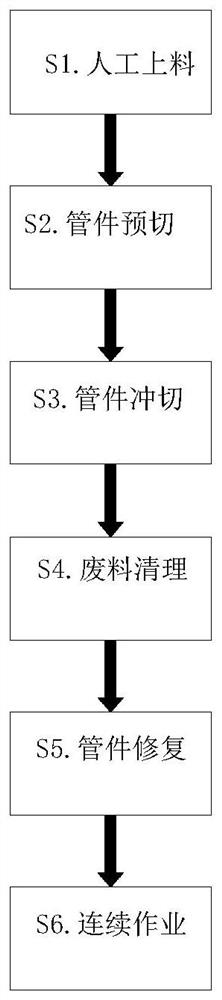

Automatic cutting process for steel structure pipe fittings

ActiveCN112045028AIncrease workloadSlow down productionEdge grinding machinesDirt cleaningSteel tubeManufacturing engineering

The invention relates to an automatic cutting process for steel structure pipe fittings, and the process is mainly completed through the cooperation of an automatic cutting machine for the steel structure pipe fittings. The automatic cutting machine for the steel structure pipe fittings comprises a mounting frame, a pre-cutting sleeve piece and a punching sleeve piece, and the pre-cutting sleeve piece and the punching sleeve piece are sequentially arranged on the mounting frame from bottom to top. The automatic cutting process for the steel structure pipe fittings solve the problems that a, when an existing steel structure pipe fitting is subjected to cutting operation, the circumference of a super-tangent plane is often deformed when an existing steel pipe is cut, burrs appear on the cutplane, and then secondary machining needs to be conducted on the cut steel pipe in order to meet the use requirement, and therefore the workload of workers is greatly increased; and b, when the existing steel pipe is subjected to vertical cutting, the situation that the cutting position is not completely cut off often occurs, cutting needs to be conducted multiple times later, the production progress is greatly slowed down, and time is wasted.

Owner:山东新宏重工有限公司

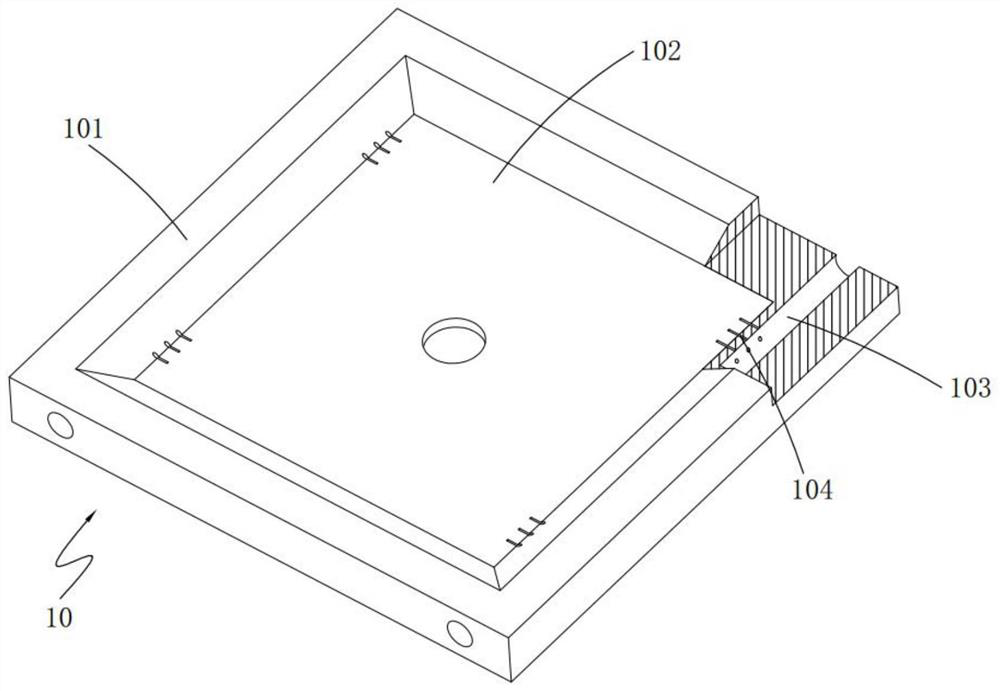

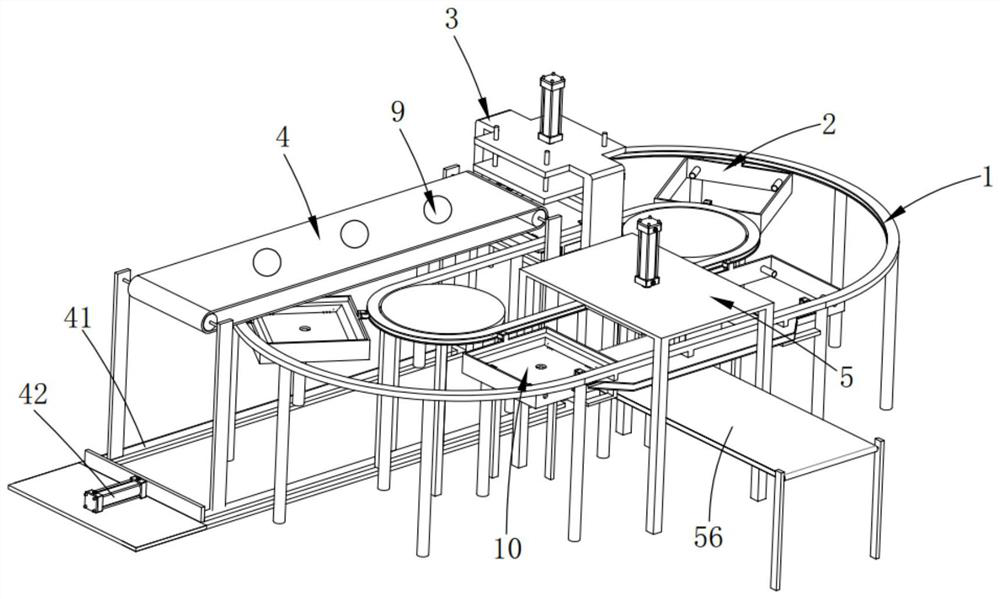

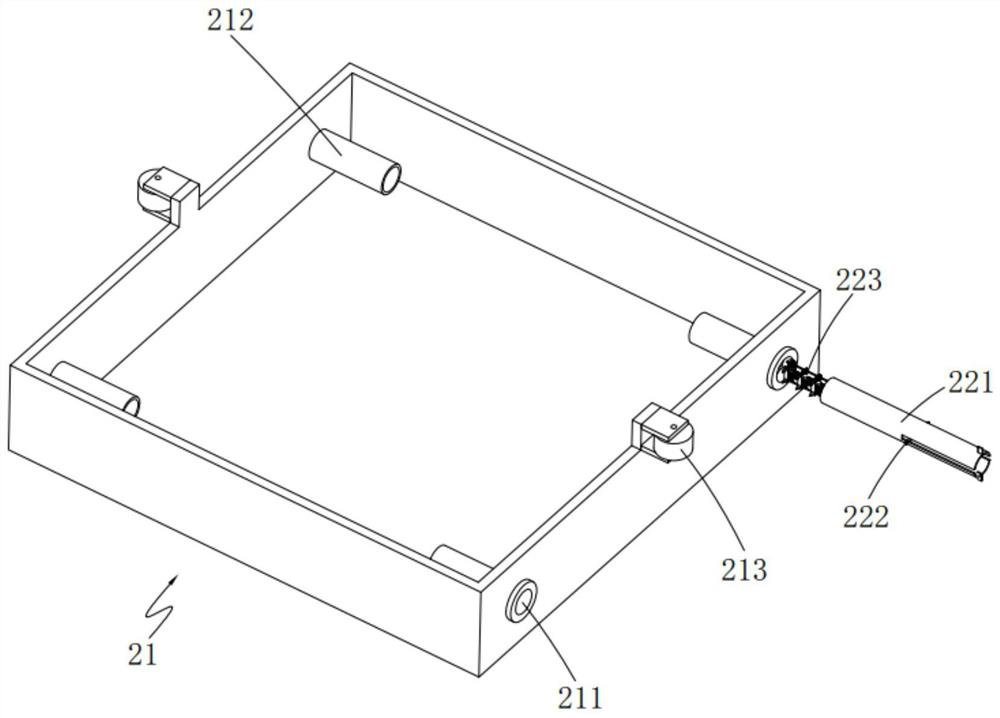

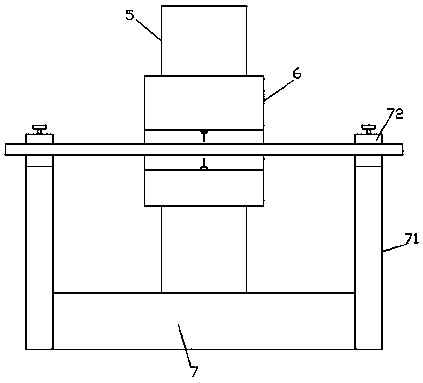

Full-automatic filter plate production equipment and process

InactiveCN112123661AImprove molding qualityRealize automatic formingDomestic articlesMetal working apparatusFilter pressMechanical engineering

Owner:浙江金鸟压滤机有限公司

Building construction drilling machine with correction function

InactiveCN113715176AEasy to fixGuaranteed uptimeWorking accessoriesStone-like material working toolsPunchingArchitectural engineering

The invention discloses a building construction drilling machine with a correction function. The building construction drilling machine with the correction function comprises a punching machine base body, a limiting protection mechanism is fixedly installed on the edge of one end of the punching machine base body, positioning clamping mechanisms are symmetrically installed on the two sides of the back face of the limiting protection mechanism, a protection bearing mechanism is welded to the bottom of one end of the punching machine base body, an oil tank is installed at the bottom end of the punching machine base body, and a supporting assembly is installed at the position, corresponding to the bottom end of the oil tank, of the bottom end of the punching machine base body. Through the limiting protection mechanism, secondary fixing of a drill bit can be facilitated, so that connection between the drill bit and a punching machine is more stable, and shaking of the drill bit in the operation process is reduced; and meanwhile through an outer conical cover, the stability between the punching machine and a wall is improved, so that shaking of the punching machine during operation is reduced, operation of the drilling machine is facilitated, interference of shaking of the punching machine during operation on drilling of the wall is reduced, and drilling treatment on the wall is facilitated.

Owner:邵燕

Voucher puncher special for accountants

InactiveCN112372742AChange the structure principleSimple structureMetal working apparatusReciprocating motionConstruction engineering

The invention discloses a voucher puncher special for accountants. The voucher puncher special for the accountants comprises an accumulator, a supporting board, a lifting device, a lifting rod, a rotating handle, a fixing edge, sleeves, telescopic rods, a connection board and punching needles, wherein the supporting board is installed at the front end of the top of the accumulator, the lifting device is installed at the top of the supporting board, the lifting rod is installed below the front end of the lifting device, the rotating handle is installed at the rear end of the lifting device, thefixing edge is integrated at the front end of the lower side of the lifting device, the sleeves are installed at both sides of the top of the fixing edge, the telescopic rods are installed at the bottom ends of the interiors of the sleeves, the connection board is installed at the bottoms of the telescopic rods at the two sides, and the punching needles are installed at both sides of the bottom of the connection board. The voucher puncher special for the accountants is simple in structure and reasonable in design, through the lifting device, repeated rotation can be conveniently converted into vertical reciprocating movement, thus the punching efficiency is improved, and meanwhile, the punching needles at the two sides are driven to rotate by a motor, so that the punching difficulty is effectively reduced.

Owner:盐城浩派沃科技服务有限公司

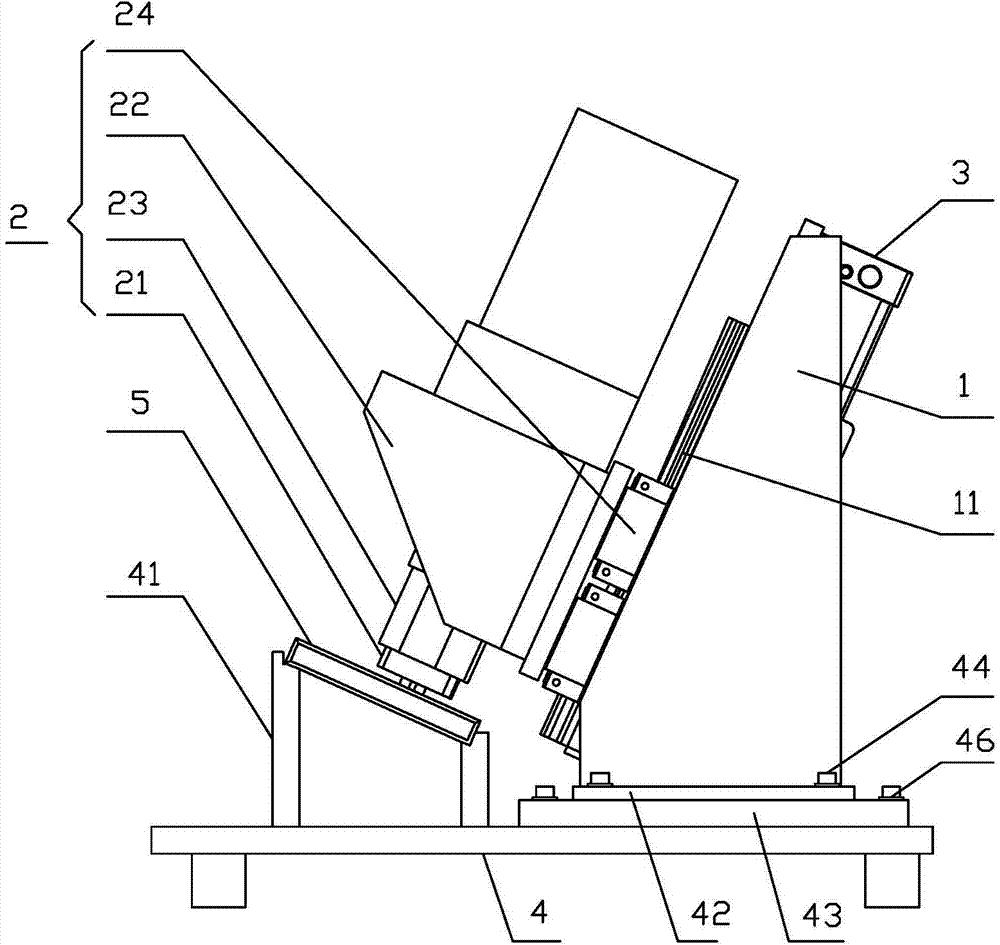

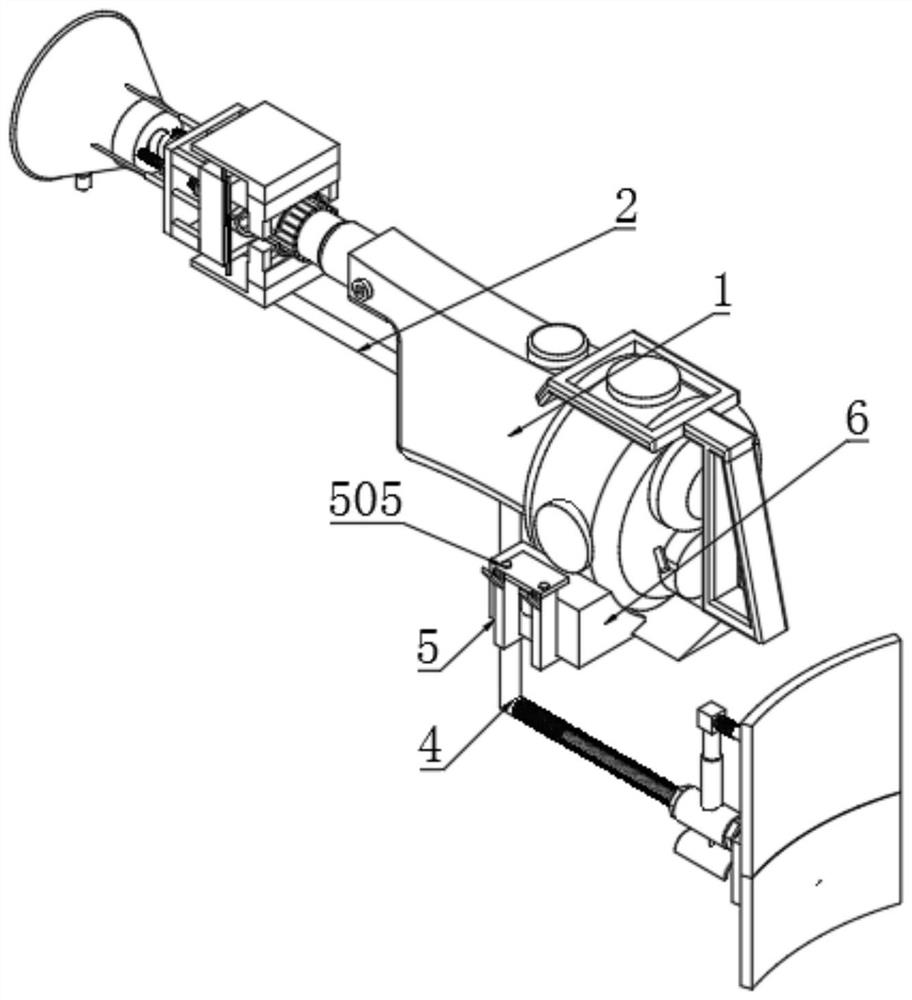

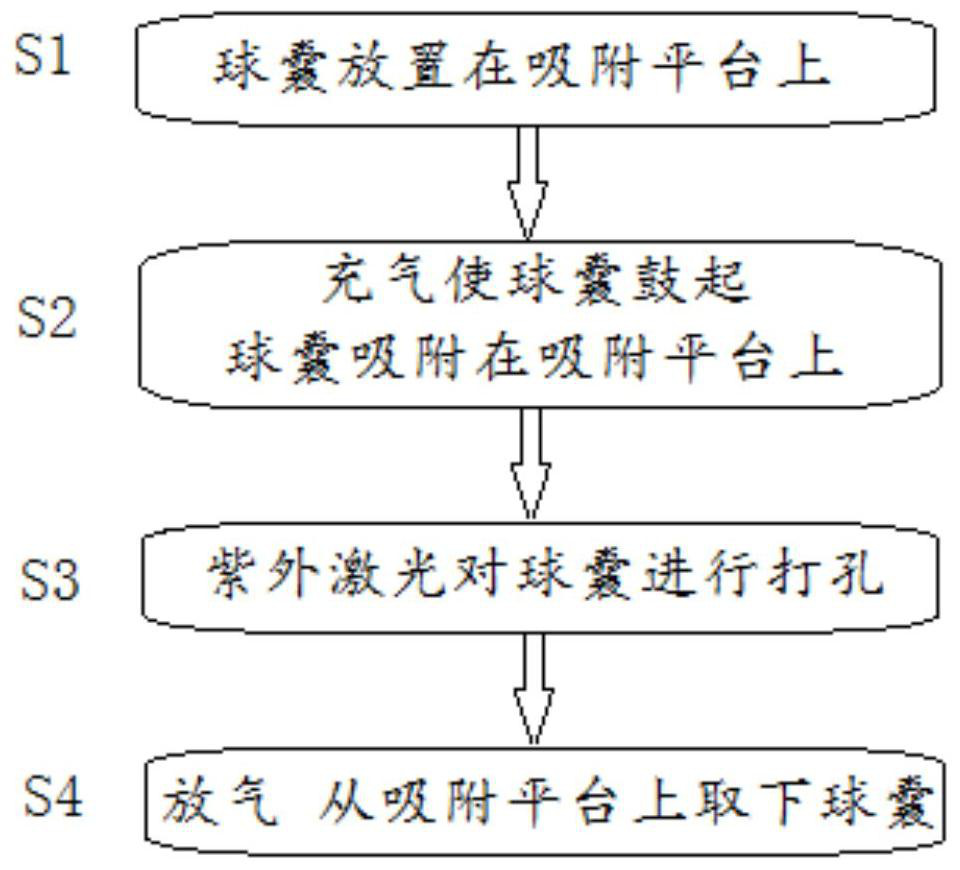

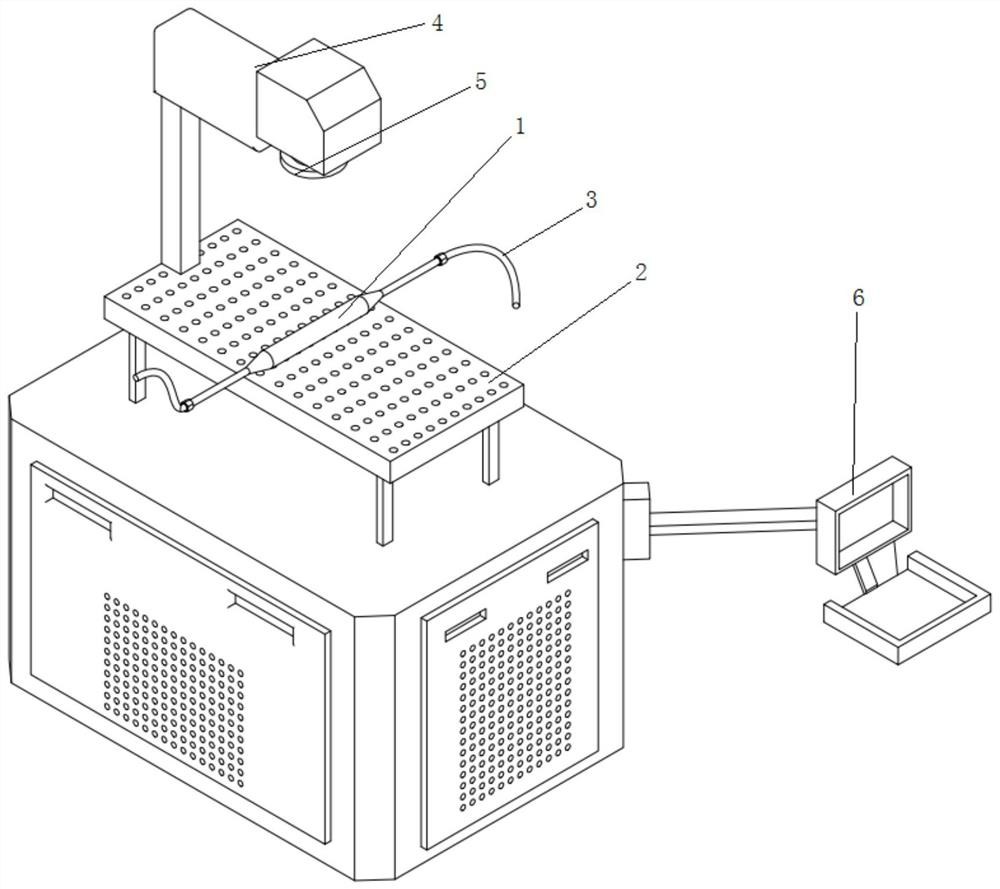

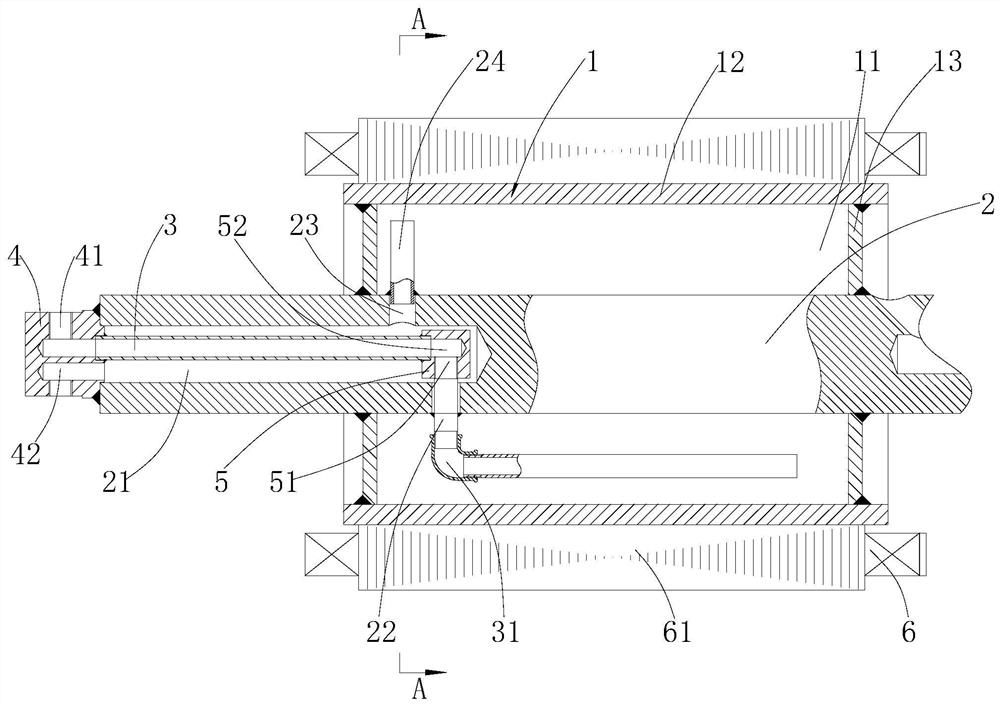

Laser perforation method and laser perforation device for medical ptca balloon

A laser perforation method and laser perforation device for a medical PTCA balloon relate to the technical field of human body drug delivery devices, and solve the problems of difficult operation and uneven aperture size of the existing medical PTCA balloon laser perforation. The perforated medical PTCA balloon is placed on the adsorption platform; the medical PTCA balloon is inflated by inflating the medical PTCA balloon, and the bulging medical PTCA balloon is adsorbed on the adsorption platform; the medical PTCA balloon is treated with ultraviolet laser. Drill holes; deflate the medical PTCA balloon, and remove the medical PTCA balloon from the adsorption platform. A laser perforating device, including a laser perforating unit, an adsorption platform, an air charging unit and a control unit. The invention has very little thermal fusion of the balloon, can drill tiny holes, and is easy to control the size and range of the holes, without special fixtures for fixing, and the fixing effect is good, and no impurities remain inside, ensuring the cleanliness of the later operation And safety, reducing the difficulty of punching, high punching efficiency.

Owner:扬州扬芯激光技术有限公司

Inner stator motor cooling device, motor and inner stator motor cooling method

ActiveCN109842243BAvoid the dangerous situation of burning the coilReduce the difficulty of punchingCooling/ventillation arrangementThermodynamicsElectric machine

The invention provides an inner stator motor cooling device, a motor and an inner stator motor cooling method, belonging to the technical field of motor heat dissipation. The inner stator motor cooling device includes a mounting seat, a connecting shaft and a liquid inlet pipe. The motor adopts the inner stator motor cooling device. The inner stator motor cooling method adopts the inner stator motor cooling device. In the inner stator motor cooling device provided by the present invention, the cooling liquid enters from the liquid inlet pipe, and flows into the sealed cavity on the mounting seat through the liquid inlet hole, and the heat generated by the stator exchanges heat with the cooling liquid in the sealed cavity to achieve For the purpose of cooling the stator, after the cooling liquid reaches a certain amount in the sealed cavity, it enters the liquid outlet hole, and flows out through the gap between the first blind hole and the liquid inlet pipe, forming a stable cooling liquid circulation system. This cooling method is less difficult to drill holes and is easy to process. It also avoids the danger of cooling water entering the motor and burning the coils due to the opening of two eccentric holes.

Owner:HEBEI NEWSTAR ELECTRIC MOTOR CO LTD

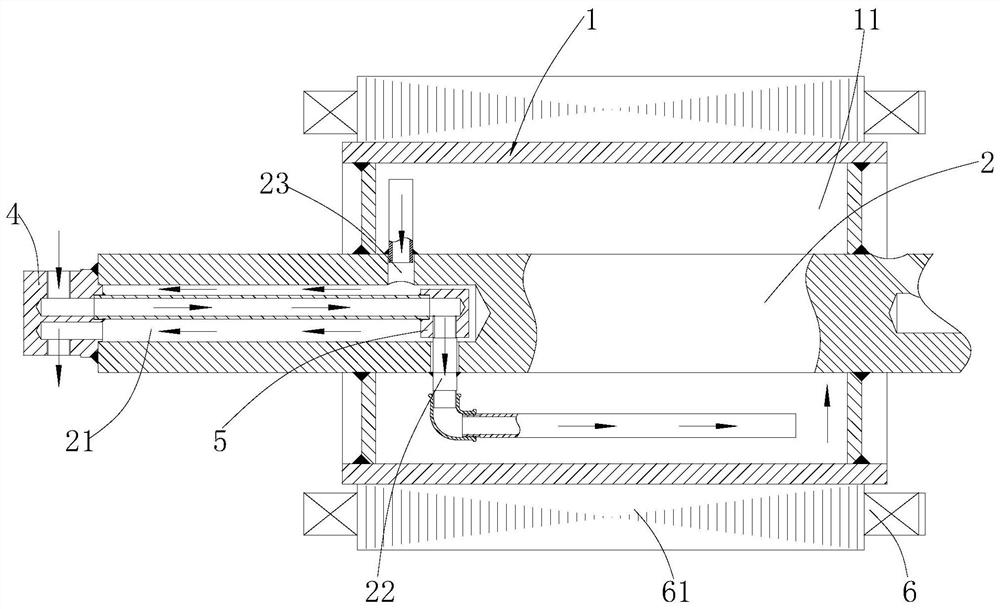

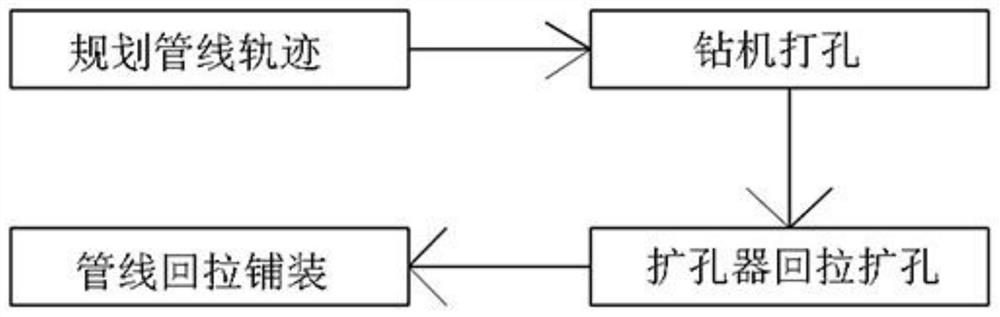

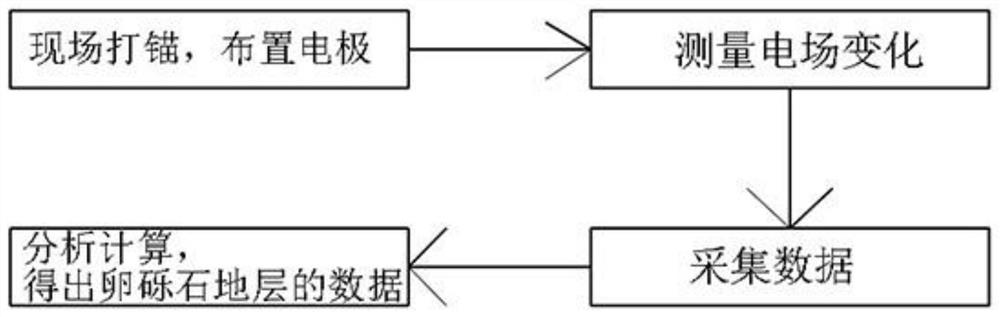

A construction method for horizontally oriented underground pipelines to cross complex pebble and gravel formations

ActiveCN112324333BImprove the strength of the connection structureNot easy to loose and slipPipe laying and repairDirectional drillingReamerUnderground pipeline

The invention belongs to the technical field of horizontal directional drilling, and in particular relates to a construction method for horizontally directional traversing complex pebble gravel formations for underground pipelines. The present invention achieves the effect of effectively laying underground pipelines in complex gravel formations by first planning the pipeline trajectory, then drilling holes by the drilling machine, then pulling back and reaming the holes by the reamer, and finally pulling the pipelines back and laying them. Drill pipe coupling for drilling operations in pebble and gravel formations with higher strength requirements. The invention has the advantages of avoiding the cobblestone formation to the greatest extent during the pipeline laying process, realizing effective drilling by increasing the drilling strength when encountering the cobblestone formation, and simple and effective operations of pulling back and expanding the hole and discharging the mud. Advantages, and the drill pipe coupling used in it has a strong connection structure, the two sections of drill pipe are not easy to loosen and slip, the coupling structure is easy to assemble and disassemble, and it is finally suitable for high-strength drilling in pebble and gravel formations. advantage.

Owner:河北省水利工程局集团有限公司

A kind of mine microseismic detector installed in deep hole

ActiveCN103941283BReduce automatic loggingRealize automatic recordingSeismic signal receiversObservational errorData acquisition

The invention discloses a mine microseism wave detector installed in a deep hole. The mine microseism wave detector installed in the deep hole comprises a wave detector sensing unit, a vibration testing unit, a variable gain and controllable filtering module, an azimuthal angle and dip angle measurement module and a core control module with data collection and communication functions. The wave detector can achieve automatic recording of related information, lowers the complexity of artificial operation, avoids introducing more artificial measurement errors, achieves self-measurement of the azimuthal angle and the dip angle, reduces the amount of the related information recorded manually, lightens the workload of manual recording and the probability of wrong recording, and guarantees normal work. A work state self-detection function of the wave detector is added, maintenance difficulty and complexity are lowered, the utilization rate is improved, variable gains and controllable filtering are increased, the grain range and the filtering frequency band are adjustable, the signal-to-noise ratio and the anti-attenuation capacity of a single source are improved, and the wave detector sensing unit is favorable for improving the signal-to-noise ratio of the wave detector array.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

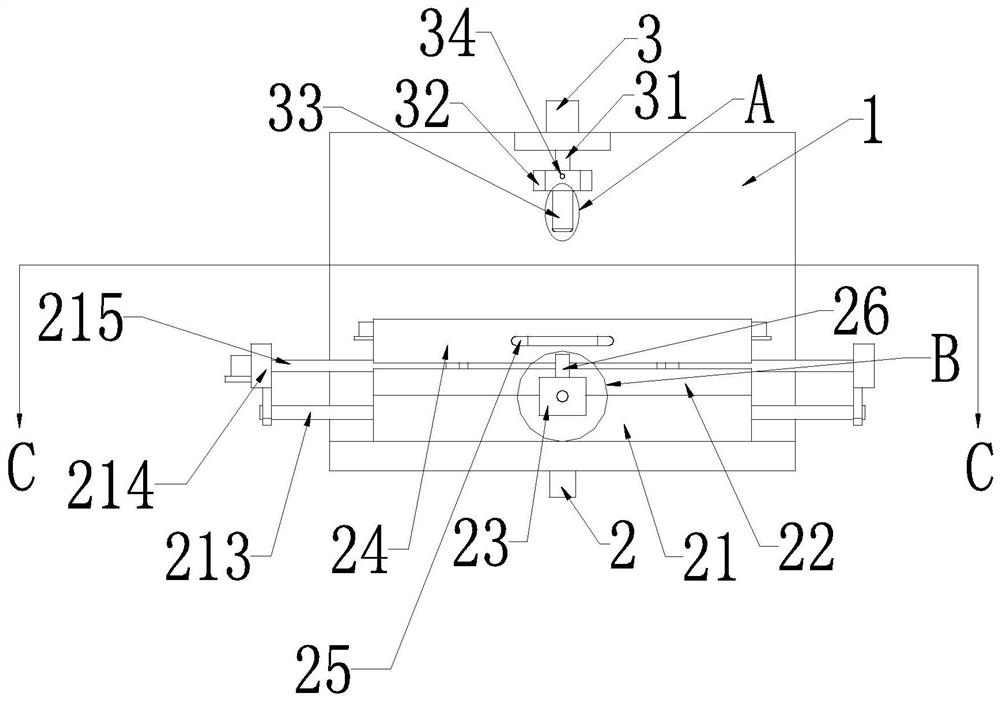

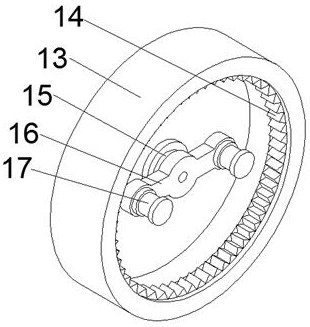

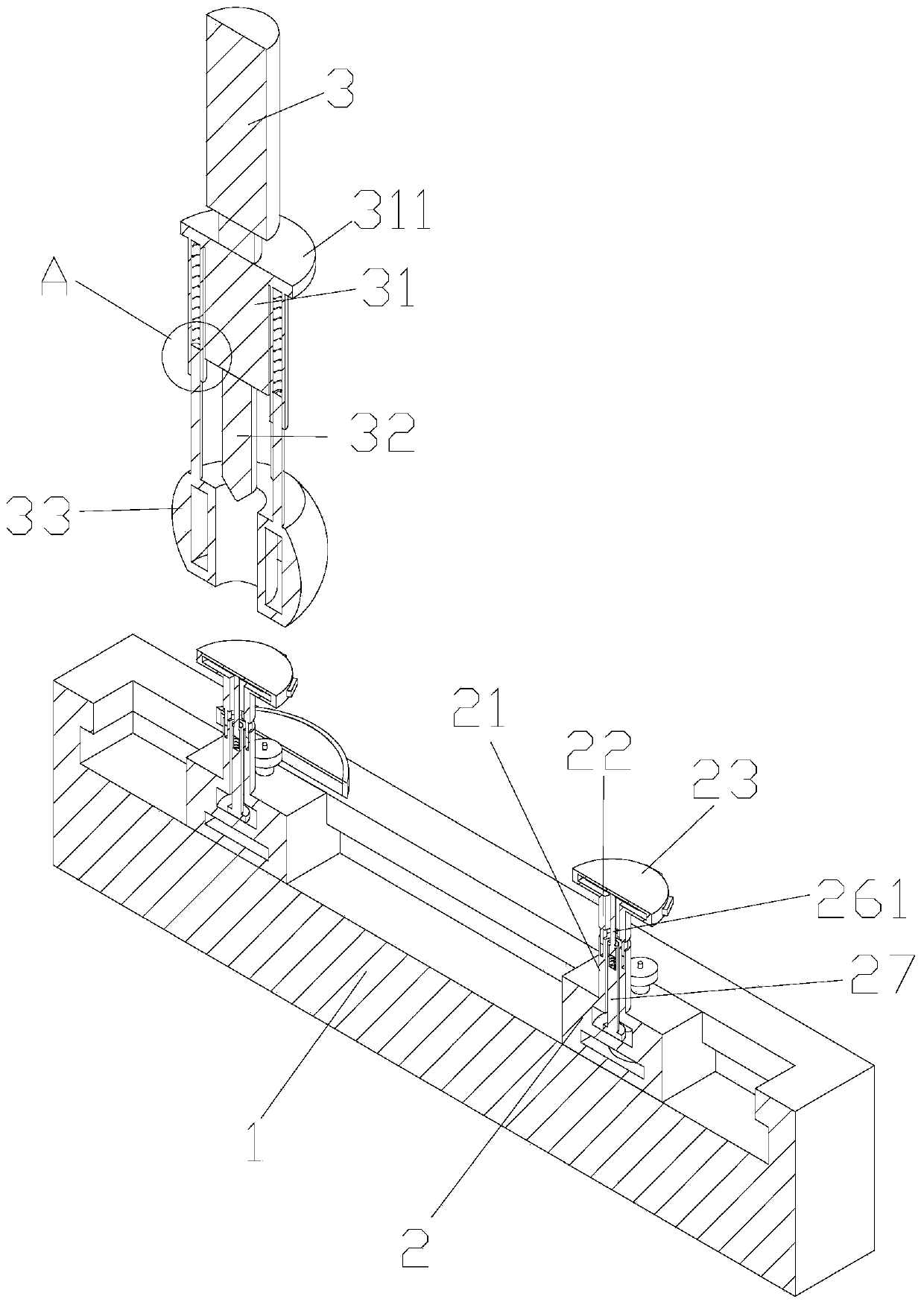

Inner hexagonal punching machine

PendingCN112893913AReliable positioning and clampingGuaranteed positioning accuracyPositioning apparatusMetal-working holdersTool bitPunching

The invention discloses an inner hexagonal punching machine which comprises a rack, wherein a tailstock and a spindle box in sliding fit with the rack are arranged on the rack, the spindle box is provided with a rotary spindle, an ejector rod for positioning one end of a workpiece is arranged on the tailstock, and a cutter acting on the other end of the workpiece is arranged on the spindle. The tool comprises a front shaft, a rear shaft and a tool bit fixed to the front shaft, the rear shaft and the main shaft are coaxially and fixedly connected, the front shaft and the rear shaft are arranged in an eccentric rotating mode, and the main shaft and the rear shaft drive the front shaft and the tool bit to generate radial vibration when rotating. A punching feeding unit for driving the spindle box to slide towards the end part of the ejector rod is arranged on the rack. The invention aims to effectively reduce the requirements on equipment and save the production cost.

Owner:浙江富冈机床有限公司

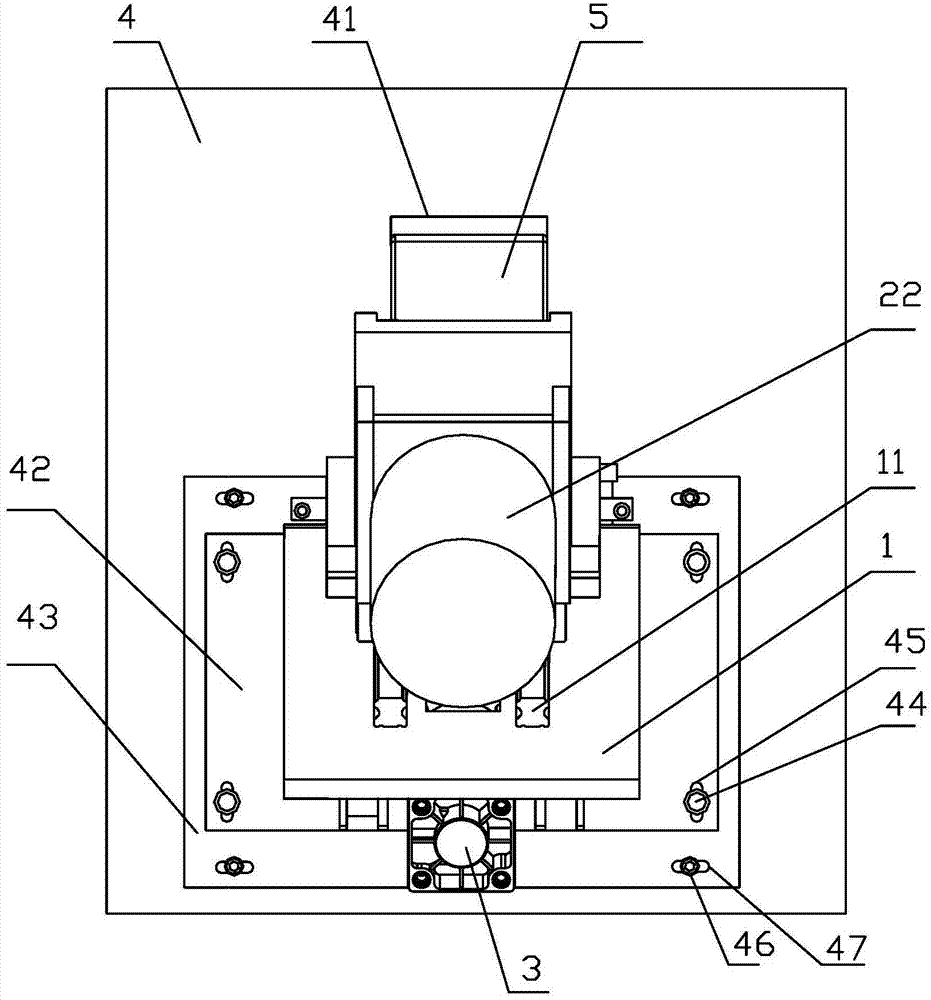

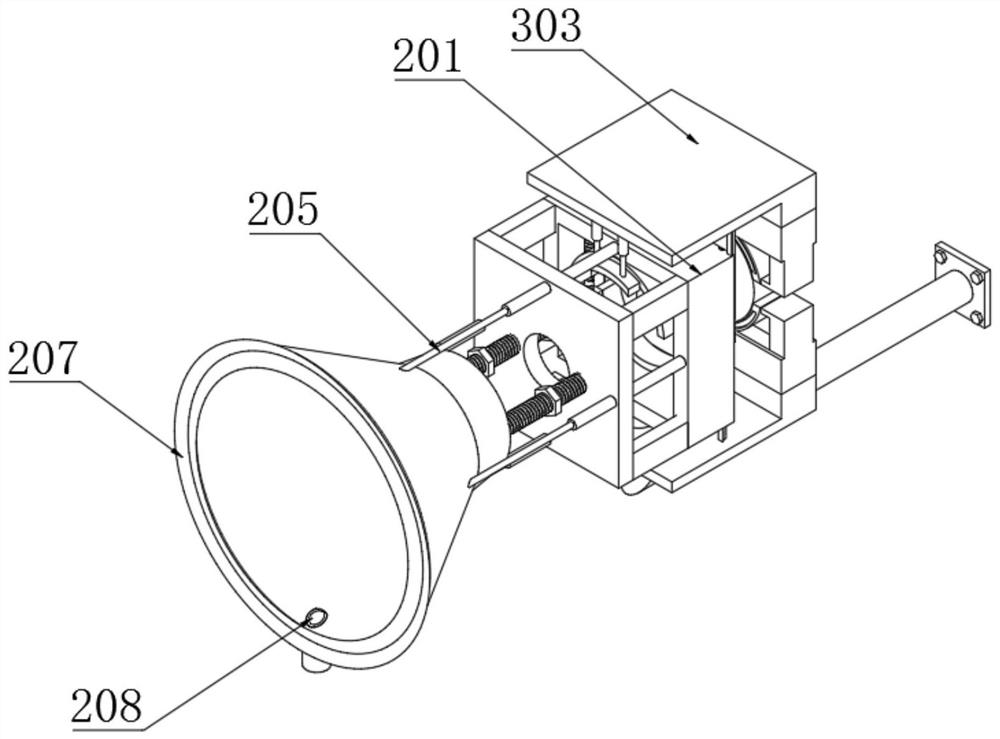

Lampshade punching device used for lighting equipment processing

ActiveCN111390598AImprove processing efficiencyReduce the difficulty of punchingFeeding apparatusLarge fixed membersLight equipmentPunching

The invention discloses a lampshade punching device used for lighting equipment processing. The lampshade punching device comprises a processing table, a fixing assembly arranged on the processing table and an electric drilling assembly arranged on the upper portion of the processing table, a moving groove is formed in the processing table, the fixing assembly comprises a sliding block arranged inthe moving groove, a first supporting rod arranged on the sliding block, a second supporting rod arranged on the first supporting rod and a fixing disc arranged on the second supporting rod, and themoving groove is of an annular structure. According to the lampshade punching device, loading, taking and punching are carried out separately by using the movement of the sliding block in the moving groove, the using safety of the device is improved, a production mode of pipeline is adopted to improve the processing efficiency of a lampshade, and the punching difficulty of the lampshade is reduced.

Owner:HANGZHOU UG PHOTOELECTRIC

Automobile interior parts processing device

ActiveCN103753641BIncrease flexibilityIncrease punching frequencyMetal working apparatusPunchingEngineering

Owner:SHANGHAI TONGLING AUTOMOTIVE TECH INC

An automatic cutting process for steel structure pipe fittings

ActiveCN112045028BIncrease workloadEfficient removalEdge grinding machinesDirt cleaningPunchingPipe fitting

The invention relates to an automatic cutting process for steel structure pipe fittings, which is mainly completed by an automatic cutting machine for steel structure pipe fittings. The automatic cutting machine for steel structure pipe fittings includes a mounting frame, a pre-cutting set and a punching set. Upwards are provided with pre-cutting set and punching set successively, and the present invention can solve the following problems that existing steel structure pipe fittings often have when cutting operations: a: existing steel pipes often cause deformation of the super-cut surface circumference when cutting, And there are burrs on the cutting surface, and then in order to meet the needs of use, it is often necessary to perform secondary processing on the cut steel pipe, which greatly increases the workload of the employees. b: When the existing steel pipe is vertically cut, it often occurs If the cutting part is not completely cut off, it needs to be cut several times later, which greatly slows down the production progress and wastes time.

Owner:山东新宏重工有限公司

A pole piece cutting manufacturing process for lithium-ion pouch battery

ActiveCN111760958BAvoid short circuit problemsQuality improvementCell electrodesSecondary cellsCell fabricationPole piece

The name of the present invention is a pole piece cutting manufacturing process for lithium-ion pouch batteries. The invention belongs to the technical field of manufacturing lithium-ion soft pack batteries. It mainly solves the problems of sharp points and burrs on the cutting edges of the existing lithium-ion pouch battery pole pieces. Its main features are: including a die-cutting machine, a positive pole fillet mold, a negative pole bevel mold, a positive pole lug mold and a negative pole lug mold; After being cut by the positive pole fillet mold station, rounded corners are formed at four right angles; the rounded corners on both sides of the positive pole piece are asymmetrical; the negative pole piece is cut by the front negative pole lug mold station to form positive pole lugs Afterwards, it is cut by the rear negative electrode fillet mold station to form obtuse angles at four right angles; the bevels on both sides of the negative pole piece are asymmetrical structures. The invention improves the quality and stability of the battery, at the same time, reduces the difficulty of punching the pole piece cutting die, and greatly improves the service life of the pole piece cutting die.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

Automatic profile steel punching device and punching method

The invention relates to an automatic profile steel punching device which comprises a machine body, and further comprises a side punching mechanism. The side punching mechanism comprises a lever, an upper sliding seat and a lower sliding seat; the lever is rotationally arranged in the machine body through a rotating shaft; the two ends of the lever are hinged to a first connecting rod and a second connecting rod respectively; the other end of the first connecting rod is hinged to the upper sliding seat; the other end of the second connecting rod is hinged to the lower sliding seat; a side punching rod is arranged at the other end of the lower sliding seat; a connecting rod is rotationally connected to the side edge of a mounting column; a third connecting rod is hinged to the bottom end of the connecting rod; a crank is rotationally connected onto a punching die; and the other end of the crank is rotationally connected to the joint of the connecting rod and the third connecting rod; According to the automatic profile steel punching device provided by the invention, the structure in the prior art is simplified, resources are saved, and the production efficiency is improved.

Owner:秦皇岛市国阳钢铁有限公司

A punching device with two-way punching function

The invention discloses a punching device with a bidirectional punching function. The punching device comprises a base, a stand column fixed to the end face of the rear side of the base, and a punching mechanism arranged on the front end side of the stand column. A punching executing groove is formed in the end face of the front side of the punching mechanism, and a punching motor is fixedly arranged in the top wall in the punching executing groove. The bottom of the punching motor is cooperatively connected with an upper drill bit, and a lower drill bit is arranged at the position, corresponding to the upper drill bit, in the punching executing groove. A switching cavity is formed in the position, above the punching motor, in the punching mechanism. A first transmission cavity is formed in the position, below the upper drill bit, in the punching mechanism, and a second transmission cavity extending vertically is formed in the position, behind the punching executing groove, in the punching mechanism. A guide groove is formed in the inner wall of the front side of the switching cavity, and a switching driving threaded rod extending in the longitudinal direction is arranged in the guide groove. An inner spline shaft bush with the bottom end rotationally and cooperatively connected with the top end of the punching motor is arranged at the inner bottom of the switching cavity. The punching device is simple in structure, bidirectional punching can be achieved, the punching difficulty is lowered, the punching precision is improved, time and labor are saved, and the rejection rate is reduced.

Owner:南京苏宁锻造有限公司

Processing method of lead-acid battery grid

ActiveCN103337636BSmall grainImprove corrosion resistanceFinal product manufactureElectrode carriers/collectorsMaterial consumptionEngineering

A processing method of lead-acid battery grid relates to the technology field of processing lead-acid battery grid. The processing method comprises following steps: the first step is transverse bar extruding, the upper and lower molds are extruded by utilizing up-down movements and left-right movements of transverse bars, the upper and lower molds are extruded and folded to form a cavity by the transverse bars, and continuous extruding is realized by utilizing movements of transverse bar extruding the upper and lower bars; the second step is longitudinal bar extruding, and continuous extruding is realized according to the same theory of the transverse extruding; the third step is extruding trimming, a up-down trimming mold moves up and down to eliminate extruding projections and burrs of transverse bars, frames, and tabs, and a V-shaped notch is formed by extruding at the boundary of two grids. The processing method of lead-acid battery grid improves the strength and processing efficiency of stamped grids, and reduces material consumption through extruding shaping. The processing method has the advantages of continuous grids such as gravity casting and stamped grids, avoids the shortages of them, and enlarges the application field of continuous grids.

Owner:JIANGSU CEMT ENERGY EQUIP

An intelligent cutting equipment for steel structure bridge pipe fittings

ActiveCN111958256BIncrease workloadEfficient removalOther manufacturing equipments/toolsPipe fittingConstruction engineering

The invention relates to an intelligent cutting equipment for steel structure bridge pipe fittings, which includes a mounting frame, a pre-cutting set and a punching set. The following problems often exist in the cutting operation of structural pipe fittings: a: when the existing steel pipe is cut, the circumference of the super-cut surface is often deformed, and burrs appear on the cut surface, and then the cut steel pipe often needs to be cut to meet the needs of use. Secondary processing is carried out, which greatly increases the workload of employees b: when the existing steel pipes are cut vertically, the cutting part is often not completely cut off, and it is necessary to perform multiple cuts later, which greatly slows down The production schedule is lost and time is wasted.

Owner:山东省华东重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com