Punching device with bidirectional punching function

A technology of punching equipment and functions, applied in drilling/drilling equipment, boring/drilling, metal processing equipment and other directions, can solve the problems of large machining error, position offset, low machining accuracy, etc. The effect of stable movement, improved stable positioning, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

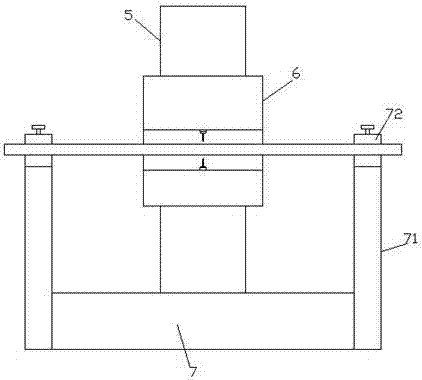

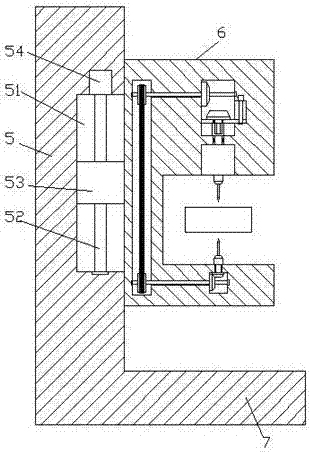

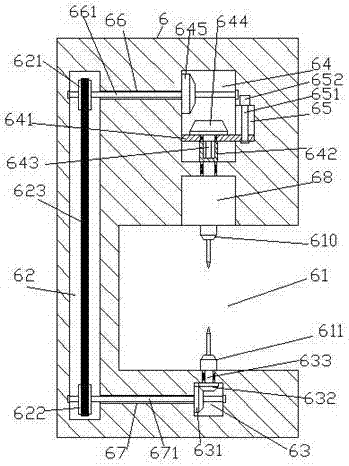

[0021] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a kind of punching equipment with two-way punching function of the present invention includes a base 7, a column 5 fixed on the rear end surface of the base 7, and a punching mechanism 6 arranged at the front end of the column 5 , the front end surface of the punching mechanism 6 is provided with a punching execution groove 61, and the inner top wall of the punching execution groove 61 is fixed with a punching motor 68, and the bottom of the punching motor 68 is connected with an upper drill bit. 610, the inner bottom of the punching execution groove 61 opposite to the upper drill bit 610 is provided with a lower drill bit 611, and the inside of the punching mechanism 6 above the punching motor 68 is provided with a switching cavity 64, and the upper drill bit 610 The punching mechanism 6 below is provided with a first transmission cavity 63 inside, and the punching mechanism 6 behind the punching execu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com