Sealing structure of vertical lift quick opening door

A sealing structure, vertical lifting technology, applied in the direction of sealing device, wing fan layout, etc., can solve the problems of affecting the flatness of the sealing surface, increasing the difficulty of punching, and the length of the blowing hole, so as to improve the overall flatness and reduce the material Cost and difficulty of punching, the effect of enhancing the strength of the back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

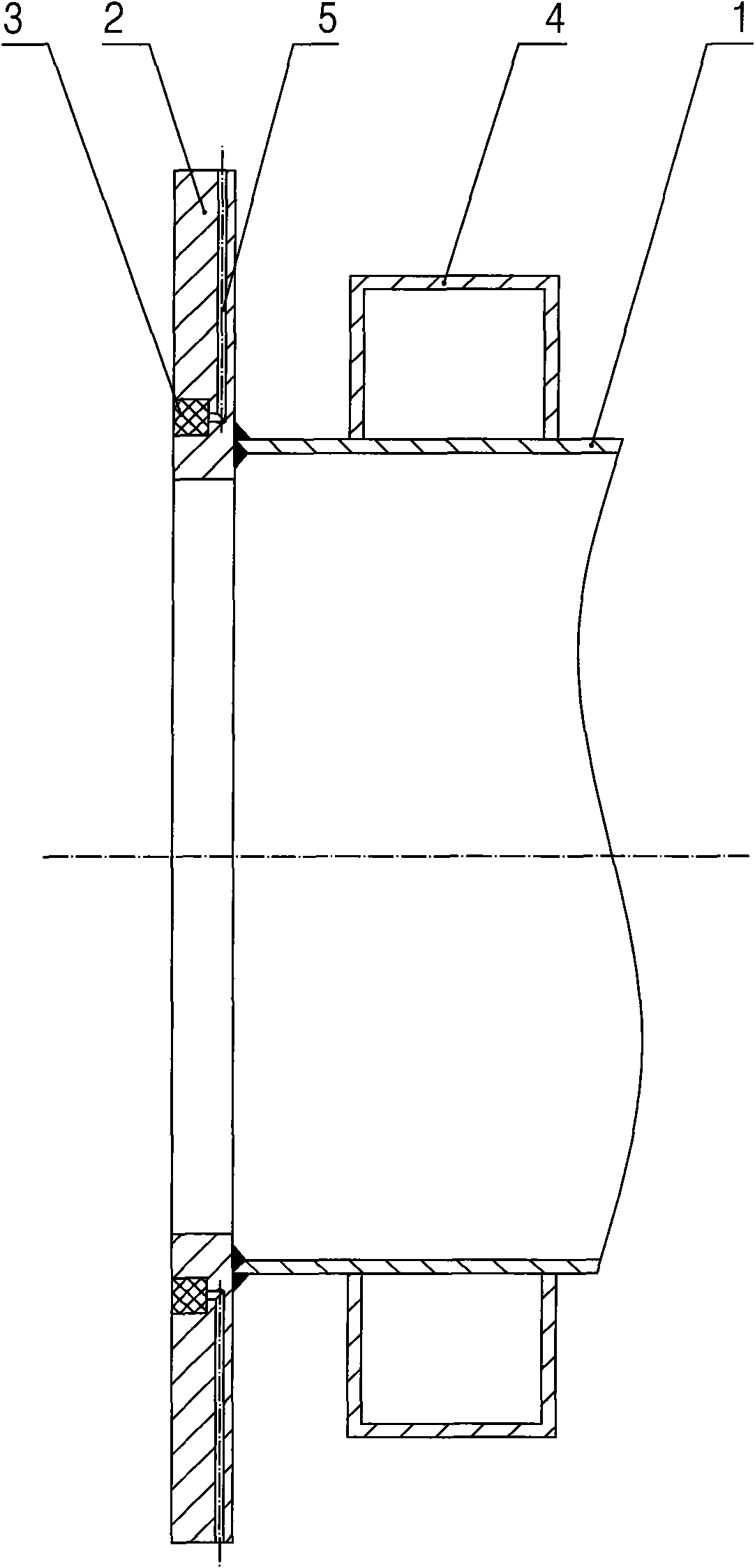

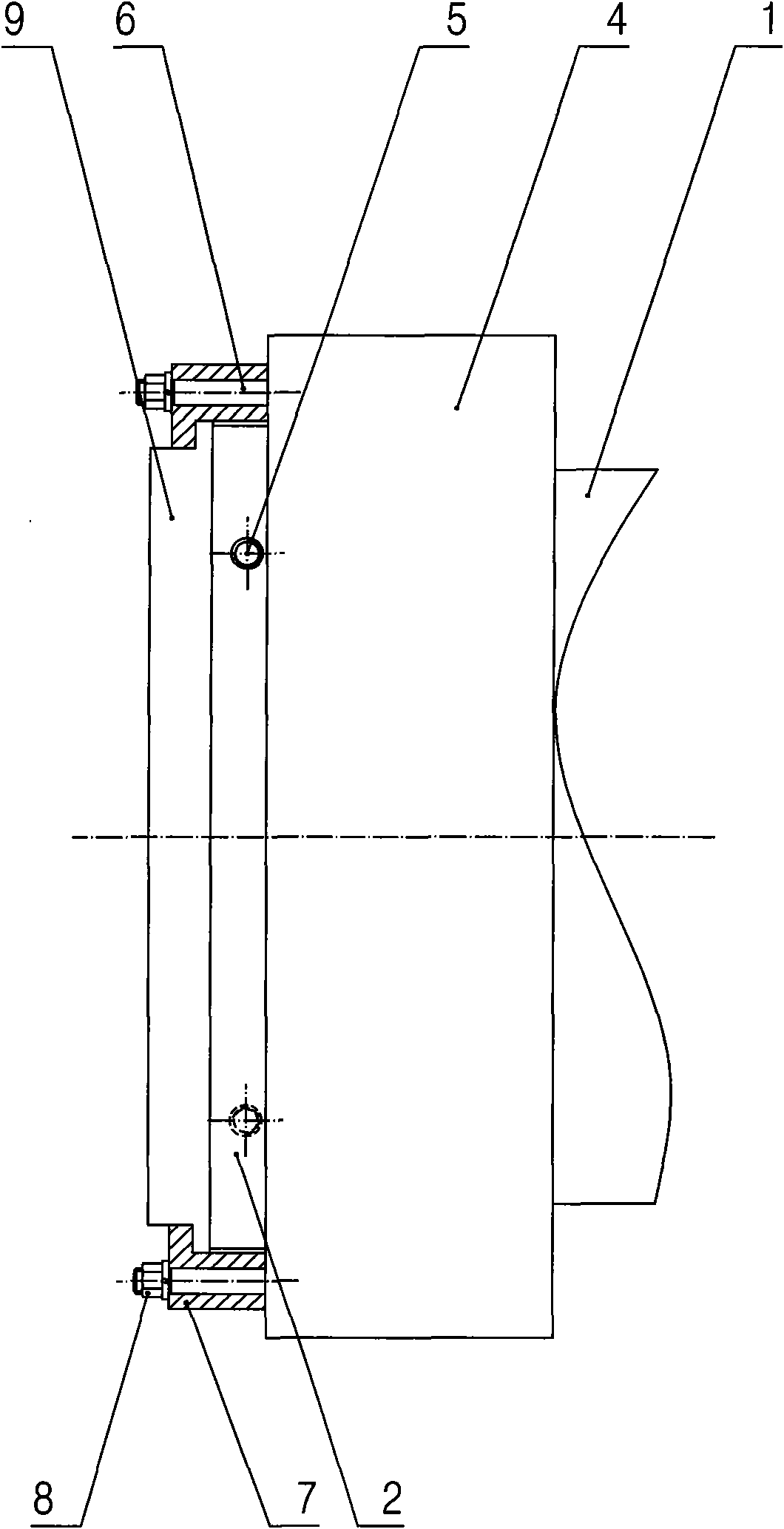

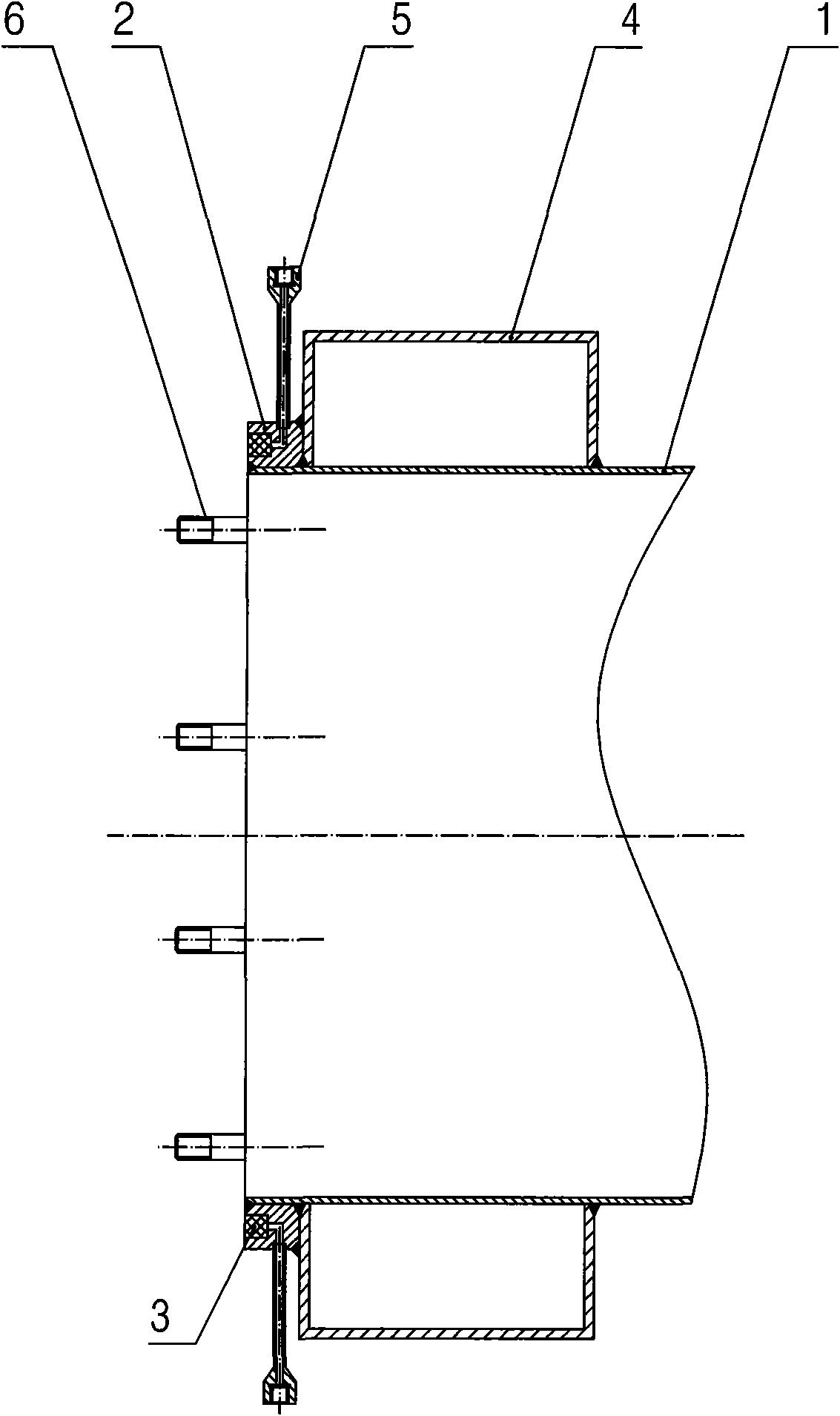

[0014] Such as figure 2 As shown, the sealing structure of the vertical lifting quick-opening door according to the present invention includes: a door baffle plate 7, a cylinder body 1, a door sealing flange 2 welded on the outer surface of the cylinder body 1 and a reinforcing groove bar 4—see image 3 As shown, the front of the door sealing flange 2 is provided with a closed-loop sealing groove on the side facing the door 9, and a sealing rubber strip 3 is embedded in the sealing groove—see image 3 , Figure 4 As shown, the door baffle 7 is fixed on the reinforcement groove 4 through the fixing bolt 6, the spring washer and the nut 8, and the wall thickness of the door sealing flange 2 is not more than 30 mm, usually 25-30 mm. mm, the width of the door sealing flange 2 is not more than 33 mm, usually between 28 and 33 mm, and the top and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com