Aluminum alloy for electrolytic capacitor outer shell and preparation method of aluminum alloy

A technology for electrolytic capacitors and aluminum alloys, applied in the field of aluminum alloys, can solve the problems of low strength, difficulty in punching capacitor casings, poor explosion-proof performance of capacitors, etc., and achieve the effects of reducing usage, reducing production costs, and promoting economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

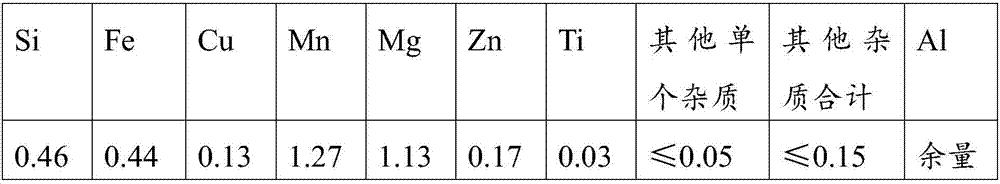

[0029] The chemical composition (WT%) of aluminum alloy of a kind of electrolytic capacitor case of the present embodiment is as follows:

[0030]

[0031] The preparation method of aluminum alloy for above-mentioned electrolytic capacitor shell, comprises the following steps:

[0032] (1) Calculate and prepare the materials according to the above ingredients (76% recycled aluminum, 23% electrolytic aluminum ingots and 1% aluminum alloy additives), put them into the melting furnace for melting, after refining, slag removal, stirring, analysis and composition adjustment Enter the static furnace, static, refining, degassing, slag removal, adding Al-5Ti-1B wire into the molten aluminum, and then enter the casting machine to cast into ingots. The surface of the ingot is milled.

[0033] (2) Soak the ingot, the heat preservation temperature of the ingot is 580° C., and the heat preservation time of the ingot is 17 hours. The starting thickness of the hot rolling is controlled ...

Embodiment 2

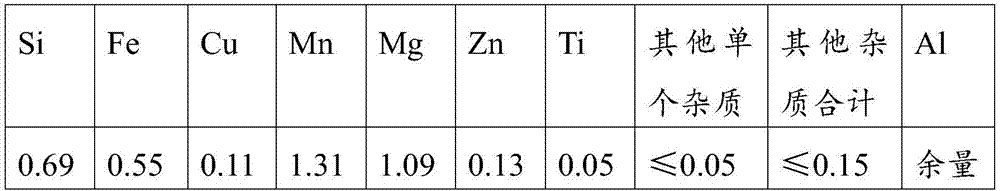

[0037] The chemical composition (WT%) of aluminum alloy of a kind of electrolytic capacitor case of the present embodiment is as follows:

[0038]

[0039] The preparation method of aluminum alloy for above-mentioned electrolytic capacitor shell, comprises the following steps:

[0040] (1) Calculate and prepare the materials according to the above ingredients (87% recycled aluminum, 12.2% electrolytic aluminum ingots and 0.8% aluminum alloy additives), put them into the melting furnace for melting, after refining, deslagging, stirring, analyzing and adjusting the ingredients Enter the static furnace, static, refining, degassing, slag removal, adding Al-5Ti-1B wire into the molten aluminum, and then enter the casting machine to cast into ingots. The surface of the ingot is milled.

[0041] (2) Soak the ingot, the heat preservation temperature of the ingot is 590° C., and the heat preservation time of the ingot is 16 hours. The hot rolling start temperature is controlled at...

Embodiment 3

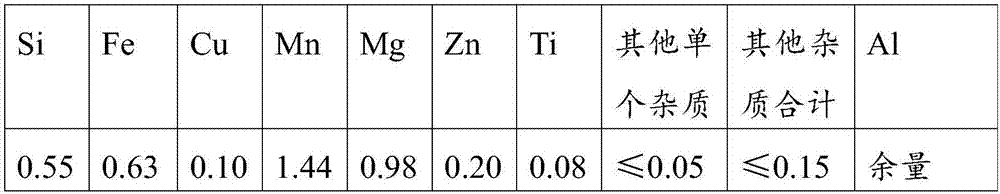

[0045] The chemical composition (WT%) of aluminum alloy of a kind of electrolytic capacitor case of the present embodiment is as follows:

[0046]

[0047] The preparation method of aluminum alloy for above-mentioned electrolytic capacitor shell, comprises the following steps:

[0048] (1) Calculate and prepare the materials according to the above ingredients (82% recycled aluminum, 17.3% electrolytic aluminum ingots and 0.7% aluminum alloy additives), put them into the melting furnace for melting, after refining, deslagging, stirring, analyzing and adjusting the ingredients Enter the static furnace, static, refining, degassing, slag removal, adding Al-5Ti-1B wire into the molten aluminum, and then enter the casting machine to cast into ingots. The surface of the ingot is milled.

[0049] (2) Soak the ingot, the heat preservation temperature of the ingot is 600° C., and the heat preservation time of the ingot is 15 hours. The starting temperature of hot rolling is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com