Pole piece cutting manufacturing process of lithium-ion soft-packed battery

A manufacturing process and soft-pack battery technology, applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of piercing the diaphragm, battery short circuit, etc., reduce the difficulty of punching, improve service life, improve quality and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be clearly and completely described below in conjunction with embodiments.

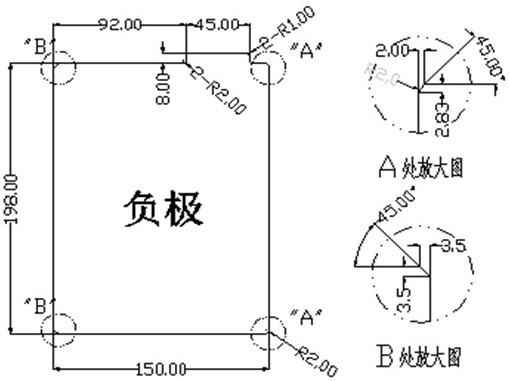

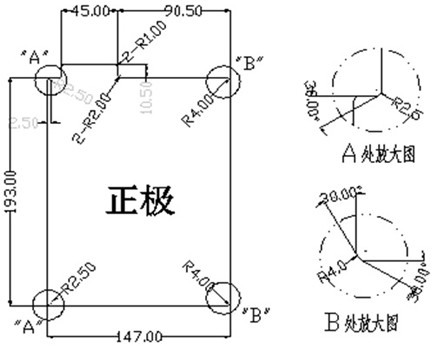

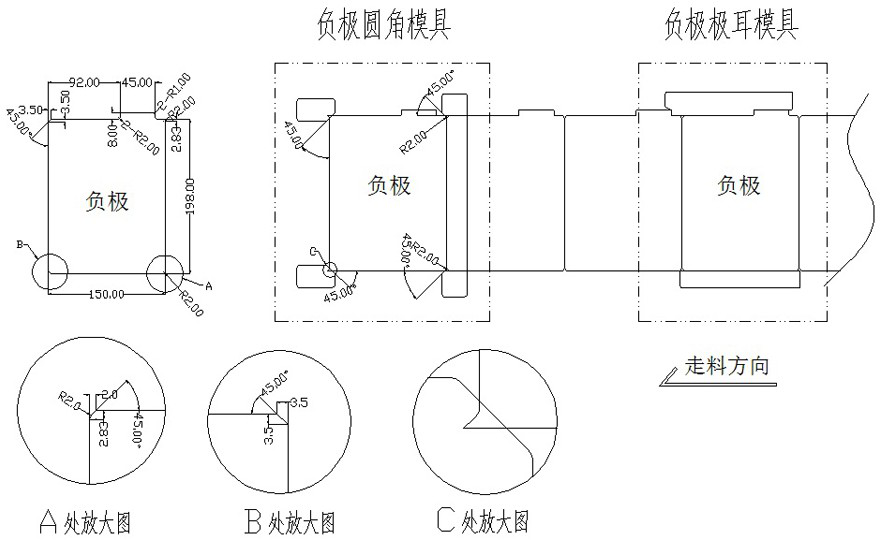

[0025] An embodiment of a pole piece cutting manufacturing process of a lithium-ion pouch battery in the present invention includes a positive pole piece cutting manufacturing process and a negative pole piece cutting manufacturing process. The positive pole sheet cutting manufacturing process includes a die-cutting machine, a positive pole lug mold installed on the right side of the die-cutting machine, and a positive pole fillet mold on the left side, and the material feeding direction is from the right side to the left side. The manufacturing process of negative pole sheet cutting includes a die-cutting machine, a negative pole lug mold installed on the right side of the die-cutting machine and a negative pole bevel mold on the left side, and the material feeding direction is from the right side to the left side.

[0026] like figure 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com