Diaphragm for lithium ion battery and lithium ion battery applying diaphragm

A lithium-ion battery and diaphragm technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems affecting the safety of lithium-ion batteries, safety accidents, and short-circuiting of opposite electrodes, and solve battery short-circuit problems , avoid safety accidents and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

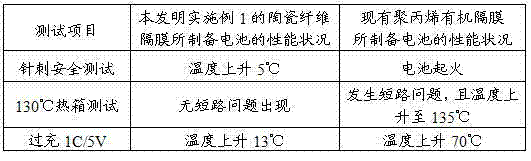

Embodiment 1

[0032] The specific preparation process of a ceramic fiber separator for a lithium-ion battery provided by the present invention is illustrated below through a specific example.

[0033] 1. Select the material step. Ceramic fiber can specifically choose solid alumina Al 2 o 3 Ceramic fiber (It should be noted that the solid alumina Al 2 o 3 Ceramic fibers can include Al in the alpha form 2 o 3 Ceramic fiber and γ-type Al 2 o 3 ceramic fiber), the solid alumina Al 2 o 3 The length of the ceramic fiber is selected as 120mm, and the solid alumina Al 2 o 3 The diameter of the ceramic fiber is selected as 2.5 μm;

[0034] The inorganic filler can specifically choose sodium carboxymethyl cellulose particles, and the inorganic glue and organic glue can be chosen to be a mixture of silane glue and polyacrylic acid glue.

[0035] In this embodiment, the mass ratio between the ceramic fiber, the inorganic filler and the two kinds of glue, the inorganic glue and the organic g...

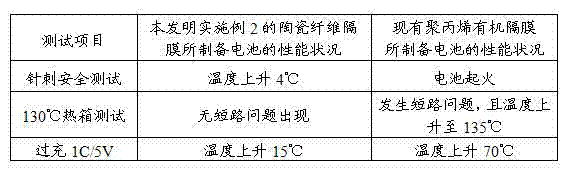

Embodiment 2

[0050] The specific preparation process of a ceramic fiber separator for a lithium-ion battery provided by the present invention is illustrated again through a specific example.

[0051] 1. Material selection steps. Ceramic fiber can choose solid silicon oxide SiO 2 and solid alumina Al 2 o 3 (alpha-type Al 2 o 3 ) ceramic fiber, the mass ratio of silicon oxide and aluminum oxide is 80:20. Solid alumina Al 2 o 3 The length of the ceramic fiber is selected as 120mm, and the solid alumina Al 2 o 3 The diameter of the ceramic fiber is chosen to be 2.5 μm. The solid silicon oxide SiO 2 The length is chosen to be 150mm, the solid silicon oxide SiO 2 The diameter is chosen to be 2.0 μm.

[0052] The inorganic filler can specifically choose sodium carboxymethyl cellulose particles, and the inorganic glue and organic glue can be chosen to be a mixture of silane glue and polyacrylic acid glue.

[0053] In this embodiment, the mass ratio between the ceramic fiber, the inorg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mass density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com