Patents

Literature

198results about How to "Does not affect the display effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

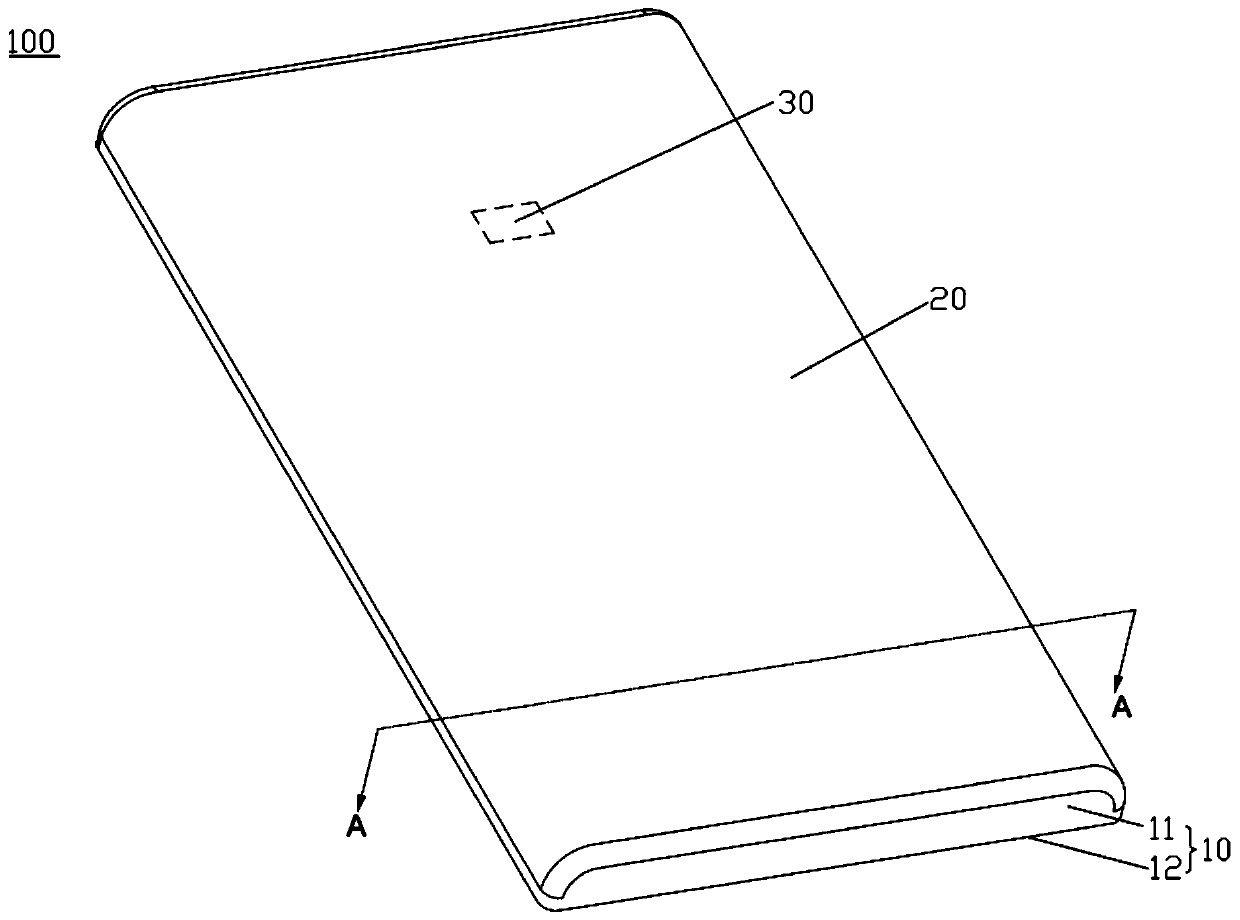

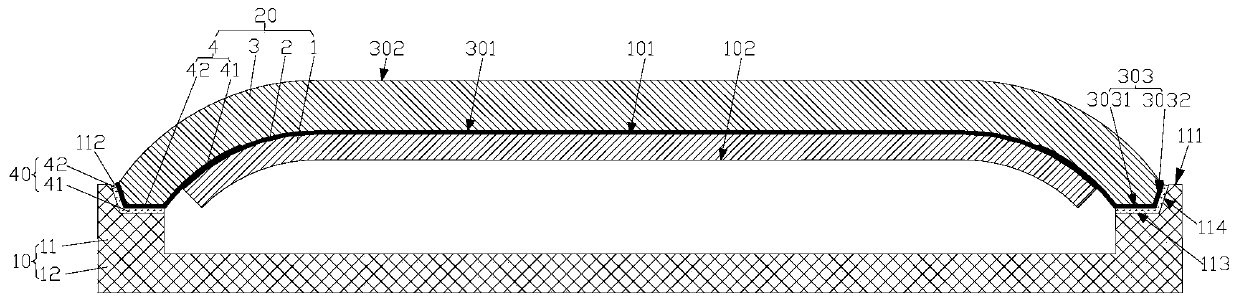

Display panel and display device

ActiveCN107293570ADoes not affect the display effectImprove bending resistanceStatic indicating devicesSolid-state devicesDisplay deviceVolumetric Mass Density

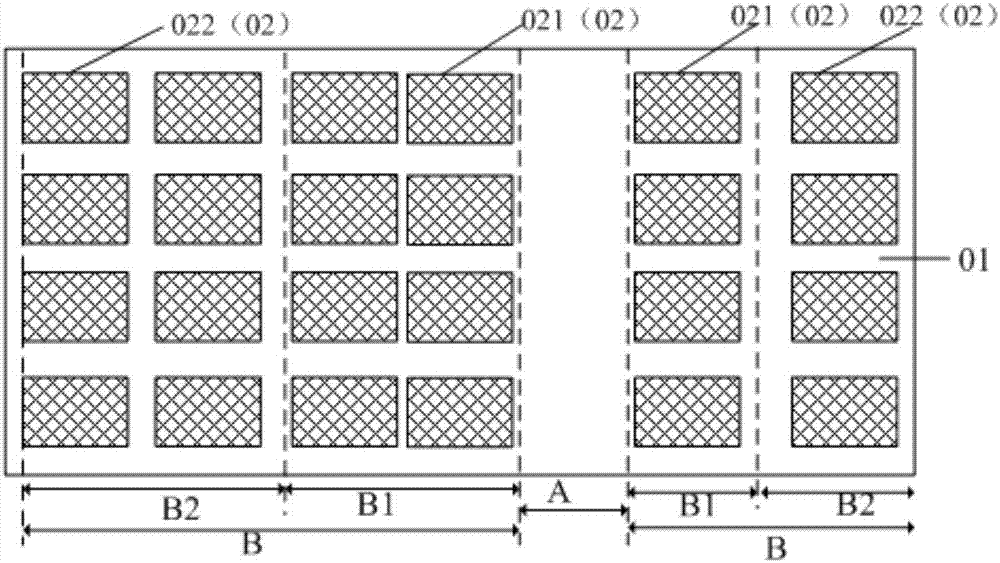

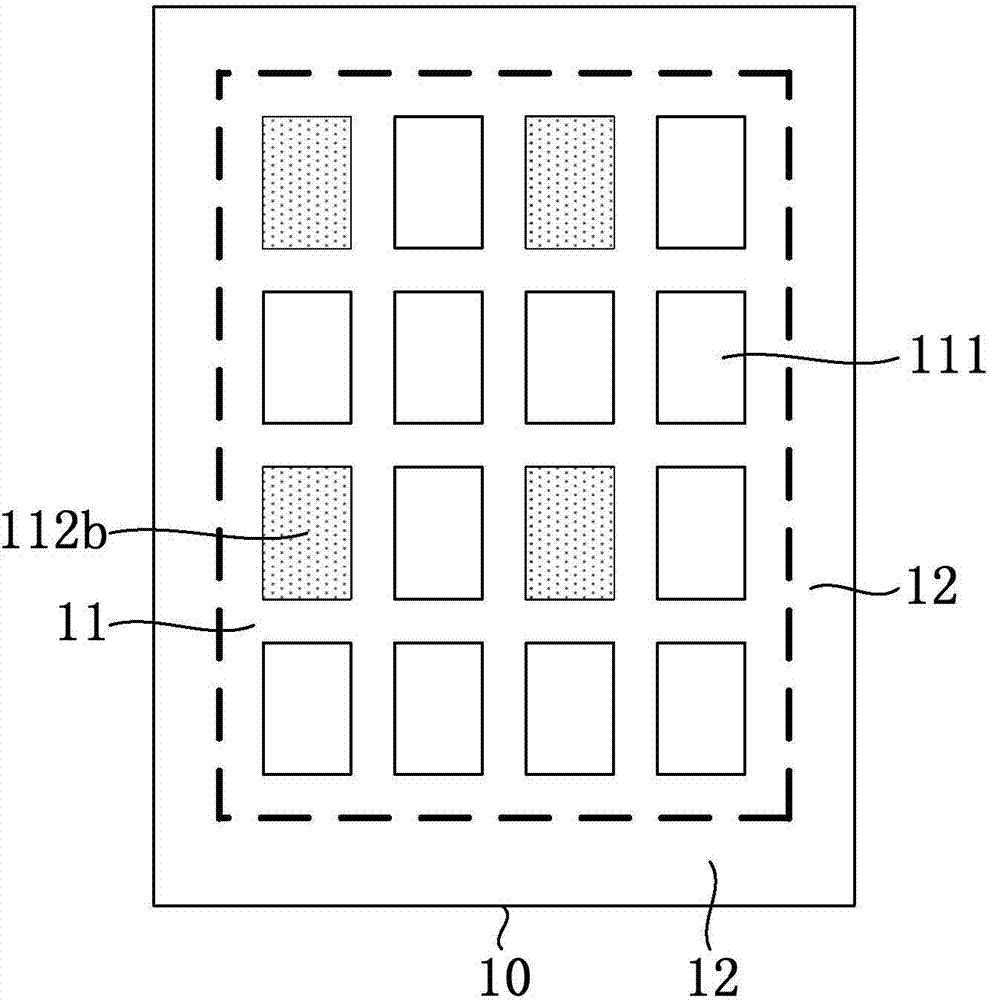

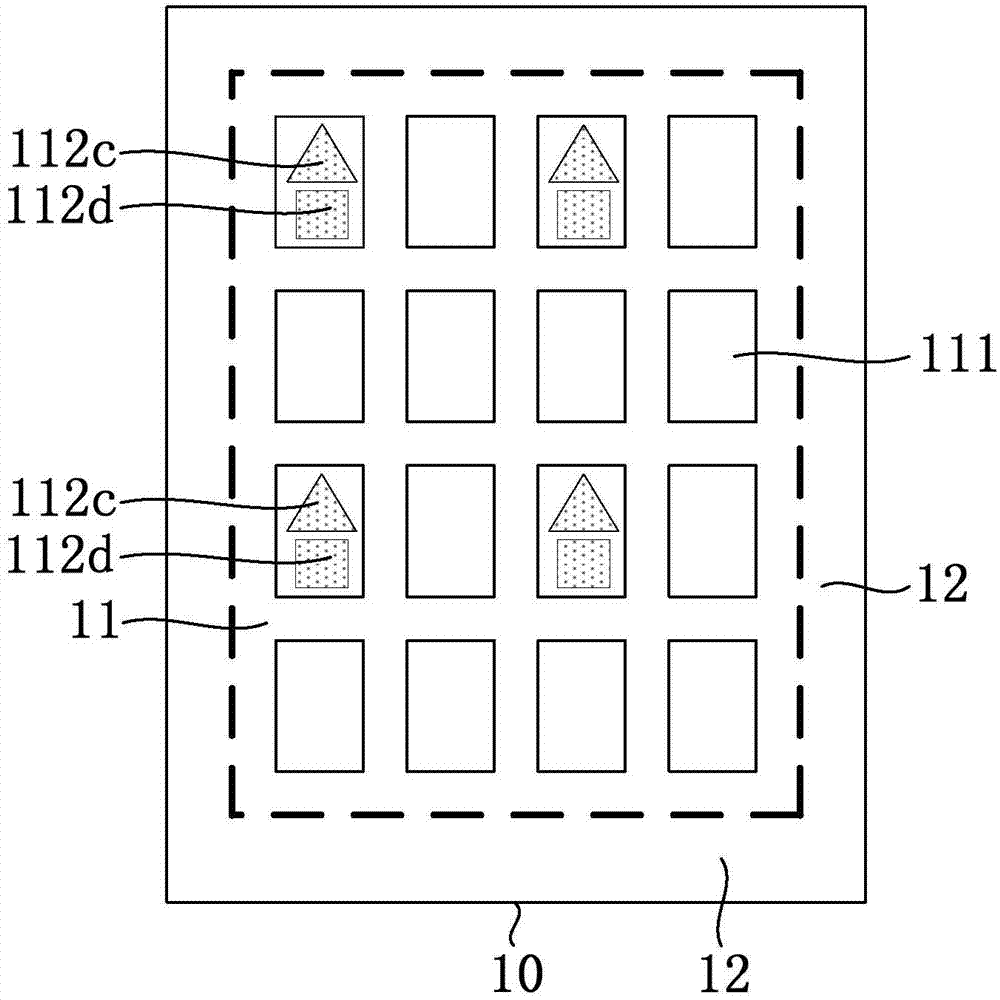

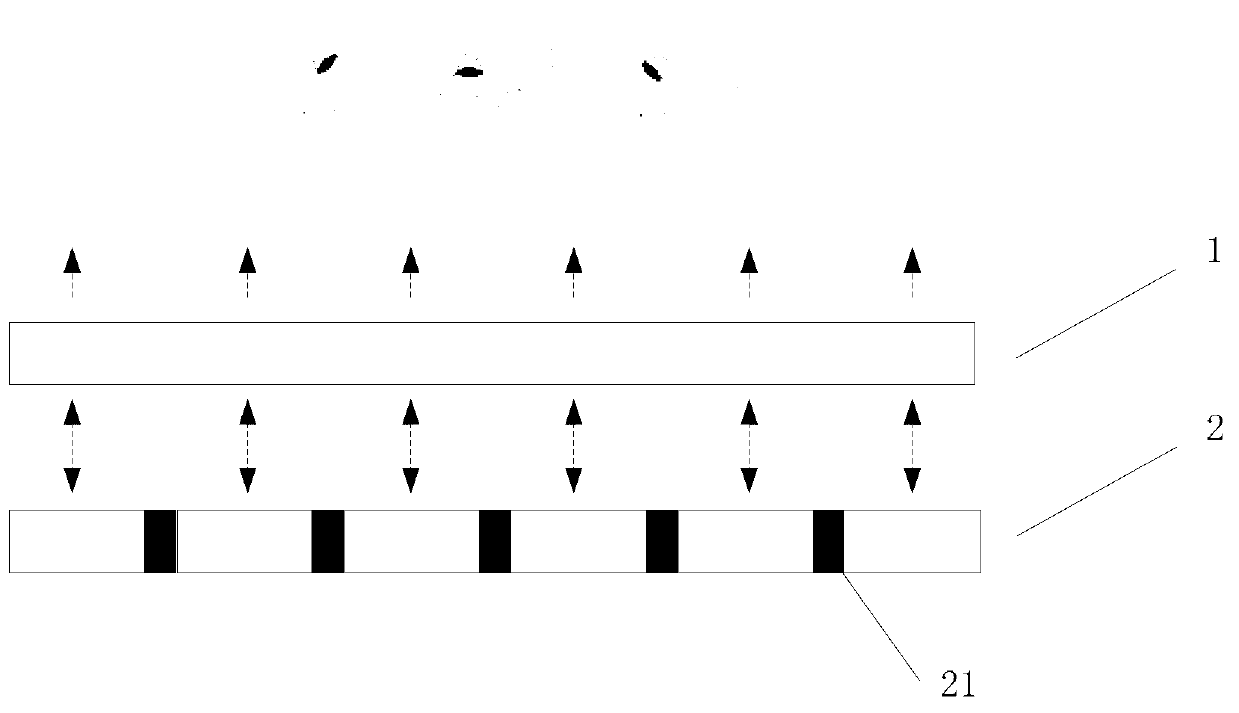

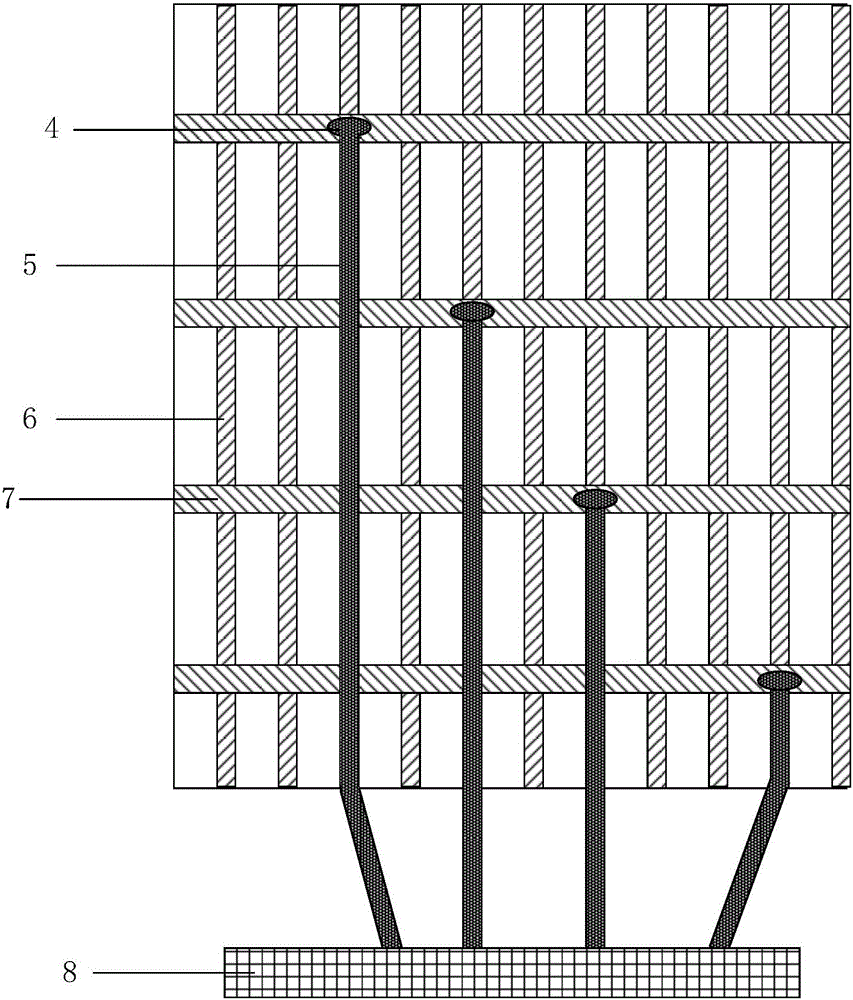

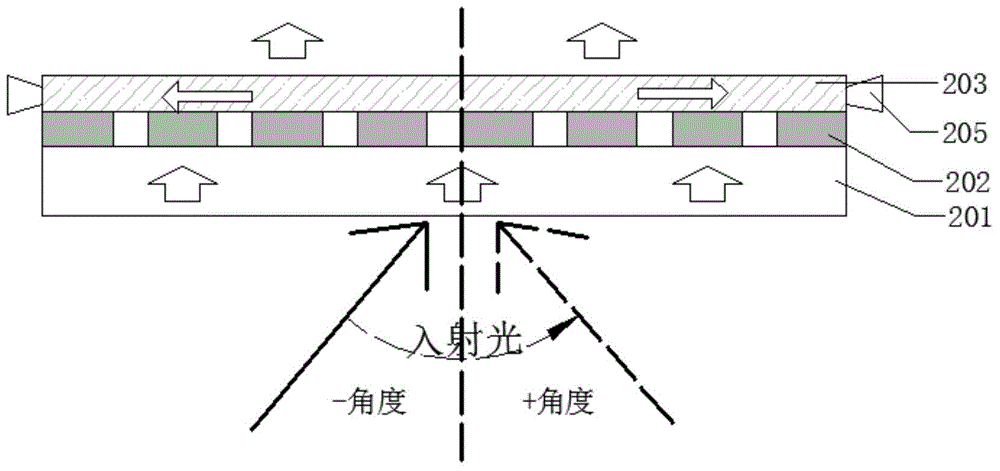

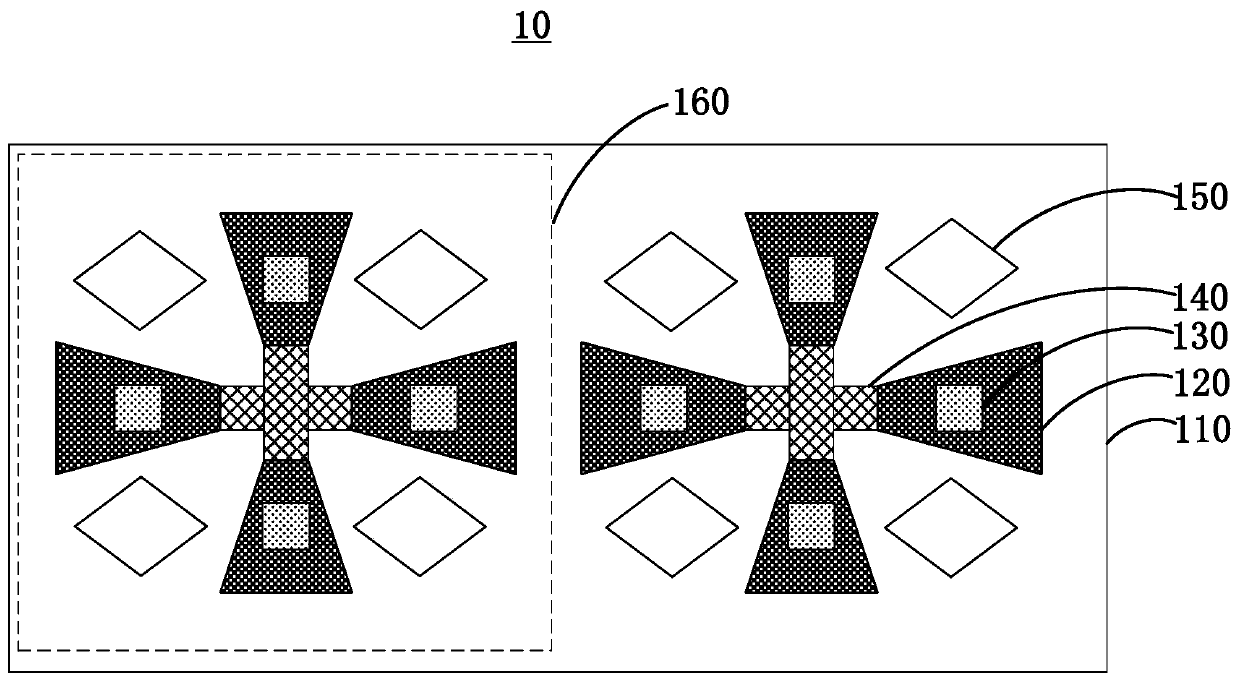

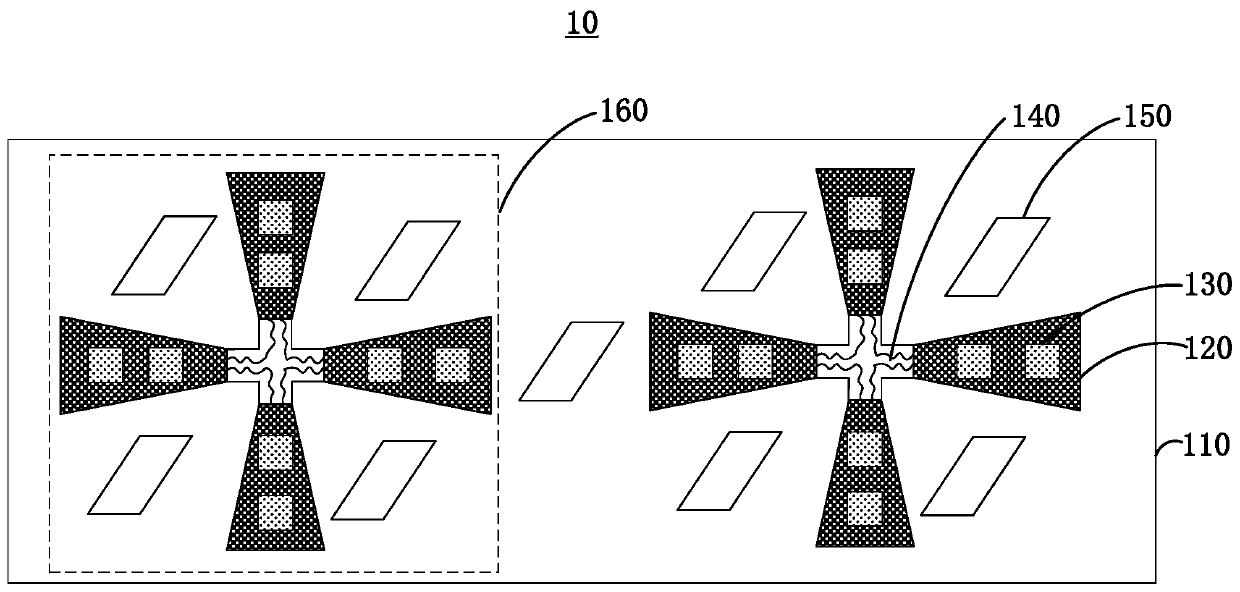

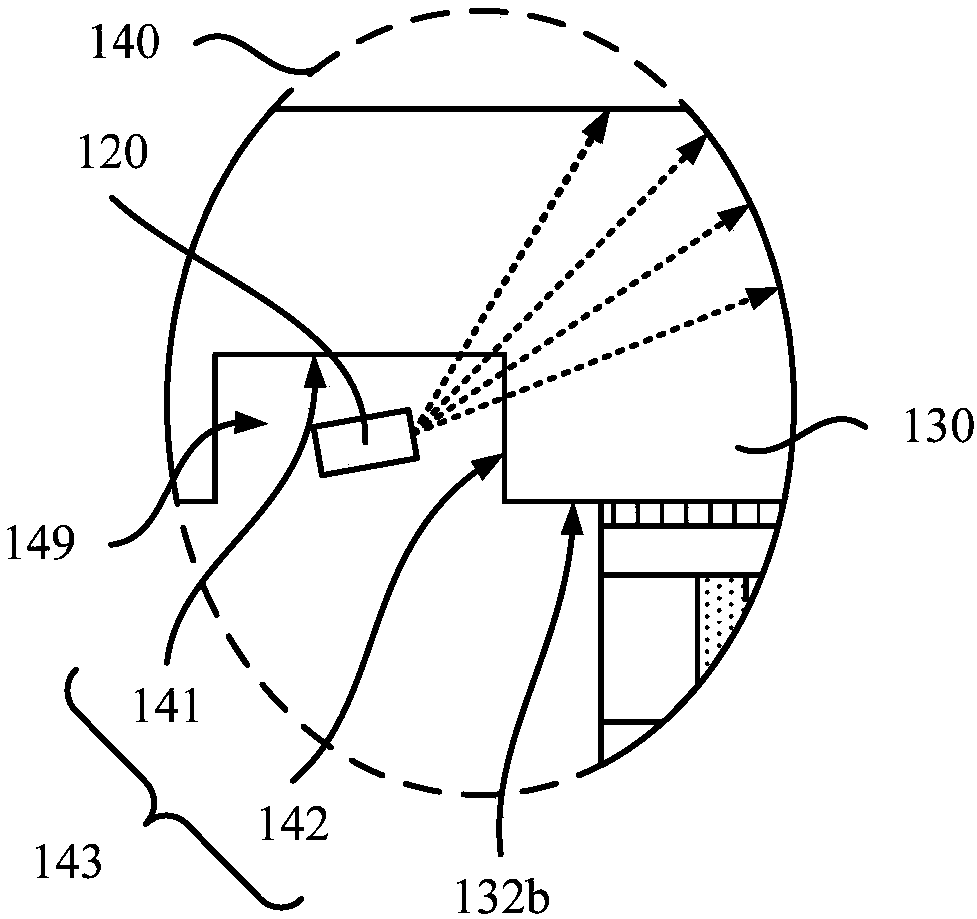

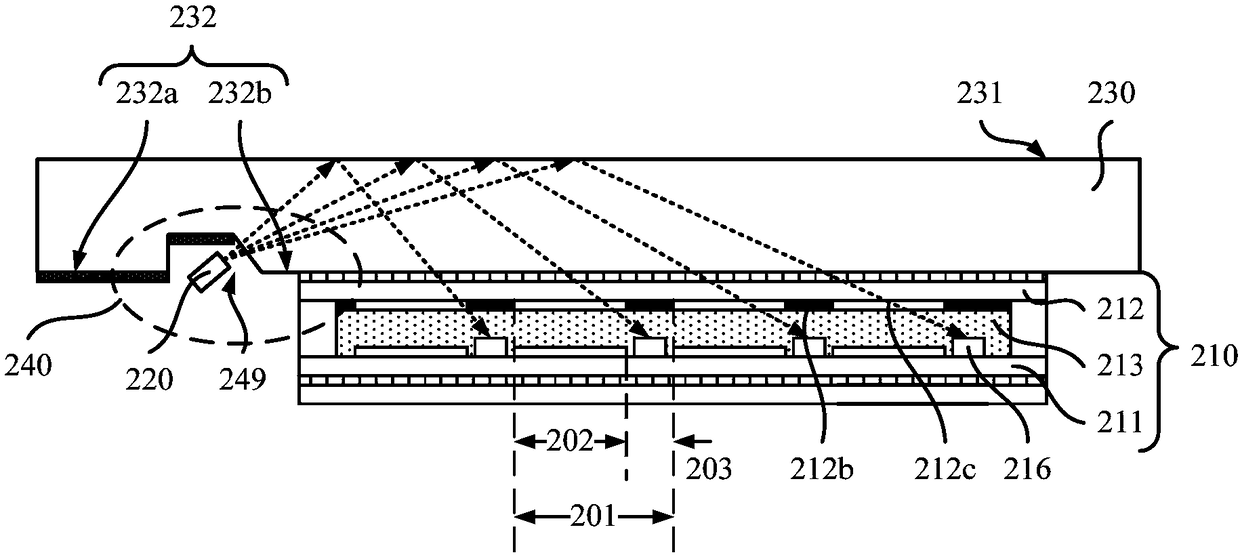

The present invention discloses a display panel and a display device. The invention aims to improve the bending resistance of the display panel without affecting the display effect of the display panel. The display panel is divided into at least one folding region and at least one non-folding region adjacent to the folding region; and the display panel comprises a substrate, a plurality of light emitting devices and a plurality of pixel circuit units, wherein the pixel circuit units are located on the substrate and are all arranged in the non-folding regions, wherein each non-folding region comprises at least one first region and at least one second region; each of the first regions and the second regions includes a plurality of pixel circuit units arranged in an array; the first regions are adjacent to the folding regions; the second regions are located at one side of each of the first regions which is far away from the folding regions; and the distribution density of the pixel circuit units in the first regions is greater than or equal to the distribution density of the pixel circuit units in the second regions.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

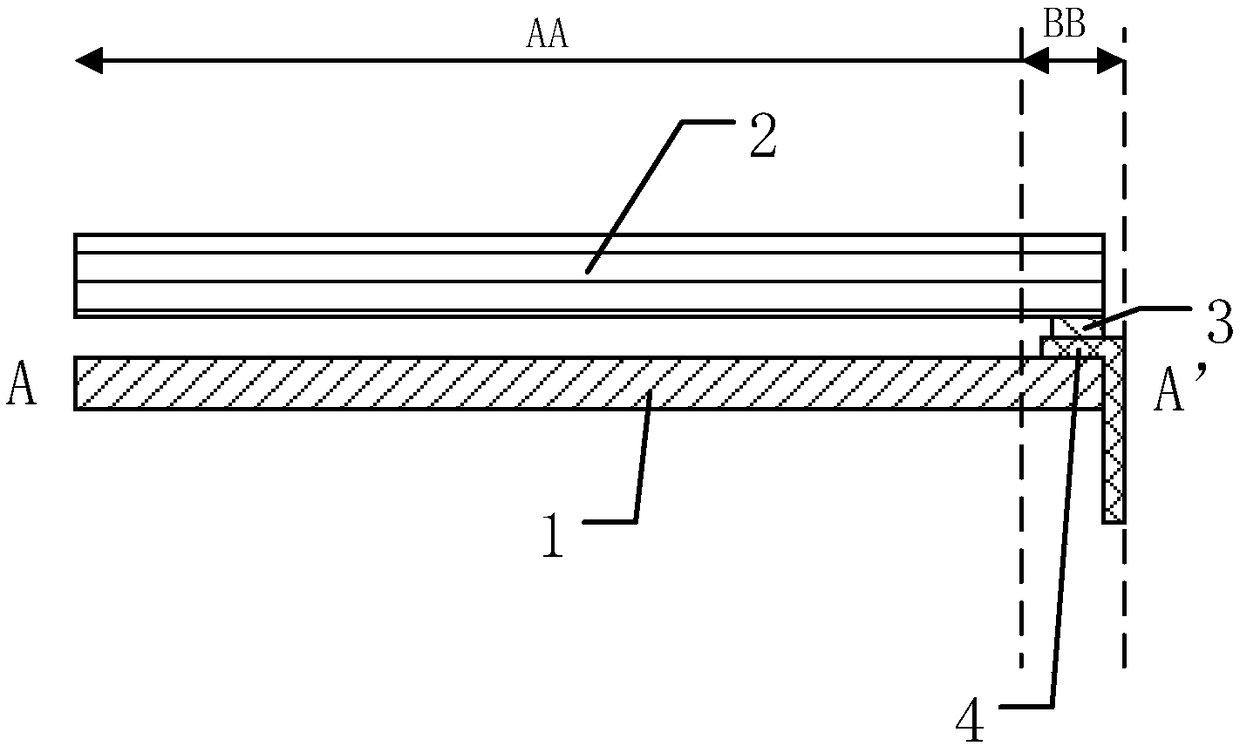

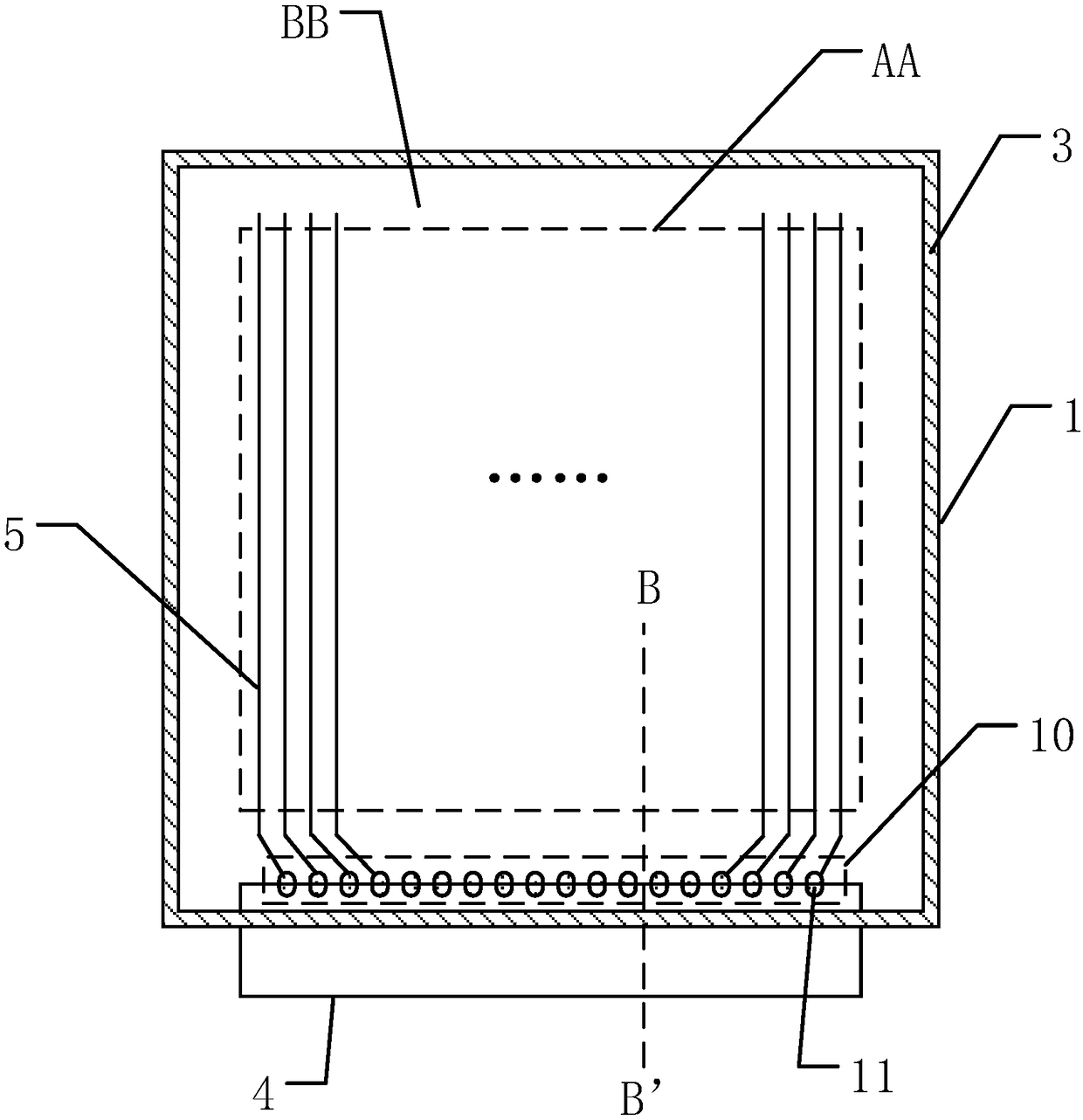

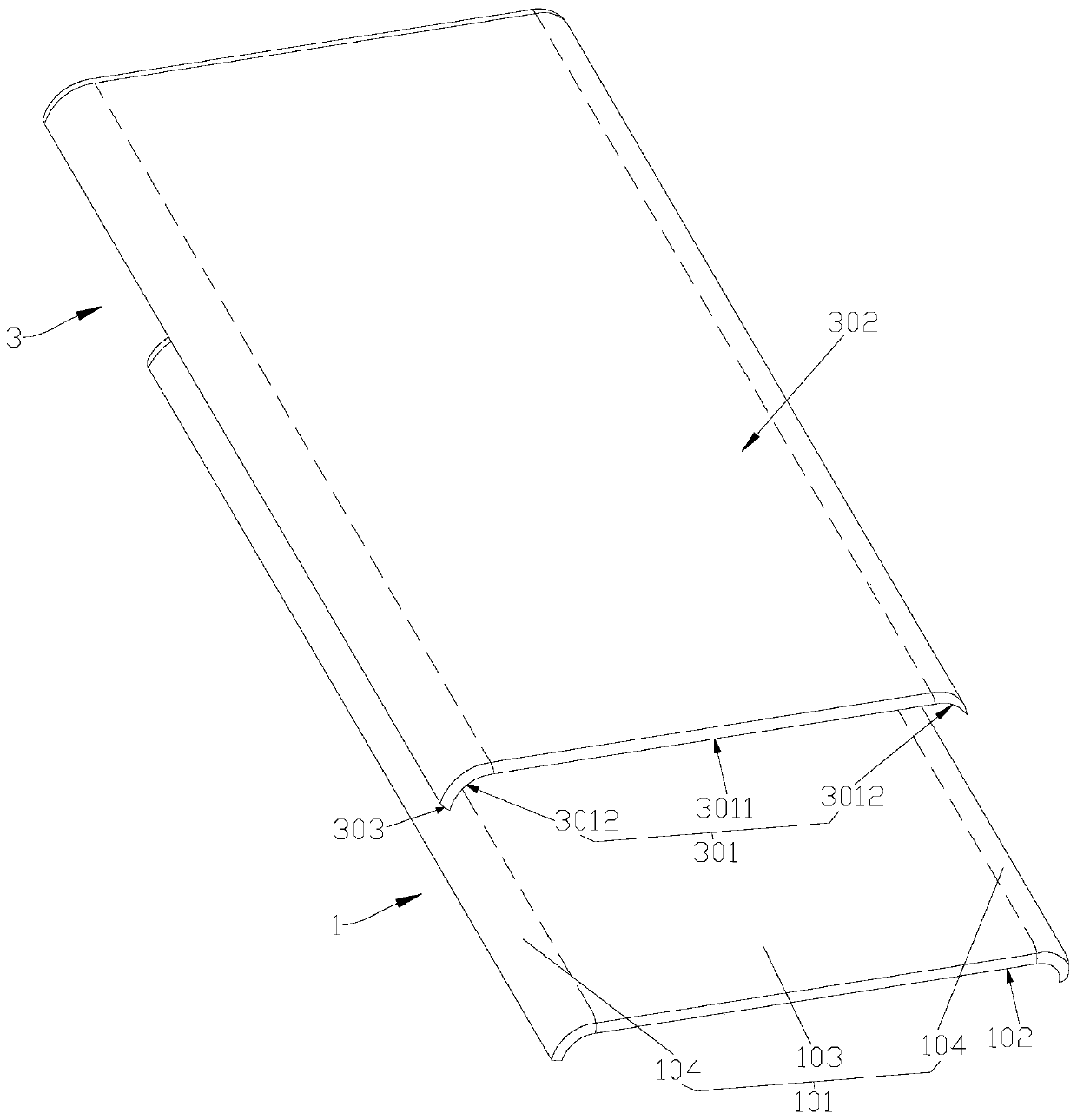

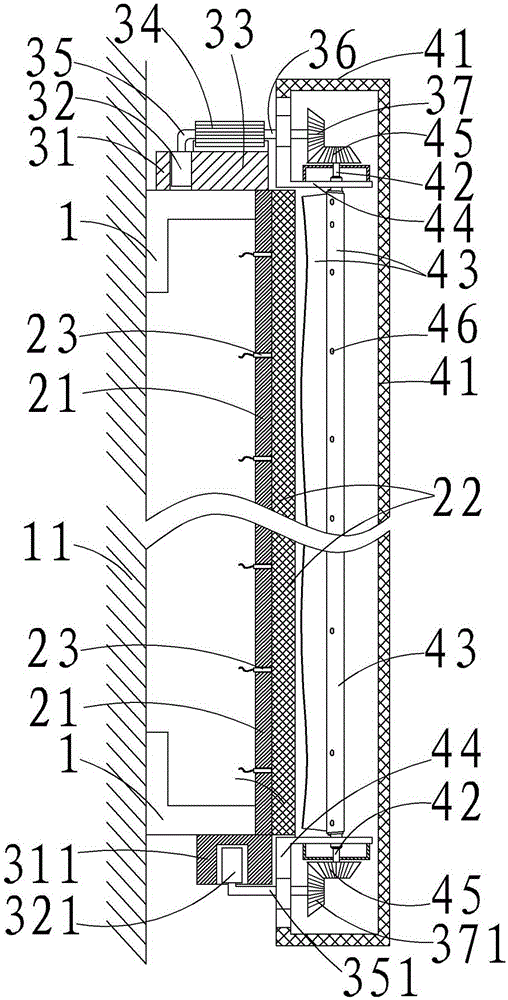

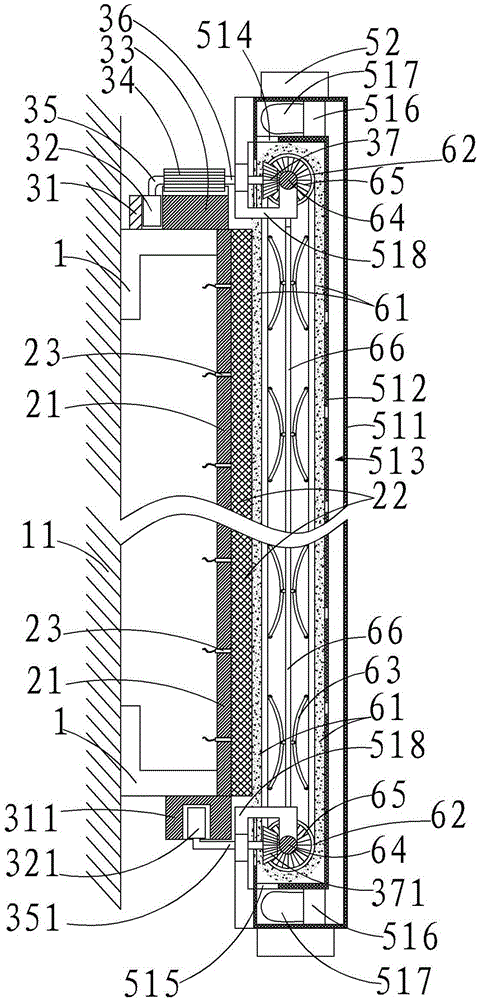

Display panel, manufacturing method thereof, display device and splicing screen

ActiveCN108777114AReduce areaDoes not affect the display effectNon-linear opticsIdentification meansFlexible circuitsDisplay device

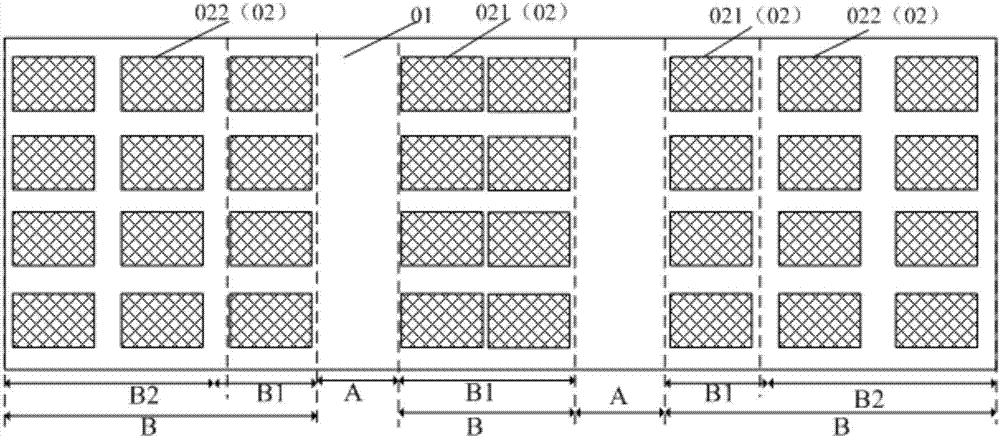

The invention discloses a display panel, a manufacturing method thereof, a display device and a splicing screen. The display panel comprises an array substrate and a first substrate which are opposite, a display area and a non-display area, wherein the non-display area comprises frame glue and a FPCB (flexible printed circuit board), the frame glue is arranged around the display area, and the frame glue is clamped and arranged between the array substrate and the first substrate; the array substrate comprises a binding area, and a plurality of conductive bonding pads are included in the bindingarea; the FPCB comprises a plurality of pins electrically connected with the conductive bonding pads; the frame glue and the FPCB are overlapped in the direction perpendicular to the array substrate.The display device comprises the display panel; the splicing screen comprises a plurality of the display devices which are connected. The narrow frame can be achieved without affecting the display effect of the display panel, the display effect of the display panel is improved, and accordingly, the process can be simplified, the manufacturing difficulty is reduced, a splicing seam of the splicingscreen manufactured by the display panel can be narrower, and accordingly, the splicing effect is not affected.

Owner:SHANGHAI AVIC OPTOELECTRONICS

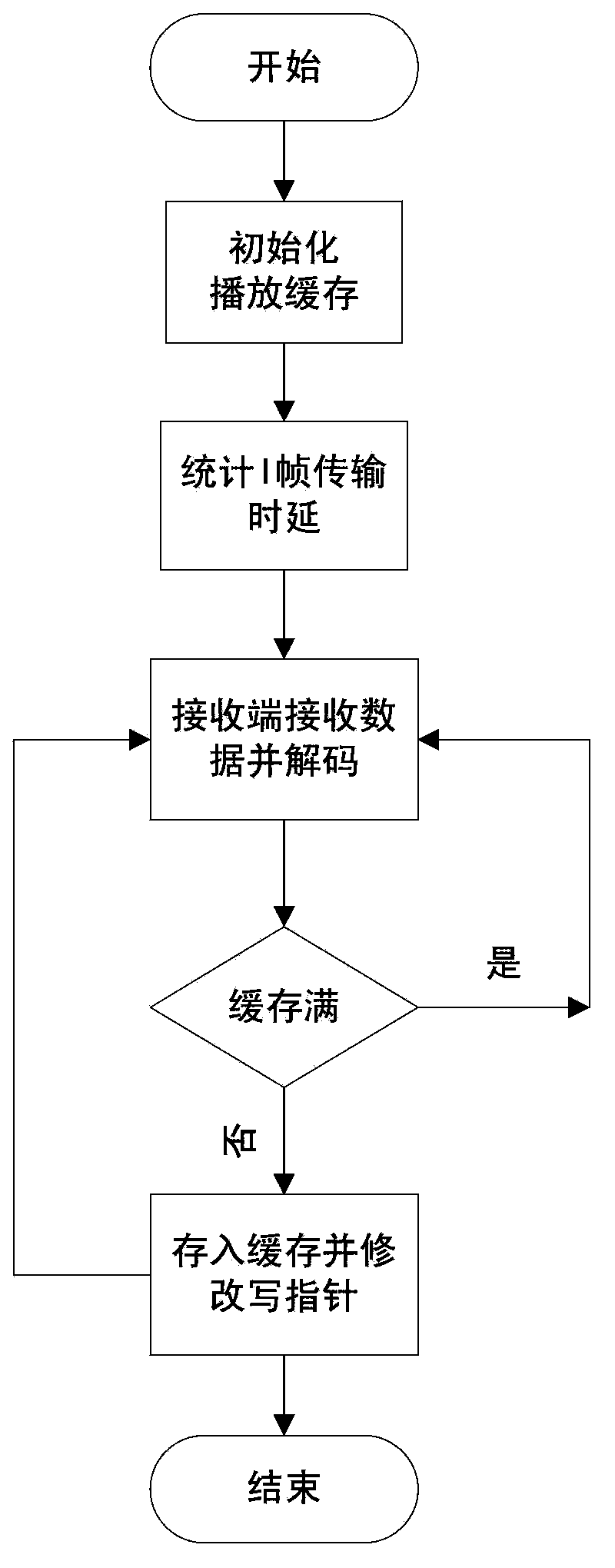

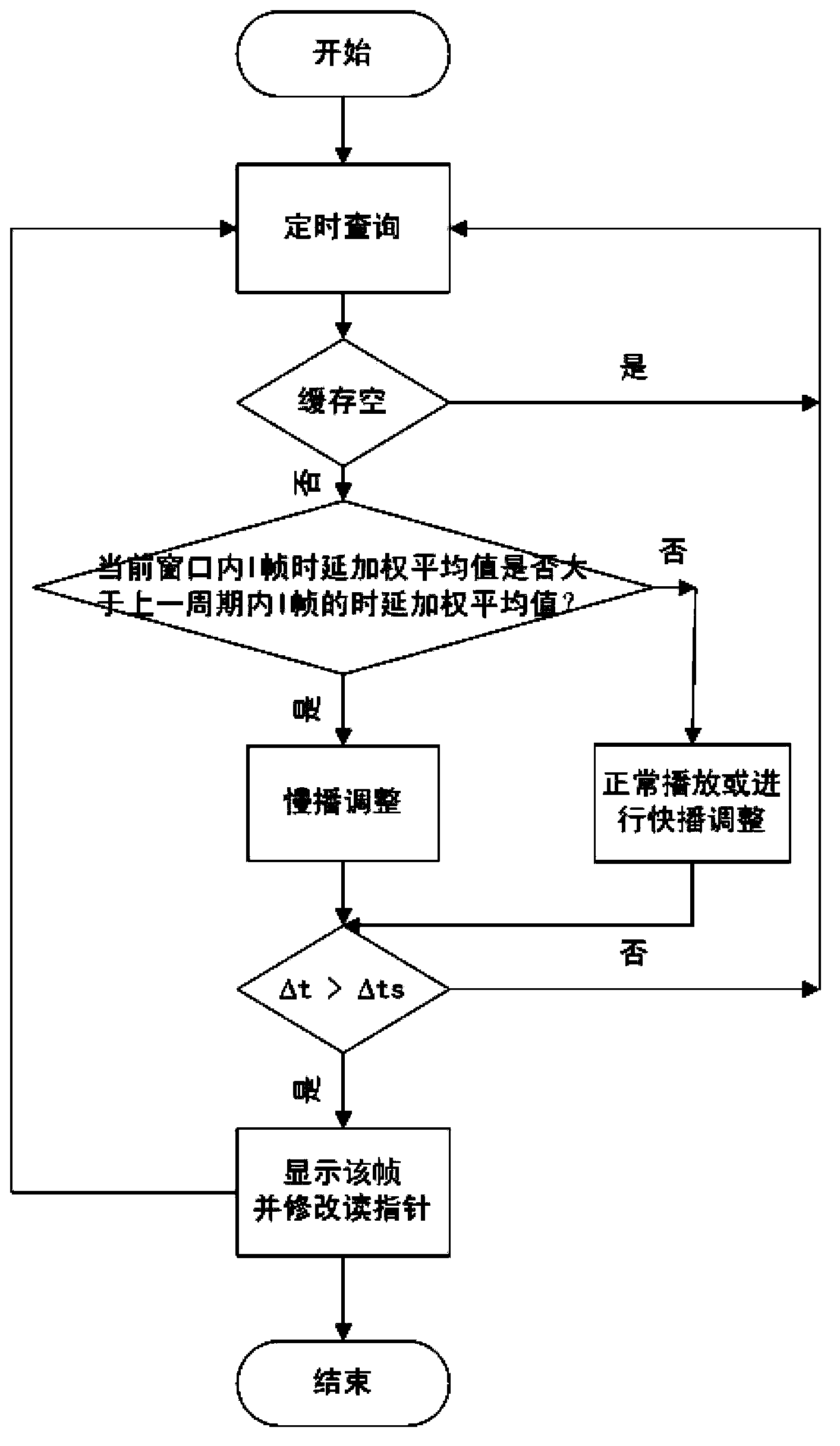

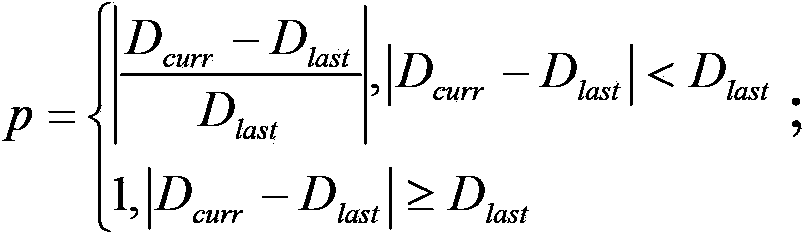

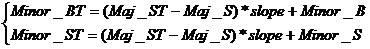

Code rate smoothing method of video live transmission through wireless network

InactiveCN103916716ASolve video freezeImprove fluencyNetwork traffic/resource managementTransmissionTransmission delayTimestamp

The invention provides a code rate smoothing method of video live transmission through wireless network. The method comprises the steps that the periodic statistics of transmission delay of video frames is conducted, when the transmission delay gets smaller, playing buffer is turned down through playing speeding up, when the transmission delay gets bigger, the playing buffer is turned up through playing slowing down, and the adjusting step length of the playing speeding up and the adjusting step of the playing slowing down are codetermined by changing of the transmission delay, the playing buffer depth and timestamp information. By means of the code rate smoothing method of video live transmission through wireless network, the statistics of the transmission delay of the video frames can be conducted, the wireless network state is perceived according to time delay information, the minimum video time delay is further found out according to the actual network condition to achieve the smooth effect, and balance between real-time performance and fluency performance of video streaming is achieved.

Owner:BEIJING XINWEI TELECOM TECH +1

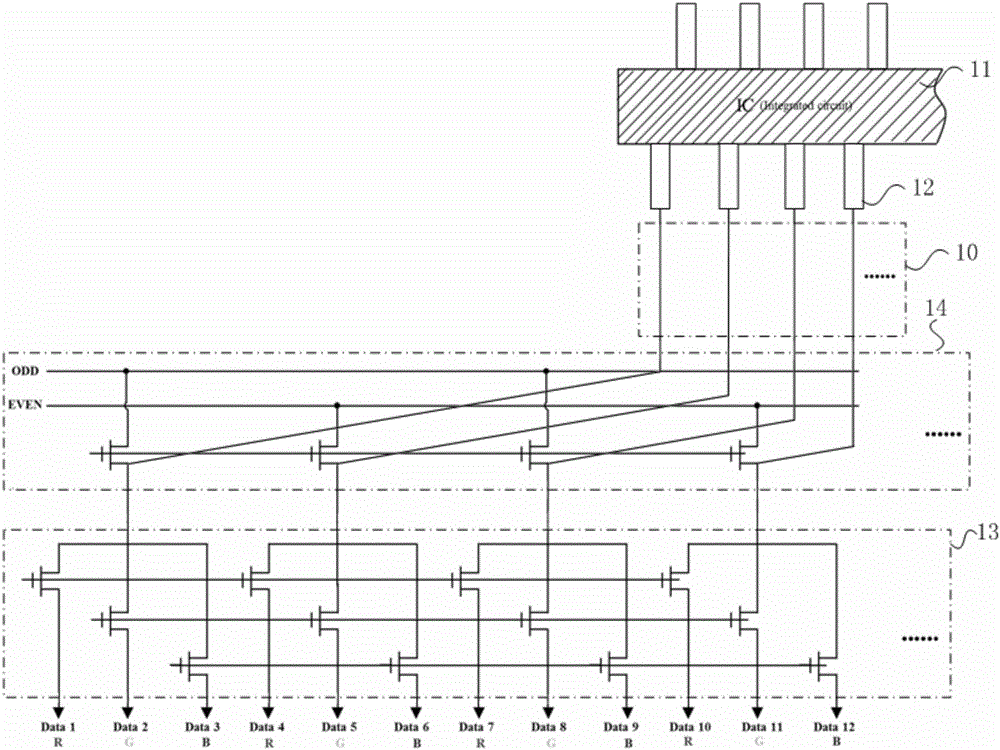

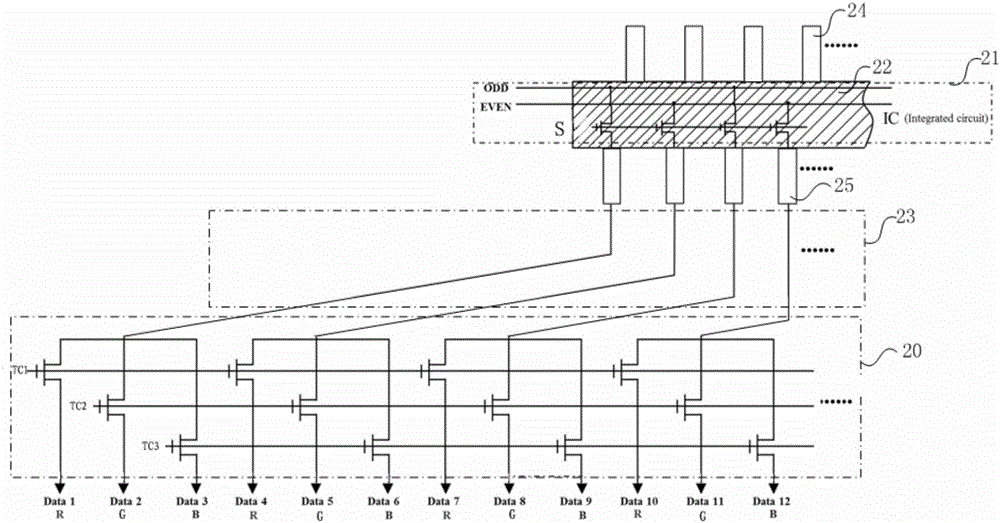

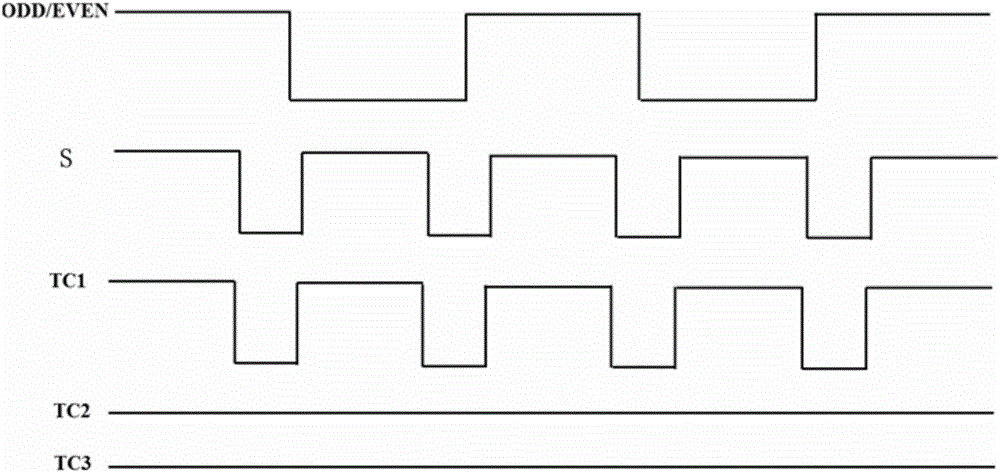

Liquid crystal display panel periphery design circuit and liquid crystal display panel adopting same

InactiveCN106200161ADoes not affect the display effectSave peripheral spaceStatic indicating devicesSolid-state devicesLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel periphery design circuit and a liquid crystal display panel adopting the same. The liquid crystal display panel periphery design circuit is applied to the liquid crystal display panel and comprises a shunt, a testing line, a driver integrated circuit area and a fan-out structure, wherein the driver integrated circuit area comprises an upper bonding pad, a lower bonding pad and a driver integrated circuit connected with the upper bonding pad and the lower bonding pad, the upper bonding pad and the lower bonding pad are oppositely arranged, and the fan-out structure is connected with the lower bonding pad and the shunt; the testing line is arranged between the upper bonding pad and the lower bonding pad, the driver integrated circuit covers the testing line, and the testing line is connected to the lower bonding pad. The liquid crystal display panel periphery design circuit has the advantage that on the premise that the display effect of the liquid crystal display panel is not affected, the peripheral space of the liquid crystal display panel is effectively saved, so that narrow-frame design of the liquid crystal display panel can be realized and the appearance of the liquid crystal display panel is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

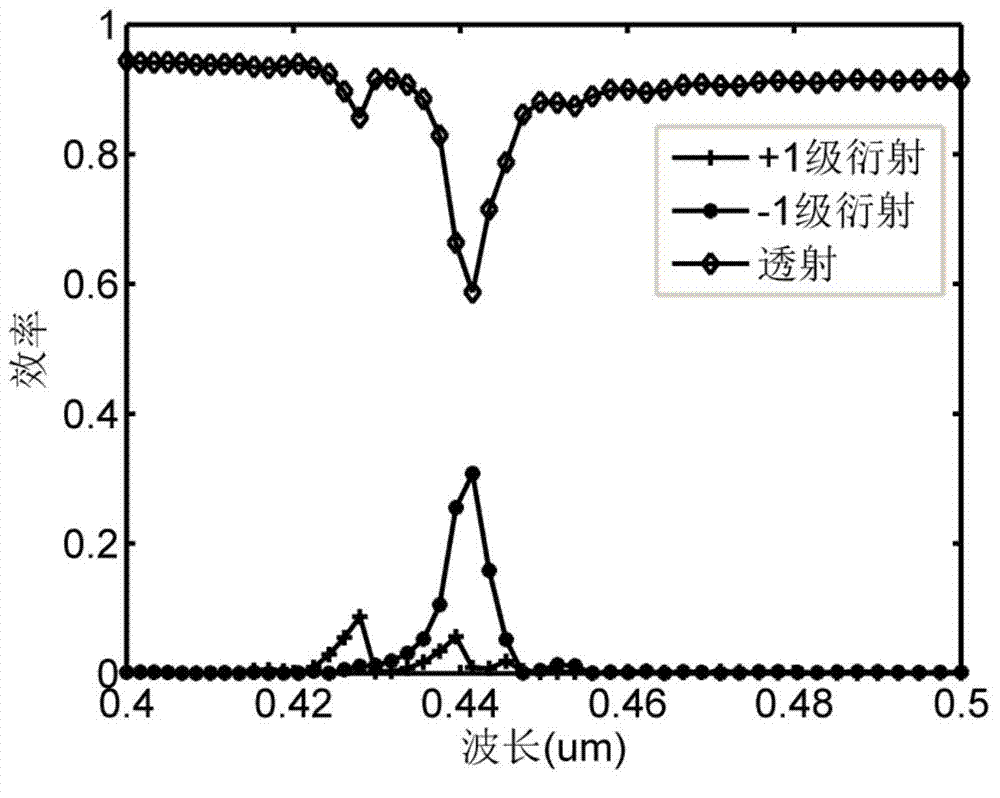

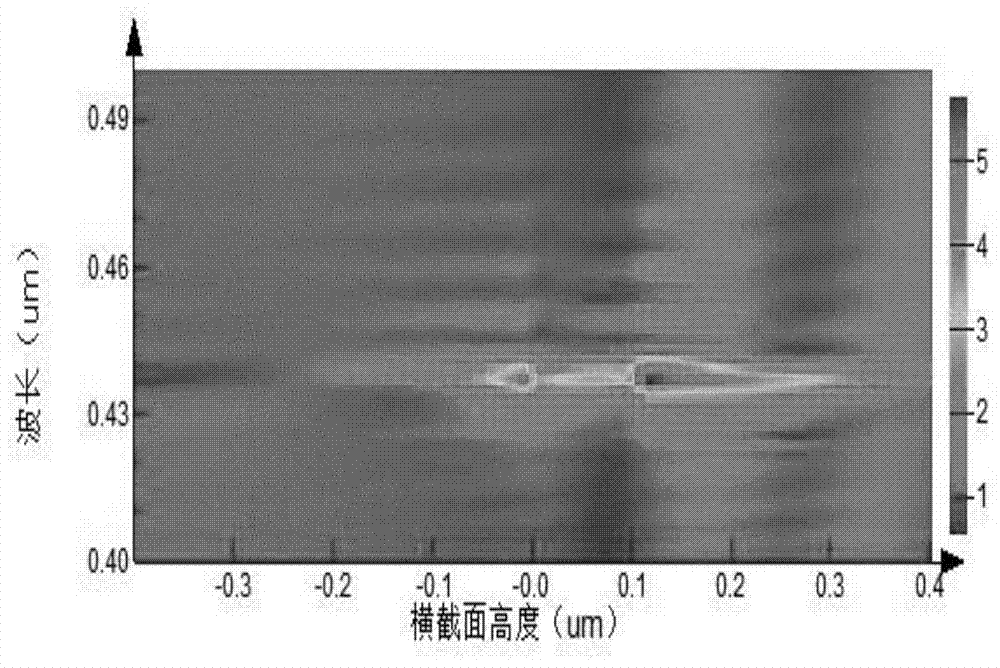

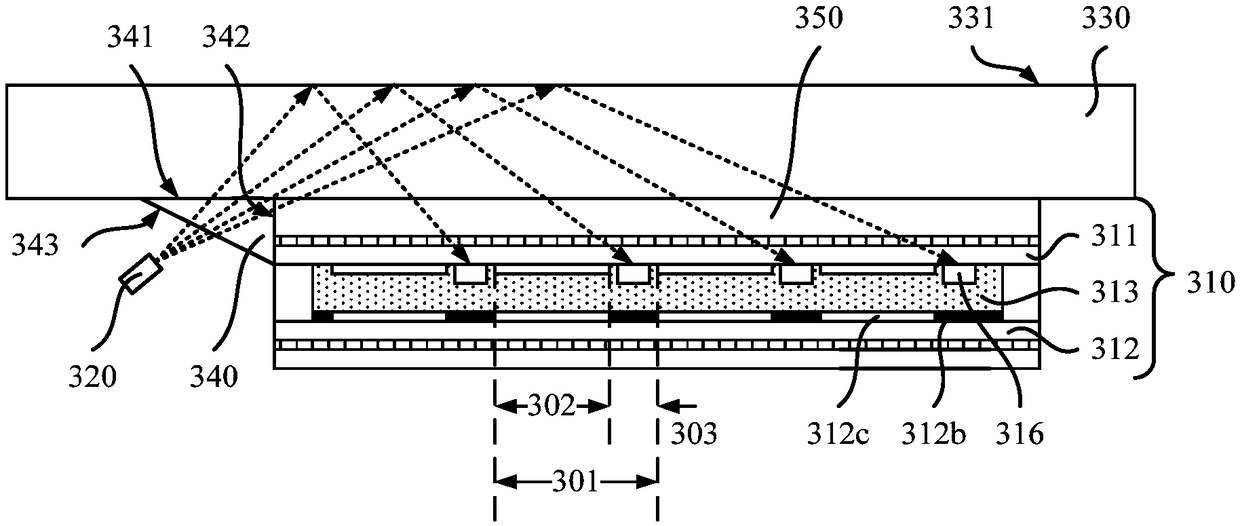

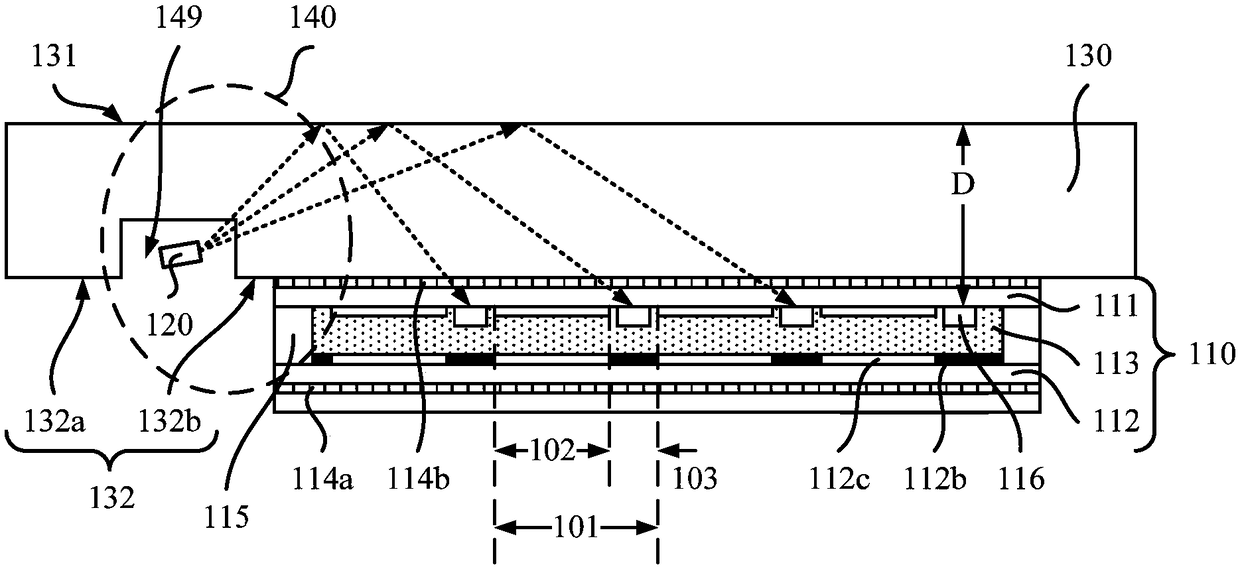

Grating structure-based optical waveguide touch screen

ActiveCN103677448ALow costHigh color purityOptical light guidesInput/output processes for data processingOptical receiversLight source

The invention discloses a grating structure-based optical waveguide touch screen, which comprises a transparent protective layer, a substrate, an optical waveguide layer, an optical grating and an optical receiver. The diffraction of the optical grating is utilized, so that light with specific short wavelength in display light becomes a waveguide mode capable of being transmitted in waveguide, the waveguide mode serves as detection light for touch, a light source is not required to be provided additionally, the cost is saved and the color purity of the display light is effectively improved. Meanwhile, the optical waveguide can effectively overcome the interference of interior light, and the touch accuracy is improved through a waveguide matrix.

Owner:SHANGHAI JIAO TONG UNIV

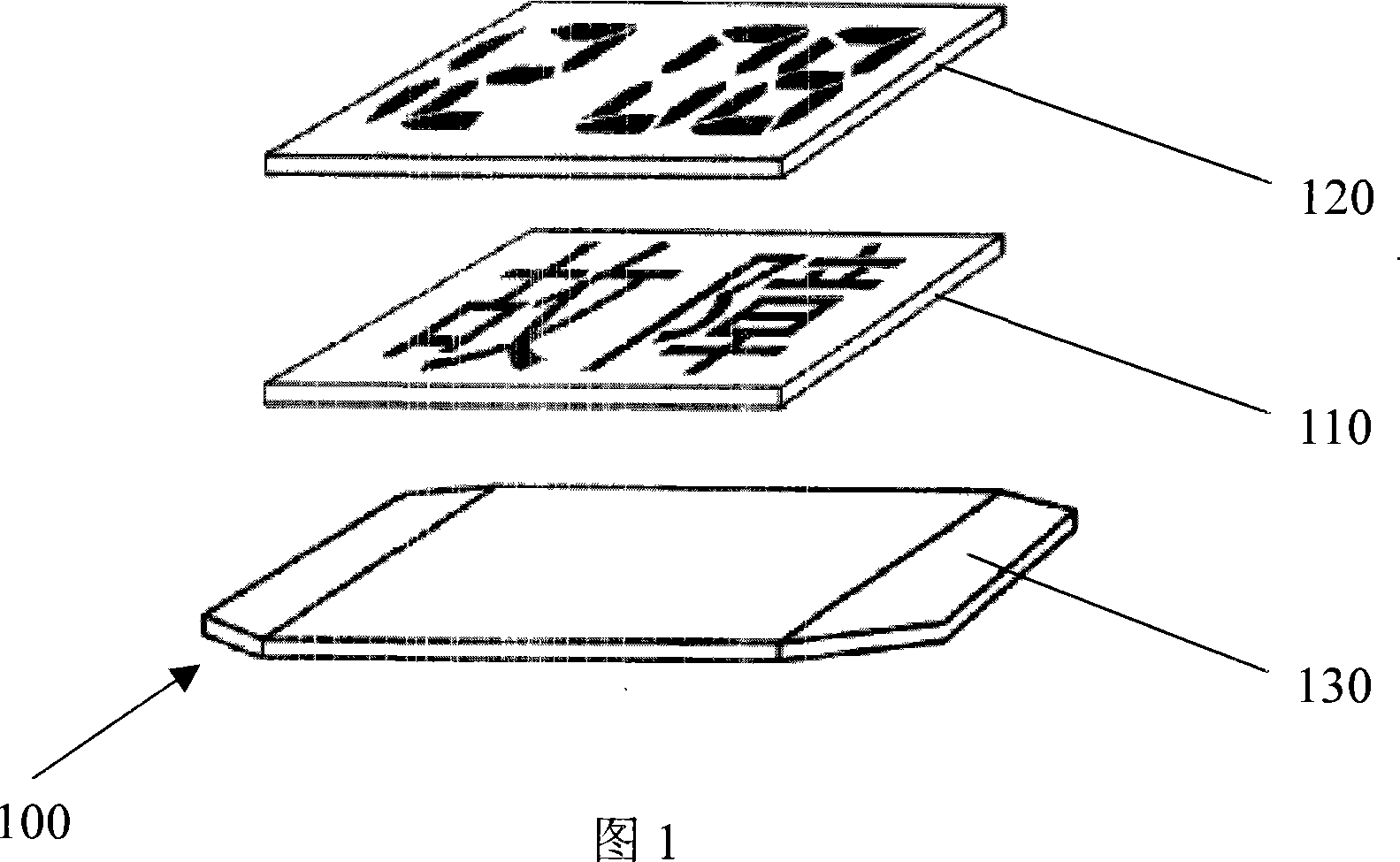

Display panel, display device and manufacturing method of display panel

ActiveCN104505373ADoes not affect the display effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a display region and a non-display region, wherein the display region comprises a plurality of pixel regions; at least one through hole is formed in at least one pixel region; the through holes penetrate through the display panel along the thickness direction of the display panel. According to the technical scheme provided by the invention, a small number of pixel regions in the display region of the display panel are sacrificed, at least one through hole is formed in the sacrificed pixel regions, and the through holes penetrate through the display panel along the thickness direction of the display panel, so the display panel is breathable through the through holes; thus the display device applying the display panel can also be breathable.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

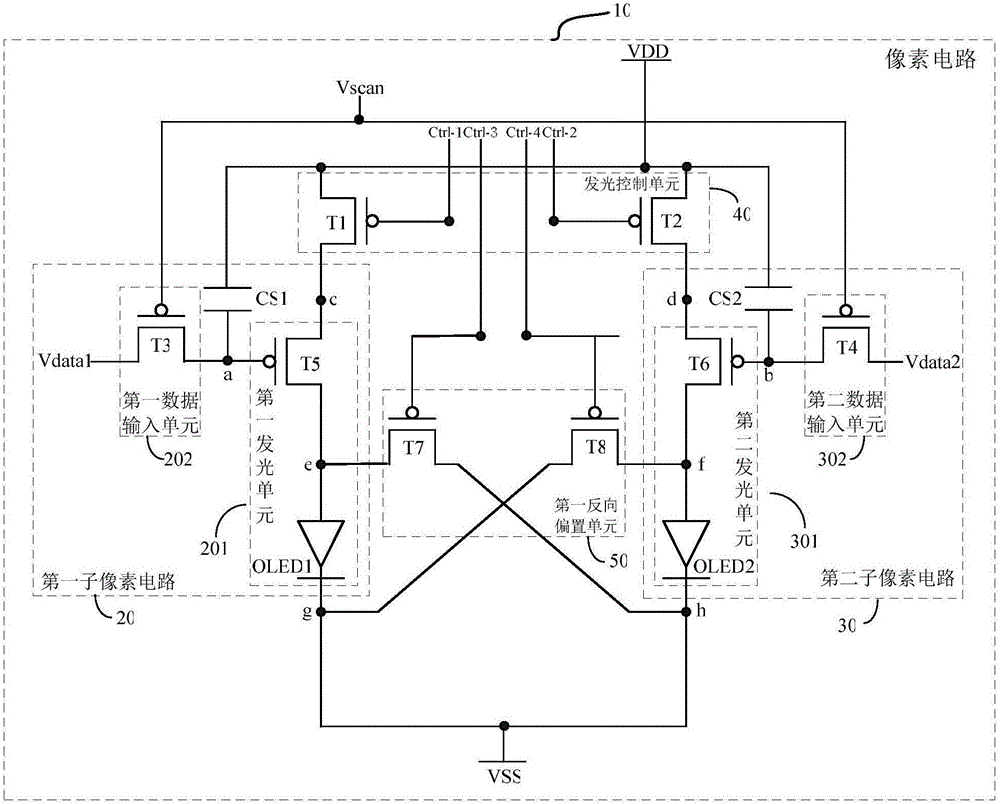

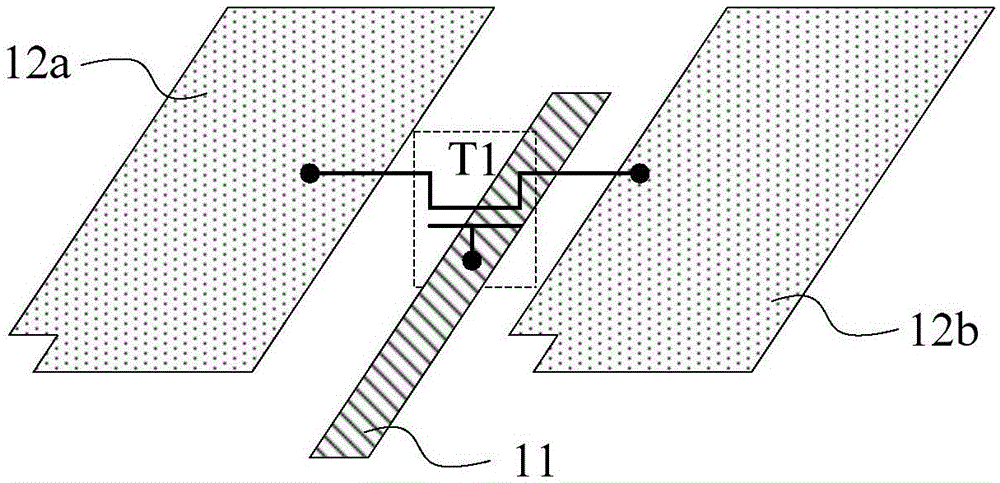

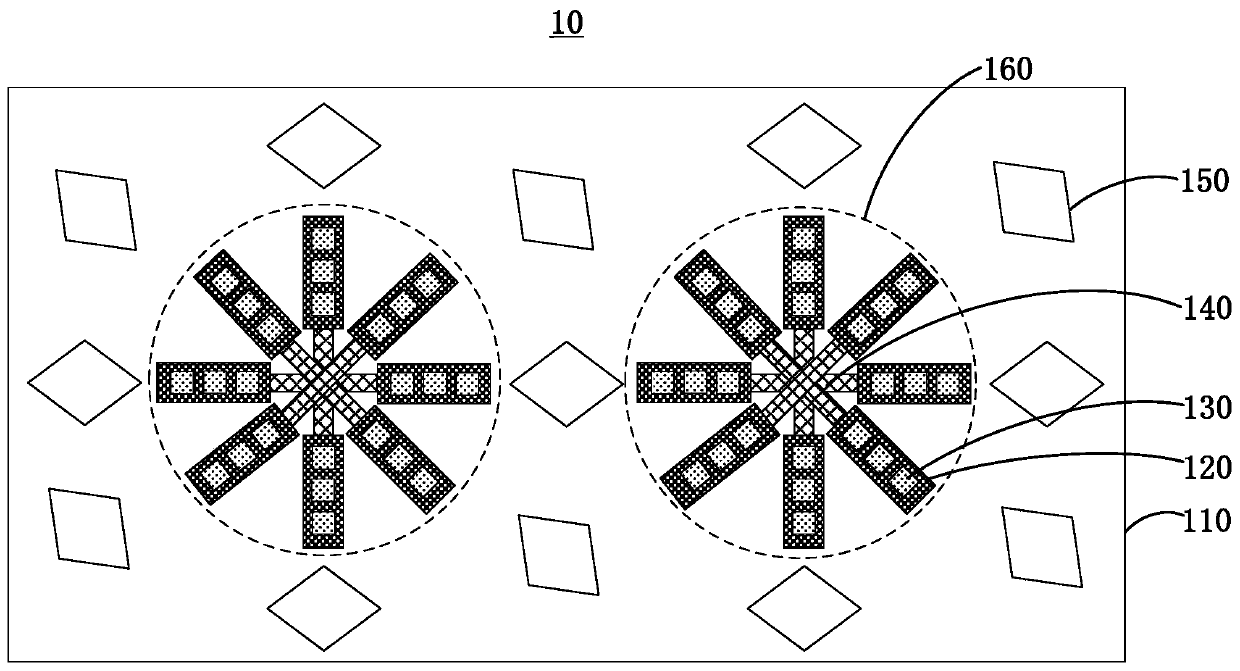

Pixel circuit, driving method and display equipment

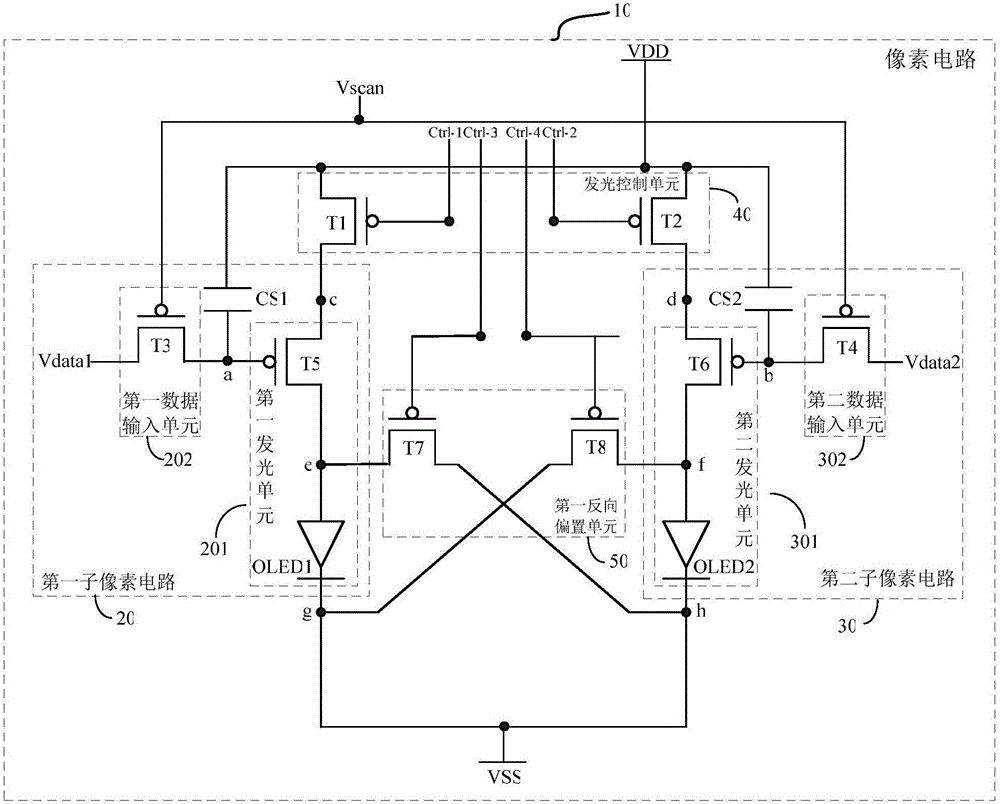

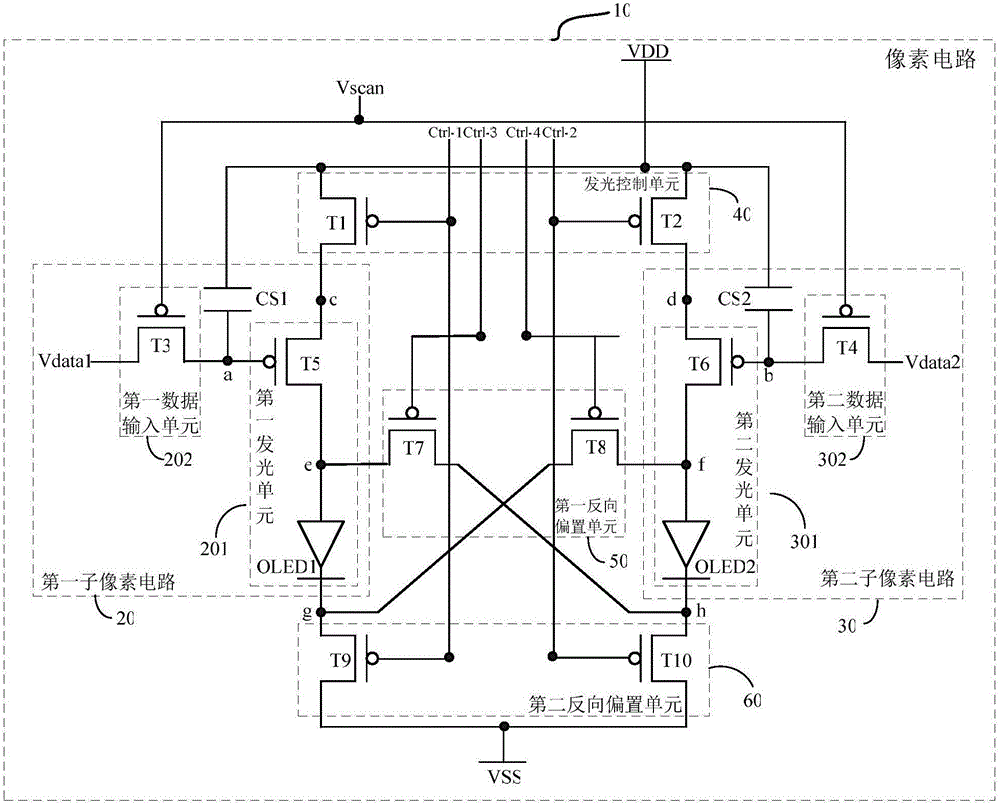

The invention provides a pixel circuit, a driving method and display equipment, and relates to the technical field of display, which solves the problem of easiness in aging of an OLED (organic light emitting diode) due to staying in direct current bias for a long time in the prior art. The pixel circuit comprises a first reverse bias unit, a first subpixel circuit and a second subpixel circuit, wherein the first subpixel circuit and the second subpixel circuit are adjacently arranged; the first subpixel circuit comprises a first light emitting unit; the second subpixel circuit comprises a second light emitting unit. The pixel unit provided by the embodiment is used for manufacturing OLED display equipment.

Owner:BOE TECH GRP CO LTD +1

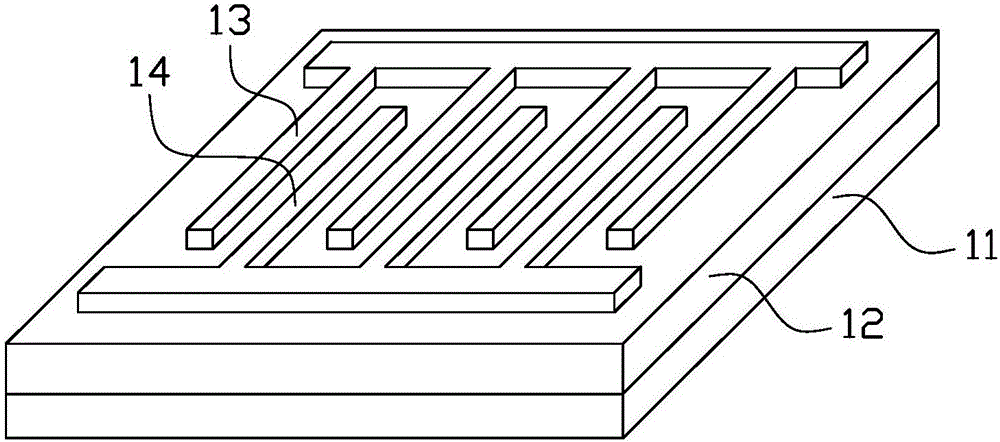

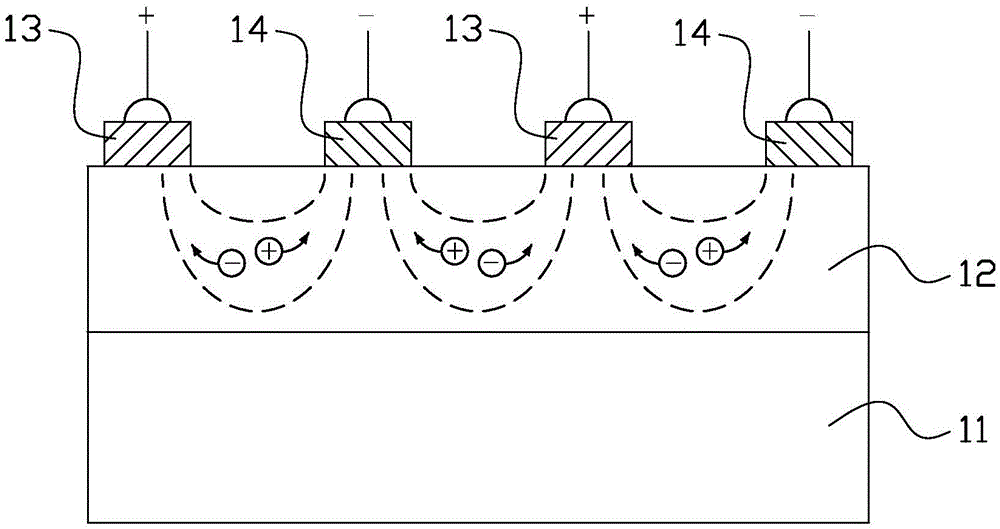

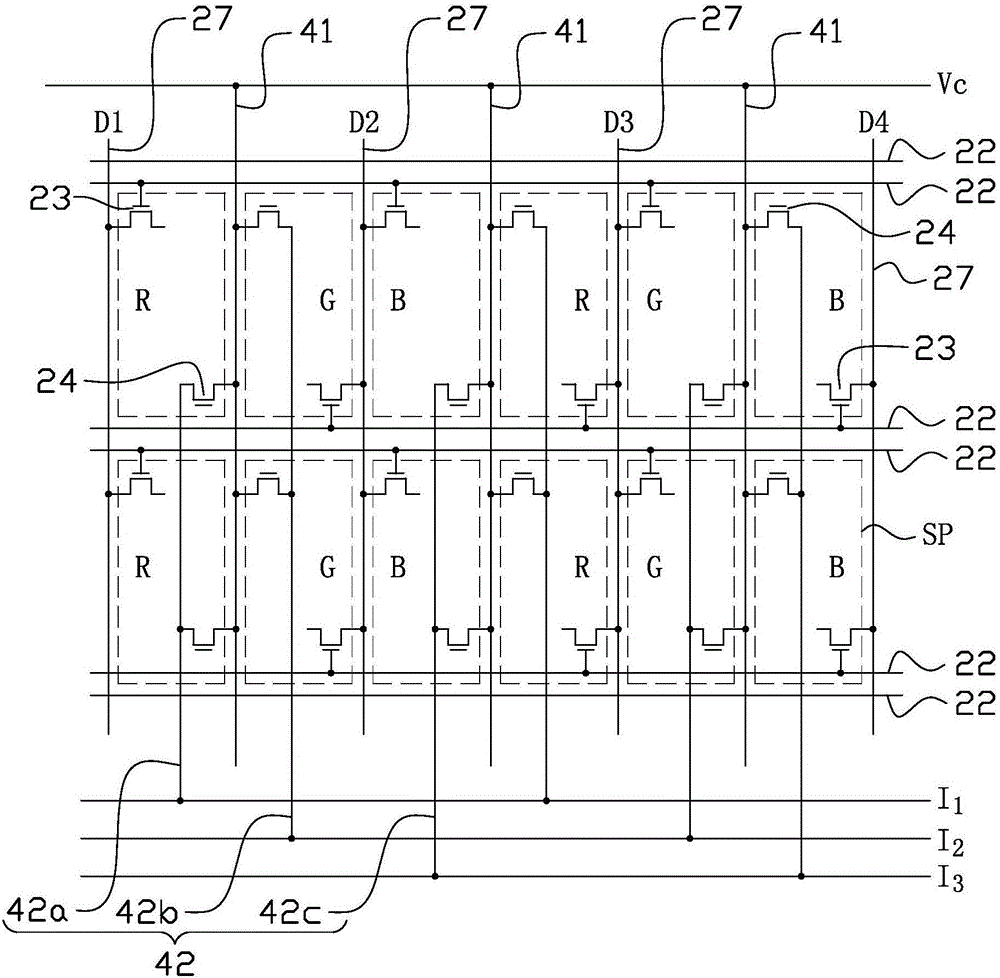

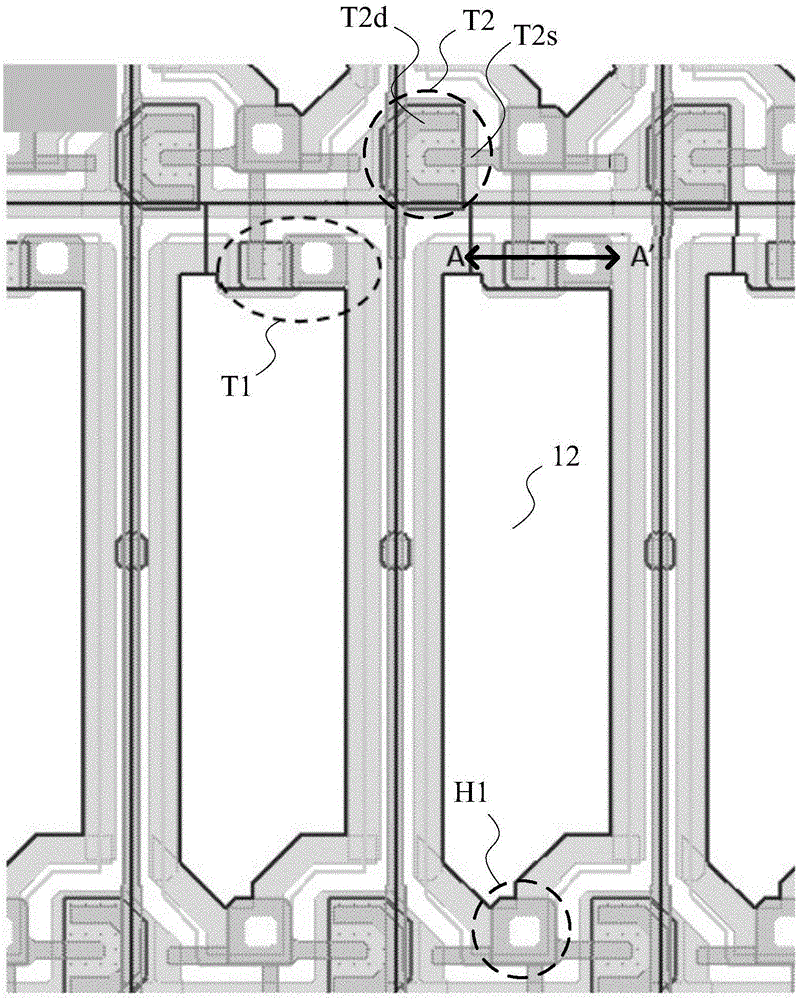

Thin film transistor array substrate, manufacturing method and liquid crystal display panel

ActiveCN106200183AReduce power consumptionLow costSolid-state devicesNon-linear opticsLiquid-crystal displaySemiconductor

The invention provides a thin film transistor array substrate, a manufacturing method and a liquid crystal display panel. The thin film transistor array substrate comprises a substrate, scanning lines, data lines, signal input lines and current feedback lines, wherein the scanning lines, the data lines, the signal input lines and the current feedback lines are formed on the substrate. The scanning lines and the data lines intersect to define multiple sub-pixels. A thin film transistor, a light sensor and a pixel electrode are formed in each sub-pixel. Each thin film transistor comprises a first grid, a first semiconductor, a first source electrode and a first drain electrode. The first grids are connected with the scanning lines, the first source electrodes and the first drain electrodes are alternately arranged and both make contact with the first semiconductors, the first source electrodes are connected with the data lines, and the first drain electrodes are connected with the pixel electrodes. Each light sensor comprises a second grid, a second semiconductor, a second source electrode and a second drain electrode. The second grids do not receive signals, the second source electrodes and the second drain electrodes are alternately arranged and both make contact with the second semiconductors, the second source electrodes are connected with the signal input lines, and the second drain electrodes are connected with the current feedback lines.

Owner:KUSN INFOVISION OPTOELECTRONICS

Display device and apparatus

ActiveCN103137024ADoes not affect the display effectImprove experienceAdvertisingPhotovoltaic energy generationLight energyDisplay device

An embodiment of the invention discloses a display device and an apparatus and belongs to the display field. Photovoltaic materials are evenly arranged in a display layer of the display device or the apparatus provided with the display deivce so that an array formed by the photovoltaic materials forms a light transmitting unit, the photovoltaic materials further form a channel, and therefore light rays emitted by the display layer and ambient light can be converted to currents on the condition of not affecting light emitting of the display layer, standby time of a mobile terminal can be prolonged after the currents obtained through luminous energy conversion are applied to the mobile terminal, and user experience is improved.

Owner:XIAOMI INC

Array substrate and preparation method thereof, display panel, and display device

ActiveCN106057820ADoes not affect the display effectReduce widthStatic indicating devicesSolid-state devicesPunchingDisplay device

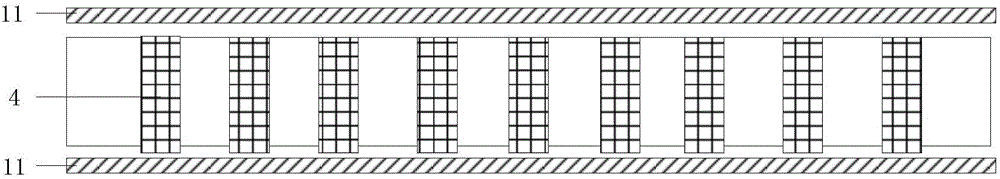

The present invention discloses an array substrate and a preparation method thereof, a display panel, and a display device. A grid fan-out line is arranged on one side of a substrate departing from the grid line, goes line along a black matrix projection area and extends to a driving binding area so as to allow the grid fan-out line not to go the side of the array substrate and reduce the width of the grid driving side frame, and because the grid fan-out line goes line on the projection area on the array substrate along the black matrix, the display effect of the array substrate cannot be influenced. Compared to the punching area of the punching technical scheme in a driving binding area in the prior art, the punching area of the technical scheme of punching in the display area and leading out the grid fan-out line from the back surface of the substrate is increased, and the array substrate and the preparation method thereof, the display panel, and the display device can punch fewer holes in a certain range compared to the technical scheme in the prior art, and therefore the difficulty of punching is reduced, the complexity of the preparation technology is reduced, and the preparation efficiency is improved.

Owner:BOE TECH GRP CO LTD +1

Optical touch control screen based on optical gratings

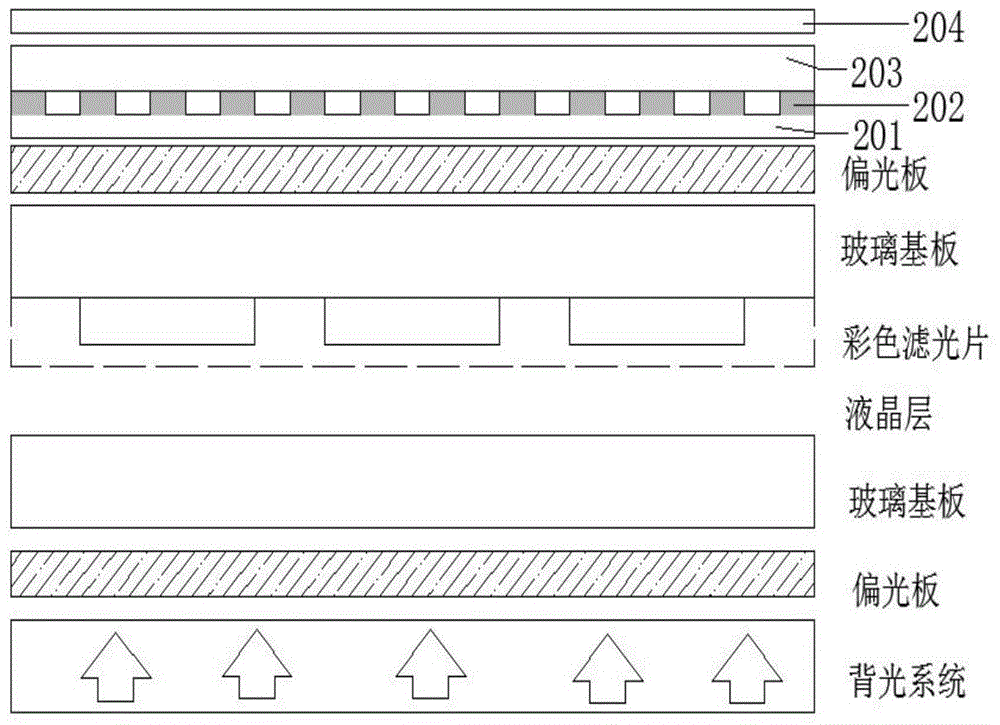

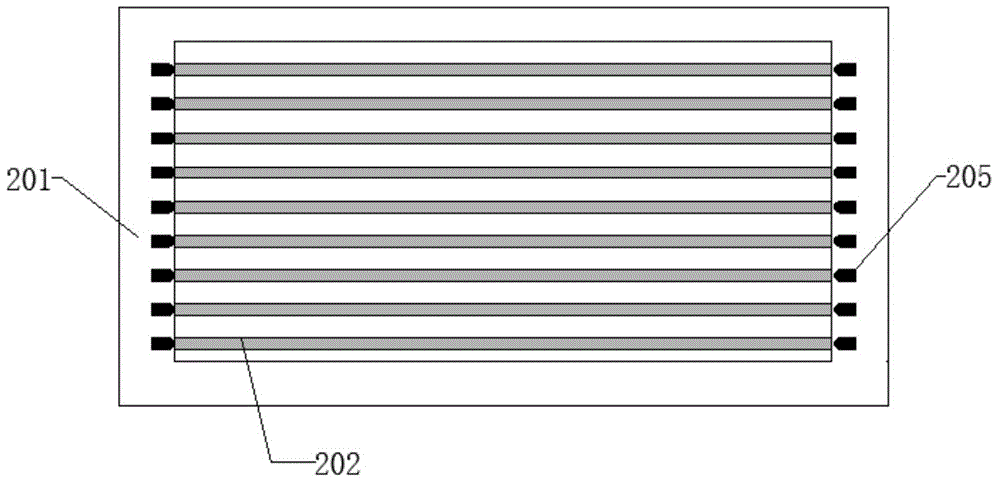

ActiveCN104020896ALow costDoes not affect the display effectNon-linear opticsInput/output processes for data processingGratingColor gel

An optical touch control screen based on optical gratings comprises a glass substrate, the optical gratings, an optical waveguide layer, optical receivers and a transparent protective layer. On the basis of a liquid crystal display system, diffraction of the optical gratings is utilized, light with a specific wave length in display light penetrating through a color filter can become a waveguide mode which can be transmitted in waveguide and serves as detection light for touch control, and cycles of the optical gratings correspond to different sub-pixels in the filter in a one-to-one mode. A light source does not need to be additionally provided, cost is saved, and color purity of display light is effectively improved. Detection light is one of three-primary colors in pixels, and touch control precision is improved and can reach the level of pixels.

Owner:SHANGHAI JIAO TONG UNIV

Splicing method of curved LED display screen

InactiveCN108230923AReduce the difficulty of splicingAccuracy controllableIdentification meansLED displayComputer science

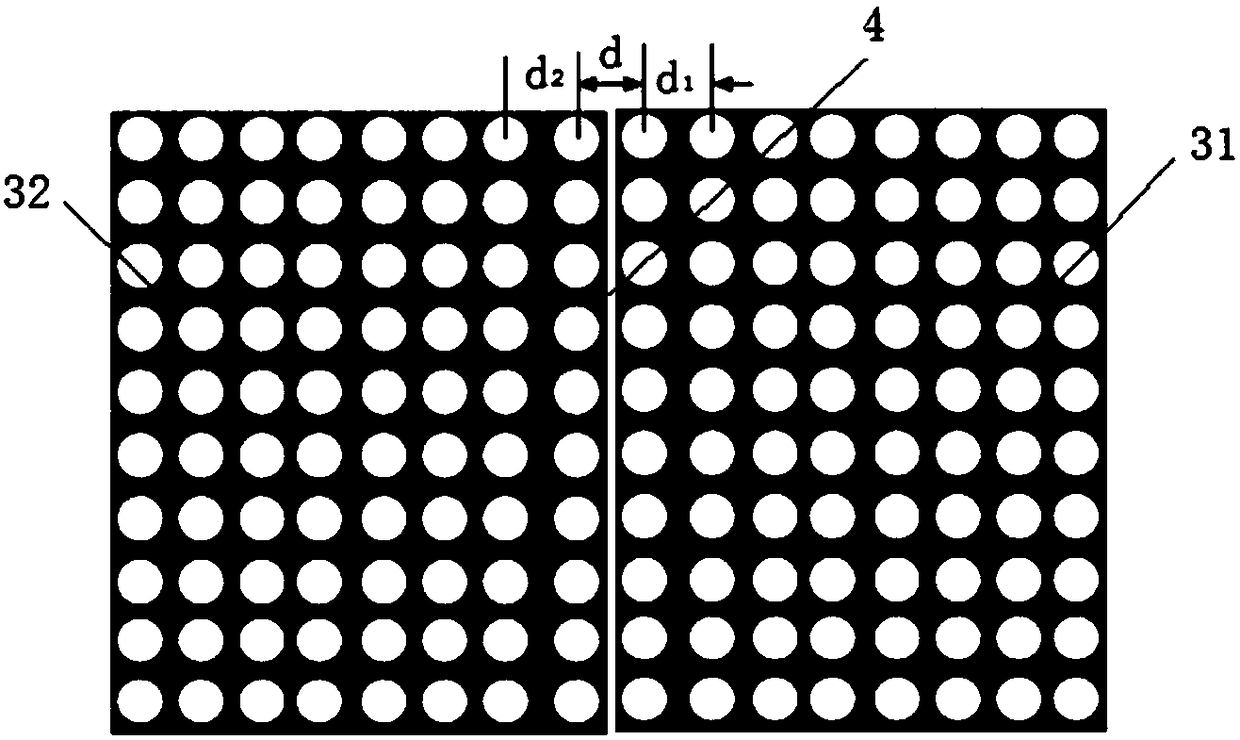

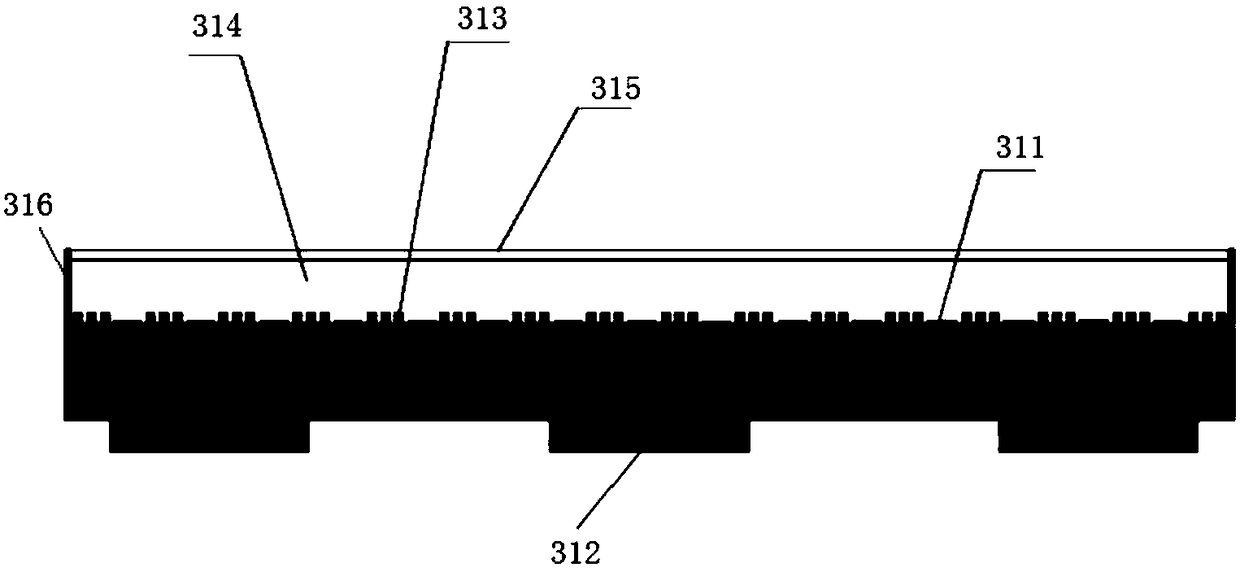

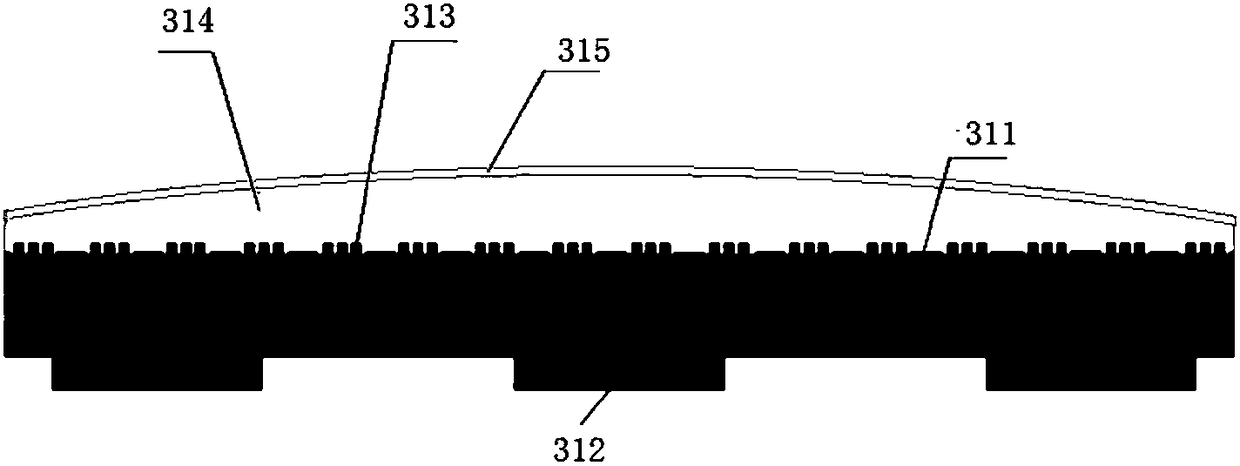

The invention relates to a splicing method of a curved LED display screen. In the method, splicing is carried out by means of a plurality of polygonal display modules; in the splicing process, splicing seams are reserved in the splicing positions of adjacent display modules; two adjacent display modules are set as the first display module and the second display module, the pixel pitch of the position, close to the seam, of the first display module is d1, the pixel pitch of the position, close to the seam, of the second display module is d2, the spacing between two closest adjacent pixel pointsof the two display modules is d, and the seam-across pixel pitch d of the splicing positions of the first display module and the second display module is not larger than the minimum value in d1 and d2. A method for splicing various basic modules into a mathematically tight and seamless curved LED display screen under traditional meanings is broken through, the basic display modules are spliced into the curved LED display screen with seams on purpose, the splicing difficulty is greatly reduced, precision is easily controlled, and the display effect is not affected.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

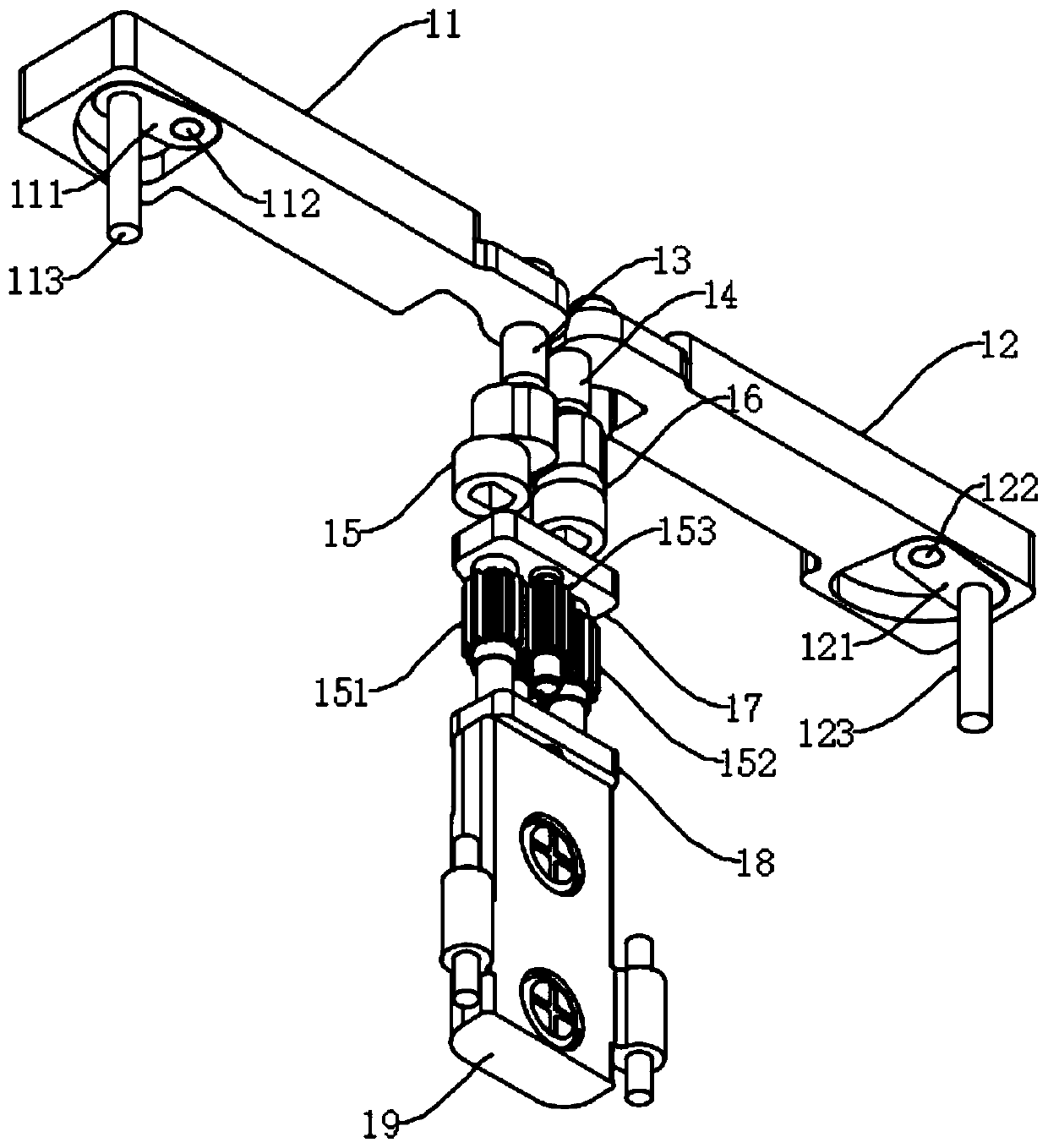

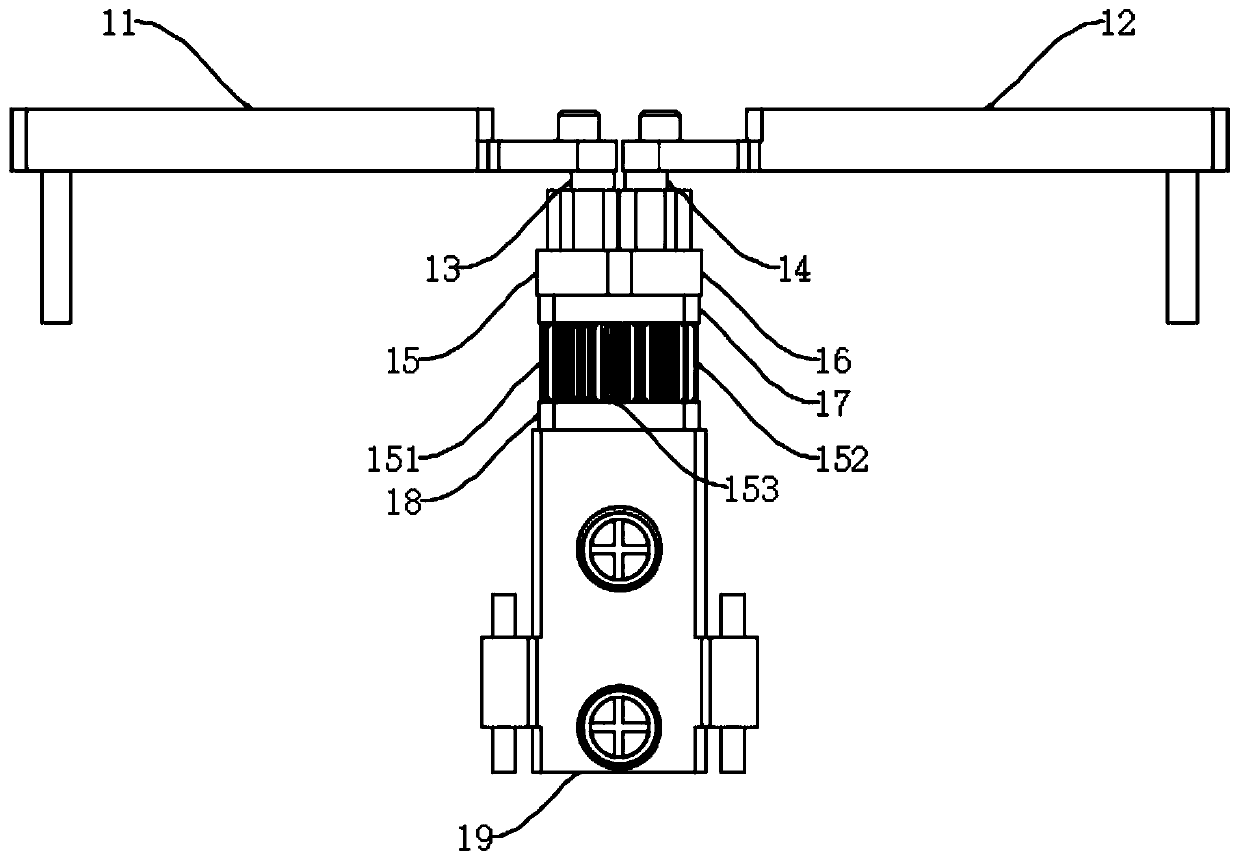

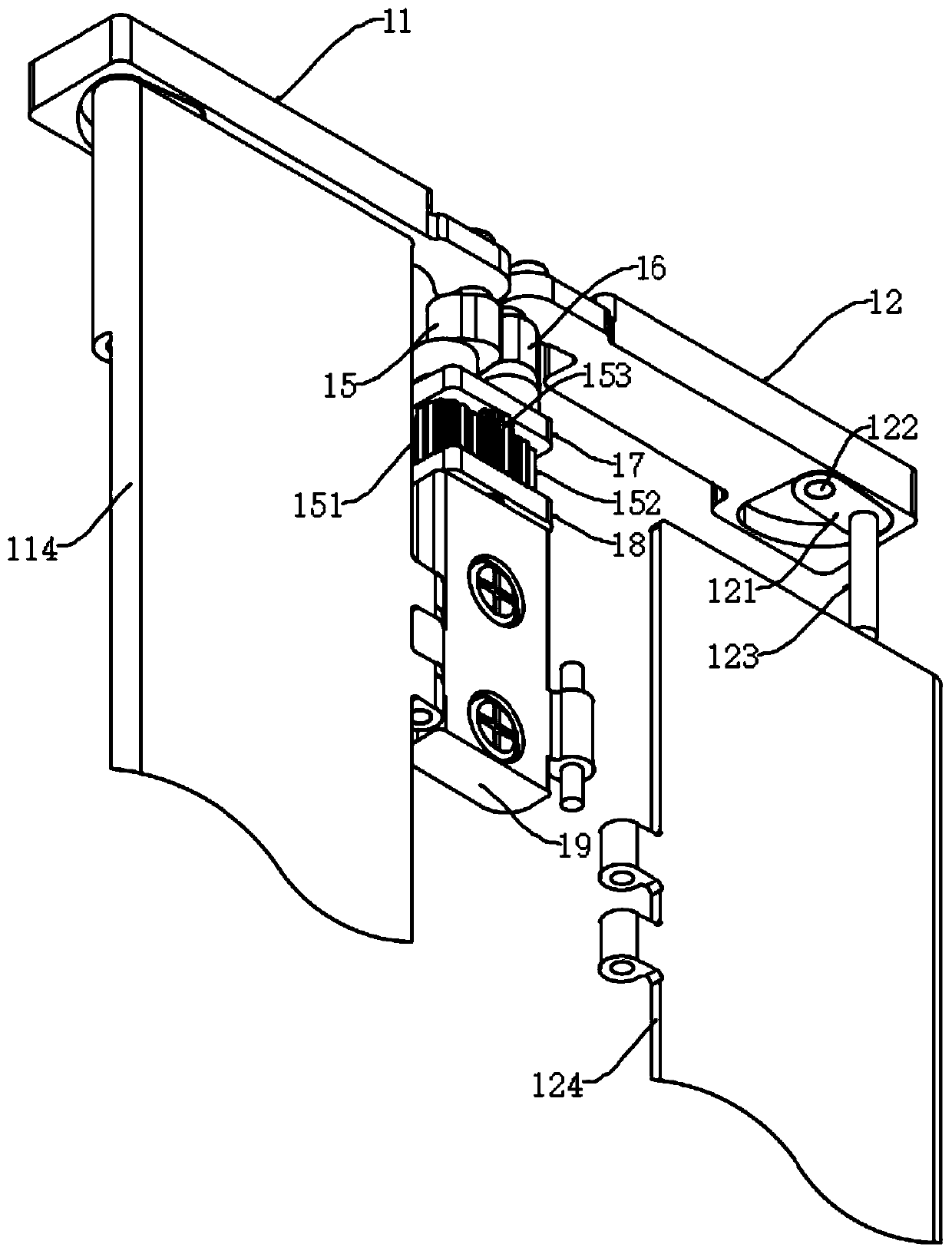

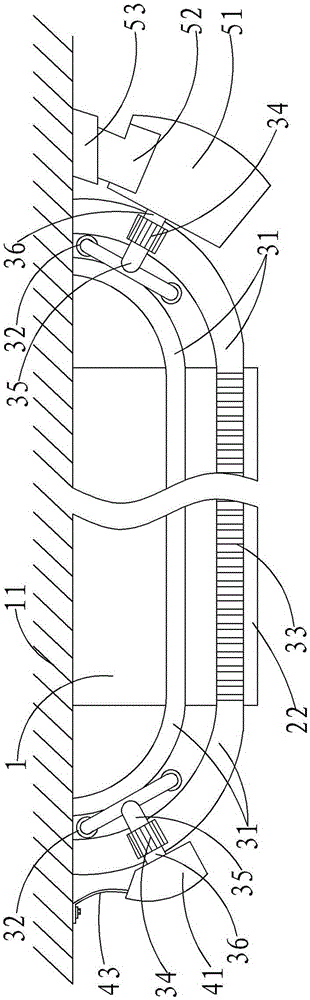

Rotating shaft mechanism for folding screen, folding screen assembly and foldable mobile terminal

ActiveCN110958337AImprove bending effectReduce frictionDigital data processing detailsTelephone set constructionsStructural engineeringMechanical engineering

The invention discloses a rotating shaft mechanism for a folding screen, a folding screen assembly and a foldable mobile terminal. The rotating shaft mechanism comprises a left supporting arm and a right supporting arm which are symmetrically arranged, and the left supporting arm and the right supporting arm are fixed to a support. A left rotating shaft on the left support arm is connected with the left cam, a right rotating shaft on the right support arm is connected with the right cam, the left gear is in transmission connection with the left cam, the right gear is in transmission connectionwith the right cam, and at least one transmission gear is in transmission connection between the left gear and the right gear. The folding screen assembly comprises the rotating shaft mechanism, andthe foldable mobile terminal comprises the folding screen assembly or the rotating shaft mechanism. The folding screen of the foldable terminal can work more reliably and more smoothly, has the outstanding advantages of being simple in structure, easy to implement, low in cost, high in reliability, long in service life, wide in application range and the like, and can be widely applied to foldablemobile terminals.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

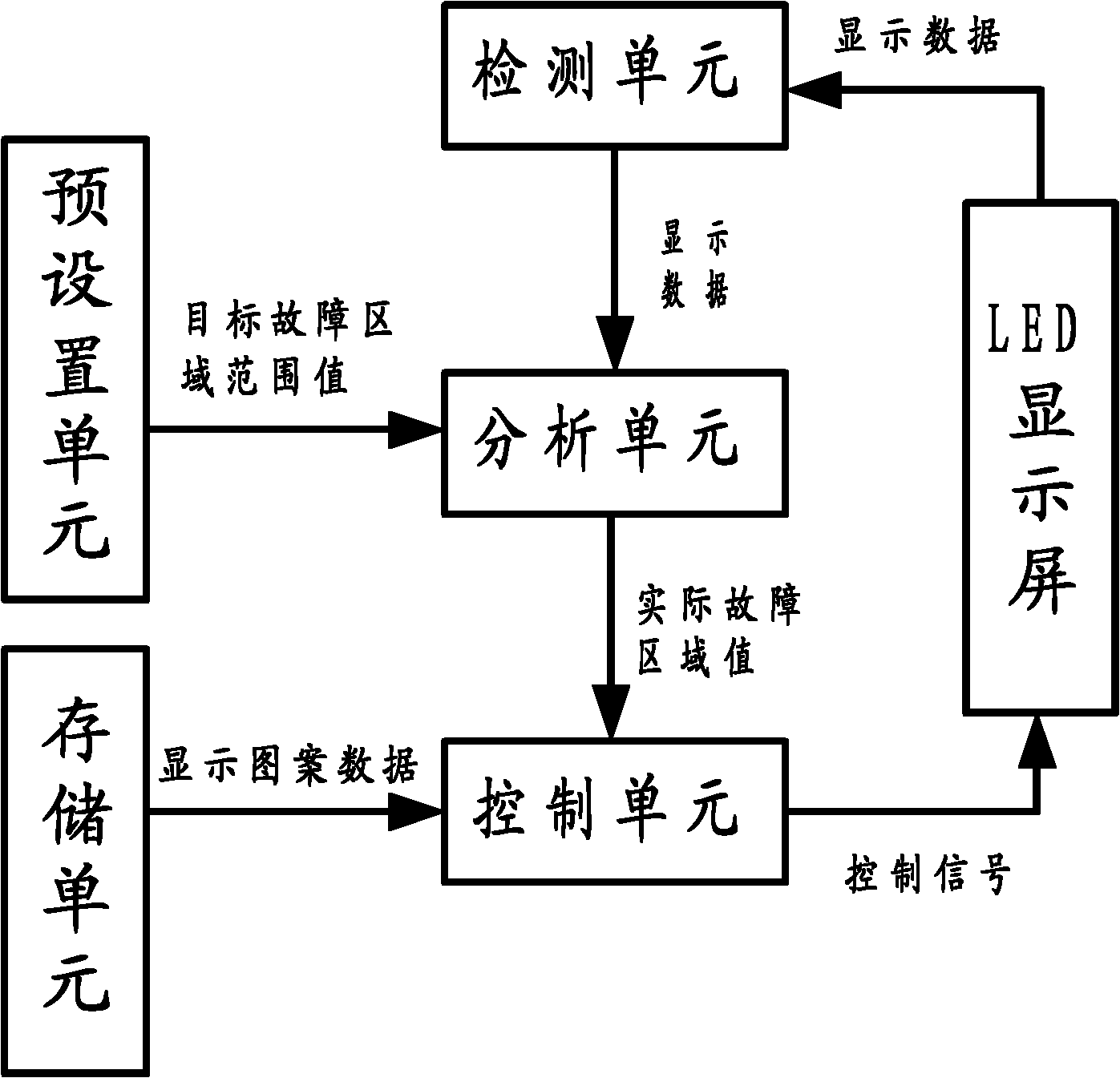

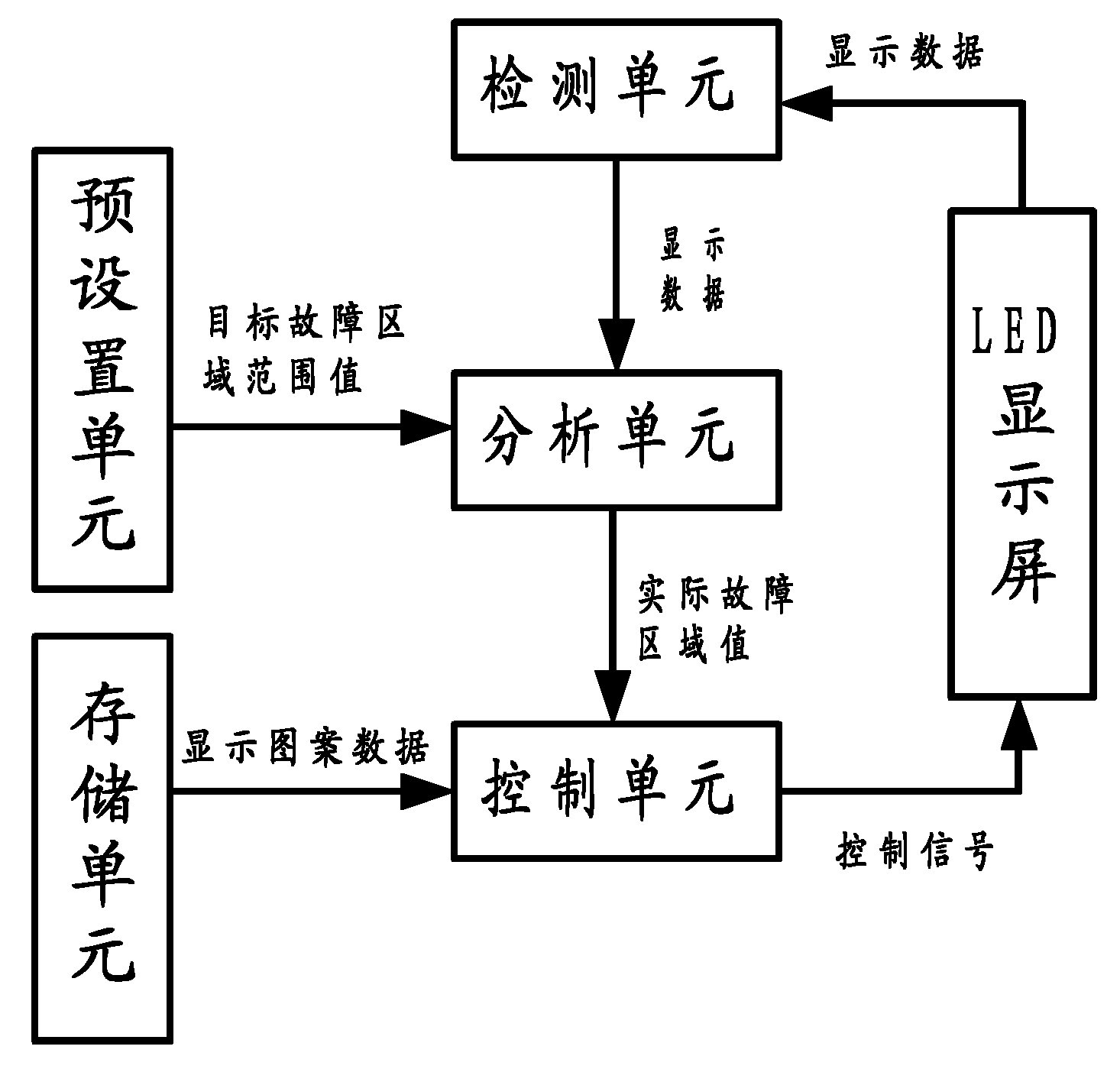

Display system for regional faults of LED display screen

InactiveCN101996545ADoes not affect the display effectTemporary fix for regional glitchesStatic indicating devicesEmbedded systemStorage cell

The invention discloses a display system for regional faults of a light-emitting diode (LED) display screen. The display system comprises a presetting unit, a storage unit, a detection unit, an analysis unit and a control unit; the presetting unit presets a target fault region range value, and the storage unit stores display pattern data of a fault region; the detection unit detects the display data of the LED display screen; the analysis unit analyzes the display data, generates an actual fault region value when the presence of the fault region is judged, and outputs the actual fault region value to the control unit when the actual fault region value in the target fault region range value is judged; and the control unit is connected with the storage unit and used for acquiring the display pattern data according to the actual fault region value, generating control signals and sending the control signals to the corresponding fault region for display. The display system can temporarily solve the regional faults, does not need to interrupt display, and does not affect the display effect of the LED display screen.

Owner:蚌埠利如电子信息科技有限公司

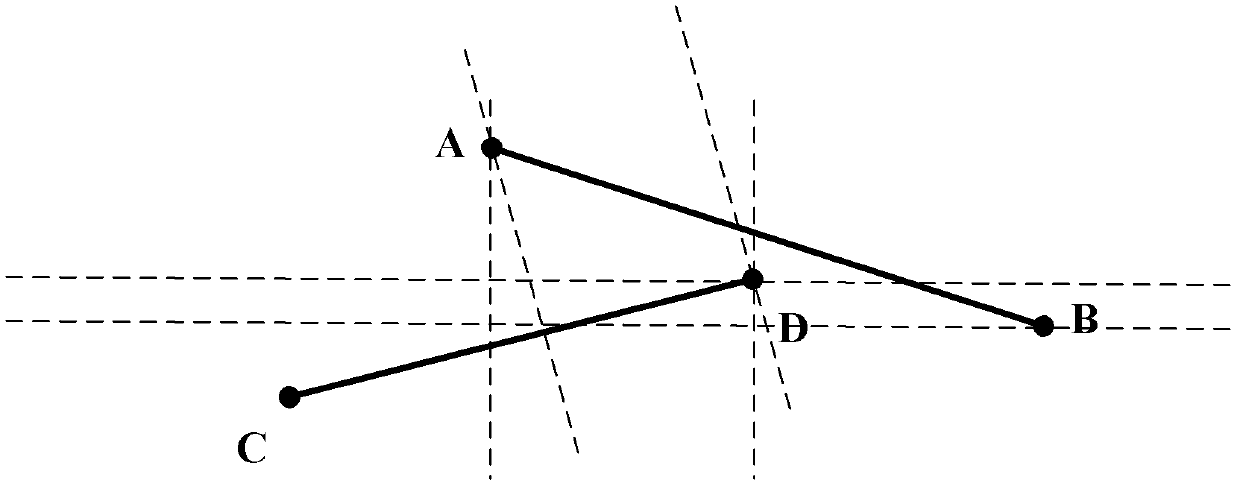

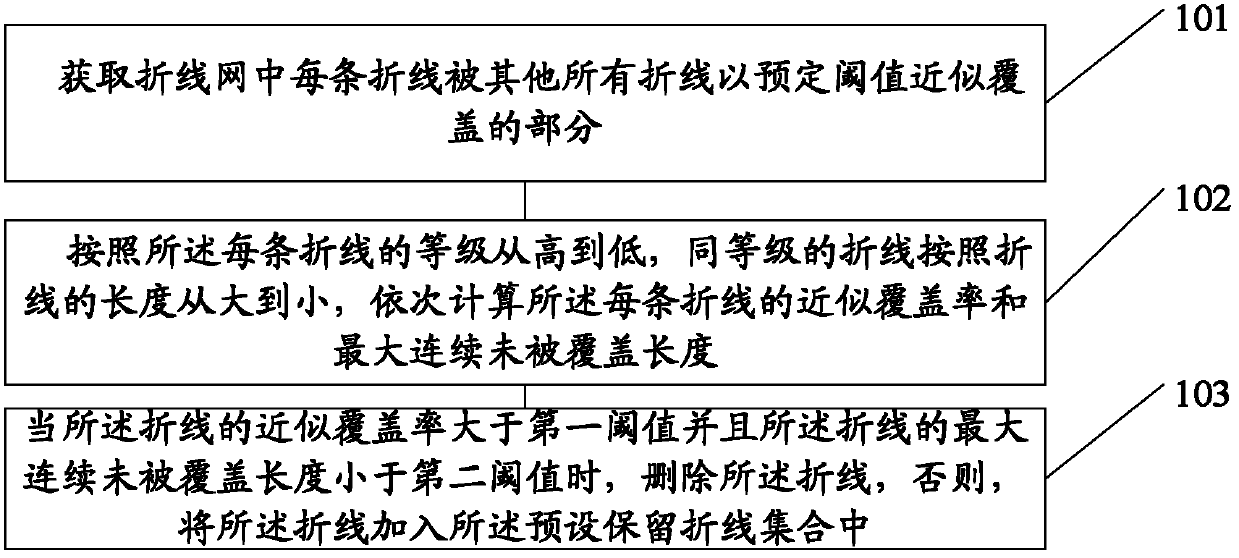

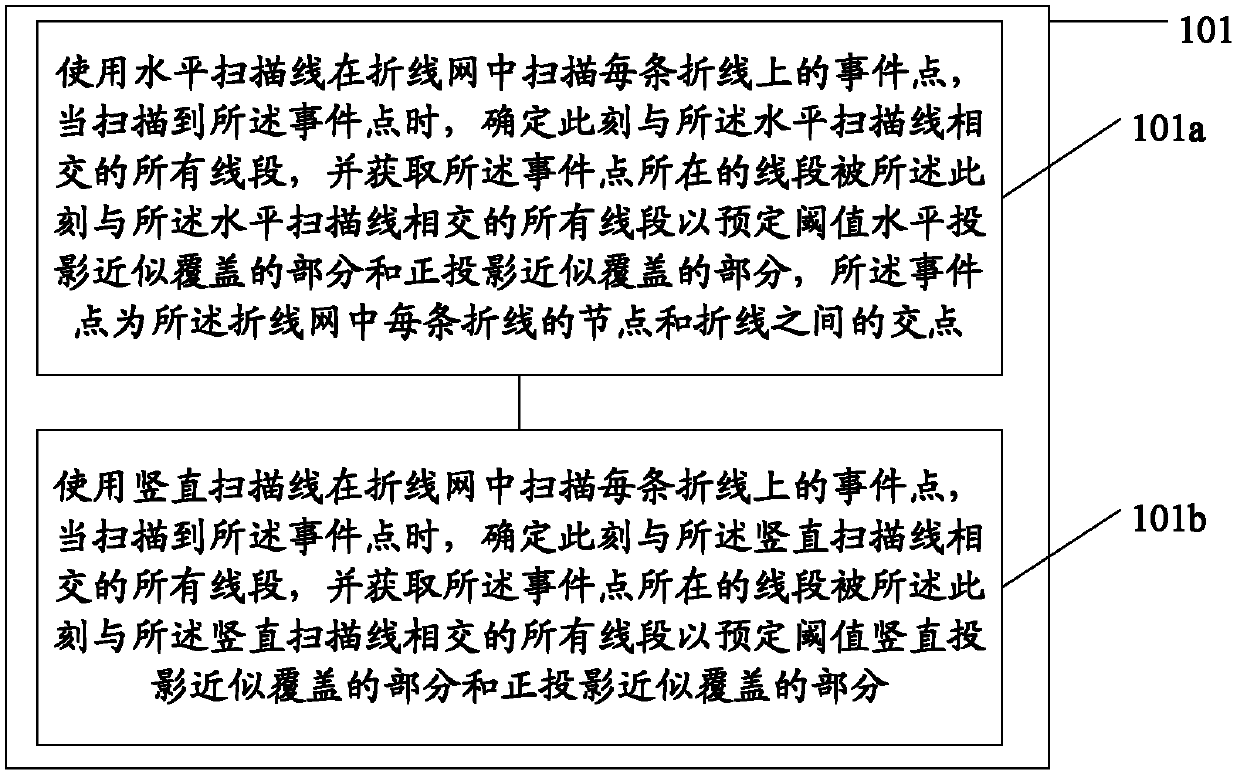

Data thinning method and device

ActiveCN103309859ADoes not affect the display effectReduce the numberSpecial data processing applicationsThinningComputer science

The embodiment of the invention discloses a data thinning method and a data thinning device, which relate to the technical field of geographic information. The method comprises the following steps of: acquiring a part of each broken line, which is approximately covered by all other broken lines by a preset threshold value, in a broken line network; calculating the approximate coverage rate and maximal continuous uncovered length of each broken line in sequence from higher-level broken lines to lower-level broken lines and from larger lengths to smaller lengths of broken lines of the same level; and when the approximate coverage rates of certain broken lines are larger than a first threshold value and the maximal continuous uncovered lengths of the broken lines are smaller than a second threshold value, deleting the broken lines, otherwise adding the broken lines into a preset reserved broken line set. According to the embodiment of the invention, data thinning processing can be performed according to the approximate overlapping relation among roads, so that the quantity of redundant data is effectively reduced on the premise of not influencing the map displaying effect.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

Display screen assembly and mobile terminal

ActiveCN110853496AGood light transmissionDoes not affect the display effectTelephone set constructionsIdentification meansEngineeringComposite plate

The invention provides a display screen assembly. The display screen assembly comprises a display screen, an adhesive layer and a screen cover plate, wherein the adhesive layer is adhered between thedisplay screen and the screen cover plate; the screen cover plate comprises at least two composite board layers, and the materials of the composite board layers comprise at least two amorphous crystalline polymers, so that the strength and the hardness of the screen cover plate are improved, the screen cover plate can effectively protect the display screen, and the risk that the screen cover plateis broken due to falling or collision is reduced. The invention further provides a mobile terminal comprising the display screen assembly.

Owner:HUAWEI TECH CO LTD

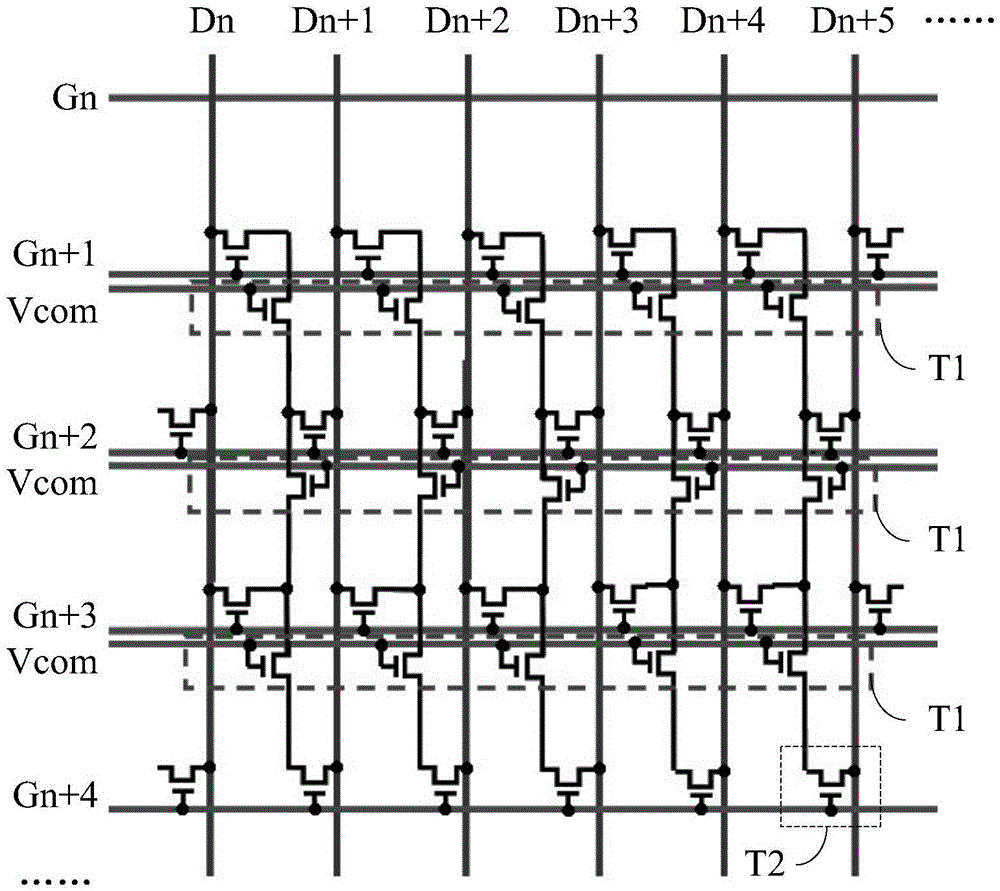

Array substrate and display driving method thereof and display device

ActiveCN105116659AReduce power consumptionDoes not affect the display effectStatic indicating devicesNon-linear opticsLinear regionDisplay device

The invention provides an array substrate and a display driving method thereof and a display device. The array substrate comprises a common voltage wire, multiple pixel electrodes arranged in rows and lines and at least one first transistor arranged between two adjacent pixel electrodes. The grids of the first transistors are connected with the common voltage wire, and the first pole and the second pole of each first transistor are connected with the two corresponding adjacent pixel electrodes respectively. In addition, the display driving method of the array substrate includes the steps that voltage is applied to the common voltage wire between adjacent display frames, and all the first transistors with the grids connected with the common voltage wire work in a linear region or a saturation region. On the basis, polarity neutralization of gray-scale voltage between adjacent pixels can be achieved on the premise that the aperture ratio of the pixels is not lowered, power consumption is greatly reduced on the premise that the display effect is not affected, and the minimum power consumption of an existing display device is broken through.

Owner:CHONGQING BOE OPTOELECTRONICS +1

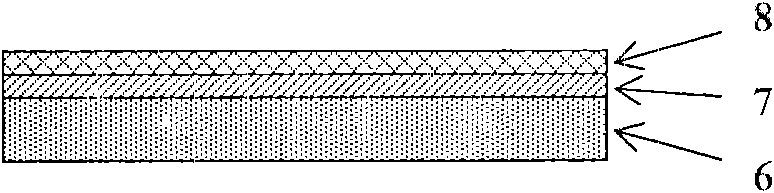

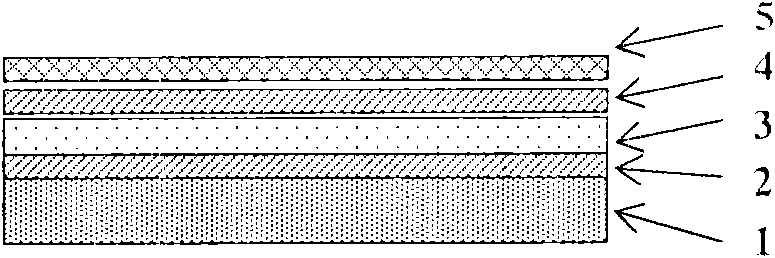

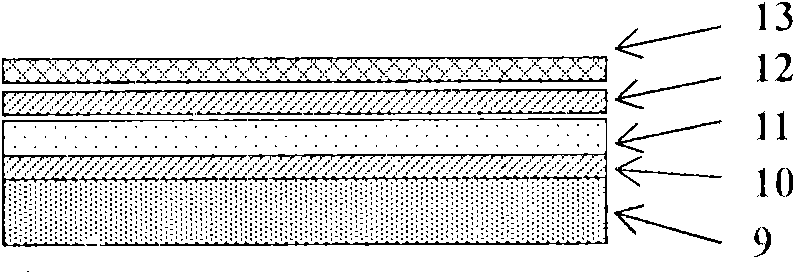

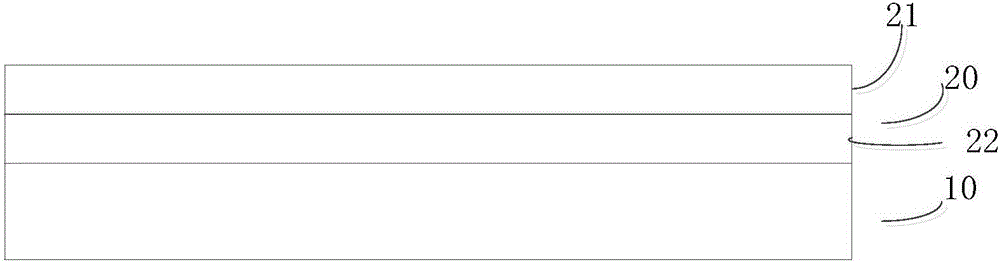

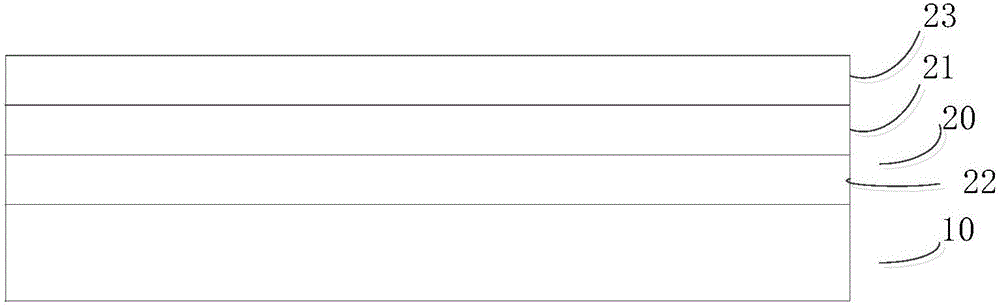

Transparent conductive material

ActiveCN102152563AImprove uniformityConsistent impedanceSynthetic resin layered productsIndium tin oxidePolyethylene glycol

The invention discloses a transparent conductive material, comprising a polyethylene glycol terephthalate (PET) base material and four layers of optical film on the surface of the base material. The difference between the reflectivity of the transparent conductive material and the reflectivity of the transparent conductive material subjected to surface ITO (Indium Tin Oxide) etching is smaller or equal to 1.5%, and the square resistance and the transmissivity of the material are high.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

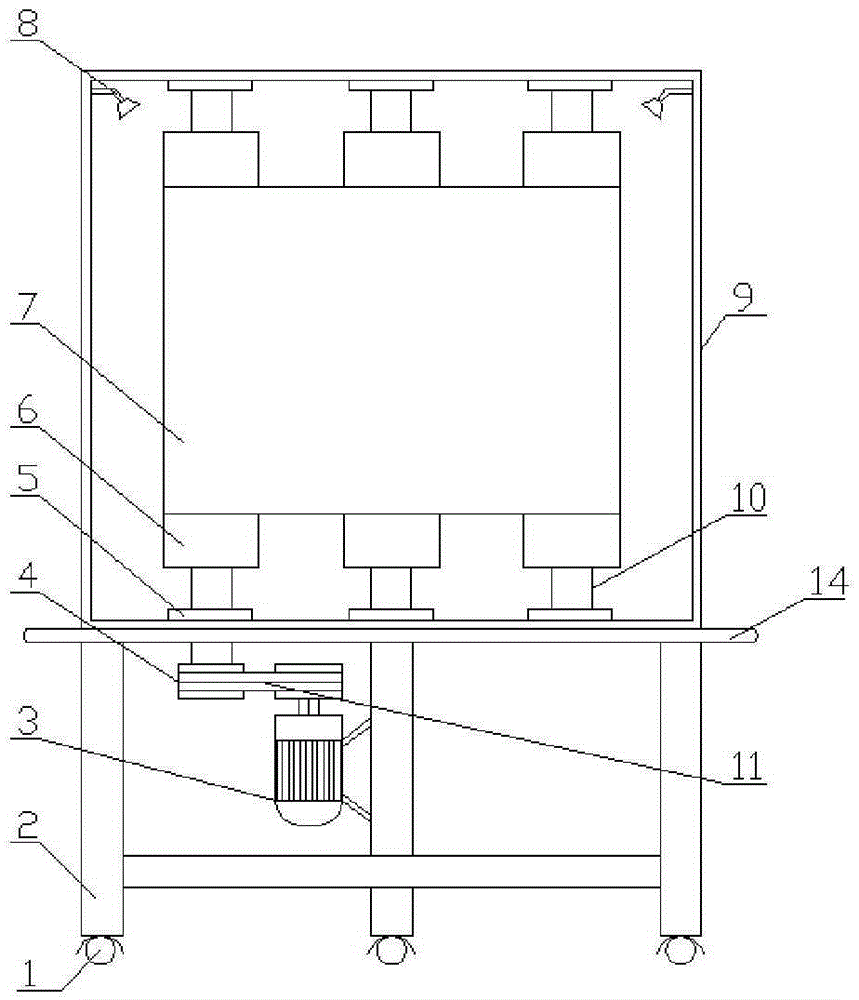

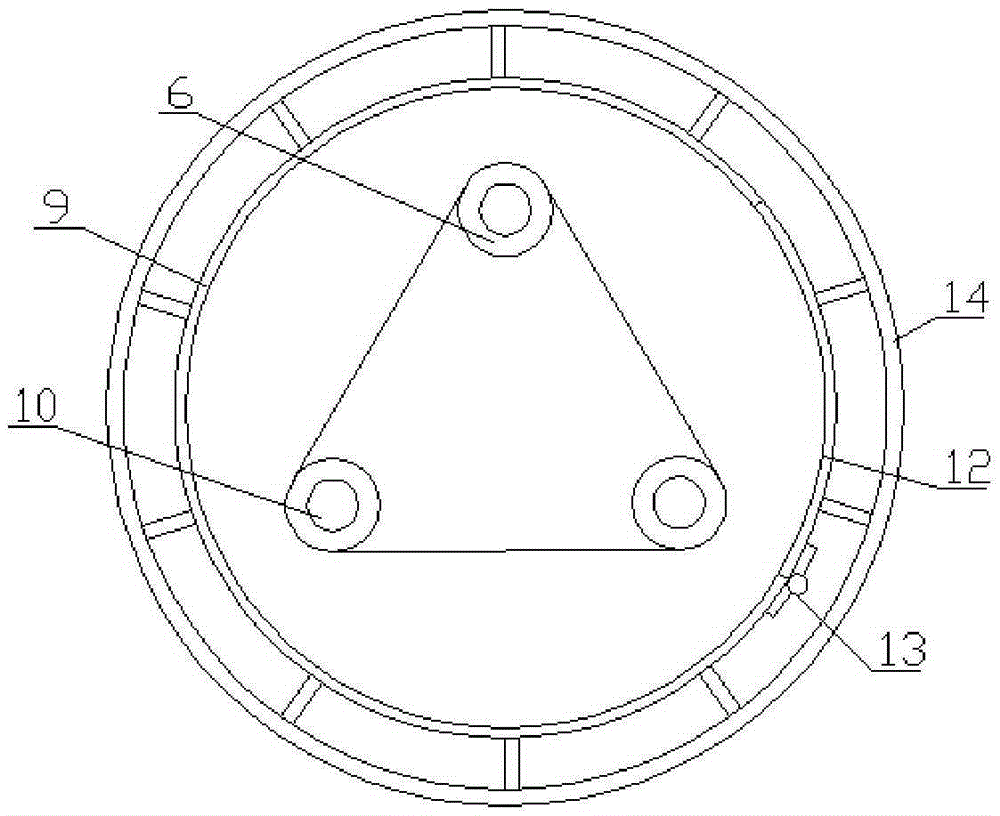

Vertical textile display device

InactiveCN105342223ALight in massStable structureShow shelvesShow hangersDynamic displaySmall footprint

The invention relates to the field of textile, and in particular relates to a vertical textile display device. The display device has the advantages of being convenient and flexible to use and transport and small in occupied space, and capable of achieving dynamic display in all directions, capable of preventing dust and the like. The structure of the display device comprises a base, a transparent box body and winding drums, wherein the transparent box body is vertically arranged on the upper surface of the base and the transparent box body is of a cylindrical hollow structure; the winding drums are fixedly arranged on rotating shafts and are of cylindrical structures; the winding drums are vertically arranged and are uniformly distributed inside the transparent box body in a triangular form; the rotating shafts are fixedly arranged inside the transparent box body by virtue of bearing bases which are embedded on the upper end face and the lower end face of the interior of the transparent box body; display cloth is wound on the outer surfaces of the winding drums; and universal wheels are arranged at the lower end of the base and are uniformly distributed on the periphery of the base. The vertical textile display device is simple in structure, low in cost of use, long in service life and convenient to transport, and is applicable to various textile display places.

Owner:SUZHOU BUWU JIAXIANG TEXTILE TECH CO LTD

Multifunctional blackboard

ActiveCN105150719AReduce usageImprove blackboard writing efficiencyBoard cleaning devicesWriting boardsEngineeringMultiple function

The invention relates to a multifunctional blackboard. The multifunctional blackboard comprises a blackboard fixed on a wall by a support and a projector mechanism and an erasing mechanism which are respectively arranged at two sides of the blackboard by a suspension device. The multifunctional blackboard is mainly formed by three parts, LED lights are embedded to a steel deck and are uniformly distributed in a matrix form, and when in use, positioning can be carried out according to light spots shown by a glass writing layer, so that use of ruler set square can be reduced, and board writing efficiency can be improved; light of the LED lights cannot affect the display effect of black and white after passing through the roughened glass writing layer; the multifunctional blackboard is further provided with a dustless module for erasing the blackboard and a releasing module for a projection screen, and therefore, the multifunctional blackboard is good in integrity and integrates multiple functions.

Owner:孙士江

On-line collecting and management system and plan for new web page information

InactiveCN1458599ADoes not affect the display effectAdd favorite functionSpecial data processing applicationsWeb siteClient-side

The present invention discloses one on-line web page information collecting and managing system named network secretary. The network secretary operates in the display mode in the same window as browser and collected web page, and the network secretary window is opened and closed via the network secretary button set in the browser. The on-line information collection, edition, management and storing are convenient and intuitive. In the client system, network secretary space icon may be established for storing the downloaded file to the personal network secretary space. There are also increased favorite function in the browser for on-line collection and web site collecting button function after the search result of search engine for storing corresponding web site to network secretary data base.

Owner:刘彬

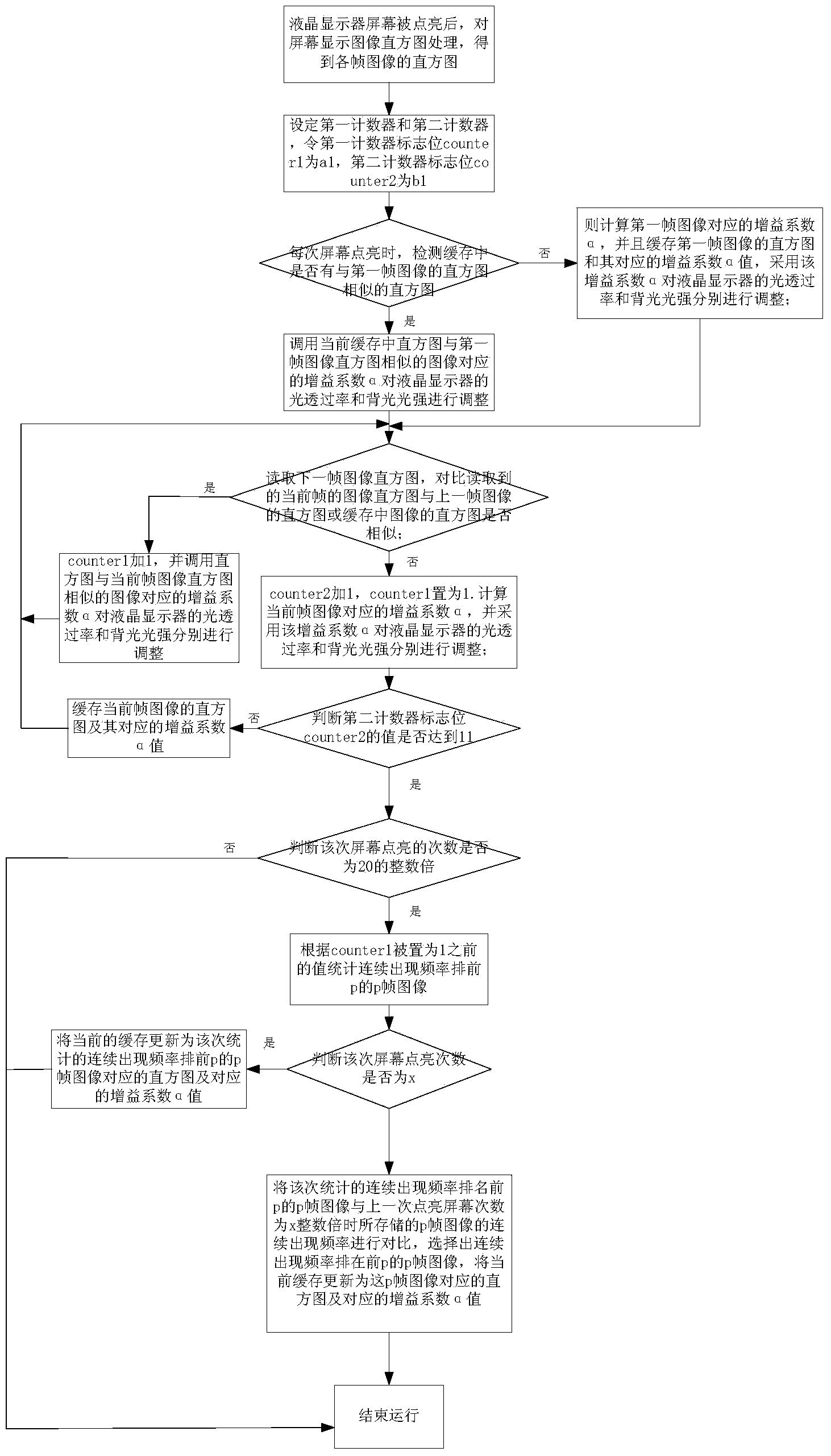

Image occurrence frequency based liquid crystal display power consumption reducing method

ActiveCN103810980ASmall amount of calculationReduce power consumptionStatic indicating devicesLiquid-crystal displayGain coefficient

The invention discloses an image occurrence frequency based liquid crystal display power consumption reducing method. A gain coefficient alpha corresponding to an image which is not similar to a histogram in cache or a histogram in a front frame image is calculated, the newly calculated gain coefficient alpha is used to respectively adjust light transmissivity and backlight intensity of a liquid crystal display; a gain coefficient alpha corresponding to an image which is similar to the histogram in cache or the histogram in the front frame image is directly called to respectively adjust light transmissivity and backlight intensity of the liquid crystal display. When the times of lightening a screen are integer multiples of x, the cache is updated to some images with higher continuous occurrence frequencies and gain coefficients alpha corresponding to the images; by means of repeated occurrence of the images and the property of infrequent changes of a lock screen and a main screen of a terminal end, backlight of the liquid crystal display is adjusted, the calculation amount of the gain coefficients alpha is greatly reduced, and the power consumption is low.

Owner:SOUTH CHINA UNIV OF TECH

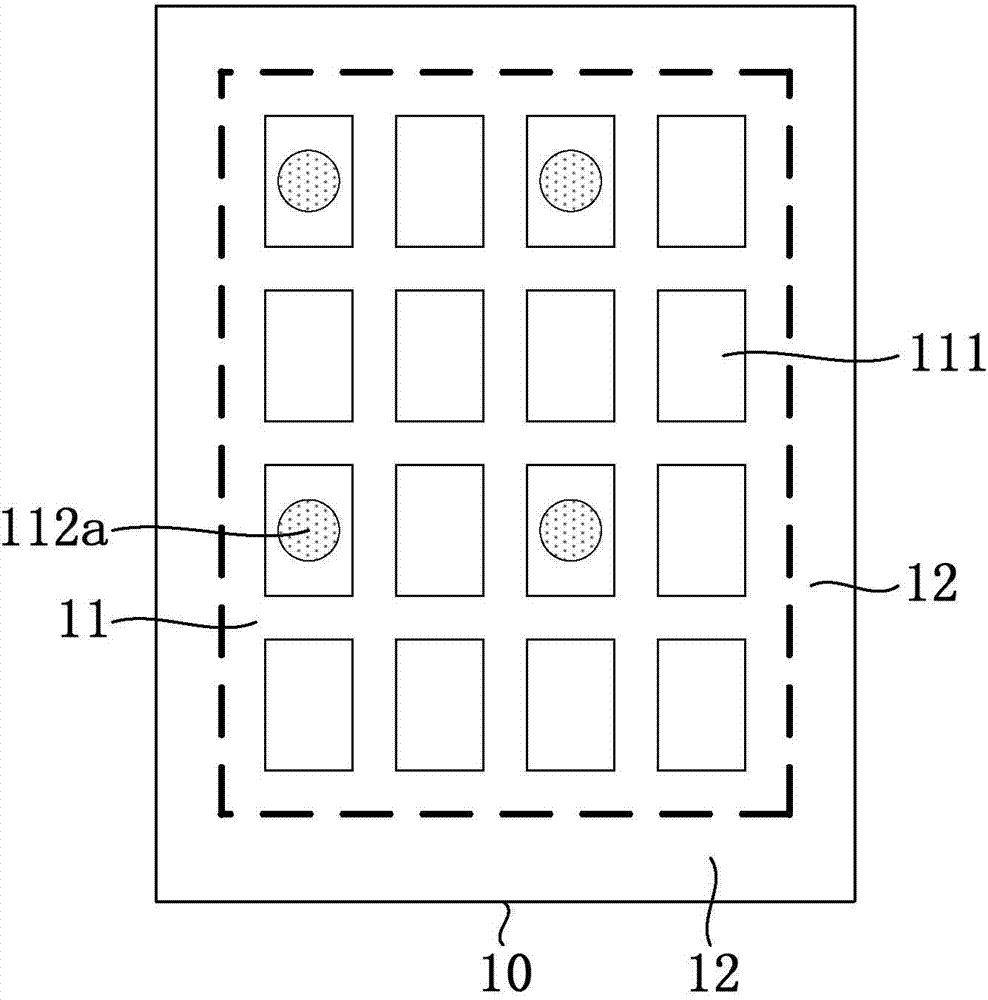

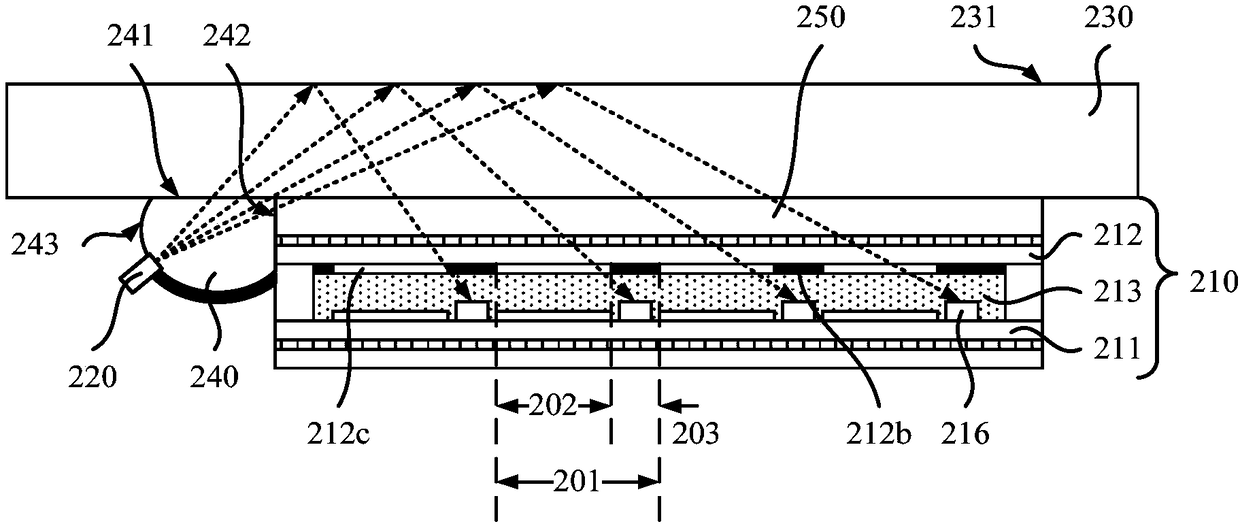

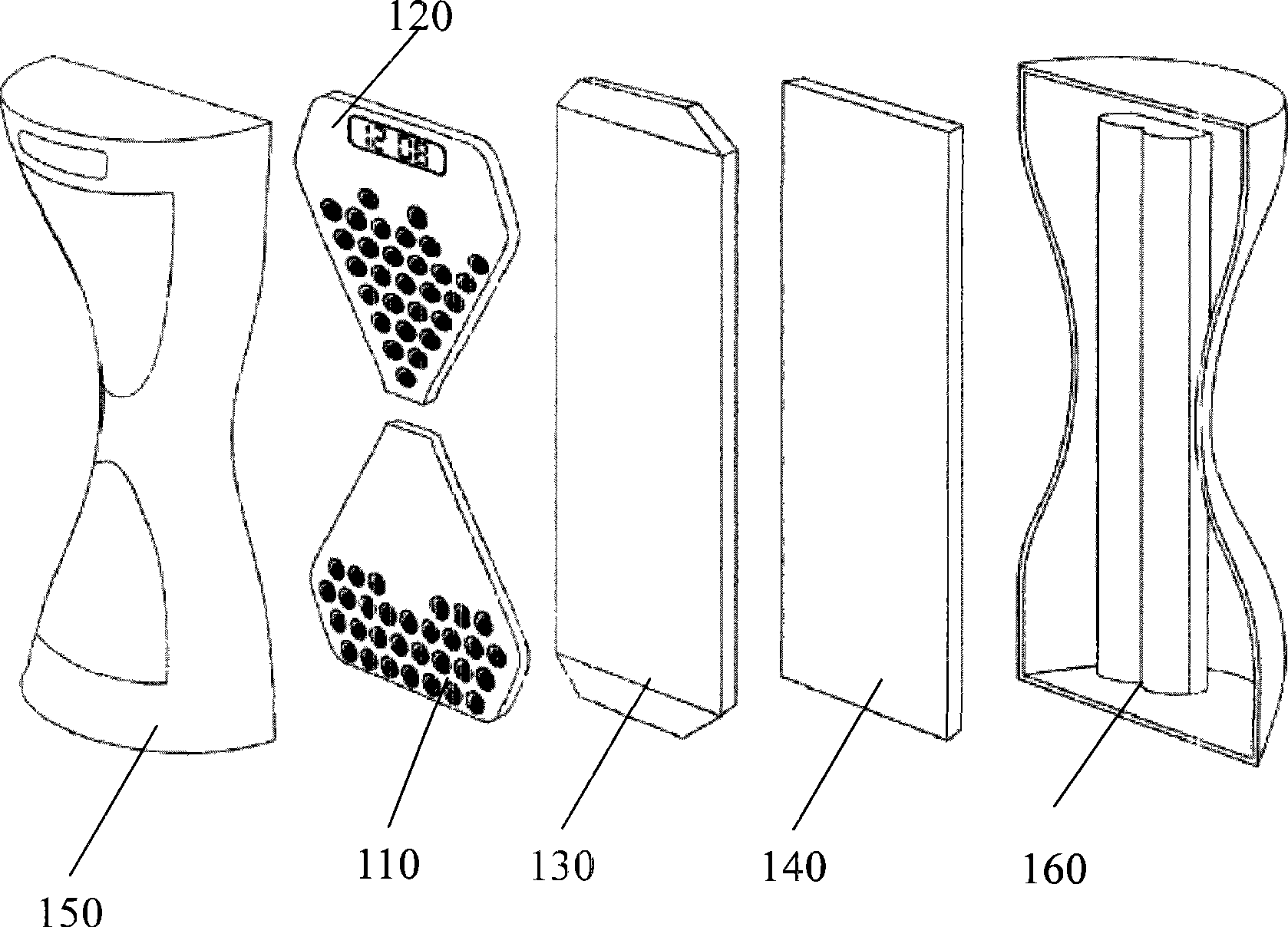

Display module

InactiveCN109426784AStrong consistencyEnsure consistencyPrint image acquisitionNon-linear opticsLiquid-crystal displayComputer science

A display module includes a liquid crystal display panel including a plurality of display pixel units, wherein the display pixel units includes a transmission area and an imtransmission area, and a photosensitive device is arranged in at least partially of the imtransmission areas of the displayg pixel units; a dot-shaped drawing light source located on one side of the liquid crystal display panel; a protective layer located above the liquid crystal display panel and the dot-shaped drawing light source, wherein the surface of the protective layer which is backward to the liquid crystal displaypanel and the surface of the dot pattern light source is a sensing surface, and the light generated by the dot pattern light source is obliquely projected into the protective layer and transmitted tothe sensing surface through the protective layer to form the reflected light carrying the fingerprint information; a photosensitive device that acquires the reflected light to obtain a fingerprint image. Through the use of the photosensitive device integrated in LCD panel and the spot light source, the display module can get clear fingerprint image on the premise of ensuring the display effect, so as to better realize the integration of fingerprint identification and image display function.

Owner:SHANGHAI OXI TECH

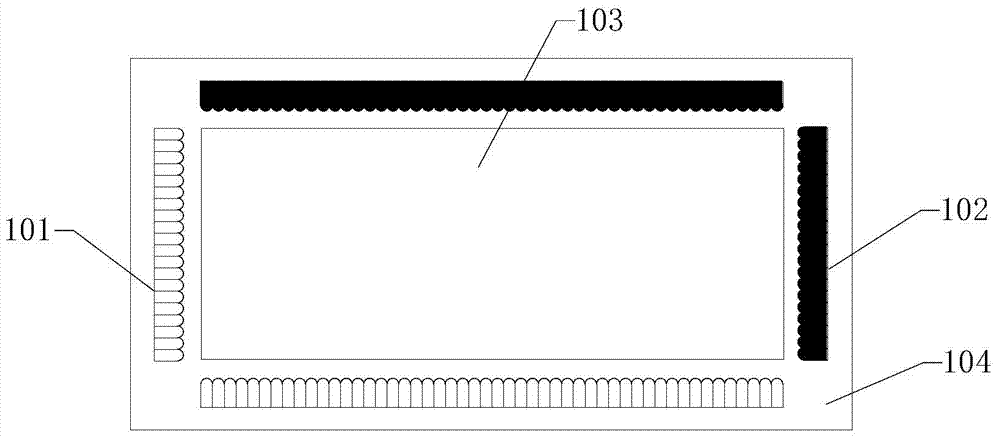

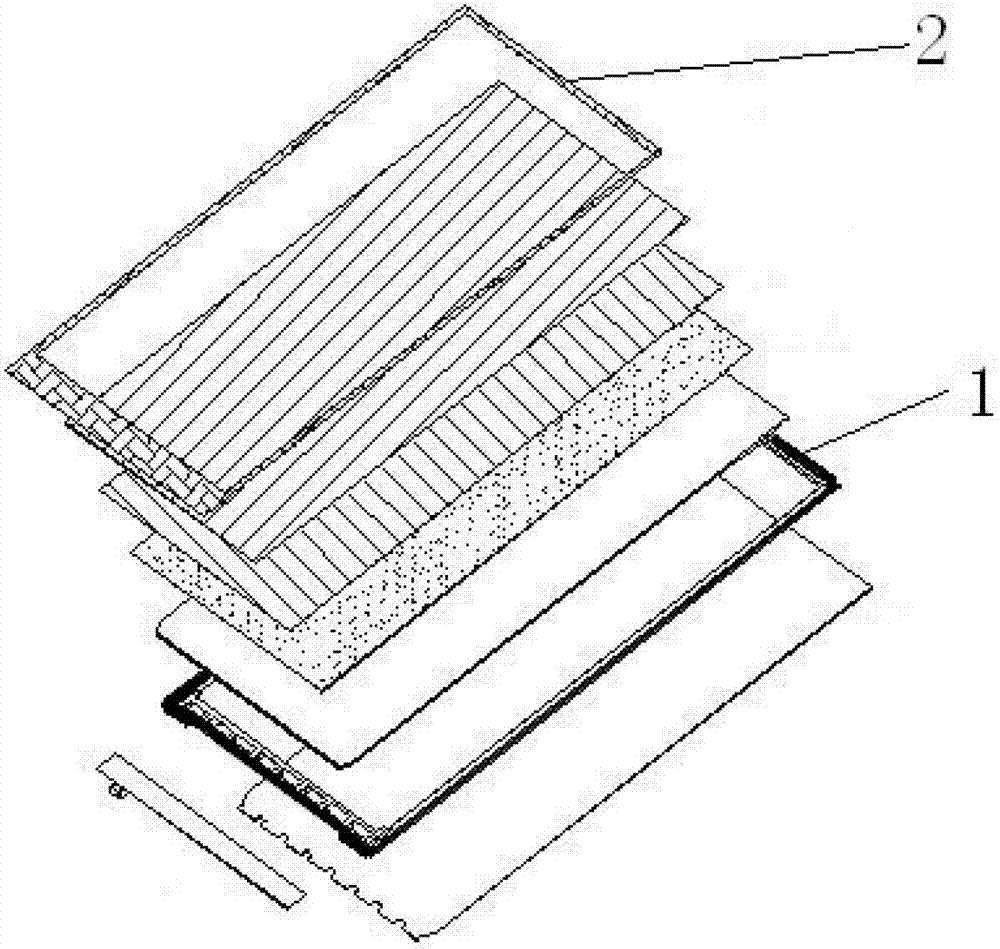

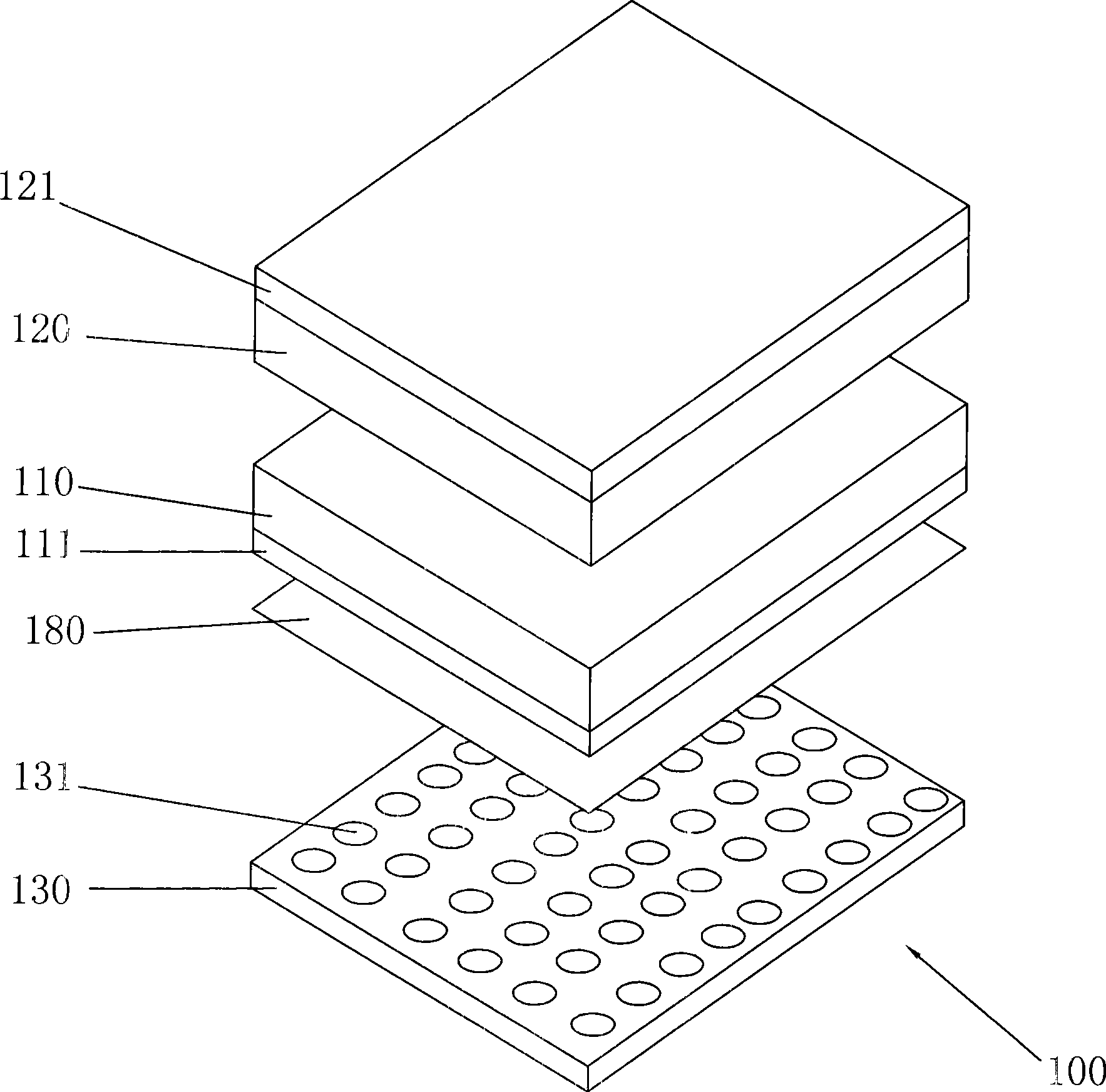

Liquid crystal backlight module

InactiveCN103591543ADoes not affect the display effectPromote absorptionNon-electric lightingPoint-like light sourceAdhesiveEngineering

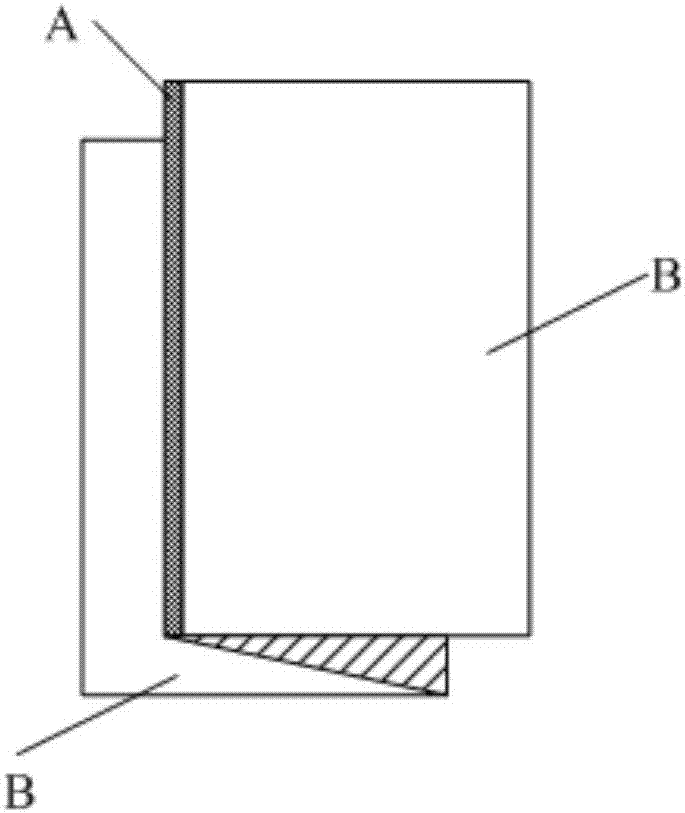

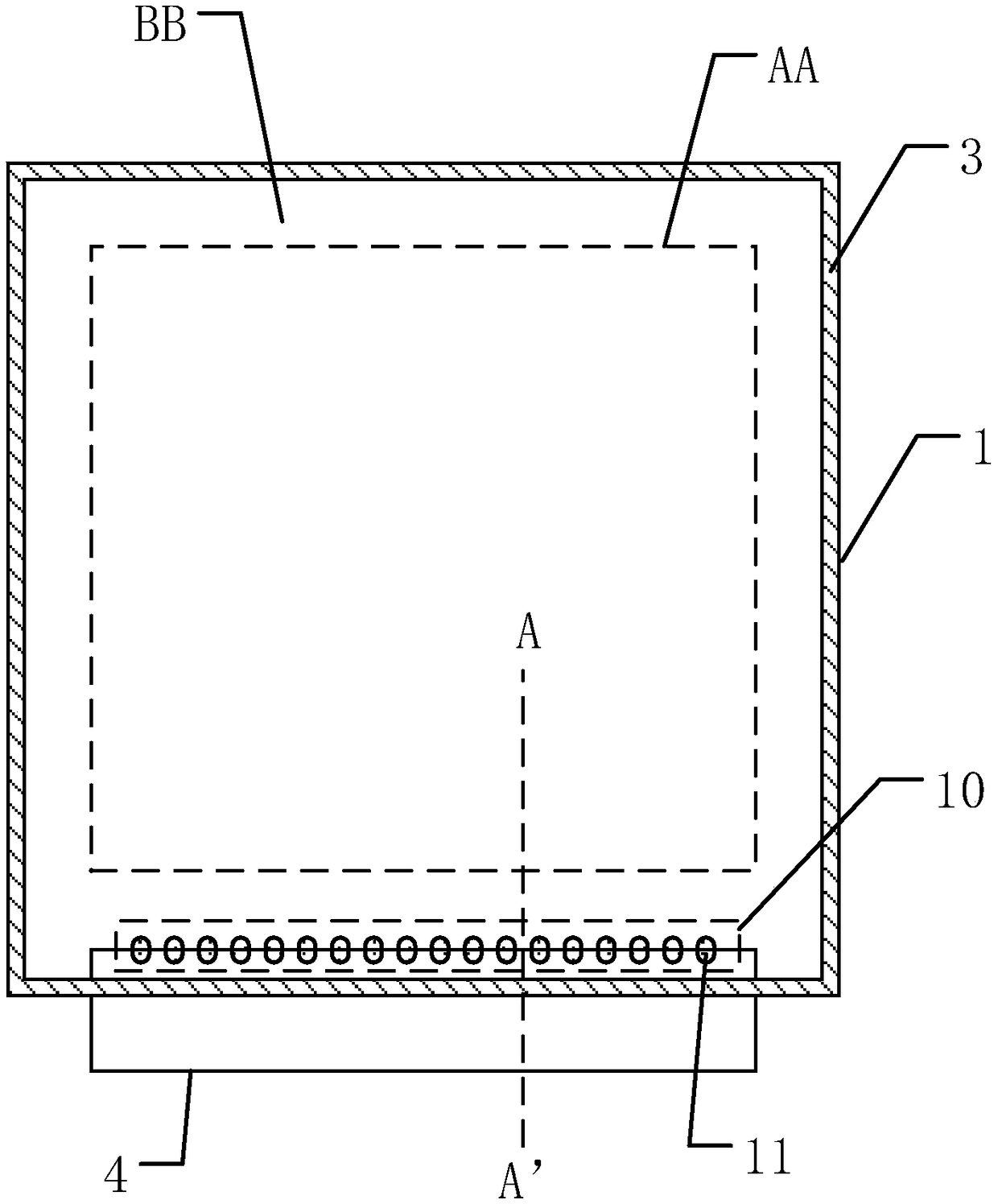

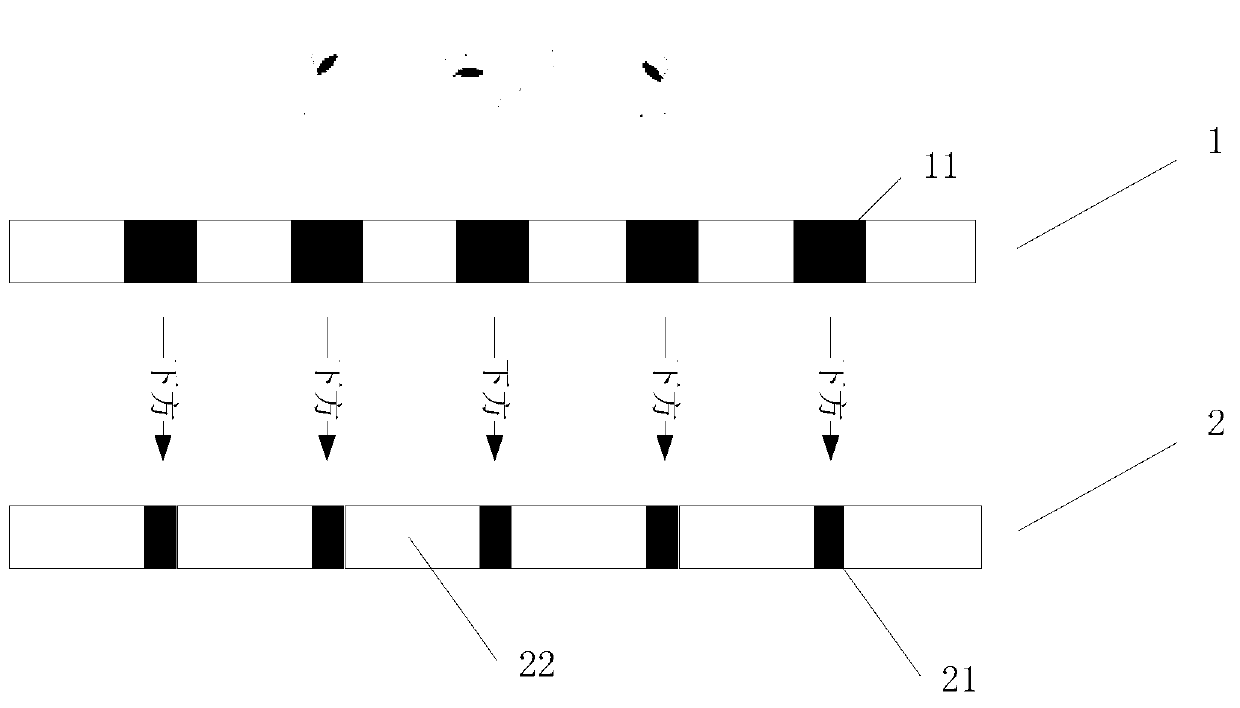

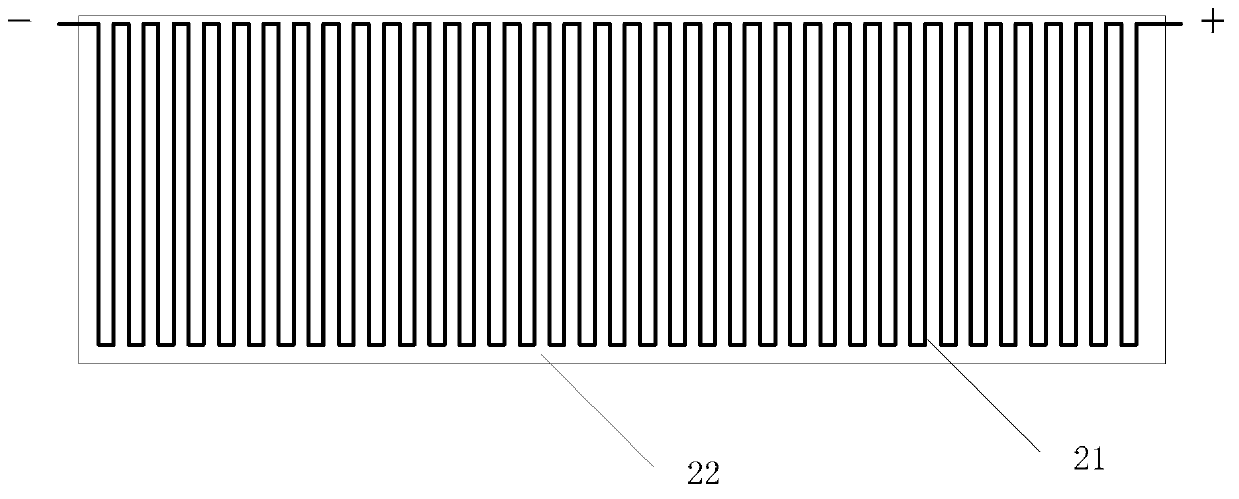

A liquid crystal backlight module comprises an adhesive frame (1) and a black and white double-sided adhesive (2); the adhesive frame (1) is of a hollow frame structure and comprises a first frame (11) which is arranged on the outer side and a second frame (12) which is arranged on the inner side; the surface of the first frame (11) is black; the surface of the second frame (12) is white; the black and white double-sided adhesive (2) is attached to the joint of the first frame (11) and the second frame (12). According to the liquid crystal backlight module, the adhesive frame is designed to be the black frame structure and the white frame structure, the outer side of the adhesive frame is provided with the first frame, the surface of the first frame is black, and accordingly the light transmitted from the black and white double-sided adhesive and the adhesive frame can be well absorbed and accordingly the display effect of the liquid crystal backlight module cannot be affected.

Owner:合肥宝龙达光电技术有限公司

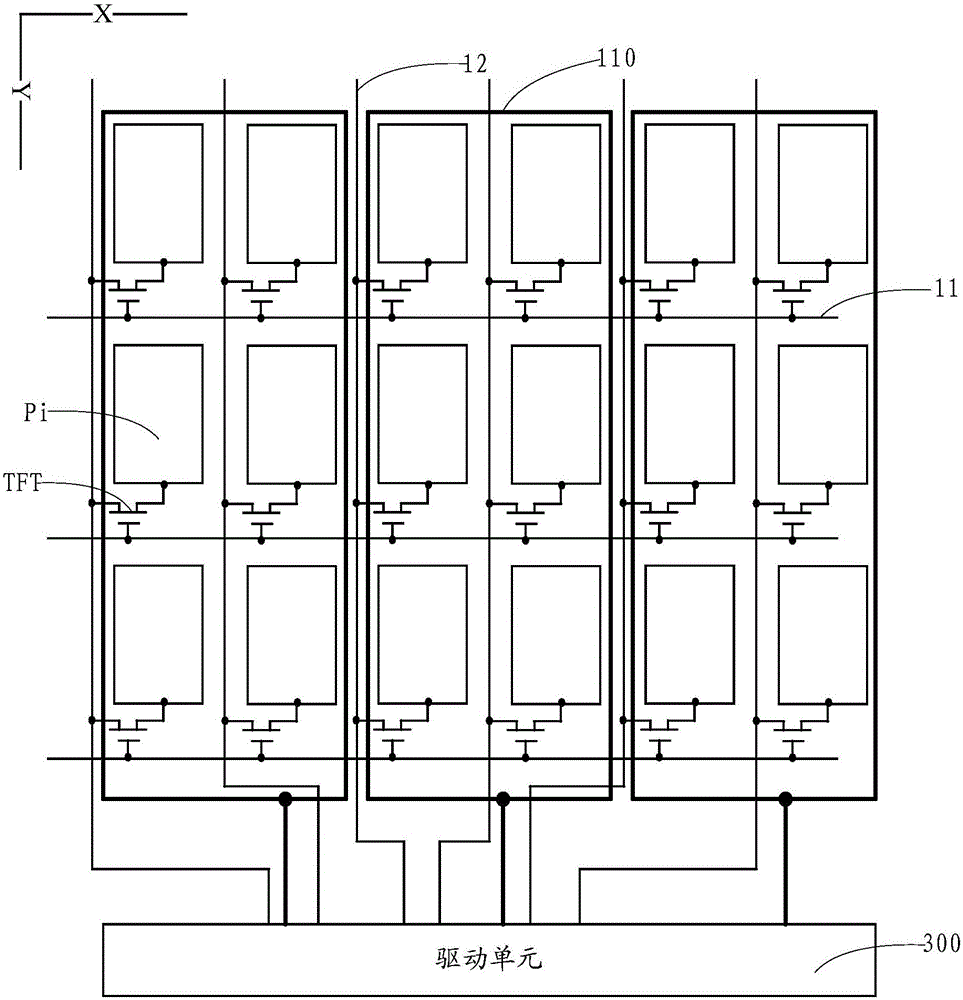

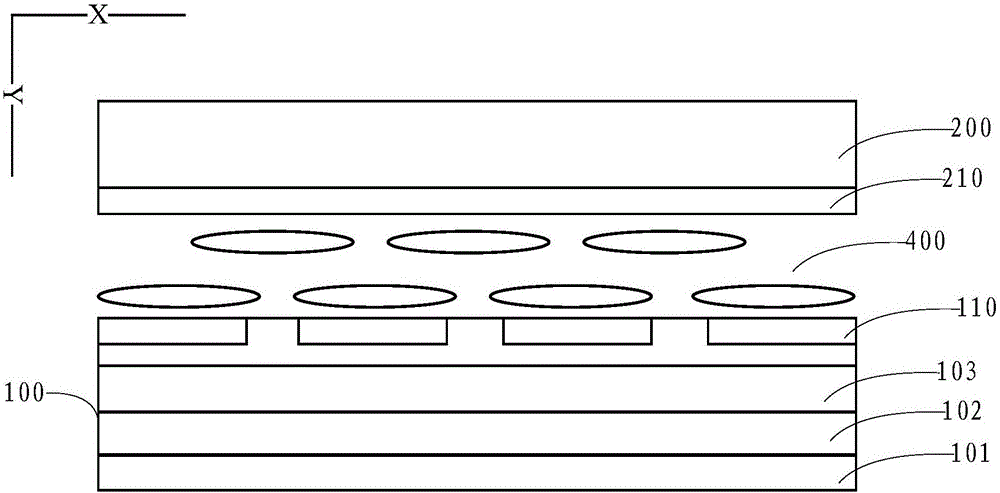

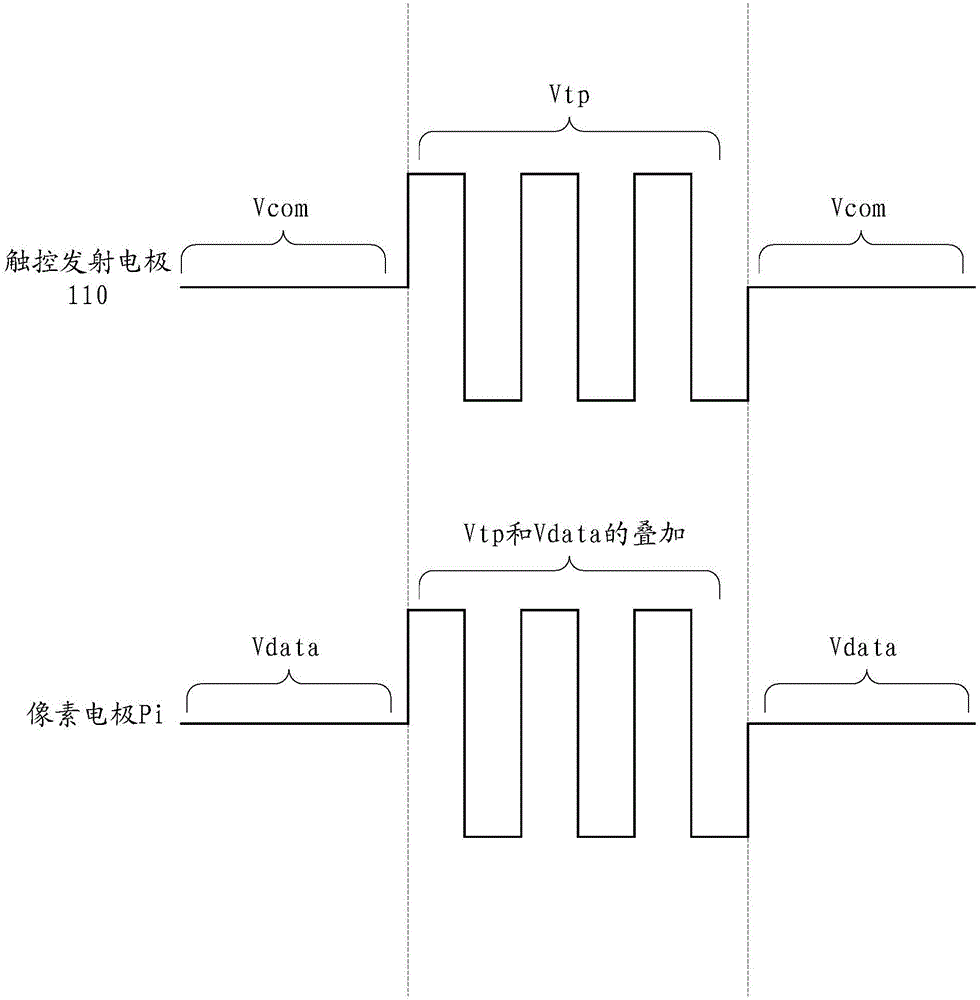

Touch control display panel, driving method and touch control display device

ActiveCN106371665AImprove reporting rateDoes not affect the display effectNon-linear opticsInput/output processes for data processingDisplay deviceHuman–computer interaction

The invention discloses a touch control display panel, a driving method and a touch control display device. The touch control display panel realizes the touch control and the display synchronous driving, i.e., the touch control detection is completed during the display; the staged proceeding of the display and the touch control is not needed; further, the point report rate improvement limitation is avoided; the point report rate of the touch control display device is enabled to be high.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

Display panel and preparation method thereof, and display device

The invention relates to a display panel and a preparation method thereof, and a display device. The display panel comprises a stretchable substrate and a plurality of display parts, wherein a plurality of deformation holes are formed in the stretchable substrate; the plurality of deformation holes are respectively formed in gaps of the plurality of display parts; and via the arrangement of the deformation holes, stress suffered by an island structure when in stretching can be fully relieved. According to the display panel provided by the invention, the stretching performance of the display panel can be improved without affecting the display effect of a pixel device.

Owner:YUNGU GUAN TECH CO LTD

Blocking-rendering based generation of anti-aliasing line segment in GPU

ActiveCN102096935AGenerate fastIncrease generation speedDrawing from basic elementsImage memory managementAnti-aliasingComputer science

The invention discloses a blocking rendering algorithm based generation technology of a sawtooth line segment in a GPU, which is carried out after finishing blocking of the line segment. The generation technology comprises the following steps of determining left and right (or up and down) intersection points of the line segment in a block according to the block where the line segment is located and a line segment generation direction; writing intersection point data in a memory; generating a coordinate which has the width of 1 after taking out the line segment from the memory; expanding the coordinate according to the width of the line segment; shearing according to a block boundary and the like. The realization mode can be matched with the blocking rendering algorithm to finish rapid generation of the sawtooth line segment.

Owner:CHANGSHA JINGJIA MICROELECTRONICS

Color liquid crystal display device driven by field sequence and drive method thereof

InactiveCN101414441AIncrease display capacityDoes not affect the display effectCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayEngineering

Owner:陈国平

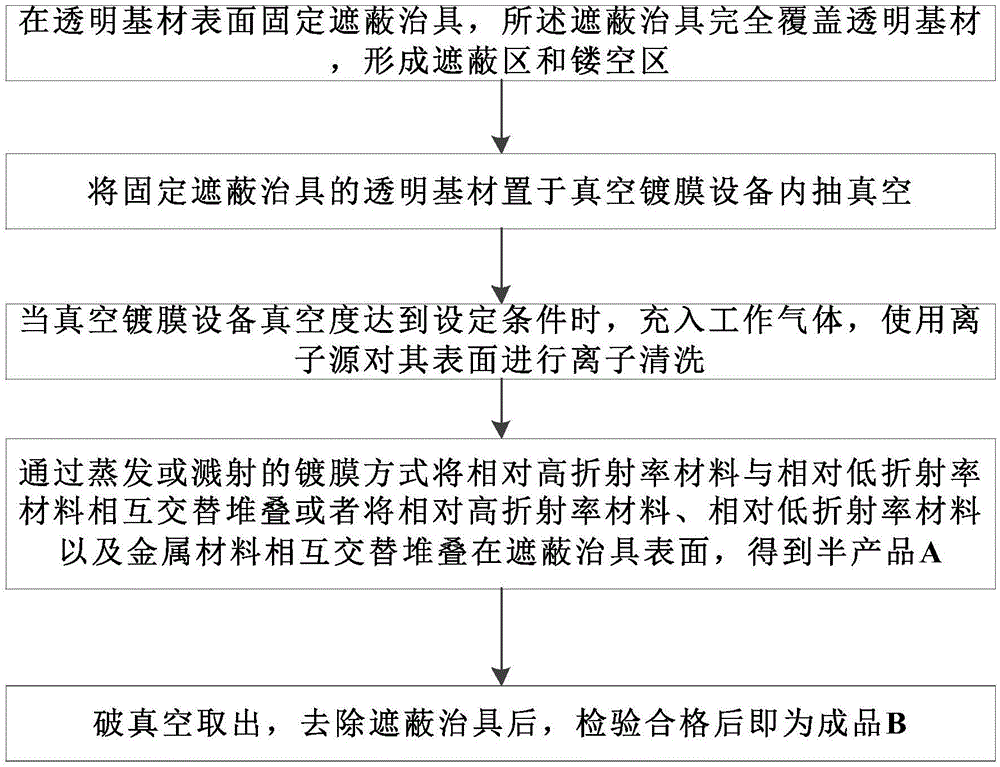

Solid material surface transparent texture coating technology

InactiveCN106337163ATransmittance adjustableDoes not affect the transparent display effectVacuum evaporation coatingSputtering coatingMetallurgyEvaporation

The invention discloses a solid material surface transparent texture coating technology. The technology comprises the steps that a shielding jig is fixed to the surface of a transparent base material, the shielding jig completely covers the transparent base material to form a shielding region and a hollow region; the transparent base material with the fixed shielding jig is placed into vacuum coating equipment to be vacuumized; working gas is charged, and an ion source is used for performing ion cleaning on the surface of the ion source; on the basis of an evaporation or sputtering coating mode, materials with the high refractive index and materials with the low refractive index are alternately stacked or materials with the high refractive index, materials with the low refractive index and metal materials are alternately stacked on the surface of the shielding jig to obtain a semi-product A; vacuum breaking is performed, the semi-product A is taken out, and after the shielding jig is removed, a finished product B is obtained after being qualified through inspection. The technology can be directly applied on the surface of a product with a window or a display region, the treated transparent base material surface texture transparency is adjustable, the texture effect scarcely affects the light transmission display effect of the base material, and the texture effect is clearly visible in the screen extinguishing state.

Owner:陈浩

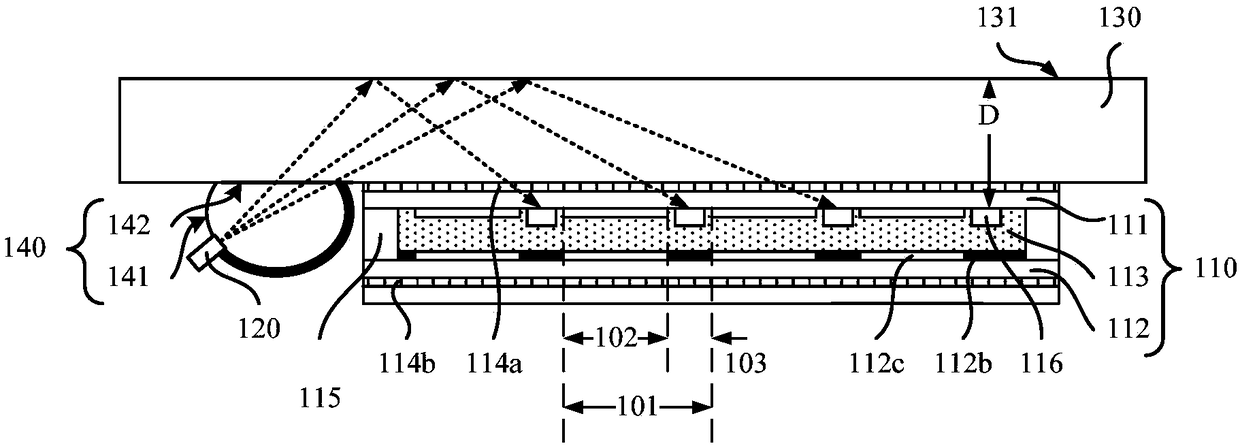

Display module

InactiveCN109426022ADisplay EffectsGuaranteed display effectPrint image acquisitionNon-linear opticsLight sensingLiquid-crystal display

The invention discloses a display module. The display module comprises a liquid crystal display panel, a protecting layer and a punctiform image collecting light source, wherein the liquid crystal display panel comprises multiple displaying pixel units, the displaying pixel units comprise permeable areas and non-permeable areas, and the non-permeable areas of part of the displaying pixel units areprovided with light sensing members, the protecting layer is located above the liquid crystal display panel, the face, facing the surface of the liquid crystal display panel, of the protecting layeris a back face, a groove is formed in the back face, the groove is located on one side of the liquid crystal display panel, at least part of the punctiform image collecting source is located in the groove, the face, back to the surface of the liquid crystal display panel, of the protecting layer is a sensing detecting face, light generated by the punctiform image collecting light source enters theprotecting layer from at least one surface of the groove, the light is transmitted to the sensing detecting surface through the protecting layer to form reflecting light which carries fingerprint information on the sensing detecting surface, and the reflecting light is collected by a light sensing member to obtain a fingerprint image. The display module has the advantages that under the premise that a displaying effect is ensured, a clear fingerprint image is obtained to well achieve the integration of fingerprint recognition and image display functions.

Owner:SHANGHAI OXI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com