Splicing method of curved LED display screen

A technology of LED display and display screen, applied in the direction of instruments, identification devices, etc., can solve the problems of cross light, affect the display effect, difficult to control the accuracy, etc., and achieve the effect of meeting the angle and position requirements, and the adjustment method is flexible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

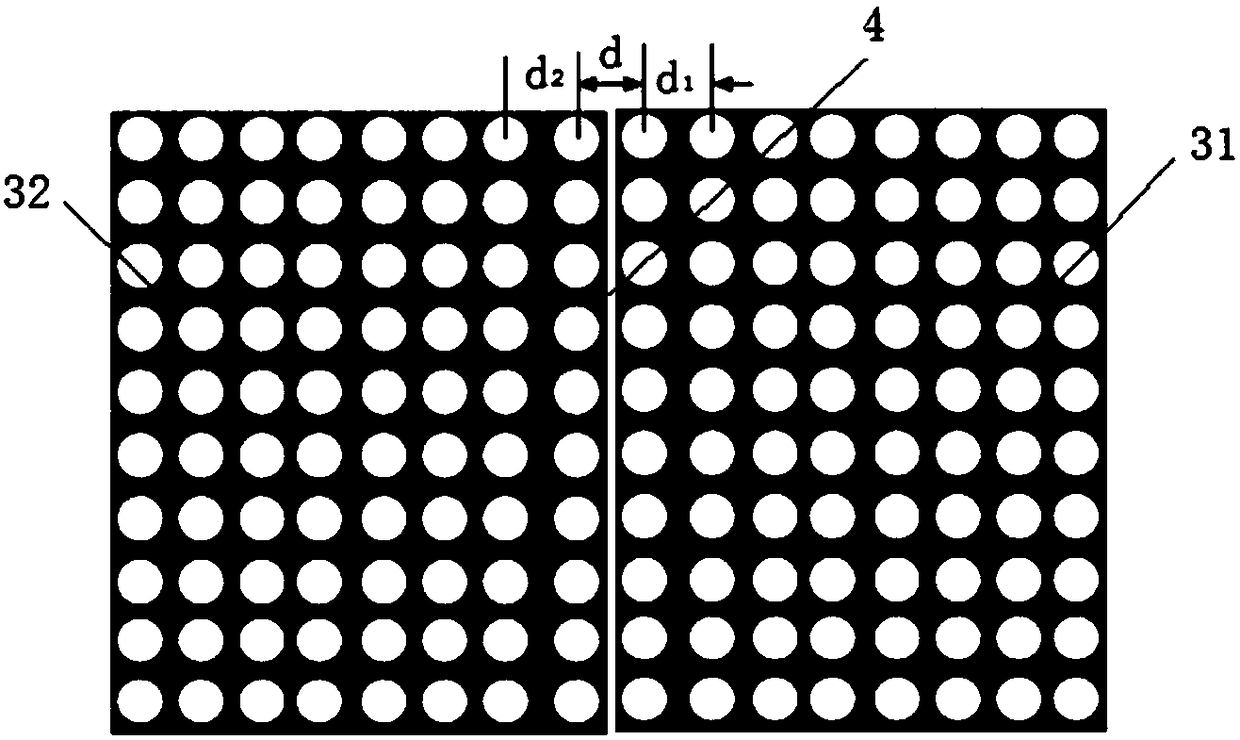

[0028] Such as figure 1 As shown, taking a rectangular display module as an example, the curved LED display screen of the present invention adopts multiple rectangular display modules for splicing. When splicing, there are seams 4 at the splicing of adjacent display modules; The display modules are the first display module 31 and the second display module 32. The pixel pitch on the first display module 31 near the seam 4 is d1, and the pixel pitch on the second display module 32 near the seam 4 is d2. The span between the nearest two adjacent pixels between the display modules is d, and the spanning pixel pitch d at the seam 4 is not greater than the minimum value of d1 or d2.

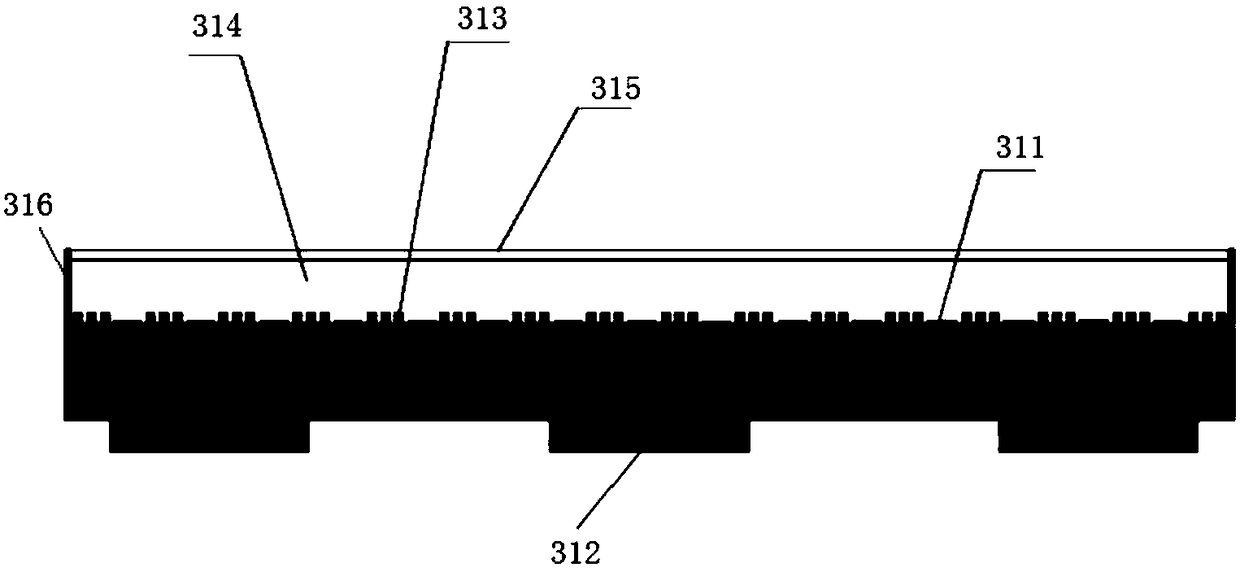

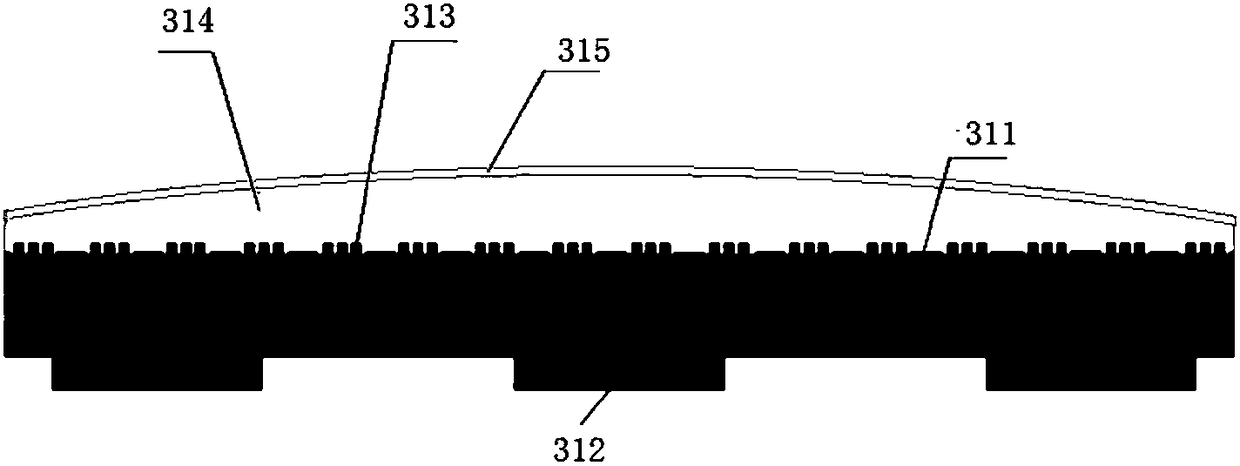

[0029] Such as figure 2 , 3 As shown, the display module includes a drive circuit board 311, at least one drive IC 312 and an LED lamp module 313; the drive IC 312 is arranged on the back of the drive circuit board 311, and the LED light-emitting chip 313 is arranged on the front of the drive circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com