Basalt fiber composite integrated wallboard

A technology of basalt fiber and wall panels, which is applied to walls, buildings, building components, etc., can solve the problems of non-environmental protection, reduced strength, and insufficient wall panels in the production process, and achieve the effect of reducing the difficulty of splicing and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

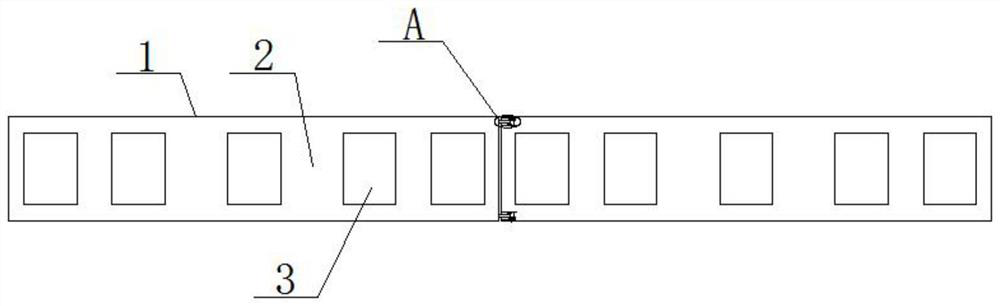

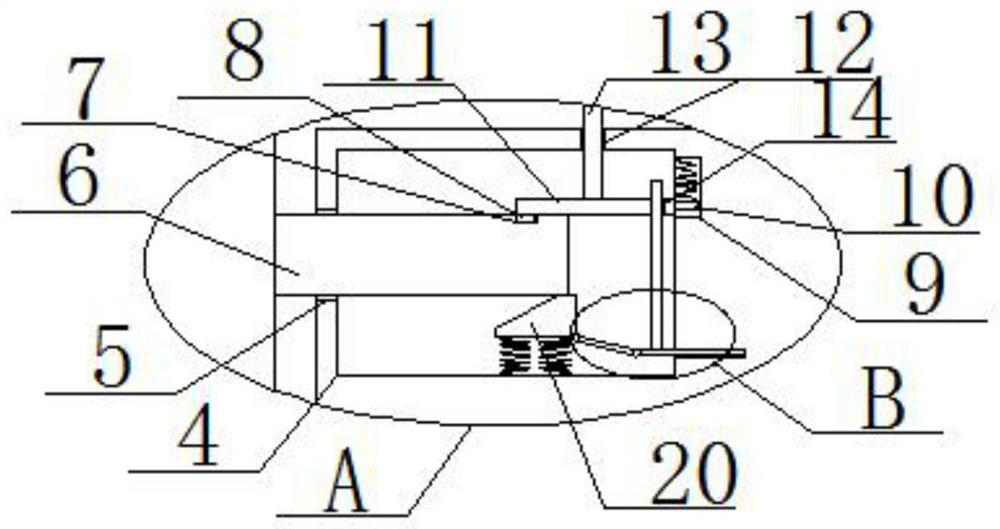

[0021] refer to Figure 1-3 , basalt fiber composite wallboard, including two wallboards 1, fiber cloth 2 and resin 3 are installed in the wallboard 1, a cavity 4 is opened on one side of the wallboard 1, and a cavity 4 is opened on the inner wall of one side of the cavity 4 There is a fixing hole 5, a fixing rod 6 is slidably installed in the fixing hole 5, one end of the fixing rod 6 extends into the cavity 4, the other end of the fixing rod 6 extends outside the cavity 4, and the fixing rod 6 extends outside the cavity 4 One end of one end is fixedly connected with one side of the wall panel 1, and the fixed rod 6 extends to the top of the cavity 4 to open a limiting groove 7, and a limiting rod 8 is slidably installed in the limiting groove 7, and one end of the limiting rod 8 extends to the limit In the positioning groove 7, the other end of the limiting rod 8 extends out of the limiting groove 7, and the limiting rod 8 is used for fixing.

[0022] In the present inventi...

Embodiment 2

[0028] The basalt fiber composite wallboard consists of two wallboards 1. Fiber cloth 2 and resin 3 are installed inside the wallboard 1. A cavity 4 is chiseled on one side of the wallboard 1, and a cavity 4 is chiseled on the inner wall of one side of the cavity 4. Fixed hole 5, fixed rod 6 is slidably installed in fixed hole 5, one end of fixed rod 6 extends into cavity 4, the other end of fixed rod 6 extends outside cavity 4, and fixed rod 6 extends to the outside of cavity 4 One end is fixedly connected to one side of the wall panel 1, the fixed rod 6 extends to the top of the cavity 4 and a limit groove 7 is chiseled, and a limit rod 8 is slidably installed in the limit groove 7, and one end of the limit rod 8 extends to the limit Inside the slot 7 , the other end of the limiting rod 8 extends out of the limiting slot 7 .

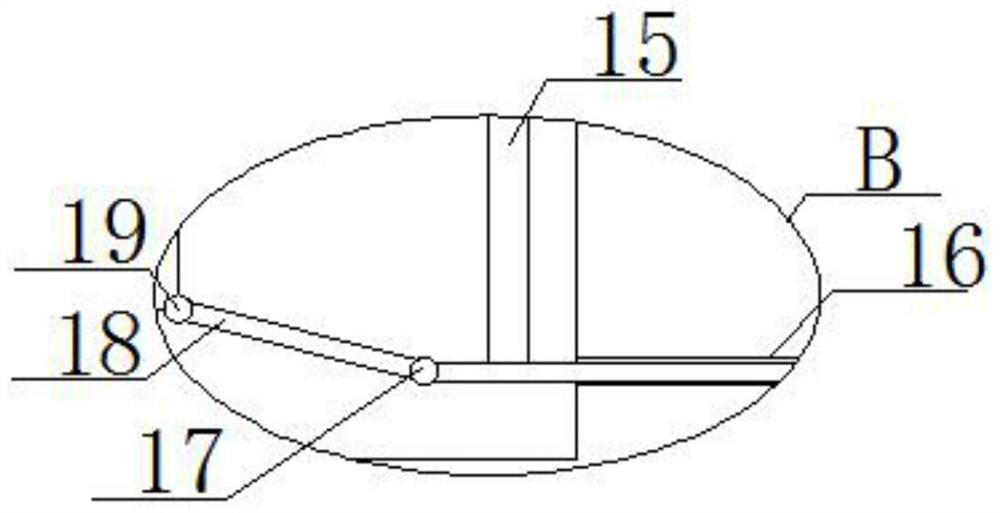

[0029] In the present invention, a sliding groove 9 is chiseled on the top inner wall of one side of the cavity 4, and a sliding block 10 is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com