Patents

Literature

84results about "Finger joining apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

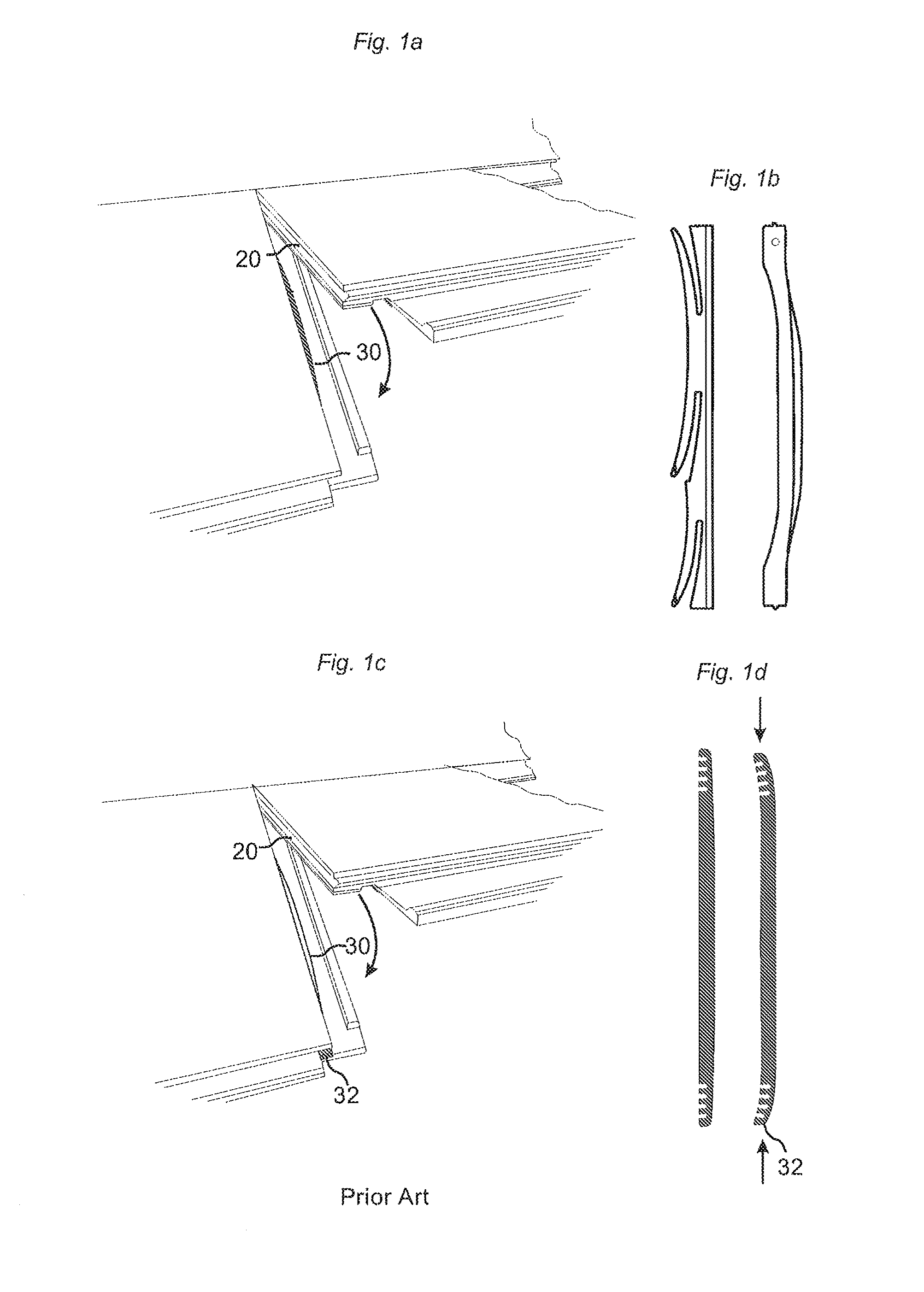

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

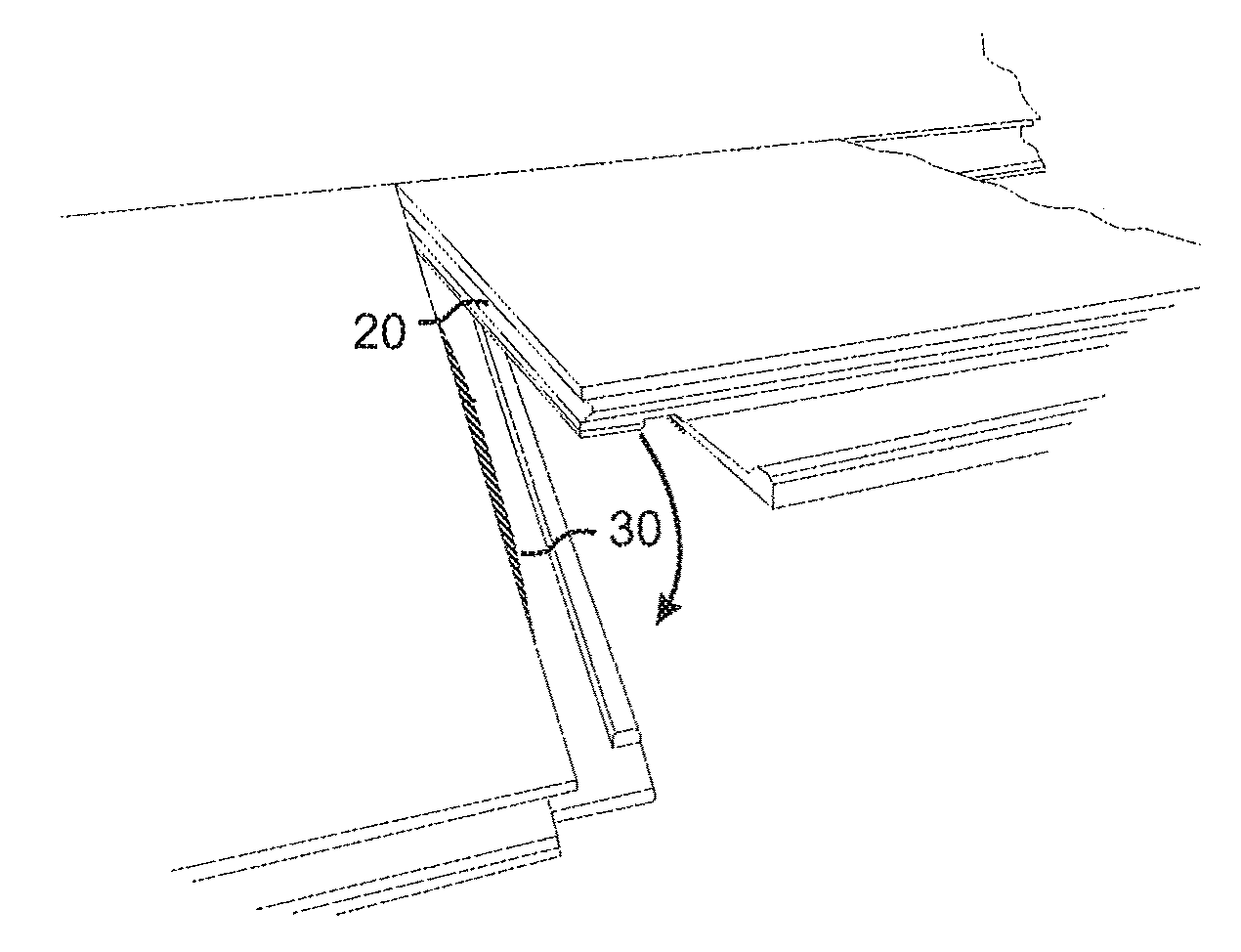

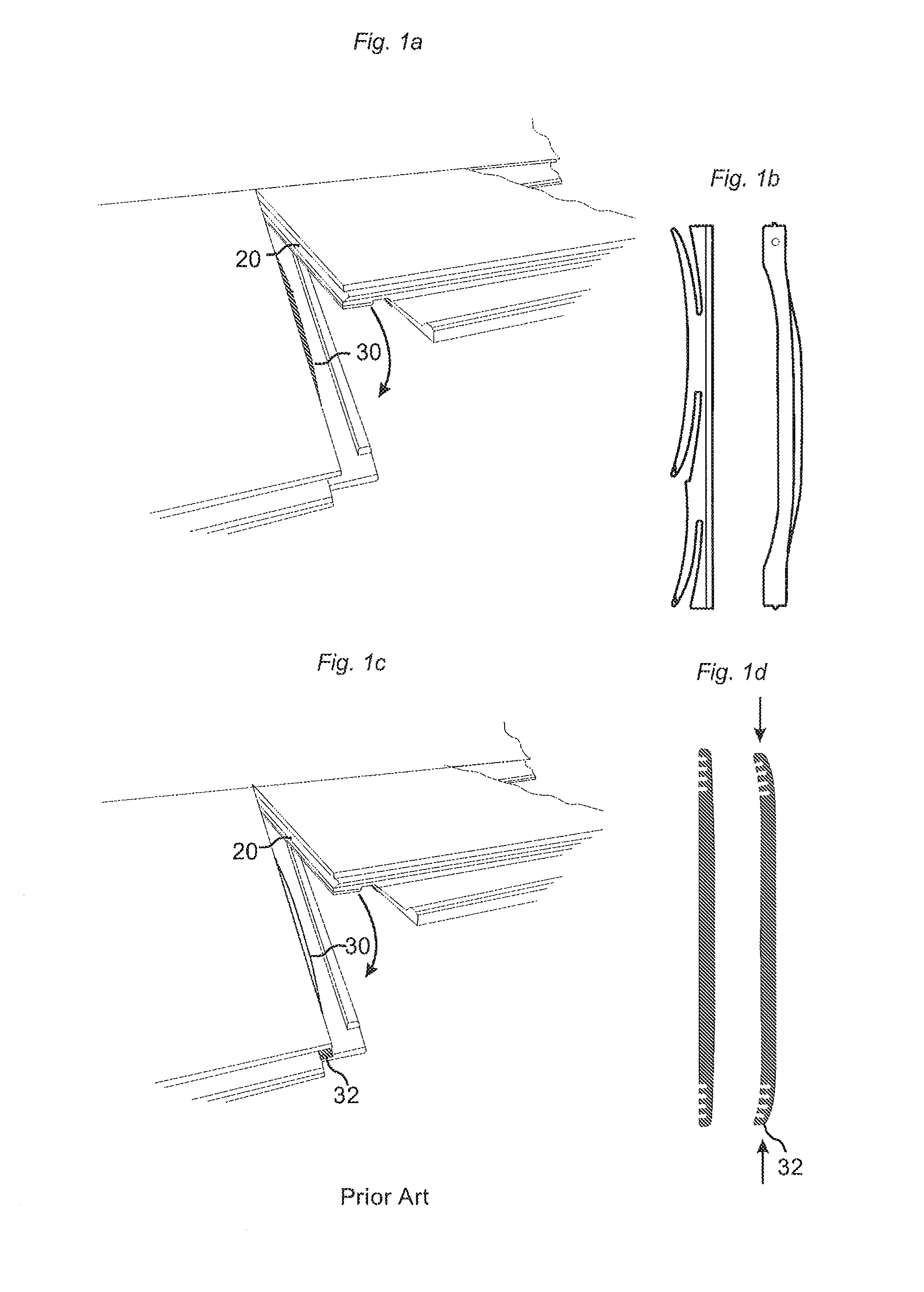

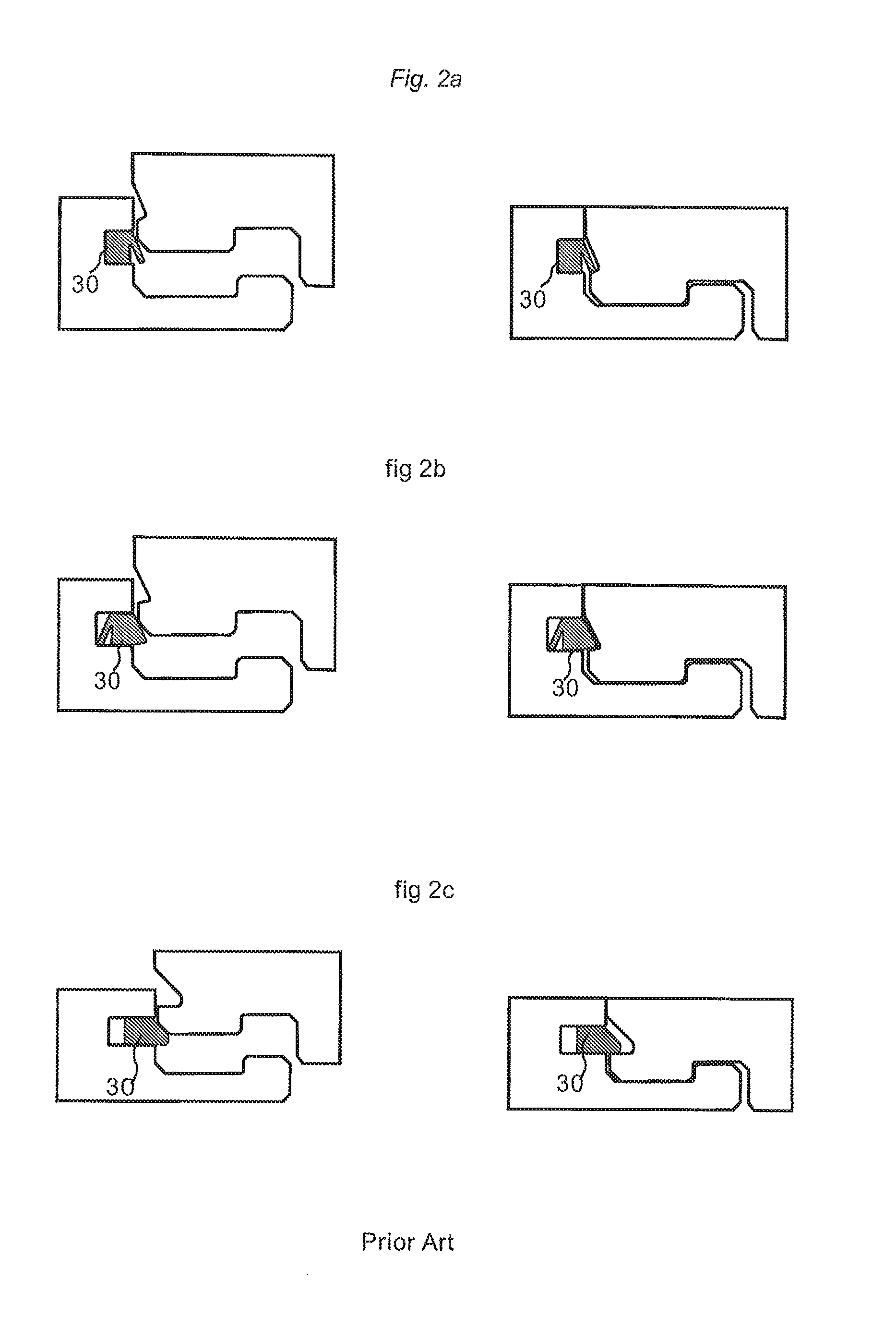

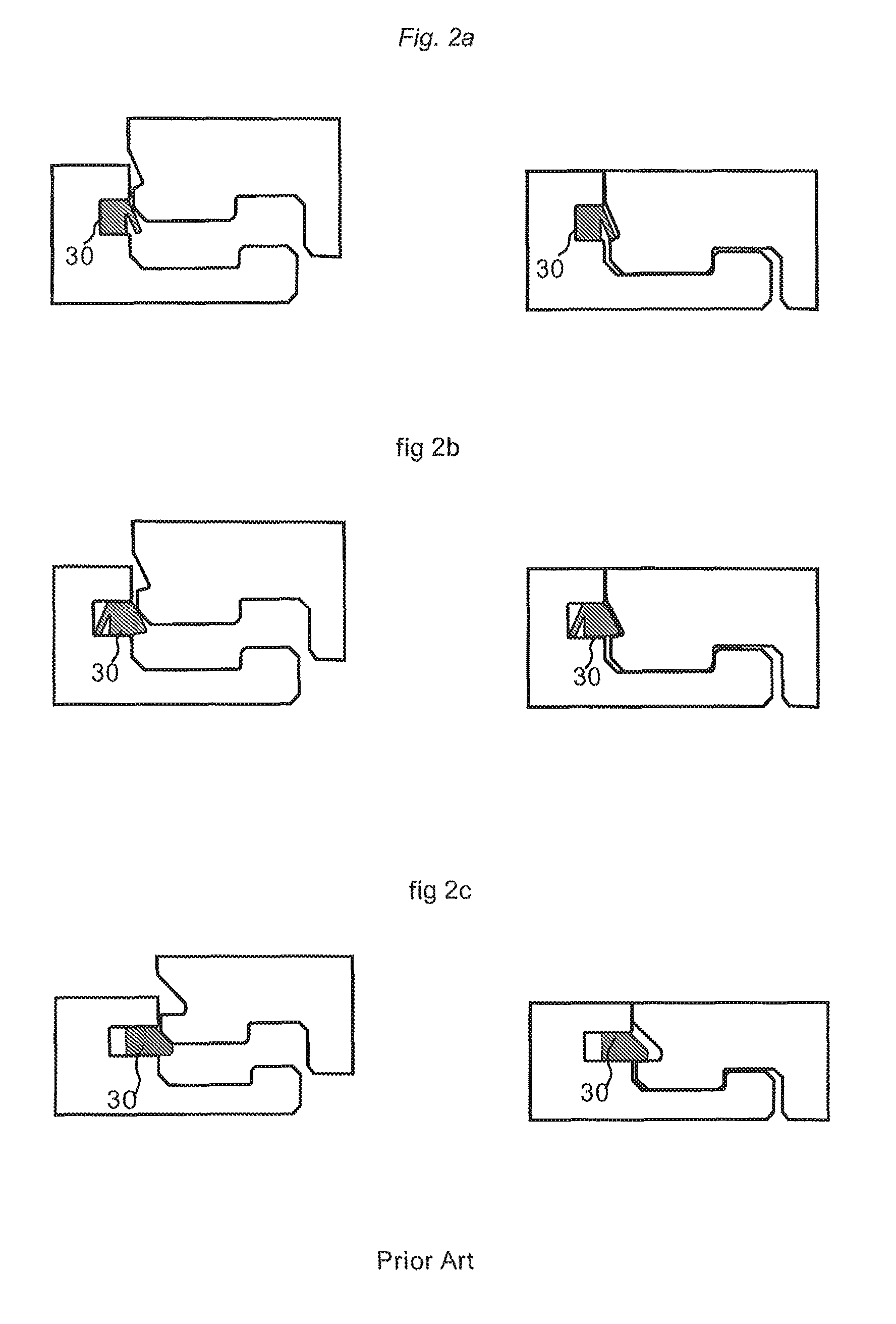

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

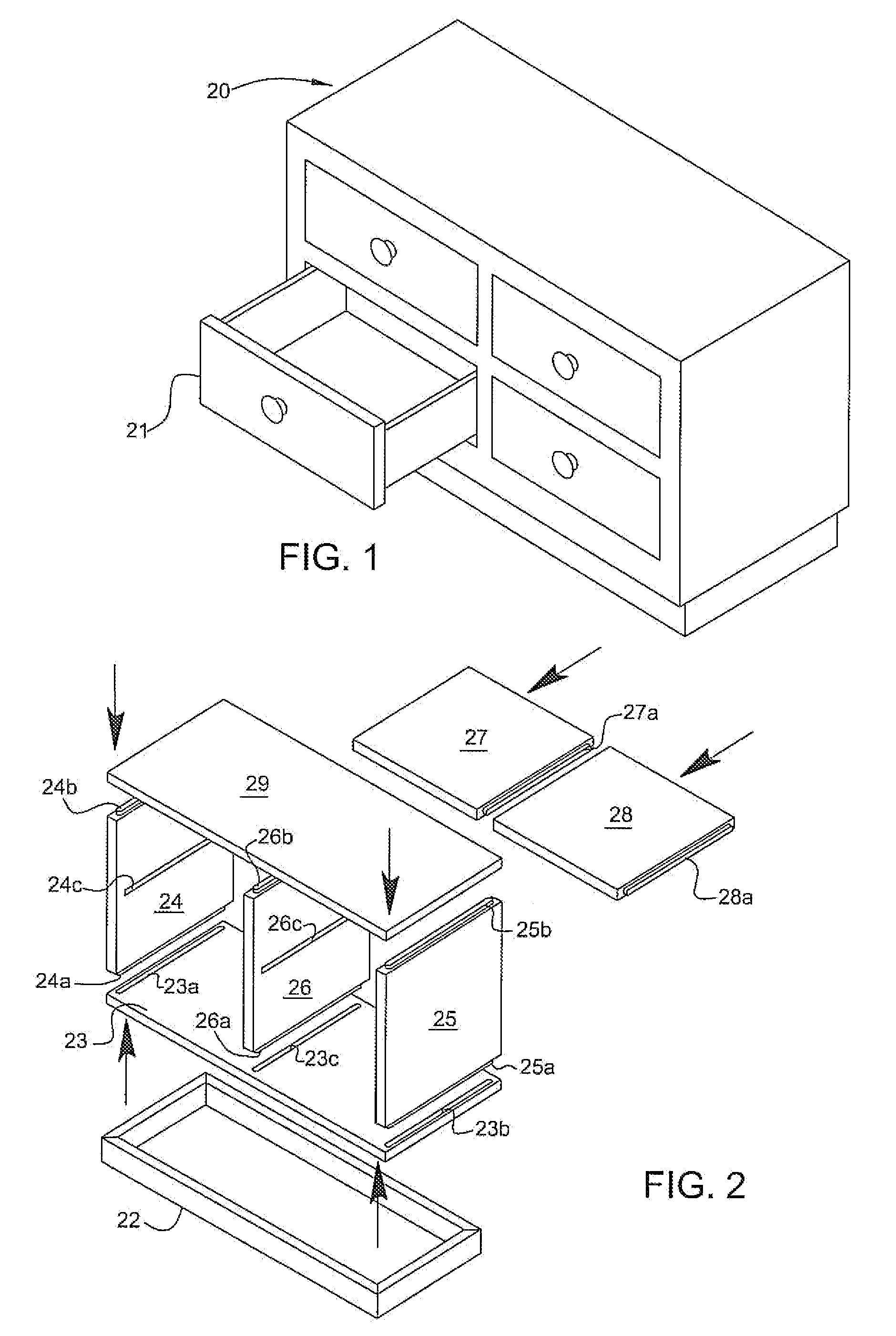

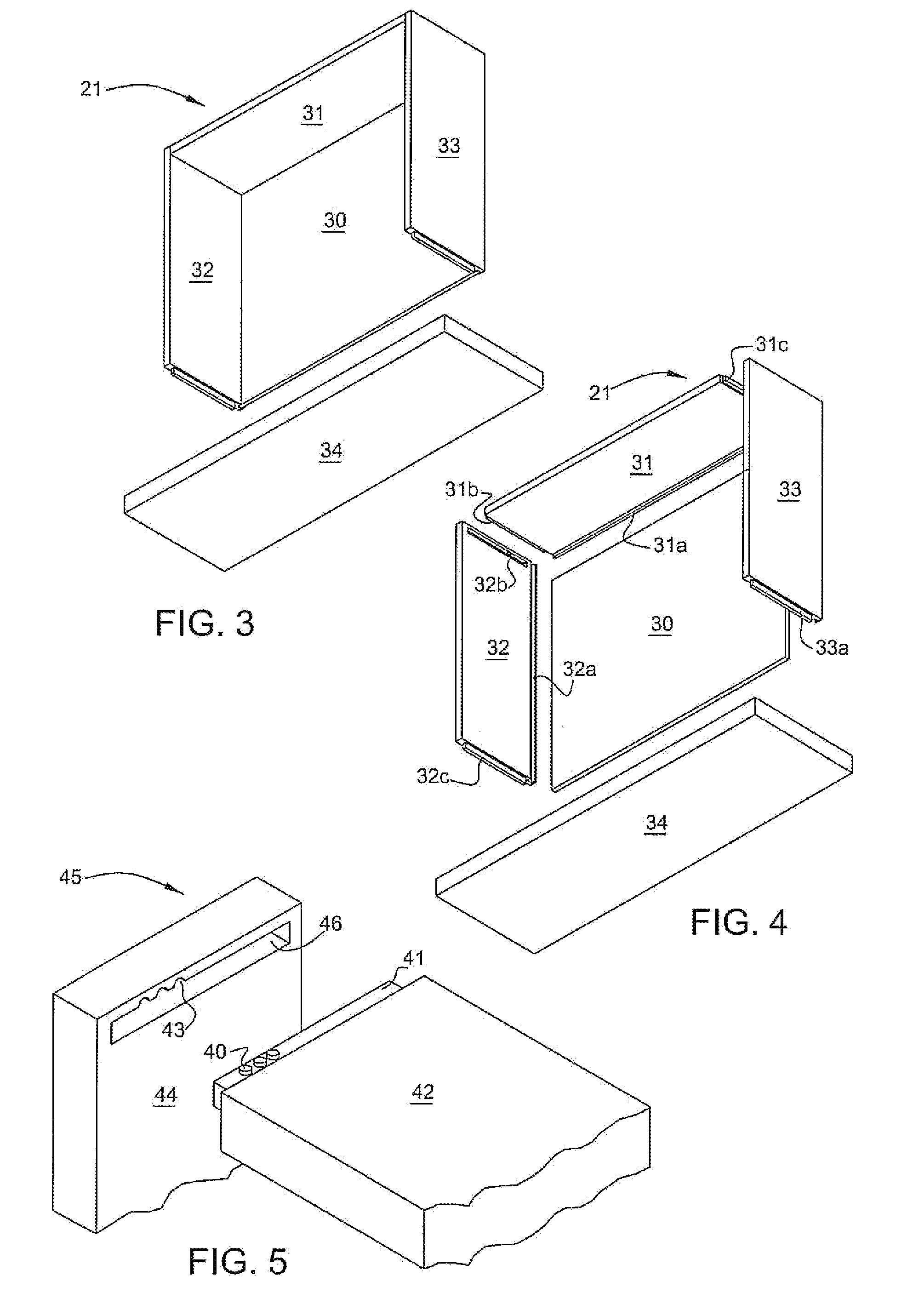

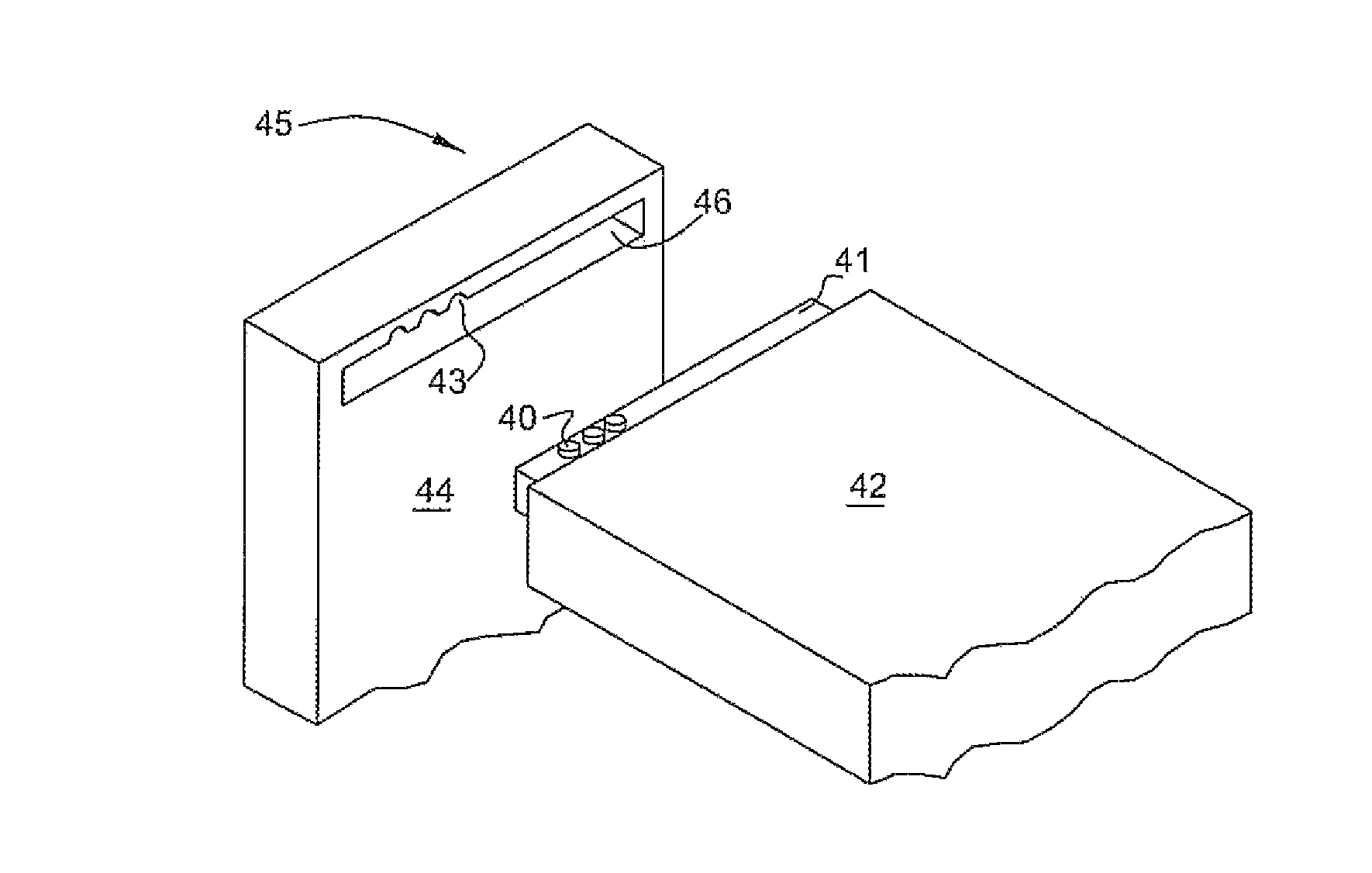

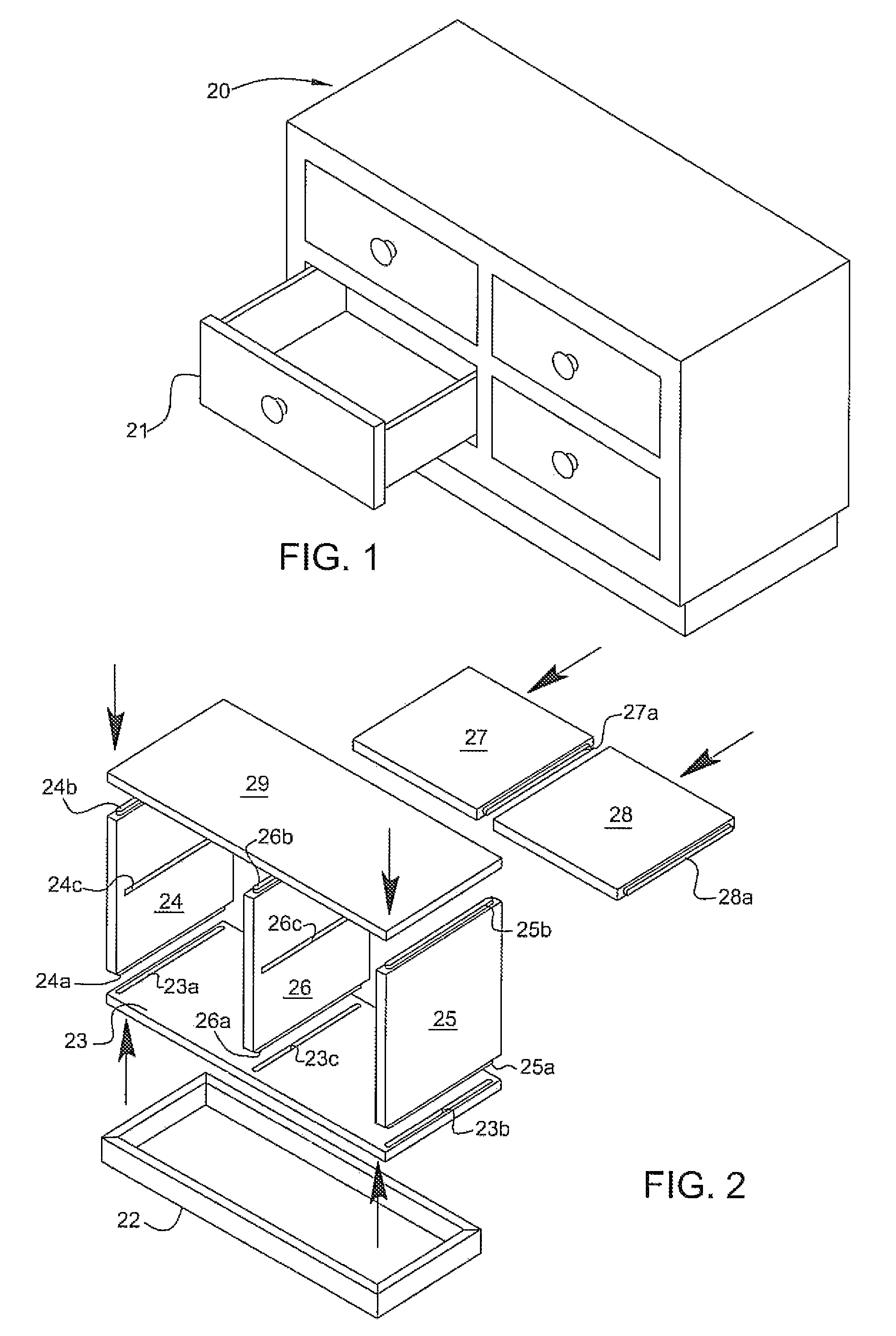

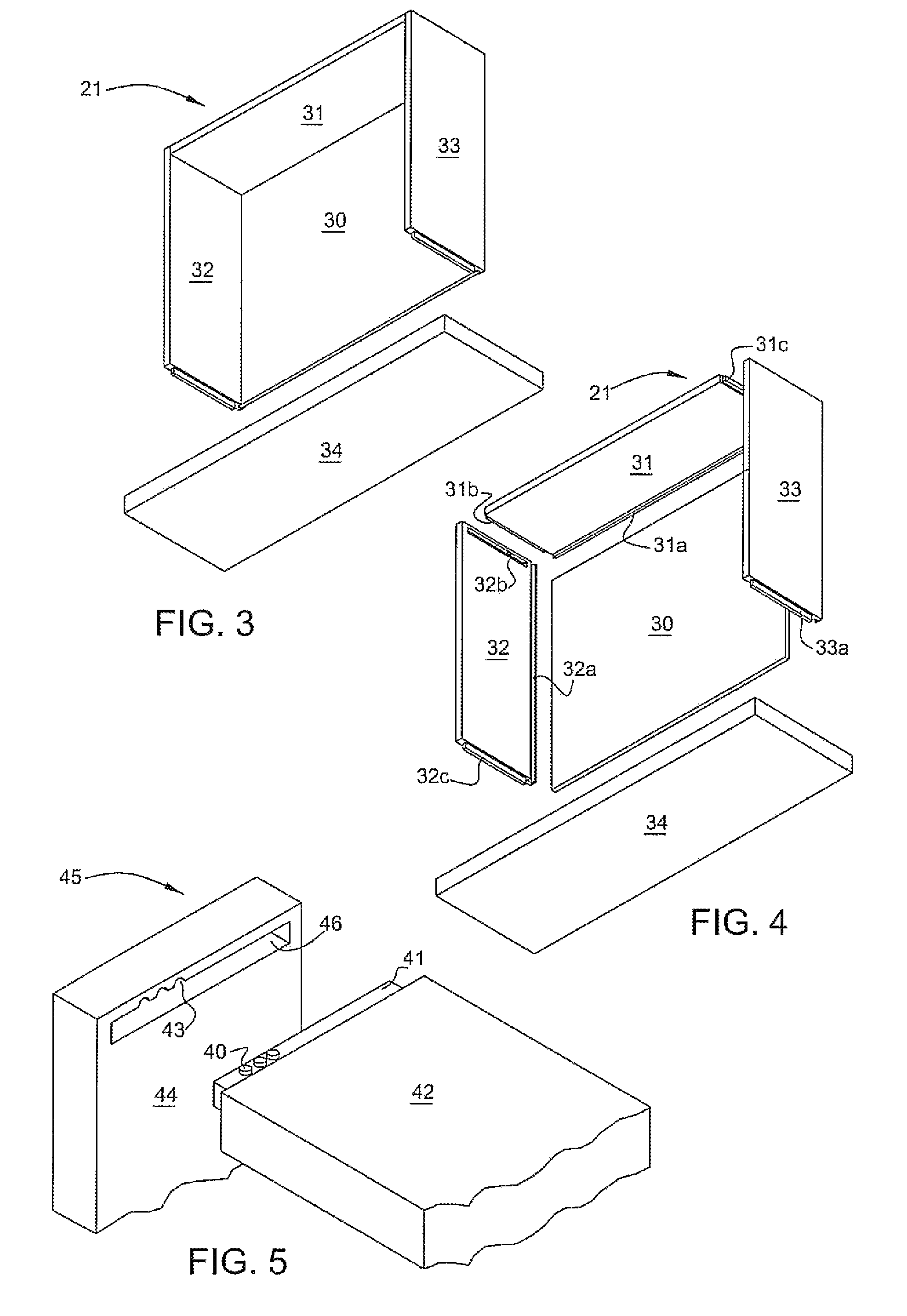

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

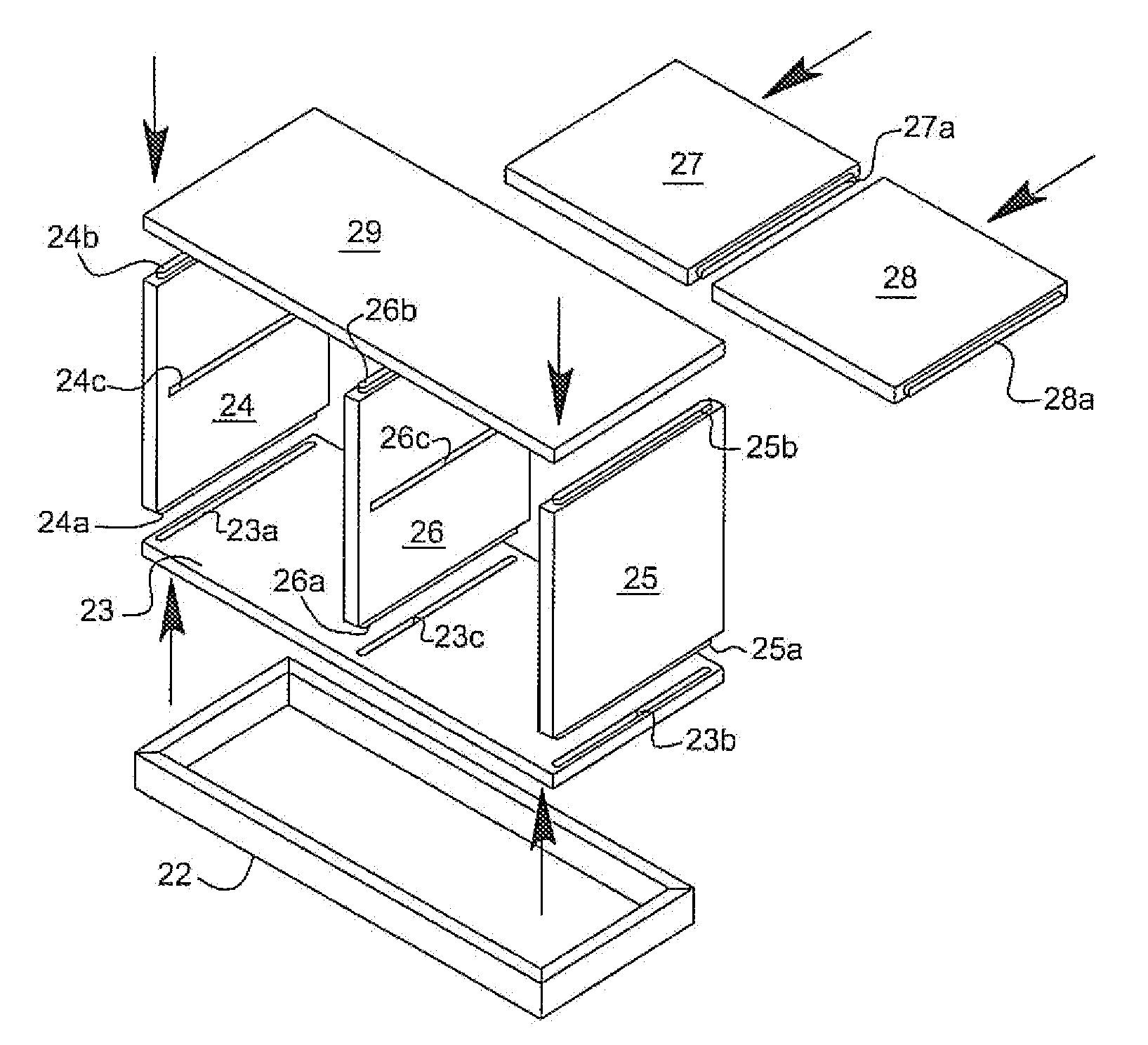

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

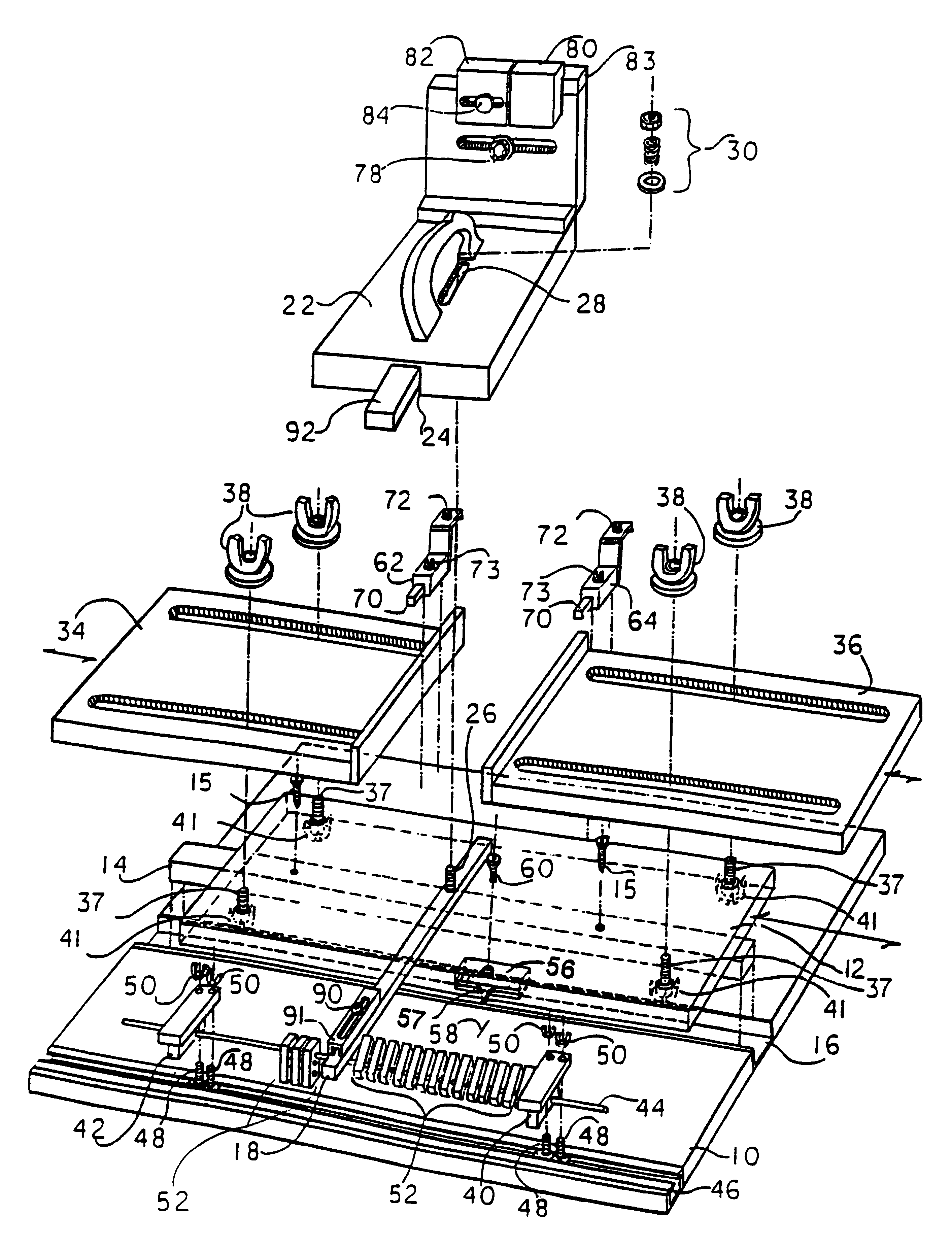

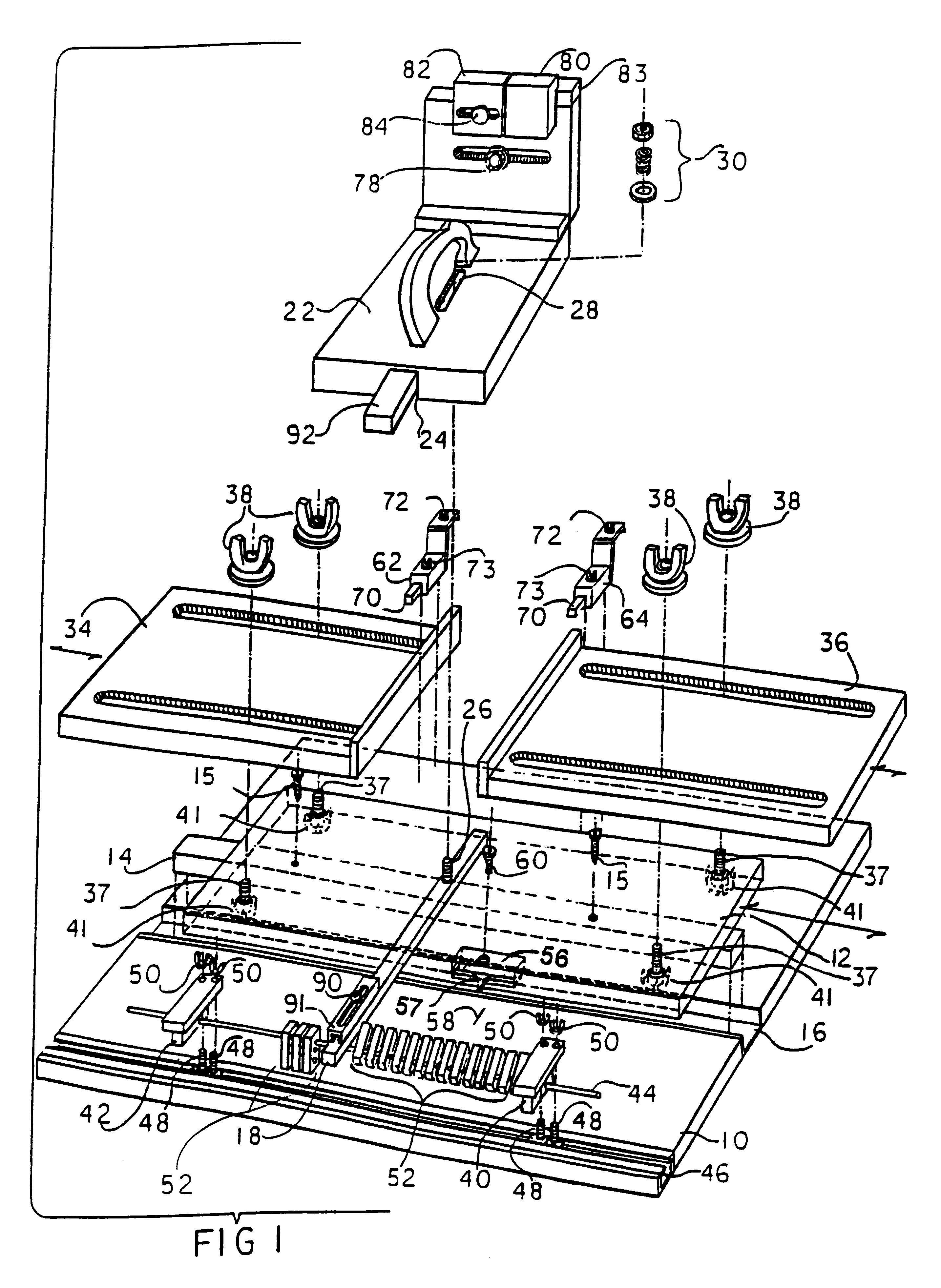

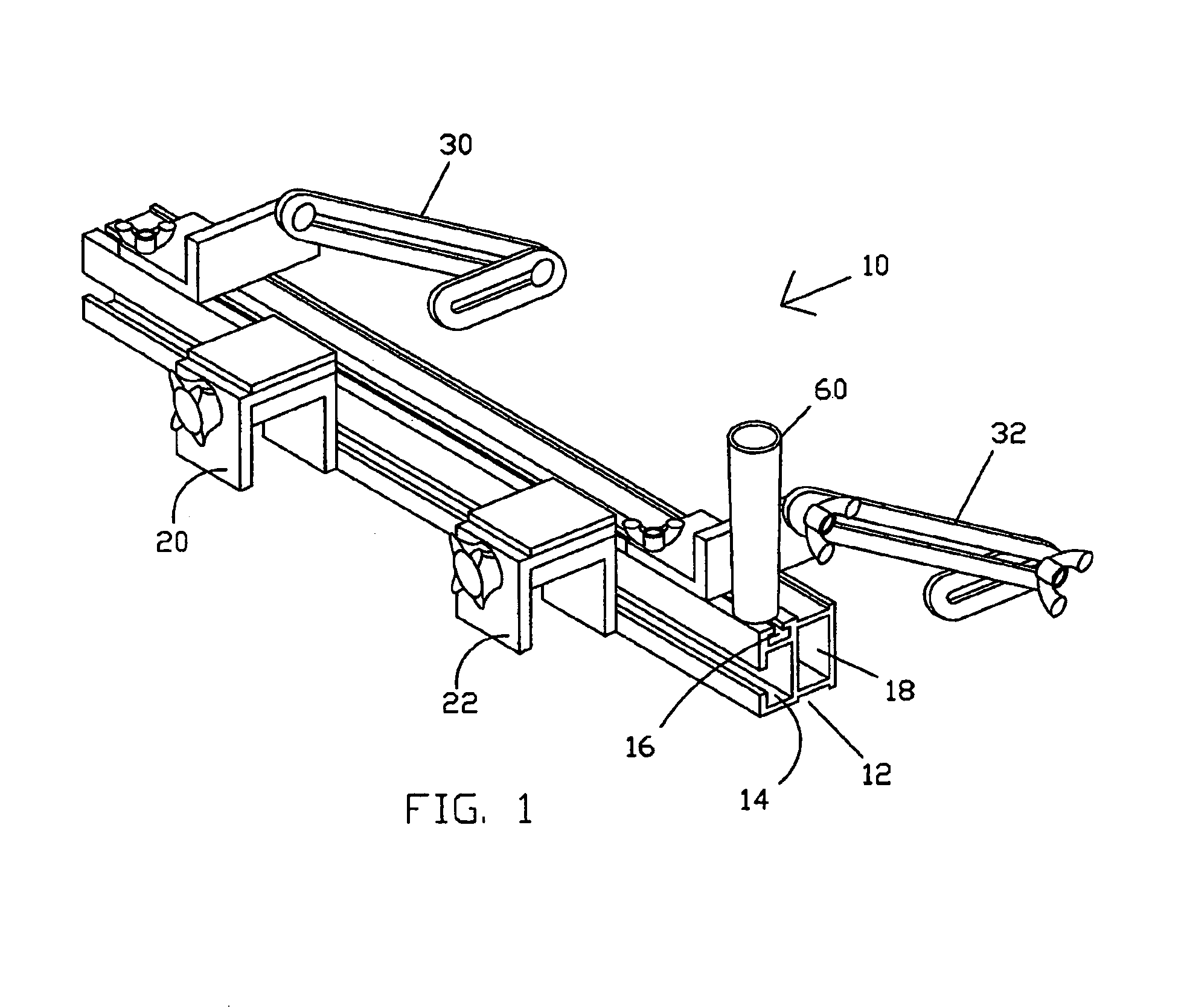

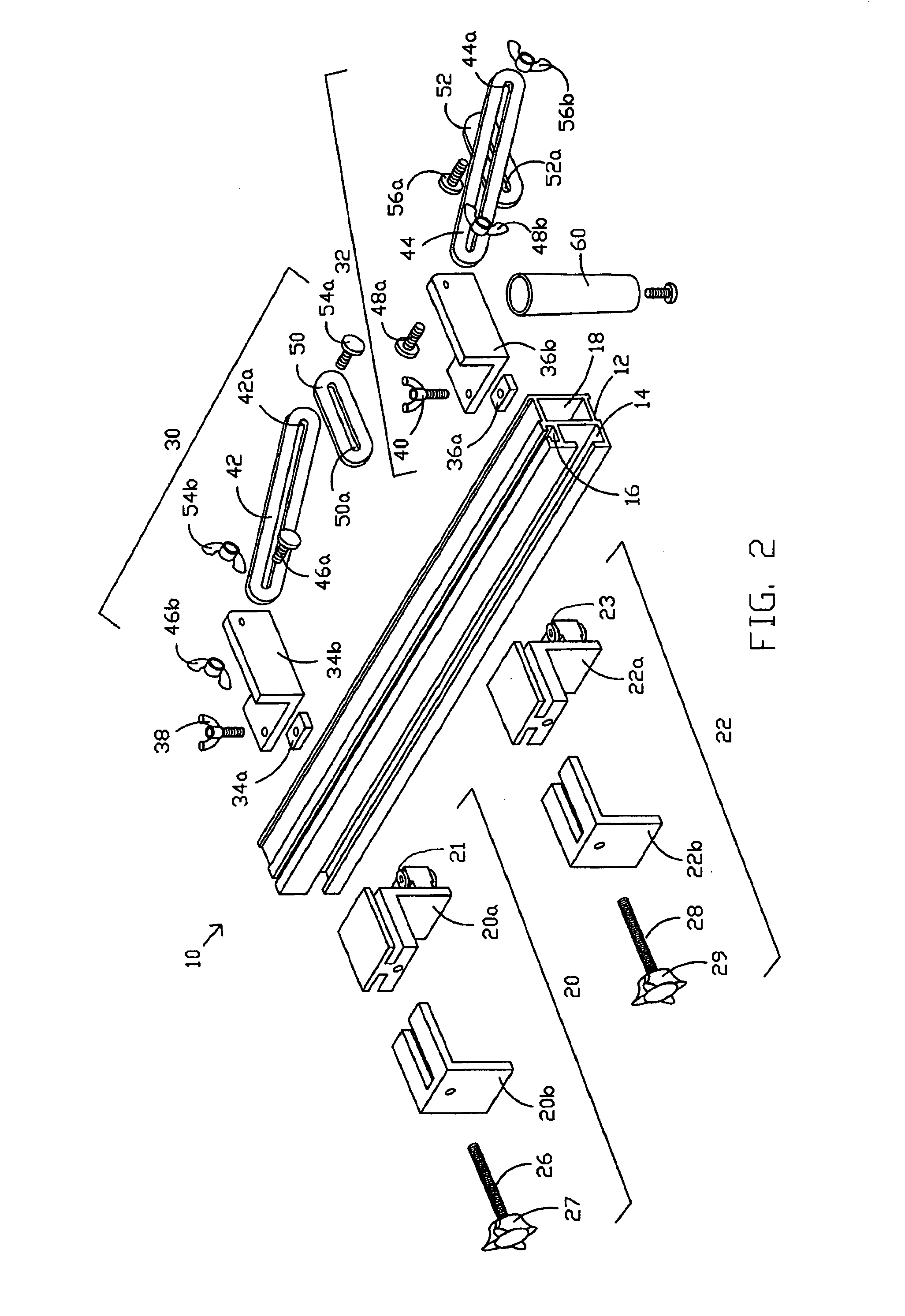

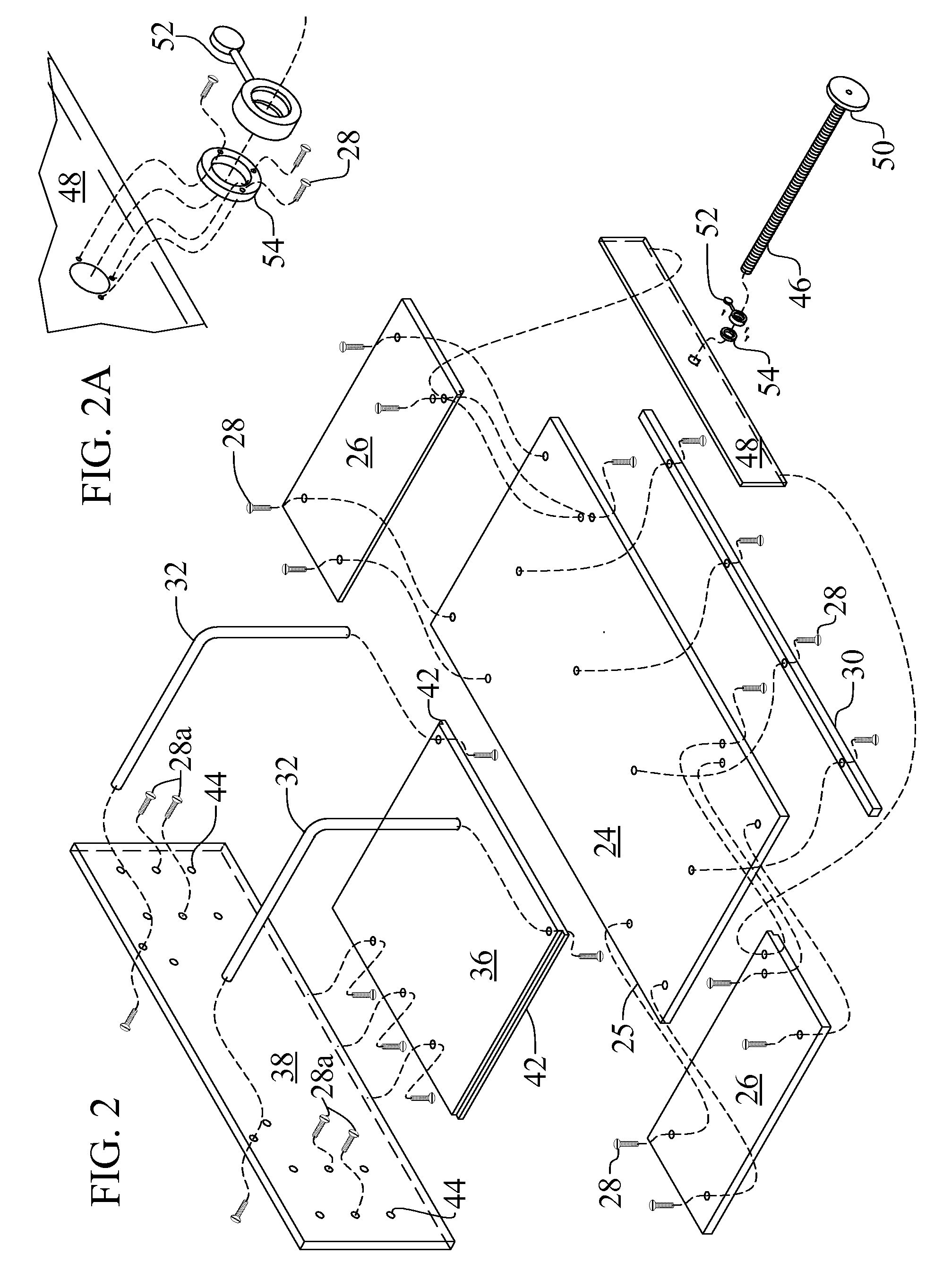

Jig system for positioning the placement of multiple cuts in a workpiece

InactiveUS6206060B1Reduce lateral movementGreat accuracy positioningDrilling/boring measurement devicesTongue/grooves making apparatusEngineeringDovetail joint

The present invention is a jig system for precisely positioning the placement of multiple cuts such as in the placement of dovetail or box joints cut in a wood panel. A row of multi-use adjustable spacers controls the indexing of a workpiece and can be used with a stationary and / or a portable cutting tool. The movability of the spacers permits a workpiece to be cut on both sides of a guide bar fence thereby assuring that the first cut will always be made on the same side of a drawer and will be esthetically pleasing regardless of the width of the workpiece. Additionally, the adjustability of the spacers accommodates any desired cutting tool height, angle and / or size. The jig system comprises: a stationary fixture; a spacer bar; a plurality of spacers engaged with the spacer bar, the spacers are adapted for lateral and rotational movement along the spacer bar thereby providing an engaged and non-engaged working mode; a sliding member adapted for lateral movement on the stationary fixture and for engaging at least one of the spacers in the engaged working mode; and means for holding the spacer bar and connecting the spacer bar to the stationary fixture while engaging with at least one of the spacers during the engaged working mode.

Owner:BLAKE F RICHARD

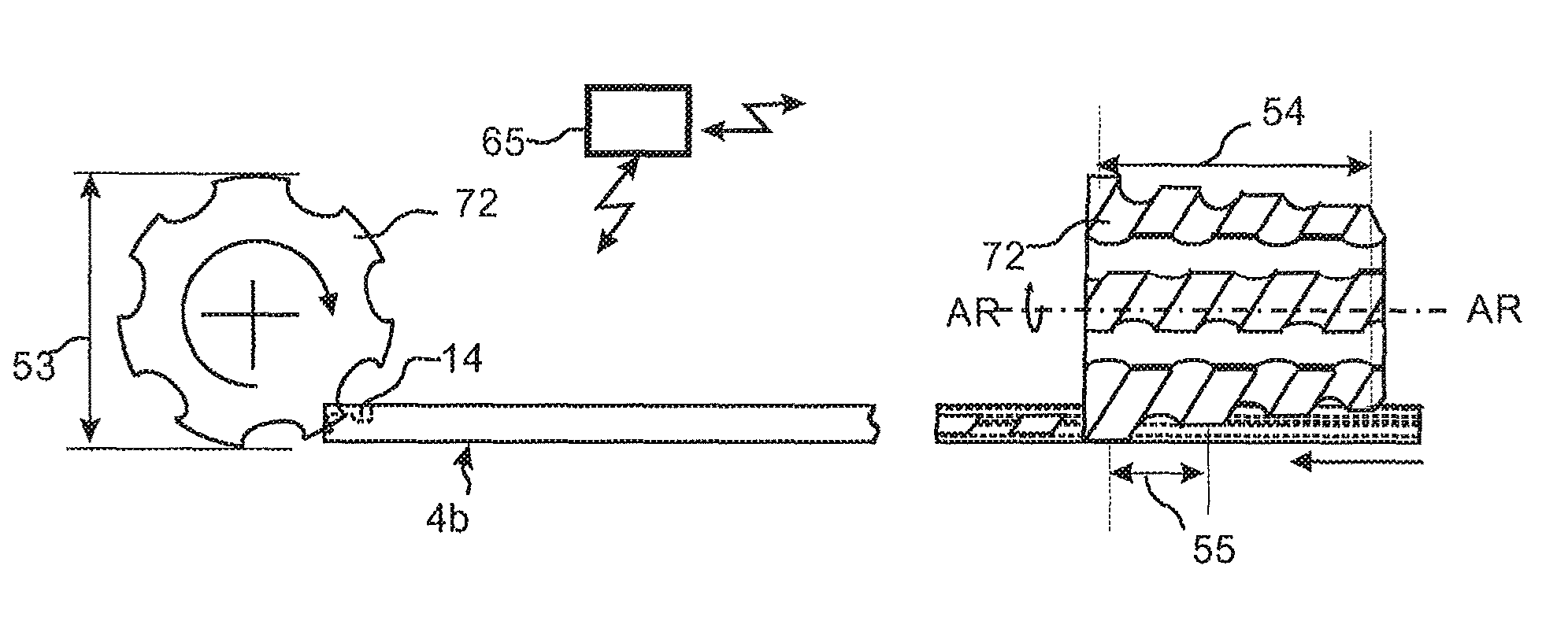

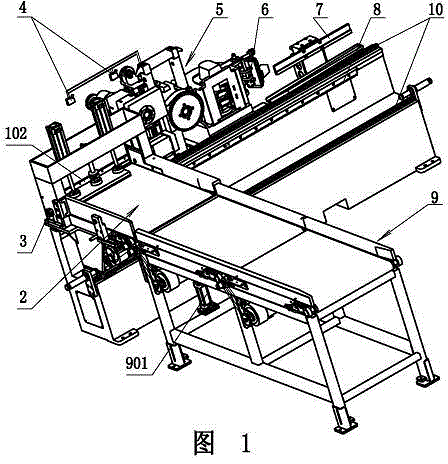

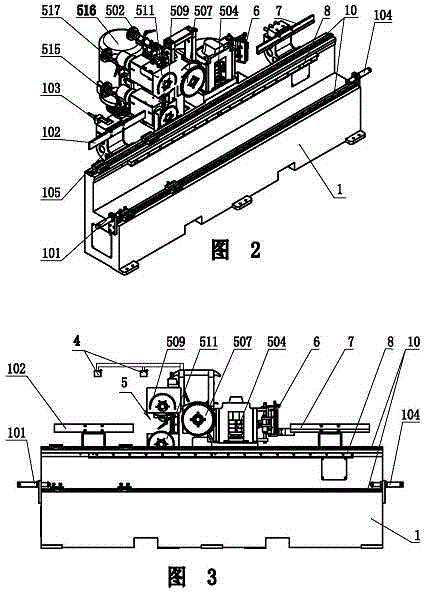

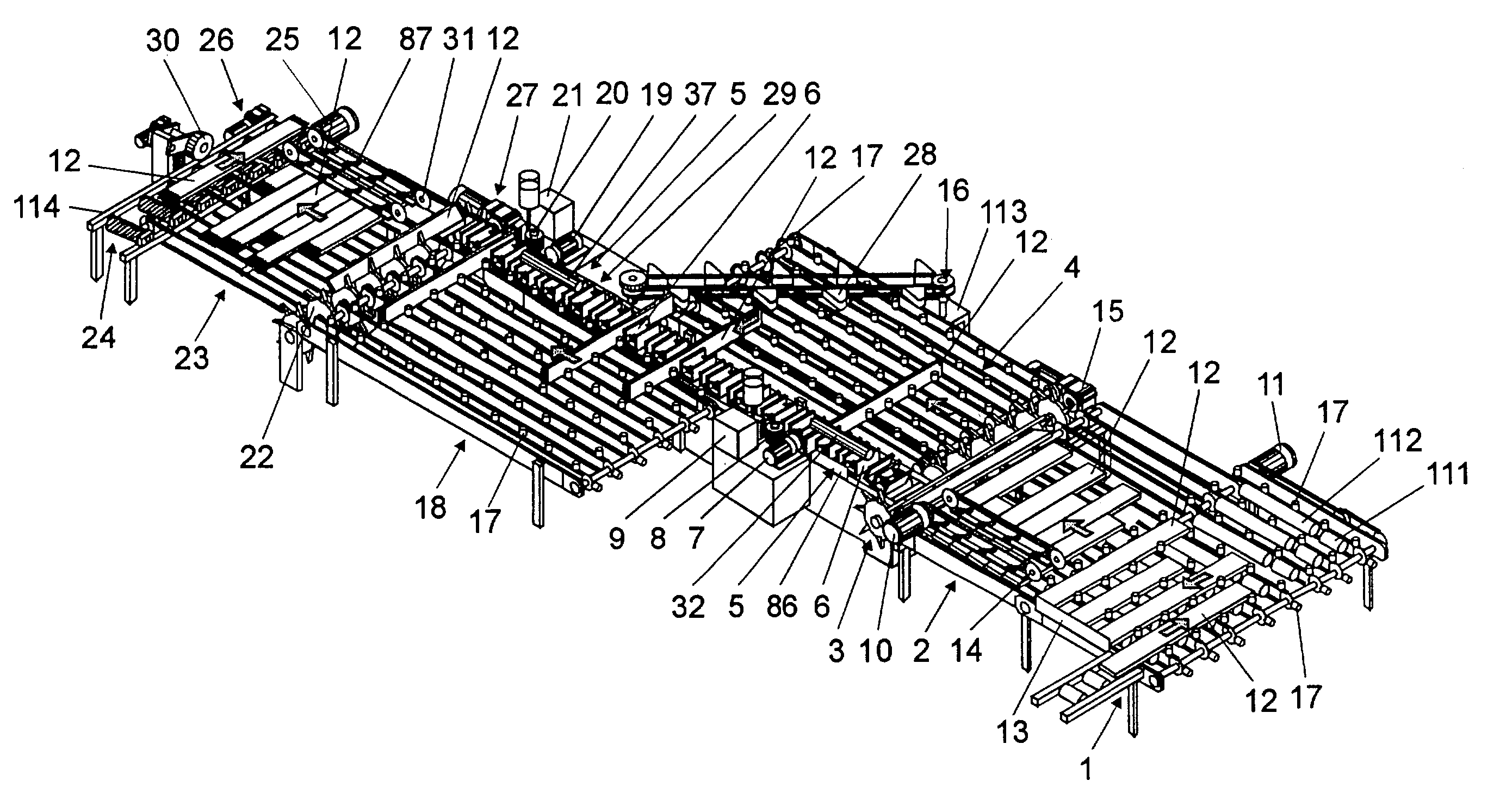

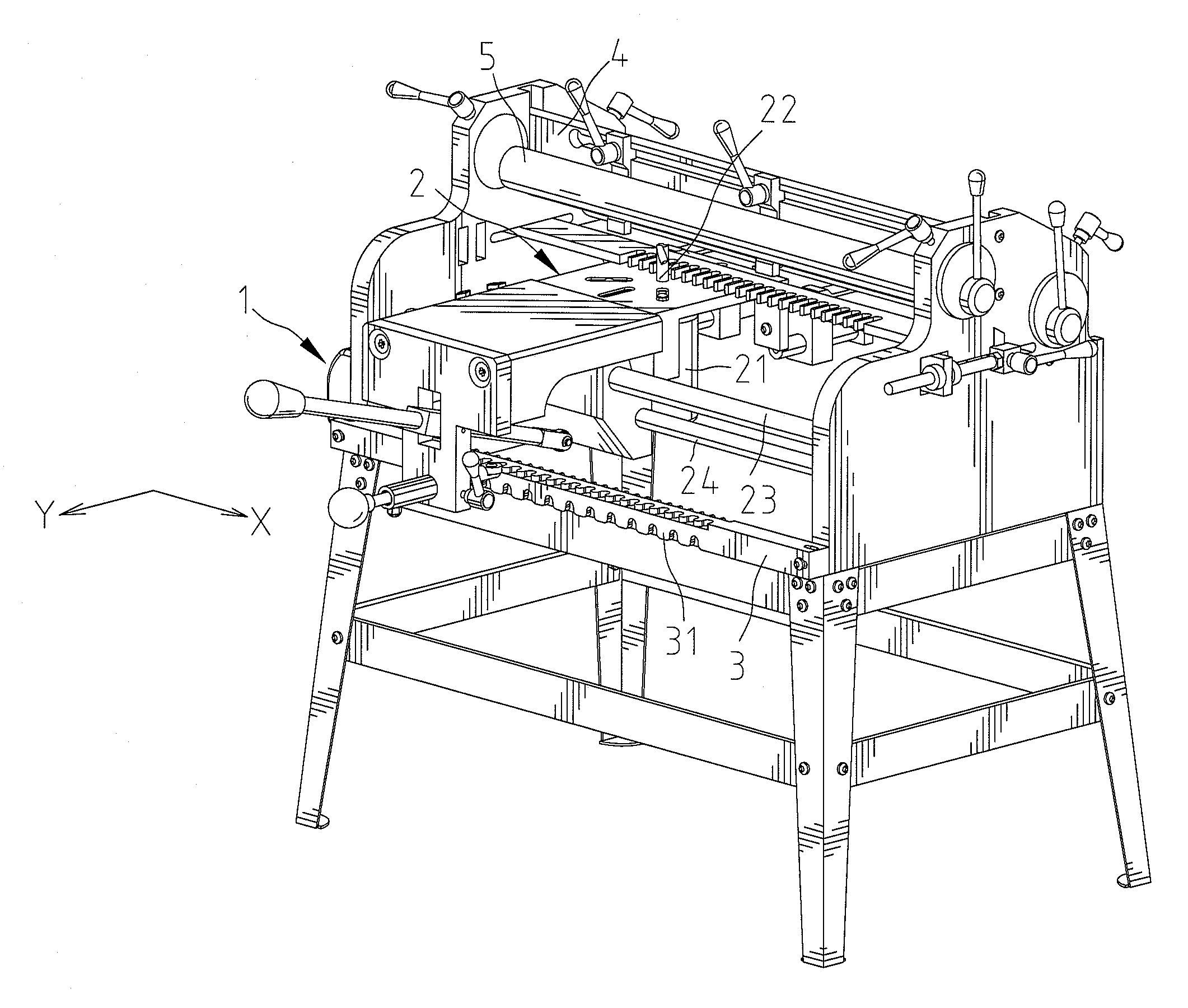

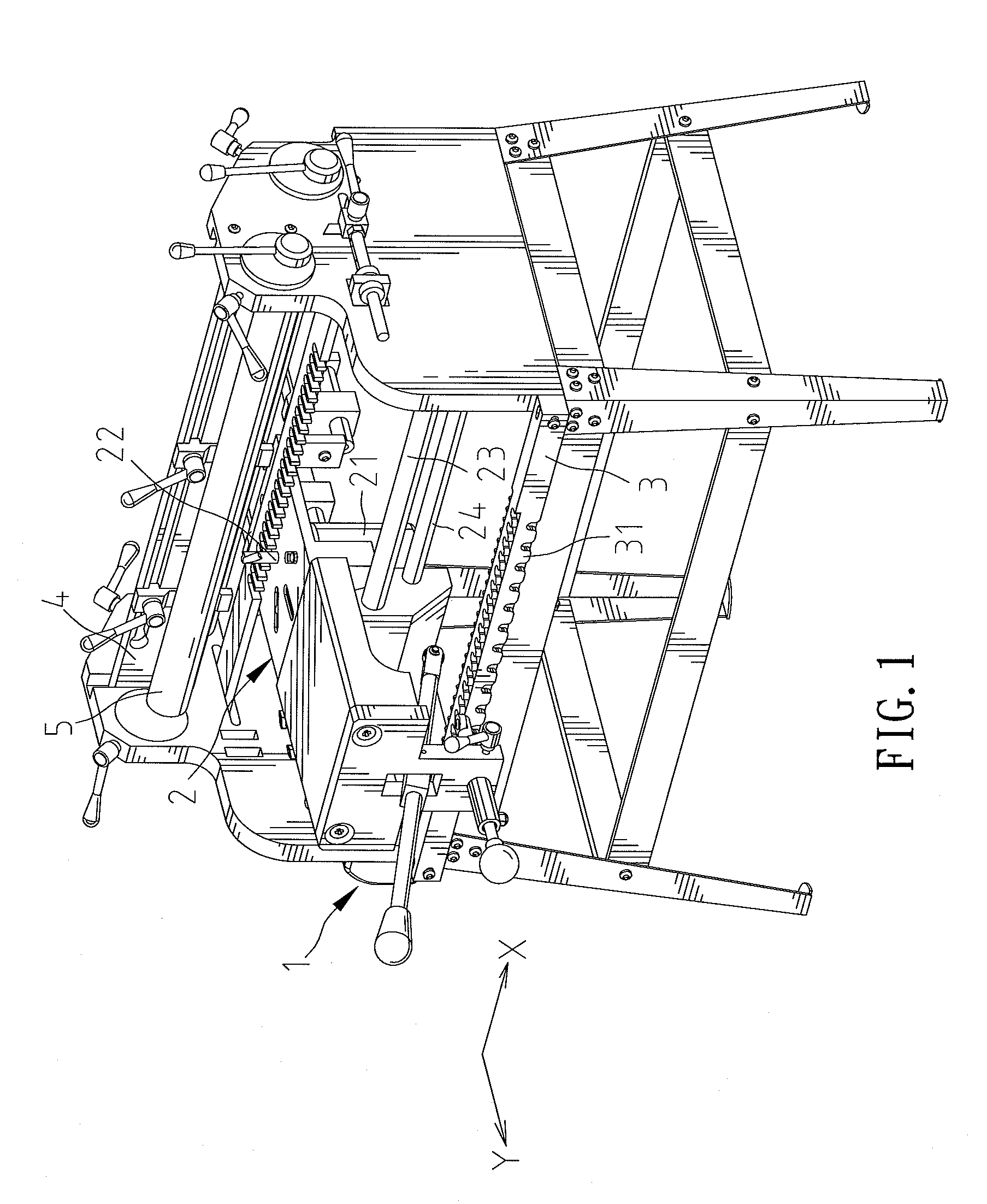

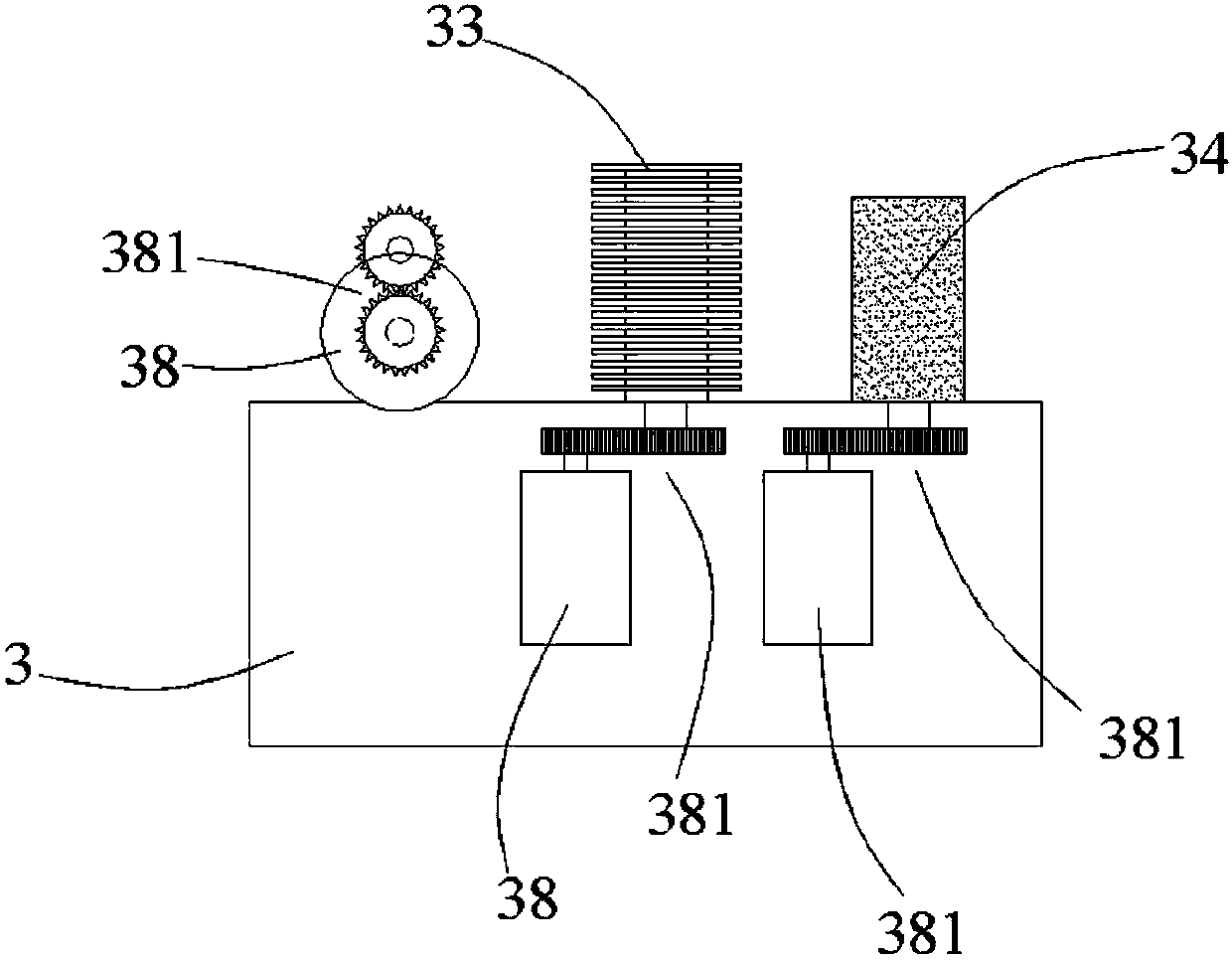

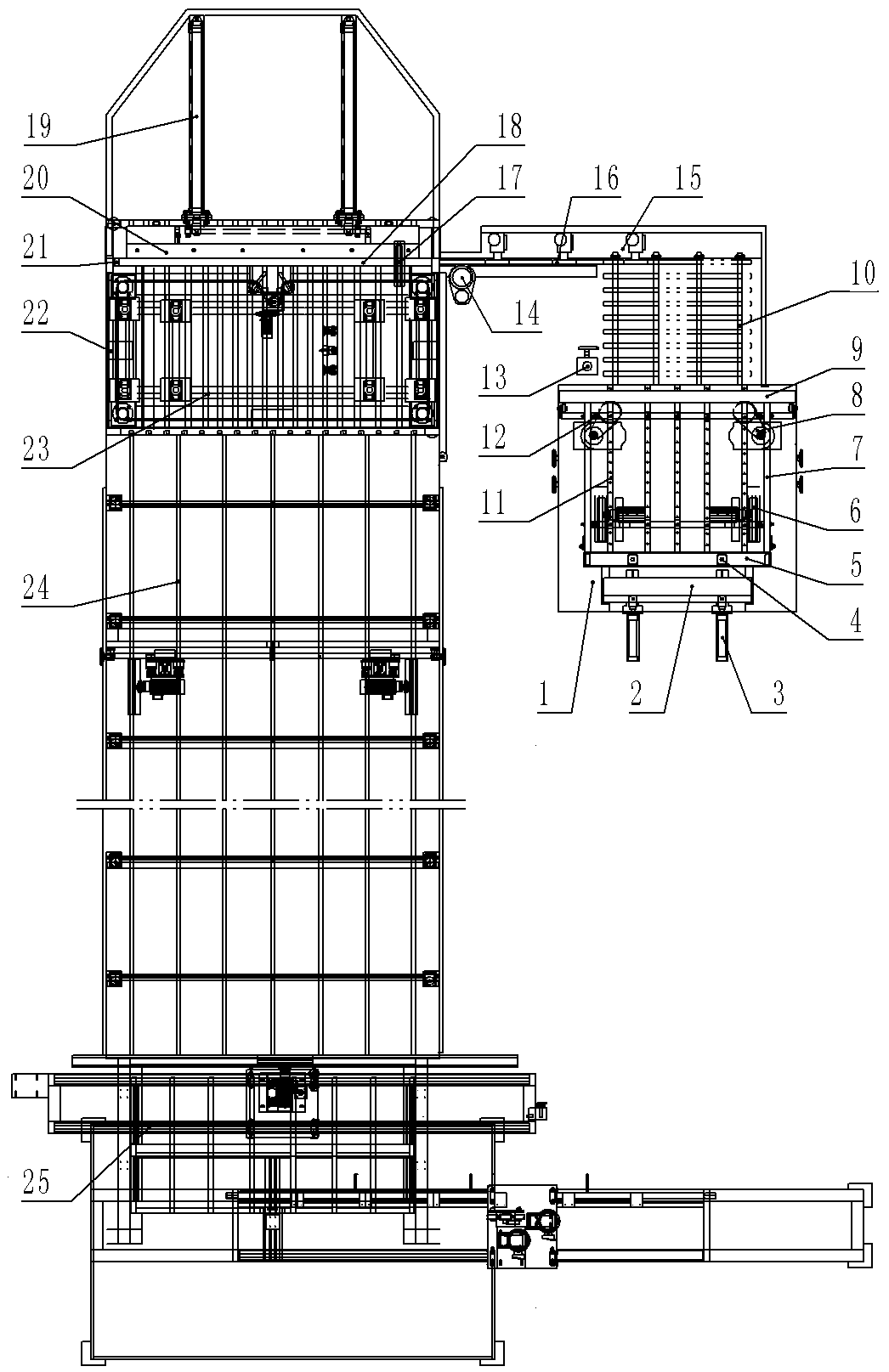

Finger-tenon combing machine of finger-joint material

ActiveCN103978527AConvenient continuous feedingEasy to tidyFinger joining apparatusGear driveFinger joint

The invention discloses a finger-tenon combing machine of a finger-joint material. The finger-tenon combing machine is characterized in that a movable sliding rail is arranged on a combing machine tool body; a pressing clamping plate is supported on a movable platform frame by a pressing cylinder; the pressing clamping plate and a feeding platform surface form a material clamping jaw for clamping wood materials to be combed; one side of the material clamping jaw is provided with a side pressing plate; the movable platform frame is also provided with a towing gear driven by a motor of a movable working platform; the towing gear is in meshed transmission with the towing gear; a tooth-tenon combing and milling device is also provided with an upper wire-groove saw blade and a lower wire-groove saw blade; the horizontal plane of a saw shaft for cutting the saw blades is positioned between the horizontal plane of a saw shaft of the upper wire-groove saw blade and the horizontal plane of a saw shaft of the lower wire-groove saw blade; the tooth-tenon combing and milling device is also provided with a neat-end control sensor; the movable clamping working platform is provided with a feeding control sensor. The finger-tenon combing machine disclosed by the invention has the advantages that the processing accuracy and the wood-material utilization rate are high, the processing quality of the surfaces of the wood materials is excellent, and the whole-machine operation efficiency is high.

Owner:JIANGSU JIANGJIA MACHINERY

Guide for a cutting tool

InactiveUS7127976B1Cutting and similar operationEasy to cutDovetailed workMulti-purpose machinesEngineeringKnife blades

A guide comprises one or more brackets for securing the guide to a cutting tool, a horizontal support member secured to and moveable with respect to the brackets, and one or more arm assemblies secured to the horizontal support member and adapted to secure a working piece relative to the horizontal support member. With the working piece secured to the guide in this manner, the working piece may be readily advanced over a blade of the cutting tool by grasping and moving the horizontal support member relative to the brackets, thus ensuring a precise cutting of the working piece while also allowing a user to keep their hands away from the blade.

Owner:FITZSIMMONS GEORGE

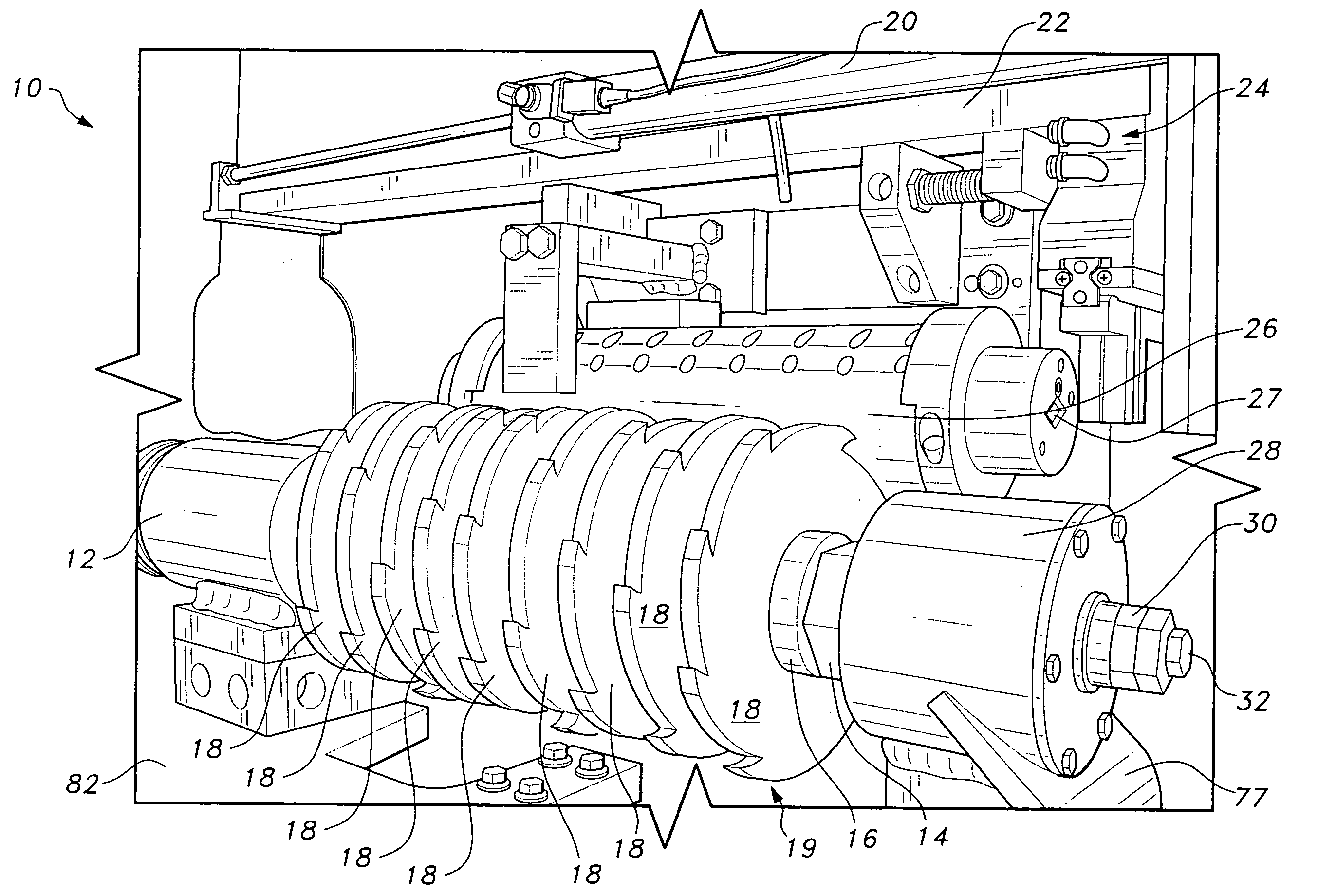

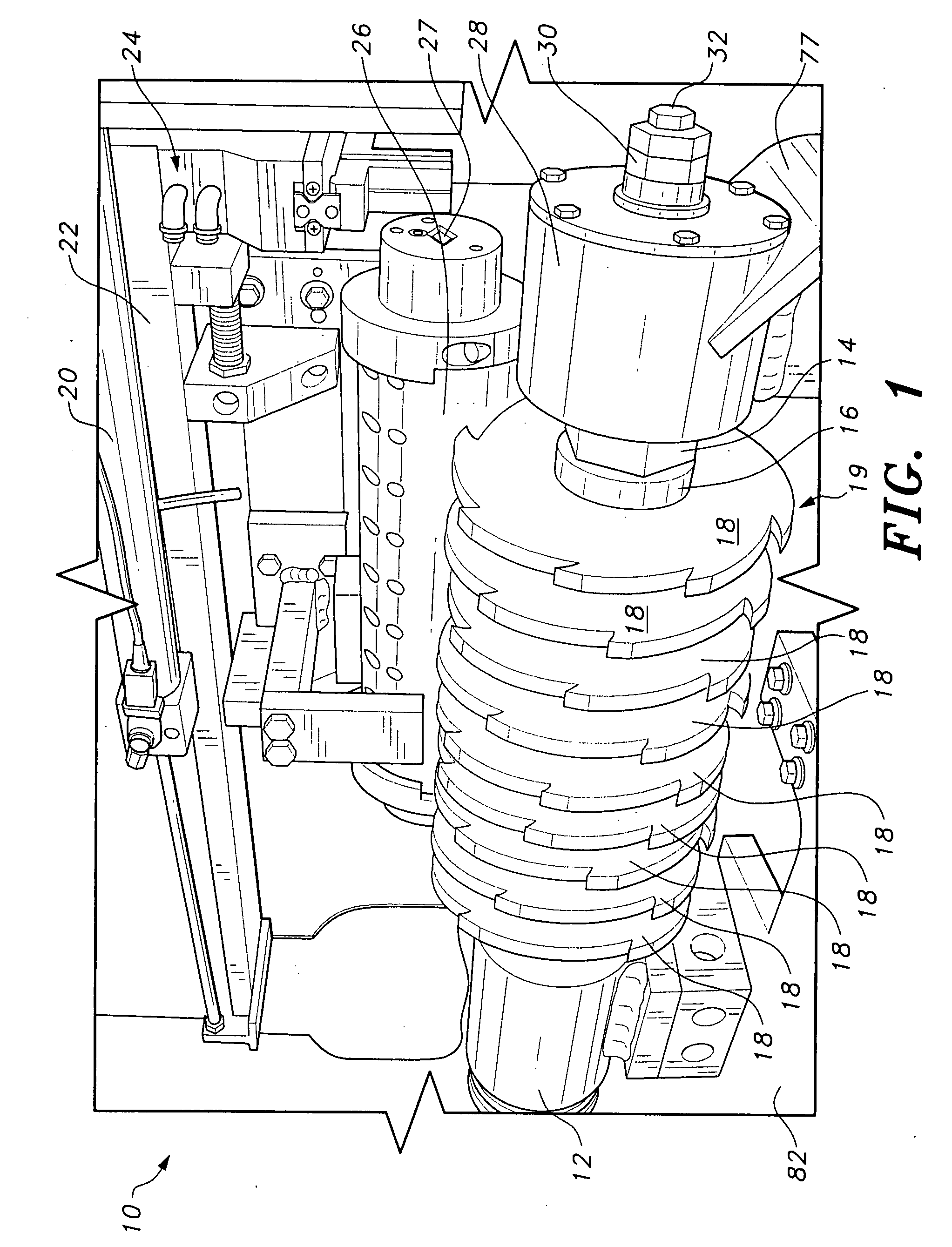

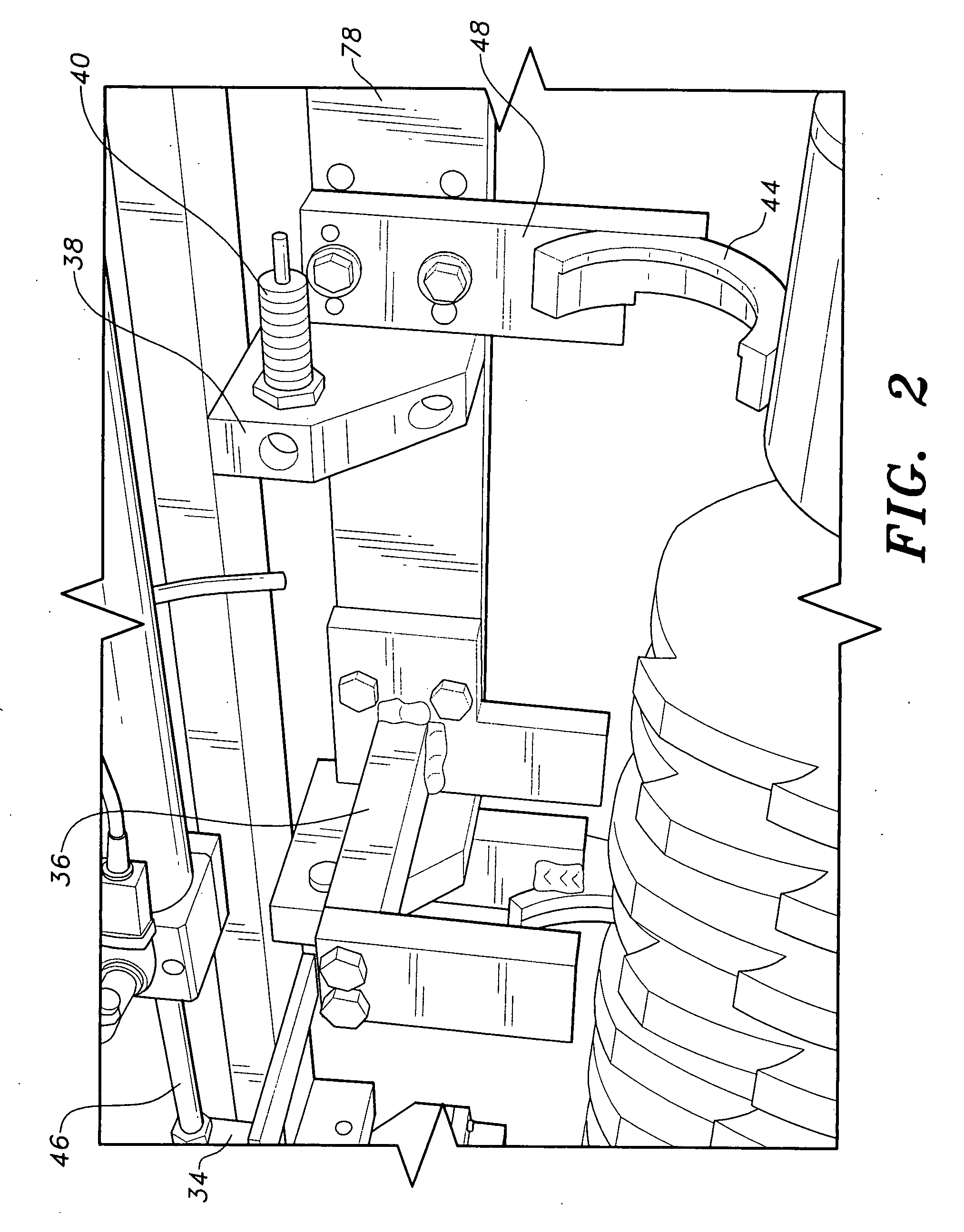

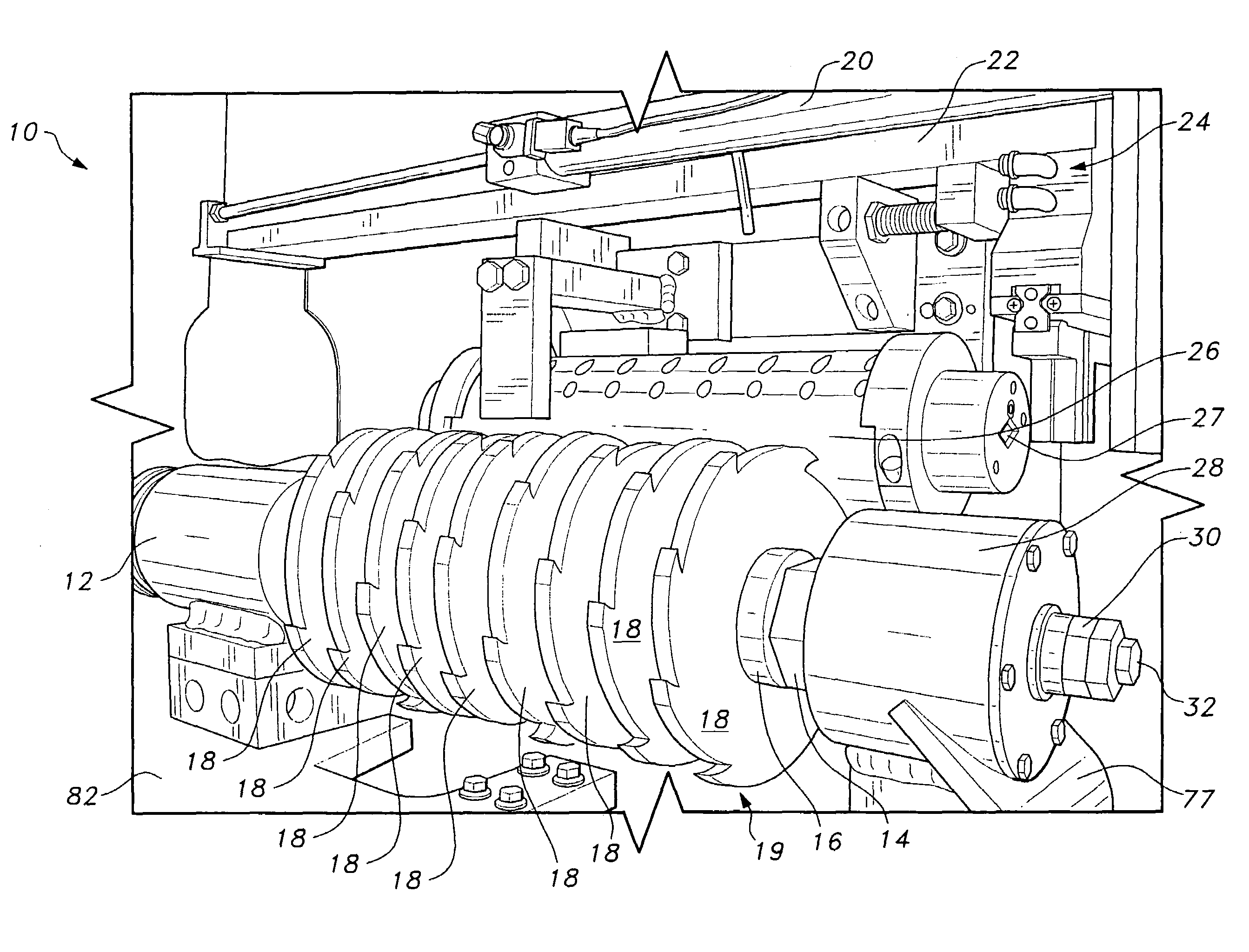

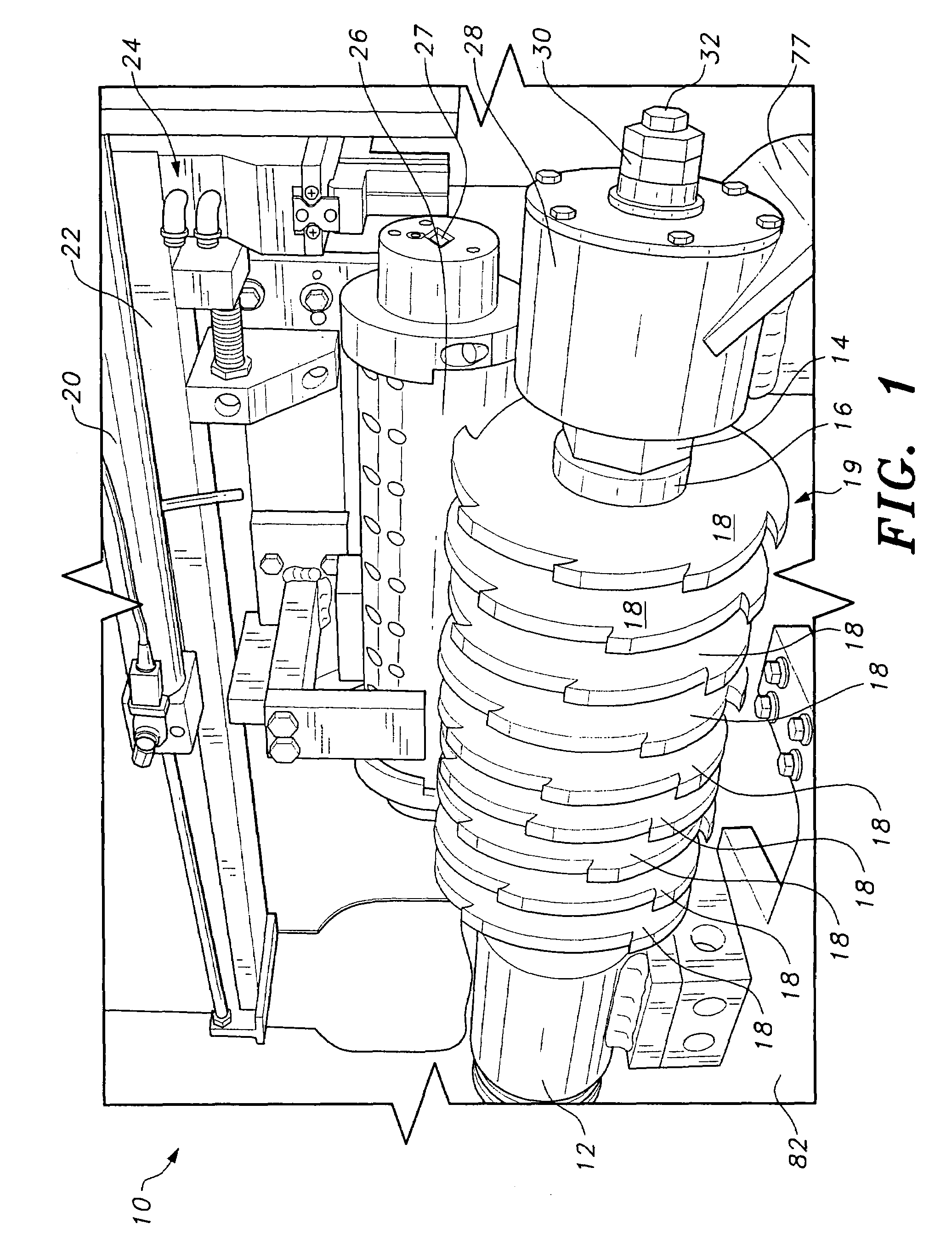

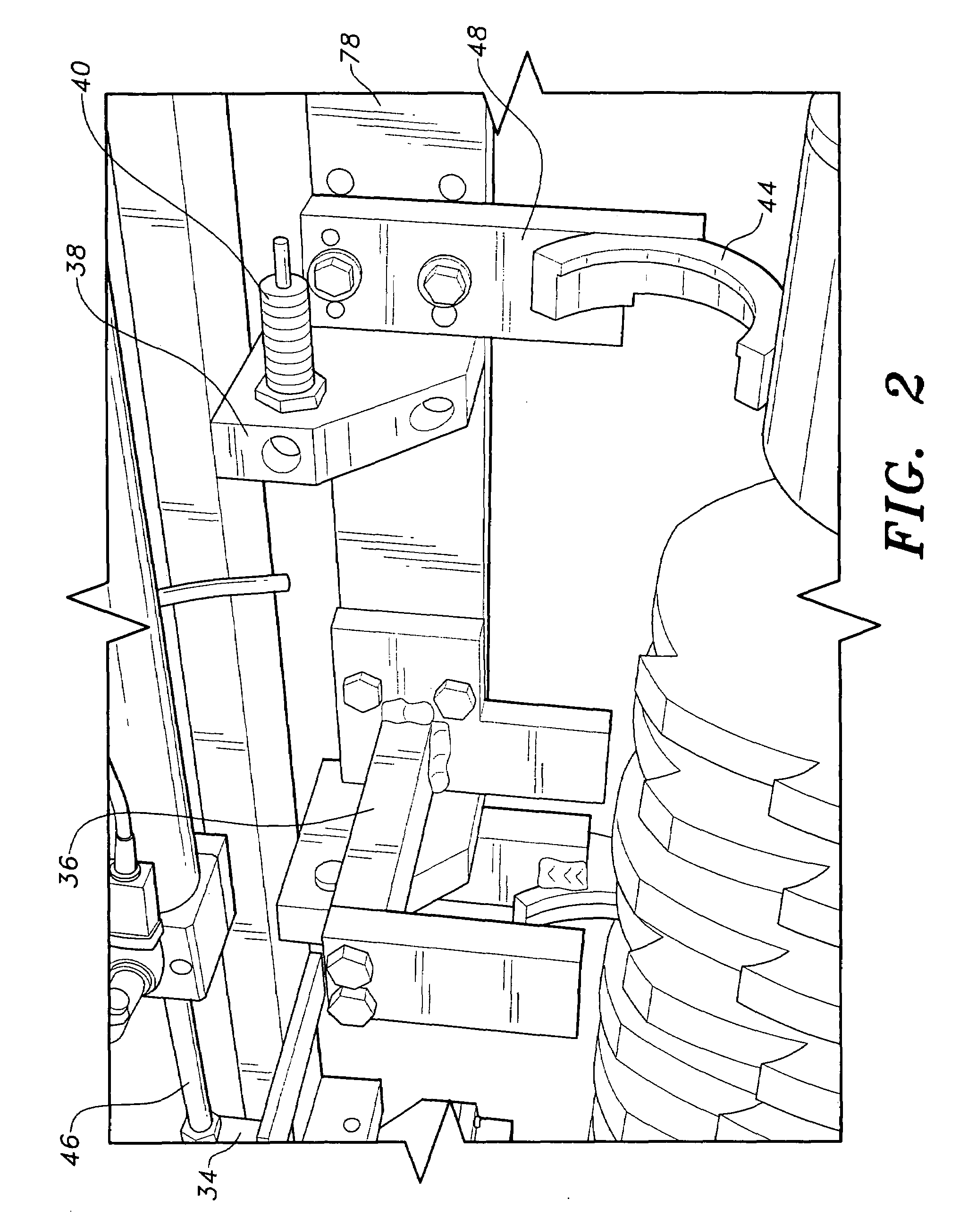

Woodworking machine for shaping molding

The woodworking machine for shaping molding has a hollow cylindrical cartridge with end caps having openings defined therein adapted for inserting a blank strip of molding through the cartridge. Robotic grippers advance the molding strip through the cartridge in indexed increments. A cutter assembly is mounted on a movable table, the cutter assembly having a plurality of spaced apart cutters. An electronic control system, preferably including a programmable logic controller, causes the grippers to grip the blank molding, insert the blank through the cartridge, actuate the cutter assembly and move the table so that the cutters simultaneously cut a plurality of notches in the molding, retract the cutter assembly, advance the molding the indexed distance, and automatically repeat the cycle, ejecting the strip when notches have been formed in the entire length of the molding. The machine may be used to form dental molding.

Owner:BURKHOLDER LEON R

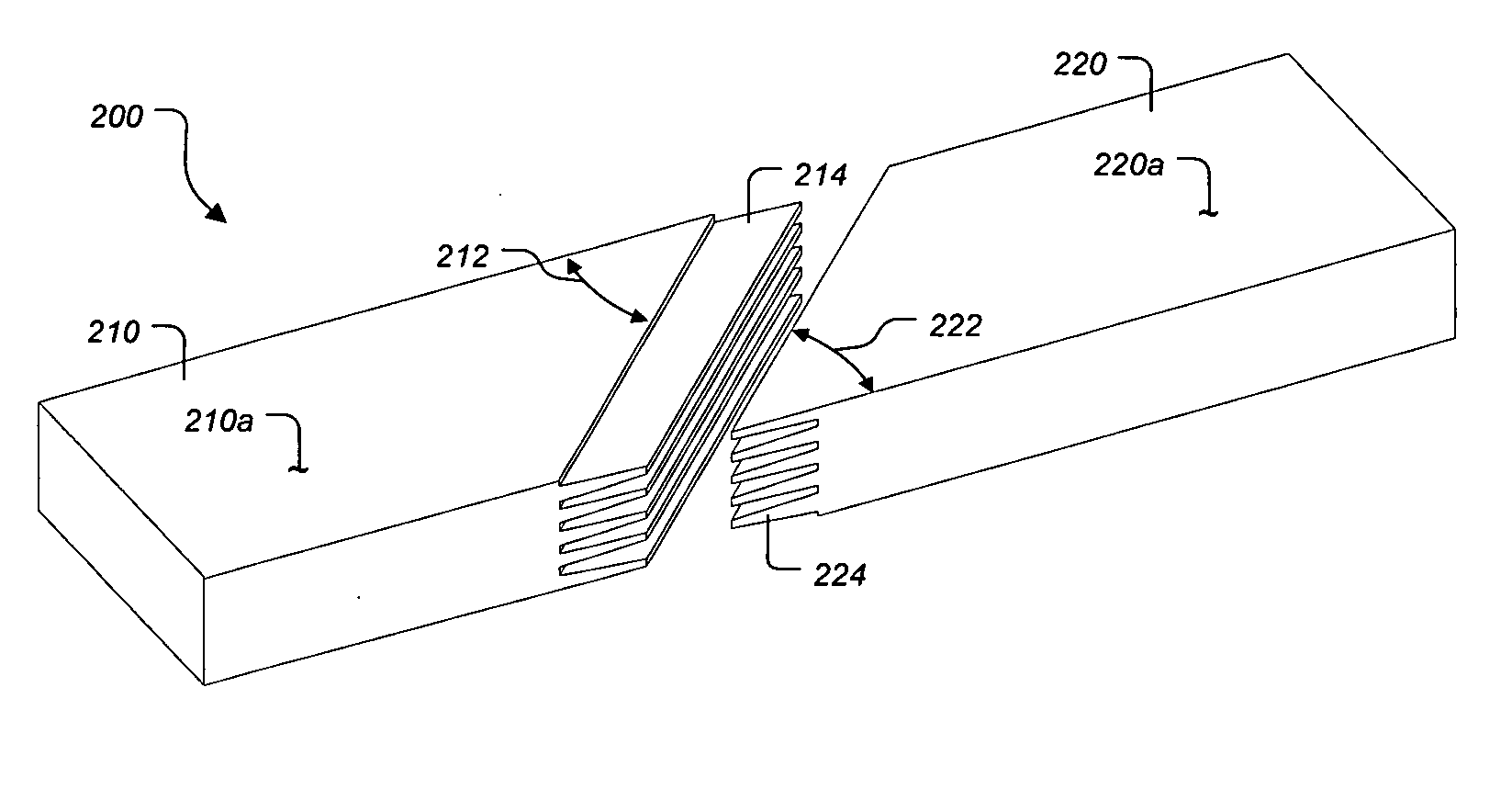

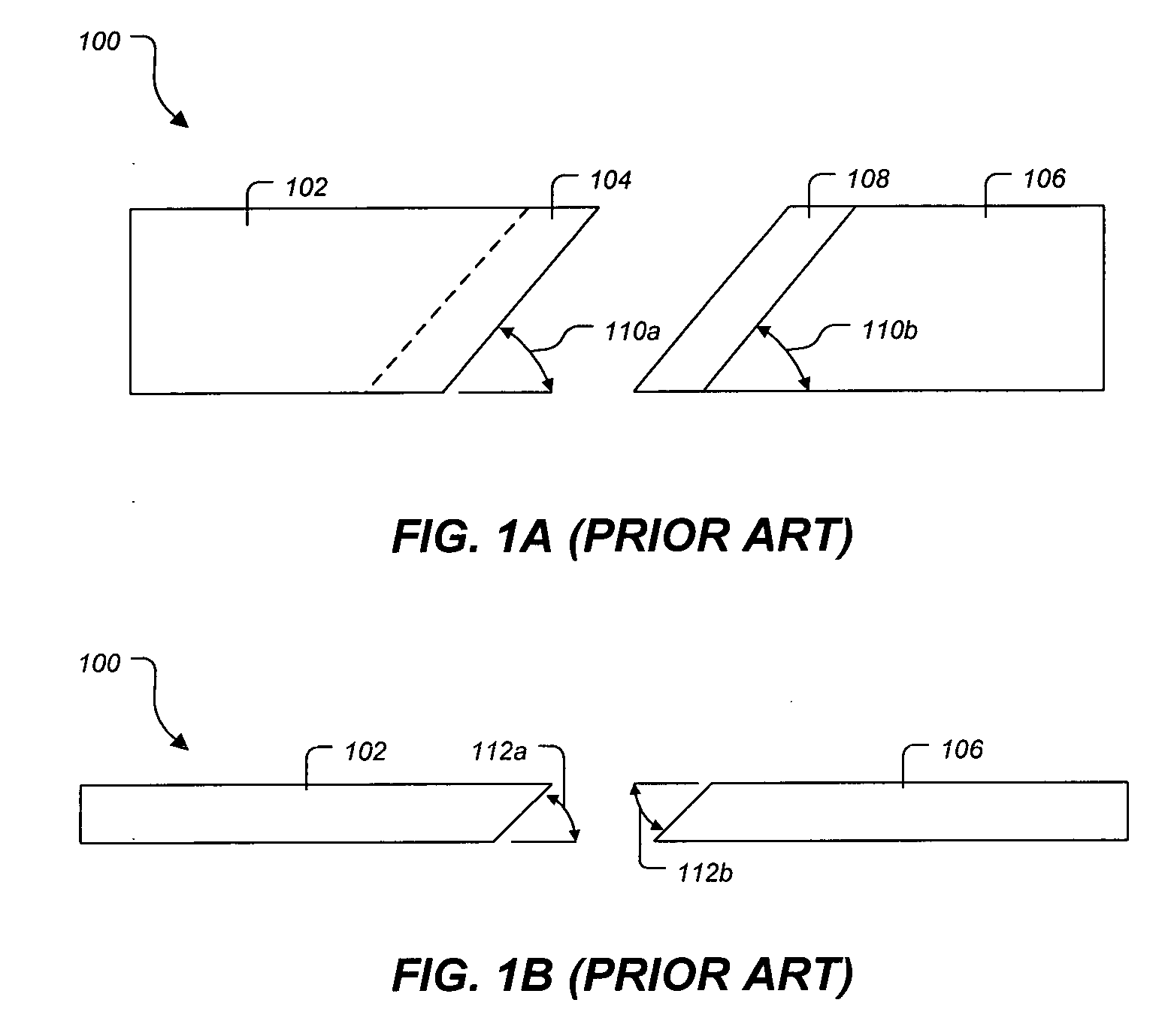

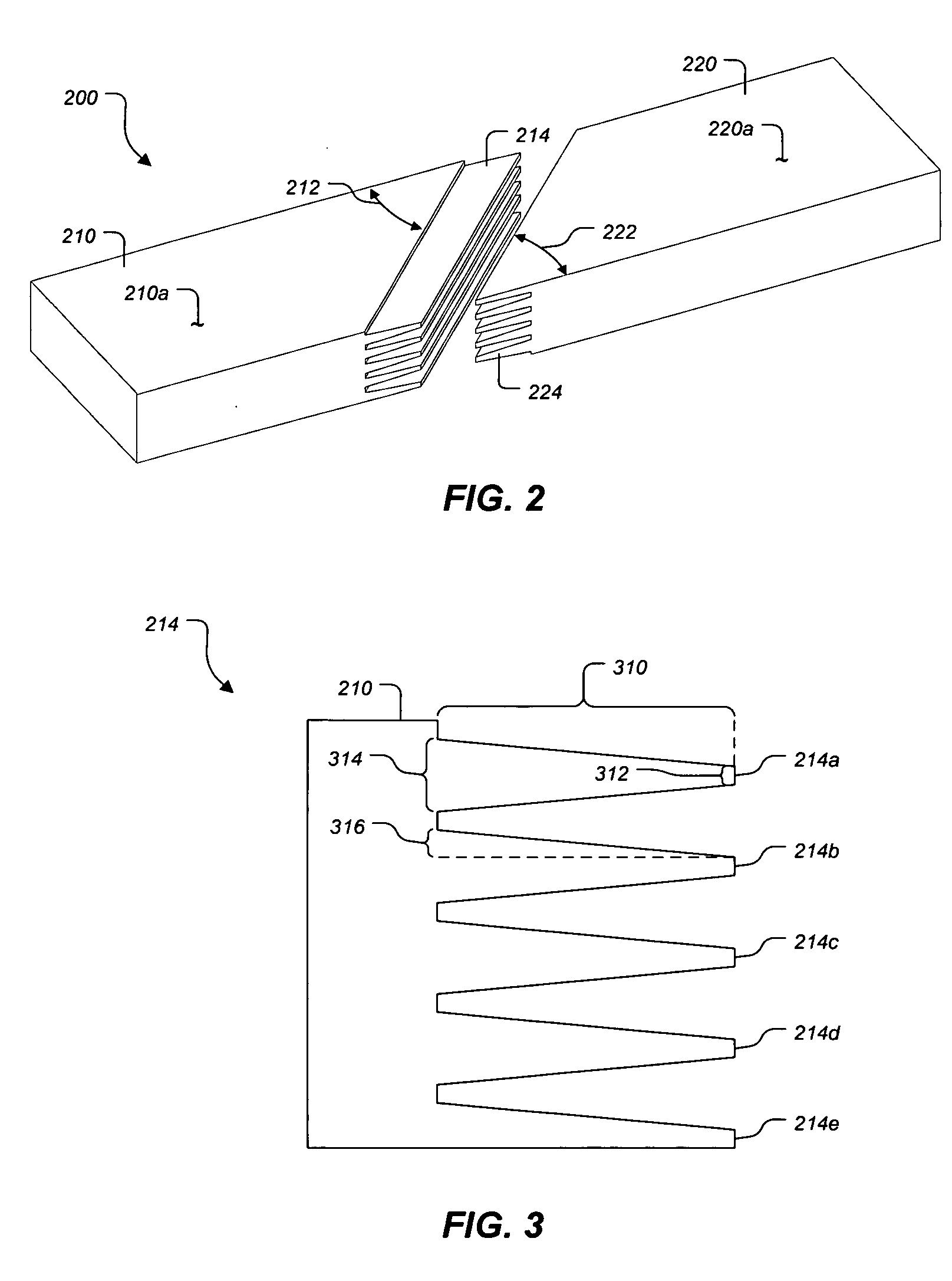

Assembly and method for providing an interlocking angular end joint

InactiveUS20070125448A1High strengthEasy to assembleDovetailed workMulti-purpose machinesEngineering

An assembly and method is disclosed for providing an interlocking angular end joint. The interlocking angular end joint is capable of providing a virtually invisible end joint and comprises at least a first board capable of being longitudinally ripped from lumber to a predetermined width, at least a first angle cut at a predetermined angle into at least one end portion relative to the longitudinal length of the first board, and at least a first interlocking member capable of being machined into at least one end portion of the first board.

Owner:ABBOTT RICHARD T

Woodworking machine for shaping molding

The woodworking machine for shaping molding has a hollow cylindrical cartridge with end caps having openings defined therein adapted for inserting a blank strip of molding through the cartridge. Robotic grippers advance the molding strip through the cartridge in indexed increments. A cutter assembly is mounted on a movable table, the cutter assembly having a plurality of spaced apart cutters. An electronic control system, preferably including a programmable logic controller, causes the grippers to grip the blank molding, insert the blank through the cartridge, actuate the cutter assembly and move the table so that the cutters simultaneously cut a plurality of notches in the molding, retract the cutter assembly, advance the molding the indexed distance, and automatically repeat the cycle, ejecting the strip when notches have been formed in the entire length of the molding. The machine may be used to form dental molding.

Owner:BURKHOLDER LEON R

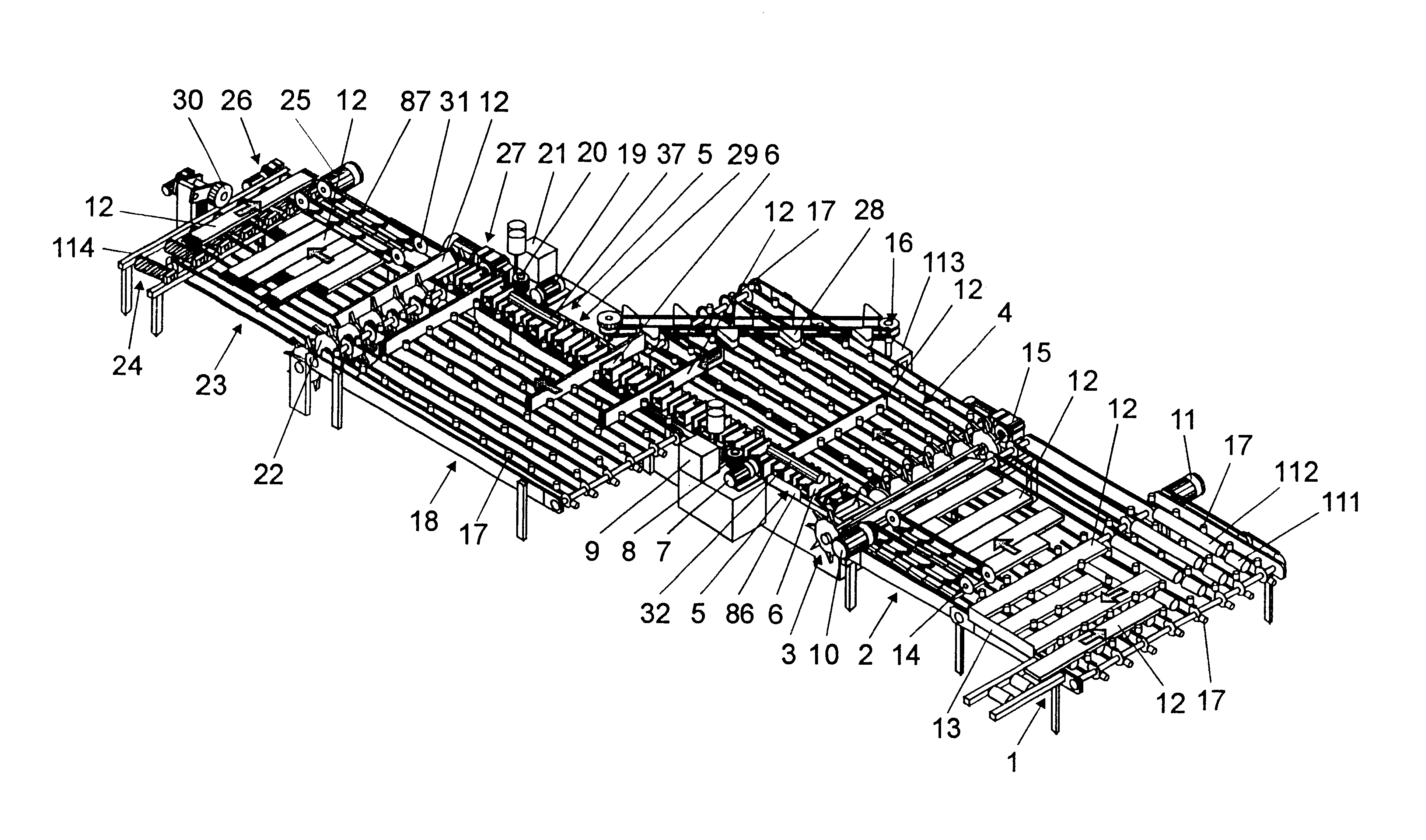

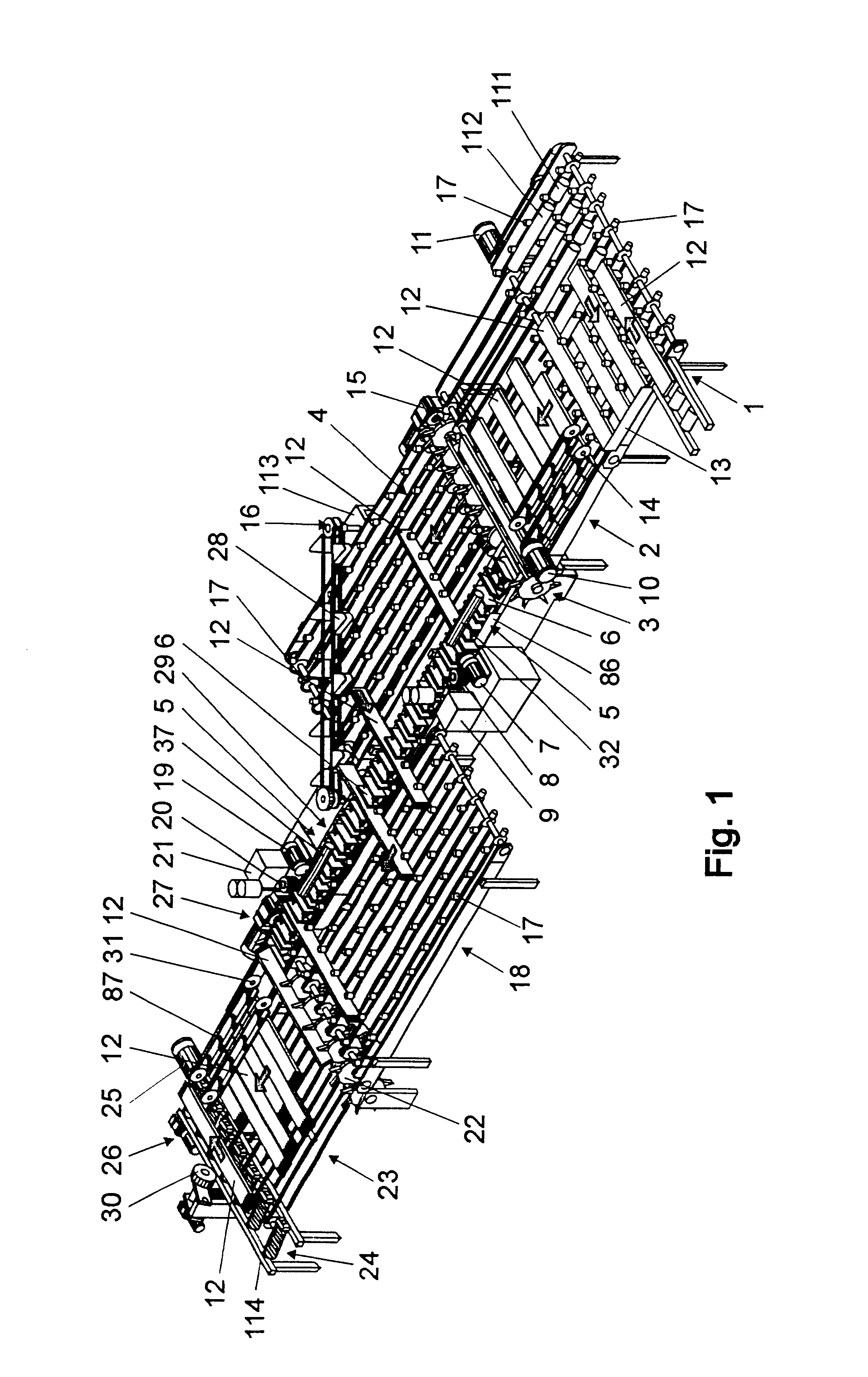

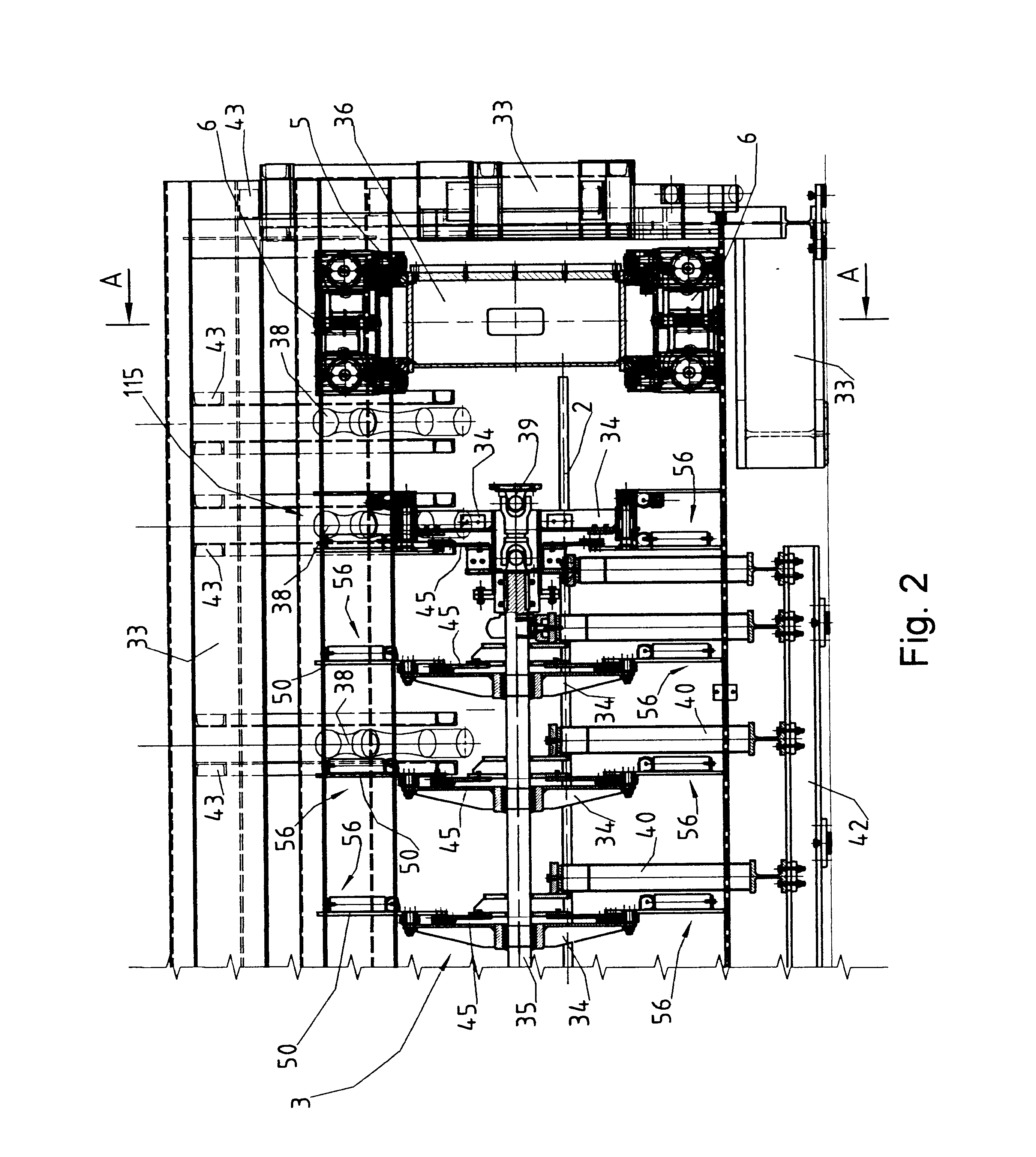

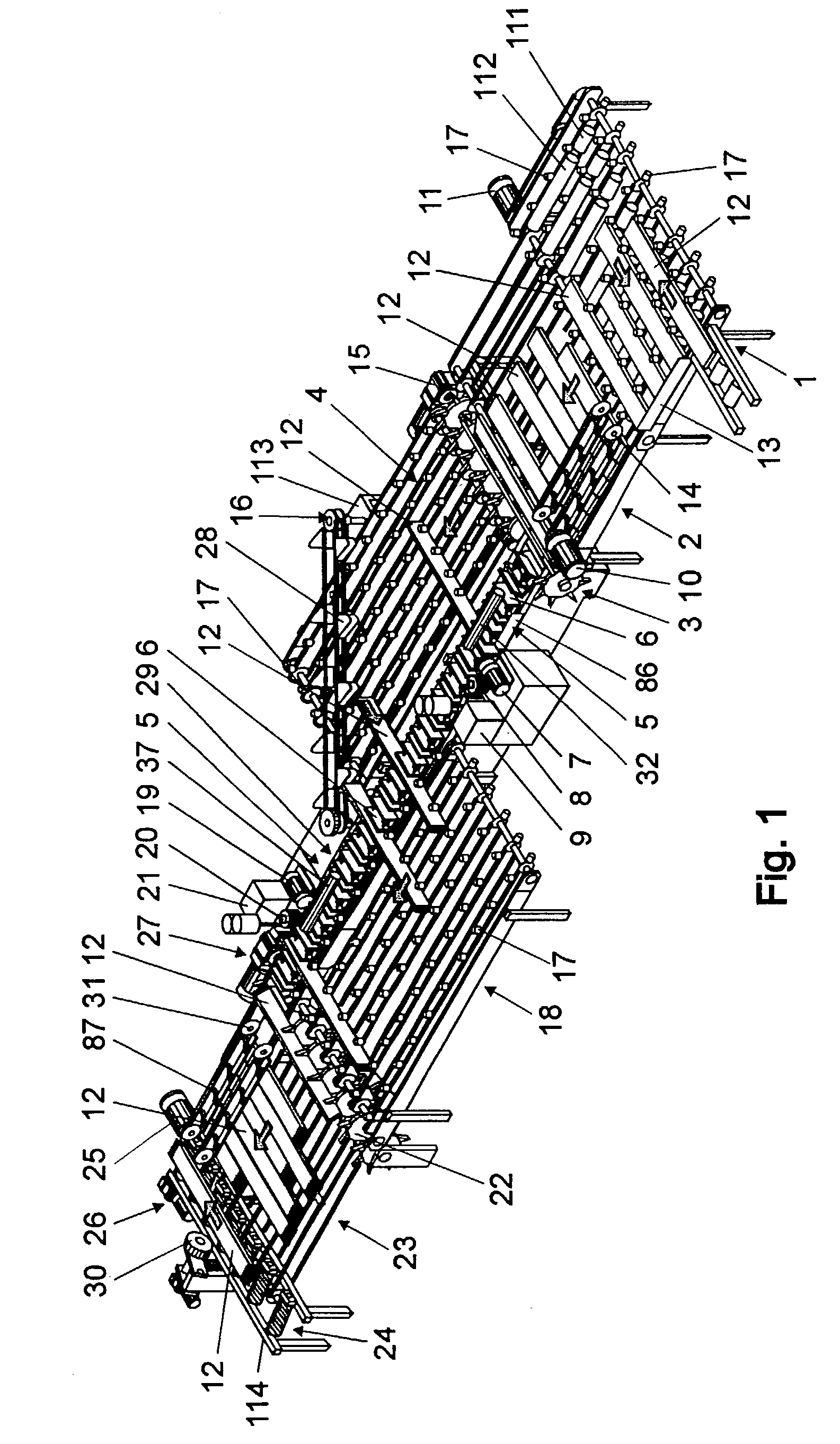

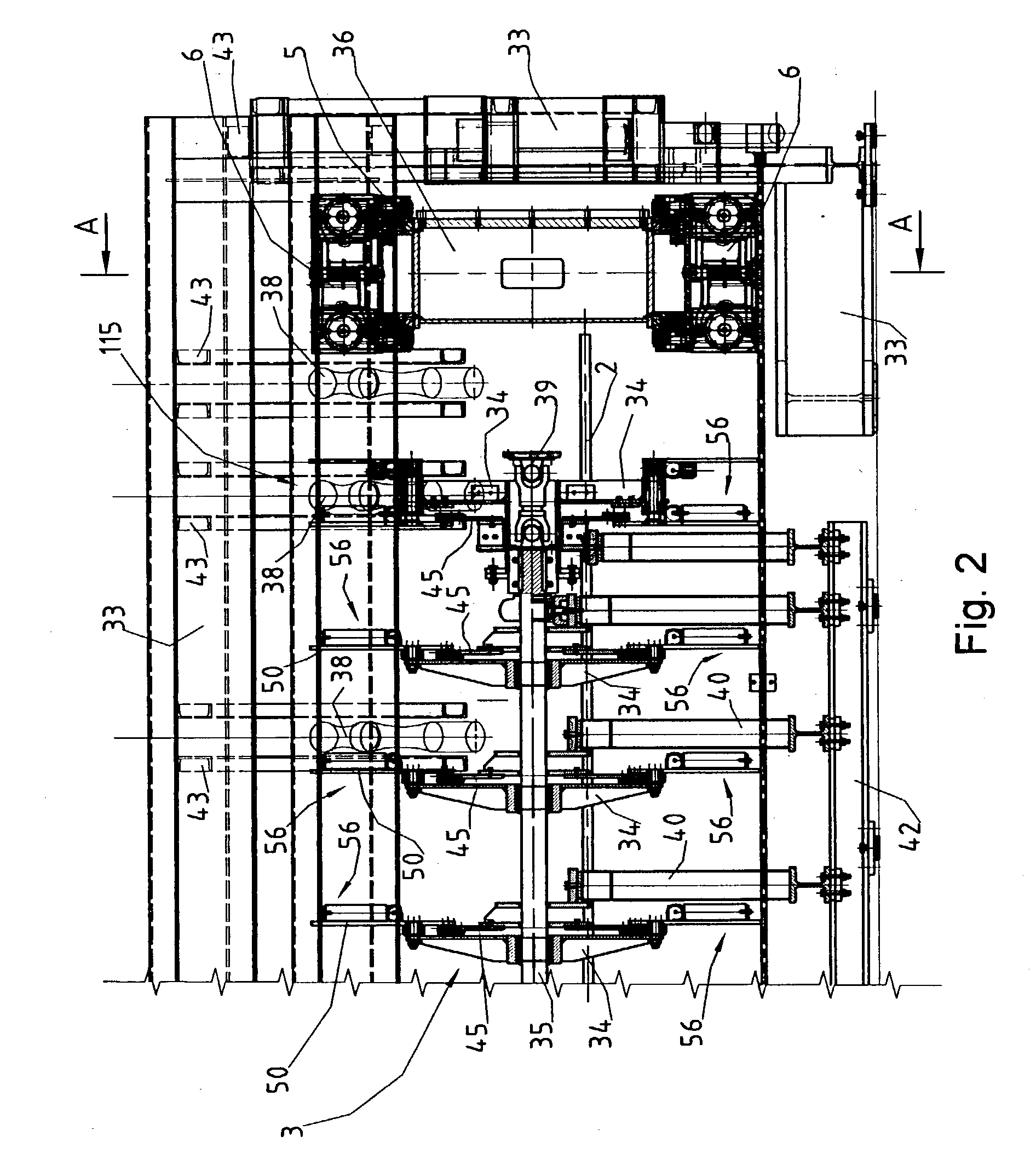

Machine for profile working of front surfaces on oblong wood workpieces

Machine for profile working of front surfaces on oblong wood workpieces resolves the problem of simple, accurate and fluent or continued working of workpieces front surfaces of various lengths and intersections, and the machine is of a compact construction. It is characteristic by the construction of the entrance turnover device transversely placed between longitudinal conveyors with carriers, which has on the periphery of rotating wheels constructed movable bearing couplings, and by them fixed guiding plates with the groove inside which there are movably inserted guided bearings of bearing couplings. In the area of the entrance turnover device there are placed under an optional angle the oblique roller conveyors, inside which there are flexibly and circularly movably inserted rolls. Between the longitudinal conveyors there is placed the endless conveying chain, which has to its entire extent fastened clamping units that have inside the fixed housing inserted the clamping mechanism, the operation of which is regulated by the control field and control indicator. Over the free corner of the longitudinal conveyor there runs the oblique conveyor with carriers tilted to the longitudinal conveyor. Between longitudinal conveyors there is transversely placed the exit turnover device, which has on the periphery of rotating wheels constructed movable bearing cranks, being through the chain connected with the control chain wheel and control panel, the guided bearing of which is movably inserted inside the channel guide fixed on the rotating wheels.

Owner:LEDINEK PAVEL +1

Structural laminwood and preparation method thereof

InactiveCN101564854AImprove structural performanceIncrease profitOther plywood/veneer working apparatusWood veneer joiningLower gradeEngineering

The invention provides a structural laminwood and a preparation method thereof. The laminwood is stacked and glued by 2-7 layers of veneers, wherein the grade of the external layer veneer of the laminwood is equal to the grade of the adjacent internal layer veneer or higher than the adjacent internal layer veneer by one grade; the veneer grade is determined by the average value of flexural elastic modulus of the target grades of all veneers; and compared with the veneers with lower grades, the veneers with higher grades have greater average value of the flexural elastic modulus of the target grades. The method lengthens the stock lumbers of short dimensions by mechanical stress grading and uses the lengthened stock lumbers as the veneers, then configures the veneer structures according to a grade configuration principle and coldly presses and glues the veneers to prepare the structural laminwood. The laminwood has excellent structural performance and can be used for the components such as beams, columns, and the like in wood structure buildings or other buildings.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Workpiece carrier for a saw

InactiveUS7077043B1Precise and predictable and safe cuttingSecurely holdMetal sawing devicesGuide fencesMechanical engineeringDepth of cut

A carrier adapted to securely hold a workpiece for manual movement through cutting engagement such as with the saw blade of a band saw in a manner that allows for precise and predictable cutting of the workpiece into boards of desired thickness. The carrier is slidably positioned in the miter guide slot that extends in the saw work table parallel to the cut of the saw blade, and is adapted for manual positioning of the workpiece transversely with respect to the guide slot to adjust the depth of cut of the blade into the workpiece.

Owner:KOERBLE THOMAS NORTON

Machine for profile working of front surfaces on oblong wood workpieces

Machine for profile working of front surfaces on oblong wood workpieces resolves the problem of simple, accurate and fluent or continued working of workpieces front surfaces of various lengths and intersections, and the machine is of a compact construction. It is characteristic by the construction of the entrance turnover device transversely placed between longitudinal conveyors with carriers, which has on the periphery of rotating wheels constructed movable bearing couplings, and by them fixed guiding plates with the groove inside which there are movably inserted guided bearings of bearing couplings. In the area of the entrance turnover device there are placed under an optional angle the oblique roller conveyors, inside which there are flexibly and circularly movably inserted rolls. Between the longitudinal conveyors there is placed the endless conveying chain, which has to its entire extent fastened clamping units that have inside the fixed housing inserted the clamping mechanism, the operation of which is regulated by the control field and control indicator. Over the free corner of the longitudinal conveyor there runs the oblique conveyor with carriers tilted to the longitudinal conveyor. Between longitudinal conveyors there is transversely placed the exit turnover device, which has on the periphery of rotating wheels constructed movable bearing cranks, being through the chain connected with the control chain wheel and control panel, the guided bearing of which is movably inserted inside the channel guide fixed on the rotating wheels.

Owner:LEDINEK PAVEL +1

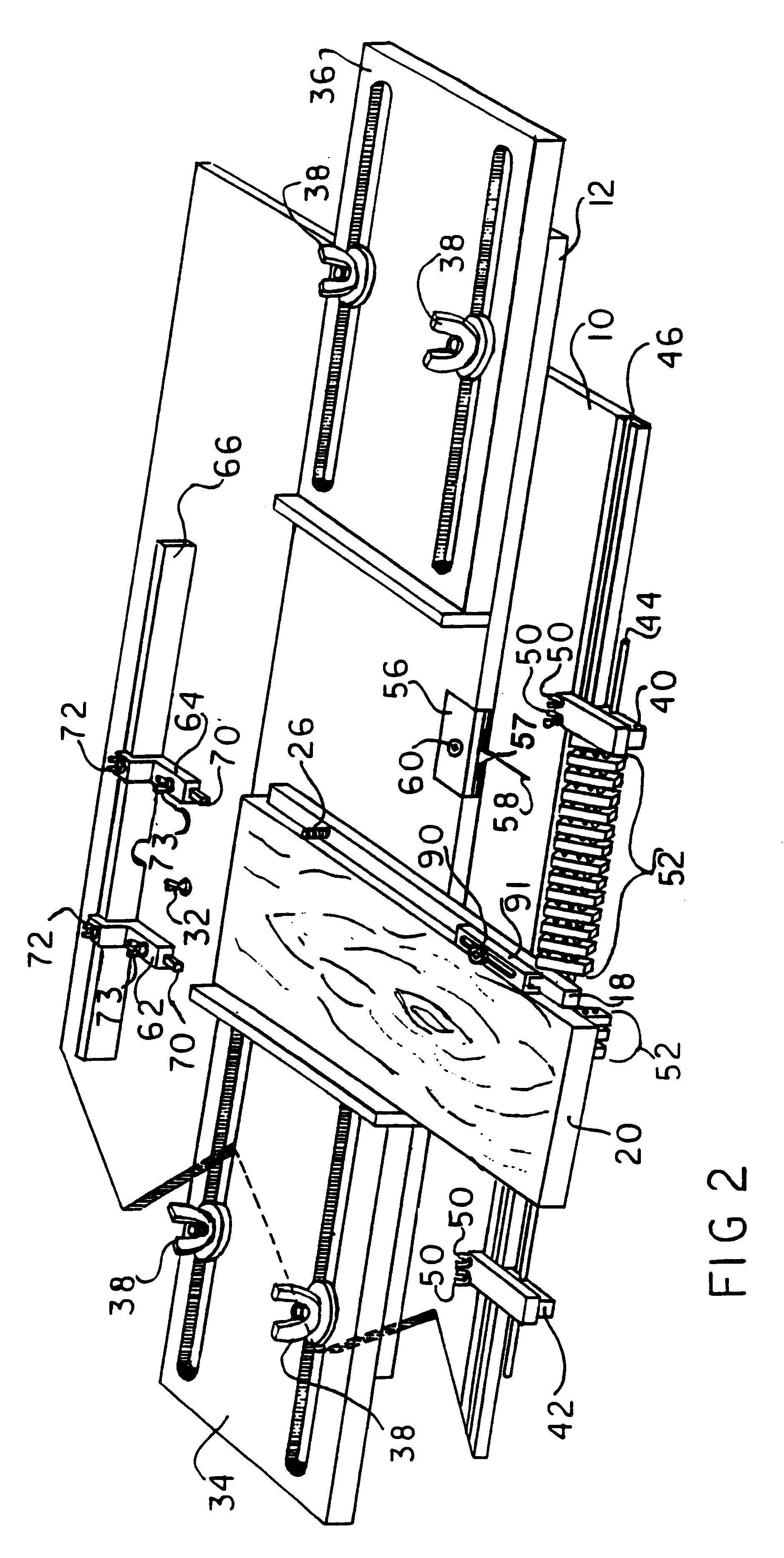

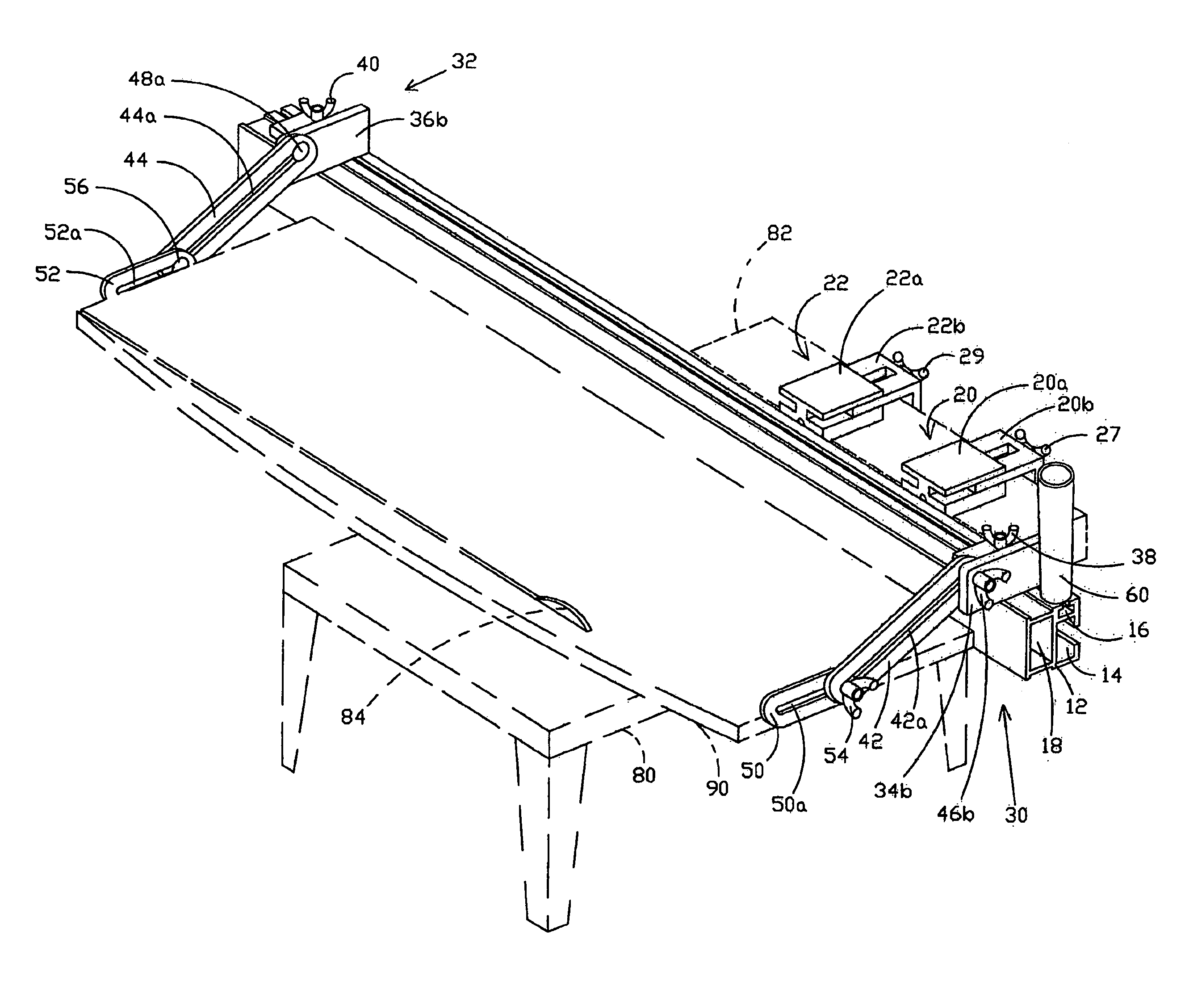

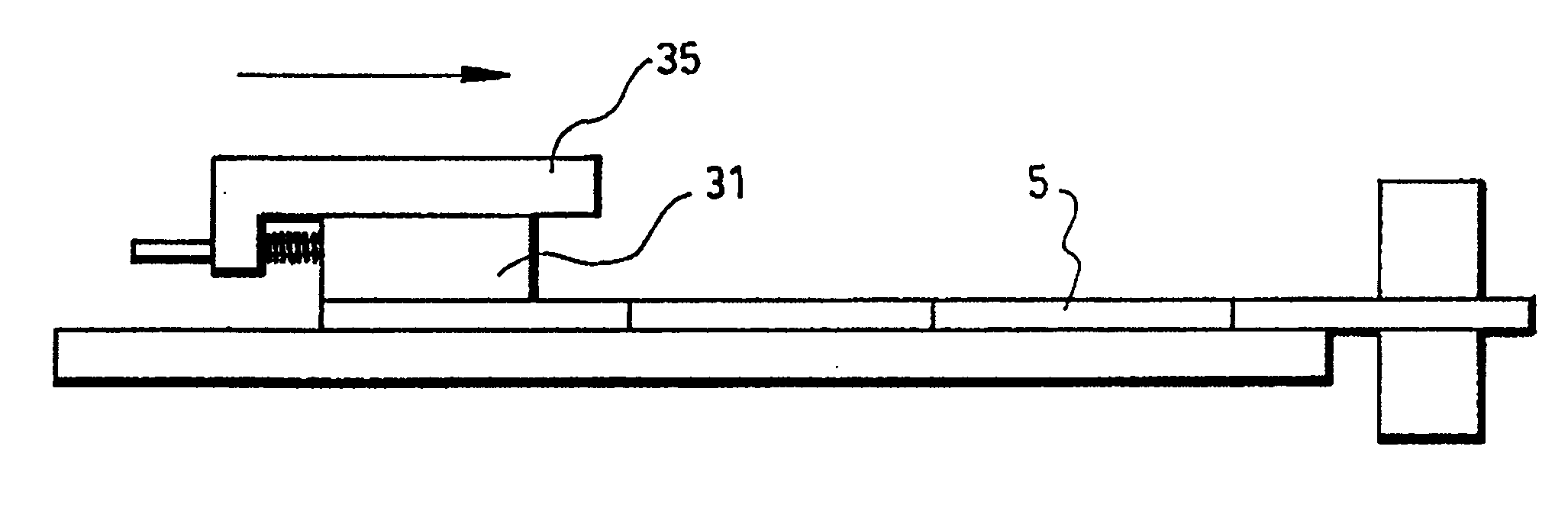

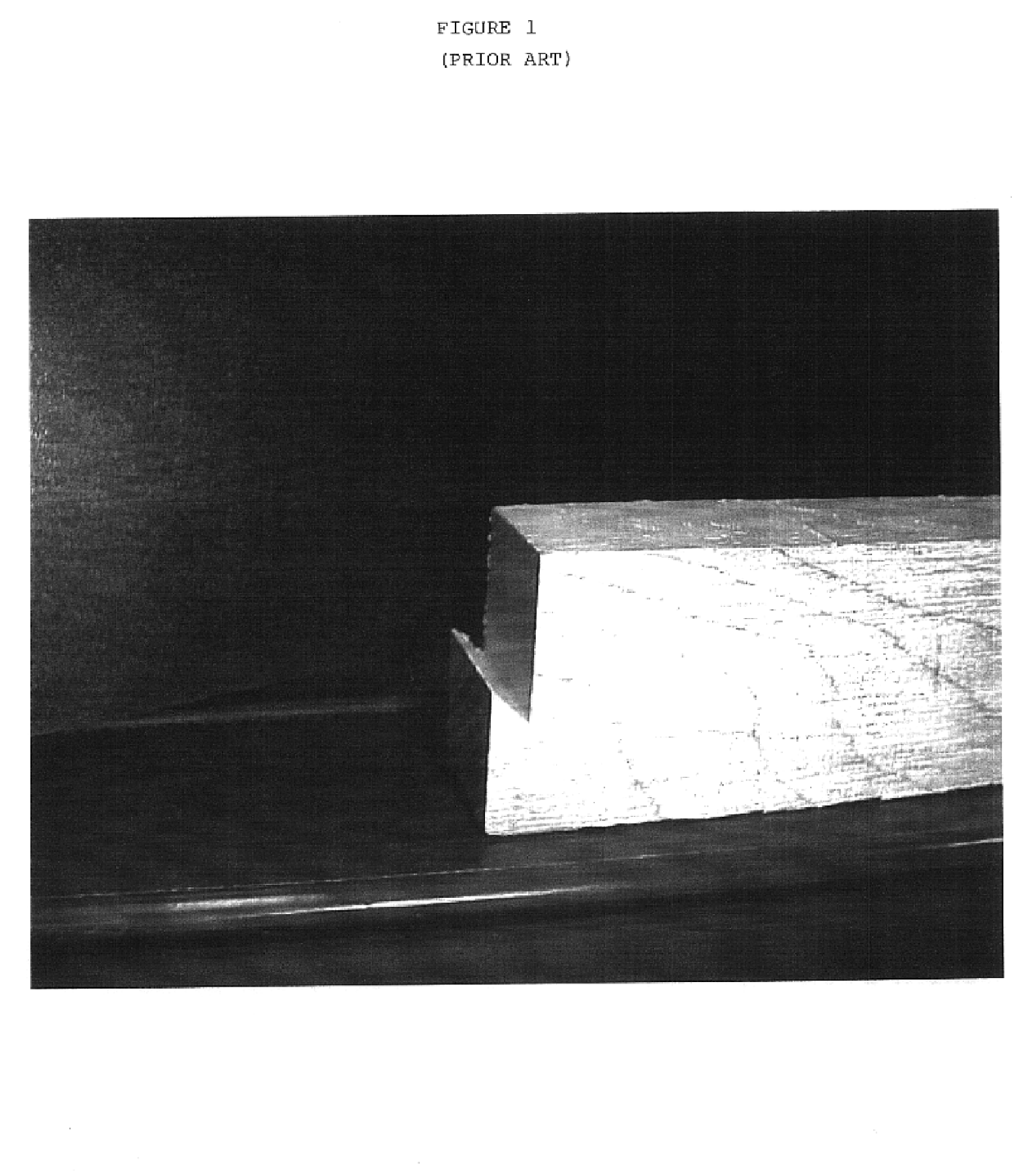

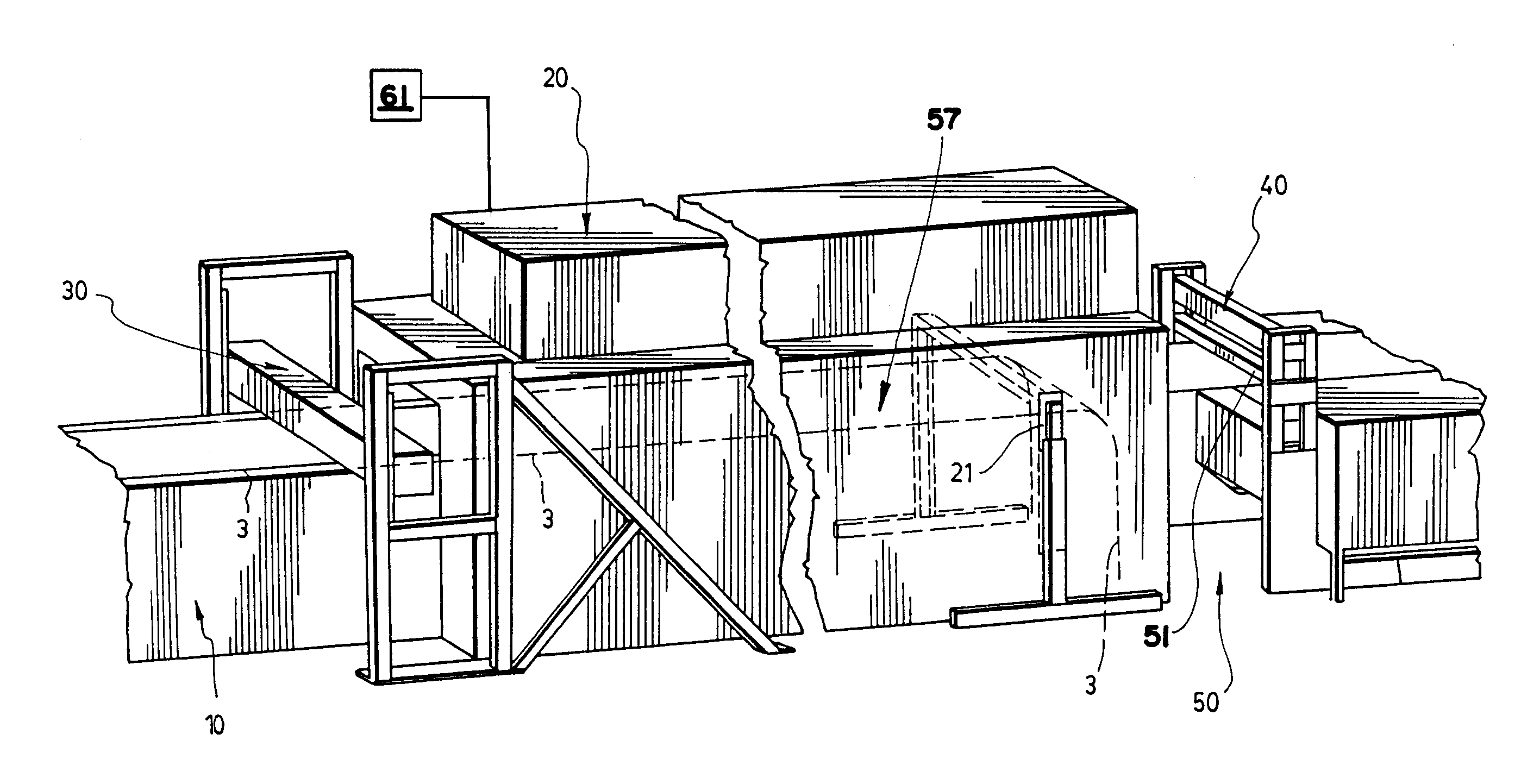

Wood flooring for use in making trailer and container floors, and method and apparatus for making the same

InactiveUS6843877B2Humidity fatigueFatigue resistancePlywood pressesDovetailed workFinger jointEngineering

An apparatus and method for simultaneously pressing together longitudinally a plurality of individual strips of wood, each strip being provided with a finger joint at each end. The strips are jointed end to end in a number of rows to form a floorboard. The apparatus includes a mechanism for simultaneously applying longitudinal pressure to each of the rows of wood strips during the curing process. The resulting floorboard is mechanically improved, has greater protection against humidity and increases the fatigue resistance of the floorboard, which can be used for trailer floors or the like.

Owner:PROLAM SOC & COMMANDITE

Wood flooring for use in making trailer and container floors, and method and apparatus for making the same

InactiveUS6957675B2Humidity fatigueFatigue resistancePlywood pressesMechanical working/deformationFinger jointMechanical engineering

An apparatus and method for simultaneously pressing together longitudinally a plurality of individual strips of wood, each strip being provided with a finger joint at each end. The strips are jointed end to end in a number of rows to form a floorboard. The apparatus includes a mechanism for simultaneously applying longitudinal pressure to each of the rows of wood strips during the curing process. The resulting floorboard is mechanically improved, has greater protection against humidity and increases the fatigue resistance of the floorboard, which can be used for trailer floors or the like.

Owner:PROLAM SOC & COMMANDITE

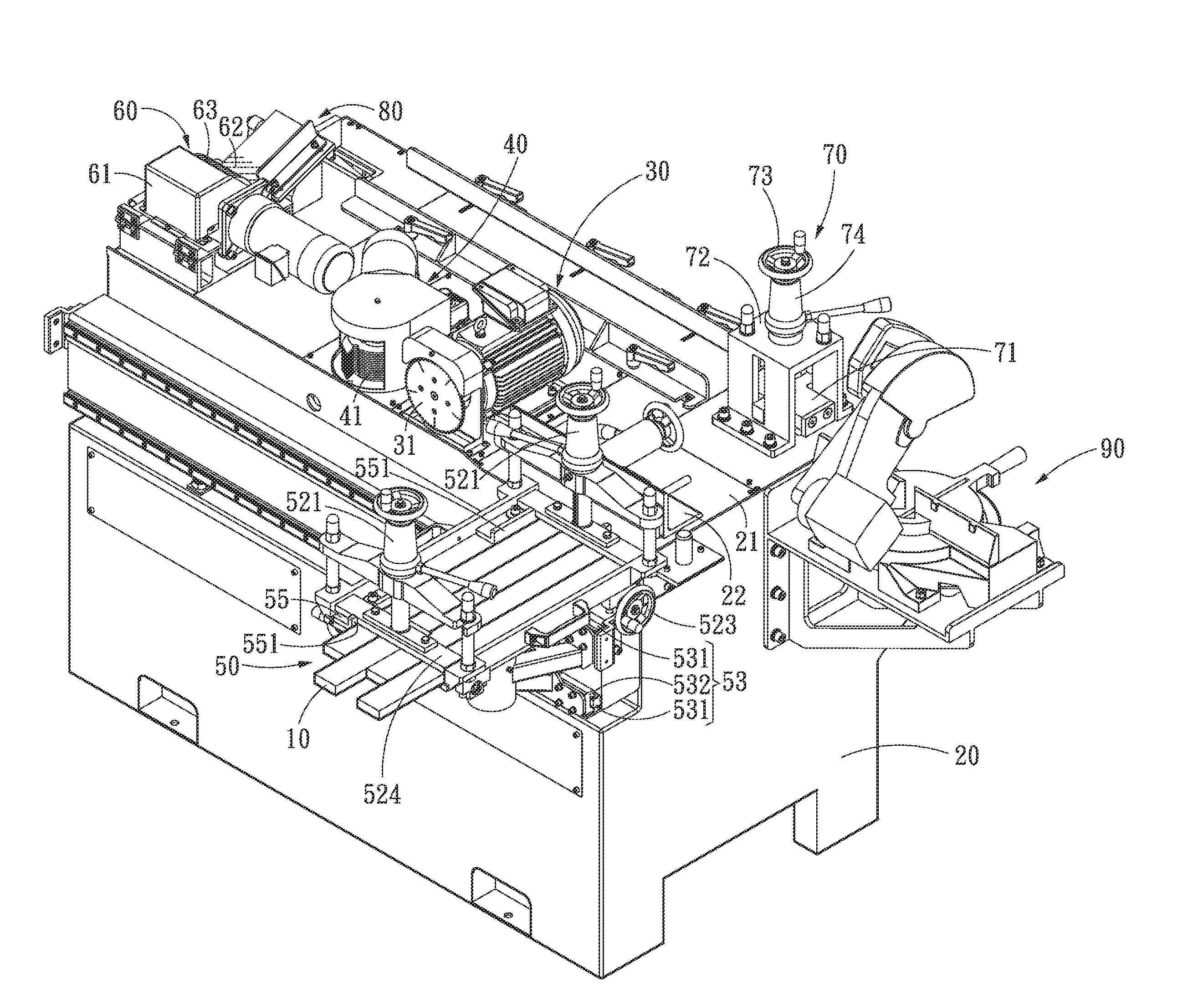

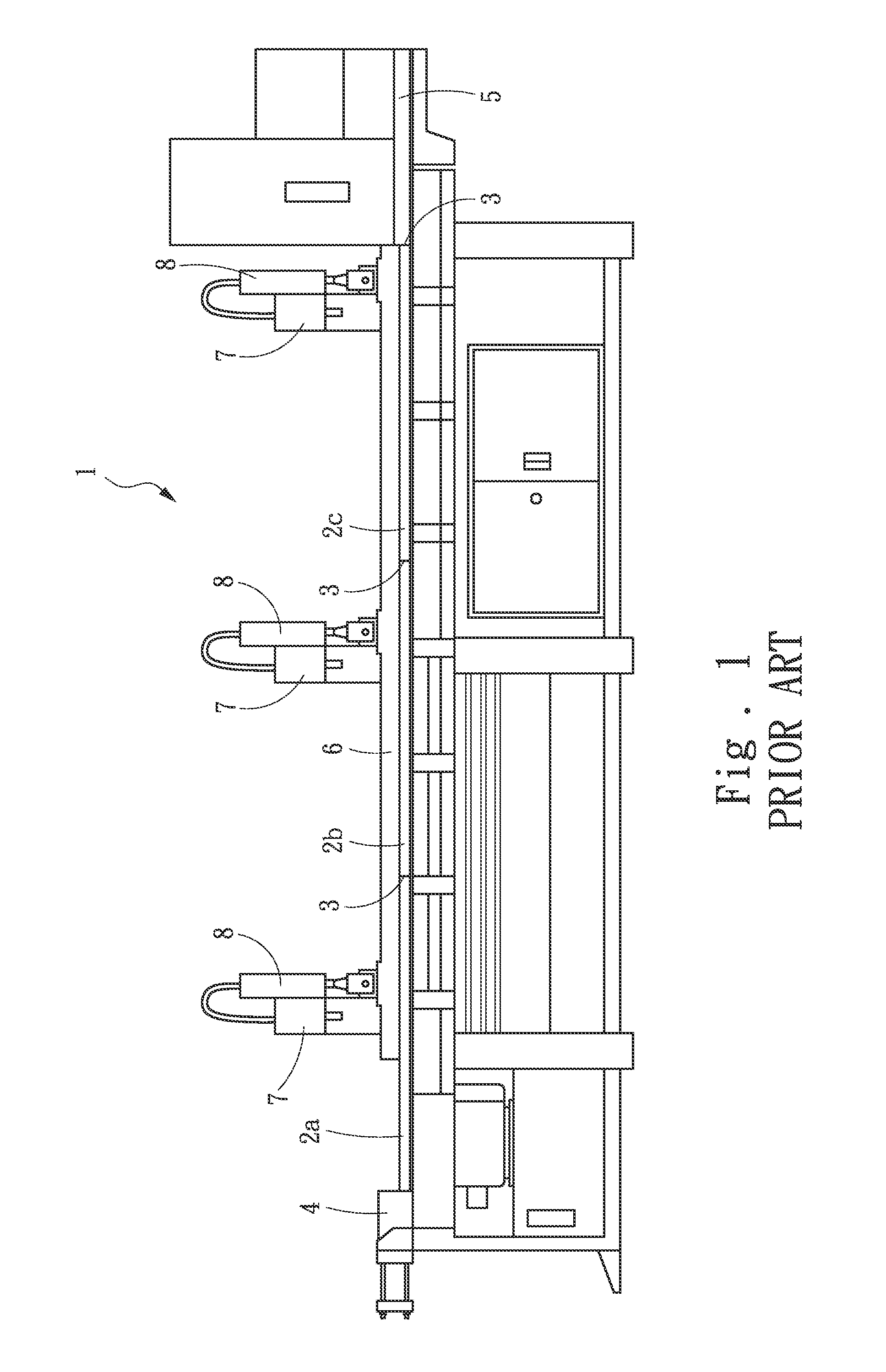

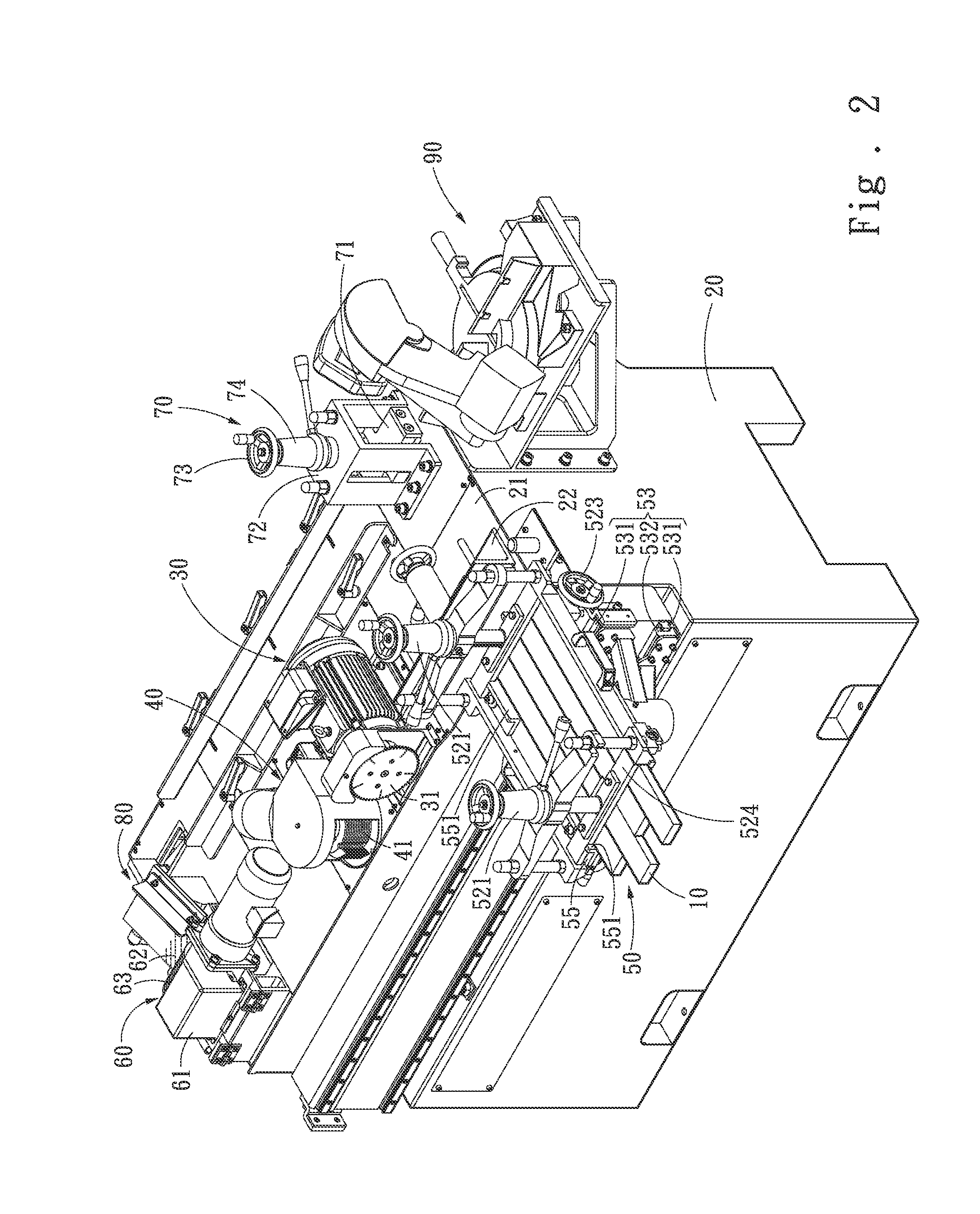

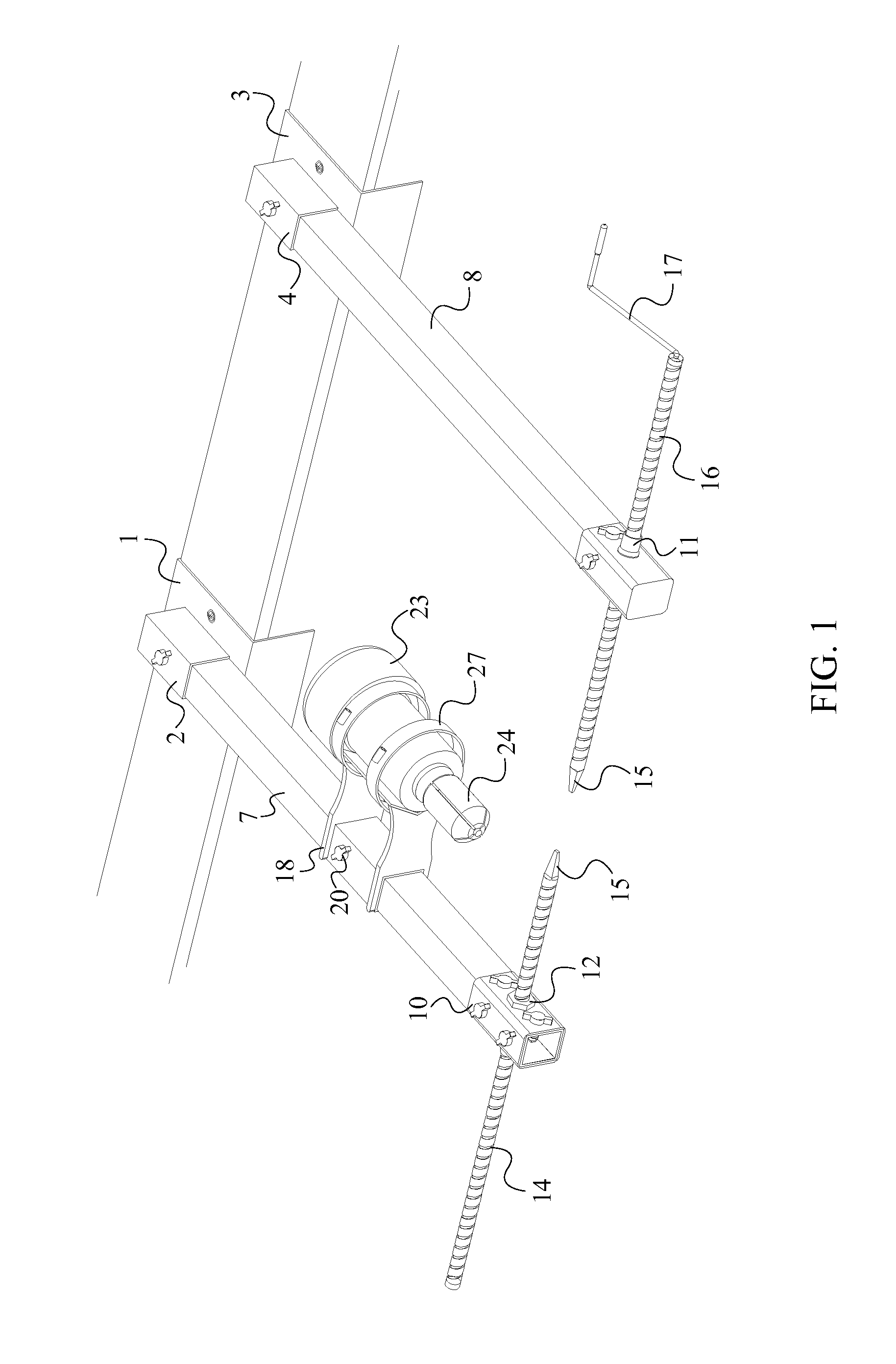

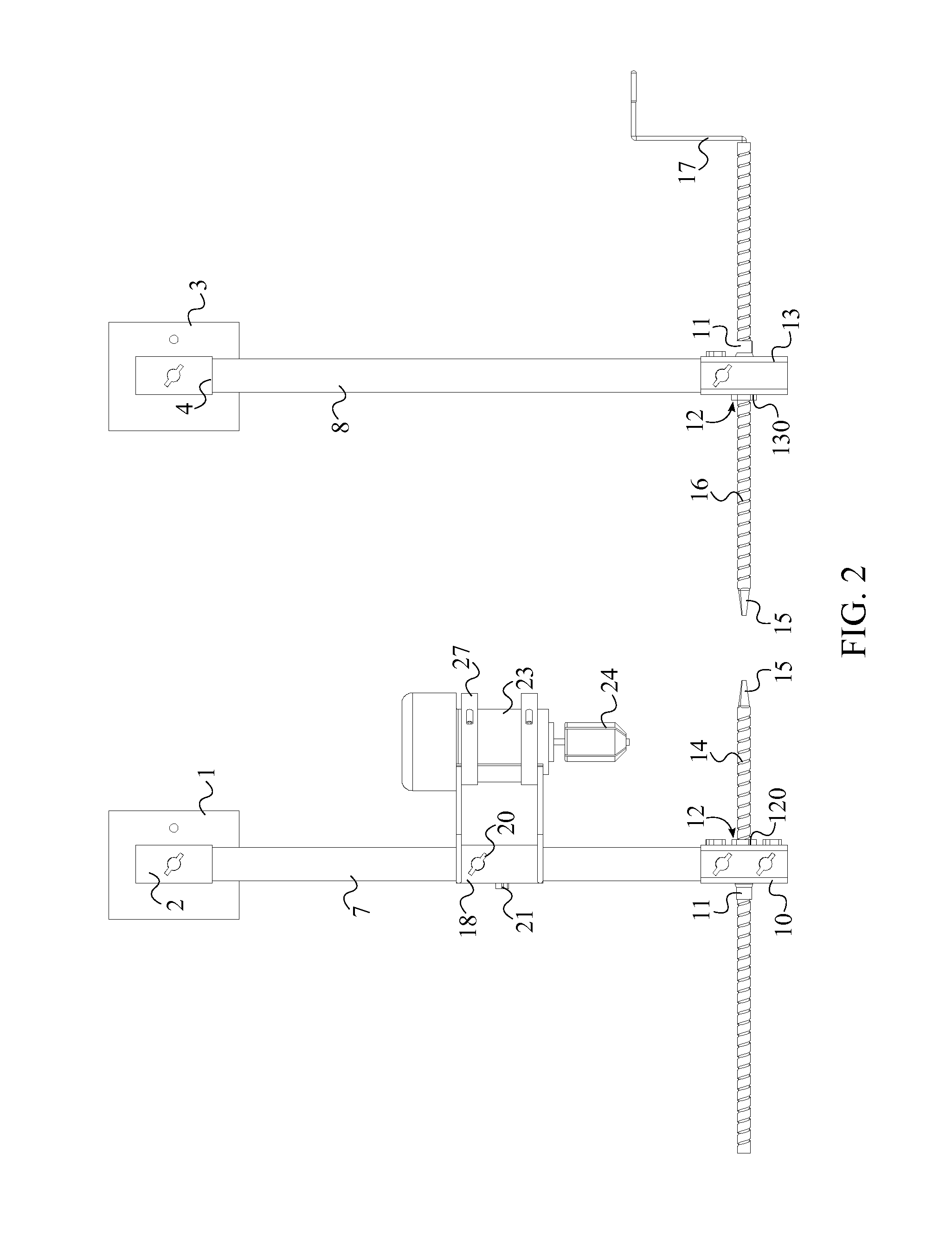

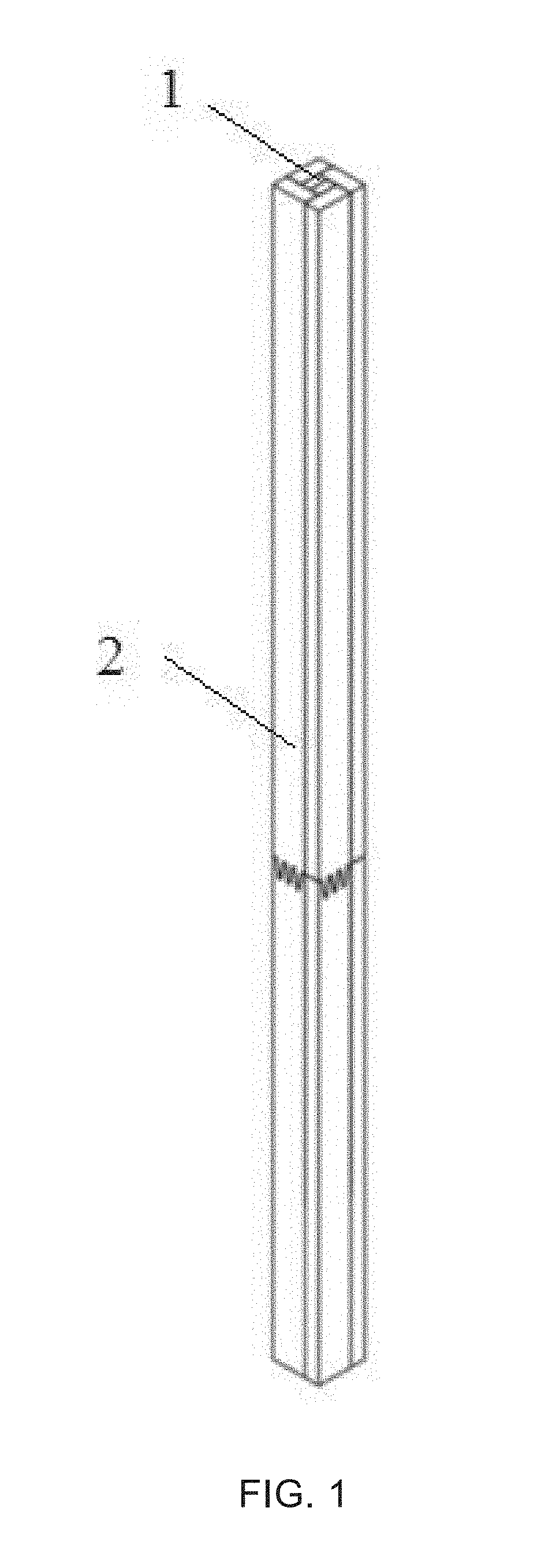

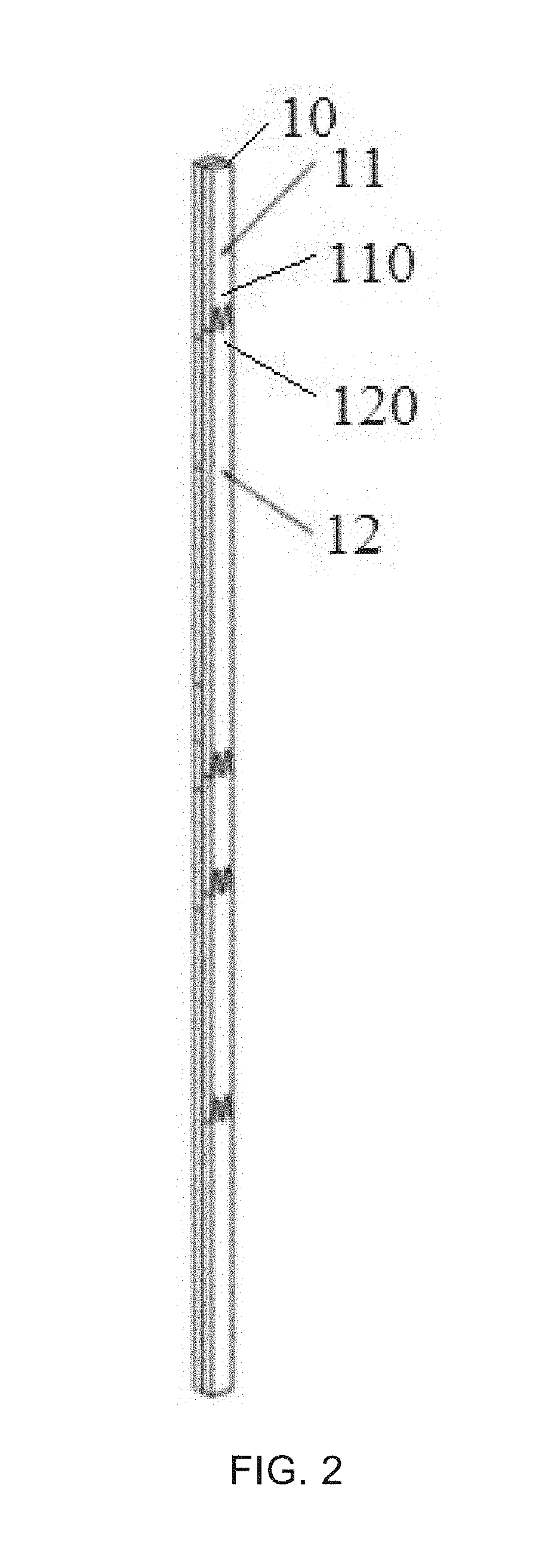

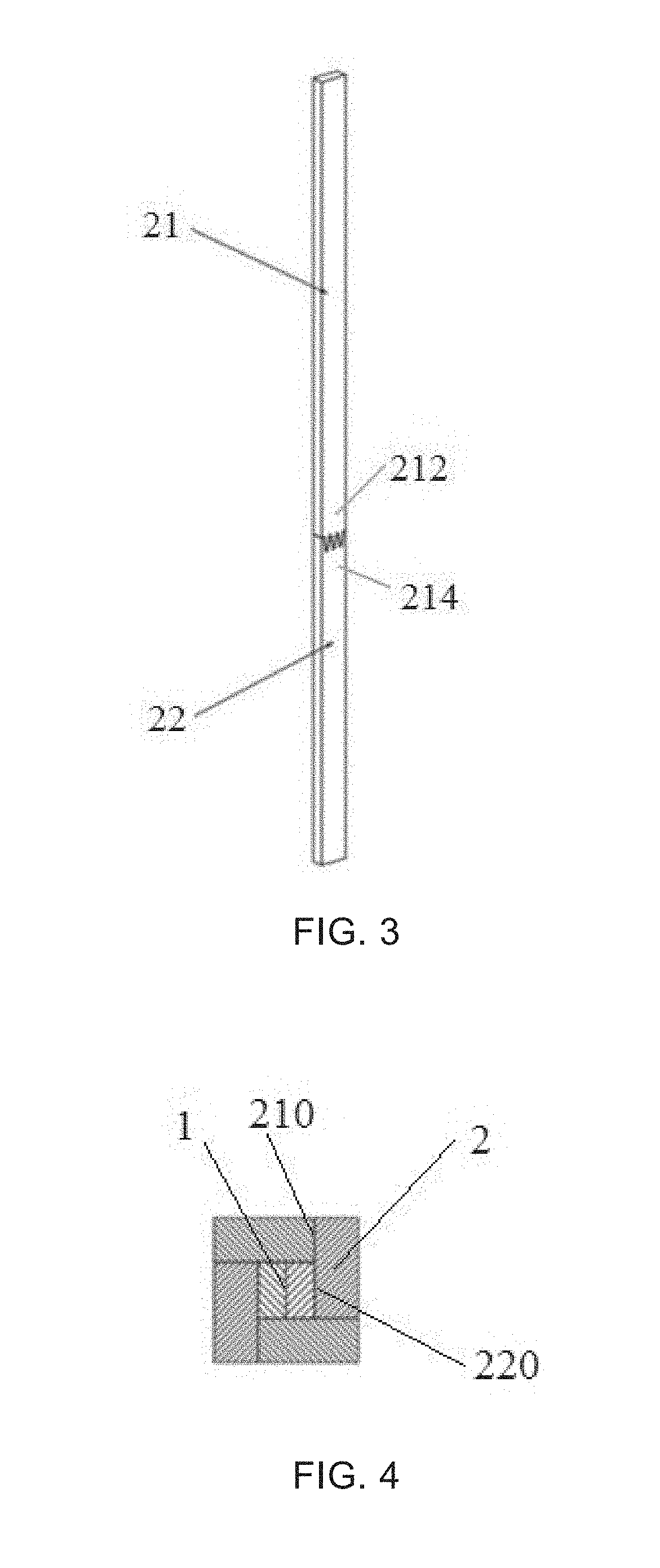

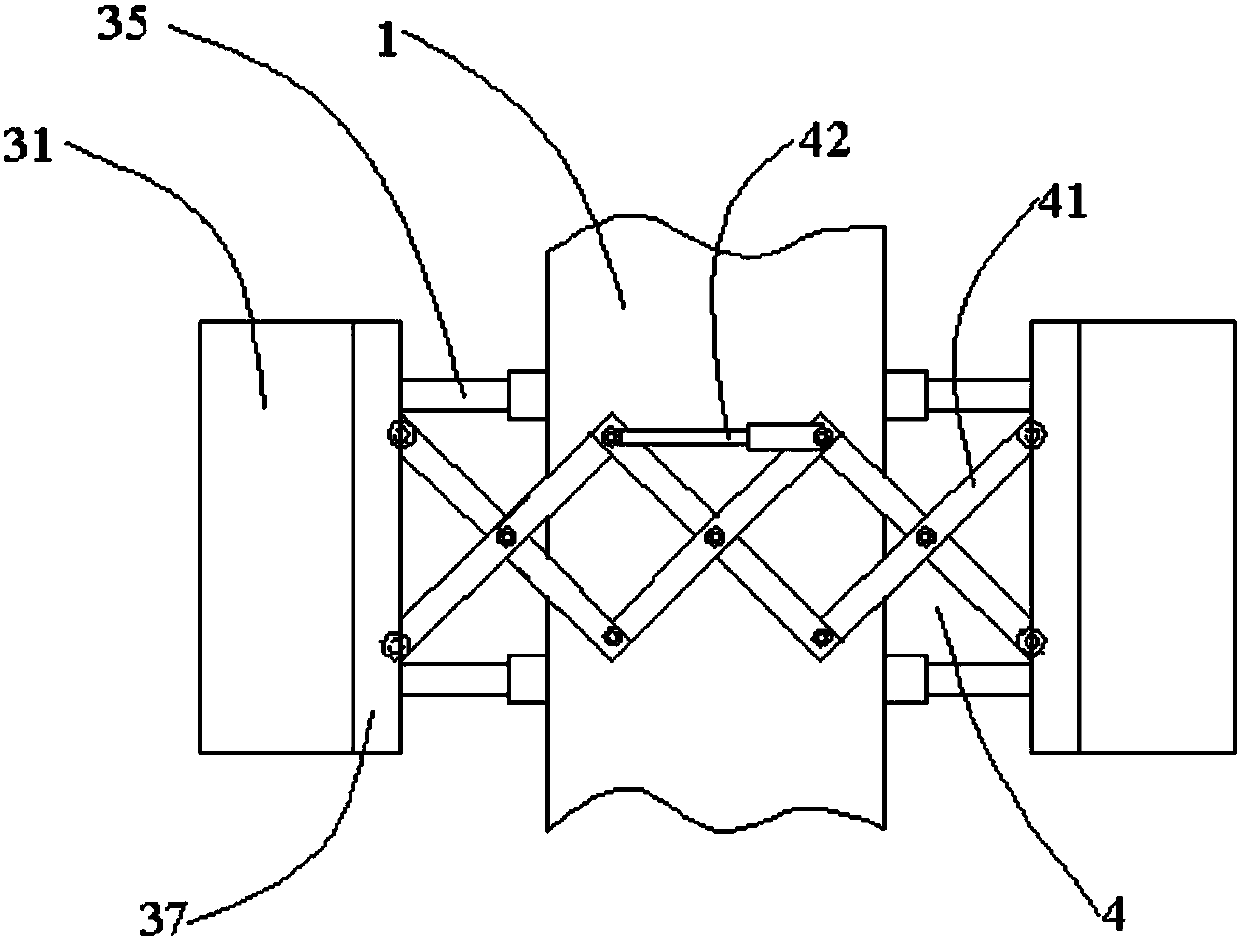

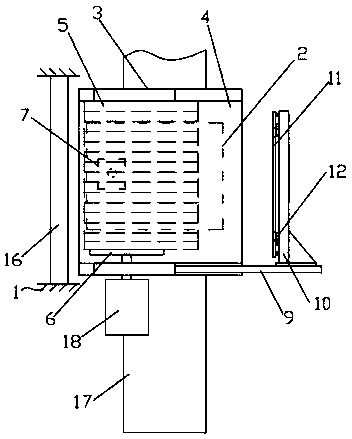

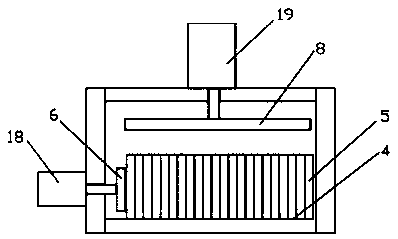

Wooden tenon press and connection machine

InactiveUS20160288360A1Increase the lengthLow costTongue/grooves making apparatusMulti-purpose machinesEngineeringMechanical engineering

A wooden tenon press and connection machine for coupling a plurality of wooden strips includes a station and a slide deck located on the station, a plane cutting device, a sawtooth cutting device, a gluing device, a thrust device and a press device that are located on the station. The slide deck carries the wooden strips sliding so that end surfaces at two sides of the wooden strips can pass through respectively a plane cutter of the plane cutting device and a sawtooth cutter of the sawtooth cutting device to form a wooden tenon on each of the end surfaces at two sides of the wooden strips. The two wooden tenons are daubed with a glue through the gluing device, and pressed through the press device and pushed and moved through the thrust device so that corresponding tenons of the wooden strips are tightly coupled together.

Owner:CHENG KUANG WOOD MACHINERY WORKS

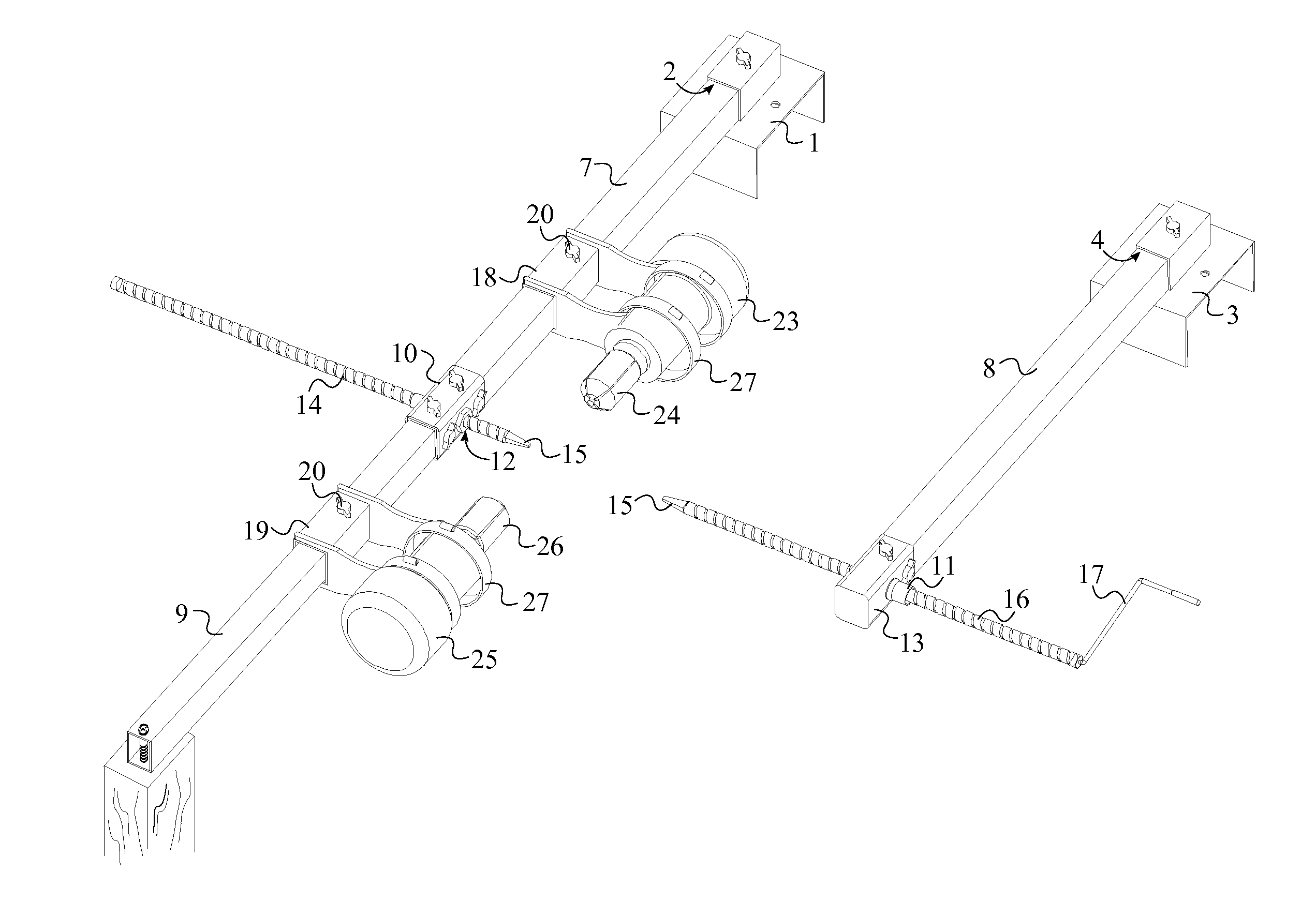

Router Jig for Producing Tenons

An apparatus used for cutting tenons consists of a plurality of mounting brackets, a plurality of arms, a motor, and a pair of threaded rods. The plurality of mounting brackets attaches the apparatus to an external platform. The motor is mounted onto one of the plurality of arms allowing the motor to slide along the length of the arm. The log in which the tenon is to be cut is placed in between the pair of threaded rods. By rotating the log with the use of one of the threaded rods or with the use of a drill, the log makes contact with the motor. The rotating motion of both the log and also the motor, results in a tenon being cut on the log. Additionally, two motors can also be used in tenon cutting such that a tenon with different diameters can be cut simultaneously.

Owner:SMITH LESLIE G

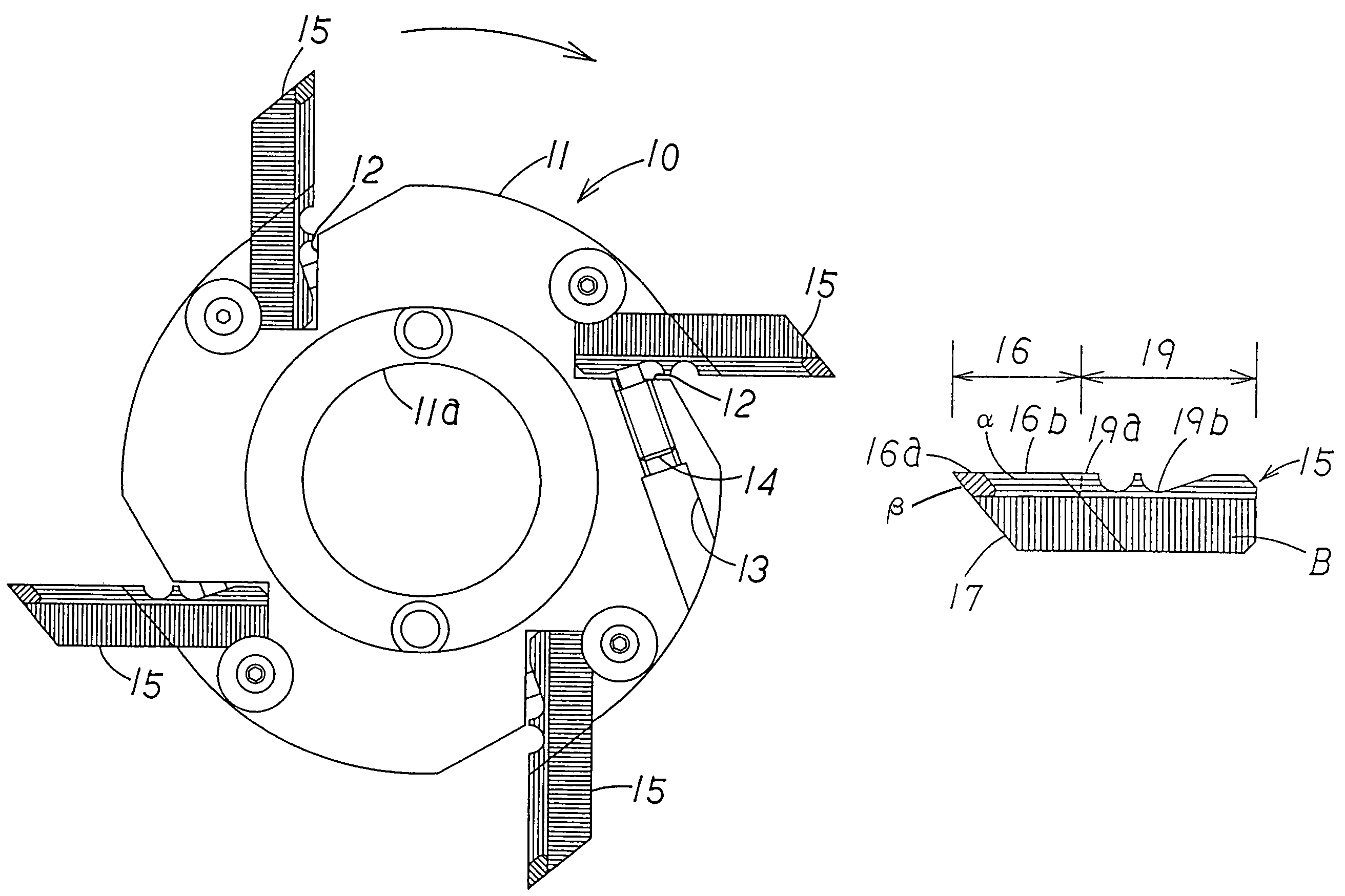

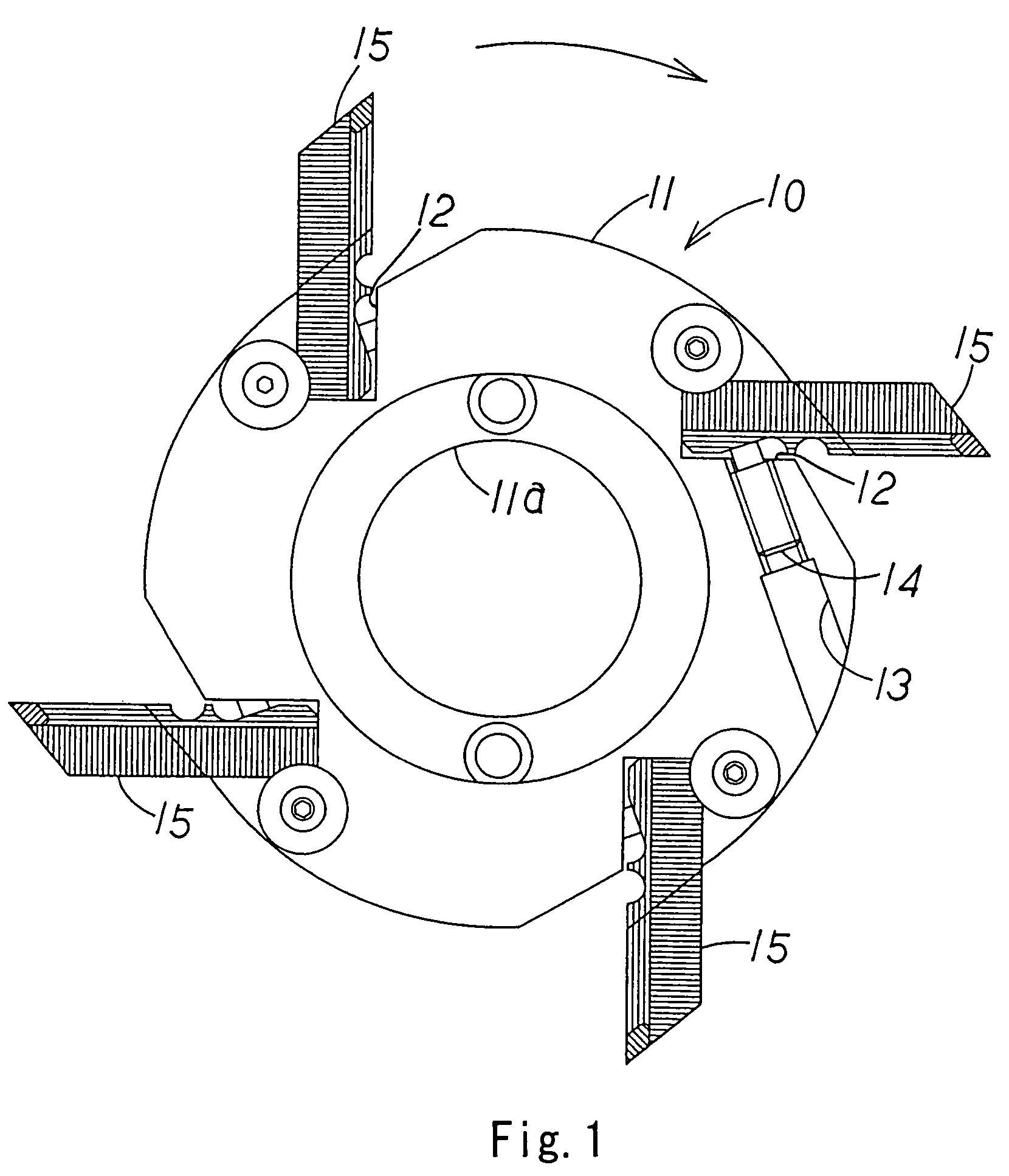

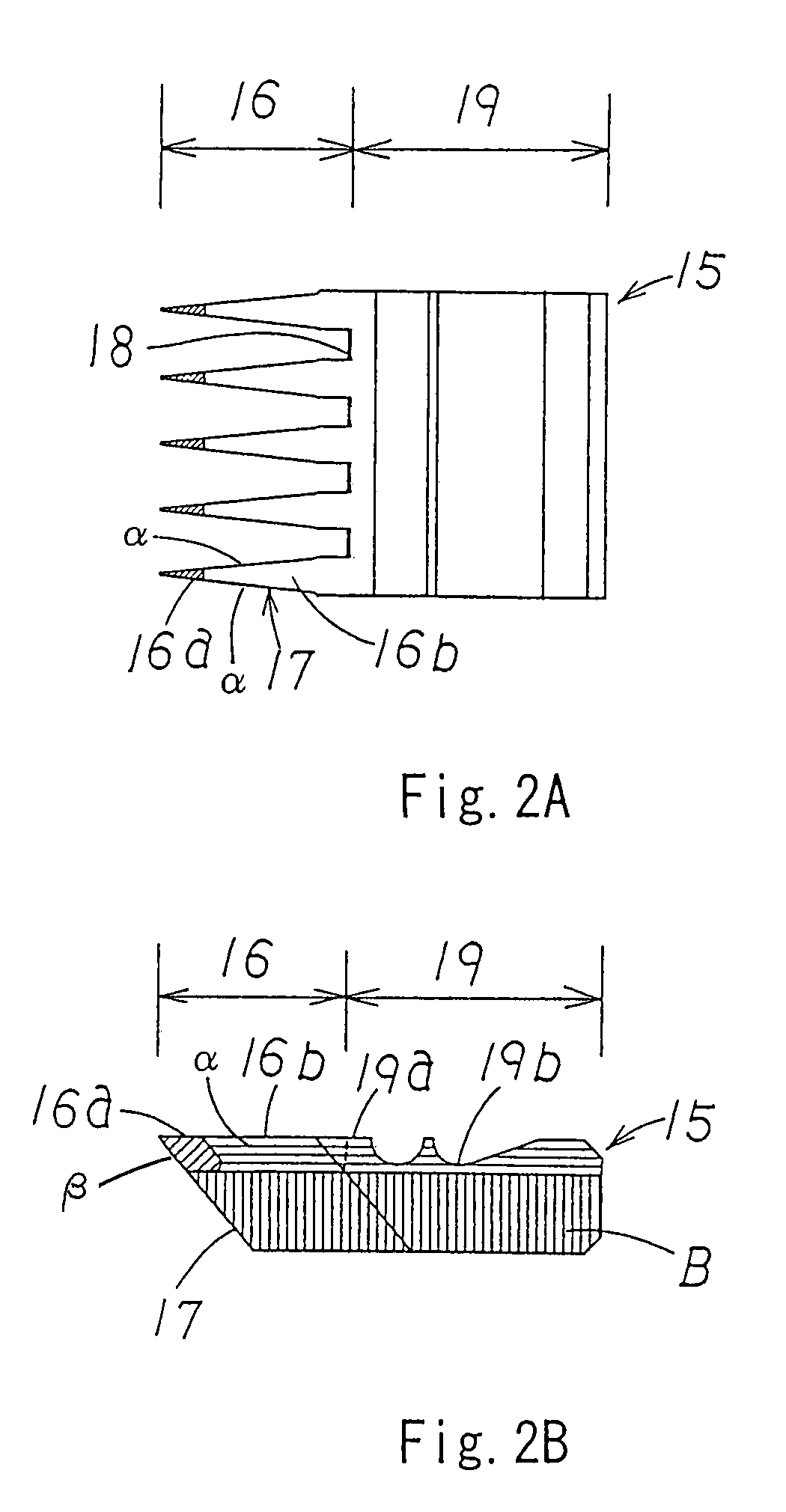

Finger cutter

InactiveUS7424900B2Restrict progress of wearHigh hardnessDovetailed workMulti-purpose machinesFinger jointHardness

Cutting portion regions of replaceable blades that extrude outward in a radial direction at a plurality of portions in a peripheral direction of an outer periphery of a body of a finger joint cutter are arranged in that, as for a cutting portion material that comprises cutting edge, tip end cutting portions are formed of a steel material of high hardness and base portion side cutting portions, which are the remaining portions, are formed of a steel material that exhibits a higher toughness than that of the tip end cutting portions. It is possible to improve the wear resistance through the tip end cutting portions and to improve the chipping resistance by the base portion side cutting portions. The steel material of high hardness comprising the tip end cutting portions and the steel material of high toughness comprising the base portion side cutting portions are successively joined through forge welding.

Owner:KANEFUSA HAMONO KOUGIYOU KK

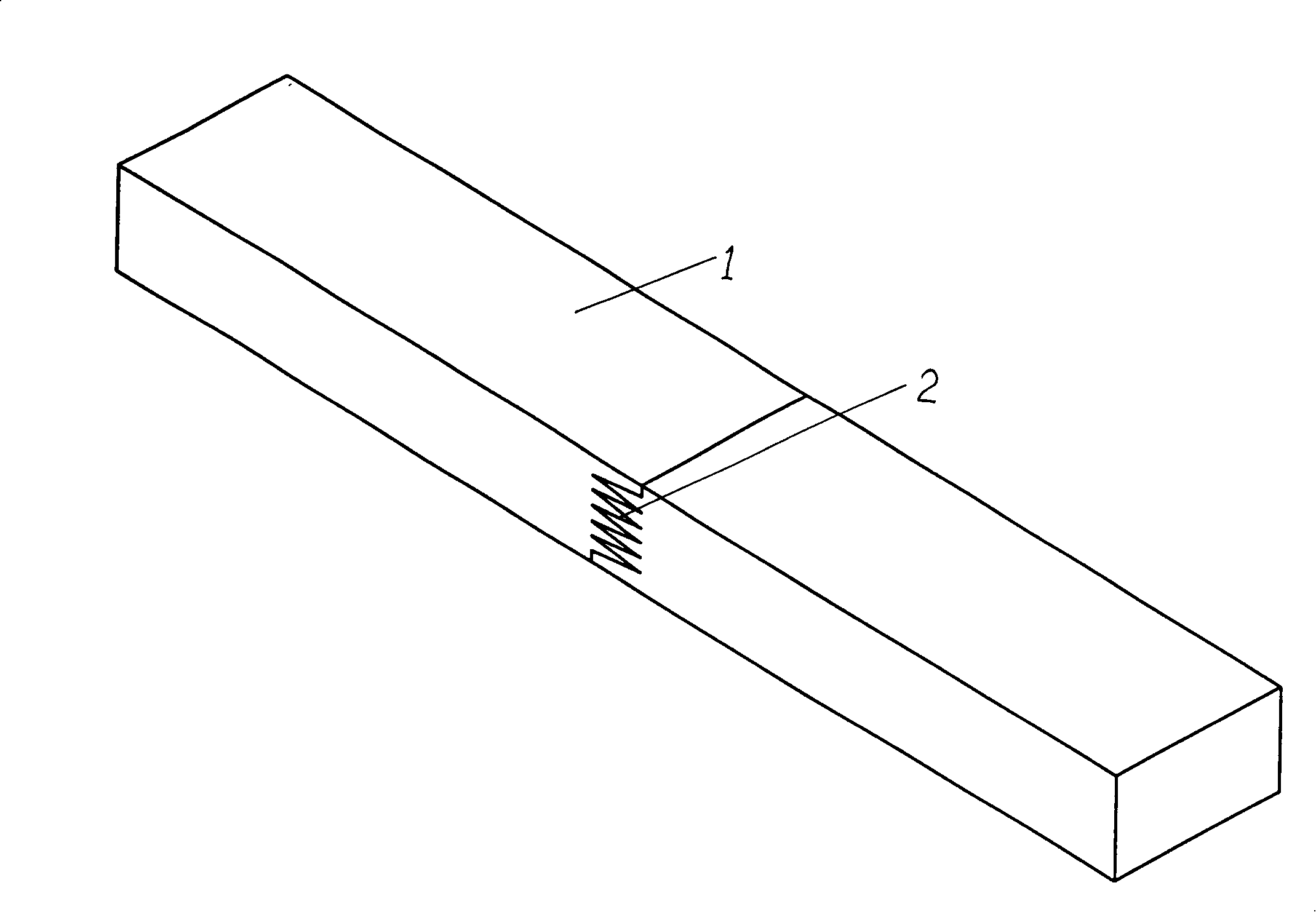

Finger joint laminated wood

InactiveCN101195227AReasonable structureSave woodWood veneer joiningFinger joining apparatusFinger jointEngineering

The invention relates to a decorating material of a finger jointed wood. Finger jointed teeth are provided in the width direction of planks by using rough edges of unedged planks. The width direction of planks is connected via the finger jointed teeth and glued. At least one or more than one finger joint teeth are not perpendicular to the surface of the glued planks. The finger jointed wood of the invention is reasonable in structure. Finger jointed teeth are arranged in the width direction of unedged planks and continuously arranged along the shape of arc-shaped rough edge of the unedged planks. The shape of the finger jointed teeth can be formed into both angle style and straight type according to requirement. When finger joint is in progress, only tooth profile joint of finger jointed teeth of two jointed planks is needed, and then finger joint is accomplished by other technical processes of glue joint, fixation and the like. Unconventional finger jointed teeth are provided according to the characteristics of unedged planks, and approximately 20% wood is saved.

Owner:王桂松

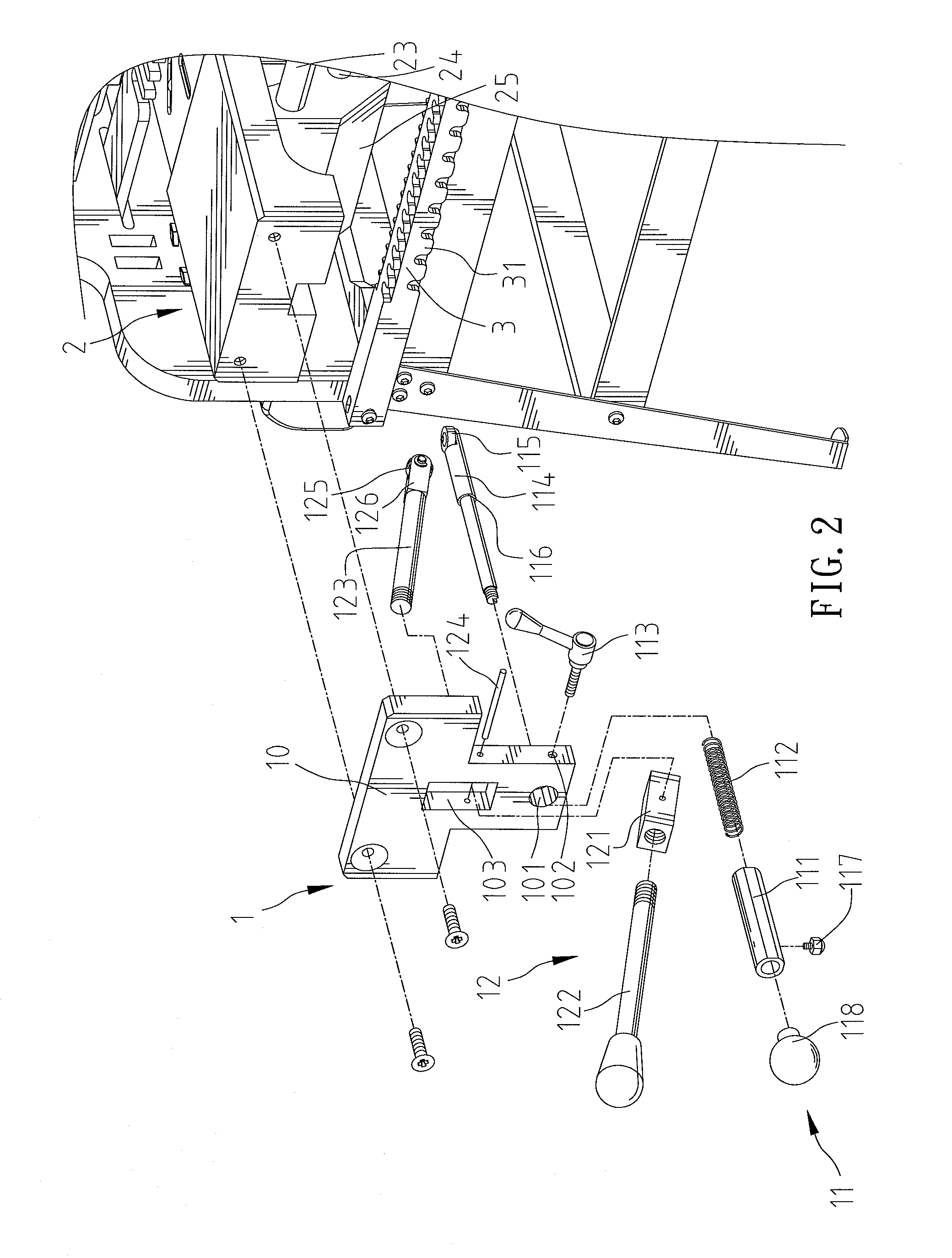

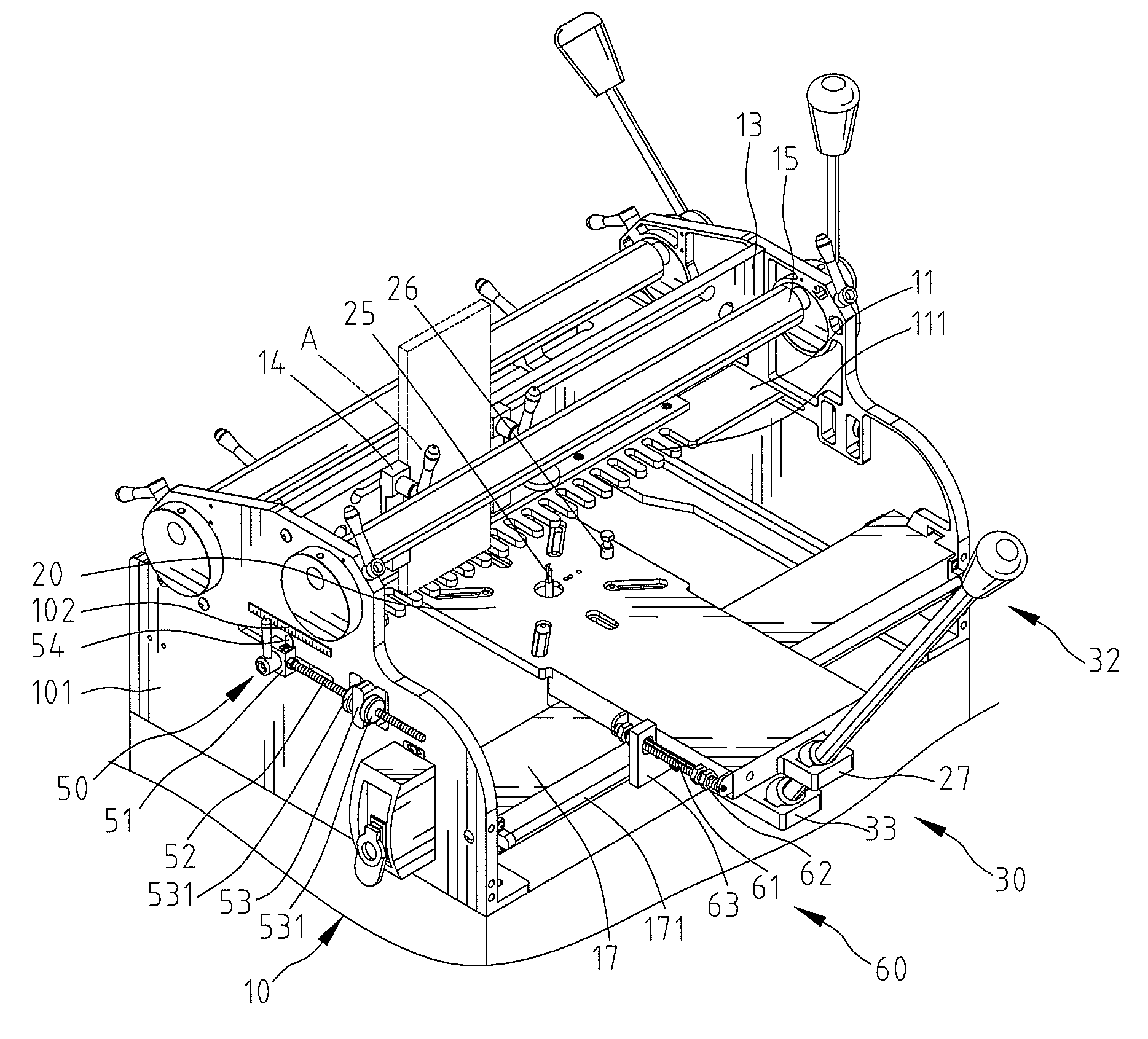

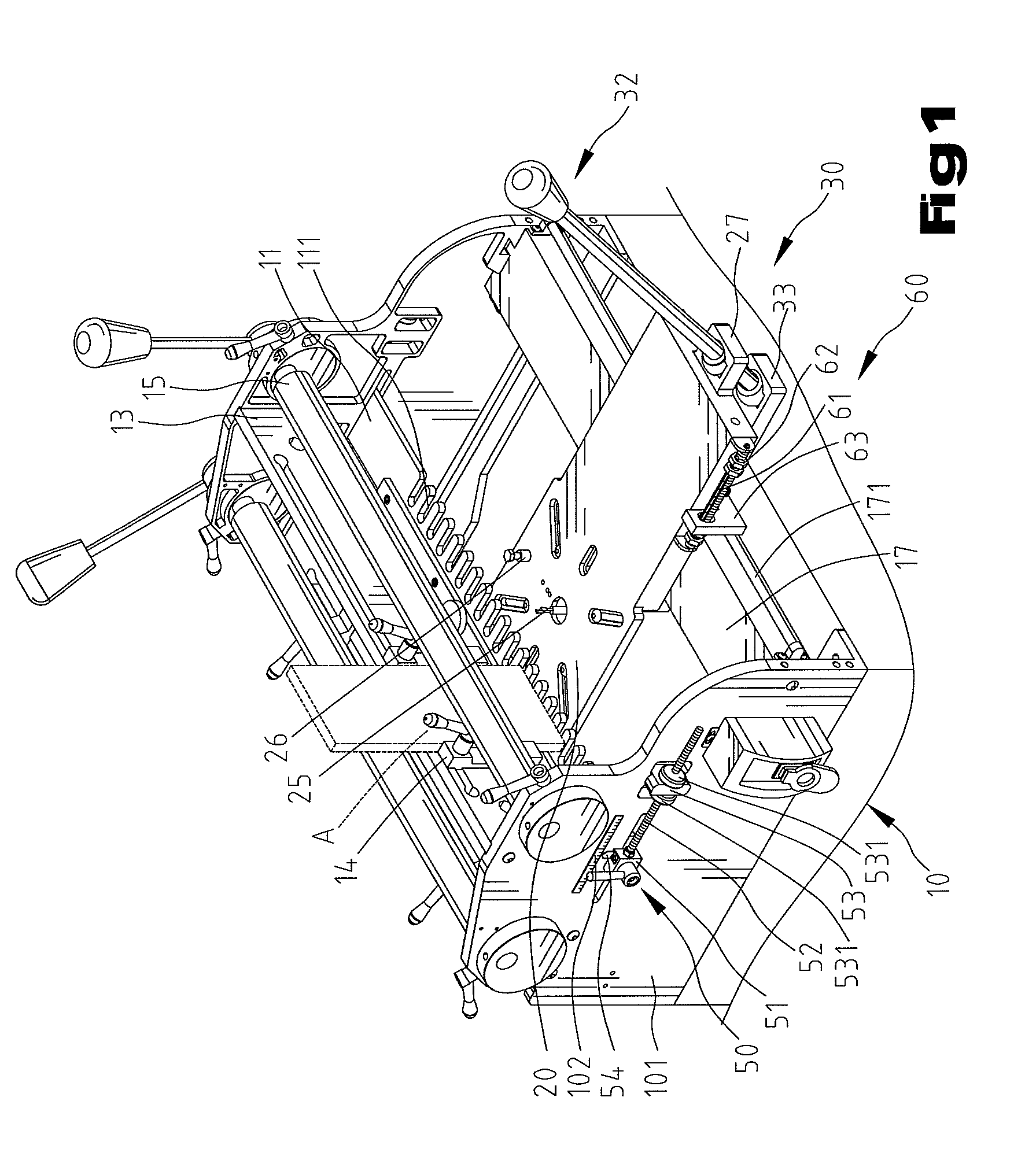

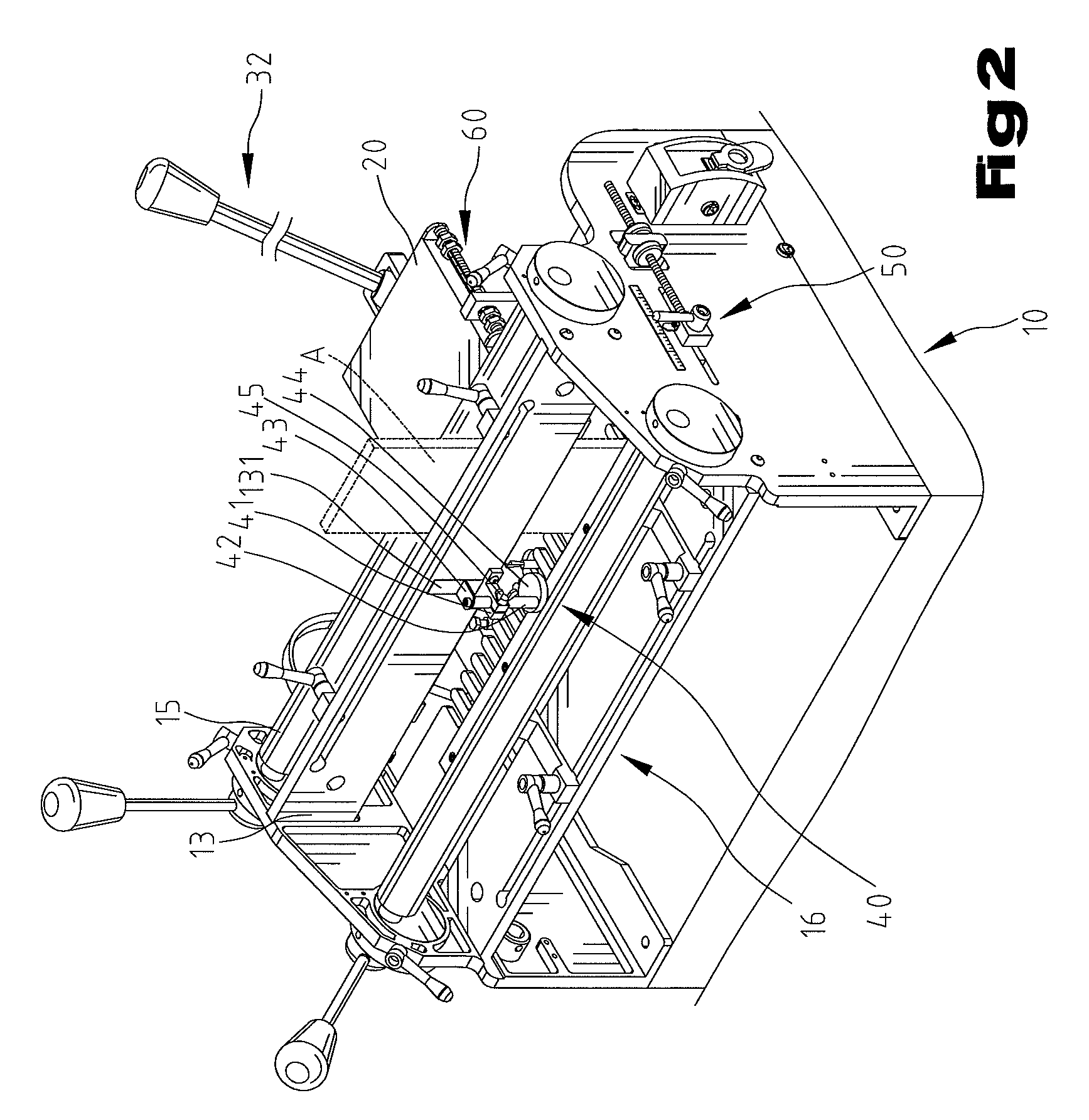

Operation Device for Quick and Accurate Control of Working Device of Tenoner

InactiveUS20090288736A1Quick and accurate mannerTongue/grooves making apparatusDovetailed workEngineeringMechanical engineering

Owner:YANG JACK

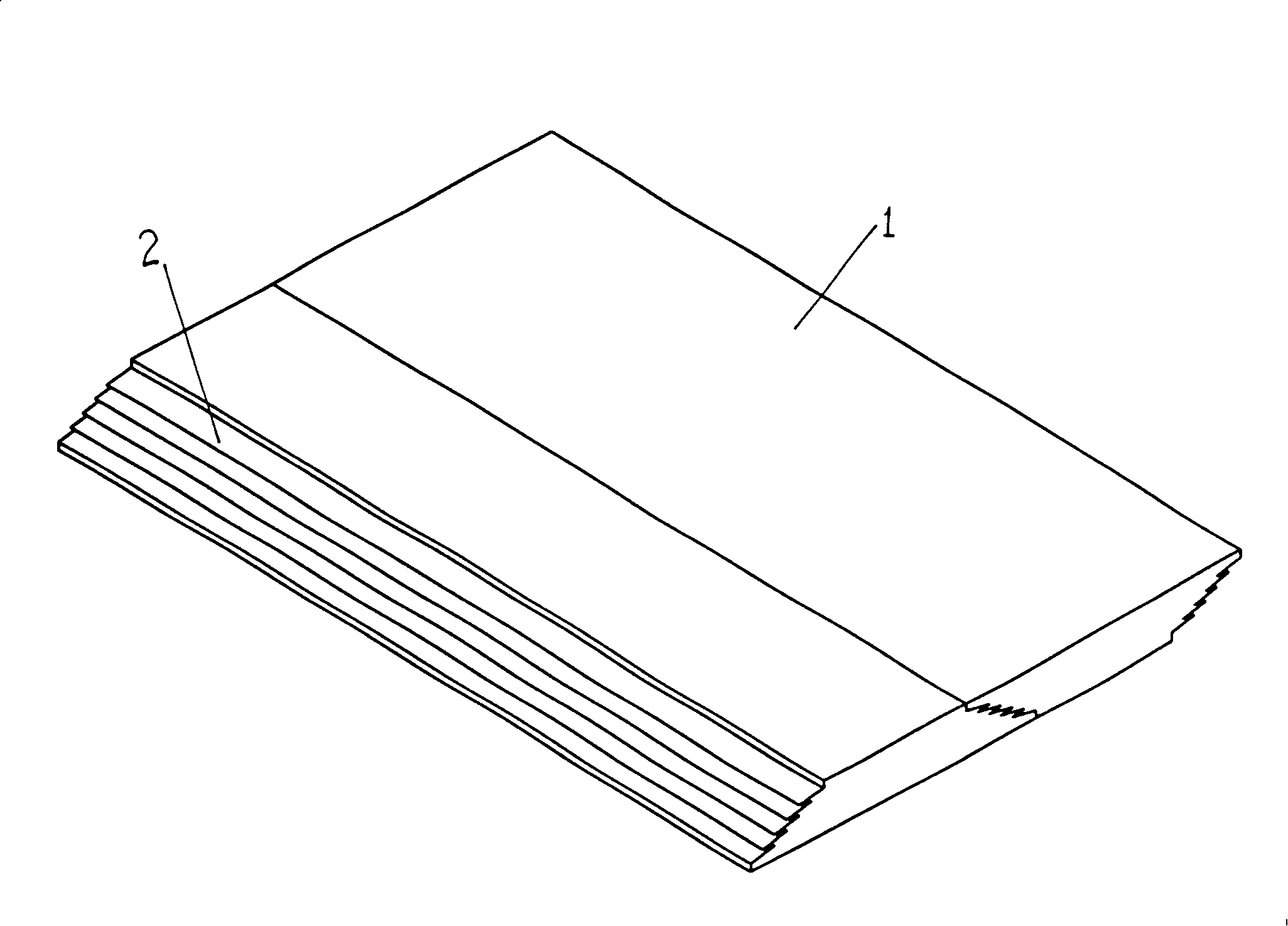

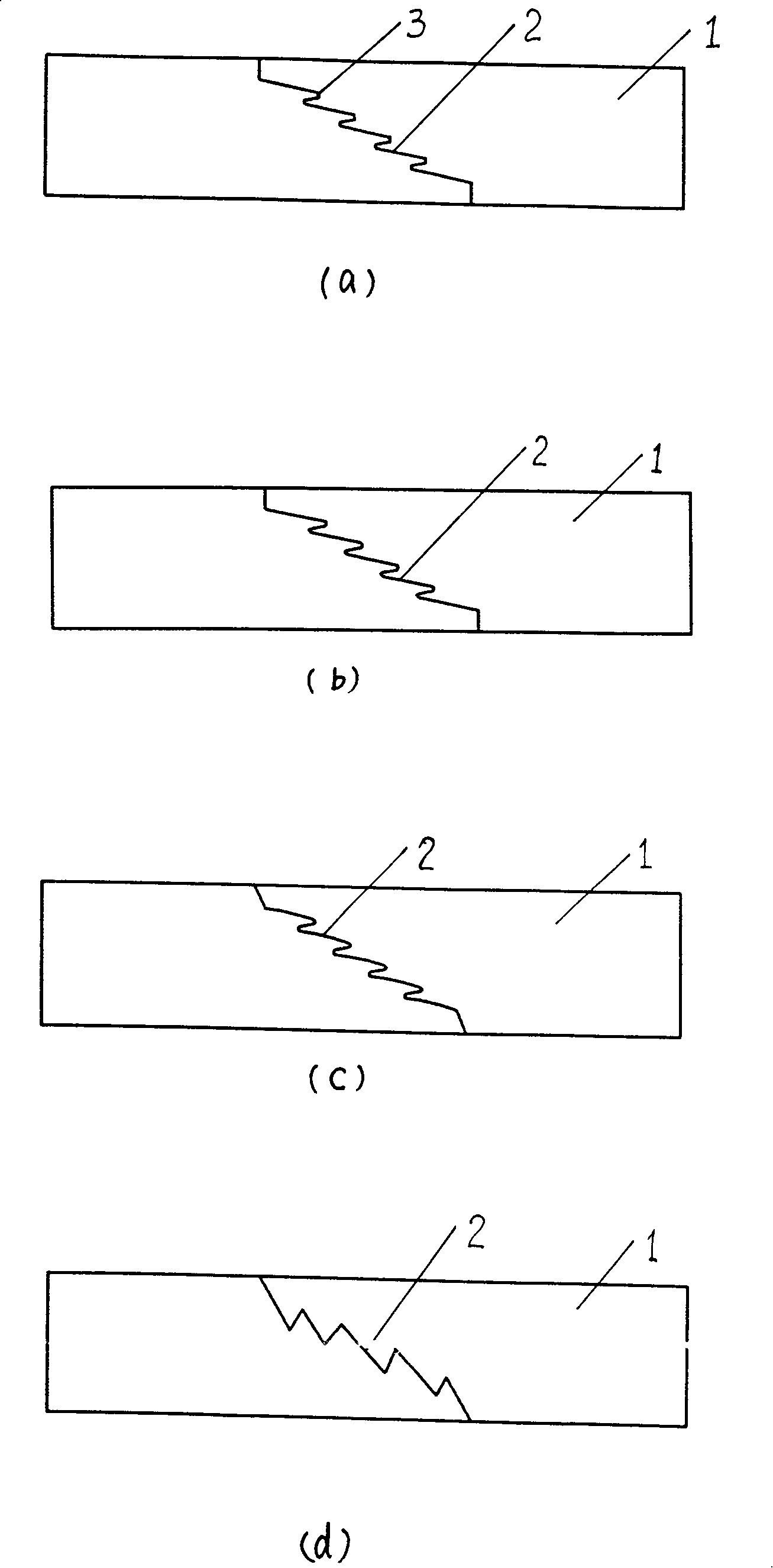

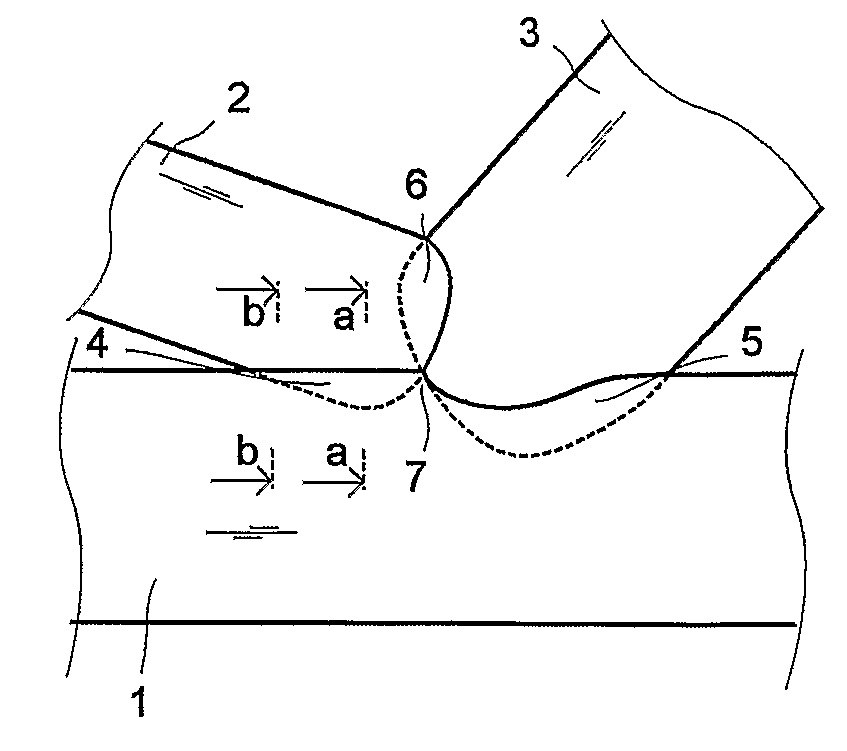

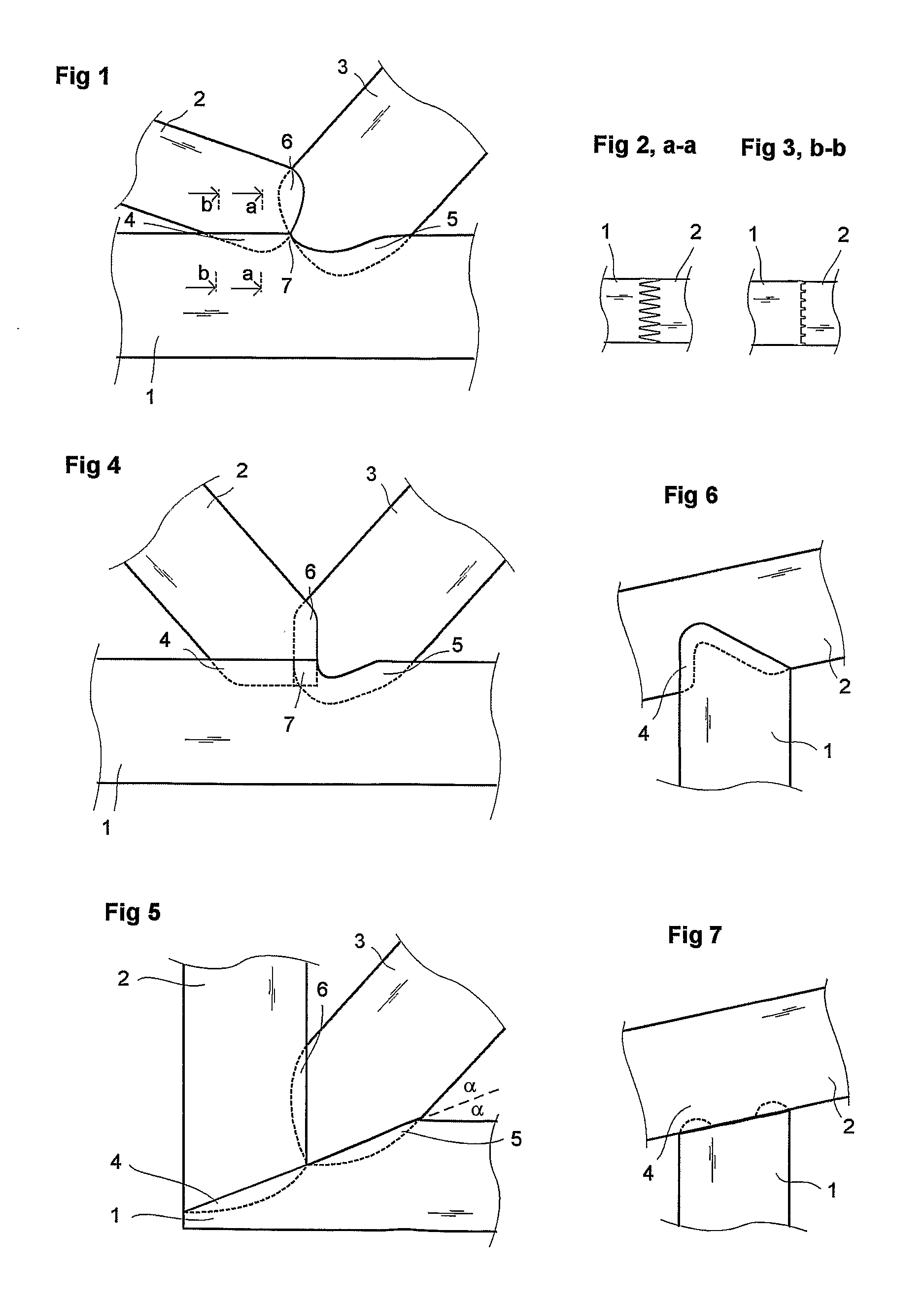

Joint Between Wood Pieces

A joint between wood pieces, as of timber, laminated timber, LVL, plywood etc., where one or more bars (2, 3), as the diagonal of a truss, is connected the side of other bar (1), as the side of the truss chord whereby in the produced joint all said bars are connected to each other by a finger joint. From chord (1) wood is cut either so that asymmetrically from the one side less is cut than from the other side or so that from the middle less is cut than from the ends.

Owner:POUTANEN TUOMO

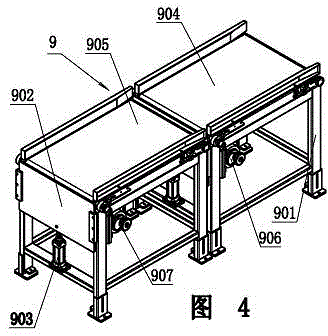

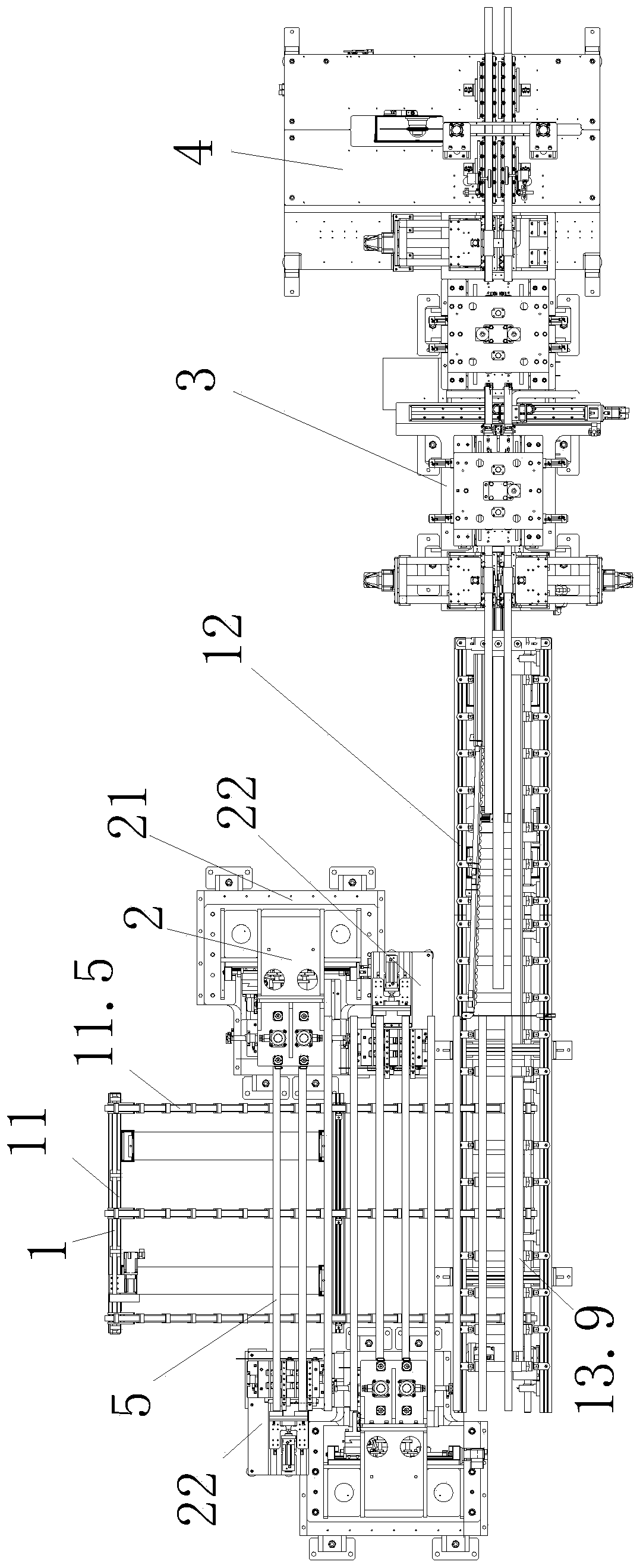

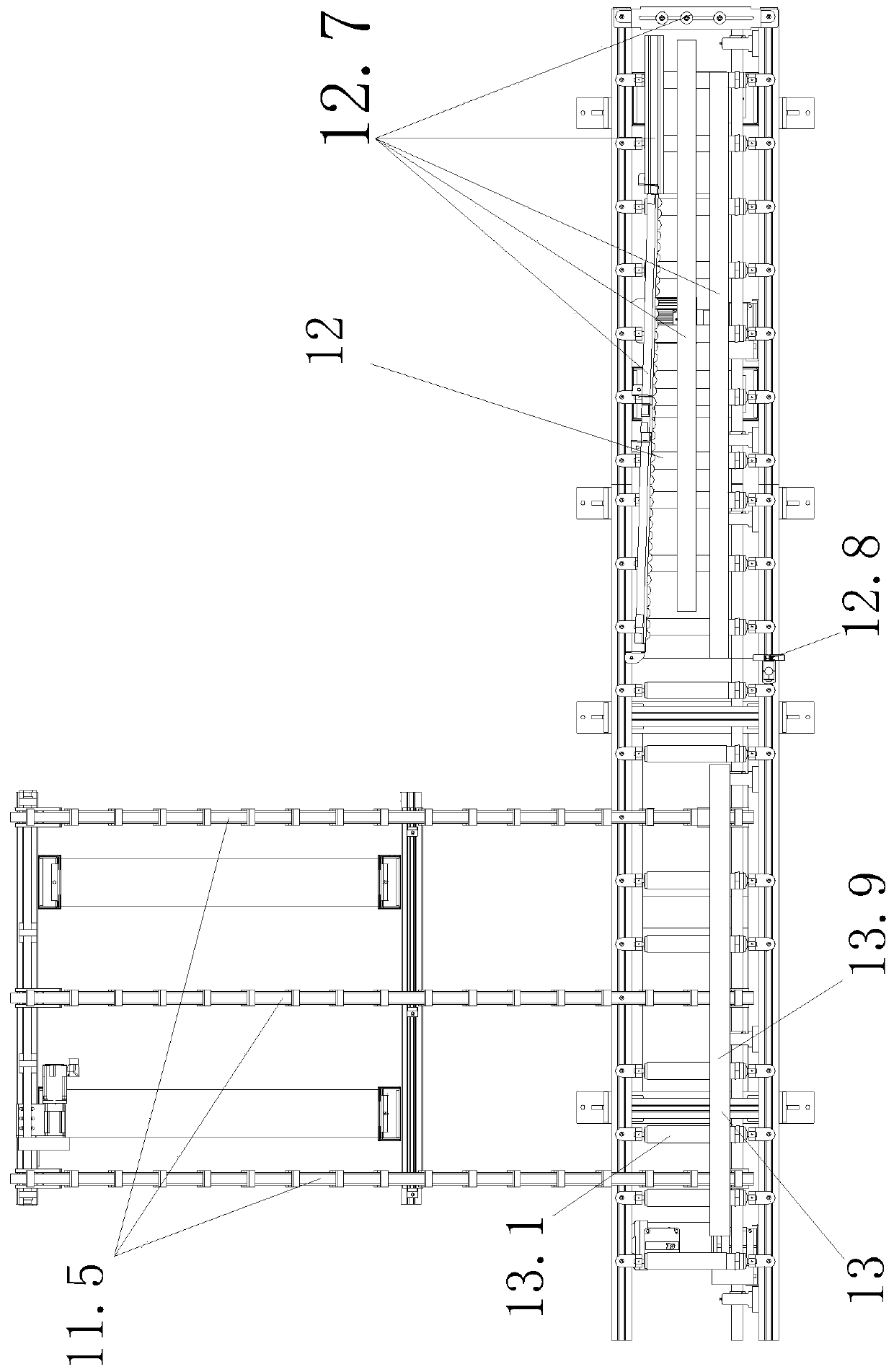

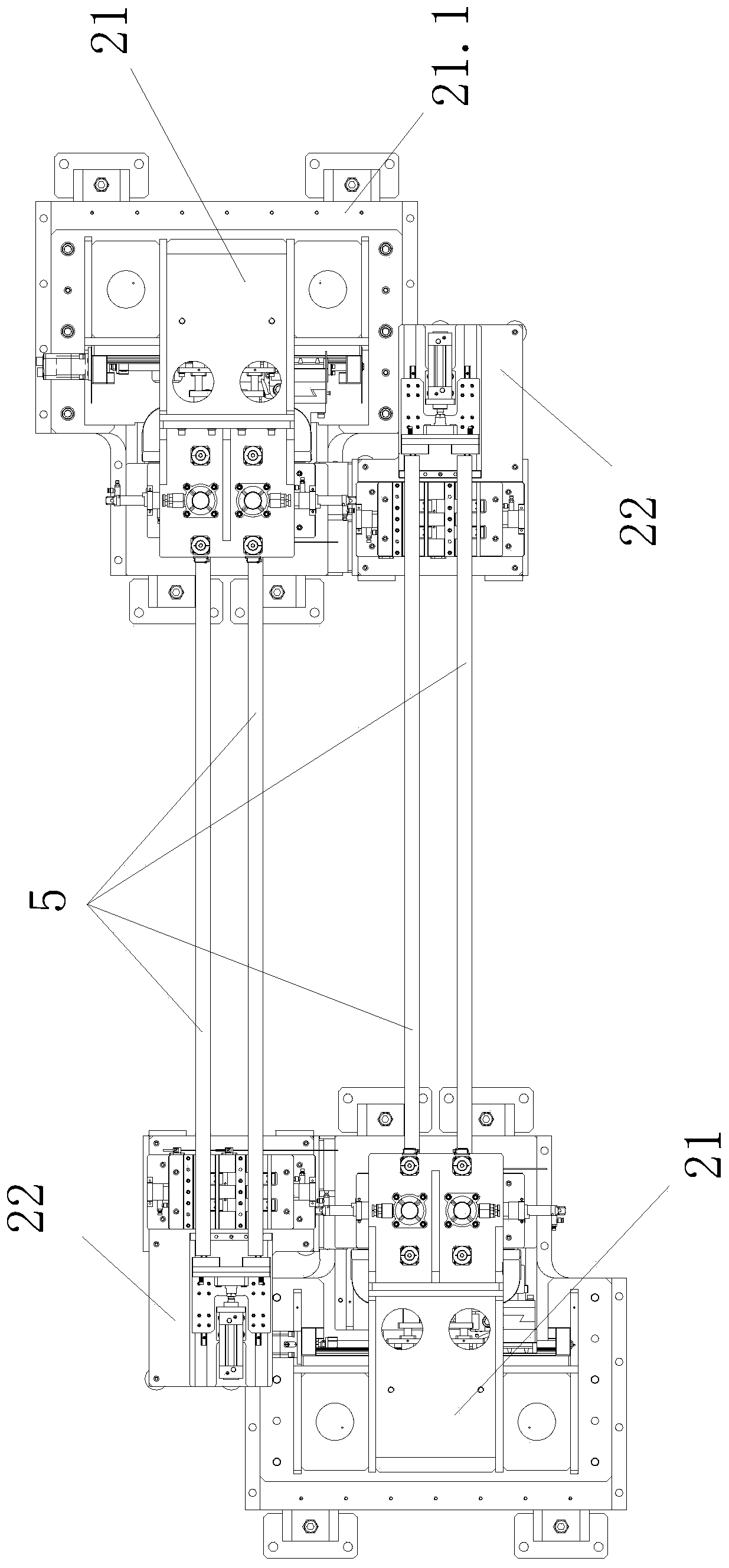

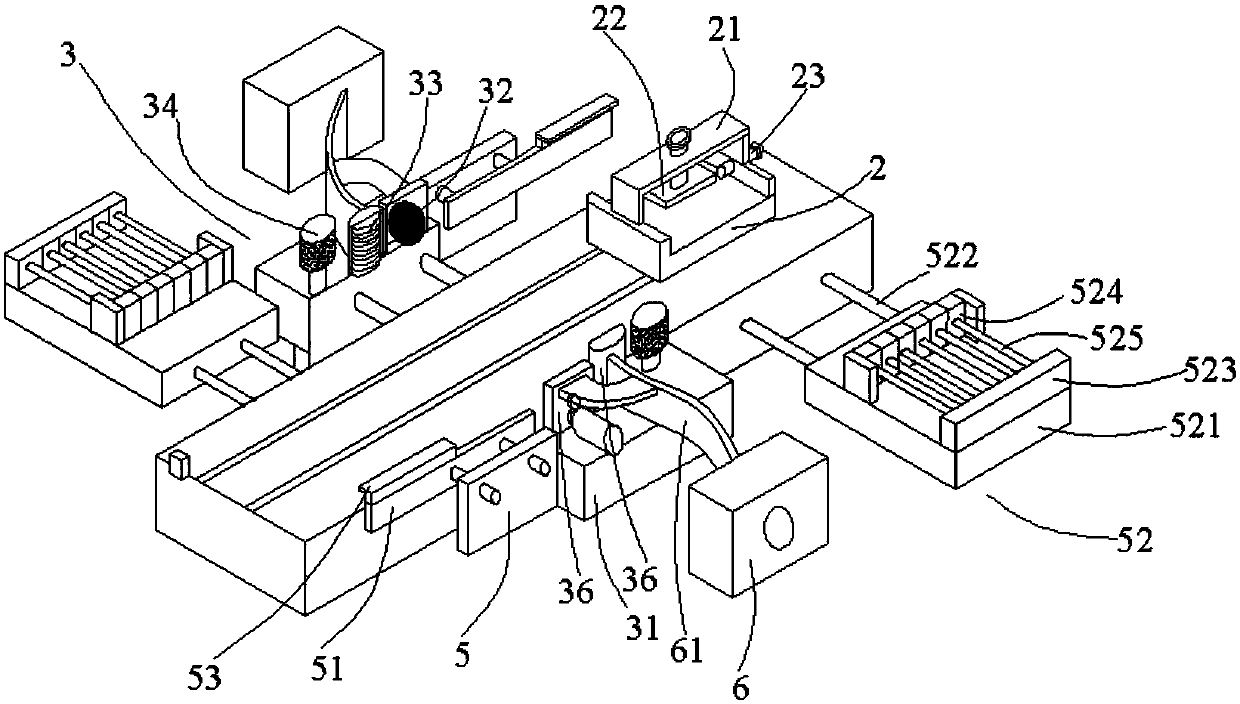

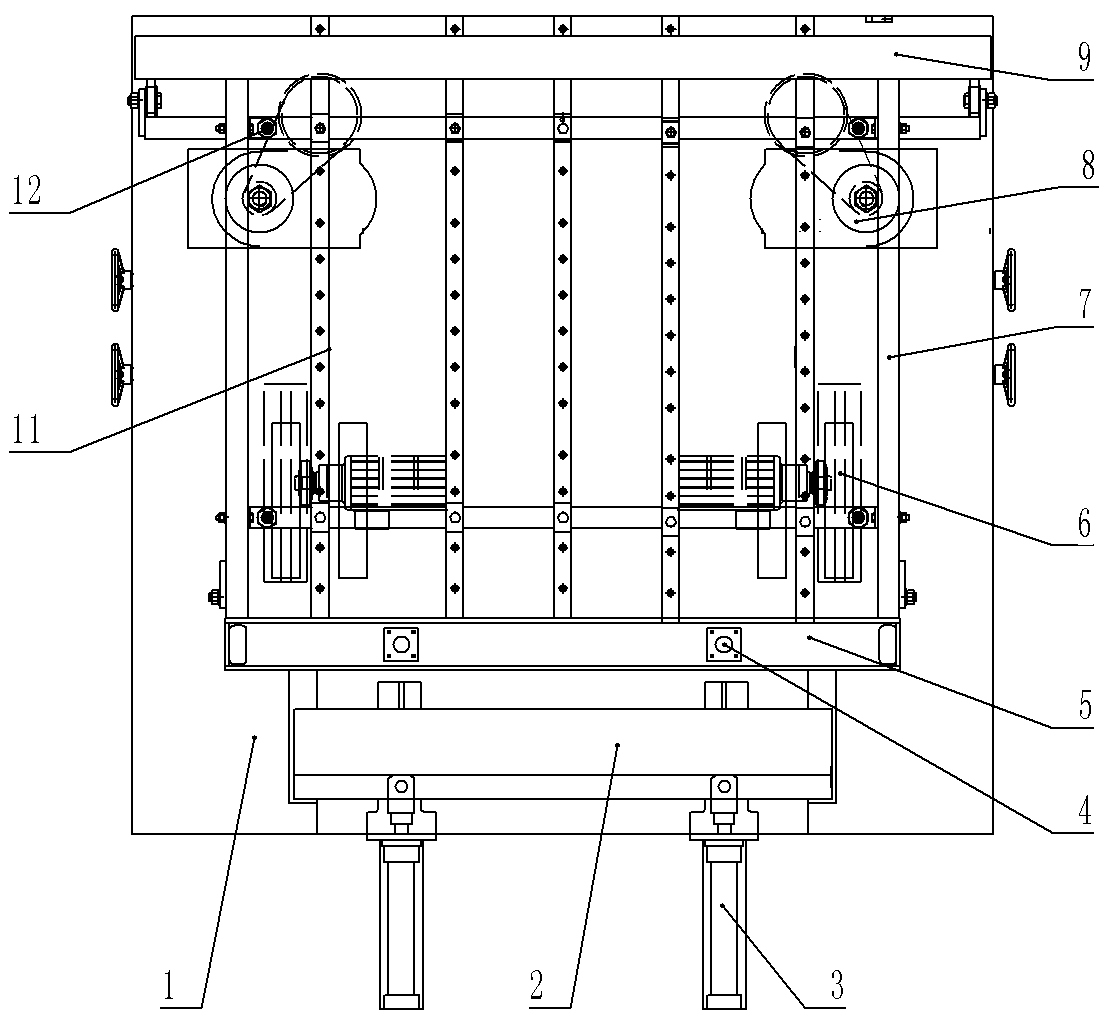

Equipment for splicing and fixed-length cutting blanking for laminated timbers

The invention discloses equipment for splicing and fixed-length cutting blanking for laminated timbers. The equipment for splicing and fixed-length cutting blanking for the laminated timbers comprisesan automatic loading device, a conveying device, a tooth milling device, a splicing device, a cutting device and a control center. The conveying device comprises a chain conveying device, a fixed roller conveying device and a lifting conveying device. The laminated timbers to be spliced are placed onto the automatic loading device at first, sequentially and intermittently placed onto the chain conveying device by the automatic loading device, and then sequentially and intermittently pushed forwards to reach the position of the tooth milling device by the chain conveying device, the right endsand the left ends of the laminated timbers to be spliced are sequentially and orderly milled, then the laminated timbers to be spliced are intermittently pushed forwards to reach the part of the lifting conveying device, then the laminated timbers to be spliced are intermittently conveyed to the right and onto the fixed roller conveying device by the lifting conveying device, finally the laminated timbers to be spliced are spliced on the splitting device, and then the spliced laminated timbers are conveyed to the right and onto the cutting device to be cut according to a specific length; andthe whole process is controlled by the control center to be automatically and orderly completed, and the advantage of high working efficiency is achieved.

Owner:SIASUN ROBOT & AUTOMATION LIMITED BY SHARE

Compound Lumber Product

InactiveUS20180361615A1Transportation and packagingWood veneer joiningEngineeringMechanical engineering

The present invention discloses a compound lumber product, relating to the technical field of wooden materials for making furniture, and particularly to a compound lumber product that may be used for making furniture. The compound lumber product includes a core lumber and side-members surrounding the core lumber. The core lumber may be one piece or formed from several core members. The side-members may be single-piece or formed by joining together several high-grade wood boards or strips. Side-members are arranged side by side around the outer surface of the core lumber, wrapping around the core lumber with tail edge of a preceding side-member secured or connected to the inner side-face of the subsequent adjoining side-member at its head edge in a head-to-tail manner, to form the enclosure structure.

Owner:WANG KUNJIE

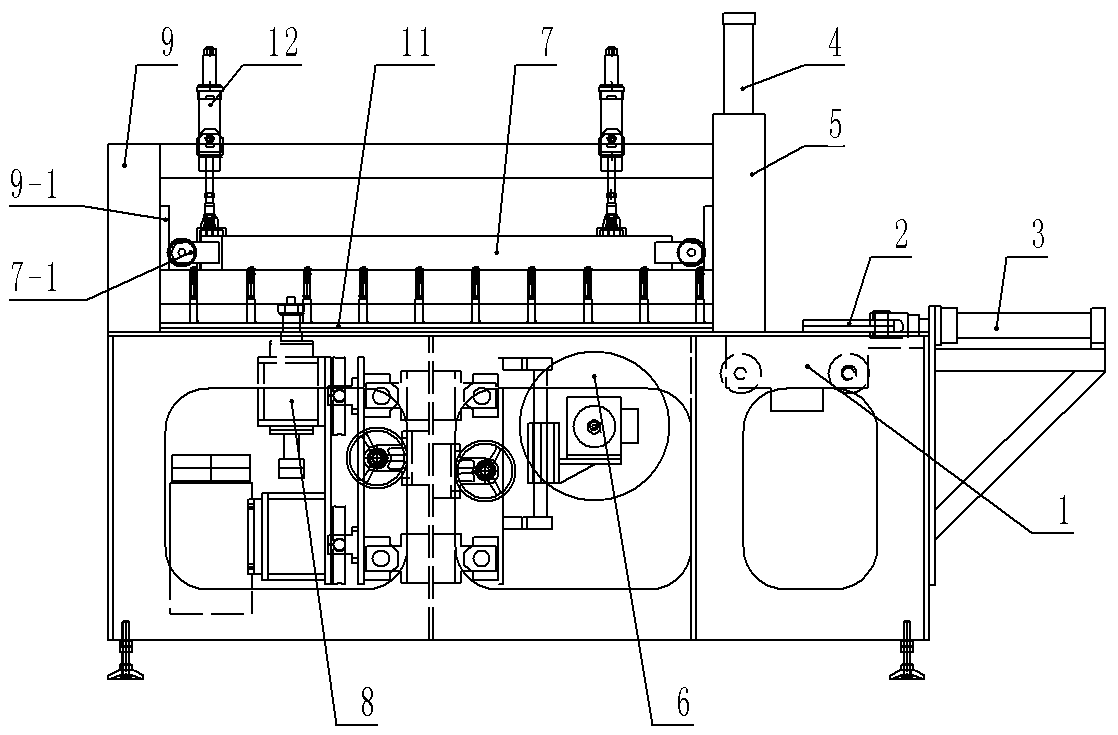

Double-end finger joint laminated board tenoning machine

PendingCN108032384APrevent tiltingReduce adverse effectsEdge grinding machinesFeeding devicesAutomatic controlReciprocating motion

The invention relates to the technical field of wood processing devices and particularly relates to a double-end finger joint laminated board tenoning machine. The double-end finger joint laminated board tenoning machine comprises a machine base, a feeding frame and a tenoning device, wherein the feeding frame is capable of doing reciprocating motion on the machine base through a transmission chain; the feeding frame is used for fixing wood boards; the tenoning device comprises placing boxes; two placing boxes are respectively located at two sides of the machine base and are connected with each other through a telescopic device; a trimming saw blade, a tenoning blade and a roughness removing hairbrush are arranged on each placing box; an aligning device is capable of aligning wood boards before tenoning. According to the double-end finger joint laminated board tenoning machine, a PLC is used as a control system; the tenoning machine has higher flexibility and is capable of tenoning long wood boards and the wood boards of various lengths and reducing roughness of tenoned grooves; the tenoning machine is automatically controlled, so that the occurrence of the safety accidents is avoided.

Owner:柳城县迪森人造板有限公司

Mortise/tenon machine

Owner:YANG JACK

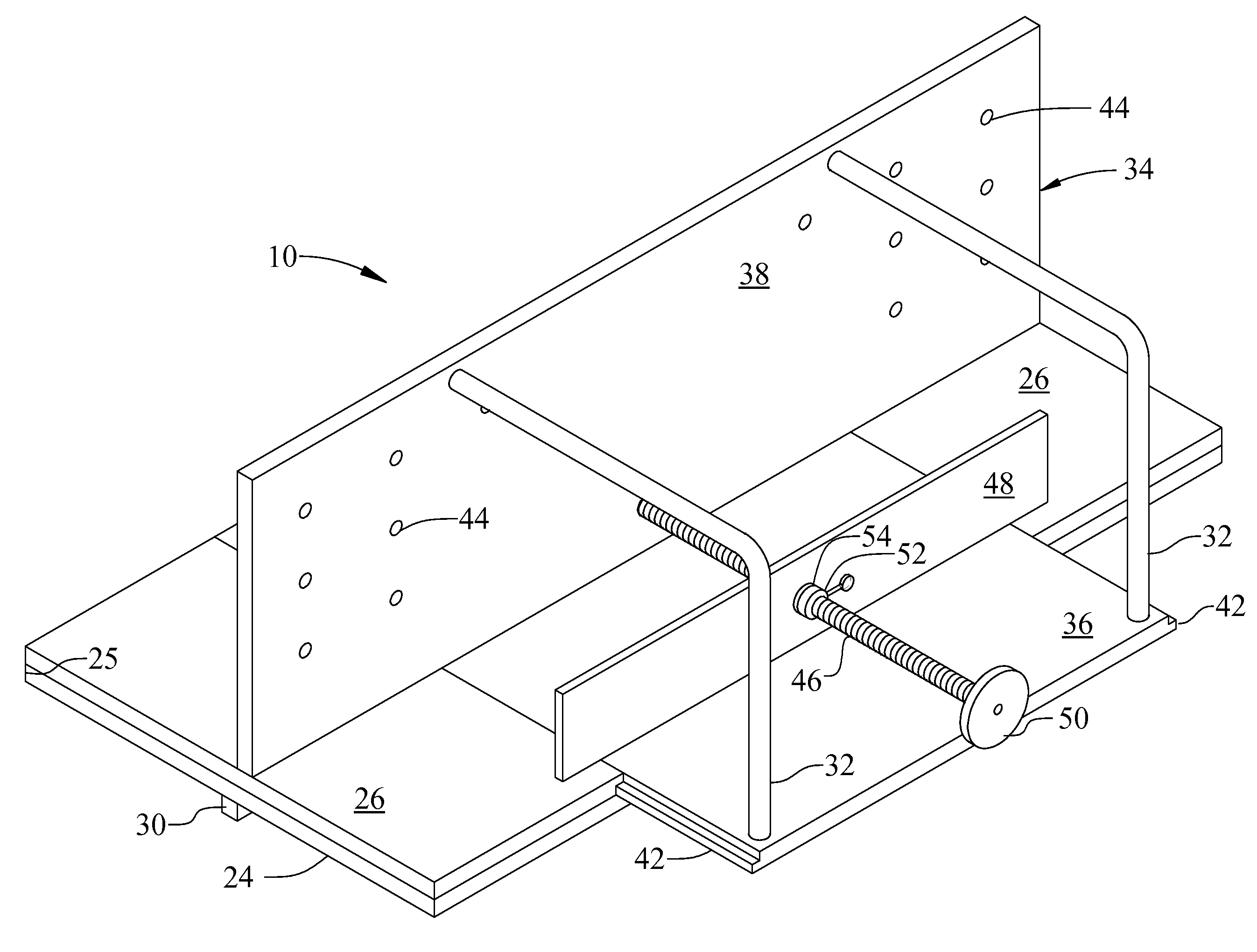

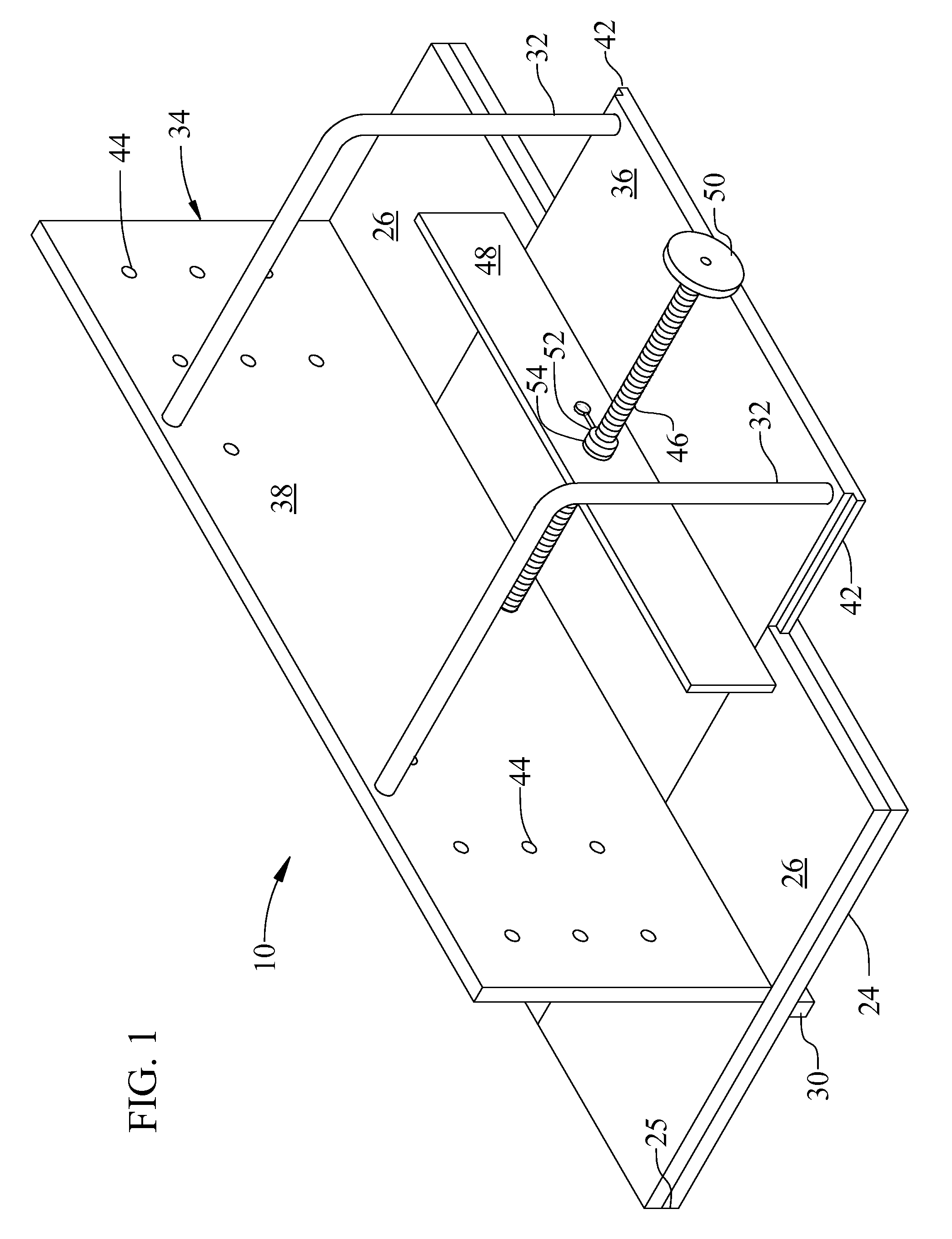

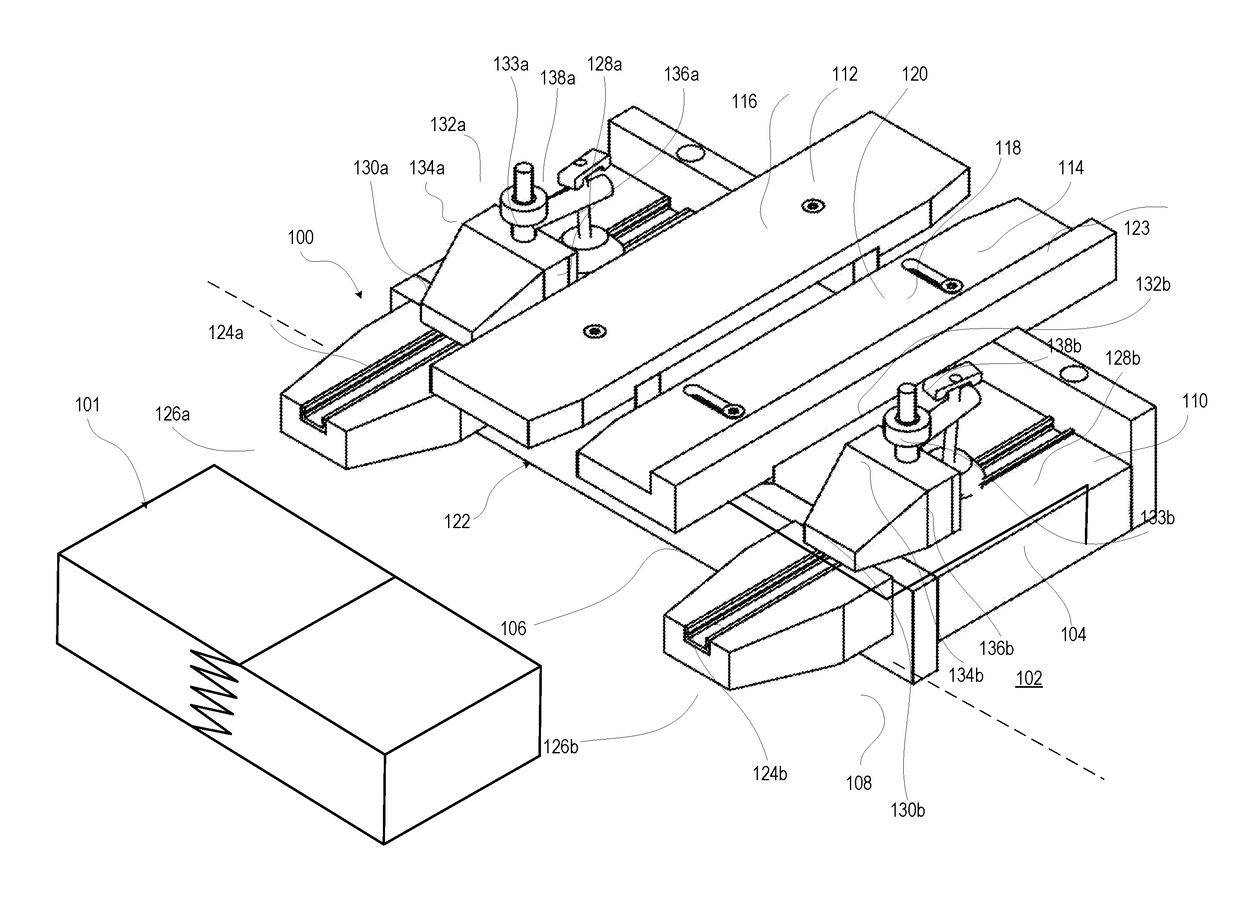

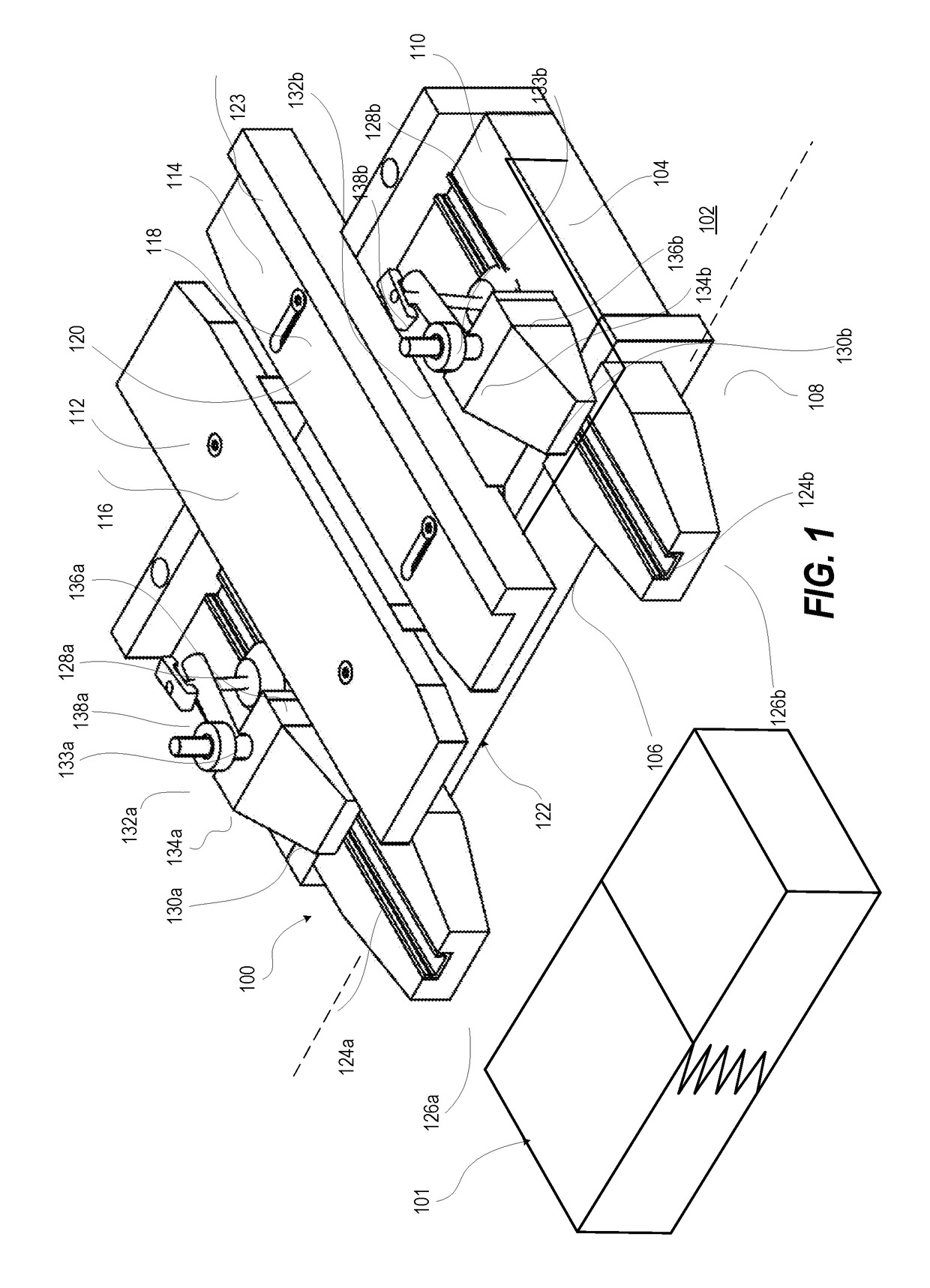

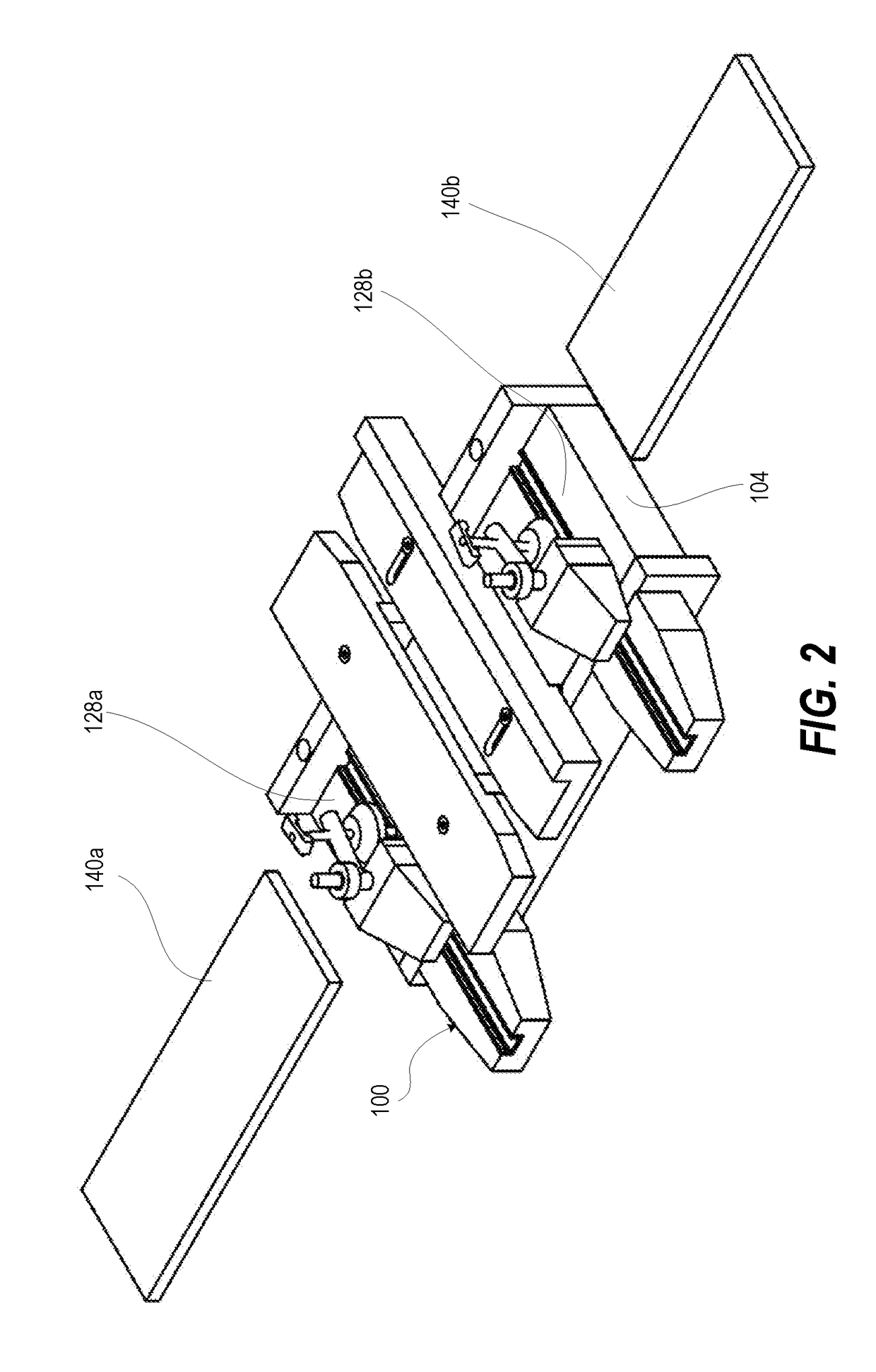

Finger Joint Router Jig

A router jig includes a router jig base having: (i) a first board guide that receives an end of a first board; (ii) a second board guide that receives an end of an aligned second board from an opposite side; and (iii) a router guide that receives an guides a finger joint tool of a hand router along a transverse direction to the first and second board guides to simultaneously impart finger joint grooves. A clamping mechanism selectively clamps the first and second boards respectively within the first and second board guides.

Owner:SAYLOR SOLUTIONS LLC

Board jointer

PendingCN108748461AHigh strengthShorten the production cycleWood veneer joiningFinger joining apparatusSprayerProduction cycle

The invention discloses a board jointer and relates to the technical field of wood processing equipment. The board jointer comprises a gumming machine and a batten board jointer. The batten board jointer is successively connected to a comb deice through a comb crimping conveying device and a conveying bridge frame; the gumming machine is mounted close to the comb crimping conveying device, and a glue sprayer is mounted on one side of the conveying bridge frame; a first feeding push plate, a batten leveling device and a leveling and straightening device are successively mounted on a comb feeding table, edge trim saws are separately mounted on two sides of the feeding end of the leveling and straightening device, and comb saws are separately mounted on two sides of the discharge end of the leveling and straightening device; a second feeding push plate is mounted on the outer side of a feeding channel of the batten board jointer, a stroke switch is mounted at the tail end of the feeding channel, a cutoff saw is mounted at the initial end, and the stroke switch and the cutoff saw are electrically connected to a control box. Compared with the prior art, it only takes 3.8 minutes from entering the comb to jointing the board, so that the production period is short; the integral strength of the panel is high, and the panel is not trimmed, so that the material is saved; and operation staff of one piece of equipment is needed, so that the manpower is saved by 50%.

Owner:LIUZHOU WUXIN WOOD WORKING MACHINERY

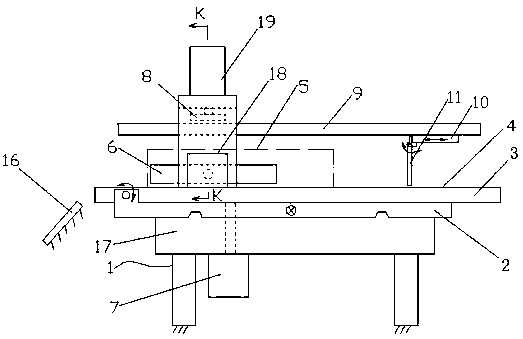

Wood board end leveling device and working method thereof

PendingCN111136731AReduce wasteImprove ergonomicsMulti-purpose machinesFinger joining apparatusAgricultural engineeringWood plank

The invention relates to a wood board end leveling device and a working method thereof. The wood board end leveling device comprises a rack and a sliding seat which are arranged on a wood processing production line, the sliding seat is provided with a turning-over table with the first end being hinged to the sliding seat, the turning-over table is provided with a platform face and a pressing plateused for pressing wood board strips, the multiple longitudinally-arrayed wood board strips can be placed on the platform face, a driving mechanism for lifting and turning over the second end of the turning-over table is arranged between the sliding seat and the turning-over table, after the second end of the turning-over table is lifted, the platform face and the wood board strips on the platformface are in an inclined state, and a blocking strip for blocking the wood board strips is arranged at the first end, close to the turning-over table, on the rack. According to the wood board end leveling device, through the inclined platform face, the wood board strips located on the platform face slide down along with the gravity, through blocking of the blocking strip located at the low position, one ends of the wood board strips located at the low position are absolutely flush, thus combs meeting the requirements are advantageously and subsequently processed, wood waste is reduced, and theworking efficiency is improved.

Owner:程传城

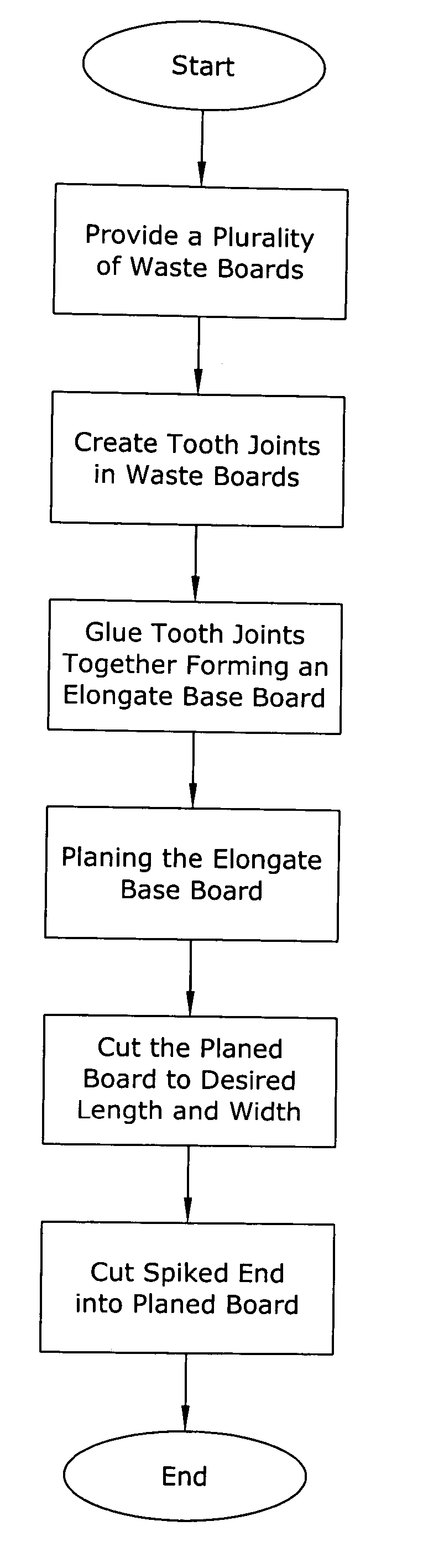

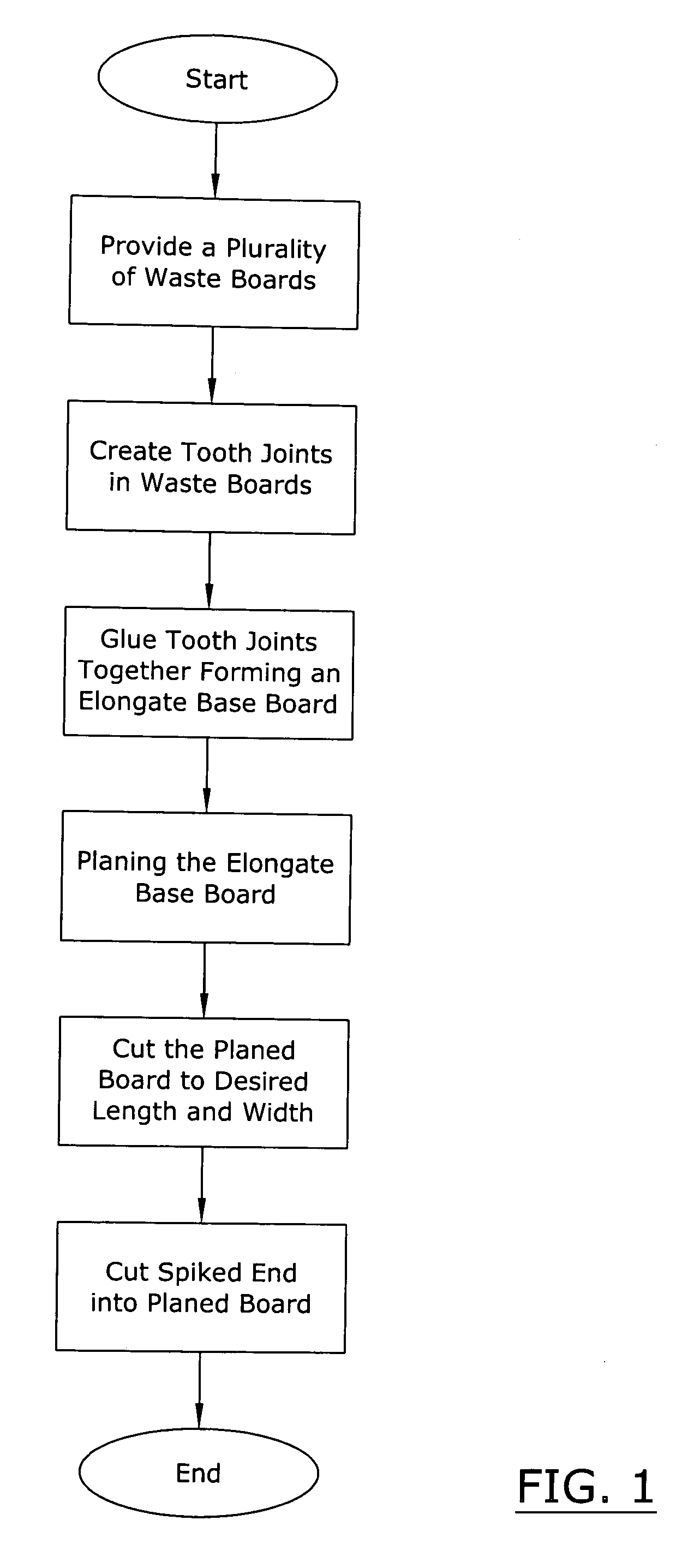

Stake manufacturing system

A stake manufacturing system for effectively recycling waste boards into a stake product. The stake manufacturing system includes providing a plurality of waste boards, creating one or more tooth joints in each of the waste boards, gluing the tooth joints together to form an elongate base board, planing the base board to a desired thickness, cutting the planed board to a desired length and width, and cutting a spiked end into the planed board. The resulting product may thereafter be utilized as a conventional stake for marking boundaries and locations.

Owner:KEMMESAT DENNIS D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com