Board jointer

A technology of jigsaw machine and pressing board, which is applied in the jointing of wooden veneers, wood processing equipment, adhesive application devices, etc., which can solve the problems of long production cycle, uneven side of the board, increased workload, etc., and achieve the production cycle The effect of shortening, material saving, and overall strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

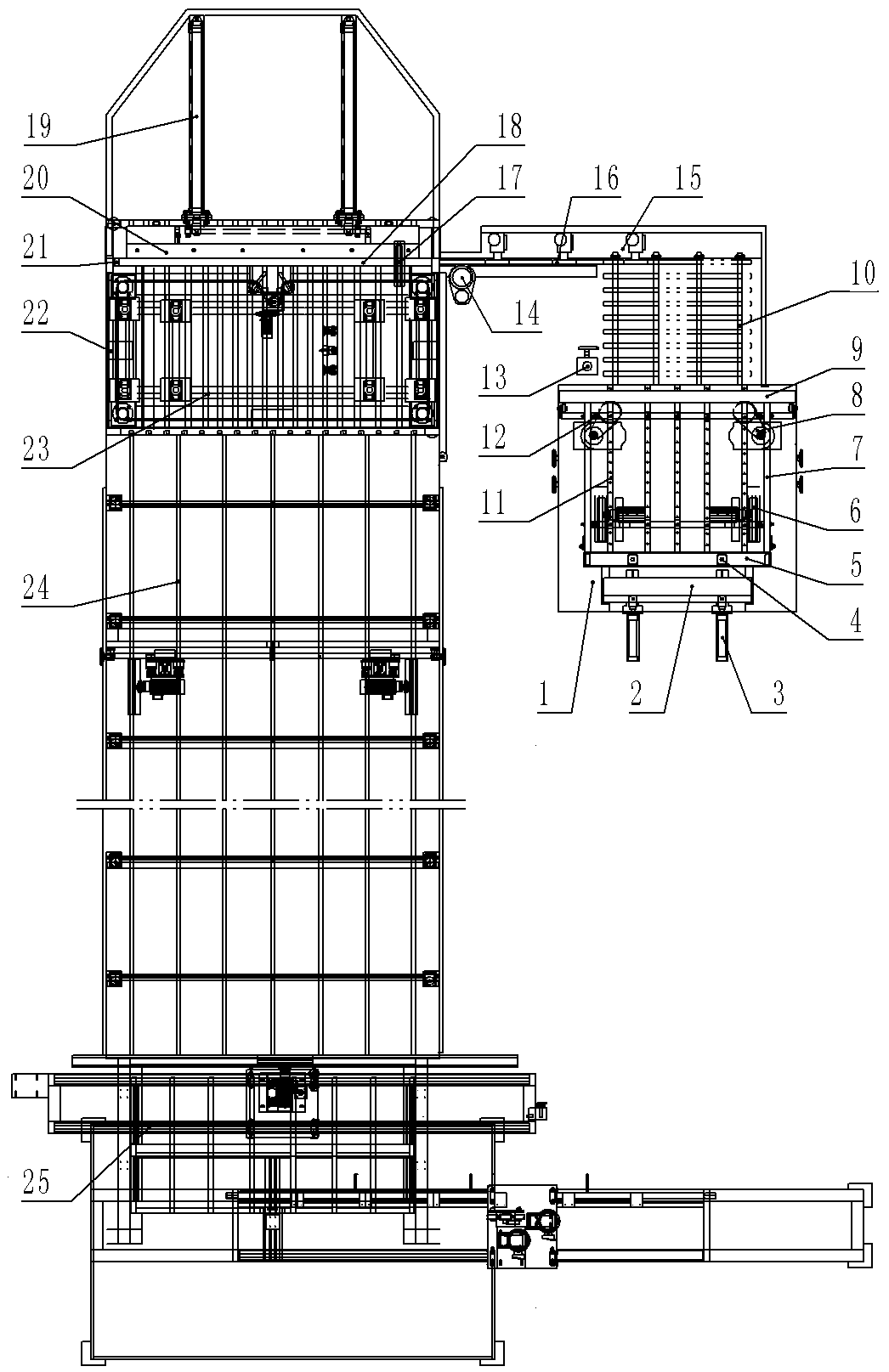

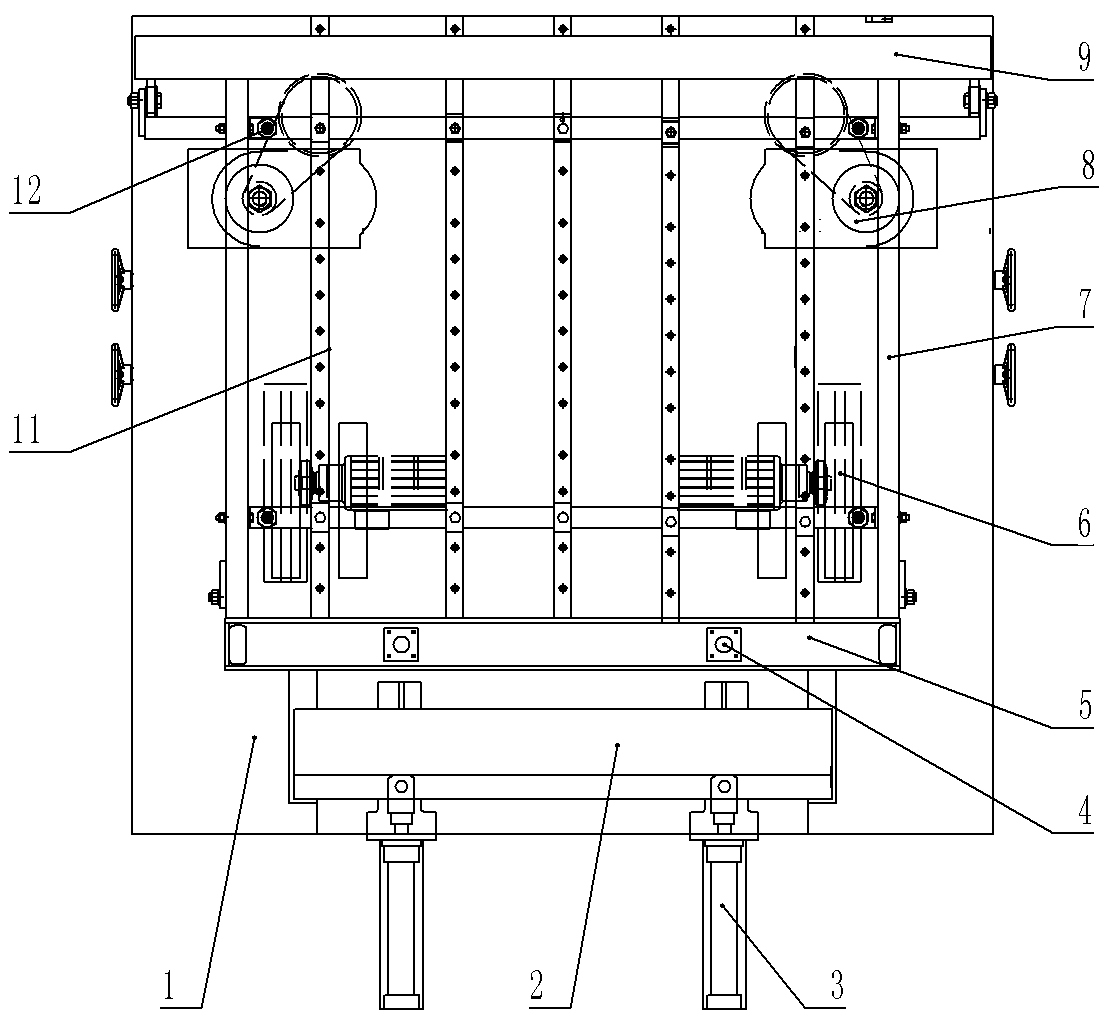

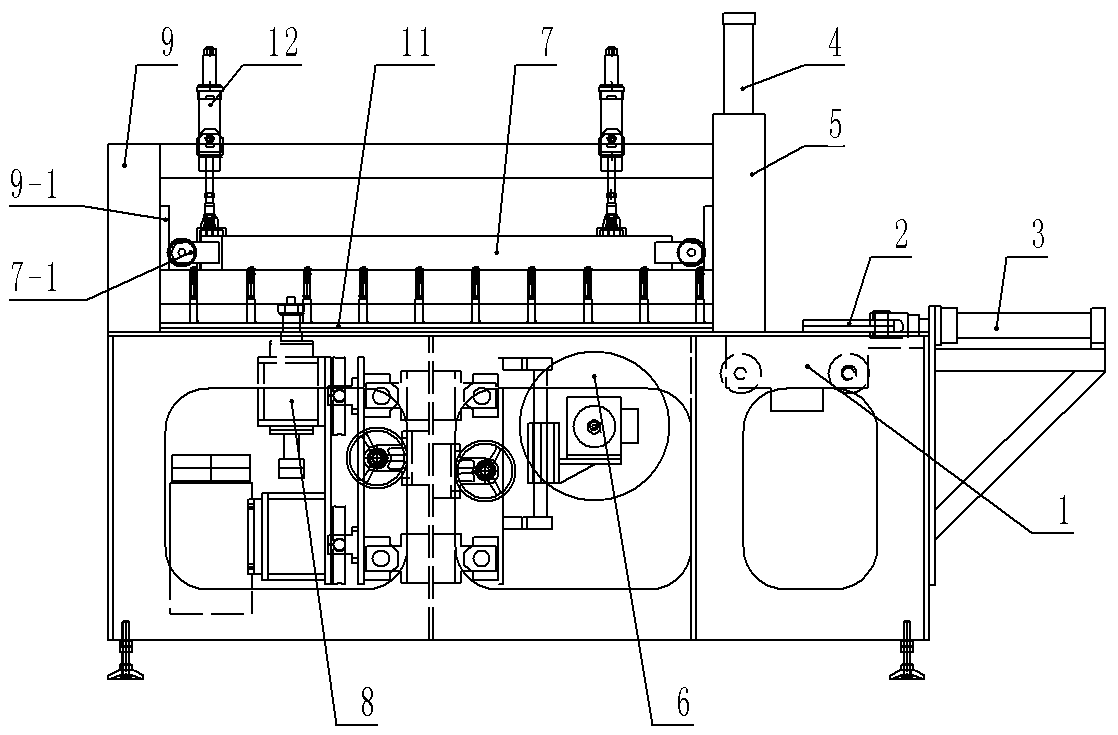

[0020] Such as figure 1 The jigsaw machine shown includes a glue applicator 14 and a splint jigsaw machine 22. The splint jigsaw machine 22 is sequentially connected to the comb-tooth device through the comb crimping conveying device 15 and the delivery bridge 10, and the glue is applied Machine 14 is installed near the conveying channel of comb crimping conveying device 15, and glue spraying machine 13 is housed on one side of conveying bridge frame 10. The comb tooth device has a comb tooth feeding table 1, and the first feeding push plate 2, the wooden strip leveling device 5 and the leveling straightening device are successively installed on the comb tooth feeding table 1, and the first feeding pushing plate 2 is connected with the comb The two first oil cylinders 3 on the tooth feeding platform 1 are connected. On both sides of the feeding end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com