Structural laminwood and preparation method thereof

A technology for glulam and structure, applied in the field of wood processing, can solve problems such as differences in test methods, high product prices, inconsistent product size systems, etc., and achieve good structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] First, the plantation fir (diameter at breast height: 20-35cm) log is processed into a standard timber with a cross-sectional size of 45mm (T) × 90mm (W) and a length (L) of about 2000mm as a finger-joint unit. The moisture content of each finger-joint unit is controlled at 10-15%. There are no knuckles, cracks and other defects within 5cm from the finger joint end.

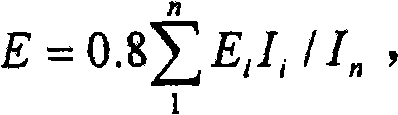

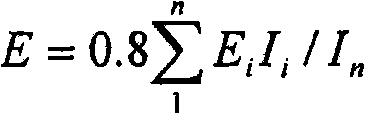

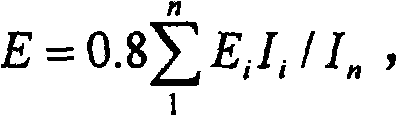

[0058] According to the following grading table, the plantation fir lumber is divided into four grades by directly measuring the flexural modulus of elasticity through a bending grading machine.

[0059]

[0060] Place the finger-joint end of the finger-joint unit upright for tooth milling, and mill out 25mm or 30mm finger-joint long teeth according to the fitting degree (t) of 0.3-0.4mm, with a slope of 1 / 10 or 1 / 12. Use structural glue resorcinol-formaldehyde to paint on one side, and the amount of glue on one side is 0.2g / cm 2 ~0.4g / cm 2 (Within this range, the difference in the amount of glue app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com