Equipment for splicing and fixed-length cutting blanking for laminated timbers

A technology for wood and equipment, applied in sawing equipment, joining of wooden veneers, sawing components, etc., can solve problems such as low production efficiency, unstable product quality, and poor production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings.

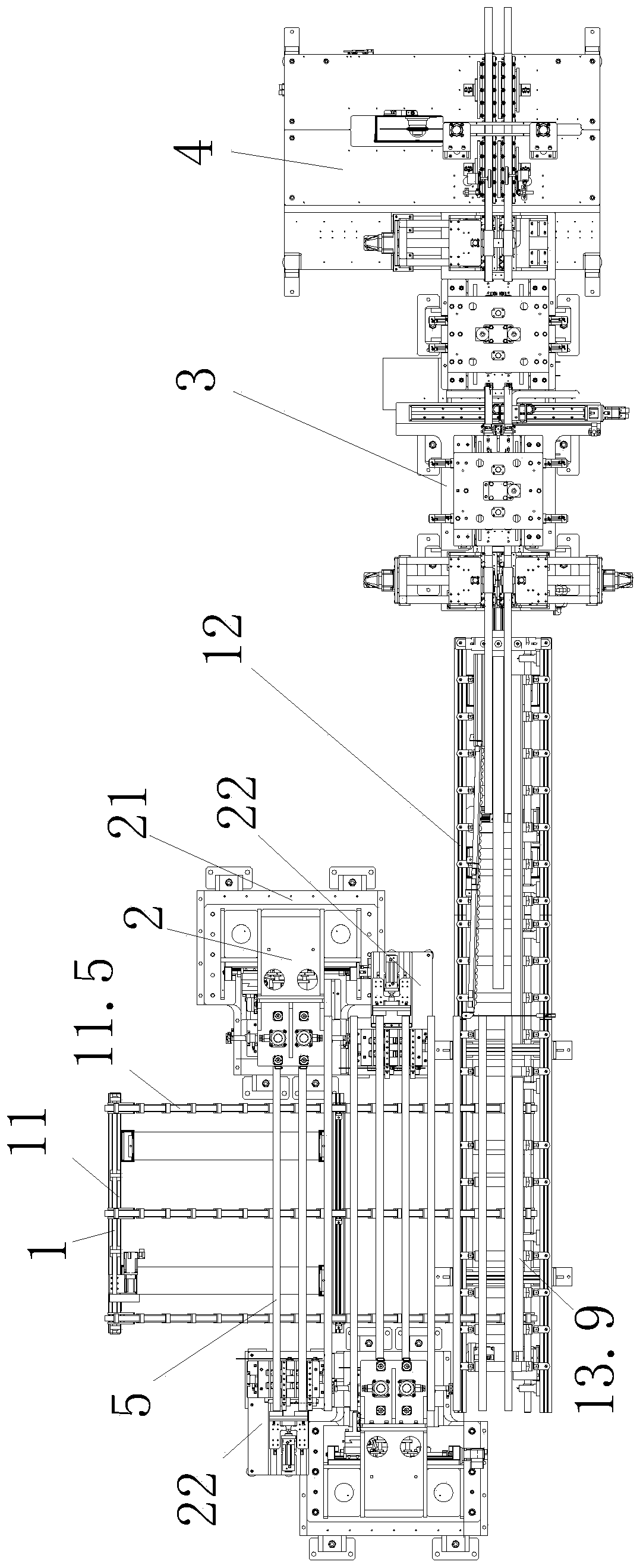

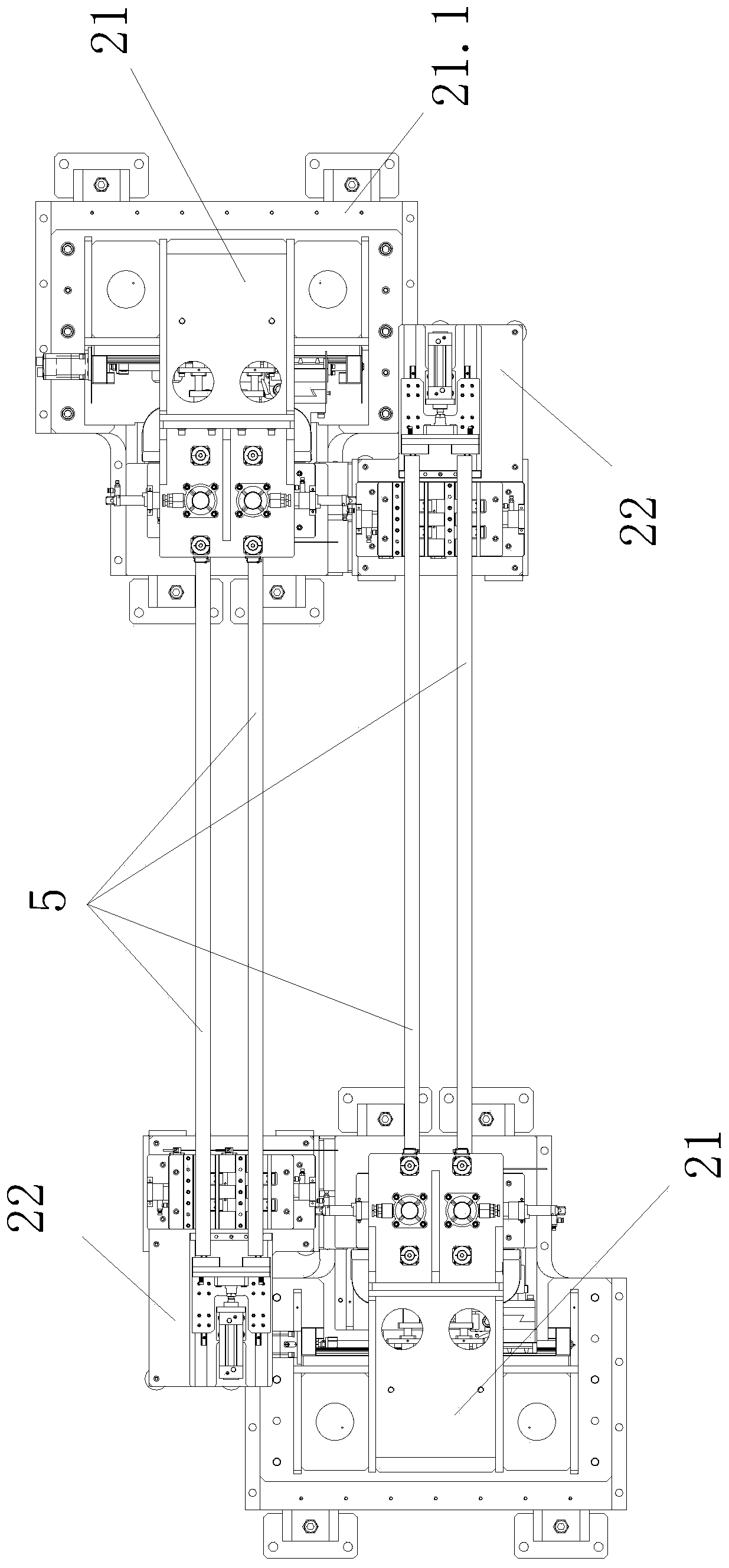

[0037] like figure 1 As shown, the present invention is composed of several parts including an automatic feeding device, a conveying device 1, a gear milling device 2, a splicing device 3, a cutting device 4 and a control center. Both the automatic feeding device and the control center are not shown in the figure.

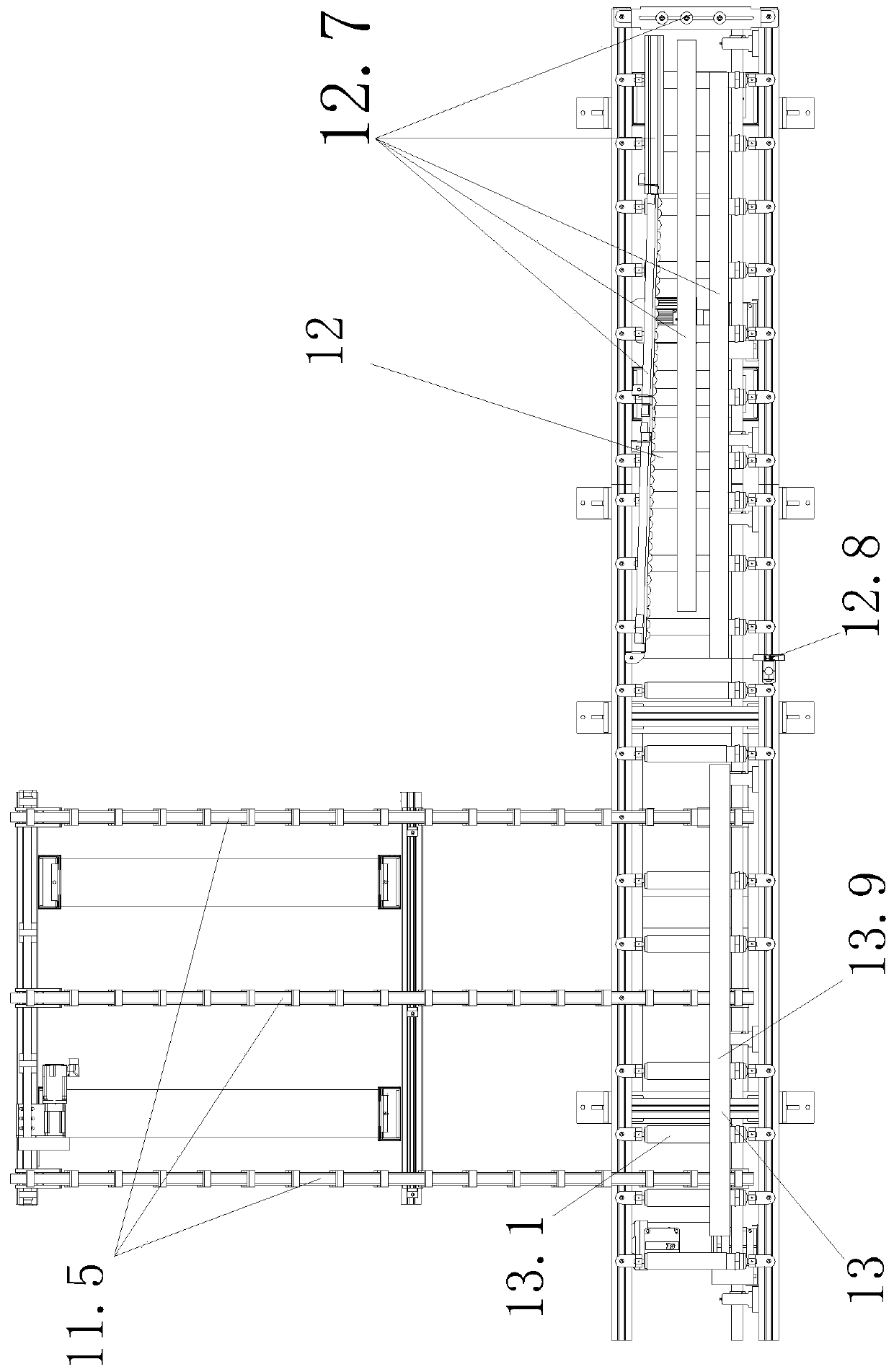

[0038] like figure 1 , figure 2 As shown, the conveying device 1 includes a chain conveying device 11 , a fixed roller conveying device 12 , and a lifting conveying device 13 . The right end of the automatic feeding device is located on the left side of the rear end of the chain conveying device, and the right part of the rear end of the frame of the corresponding chain conveying device is provided with a not shown in the figure for detecting that the wood to be spliced is transferred from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com