Finger joint laminated wood

A technology of glulam and finger-jointed teeth, which is applied in the field of glulam and can solve problems such as material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

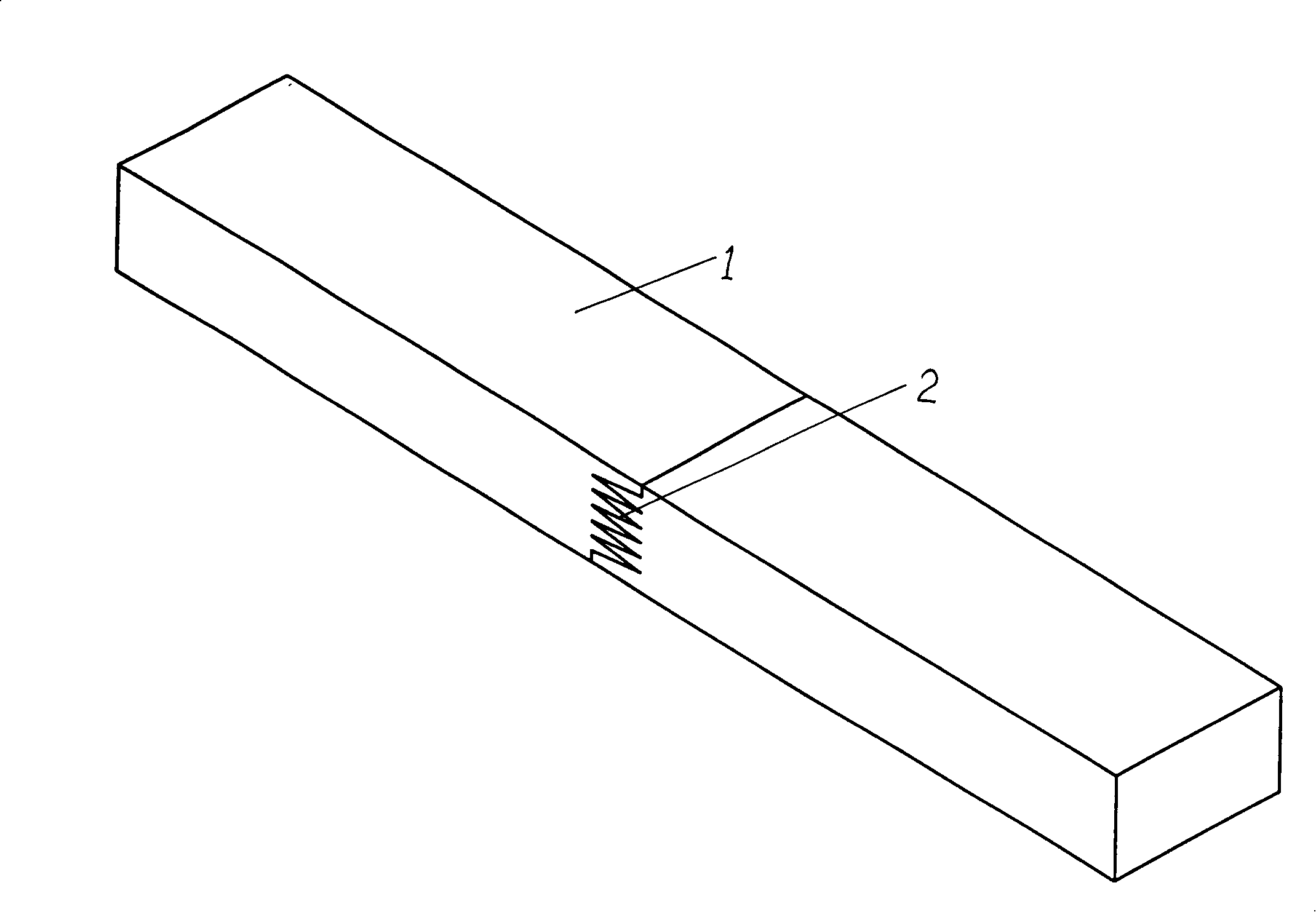

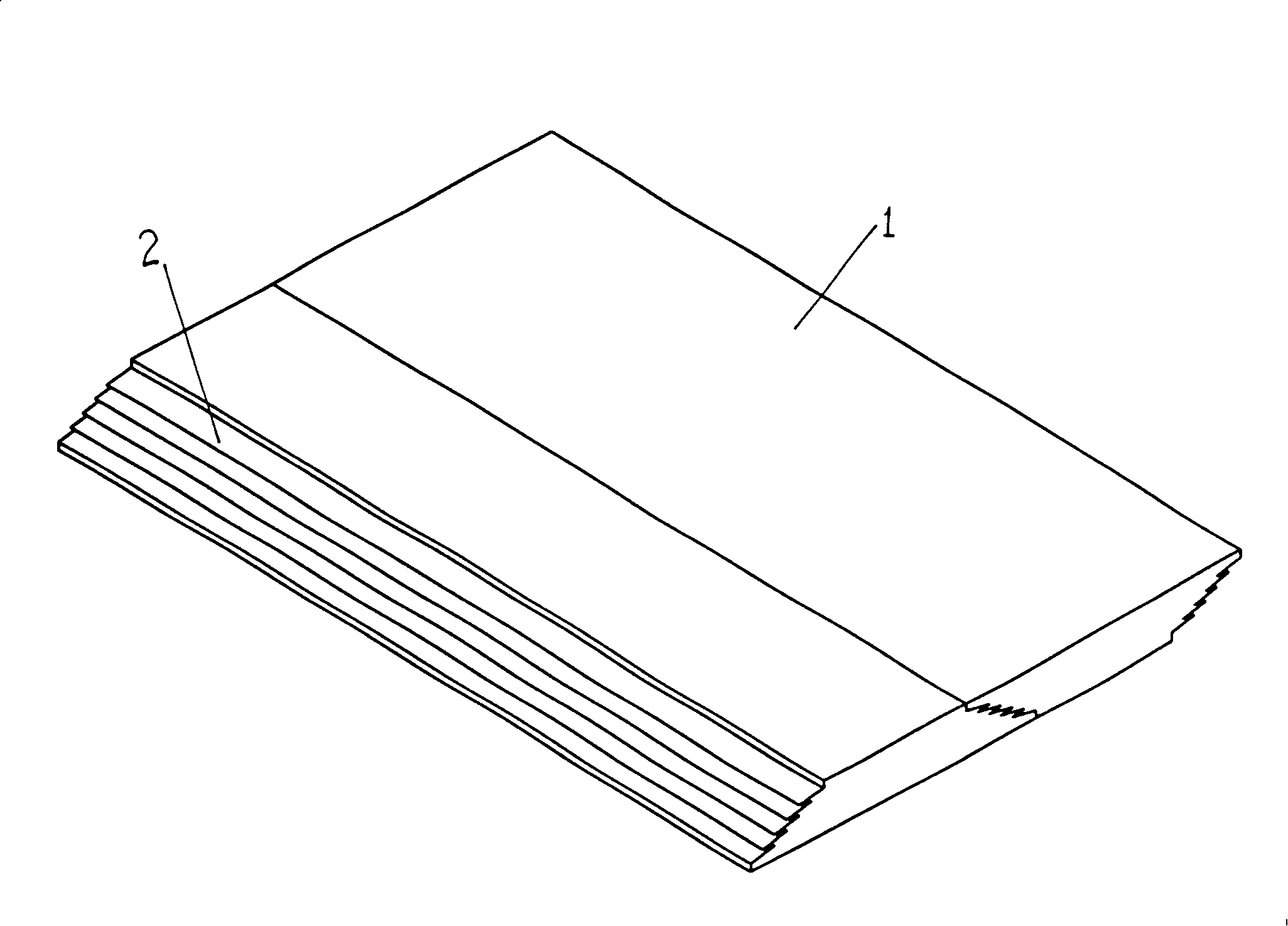

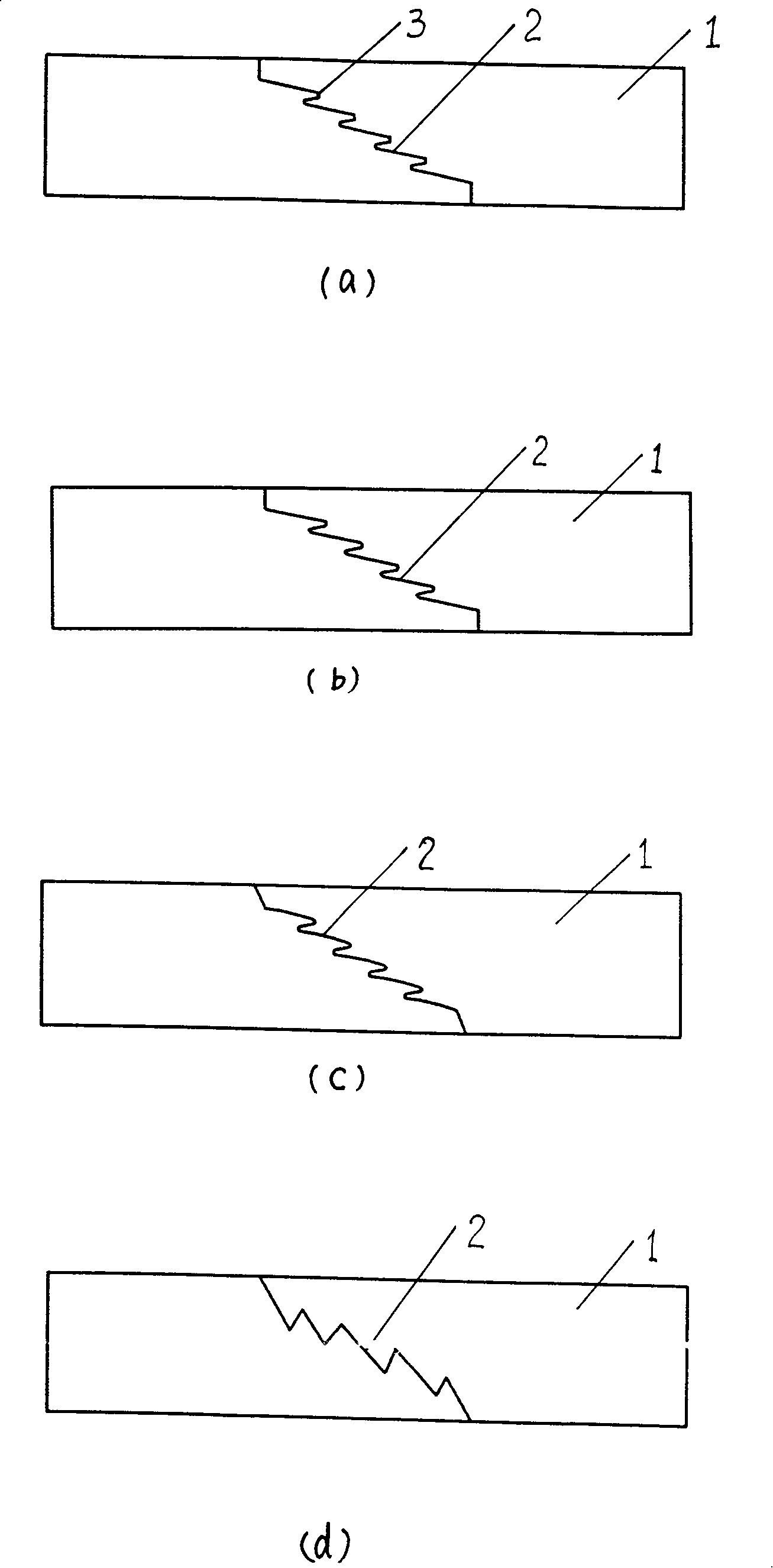

[0013] Such as figure 2 The finger-joined glulam shown in the figure uses the burr of the unedged board to have finger-joining teeth 2 in the width direction of the board 1. The tooth tips 3 are like image 3 (b), (c), (d) are angular shapes, or they can be as image 3 (a) The linear shape shown in (a), or the shape of a broken line, an arc, or a curve. The width direction of the wood board is connected and glued by finger joint teeth. At least one or more finger joint teeth are connected to the plywood surface. not vertical. Finger teeth are shaped like image 3 (a) Straight tooth tip, (b) angular tooth tip, (c) curved tooth edge, (d) irregular tooth, all unequal tooth edges, two adjacent finger teeth are short edges The root of the tooth is directly connected with the root of the long side of the next tooth or connected by a straight line, a broken line, an arc or a curve, and a plurality of finger joint teeth are continuously connected to form a continuous finger joint tooth with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com