Patents

Literature

32results about How to "Achieve a smooth effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

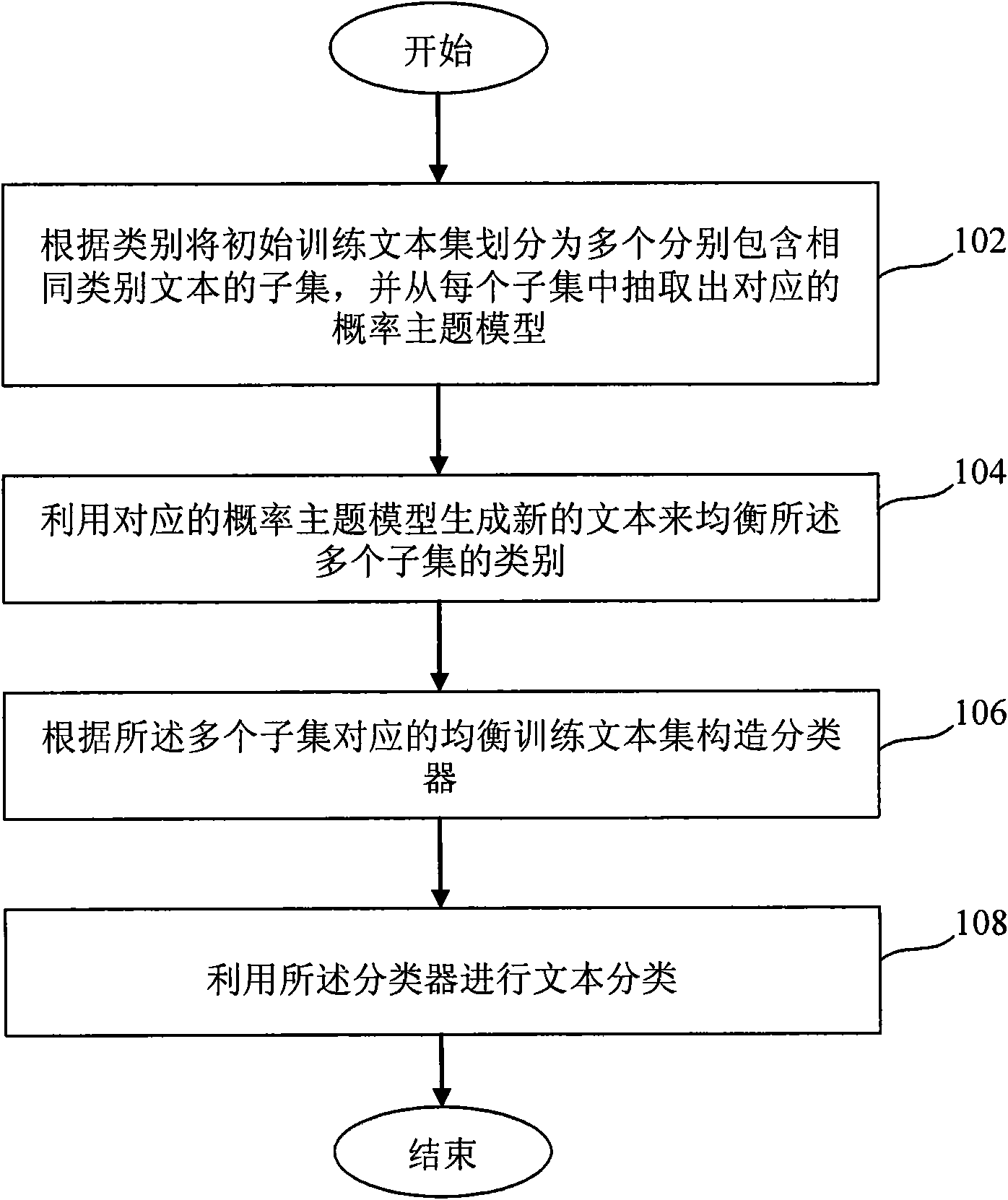

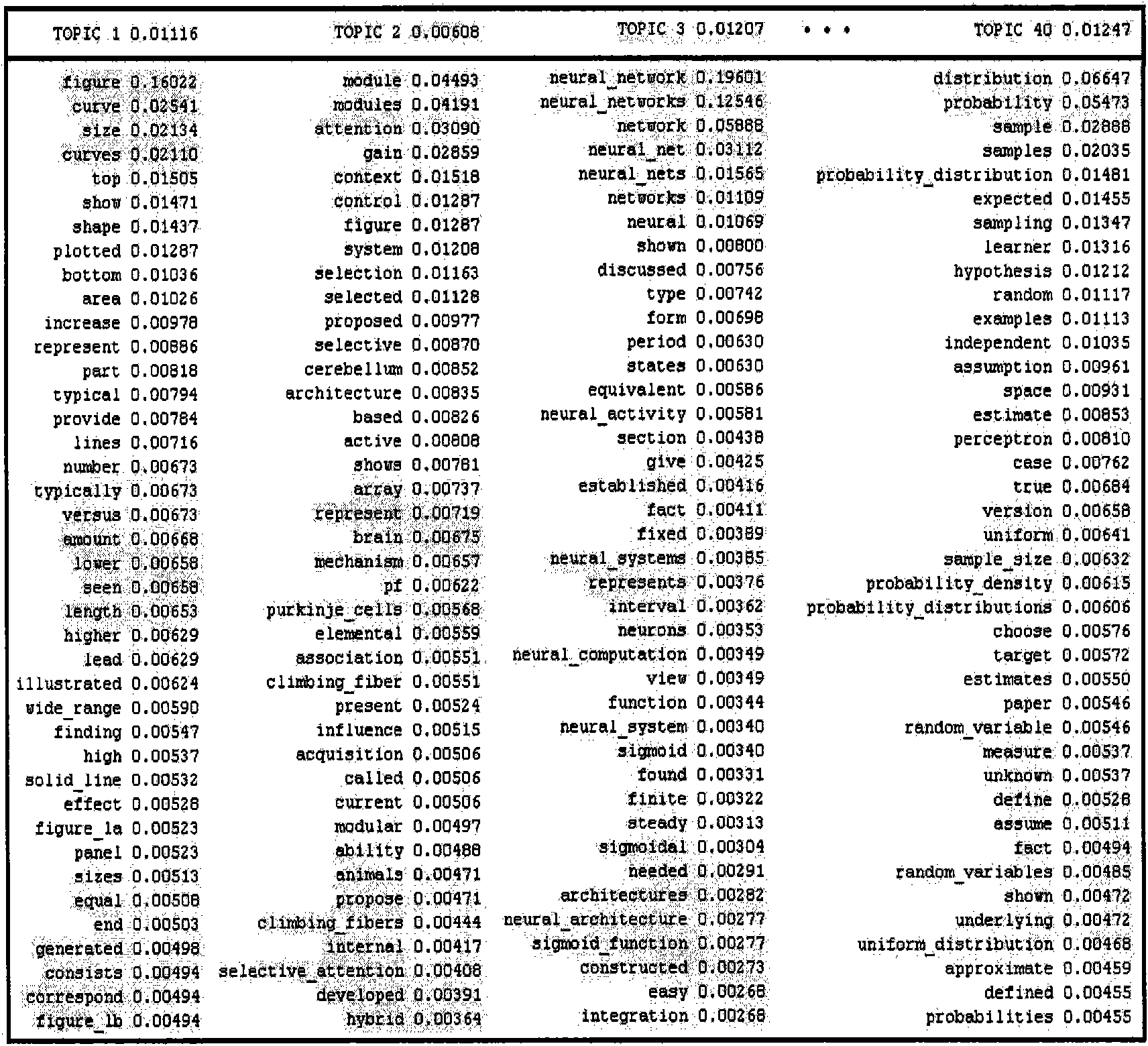

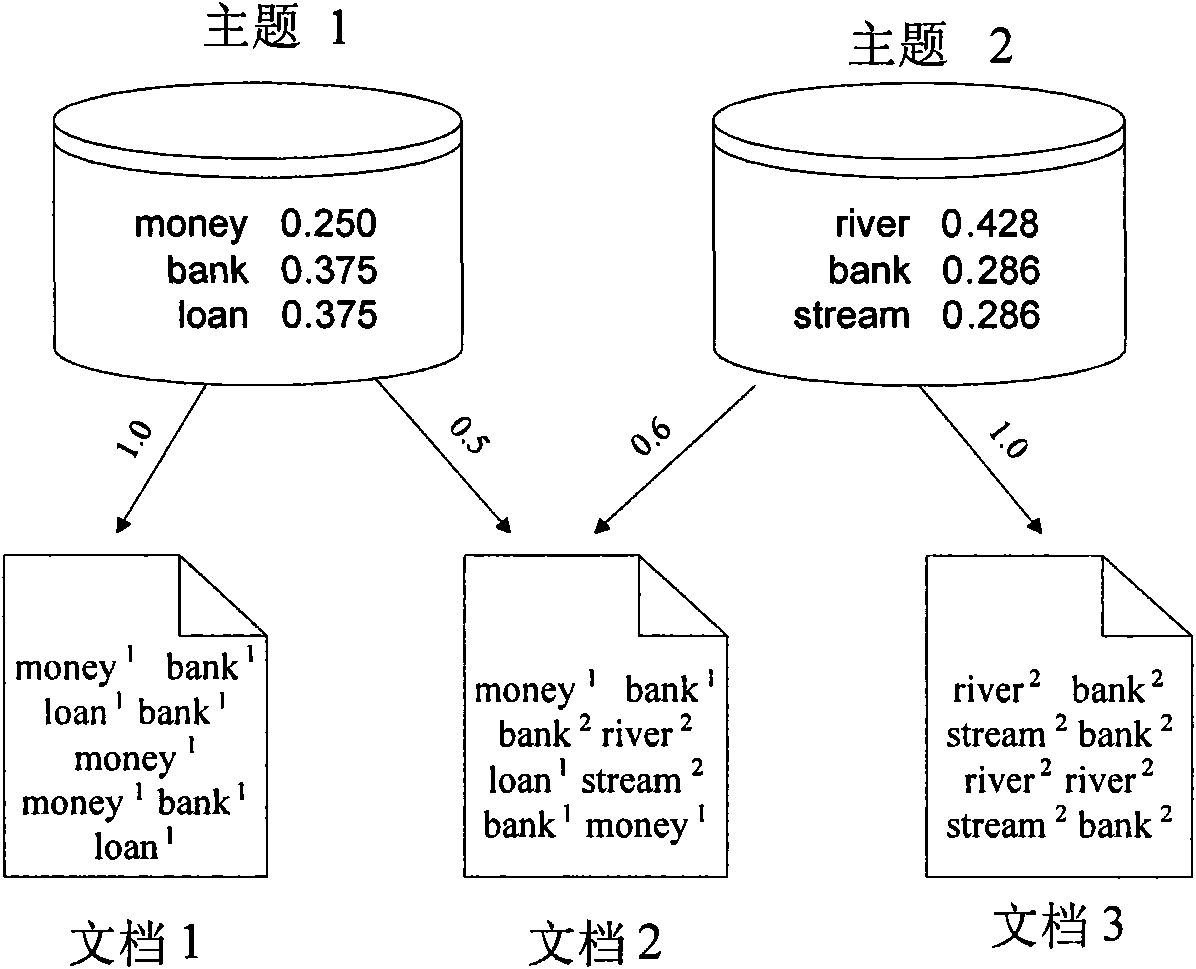

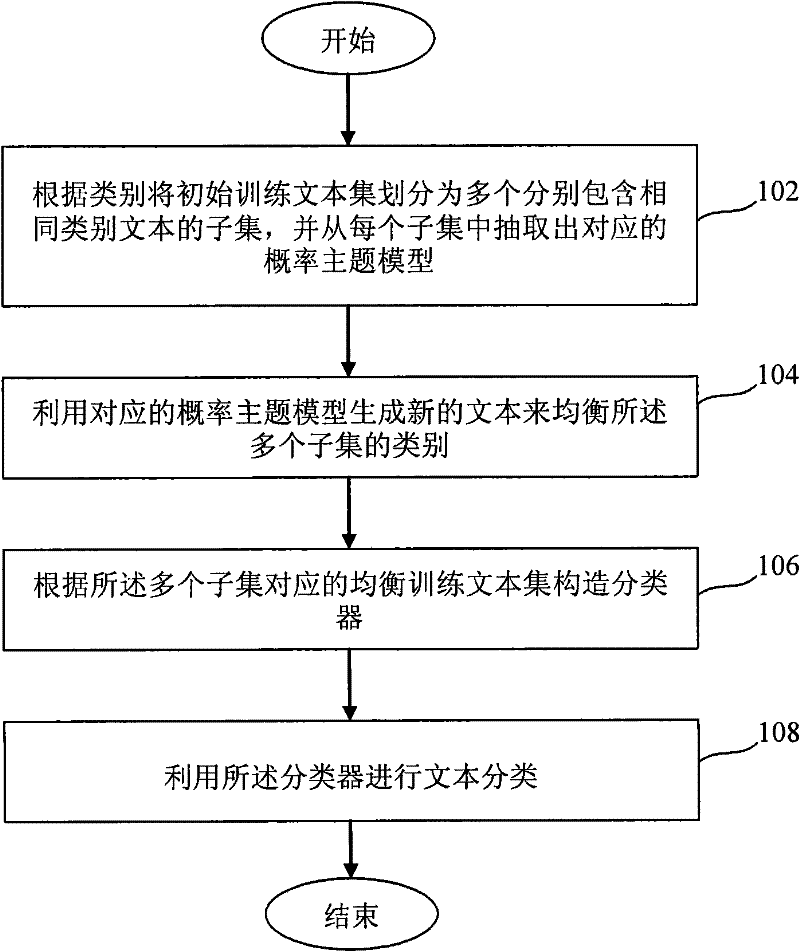

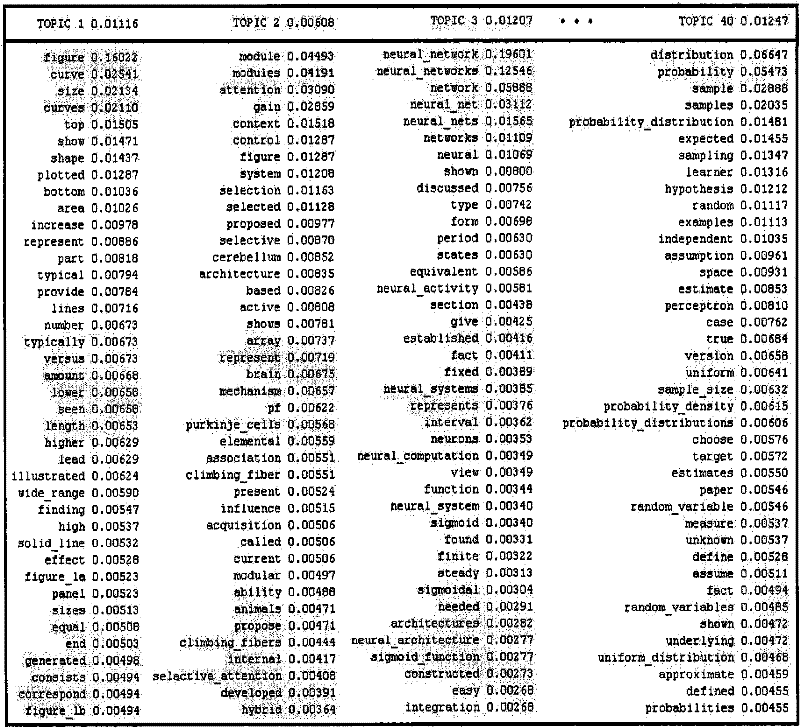

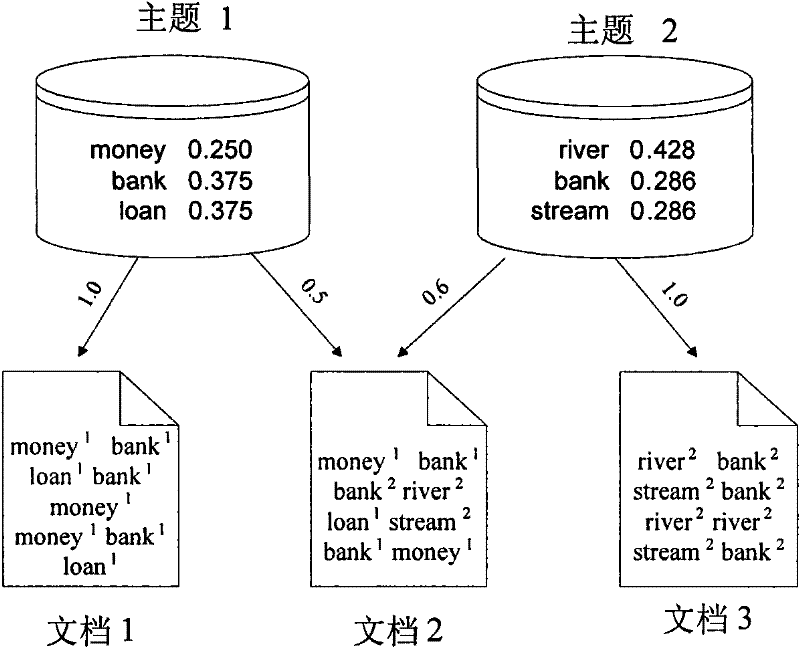

Text classification method

InactiveCN101587493AImprove classification performanceRaise the ratioSpecial data processing applicationsText categorizationSubject matter

A text classification method comprises following steps: dividing the initial training text collection into a plurality of subsets including the text in the same category based on the category, extracting the corresponding probability topic model from each subset; generating new text to balance the categories of the subsets by the corresponding probability topic model; constructing a classifier based on the balance training text collection corresponding to plural subsets; and processing text classification by the classifier. The invention can improve the classification effect of the text classification method under the condition of data skew.

Owner:UNIV OF SCI & TECH OF CHINA

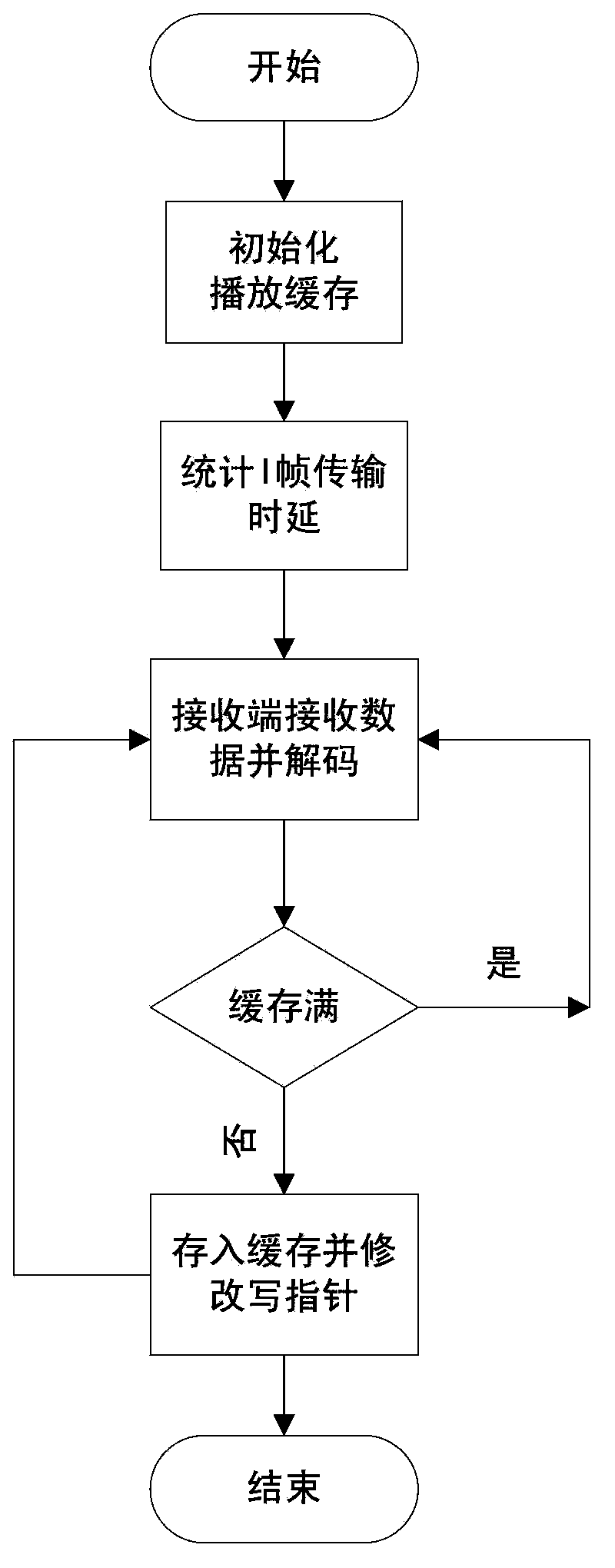

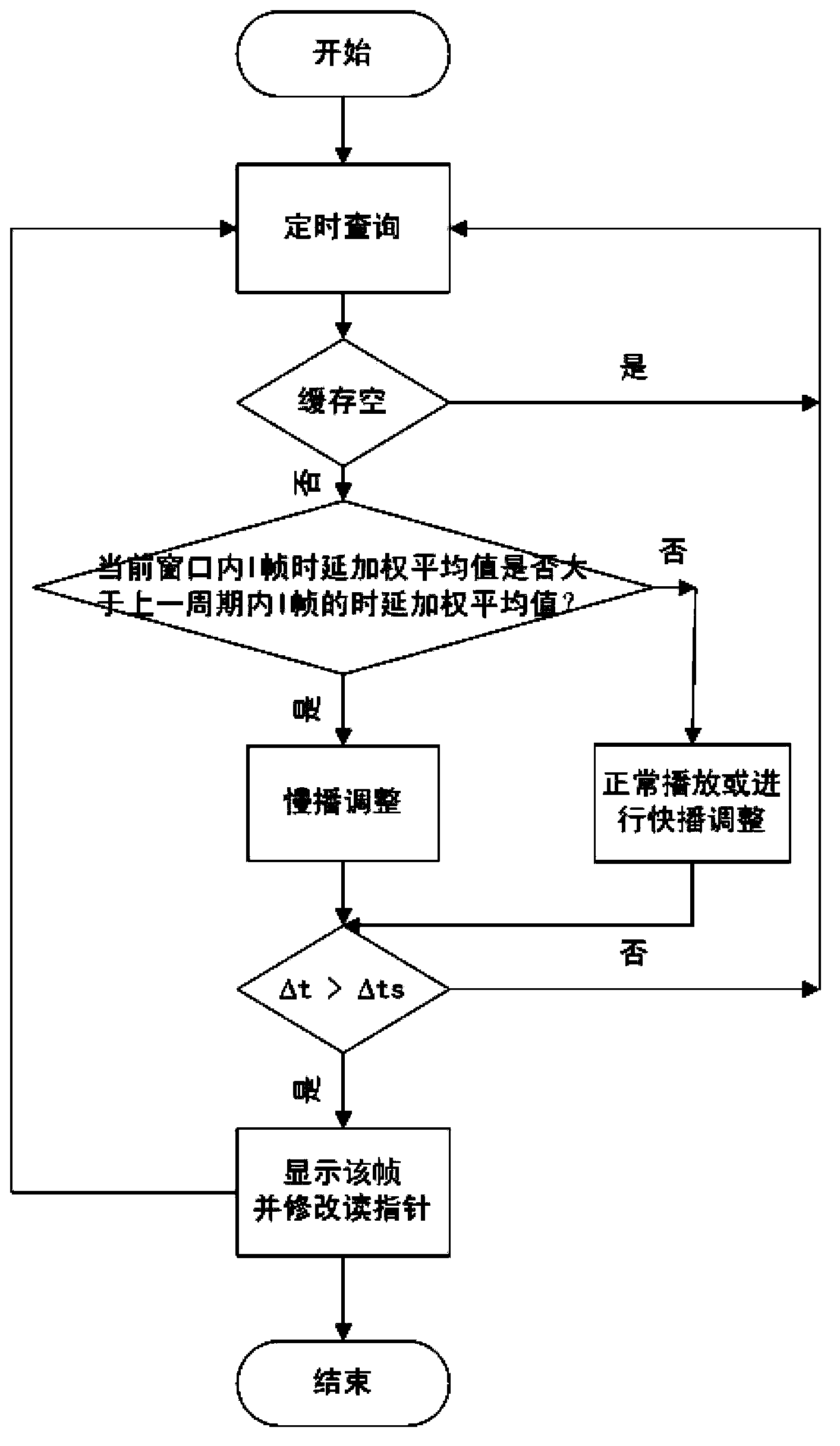

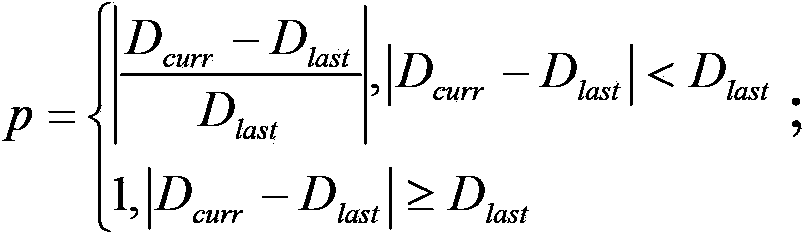

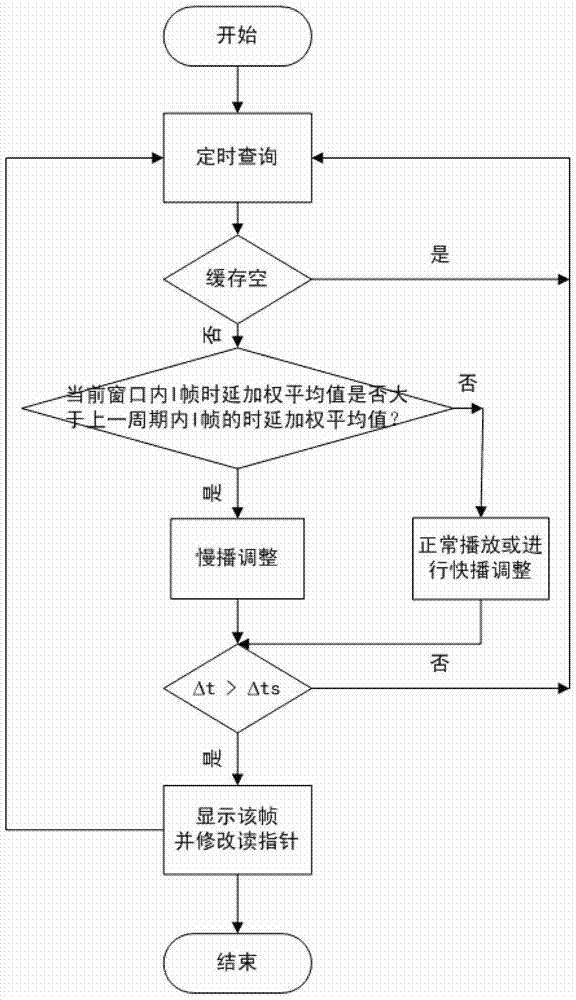

Code rate smoothing method of video live transmission through wireless network

InactiveCN103916716ASolve video freezeImprove fluencyNetwork traffic/resource managementTransmissionTransmission delayTimestamp

The invention provides a code rate smoothing method of video live transmission through wireless network. The method comprises the steps that the periodic statistics of transmission delay of video frames is conducted, when the transmission delay gets smaller, playing buffer is turned down through playing speeding up, when the transmission delay gets bigger, the playing buffer is turned up through playing slowing down, and the adjusting step length of the playing speeding up and the adjusting step of the playing slowing down are codetermined by changing of the transmission delay, the playing buffer depth and timestamp information. By means of the code rate smoothing method of video live transmission through wireless network, the statistics of the transmission delay of the video frames can be conducted, the wireless network state is perceived according to time delay information, the minimum video time delay is further found out according to the actual network condition to achieve the smooth effect, and balance between real-time performance and fluency performance of video streaming is achieved.

Owner:BEIJING XINWEI TELECOM TECH +1

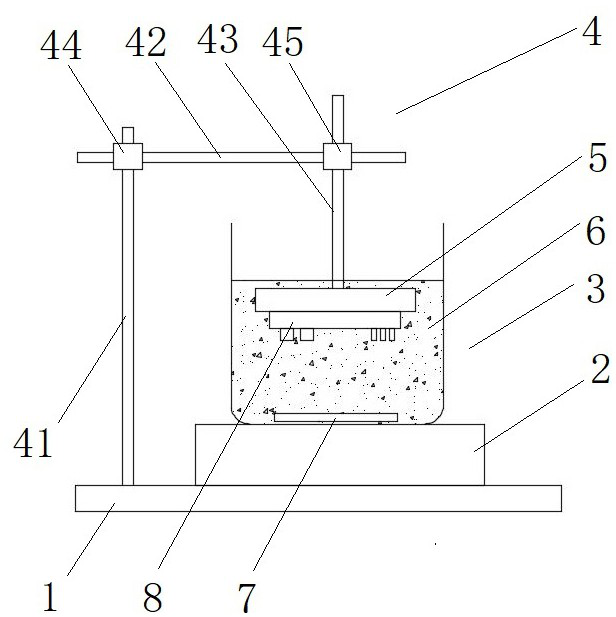

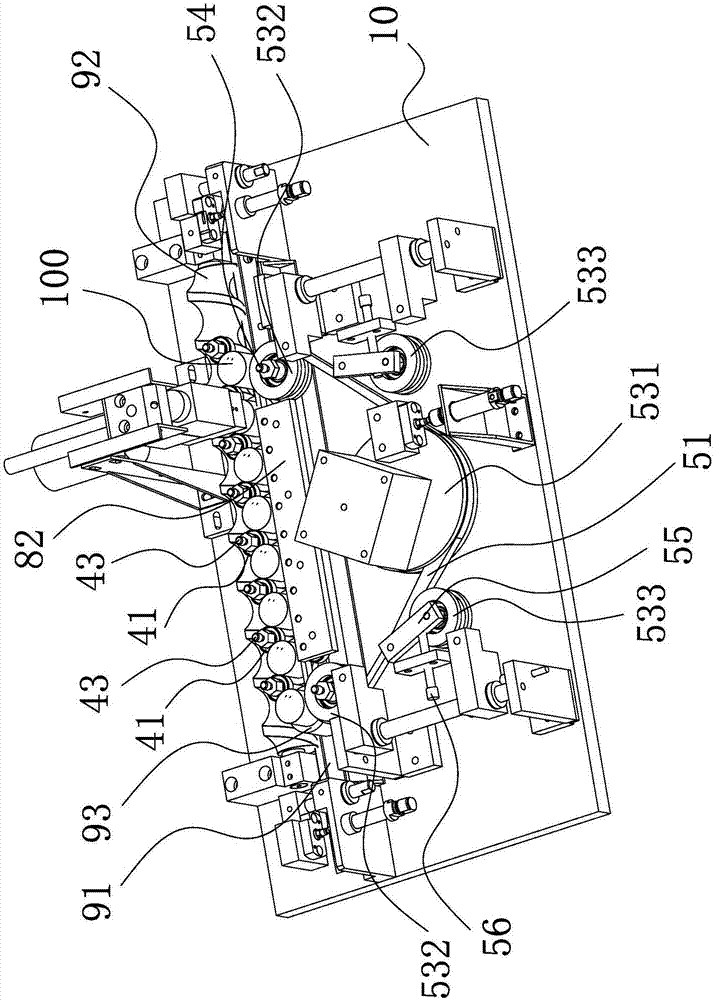

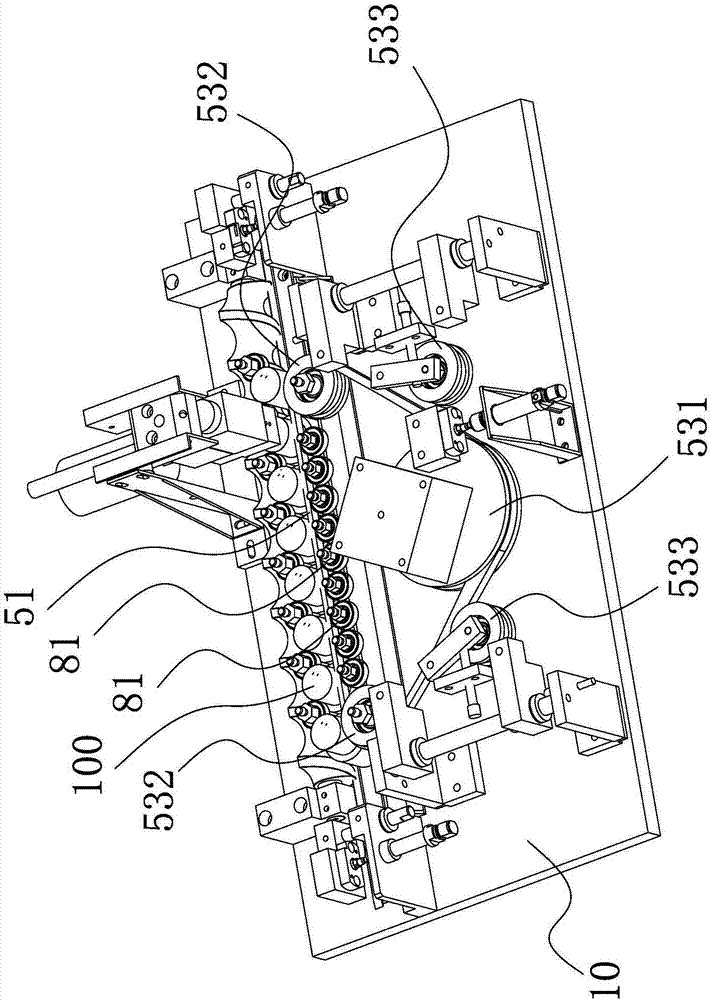

Automatic spraying device, spraying production equipment and automatic spraying method for floor side

InactiveCN101733224AUniform amount of sprayingIncrease profitSpraying apparatusPretreated surfacesEngineeringContinuous operation

The invention relates to a processing technology of floors. An automatic spraying device for a floor side comprises a containing slot, wherein the containing slot can be used for containing the floor side, the containing slot is provided with a spray head and a paint recovering opening, the spray head is connected with a paint transmission pipeline, and the paint recovering opening is connected with a paint recovering pipeline. Automatic spraying production equipment for the floor side comprises a floor feeding device, an automatic spraying device, a drying device and a polishing device, wherein the automatic spraying device comprises the containing slot which can be used for containing the floor side, the containing slot is provided with the spray head and the paint recovering opening, the spray head is connected with the paint transmission pipeline, and the paint recovering opening is connected with the paint recovering pipeline. The automatic spraying device for the floor side is used for spraying, the automation degree is high, and both sides of the floor have uniform spray amount and uniform color, thereby solving the problem of a manually operated original method, lowering the labor intensity of workers and realizing continuous operation; and the paint recovering opening is arranged, thereby improving the utilization ratio of paint and greatly lowering the production cost.

Owner:GUANGDONG YINGRAN WOOD IND

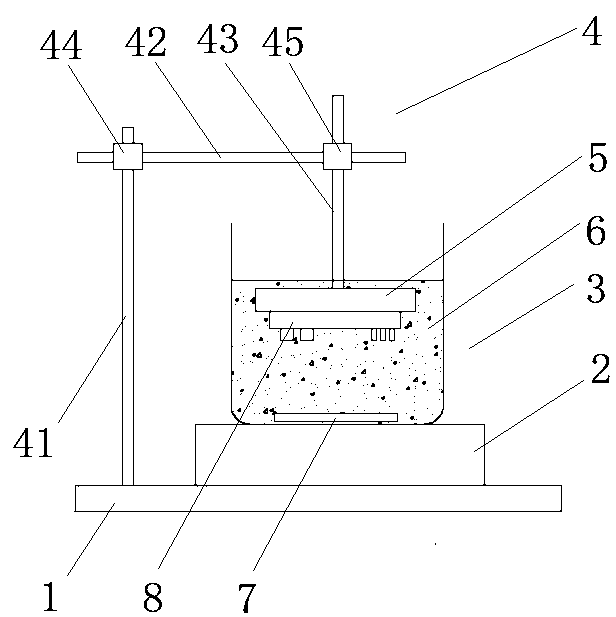

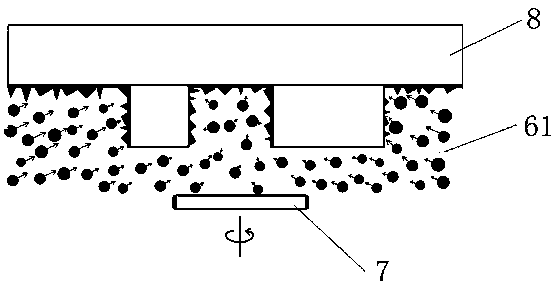

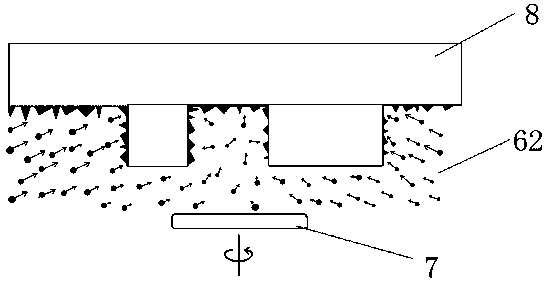

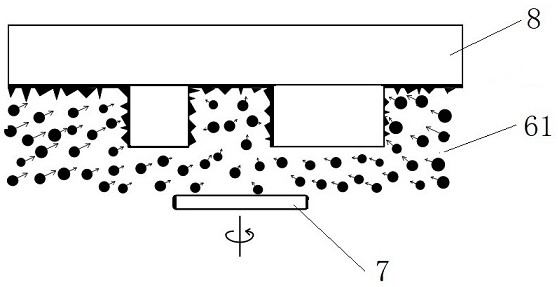

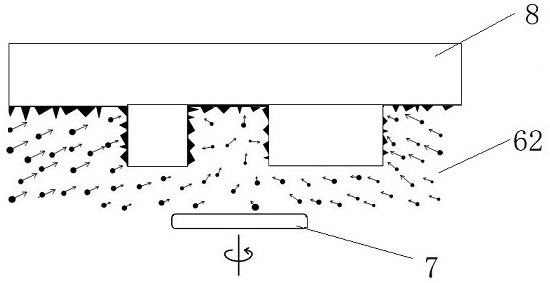

Film lithium niobate optical waveguide chip polishing device and polishing method thereof

The invention provides a film lithium niobate optical waveguide chip polishing device and a polishing method thereof. A magnetic stirring table is used for driving a magnetic rotor to rotate in a polishing solution, then the polishing solution is stirred to generate flowing contact with the surface of a chip, polishing particles in the polishing solution generate half contact or sliding contact with the surface of the chip subjected to dry etching, slight particle bombardment is associated, meanwhile, alkali ions in a polishing solvent and the etched surface generate a chemical etching reaction, chemical etching and particle bombardment in the direction parallel to the etched surface are achieved through instant stirring of the polishing solution, then etching products deposited on the dryetched surface and spikes and protrusions generated by dry etching are removed, and the effect that the etched surface and the waveguide side wall are smooth is achieved. Compared with traditional contact type mechanical grinding and polishing and chemical-mechanical grinding methods, the device and the method have the advantages that the structure is simple, operation is simple and convenient, cost is low, and surface damage is small.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

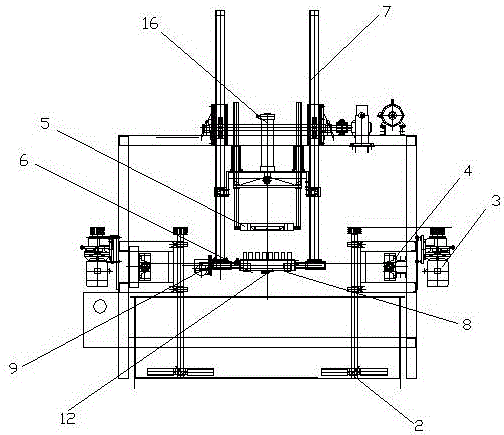

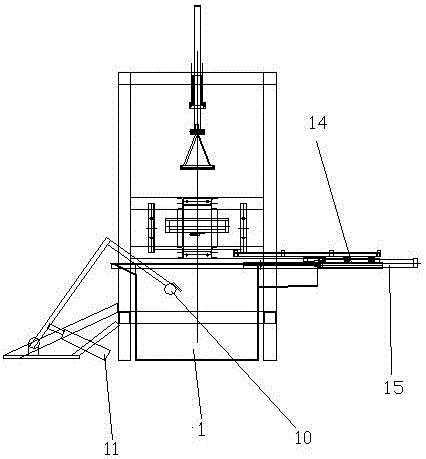

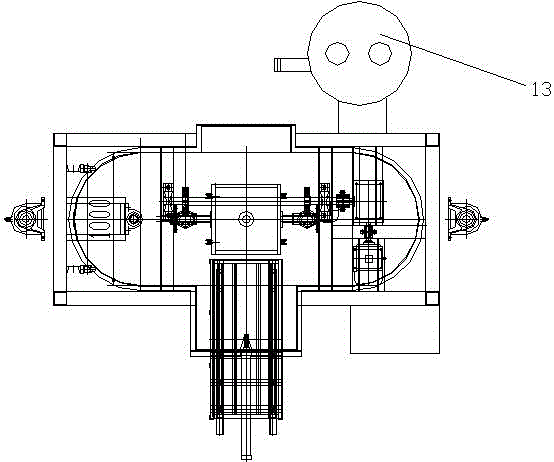

Riser forming machine

InactiveCN105798237AReduce physical laborUniform and stable outputFoundry mouldsFoundry coresEngineeringMaterial storage

The invention discloses a riser forming machine which comprises a slurry tank, a die, a scraping device and a vacuum absorbing device. Two stirring devices opposite in stirring direction are arranged in the slurry tank. The die is arranged on the upper side of the slurry tank through a rack elevating shaft and slides along the rack elevating shaft vertically. The die comprises an inner die body and an outer die body. Four hammers are arranged on the periphery of the inner die body. The die is provided with an exhausting hole. The scraping device is arranged between the slurry tank and the die and comprises a brush oil cylinder, a stainless steel roller and a brush. The vacuum absorbing device comprises a vacuum box and a vacuum settling tank. The vacuum settling tank is provided with a gas inlet hole and a sewage draining opening. The gas inlet hole is connected with the exhausting hole of the die through a hose. The riser forming machine enables whole mixed materials to be turned over upwards, so that the effects of dead-angle-free material storage and uniform mixing are achieved. By means of automatic die releasing, the defects that due to the fact that a die is hammered manually, a riser can not be released from the die easily, and manpower is wasted are overcome, the inner wall and the outer surface of the produced riser are smooth, and the quality and the working efficiency of the riser are improved.

Owner:NANJING NINGJINYAO MACHINERY CO LTD

PVC sheet and preparation process thereof

The invention relates to a PVC sheet and a preparation process thereof. The product is obtained by stirring and mixing PVC resin, a slipping agent, an enhancer, a stabilizer, a processing aid, a lubricating agent and a compatilizer at certain temperature to obtain a mixture, extruding the mixture through an extruder, and rolling the extruded mixture by a roller shaft at certain temperature. According to the PVC sheet and the preparation process thereof, a proper amount of silicon dioxide is added into PVC, and methyl acryloyl oxygen propyl trimethoxy silane and tetraethoxysilane are added simultaneously for cohydrolysis; a polar group compatible with the PVC is introduced into the silicon dioxide surface, so that the transparency of the silicon dioxide is improved, and the transparency of the prepared product is guaranteed; furthermore, due to the cooperation of the components, extremely tiny pores are formed in the surface of the PVC sheet, so that the shearing force of the PVC in a rolling process of the extruder is enhanced, and the microscopic roughness of the surface of a thin film is increased; therefore, a little of air can be accommodated between the thin films during winding to prevent the thin films from being adhered, and the smooth effect can be achieved.

Owner:YANGZHOU SANXING PLASTIC

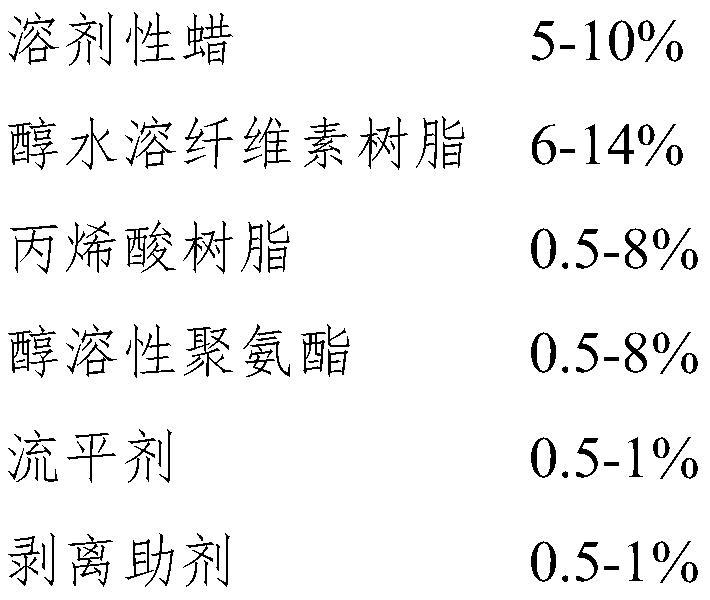

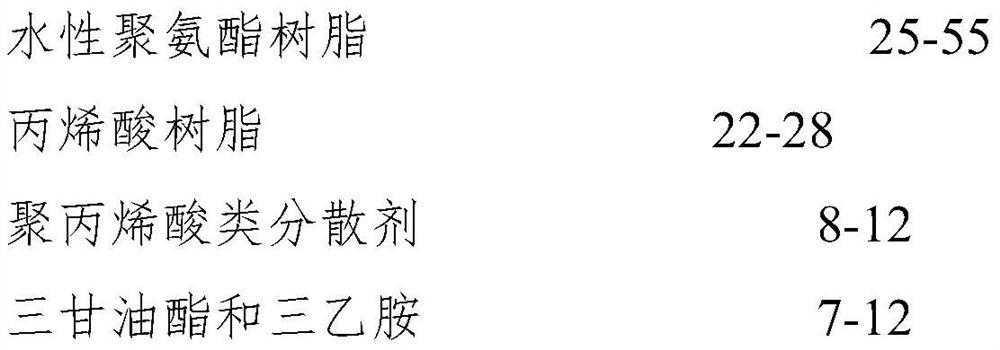

Highlight gold stamping foil

InactiveCN112026420AExcellent peelabilityGood light transmissionWax coatingsDecorative surface effectsHot stampingAcrylic resin

The invention discloses a highlight gold stamping foil in the technical field of gold stamping foils. The highlight gold stamping foil comprises a hot melt adhesive layer, an aluminized coating, a protective layer, a release layer and a base layer, wherein the base layer is a biaxially oriented polyester film; the release layer is formed by coating release paint; the release layer is formed by mixing solvent wax and acrylic resin; the protective layer is formed by coating polyurethane resin paint; and the hot melt adhesive layer is made of copolymer resin. According to the highlight gold stamping foil, the release layer is made of a mixture of the solvent wax and the acrylic resin, so that the stripping performance is good, the release surface is smooth, and the surface gloss of a printedor aluminized coating after heat transfer printing is not affected; the protective layer is made of waterborne polyurethane resin, so that the metal luster is not blocked while the aluminized coatingis protected, and the highlight characteristic is provided; and the hot melt adhesive layer adopts a copolymer resin hot melt adhesive to improve the effect of rotary viscosity and improve the interlayer adhesive force between the aluminized coating and a stamped layer, so that the clearness of hot stamping handwriting is improved.

Owner:浙江驰怀烫印科技股份有限公司

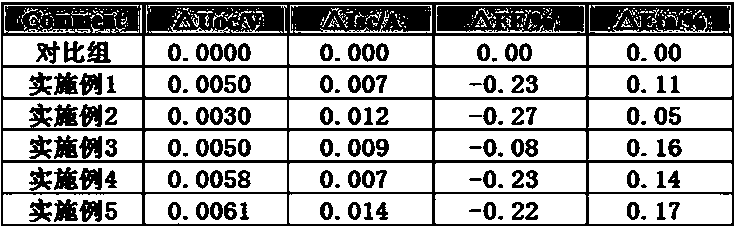

Preparation method of N-type PERT dual-side battery

InactiveCN108447944AImprove square resistance uniformityImprove passivation effectFinal product manufactureSemiconductor devicesSheet resistanceSurface oxidation

The invention relates to a preparation method of an N-type PERT dual-side battery. The preparation method comprises the following steps of S1, texturing; S2, front-surface boron doping and junction fabrication; S3, back-surface etching to remove an edge and a back-surface PN junction; S4, back-surface phosphor doping and junction fabrication; S5, back-surface PSG and front-surface BSG removal; S6,alkali / acid washing, in which a surface of a silicon wafer is slightly etched by a mixed liquid of an alkali and hydrogen peroxide, residual impurity is removed, an HF acid solution is used for pickling to neutralize the alkali liquid, and a silicon oxide layer on the surface is removed; S7, wet oxygen passivation; S8, aluminum oxide deposition on a front surface; S9, SiNx deposition on the frontsurface by PECVD; S10, SiNx deposition on a back surface by PEVCD; S11, silk-screen printing and sintering; and S12, laser isolation. By the preparation method, extremely high boron-rich layer dopedon a surface of a boron expansion surface can be removed, the sheet resistance uniformity is improved, meanwhile, the passivation effect of the N-type battery is improved, and the open voltage and theconversion efficiency of the battery are obviously improved.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

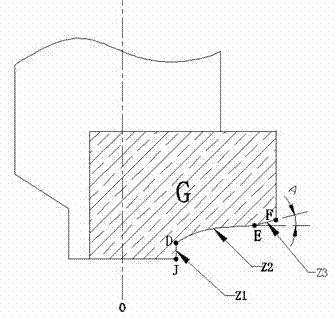

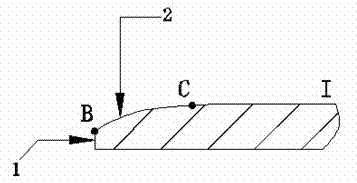

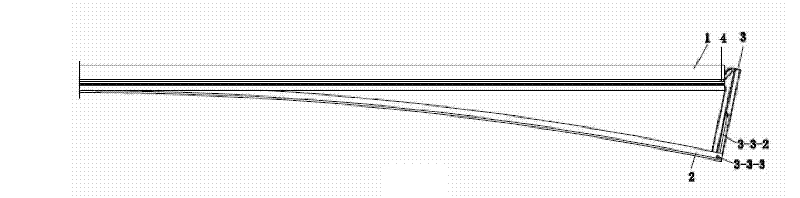

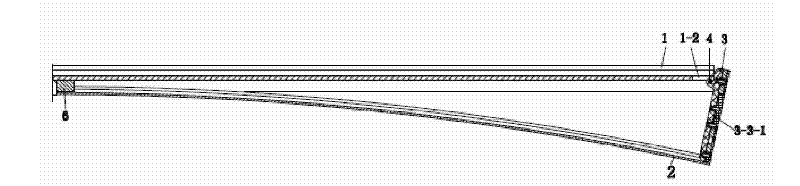

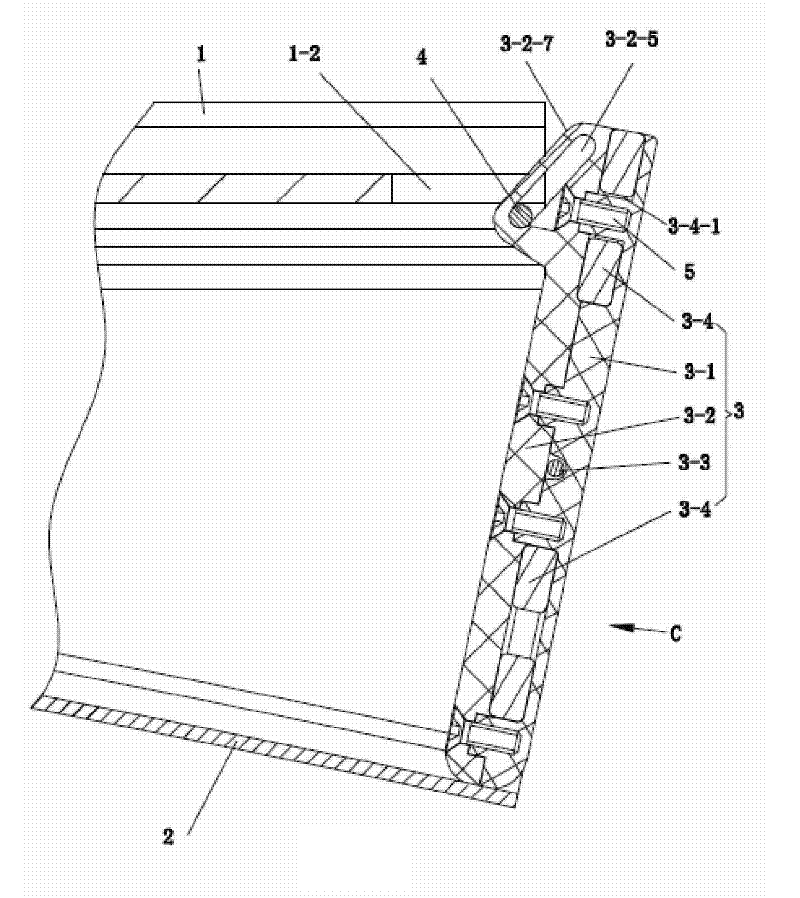

One-step forming combined tool of curved surface for plastic boards

InactiveCN103611959AAchieve a smooth effectTurning toolsDrilling toolsEngineeringMechanical engineering

The invention relates to a one-step forming combined tool of curved surface for plastic boards. A bit of the tool comprises a main cutting edge, a curve cutting edge and a safety slant edge. The main cutting edge is longitudinally vertical. A start of the arc cutting edge locates at the upper end of the main cutting edge. A start of the safety slant edge locates at an end of the arc cutting edge. The safety slant edge and the horizontal plane form an included angle. A work piece can be cut into independent size parts by the main cutting edge. The design of the arc cutting edge fully meets the design requirements of the curved surface; the design of intact transition between the safety slant edge Z3 and the arc cutting edge Z2 allows the curved part of the front surface of the finished work piece well intersects the plane part, with no intersecting mark occurring. The bit part for cutting is made of PCD material; one-cut forming can still be achieved even when the horizontal length of the curved part of the work piece is far larger than the radius of a tool handle, and the curved surface of the work piece can be smooth with no cut.

Owner:TIANJIN ZHONGHUAN HI TECH

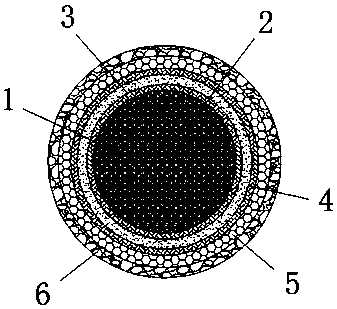

Forming method of carbon fiber pipe type piece

The invention discloses a forming method of a carbon fiber pipe type piece. The forming of the carbon fiber pipe type piece comprises the following steps that S1, a heat-shrinkable plastic pipe layeris pre-treated, the inner surface and the outer surface of the heat-shrinkable plastic pipe layer are coated with a second isolation layer, and the surface of a mold is coated with a first isolation layer; S2, the carbon fiber material is immersed in a solution in advance, and then paving of the pre-immersed material is carried out; and S3, the pre-sucking process is carried out, under the condition of certain temperature and pressure, a certain amount of resin is sucked from carbon fiber material layer laminated blocks, so that the resin content of the carbon fiber material layer is controlled. According to the forming method, the heat-shrinkable plastic pipe layer is automatically shrunk under the high-temperature condition, meanwhile, the resin of the carbon fiber material layer is softened under the condition of high temperature, the carbon fiber material layer can be uniformly pressed by the shrinkage of the heat-shrinkable plastic pipe layer, so that the resin is flat, the effectof enabling the surface of the workpiece to be smooth is achieved, and the method is suitable for being widely popularized and used.

Owner:滁州市润琦碳纤维制品有限公司

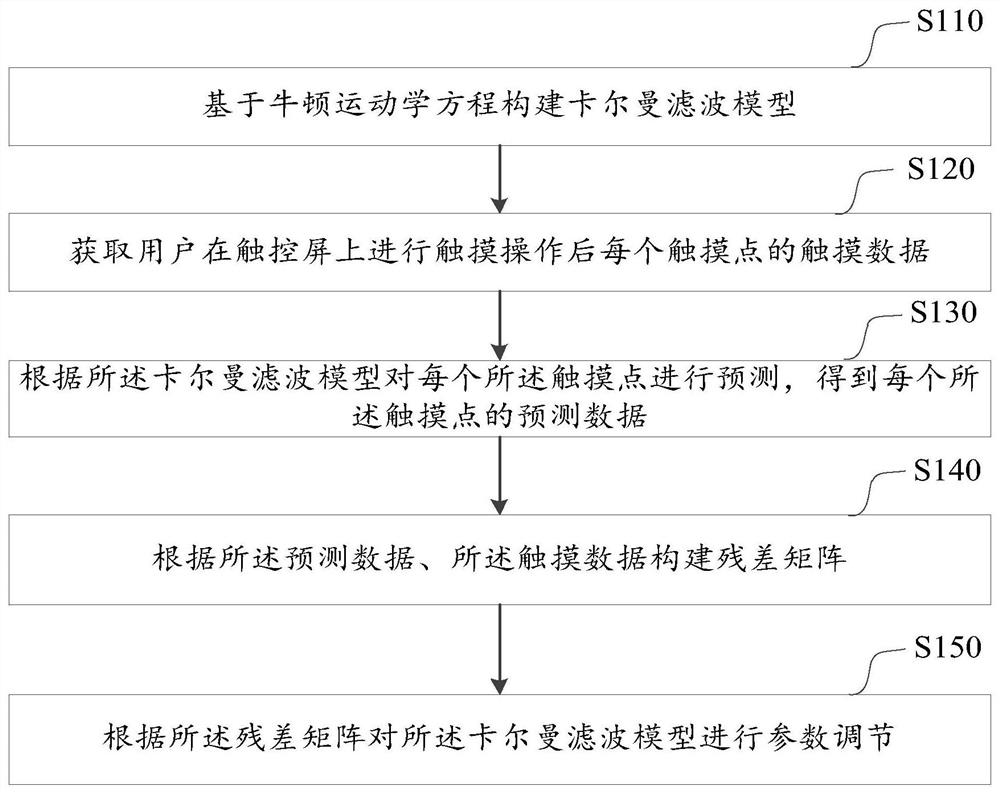

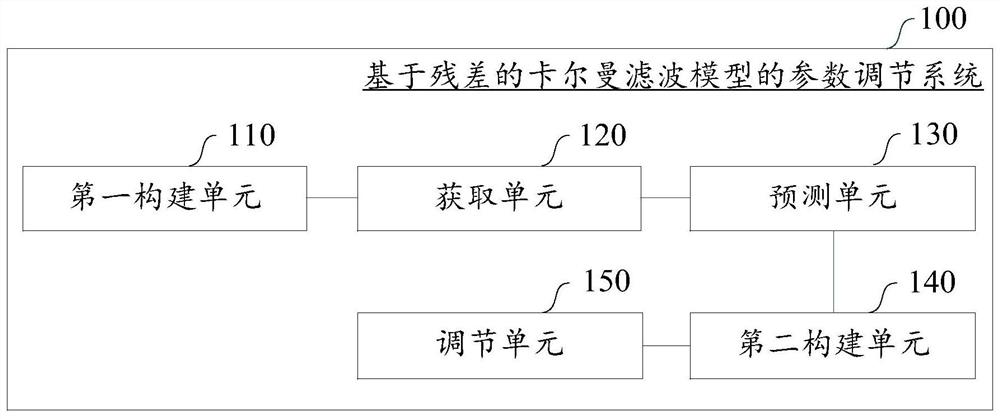

Parameter adjustment method and system of Kalman filtering model based on residual error and equipment

PendingCN113534997AAchieve a smooth effectDigital technique networkInput/output processes for data processingKinematics equationsAlgorithm

The invention discloses a parameter adjustment method and system of a Kalman filtering model based on residual errors, and equipment. The method comprises the following steps: constructing a Kalman filtering model based on a Newton kinematics equation; obtaining touch data of each touch point after a user performs touch operation on a touch screen; according to the Kalman filtering model, predicting each touch point to obtain prediction data of each touch point; constructing a residual matrix according to the prediction data and the touch data; and performing parameter adjustment on the Kalman filtering model according to the residual matrix. According to the method, the Kalman filtering model is constructed by using the Newton kinematics equation, and meanwhile, the residual matrix is constructed through the prediction data and the touch data to adjust a ratio of process noise Q to measurement noise R in the Kalman filtering model, so that a final output result can achieve a smooth effect, and the phenomena of delay and short stroke cannot be generated.

Owner:SHENZHEN KTC COMMERCIAL DISPLAY TECHNOLOGY CO LTD

Foam board cutting device capable of removing adhesion objects

InactiveCN111409135AAchieve a smooth effectIncreased cutting resistanceMetal working apparatusElectric heatingEngineering

The invention relates to the technical field of foam processing, and discloses a foam board cutting device capable of removing adhesion objects. The foam board cutting device comprises a bottom plate,the top of the bottom plate is fixedly connected with a horizontal hydraulic cylinder, the right side of the horizontal hydraulic cylinder is fixedly connected with a water outlet valve, the right side of a buffer spring is fixedly connected with a vertical hydraulic cylinder, a horizontal supporting plate is arranged at the bottom of the bottom plate, the top of the horizontal supporting plate is fixedly connected with a water tank, an electric heating knife belt is arranged at the top of the water tank, the interior of the electric heating knife belt is in rolling connection with a belt pulley, the interior of the belt pulley is fixedly connected with a power wheel through a connecting rod, and a supporting wheel is arranged in the power wheel. According to the foam board cutting devicecapable of removing the adhesion objects, through matched use of the horizontal hydraulic cylinder and the vertical hydraulic cylinder, by combining with matched use of the buffer spring and a resetspring, the effect of removing the adhesion objects on an electric heating cutting mechanism is achieved.

Owner:赵朋辉

Text classification method

InactiveCN101587493BImprove classification performanceRaise the ratioSpecial data processing applicationsMedicineAlgorithm

A text classification method comprises following steps: dividing the initial training text collection into a plurality of subsets including the text in the same category based on the category, extracting the corresponding probability topic model from each subset; generating new text to balance the categories of the subsets by the corresponding probability topic model; constructing a classifier based on the balance training text collection corresponding to plural subsets; and processing text classification by the classifier. The invention can improve the classification effect of the text classification method under the condition of data skew.

Owner:UNIV OF SCI & TECH OF CHINA

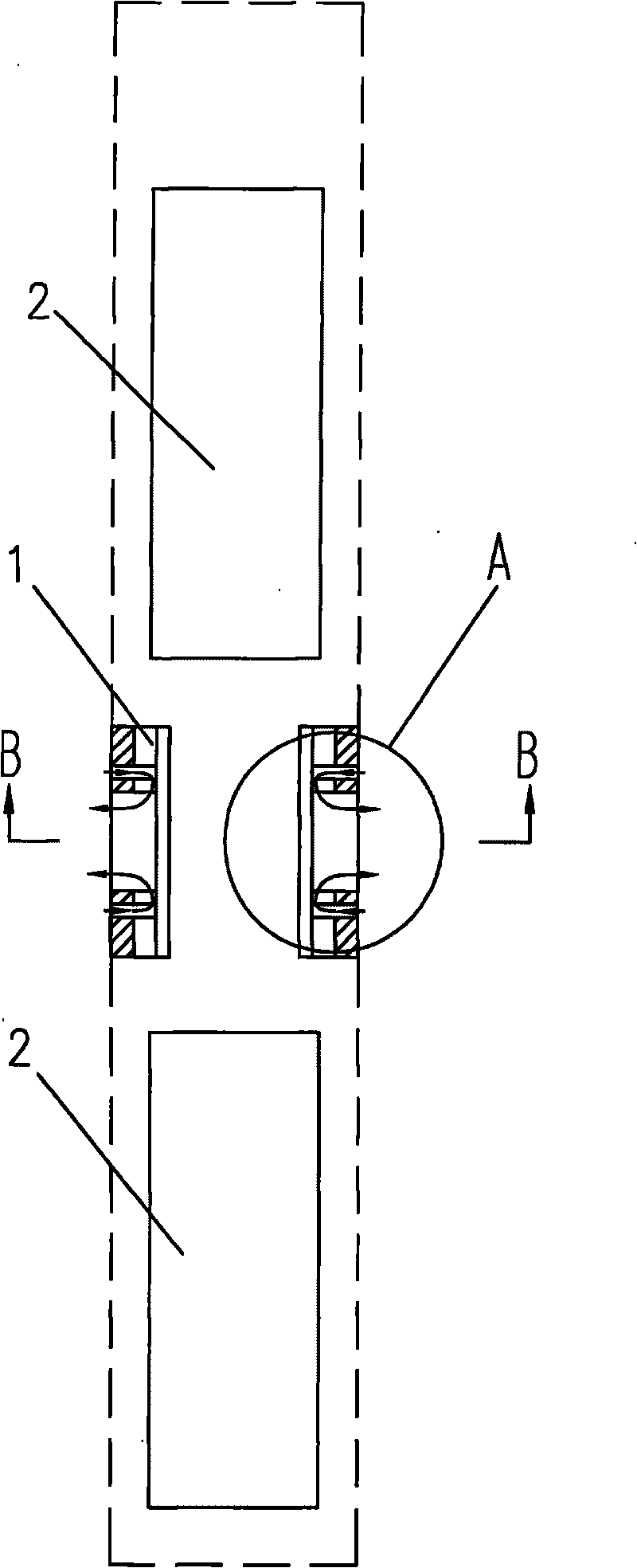

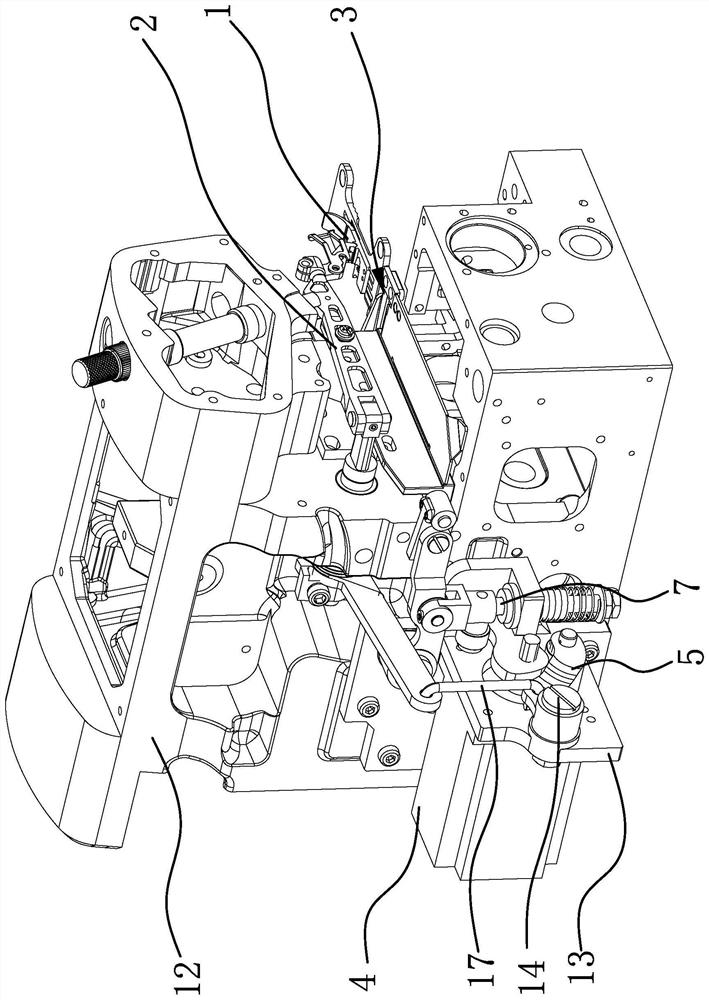

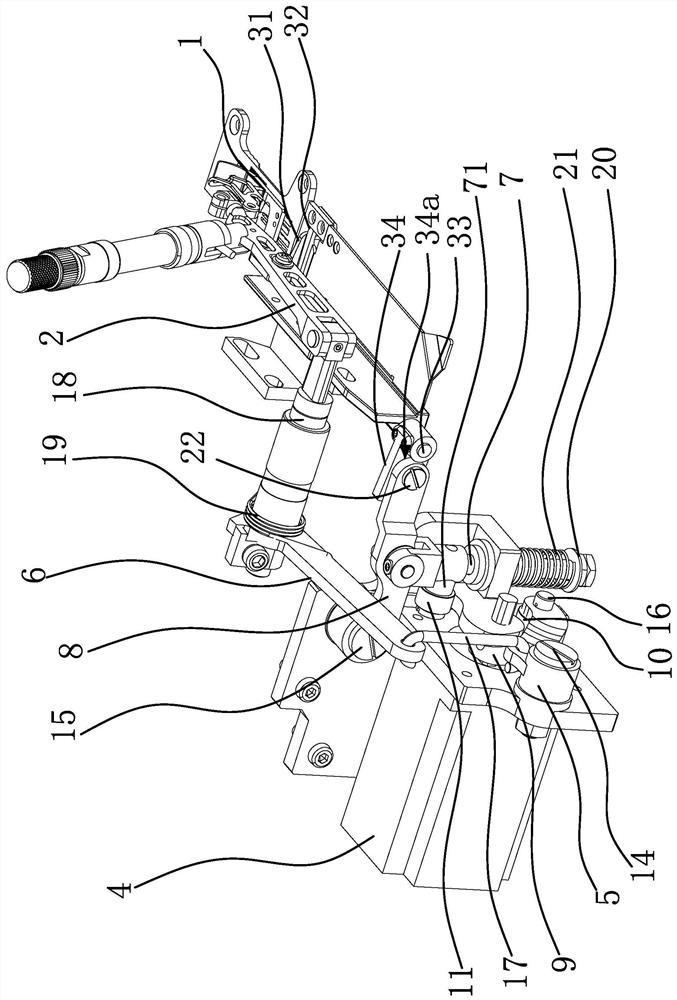

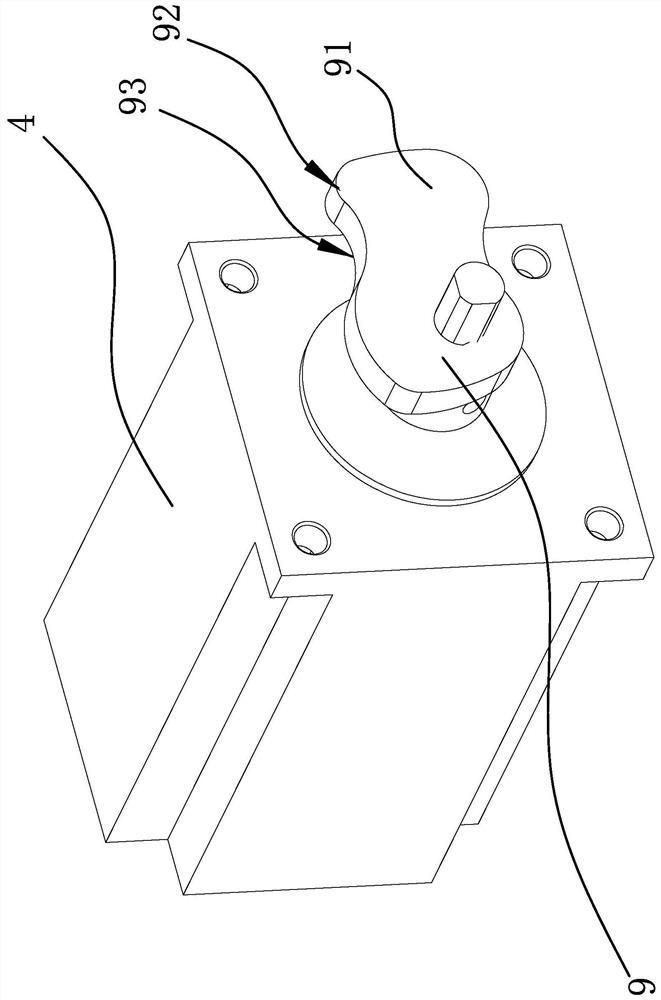

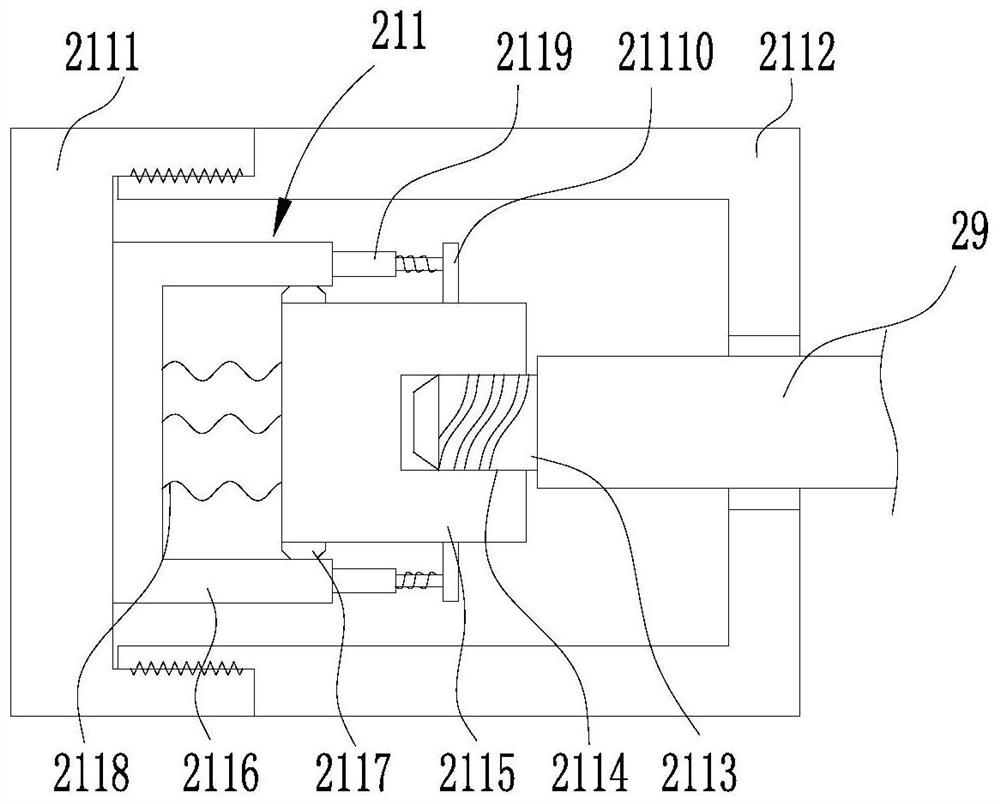

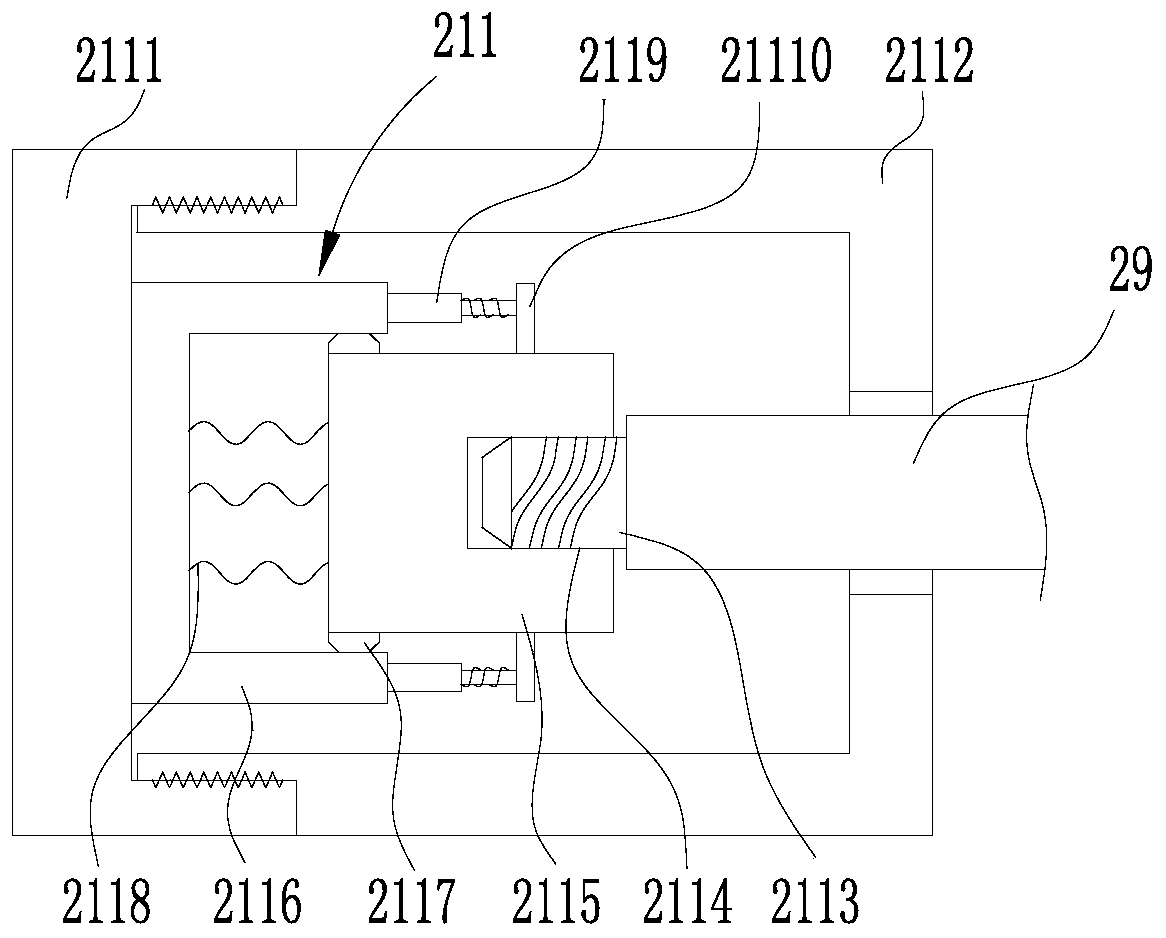

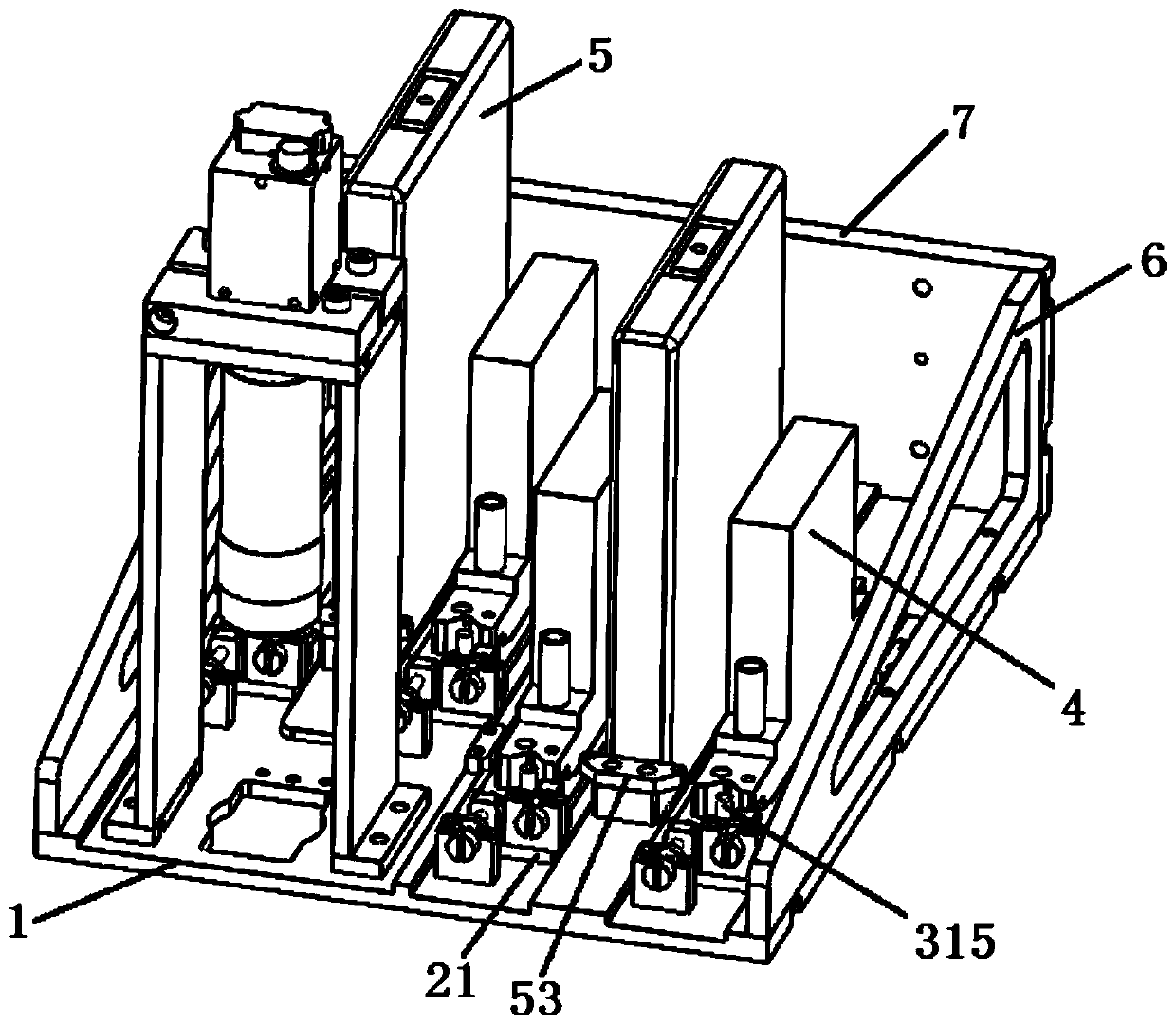

Presser foot lifting and trimming driving structure of sewing machine and control method thereof

ActiveCN112391745AReduce in quantityContour drive travel is accurate and reliableSewing-machine casingsNeedle severing devicesCrankElectric machinery

The invention provides a presser foot lifting and trimming driving structure of a sewing machine and a control method thereof, and belongs to the technical field of sewing machines. The technical problems that an existing presser foot lifting and trimming driving structure is not convenient and accurate enough to control and the like are solved. The sewing machine comprises a thread trimming assembly, a presser foot arm and a presser foot. The driving structure comprises a stepping motor, a presser foot lifting crank, a presser foot lifting lever, a vertically-arranged pushing rod and a threadtrimming connecting rod. A driving cam is fixedly arranged on an output shaft of the stepping motor; a roller I making contact with the outer contour of the driving cam is arranged on the presser foot lifting crank; the presser foot lifting lever is connected with the presser foot lifting crank; the presser foot lifting lever can drive a presser foot at the end of the presser foot arm to be lifted; a roller II matched with the driving cam is arranged on one side of the pushing rod; and the thread trimming connecting rod is connected to the upper end of the pushing rod and can drive a movablecutter and a fixed cutter in the thread trimming assembly to do shearing motion. According to the presser foot lifting and trimming driving structure of the sewing machine and the control method thereof provided by the invention, the driving structure is accurate and reliable in control and convenient to adjust.

Owner:JACK SEWING MASCH CO LTD

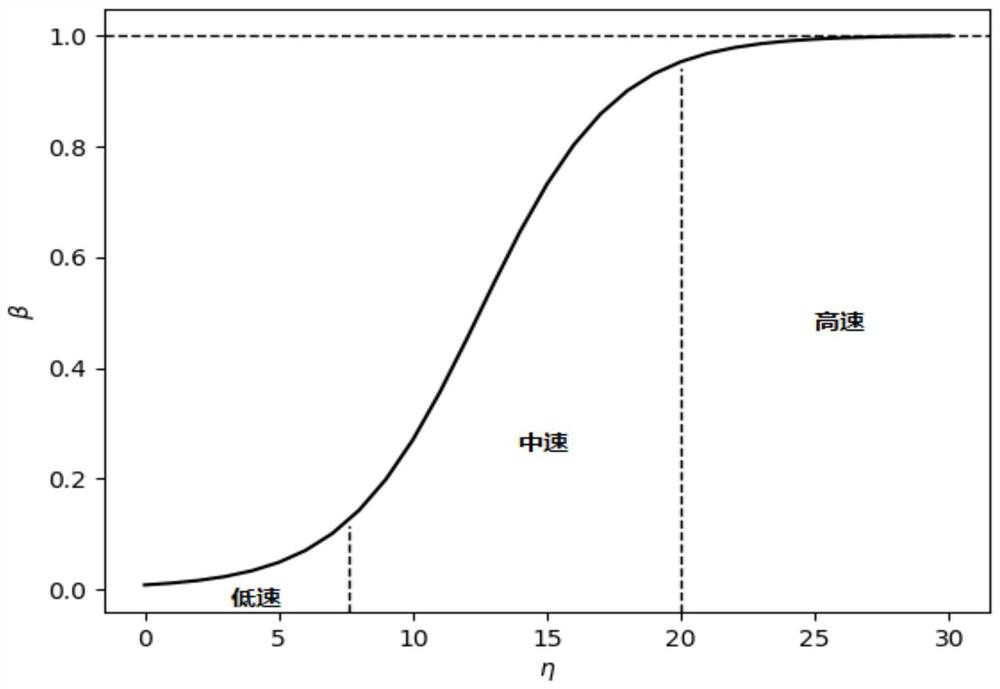

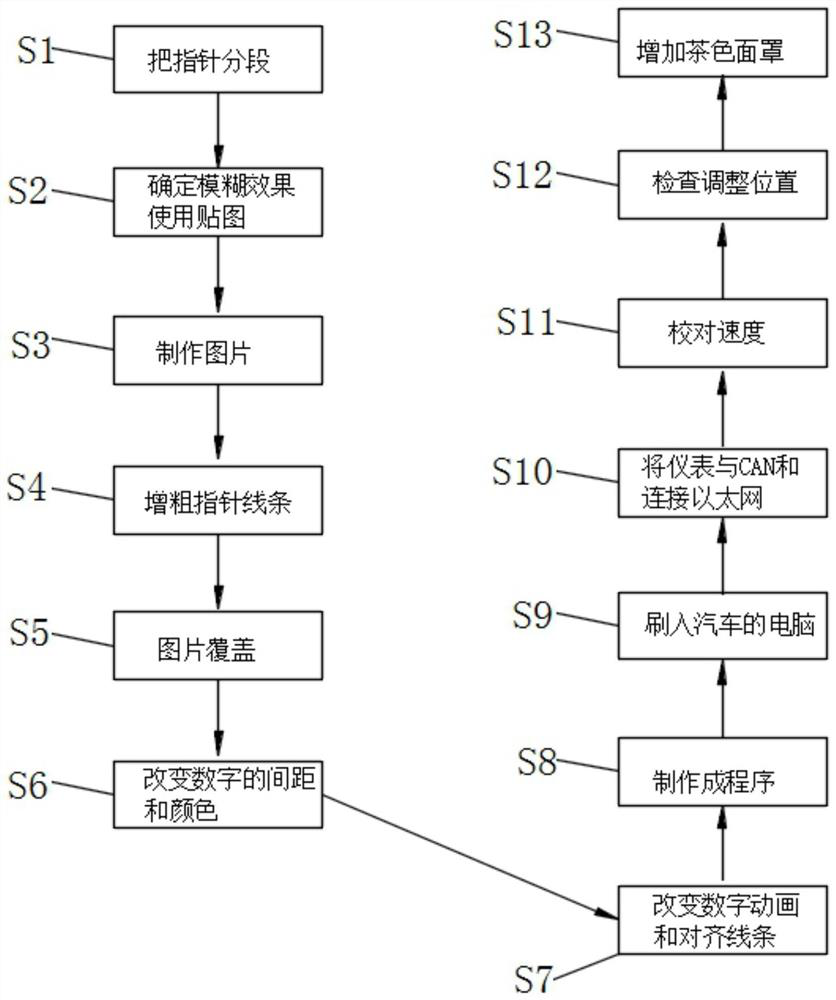

Display optimization method of automobile liquid crystal instrument pointer

ActiveCN111845346AAchieve a smooth effectCreate smooth feelingInternal combustion piston enginesElectric/fluid circuitSimulationComputer design

The invention provides a display optimization method of an automobile liquid crystal instrument pointer, and relates to the technical field of liquid crystal screen display. The display optimization method of the automobile liquid crystal instrument pointer comprises the following steps that the fuzzy degree of the pointer under different speed conditions is designed in advance through a computer,and corresponding pictures are replaced along with speed changes. The invention discloses a fuzzy optimization method of the automobile liquid crystal instrument pointer, the visual coherent effect is achieved; the pointer of the liquid crystal instrument moves quickly and slowly; a difference value between an actual value and a target value of the pointer is used as a reference value, the reference value is divided into multiple sections, the larger the reference value is, the heavier the fuzzy effect is, the larger the fuzzy range is, the smaller the reference value is, the smaller the fuzzy effect is, the smaller the fuzzy range is, or no fuzzy exists, a Gaussian fuzzy special effect is added to the pointer, and a visual smooth feeling is created.

Owner:江苏协和电子股份有限公司 +1

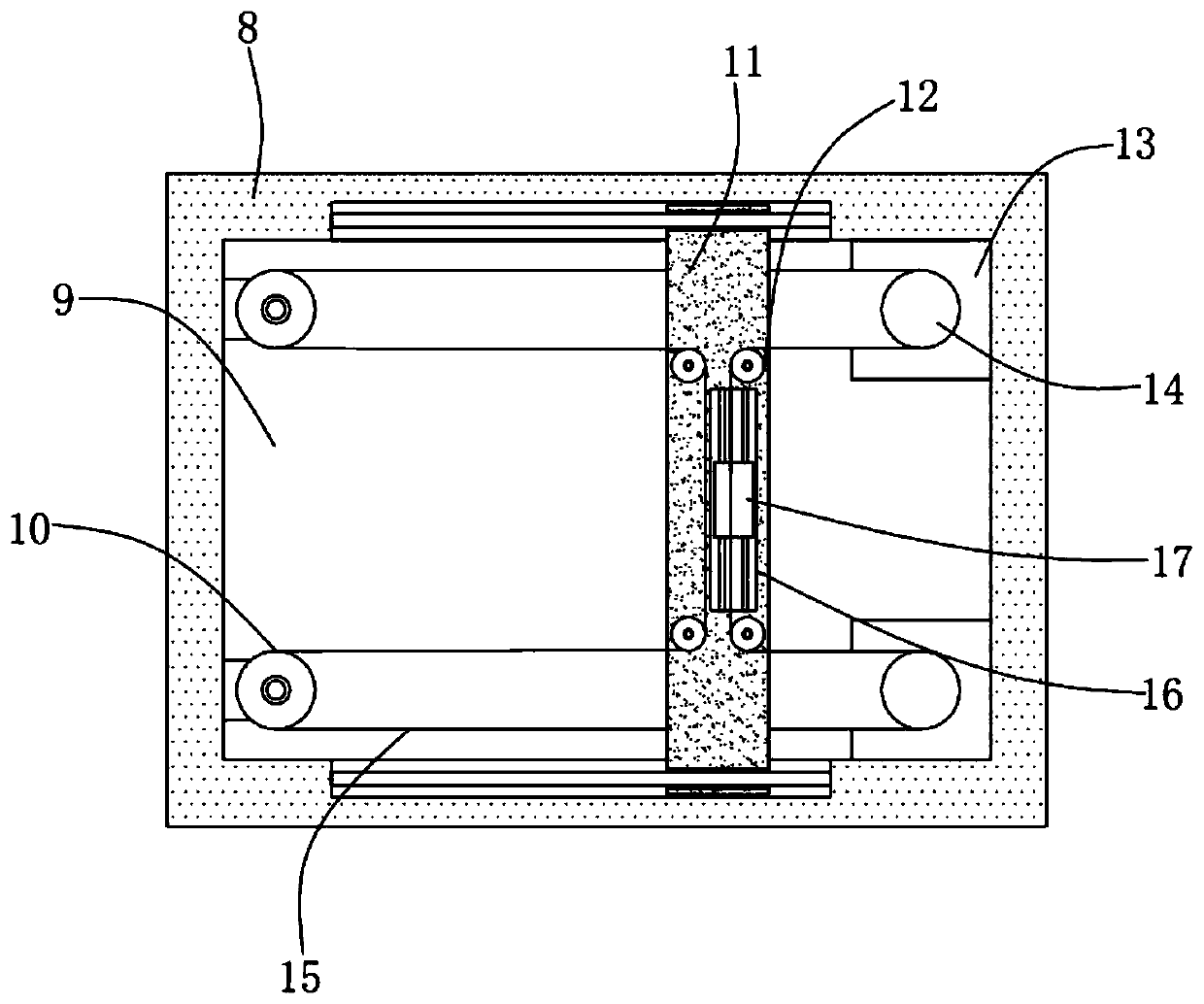

3D printer

InactiveCN110561741ASimple structureReduce manufacturing costManufacturing driving means3D object support structuresOptical axisContact layer

The invention discloses a 3D printer. The 3D printer comprises a shell, wherein two optical shafts are symmetrically and fixedly installed in the shell, and the same printing table is installed on thetwo optical shafts in a sliding mode; a hot bed for bearing products is arranged on the printing table; a printing nozzle which faces the hot bed is arranged above the hot bed; the hot bed comprisesa contact layer and gluing layer group which is arranged in an overlapping mode up and down and is used for providing the adsorption force and of which the surface is smooth and a magnet layer which is used for providing magnetism; and the smooth surface of the contact layer is the contact surface of a model. The 3D printer has the advantages that the structure is simple, the manufacturing cost islow, the use barrier of a user is low, the effect that the surface of the hot bed can be as smooth as the surface of a glass iron sheet is achieved, the model is convenient to remove, and solid gum and masking paper do not need to be applied.

Owner:FOSHAN UNIVERSITY

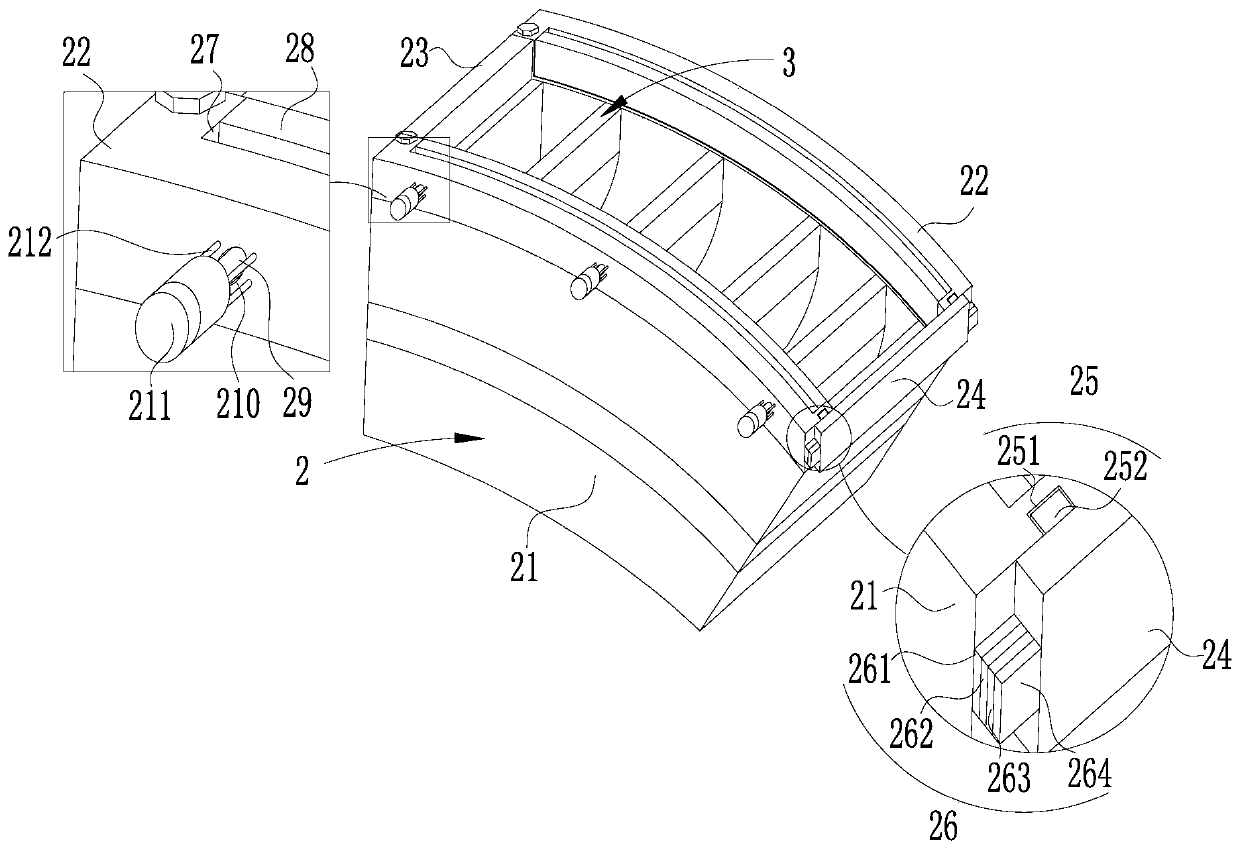

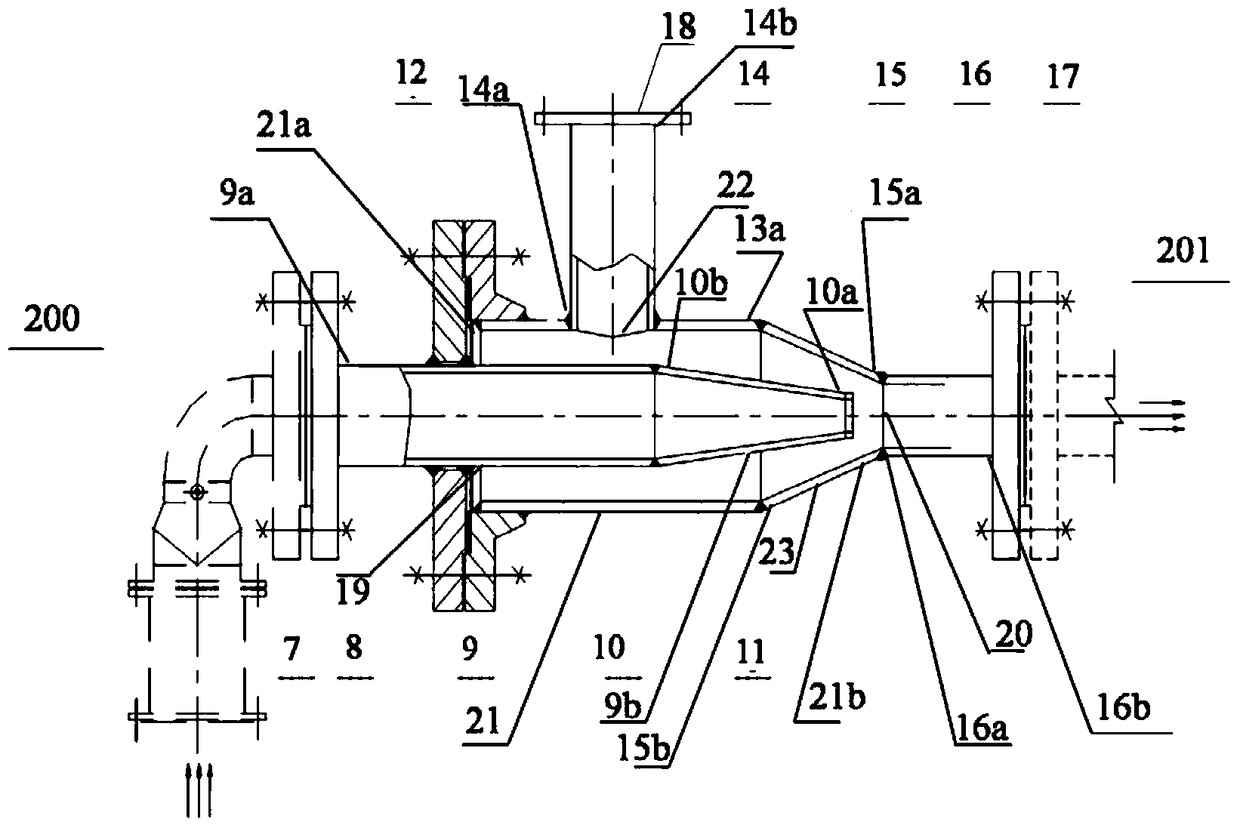

A sprayed concrete device for tunnel construction with reduced rebound rate

ActiveCN111520165BReduce rebound ratePrevent splashUnderground chambersTunnel liningArchitectural engineeringPipe

The invention relates to a concrete spraying device for tunnel construction and capable of reducing resilience. The concrete spraying device for tunnel construction and capable of reducing resiliencecomprises an arc-shaped pipe, a first anti-sputtering plate, a second anti-sputtering plate, a third anti-sputtering plate, a movable insert, an insertion groove, an insertion rod, fixing adsorption mechanisms, a first magnet, a first gasket, a second gasket, a second magnet, a movable groove, a movable plate, a movable rod, a movable through hole and buffer assemblies. According to the concrete spraying device for tunnel construction and capable of reducing resilience, the arc-shaped pipe and the strong electromagnet combination structure are additionally arranged, and a closed cavity is formed through the synergistic effect of the arc-shaped pipe and the strong electromagnets, so that during specific construction, a relatively closed environment is created for sprayed concrete mixture, the sprayed rebound material is automatically collected in the closed environment, and the concrete mixture is sprayed and formed in the closed environment. Therefore, the resilience rate of the backfilled sprayed concrete can be effectively reduced.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD +1

Concrete spraying device for tunnel construction and capable of reducing resilience

ActiveCN111520165AReduce rebound ratePrevent splashUnderground chambersTunnel liningArchitectural engineeringClosed cavity

The invention relates to a concrete spraying device for tunnel construction and capable of reducing resilience. The concrete spraying device for tunnel construction and capable of reducing resiliencecomprises an arc-shaped pipe, a first anti-sputtering plate, a second anti-sputtering plate, a third anti-sputtering plate, a movable insert, an insertion groove, an insertion rod, fixing adsorption mechanisms, a first magnet, a first gasket, a second gasket, a second magnet, a movable groove, a movable plate, a movable rod, a movable through hole and buffer assemblies. According to the concrete spraying device for tunnel construction and capable of reducing resilience, the arc-shaped pipe and the strong electromagnet combination structure are additionally arranged, and a closed cavity is formed through the synergistic effect of the arc-shaped pipe and the strong electromagnets, so that during specific construction, a relatively closed environment is created for sprayed concrete mixture, the sprayed rebound material is automatically collected in the closed environment, and the concrete mixture is sprayed and formed in the closed environment. Therefore, the resilience rate of the backfilled sprayed concrete can be effectively reduced.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD +1

A polishing method for a thin-film lithium niobate optical waveguide chip polishing device

A thin-film lithium niobate optical waveguide chip polishing device and polishing method proposed by the present invention use a magnetic stirring table to drive a magnetic rotor to rotate in a polishing solution, and then stir the polishing solution to flow into contact with the surface of the chip, and the polishing particles therein are in contact with the dry Semi-contact or sliding contact occurs on the surface of the chip etched by the method, accompanied by a small amount of particle bombardment. At the same time, the alkaline ions in the polishing solvent react chemically with the etched surface. Chemical etching and particle bombardment in the parallel direction of the surface, and then remove the etching products deposited on the dry etching surface and the peaks and protrusions produced by dry etching, so as to achieve the smoothing effect of the etching surface and the side wall of the waveguide. Compared with traditional contact mechanical grinding and polishing and chemical mechanical polishing methods, it has the advantages of simple structure, easy operation, low cost and less surface damage.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Gas-phase anti-rust composite packaging film for industry and preparation method thereof

ActiveCN101319067BHigh mechanical strengthIncrease elasticityFlat articlesLow-density polyethyleneBenzoic acid

Owner:金荣范

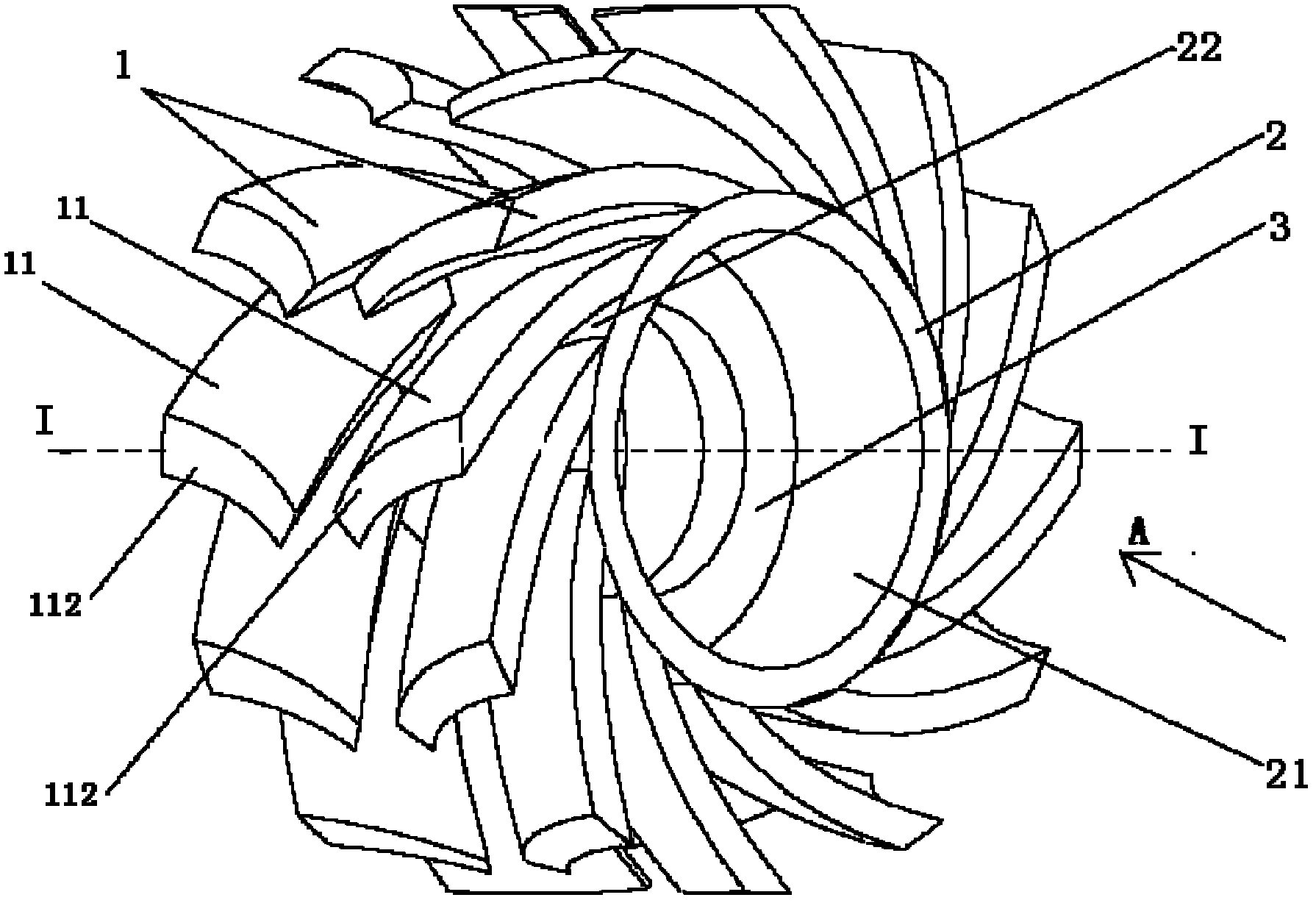

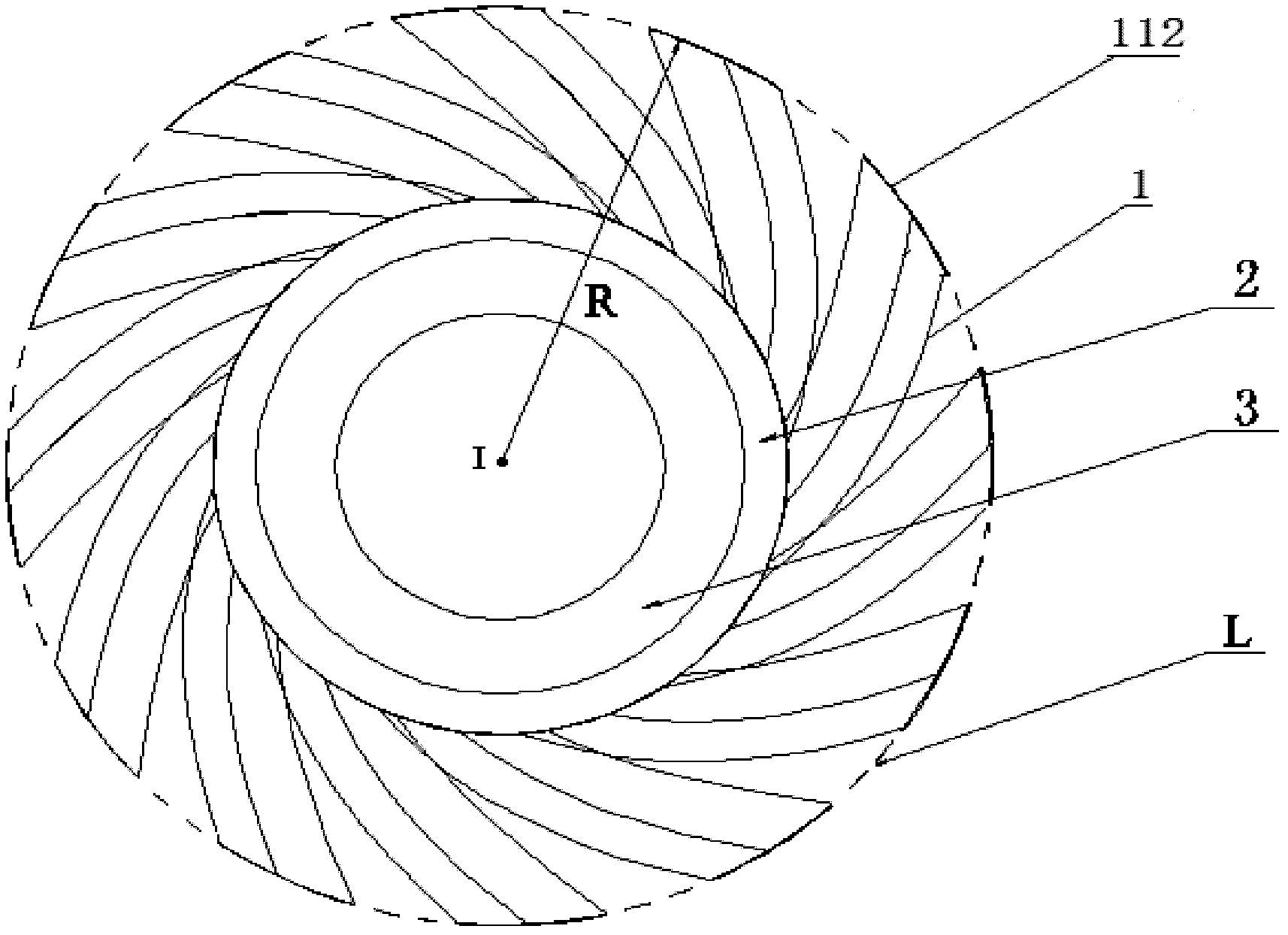

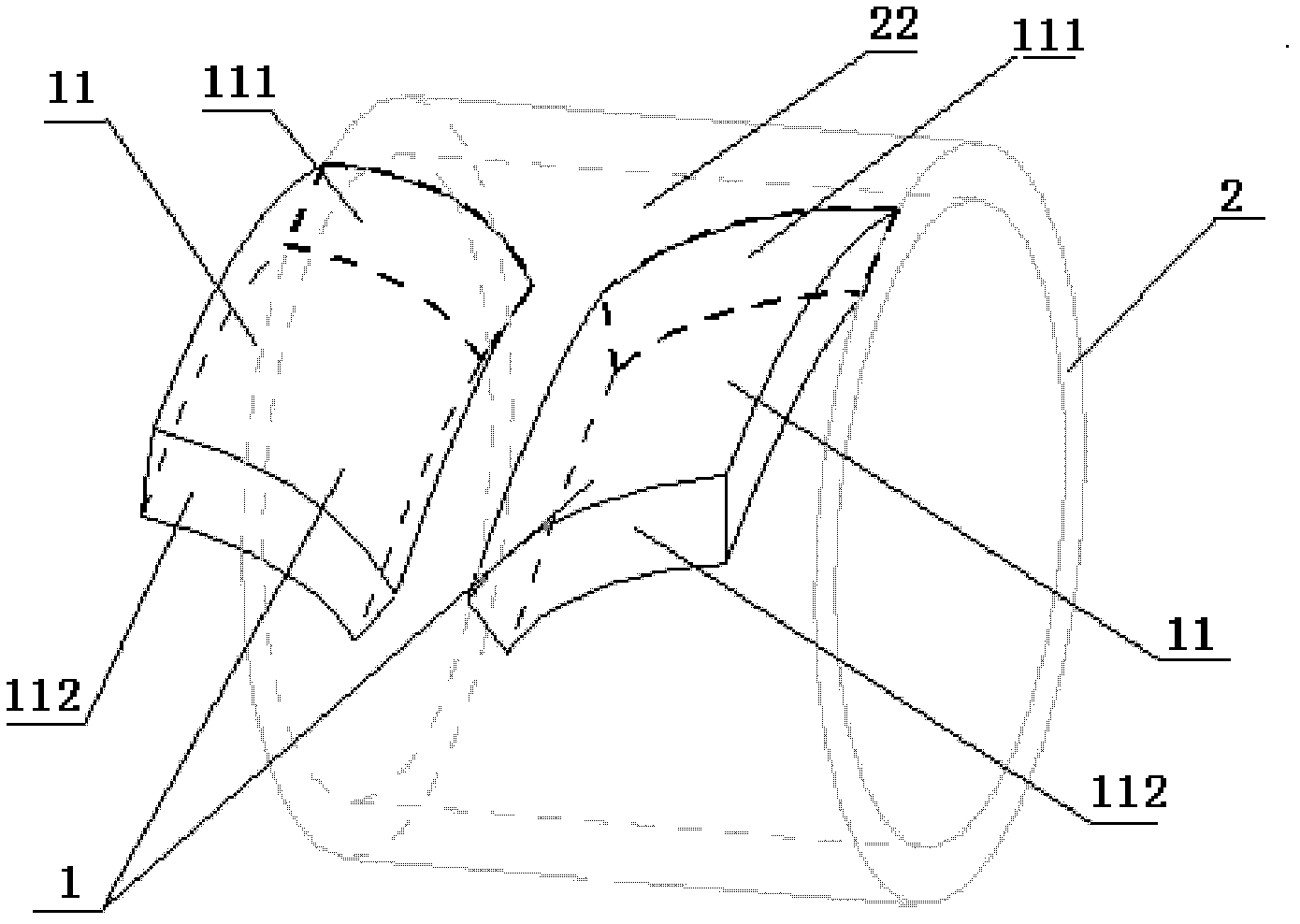

Impeller imitated semi-walking wheel

The invention provides an impeller imitated semi-walking wheel which comprises at least twelve blade groups, an inner wheel ring and a connecting flange plate, wherein the blade groups are uniformly distributed and fixedly connected to the outer circumference surface of the inner wheel ring; each blade group comprises two arc-shaped blades in mirror symmetry, arranged in an inverse 'splayed' shape and bent in a regular direction, the surface of each blade is an oblique arc surface, the outer section of the arc-shaped blade is a curved surface, and the outer section of the arc-shaped blade is tangential to a cylindrical surface using the axis of the inner wheel ring as a central shaft and the outside diameter of the impeller imitated semi-walking wheel as a rotating radius; and the connecting flange plate is fixedly connected to the inner circumference surface of the inner wheel ring. The impeller imitated semi-walking wheel can be used for a deep space detection vehicle or a vehicle running on the loose ground such as desert, marsh or the like; the blade groups have the effect of improving the adhesive force of the wheel on the ground, so that the traction force is increased; and the arrangement mode and shape of the arc-shaped blades have the effect of reducing the resistance and can avoid a polygon effect, so that the passing property and smoothness of the vehicle are enhanced.

Owner:DALIAN UNIV OF TECH

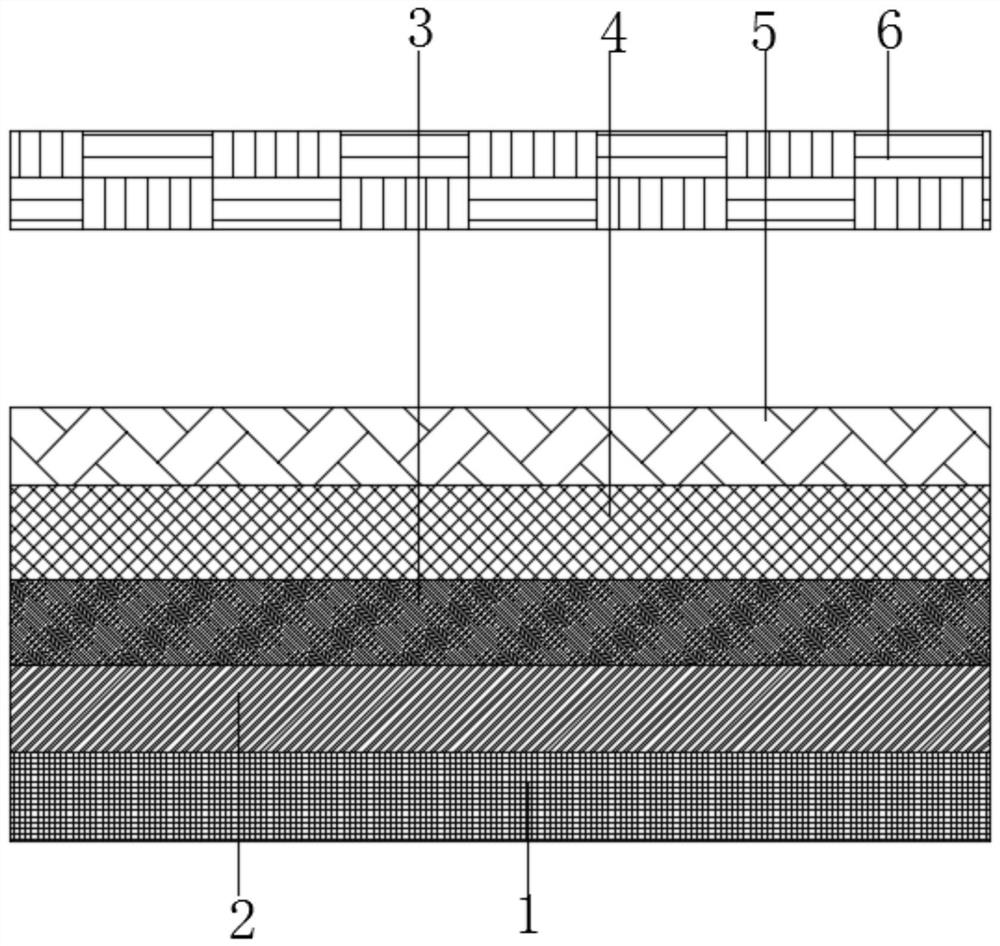

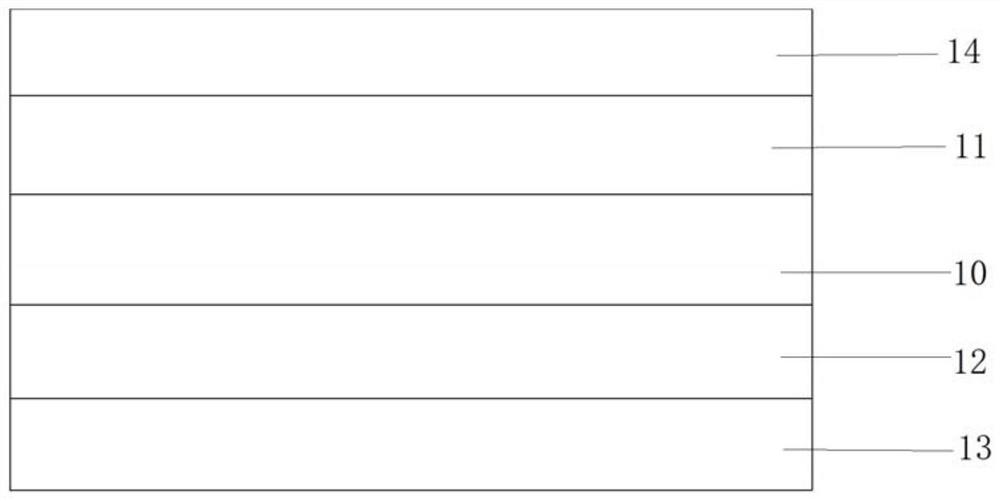

Composite self-adhesive dimming film

PendingCN112622356AOil-resistantAnti-fingerprintSynthetic resin layered productsCoatingsStainFinger print

The invention discloses a composite self-adhesion dimming film. The composite self-adhesion dimming film comprises a first PET base material and a smooth coating, wherein the first PET base material is coated with the smooth coating. Compared with the prior art, the PET base material is coated with the smooth coating; pencil hardness tests show that the PET base material cannot be scratched in daily cleaning; and the PET base material has the effects of oil stain resistance, fingerprint resistance and the like.

Owner:UPASS MATERIAL TECH JIANGSU

Tube end groove polishing all-in-one machine

InactiveCN110774133AAchieve a smooth effectEasy to operatePolishing machinesGrinding drivesElectric machineryPolishing

The invention discloses a tube end groove polishing all-in-one machine. The tube end groove polishing all-in-one machine comprises a fixed disc, a rotary shaft, a shaft sleeve, a circular sleeve, a polishing mechanism and a rotary handle, wherein the rotary shaft sleeves the outer part of the shaft; one end of the rotary shaft is connected to the fixed disc; the other end of the rotary shaft is fixed to the rotary handle; the circular sleeve sleeves the outer part of the shaft sleeve; the polishing mechanism is fixed to the circular disc; the polishing mechanism comprises a polishing motor, apolishing wheel and a bracket; the polishing motor is fixed to the bracket; and the output end of the polishing motor is fixed to the polishing wheel. The tube end groove polishing all-in-one machinehas the beneficial effects that: the fixed disc, the rotary shaft, the shaft sleeve, the circular sleeve, the polishing mechanism and the rotary handle are arranged, the fixed disc is fixed to the inner wall of a tube, and the polishing mechanism rotates along the shaft sleeve through the circular sleeve, so that peripheral-form polishing can be performed on the end opening of the tube, and therefore, the smooth effect is achieved; and a slide block of the fixed disc can regulate jacking height through the rotary handle and the rotary shaft, so that regulating and fixing can be achieved according to inner diameters of different tubes.

Owner:武汉威研工程技术有限公司

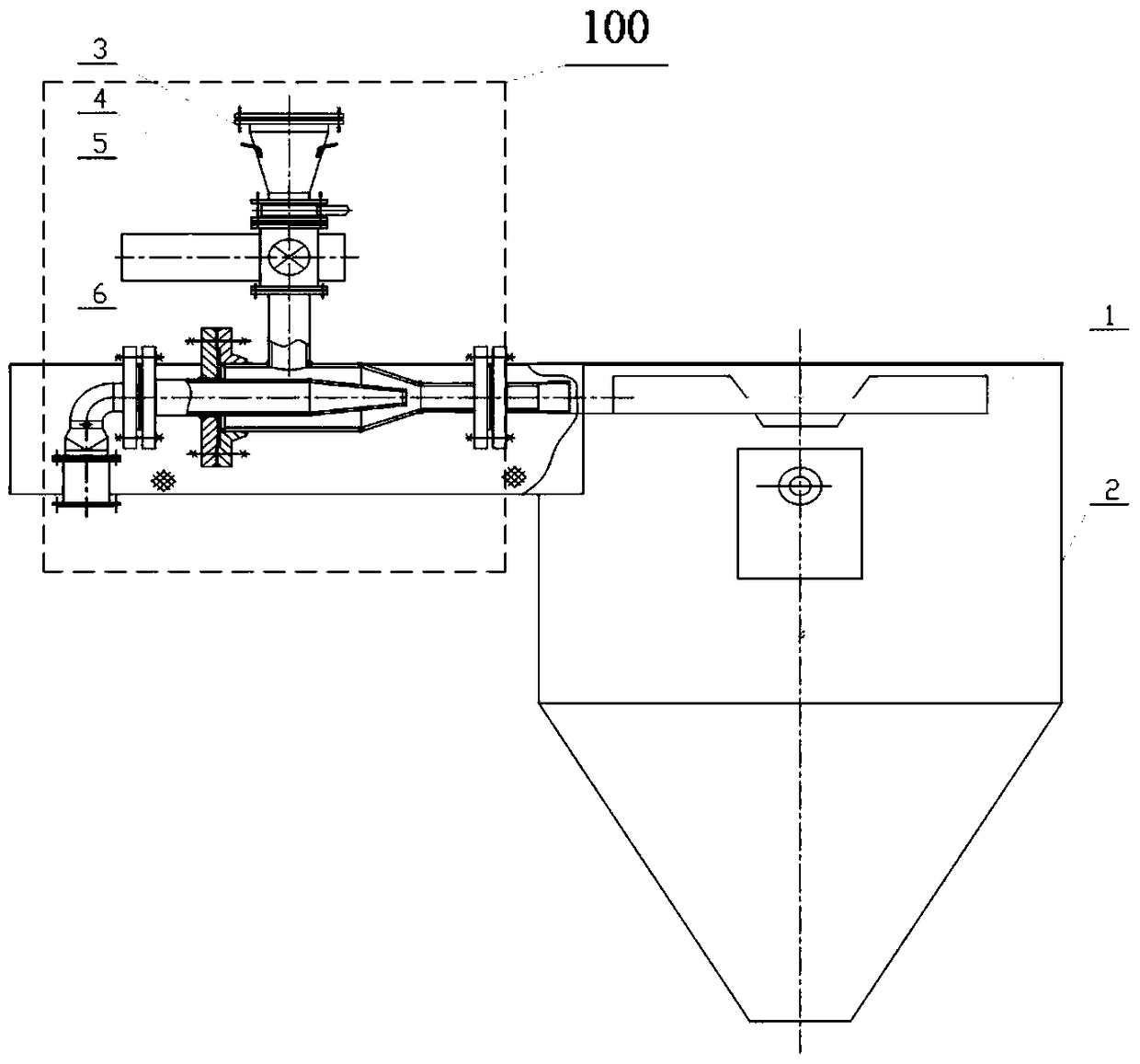

A device and method for preventing wall sticking of spray drying tower

ActiveCN105588418BThe need for continuous productionAchieve a smooth effectDrying gas arrangementsDrying solid materialsPulp and paper industryTower

The invention provides a mechanism and a method for preventing wall adhesion of a spray drying tower. The mechanism comprises an outer cylinder and a suction port, wherein the outer cylinder is provided with an air inlet and an air outlet; the suction port is formed in the outer cylinder and is used for providing an adhesion preventing material to the inside of the outer cylinder; and air current flowing in the outer cylinder can carry the adhesion preventing material to flow out through the air outlet. The invention also provides a device for preventing the wall adhesion of the spray drying tower. The device comprises the mechanism and an air current distributor connected with the air outlet of the outer cylinder. The invention further provides the method for preventing the wall adhesion of the spray drying tower. According to the method, air current and the adhesion preventing material are fed into a spray drying area by the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

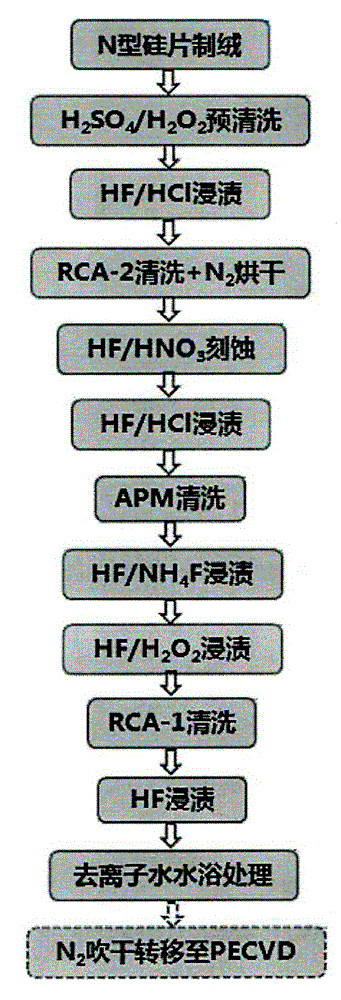

Cleaning treatment method for n-type crystalline silicon substrate of solar cell

ActiveCN103700733BOvercome preparation thorny issuesLess preparation troublesFinal product manufactureSemiconductor/solid-state device manufacturingOpen-circuit voltageHydrogen peroxide

The invention discloses a cleaning treatment method of an N-type crystalline silicon substrate of a solar cell. The method comprises the following steps of washing a textured N-type crystalline silicon substrate with deionized water, then impregnating the N-type crystalline silicon substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide, and then washing the substrate with deionized water after completion; then soaking the substrate in a mixed solution containing 2% of hydrogen chloride and 3% of hydrofluoric acid for 2-3 minutes, and then washing the substrate with deionized water until the substrate is clean; then impregnating the substrate in a mixed solution of hydrogen chloride, hydrogen peroxide and water in a ratio of 1:1:6 to be washed for 10-15 minutes, then washing the substrate with deionized water, and then drying the substrate surface for later use; then etching the dried substrate, and then washing the substrate with deionized water, wherein the temperature of the mixed solution of hydrogen chloride, hydrogen peroxide and water is 60-80 DEG C. By adopting the method, the cleanliness of the substrate surface can be improved and the substrate surface is flat and smooth, thus improving the open-circuit voltage, short-circuit current and filling factors of the prepared solar cell and improving the photoelectric conversion property of the cell.

Owner:TRINA SOLAR CO LTD

Glue injection device of battery

PendingCN107452977AThe overall structure design is reasonableWork reliablyPrimary cell manufactureAssembling battery machinesEngineeringElectrical and Electronics engineering

The invention provides a glue injection device of a battery, and belongs to the technical field of battery production. The glue injection device of the battery comprises a mainboard, a glue injection assembly, a rotation assembly and a transmission assembly, wherein a transmission passage is arranged on the mainboard and is used for transmitting battery steel shells arranged in a line, the glue injection assembly is used for injecting glue into the battery steel shells, the rotation assembly comprises rotation bearings, the rotation bearings are arranged at intervals with the battery steel shells in the transmission passage and are arranged in a line, the whole line of rotation bearings synchronously move and can be near to or far away from the transmission passage, each rotation bearing is clamped into a gap between two corresponding battery steel shells when the whole line of rotation bearings synchronously move, at the moment, an outer wall of each rotation bearing is rotatably connected with outer walls of the two corresponding battery steel shells, the transmission assembly and the rotation assembly are arranged at two sides of the transmission passage, the transmission assembly comprises a transmission belt, the transmission belt is movably arranged and can be near to or far away from the transmission passage, and the transmission belt can be simultaneously in contact with the whole line of battery steel shells and drives the battery steel shells to rotate when getting close to the transmission passage. By the glue injection device of the battery, the glue can be uniformly coated at the bottom of isolation paper.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

A Bit Rate Smoothing Method for Real-time Video Transmission under Wireless Network

InactiveCN103916716BDoes not affect the display effectAchieve a smooth effectNetwork traffic/resource managementTransmissionNetwork conditionsComputer science

The present invention proposes a code rate smoothing method for real-time video transmission under a wireless network. The method includes: periodically counting the transmission delay of the video frame, and when the transmission delay becomes small, the playback buffer is reduced by fast forwarding. When the delay becomes large, the playback buffer is enlarged through slow playback, and the adjustment steps of the fast forward and the slow playback are jointly determined by transmission delay variation, playback buffer depth, and time stamp information. The present invention can count the transmission time delay of video frames, perceive the state of the wireless network according to the time delay information, and then find the minimum video time delay according to the actual network conditions to achieve a smooth effect, realizing the balance between real-time and fluency of video streams .

Owner:BEIJING XINWEI TELECOM TECH +1

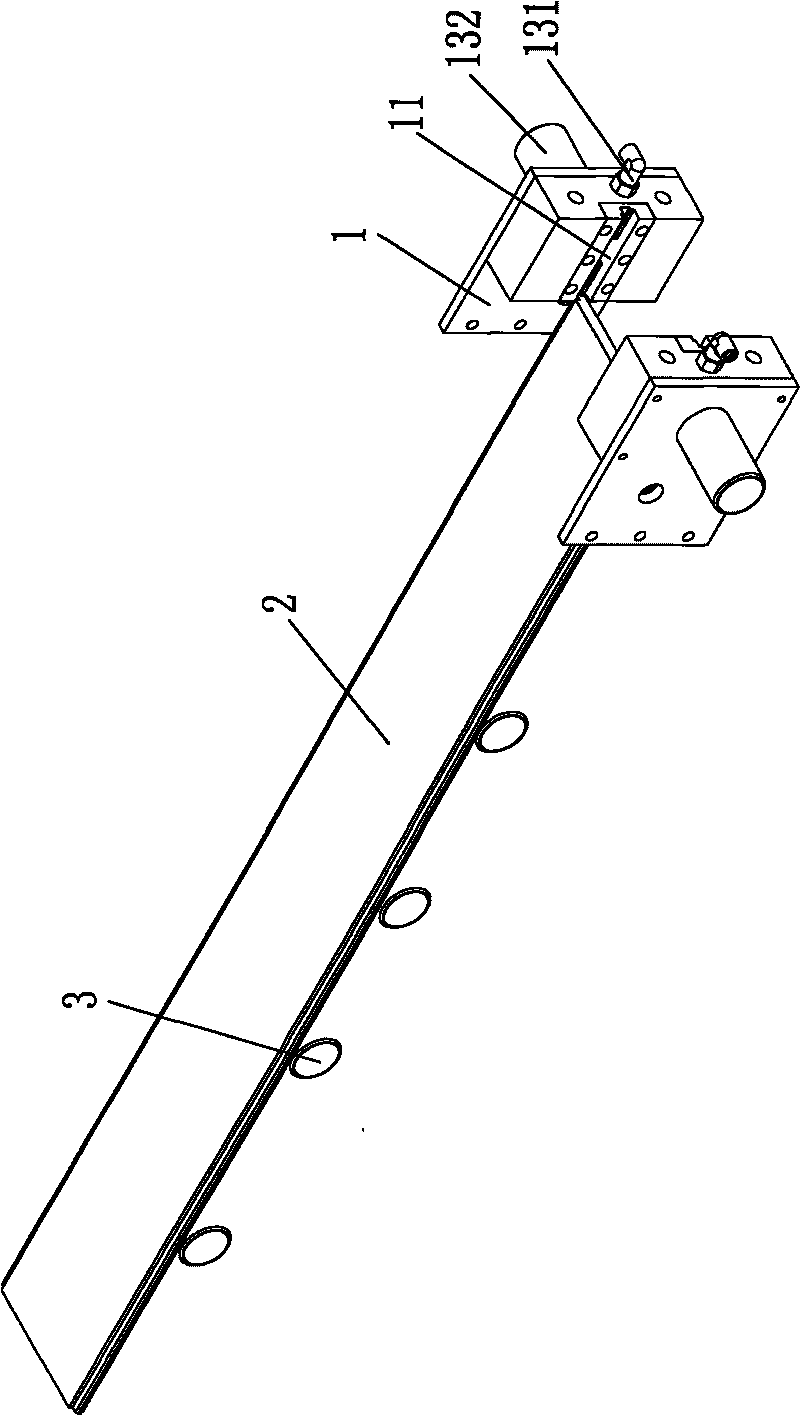

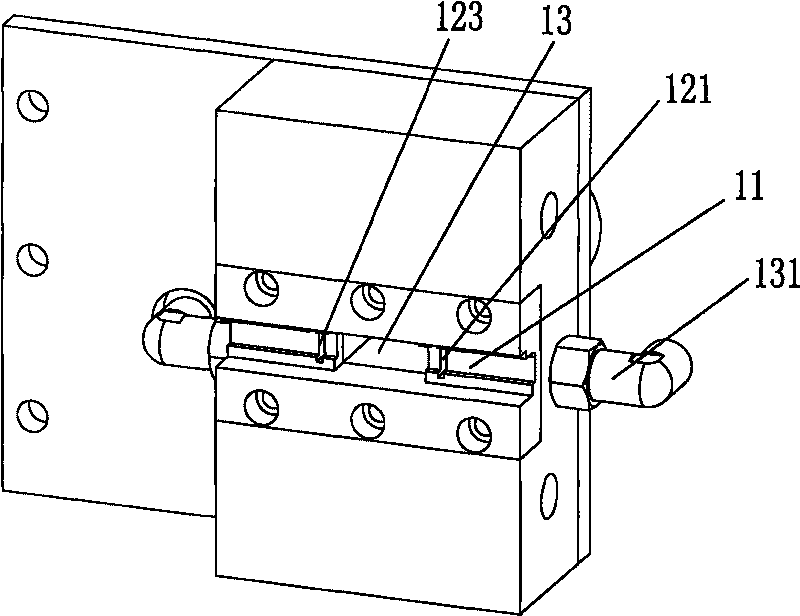

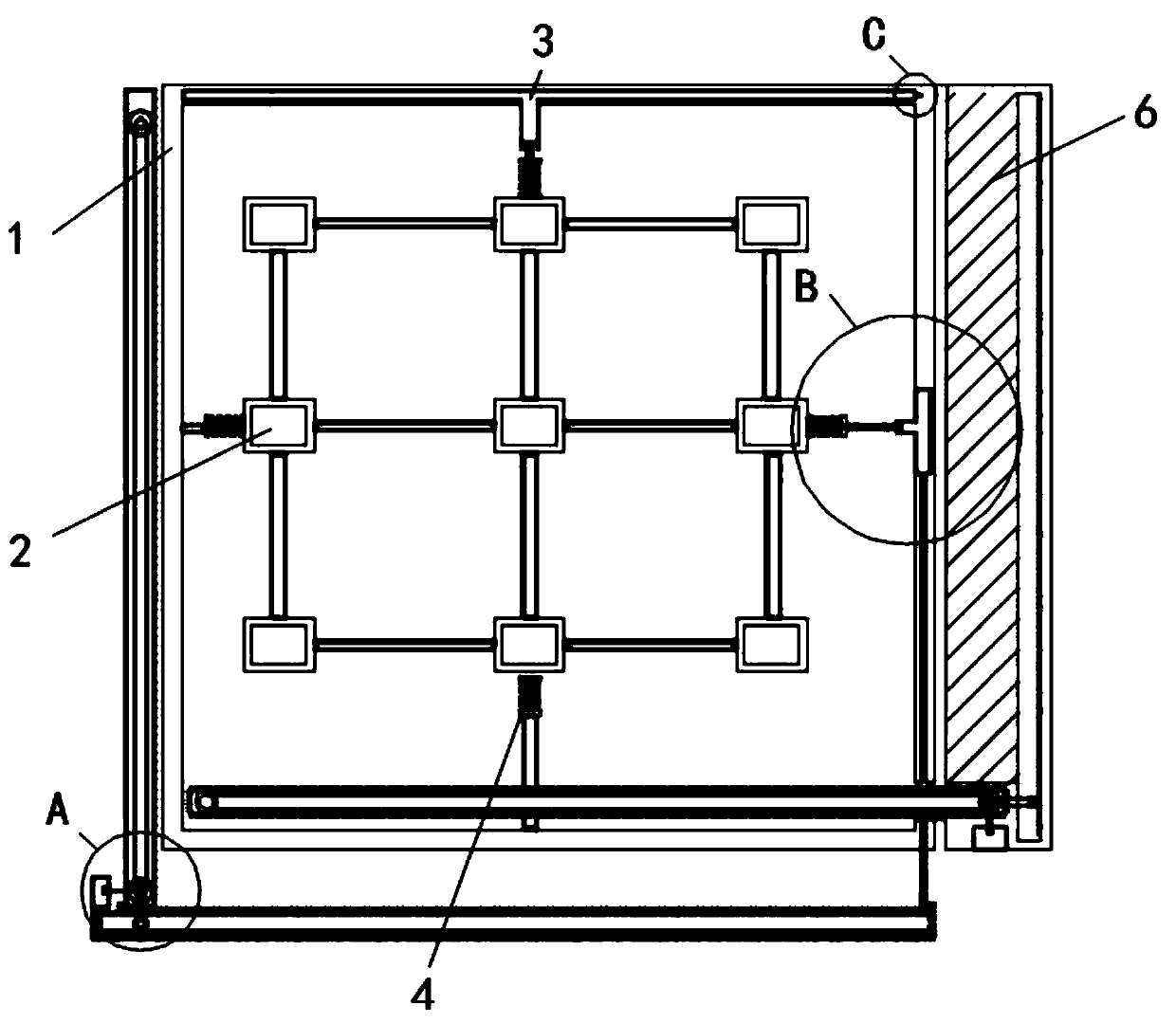

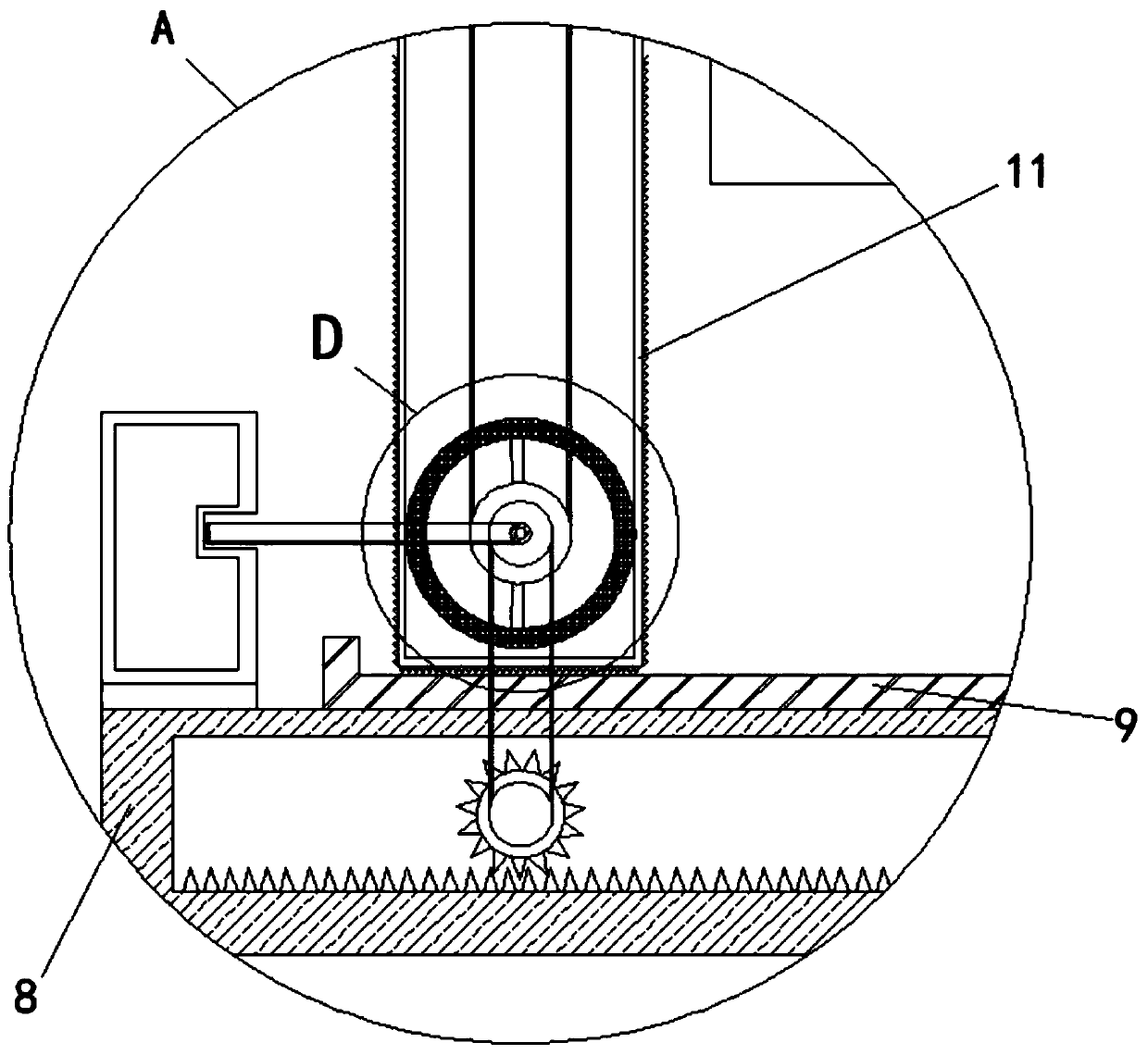

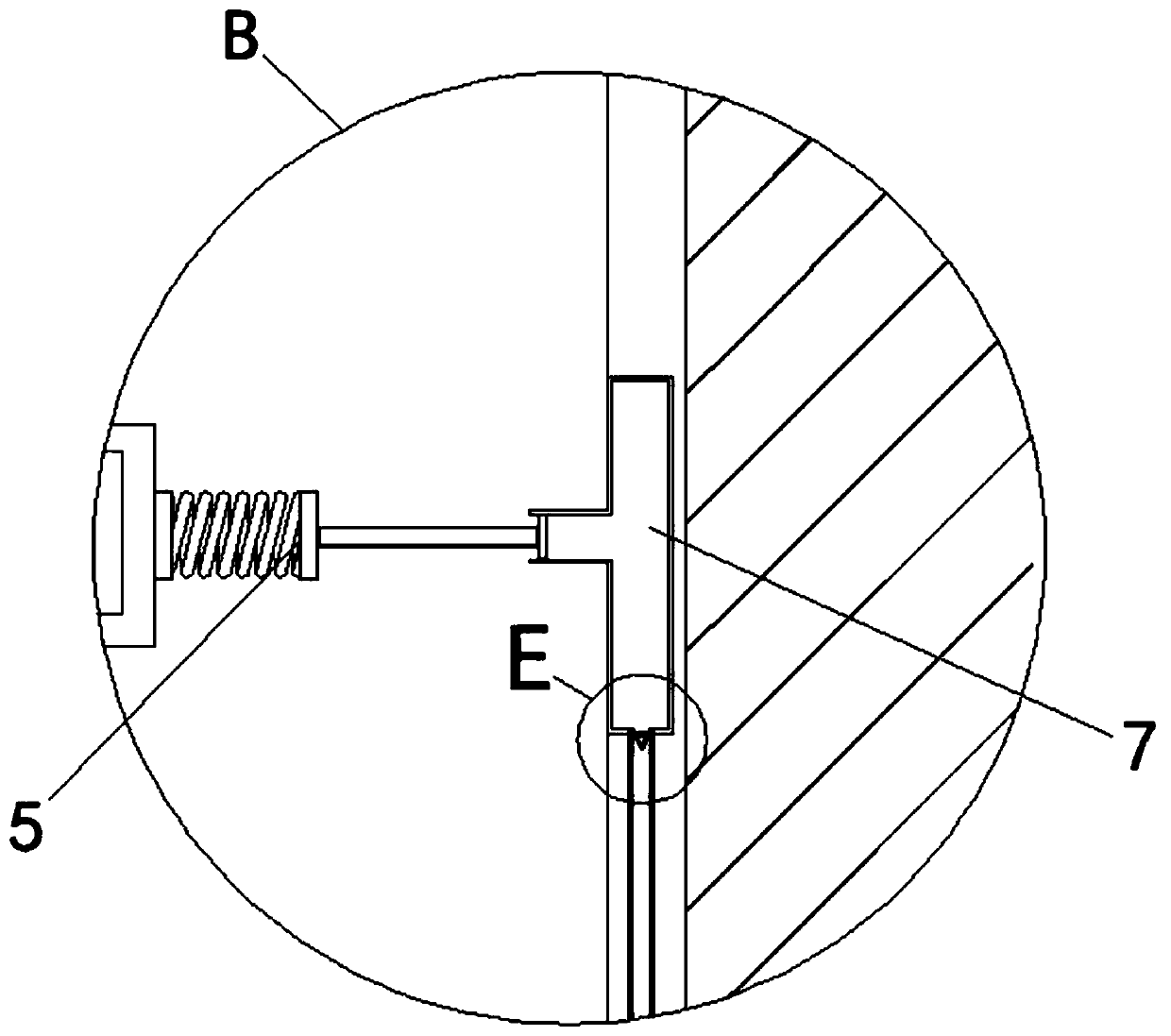

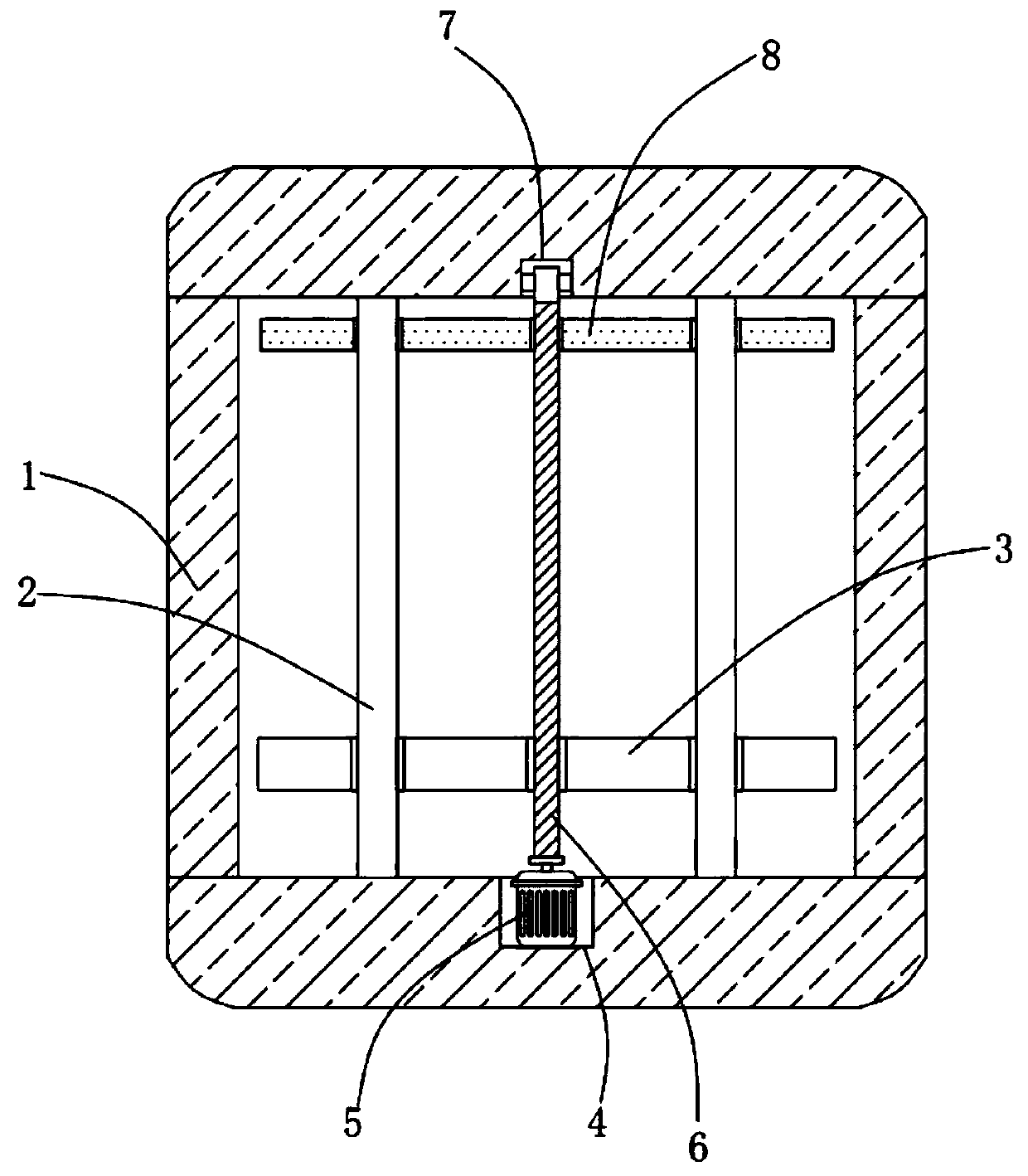

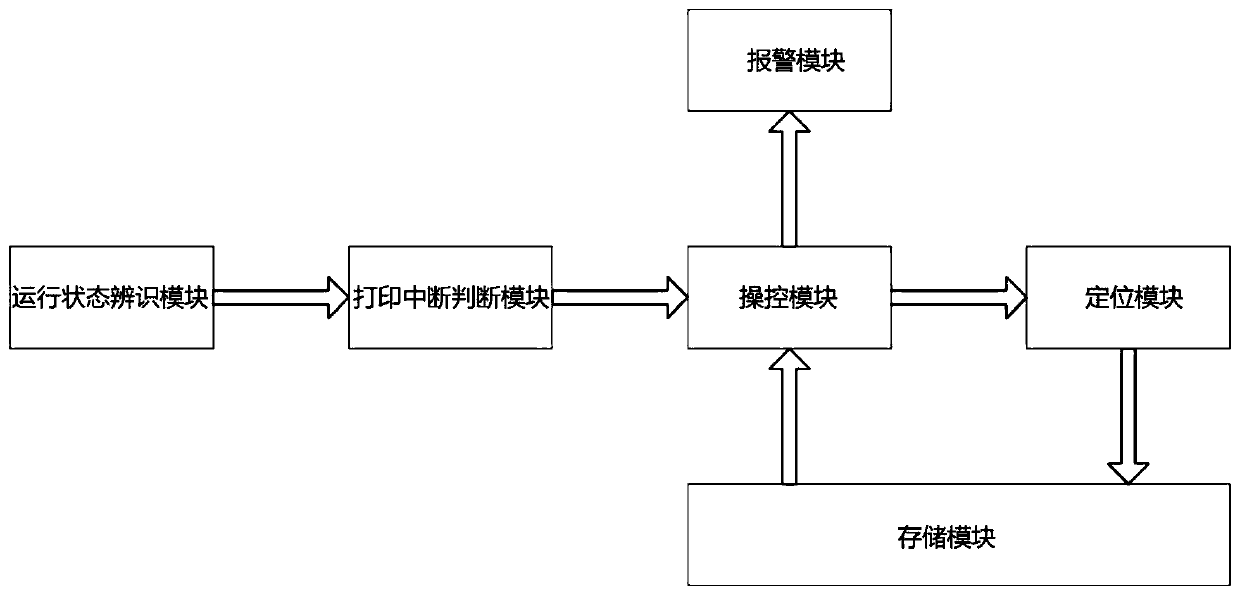

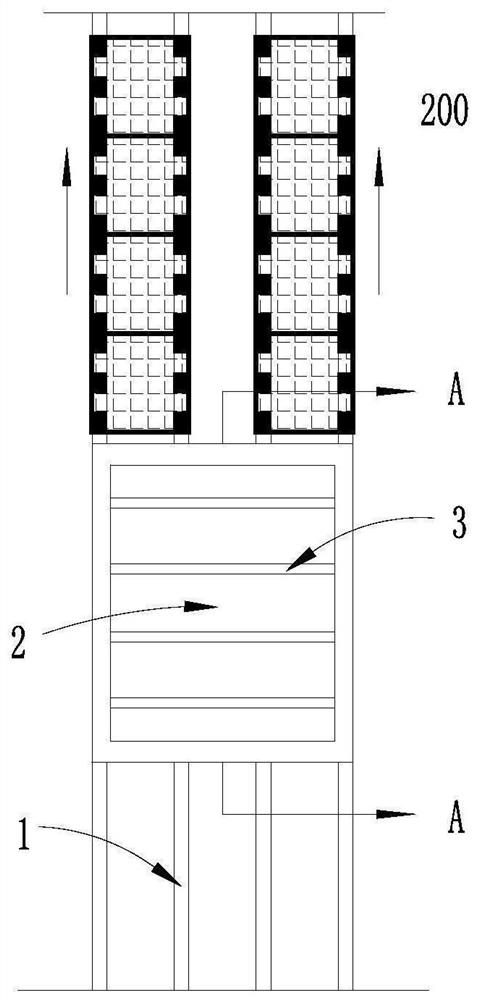

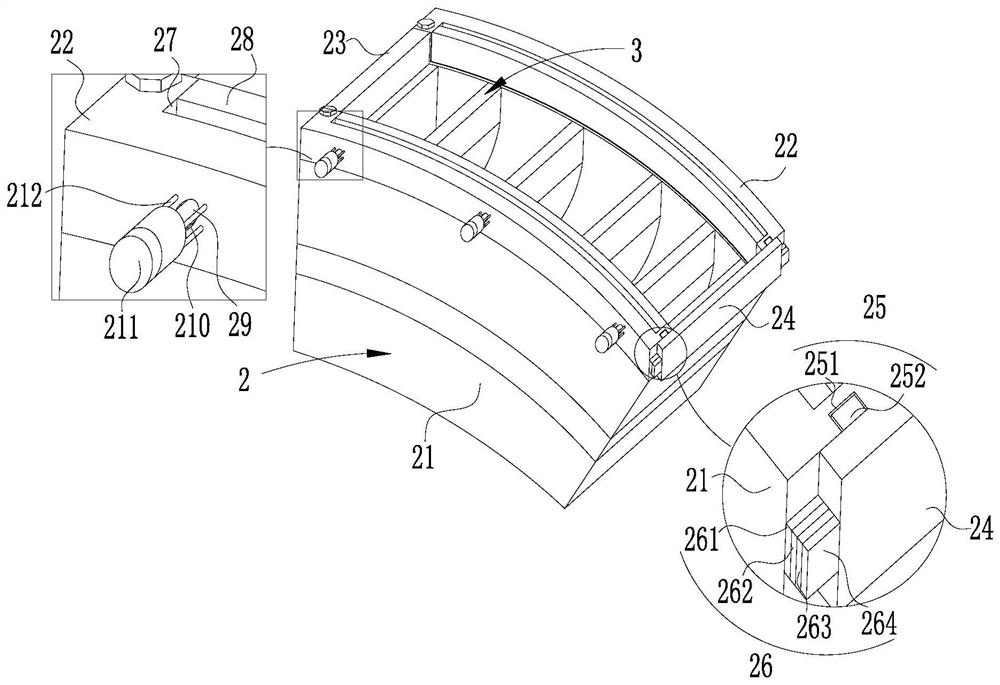

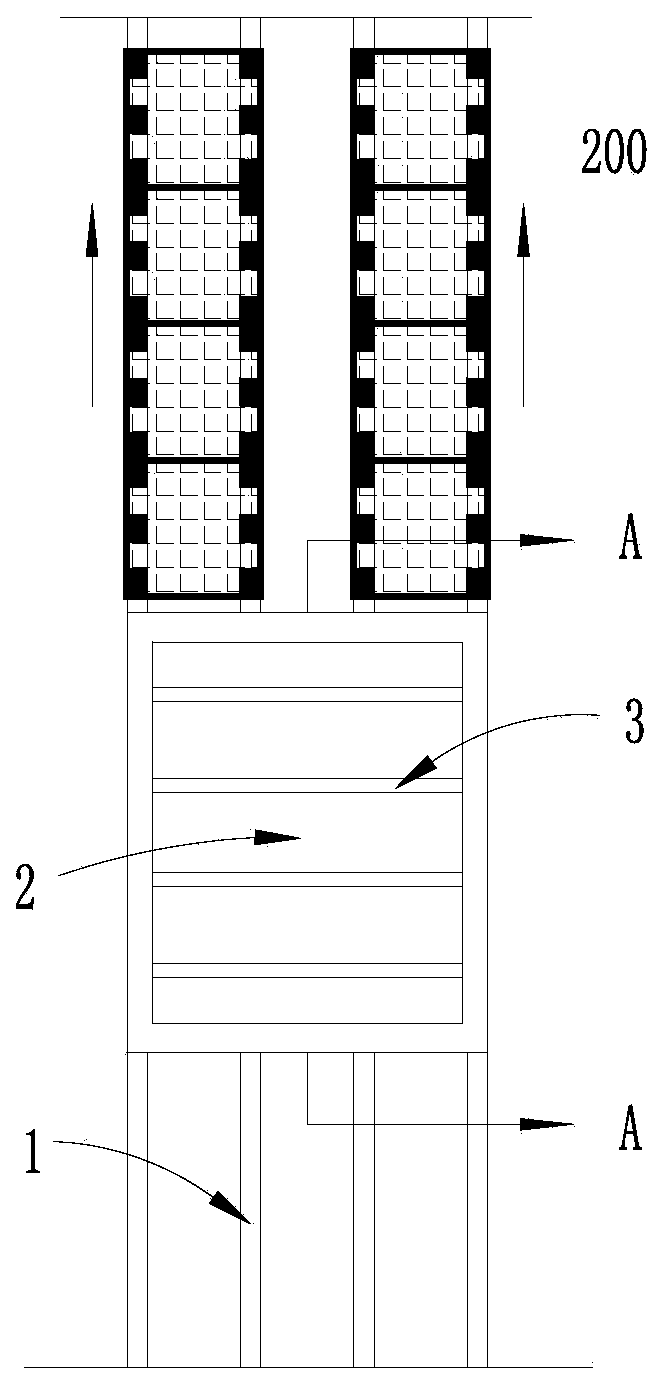

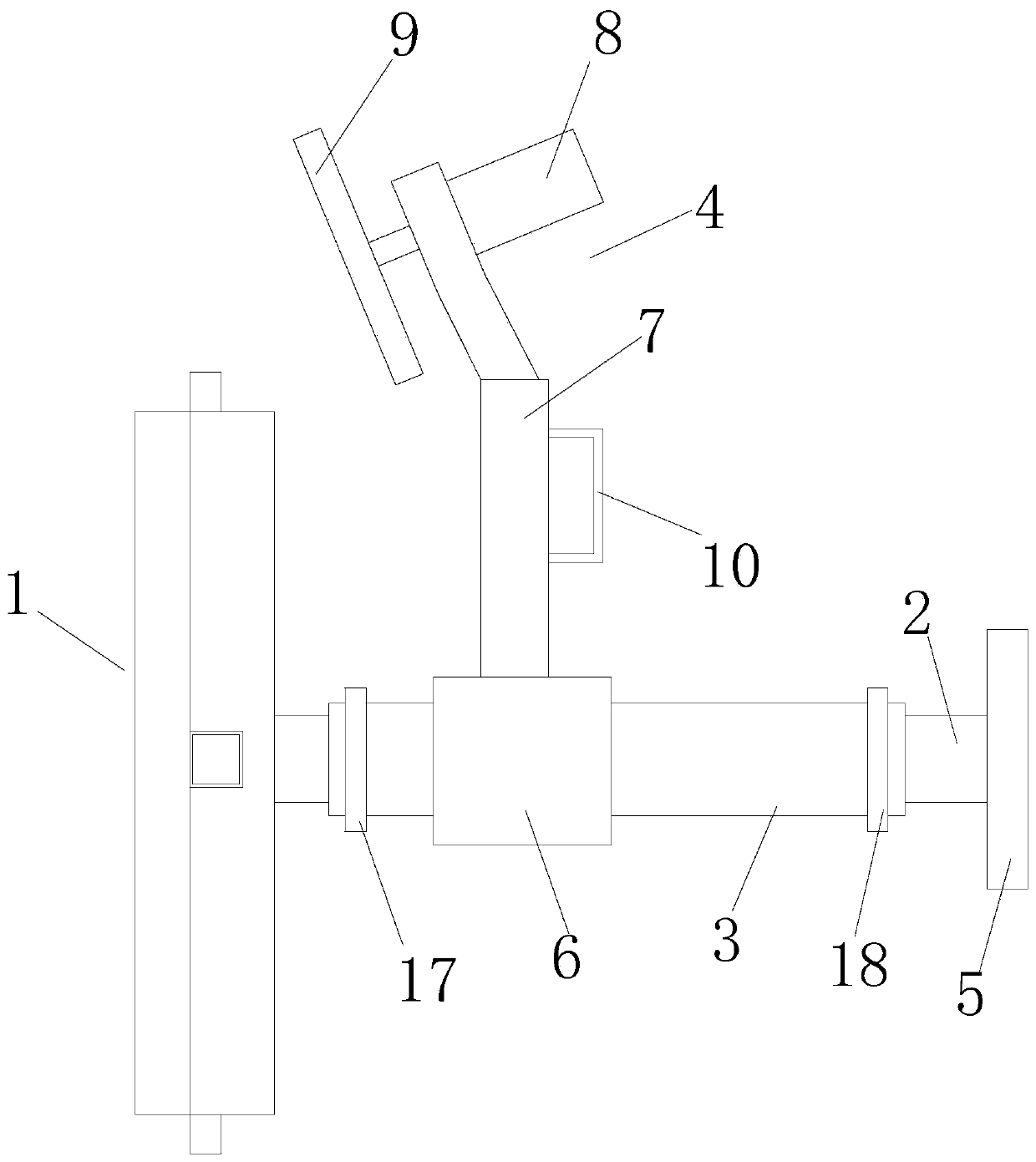

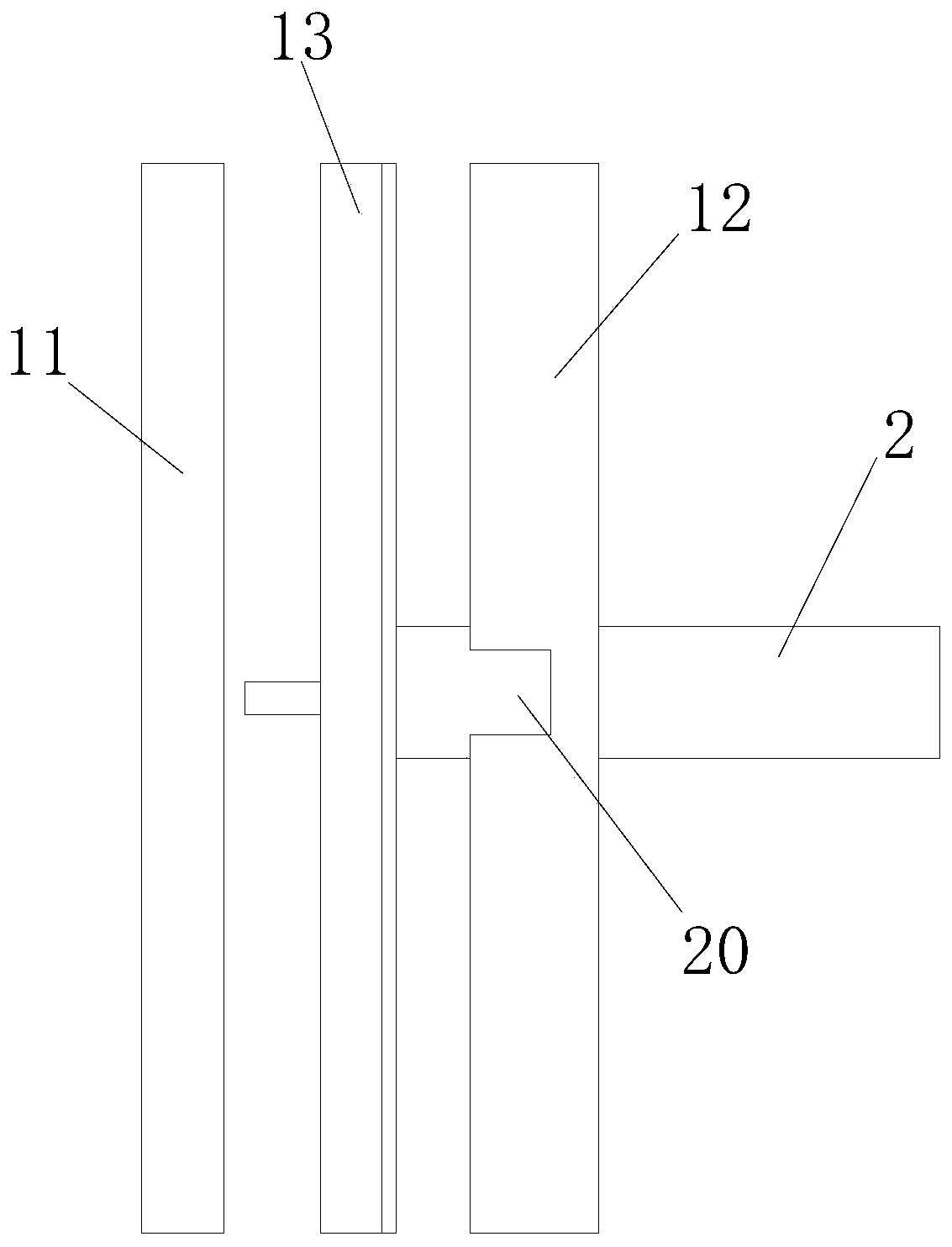

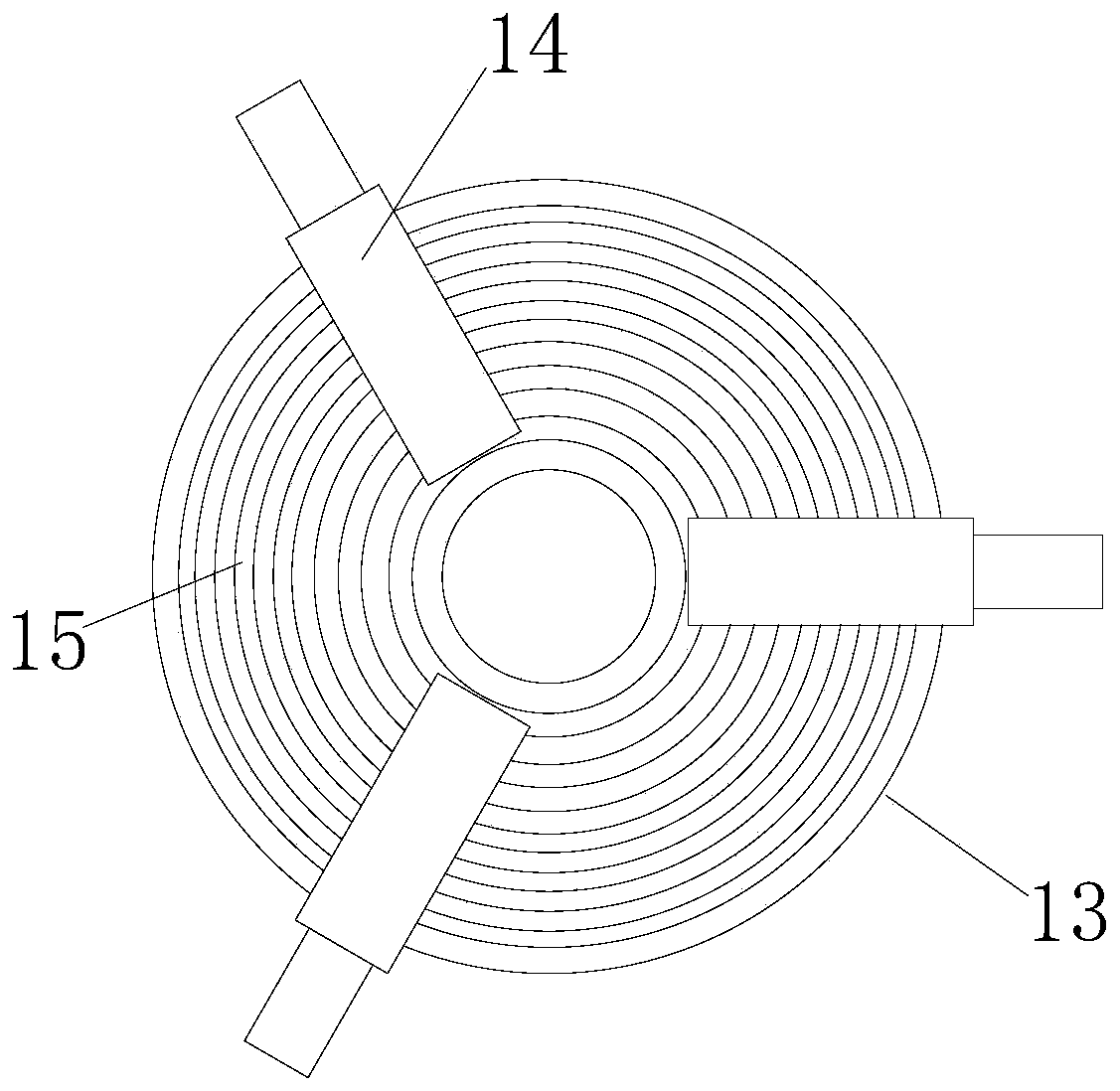

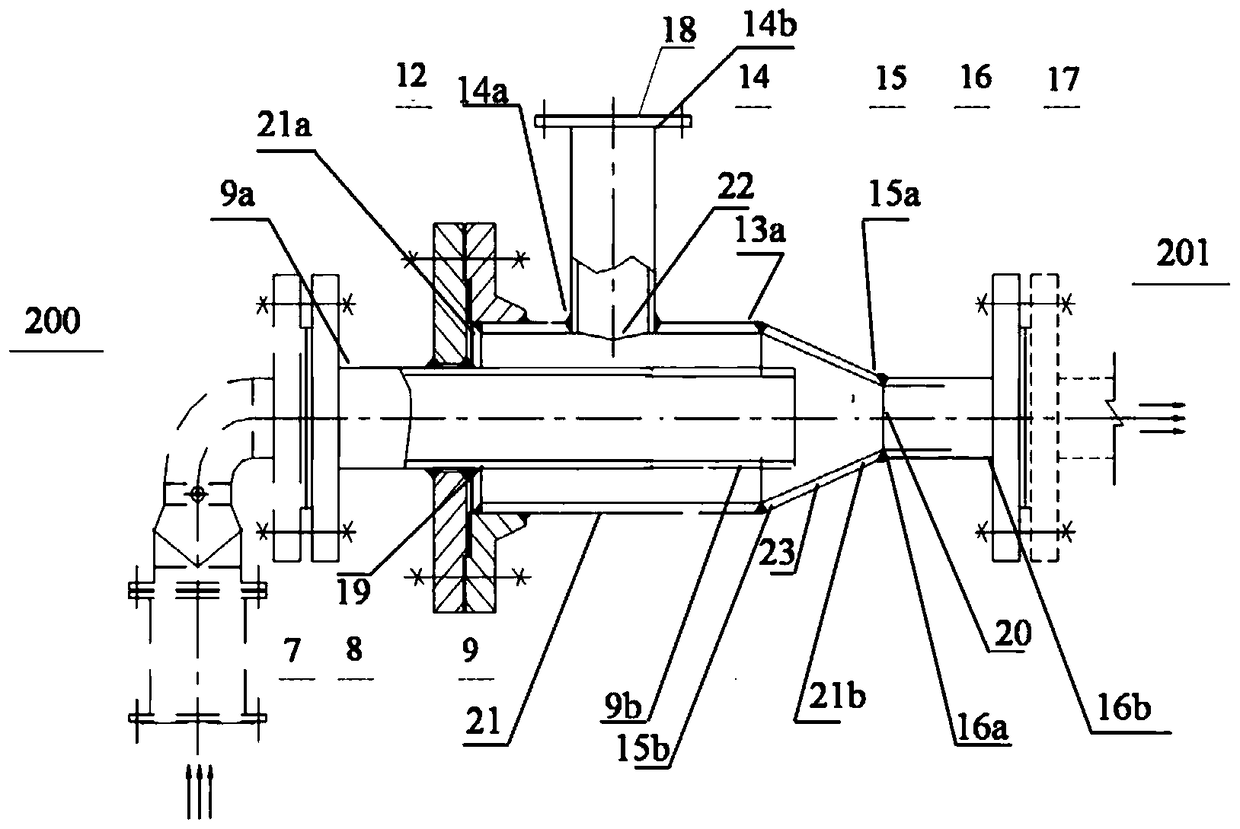

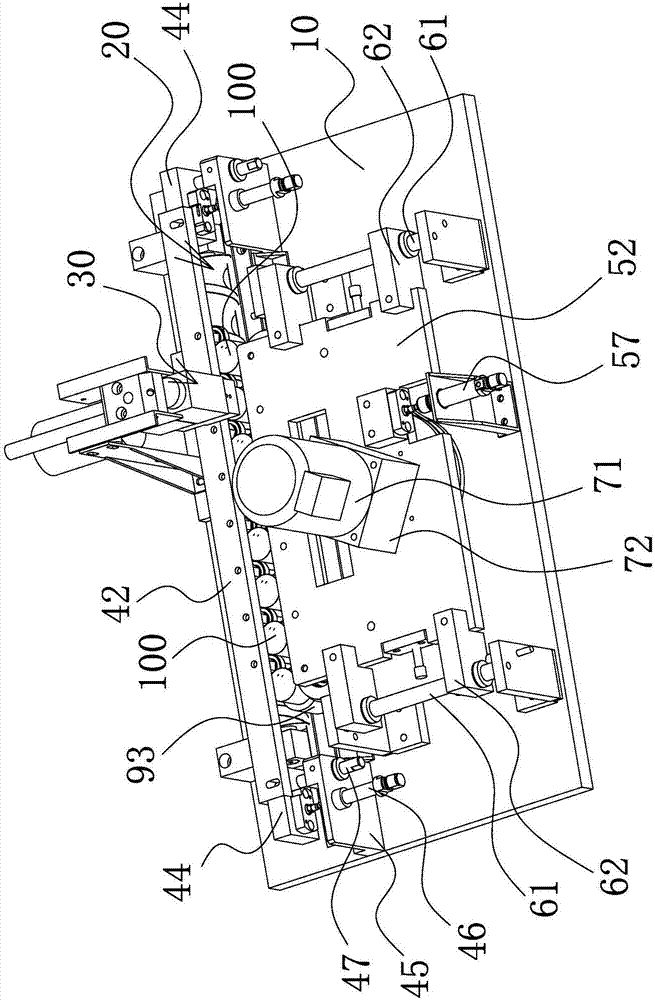

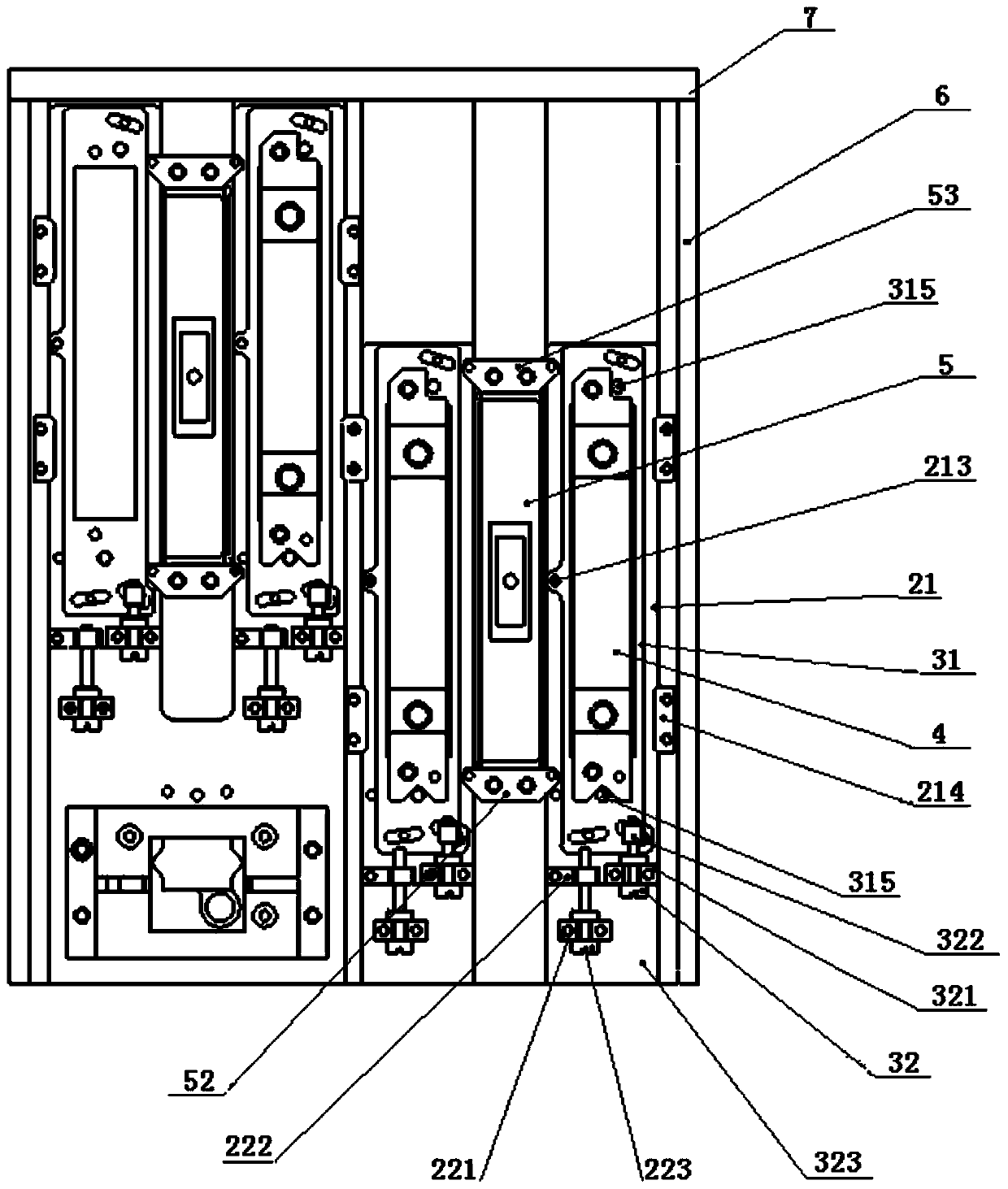

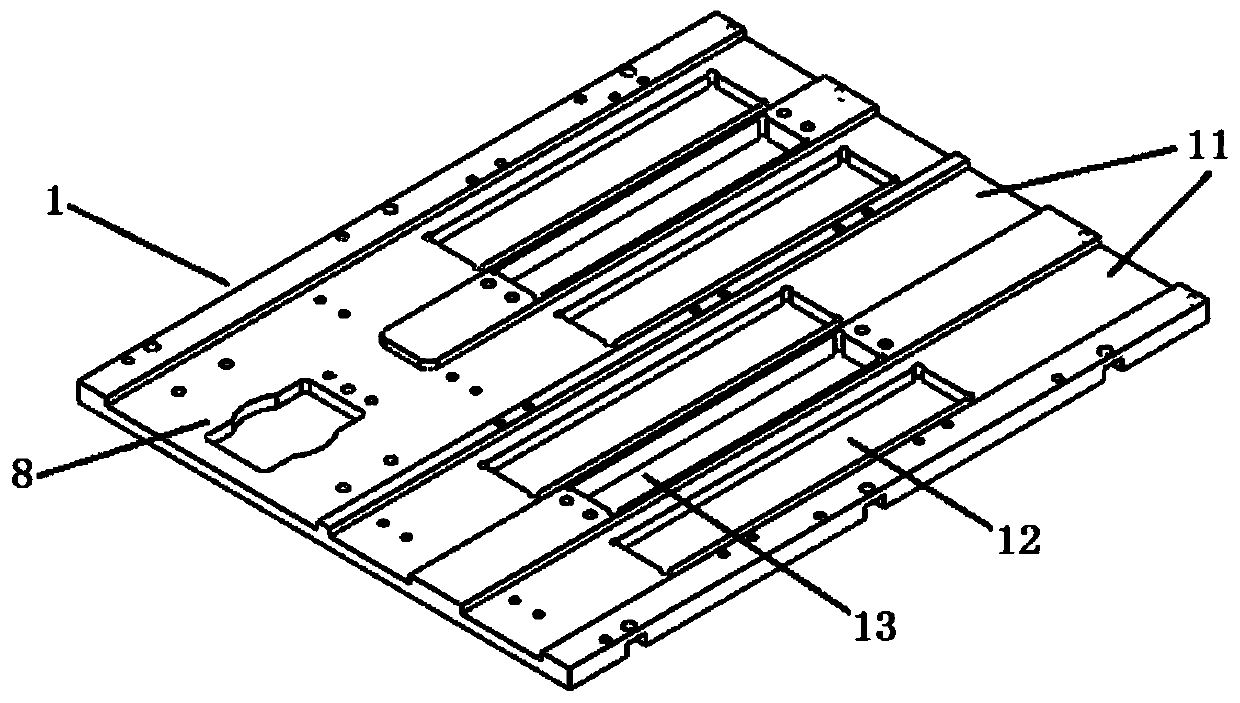

A nozzle support device and a character jet printing machine with the nozzle support device

Disclosed are a print head supporting frame device and a character printer with the same, comprising: a bottom plate (1), at least four first adjusting assemblies, at least four second adjusting assemblies, and print heads (4). At least two sets of sliding grooves (11) are formed in the bottom plate (1). Long-strip-shaped holes (12) are formed in the sliding grooves (11) correspondingly one by one. A UVLED lamp installing groove (13) for installing a UVLED lamp (5) is formed between each set of the long-strip-shaped holes (12). The at least four first adjusting assemblies are installed in the sliding grooves (11) of the bottom plate and correspond to the long-strip-shaped holes (12) one by one. The first adjusting assemblies are used for adjusting the sliding positions of the print heads (4) in the length direction of the long-strip-shaped holes (12) in the long-strip-shaped holes (12) solely. The at least four second adjusting assemblies are installed on a sliding plate (21) and correspond to the long-strip-shaped holes (12) one by one. Each second adjusting assembly comprises a rotation fixing plate (31) and a second adjusting structure (32). The print heads (4) are fixed on the rotation fixing plates (31) correspondingly one by one. The second adjusting structure (32) is used for adjusting rotation angles of the print heads (4) solely.

Owner:JOINT STARS TECH

A kind of toothbrush bristles and processing method thereof

The invention discloses a toothbrush bristle and a processing method thereof, wherein the processing method of the toothbrush bristle includes: heat-treating the toothbrush so that the free end of the toothbrush bristle has an irregular compound curved surface. The invention heat-treats the sharp edges and corners of the free ends of the bristles of the toothbrush to achieve a smooth effect, thereby avoiding damage to gums and enamel. At the same time, only the free ends of the toothbrush bristles are subjected to heat treatment, which can avoid heat treatment from causing damage to the rest of the toothbrush bristles and the rest of the toothbrush, and affect the overall quality of the toothbrush. Controlling the heating process allows the free ends of the bristles to be rounded, so that all sharp corners (including edge corners) are rounded, resulting in free ends with irregular compound surfaces.

Owner:杨松

Arc and straight combined horizontal strut for advertisement display rack

The invention relates to an arc and straight combined horizontal strut for an advertisement display rack, which comprises a substrate and a cover plate capable of bending. Both ends of the substrate and the cover plate are provided with a support piece respectively; and each of the two support pieces comprises a support base, a support cover, a curved pin roll and magnetic steel; the back part ofthe support cover is provided with a chute; the curved pin roll is connected between the middle parts of the support base and the support cover; the magnetic steel is fixed between the support base and the support cover; the support cover is connected to the support base; the side walls close to end heads of the substrate are provided with a pair of pin roll holes respectively; the side walls at both ends of the cover plate are provided with a pair of pin roll holes respectively; the support pieces are inserted into the chute of the support cover and the pair of pin roll holes on the substrate through a straight pin roll so as to be connected with the substrate; and the support pieces are inserted into the pair of pin roll holes on the cover plate through the curved pin roll so as to be connected with the cover plate. The combined horizontal strut supports the both ends of the cover plate through the support pieces to form an arc so as to be used in arc and straight ways. The adjacentcover plates are attracted due to the magnetism on the support pieces, so the combined horizontal strut has simple structure and is convenient to connect.

Owner:CHANGZHOU HAWK DISPLAY SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com