Riser forming machine

A molding machine and mold technology, applied to casting molding equipment, casting molds, cores, etc., can solve problems such as waste of manpower, achieve the effects of reducing labor intensity, turning over smoothly, and avoiding difficult demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

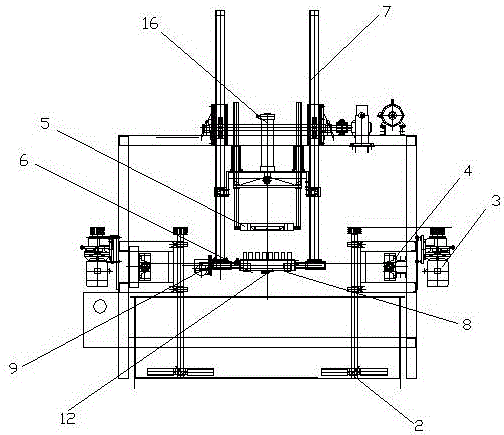

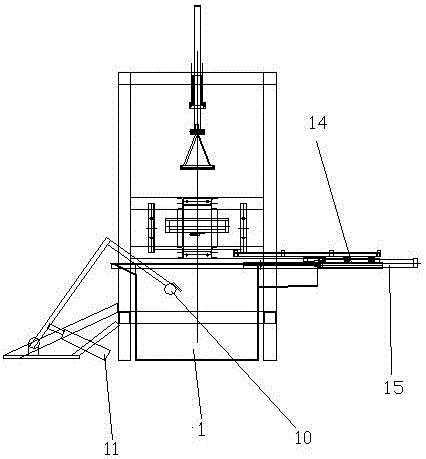

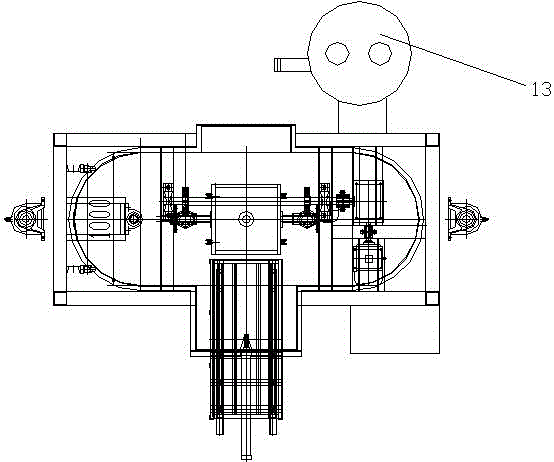

[0021] Such as figure 1 , figure 2 and image 3 A riser forming machine shown in and includes: a slurry tank 1, which is provided with two sets of stirring devices 2 with opposite stirring directions inside, and the stirring device is controlled by a rotating cylinder 4 and a reducer 3; The bar ascending shaft 7 is arranged on the upper side of the slurry tank 1, and slides up and down along the rack ascending shaft. The mold includes an inner mold 6 and an outer mold 5, and four nylon hammers 8 are arranged on the outer periphery of the inner mold, and the mold is provided with air extraction holes. A sliding track is provided below, the inner mold is turned over by the rotary cylinder 9, and the outer mold is controlled by the outer mold cylinder 16; the scraping device is arranged between the slurry pool and the mould, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com