Patents

Literature

67results about How to "Uniform and stable output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

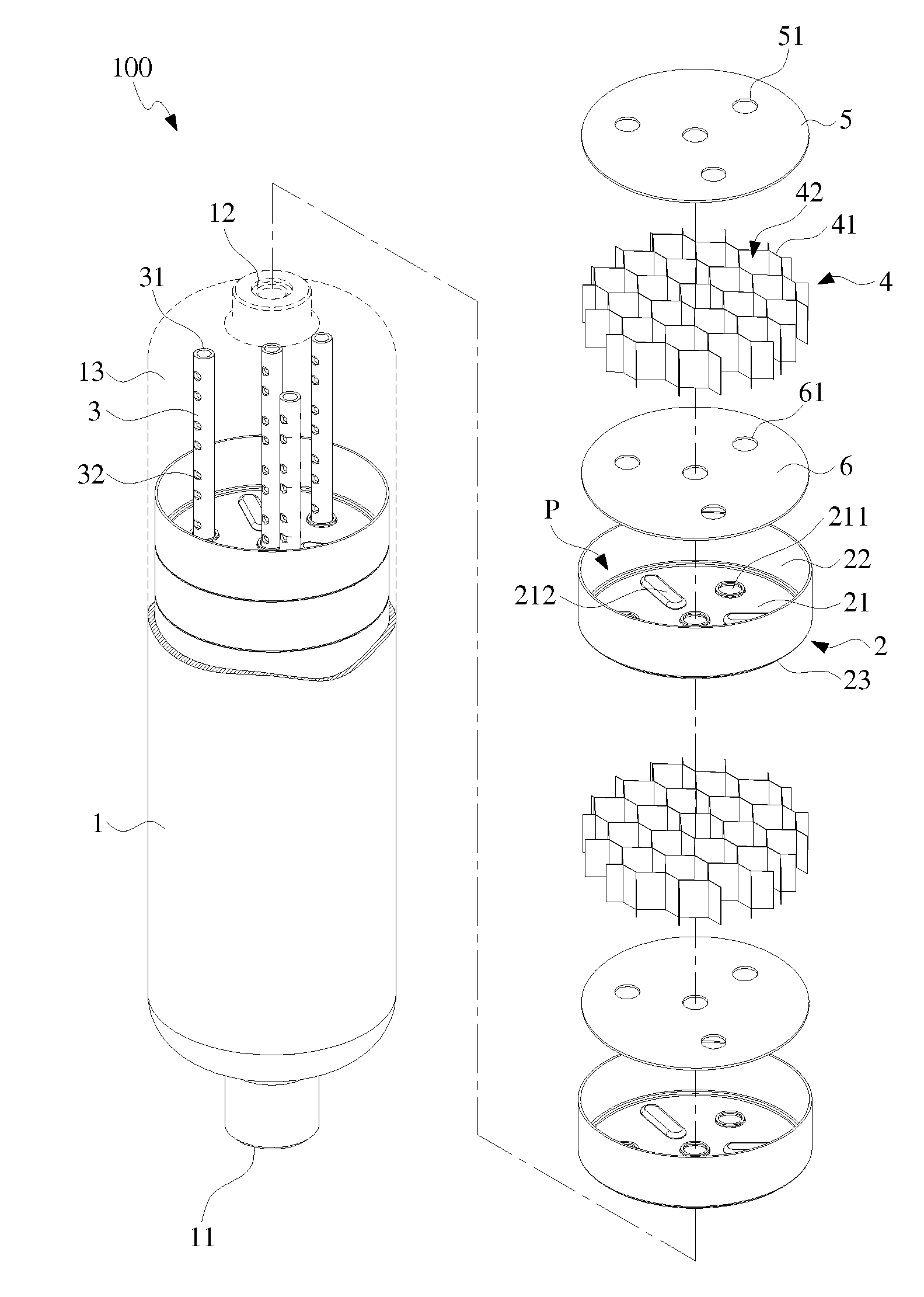

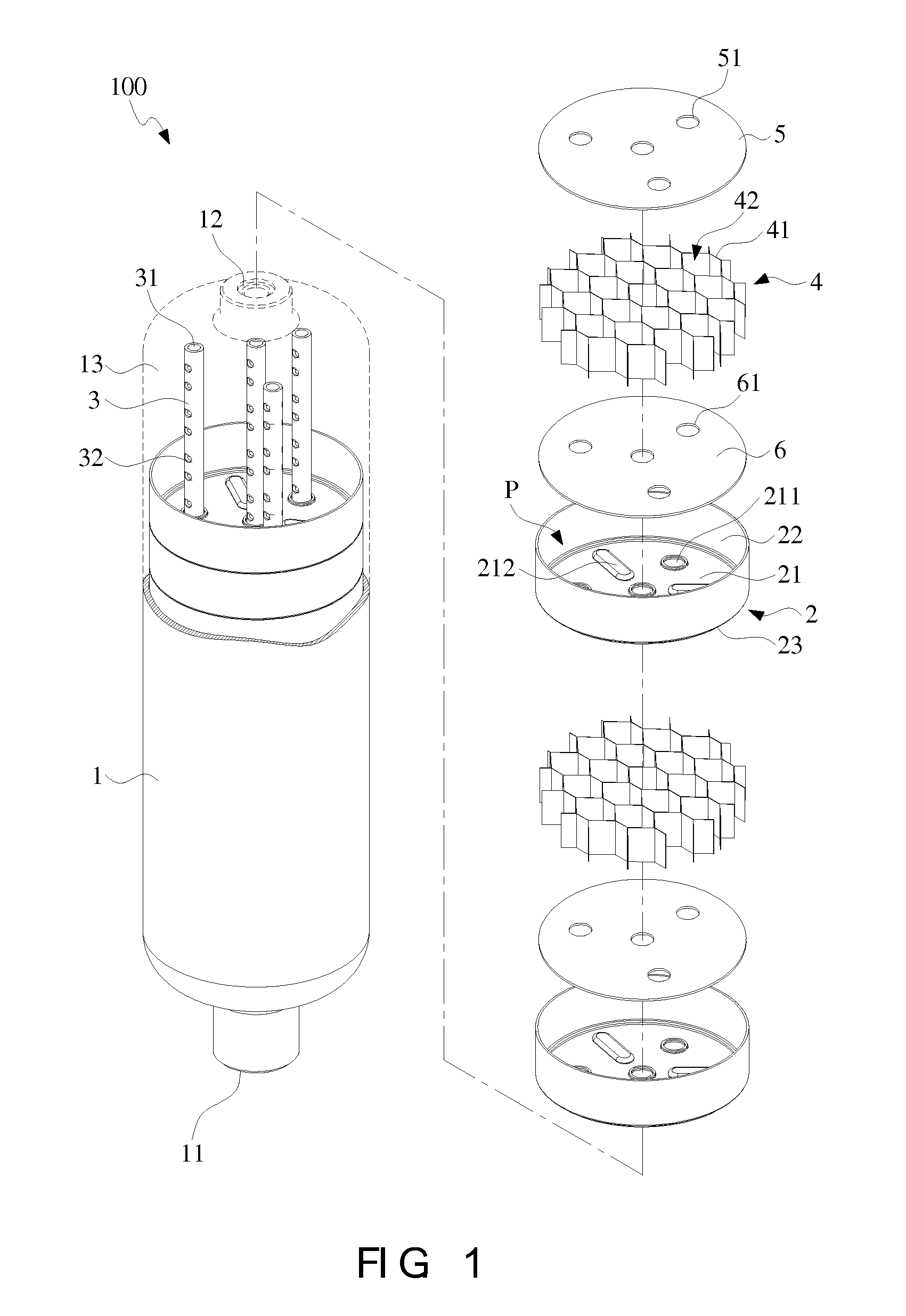

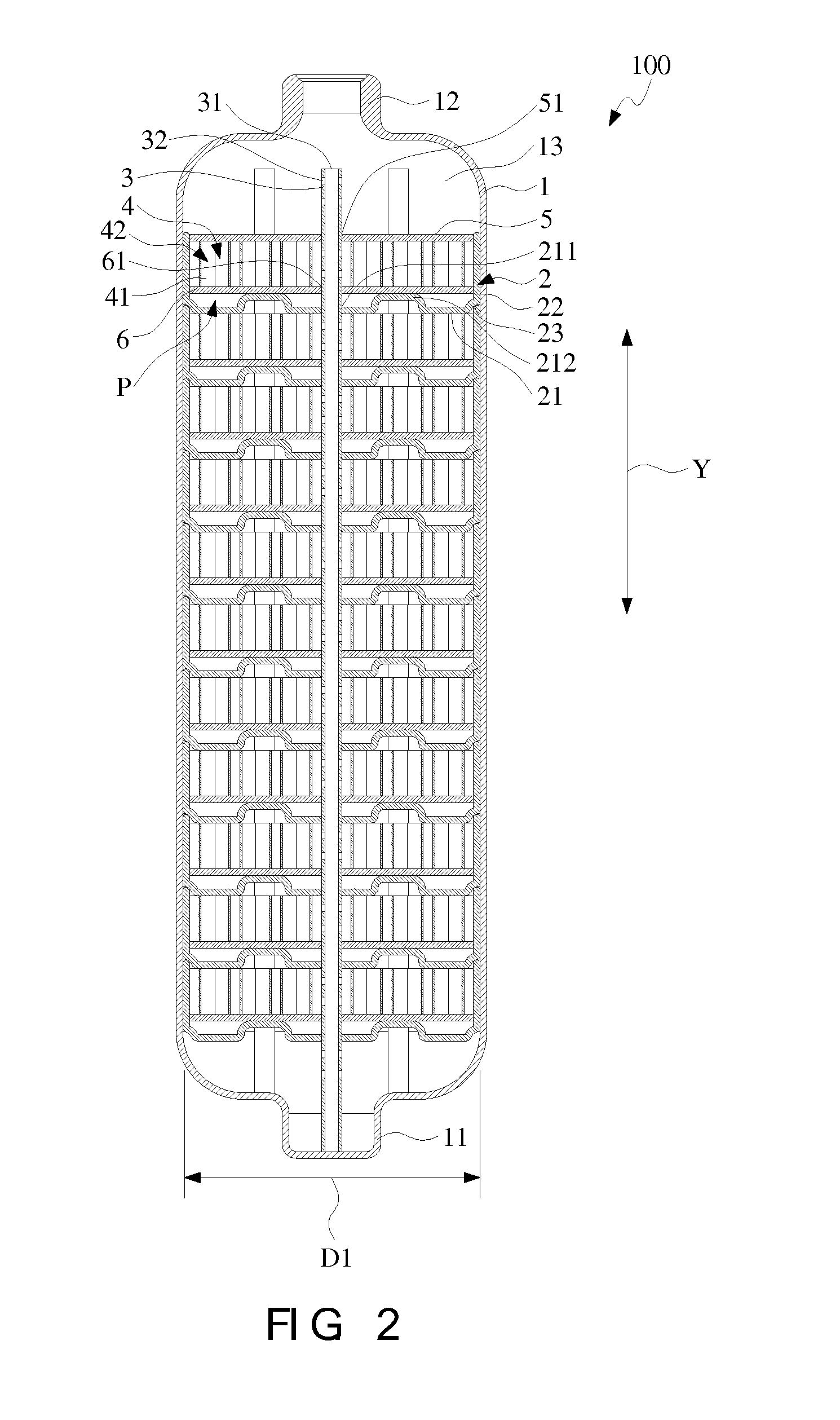

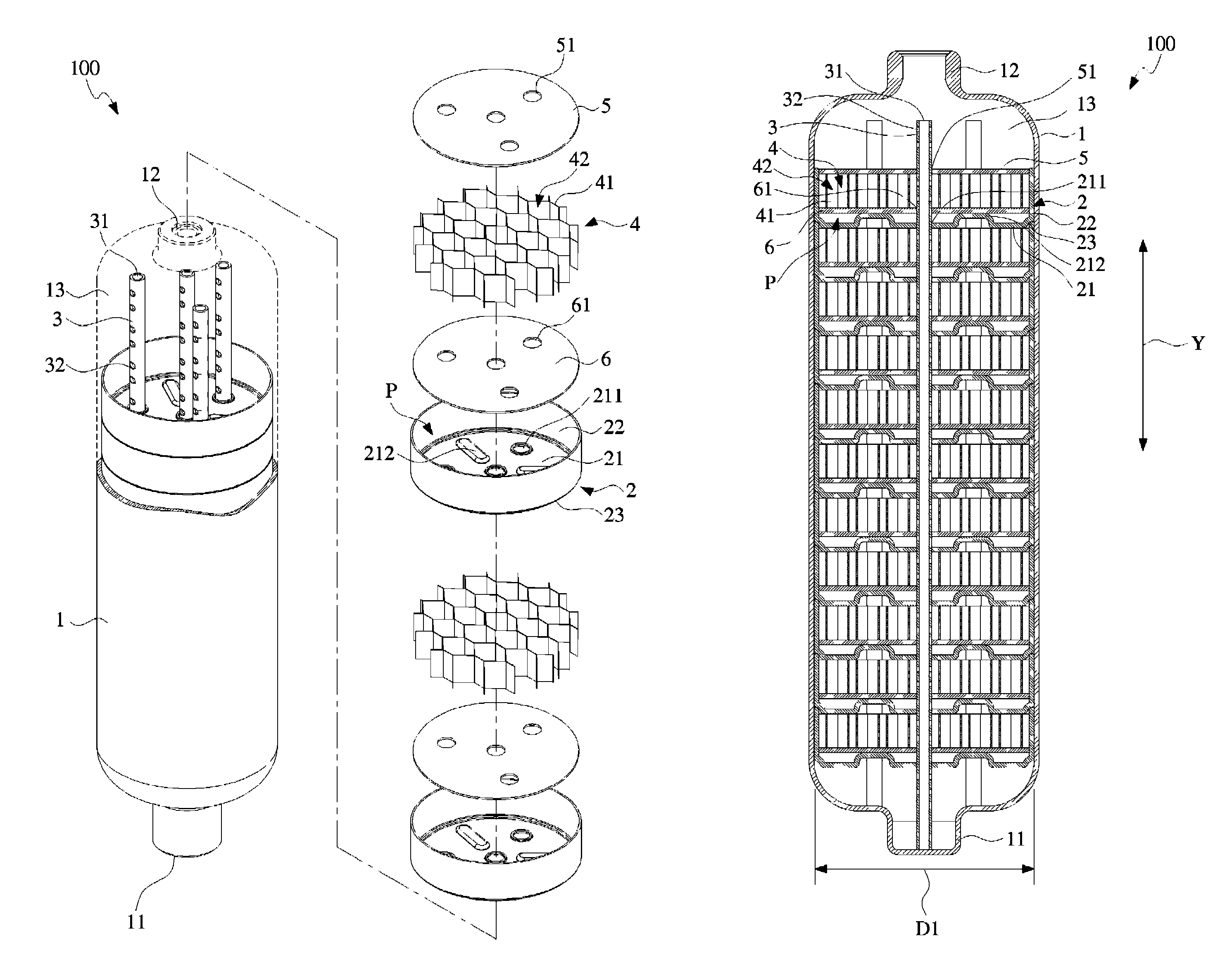

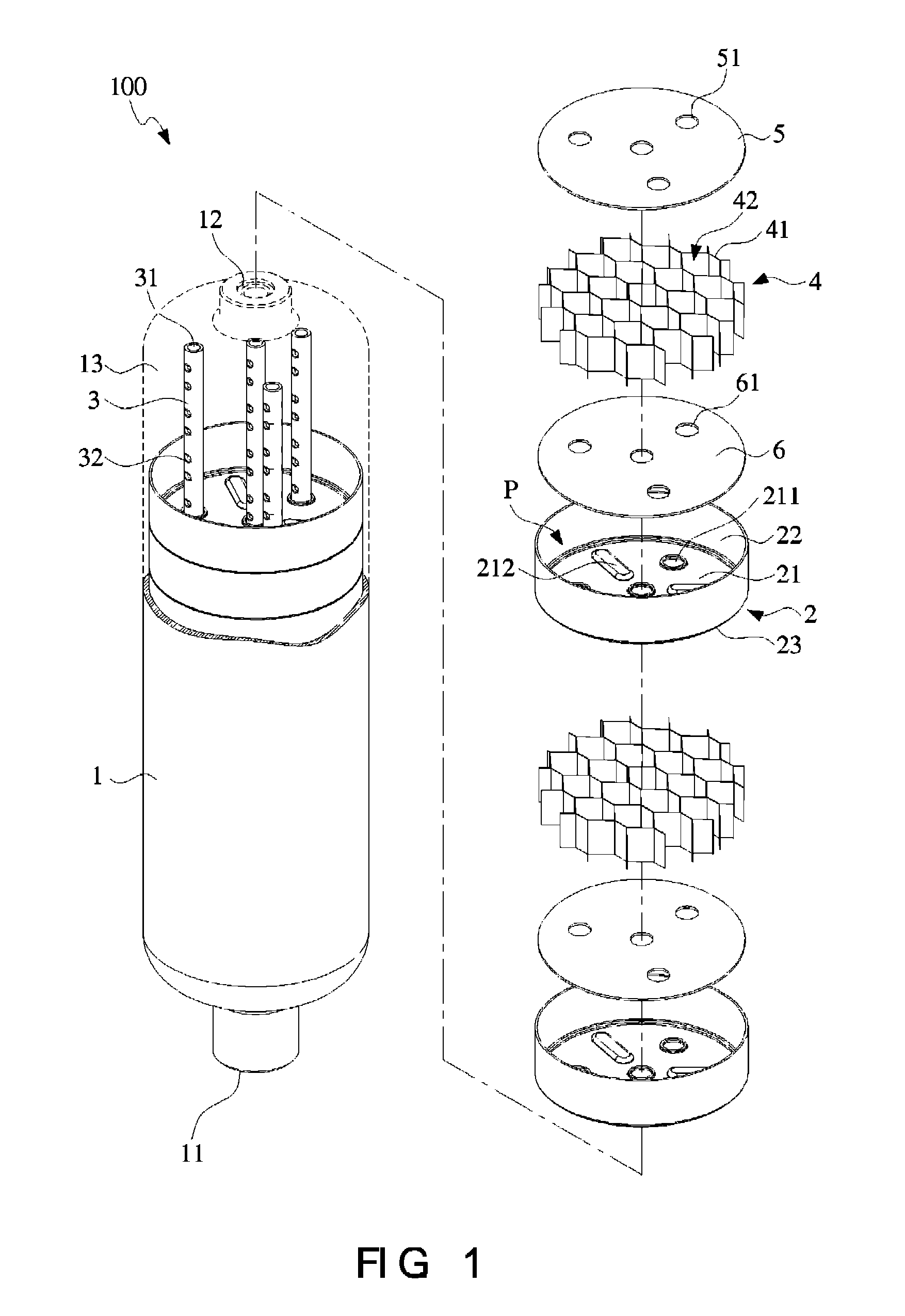

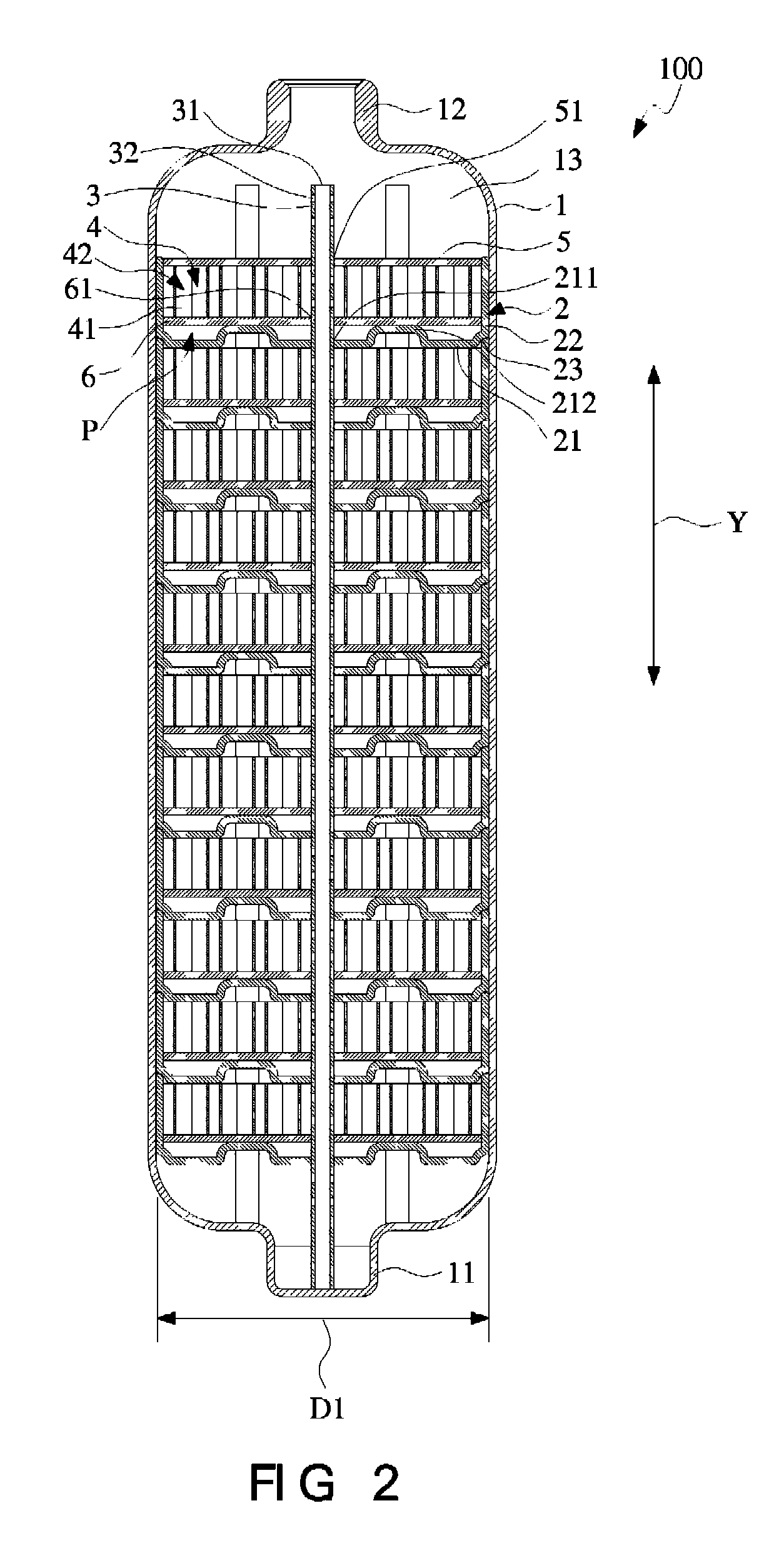

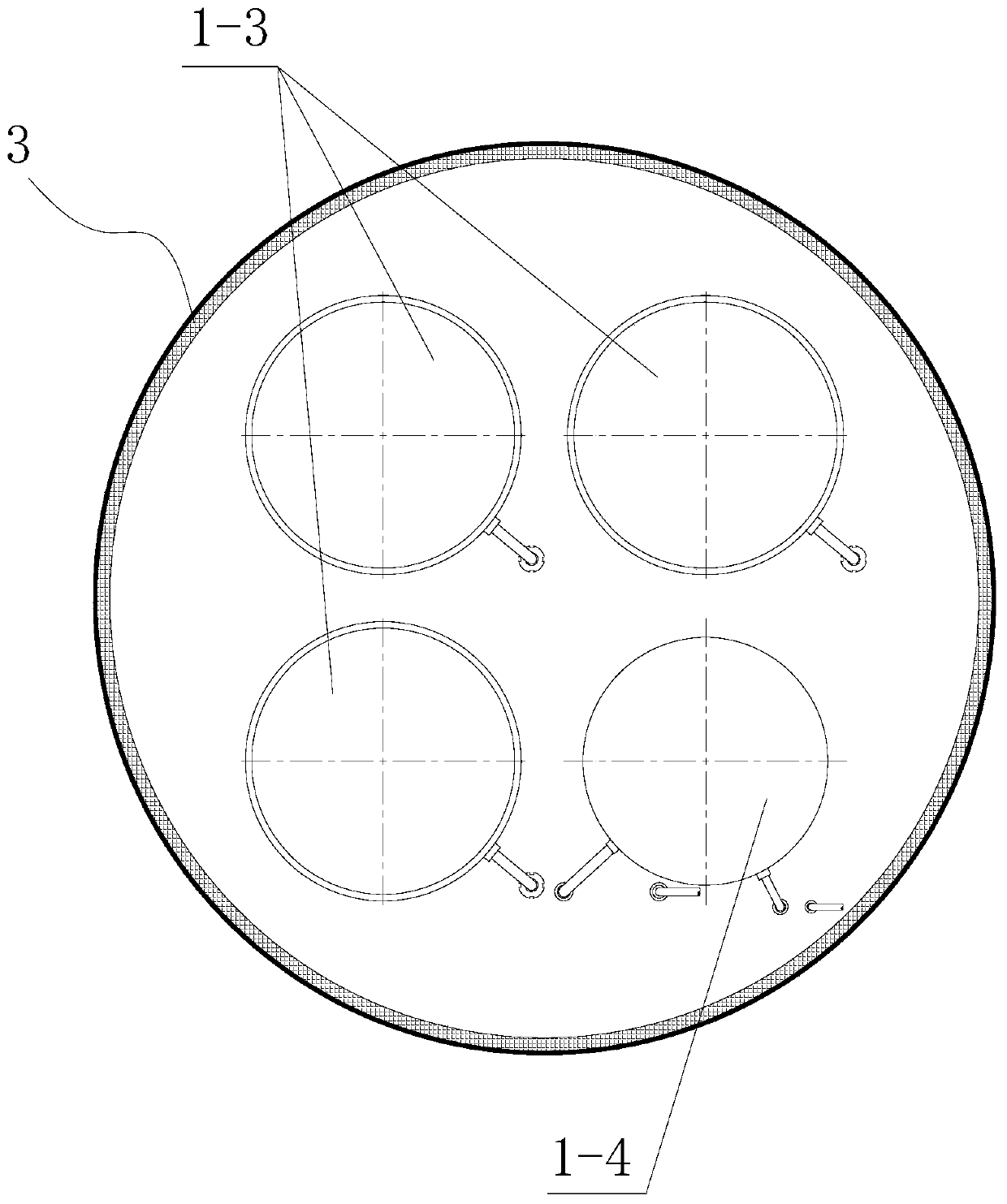

Gas storage canister with compartment structure

ActiveUS20120160712A1Enhanced structural strength and tightnessImprove structural strengthPressure vesselsLiquid materialInterior spaceLong axis

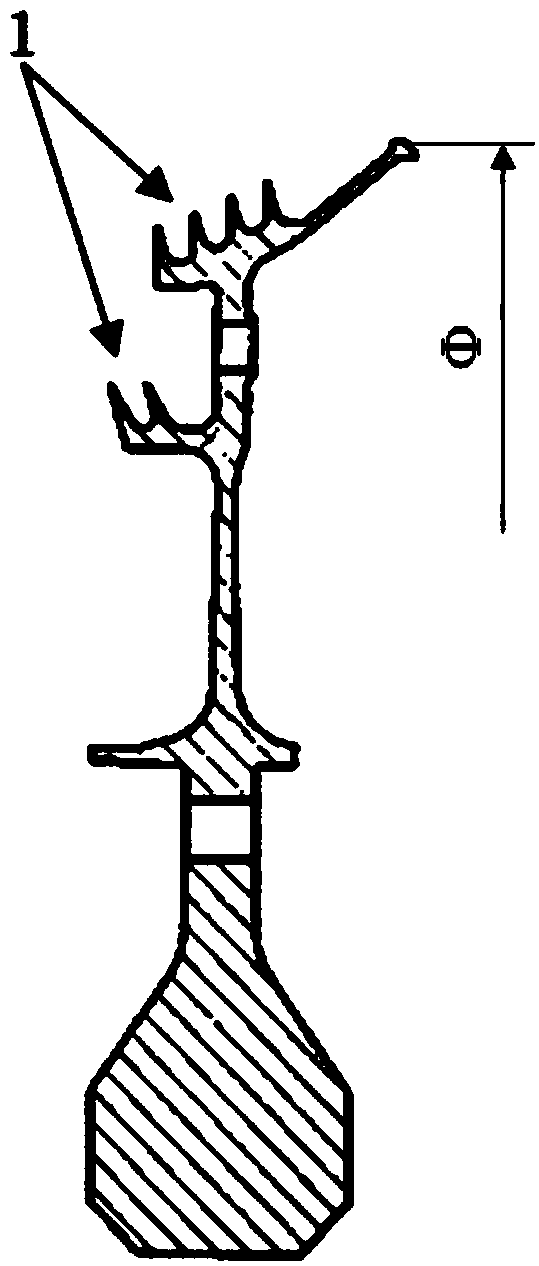

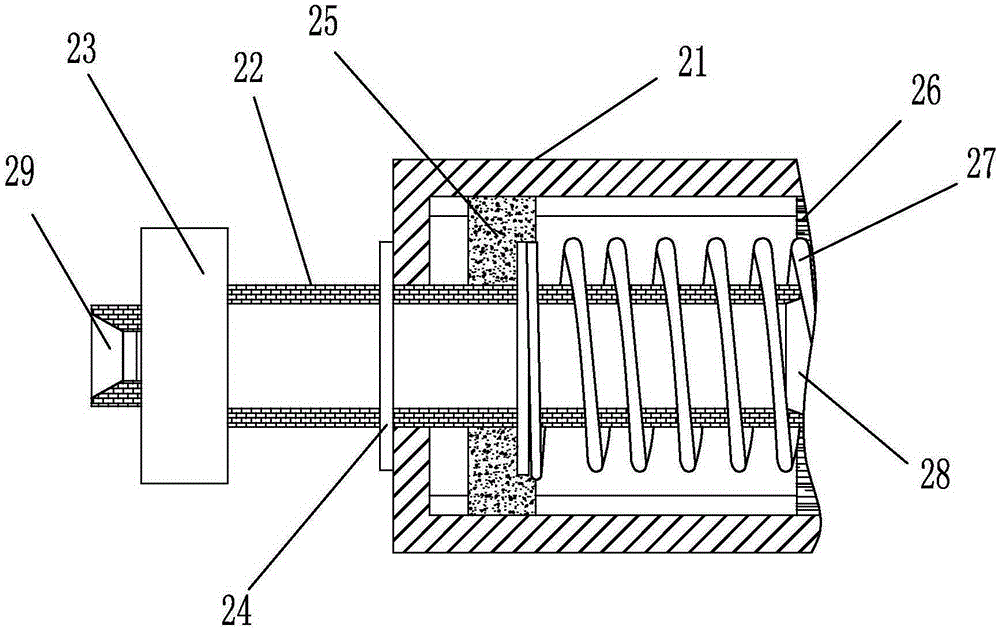

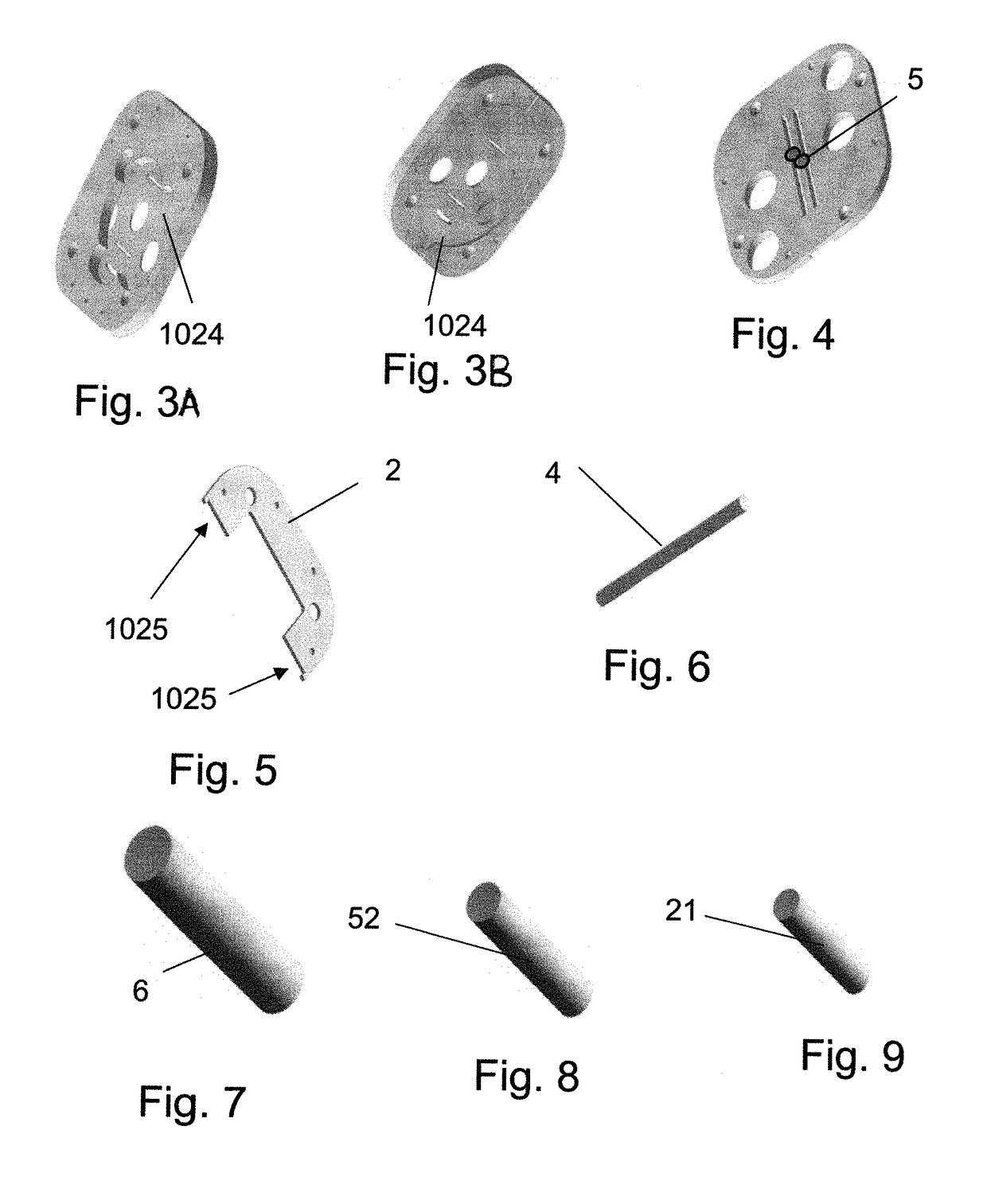

A gas storage canister includes a canister body, at least one supporting plate, at least one gas-guiding rod, and at least one compartment structure. The canister body has a bottom end, an outlet opposed to the bottom end, and an inner space. The bottom end and the outlet are arranged along a long axis direction. The supporting plate is accommodated within the inner space along the long axis direction. The supporting plate has at least one communication part. The gas-guiding rod is penetrated through the communication part of the supporting plate. The gas-guiding rod has at least one gas inlet / outlet end for guiding a gas. The compartment structure includes a plurality of compartments. The compartment structure and the supporting plate are accommodated within the inner space of the canister body. Each of the compartments stores a predetermined amount of gas storage material.

Owner:ASIA PACIFIC FUEL CELL TECH

Gas storage canister with compartment structure

ActiveUS8646597B2Enhanced structural strength and tightnessImprove structural strengthFuel cell auxillariesPressure vesselsLong axisEngineering

Owner:ASIA PACIFIC FUEL CELL TECH

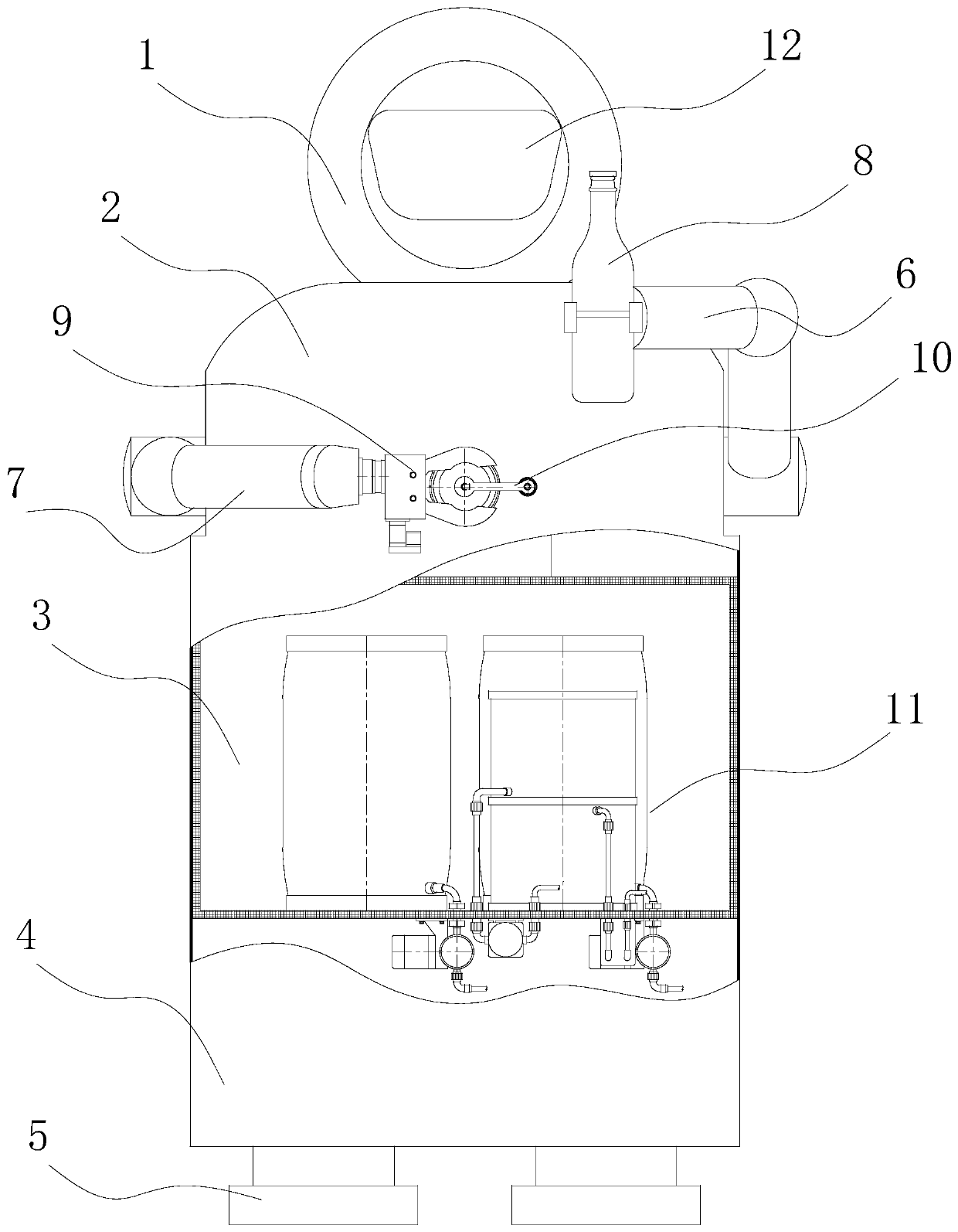

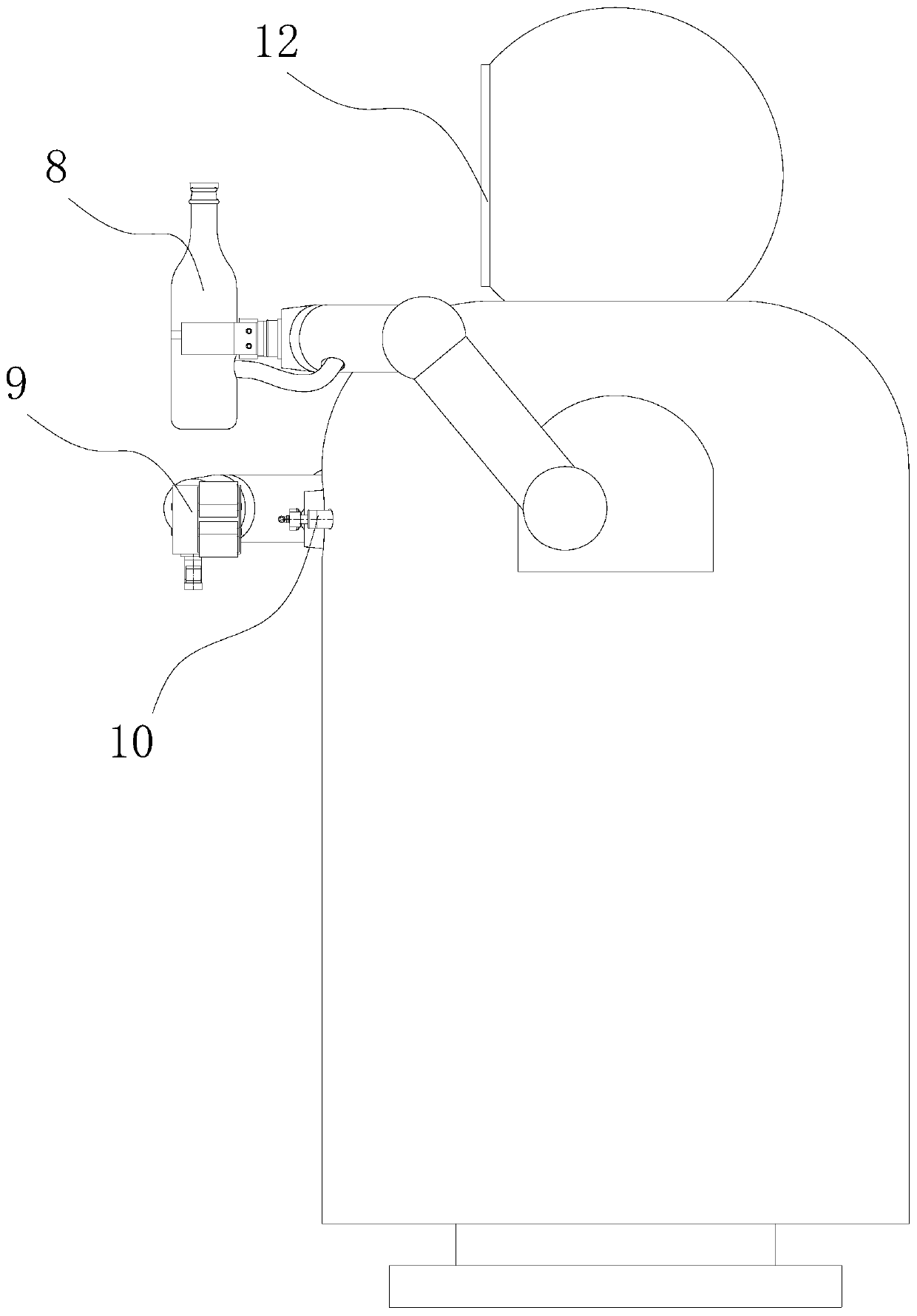

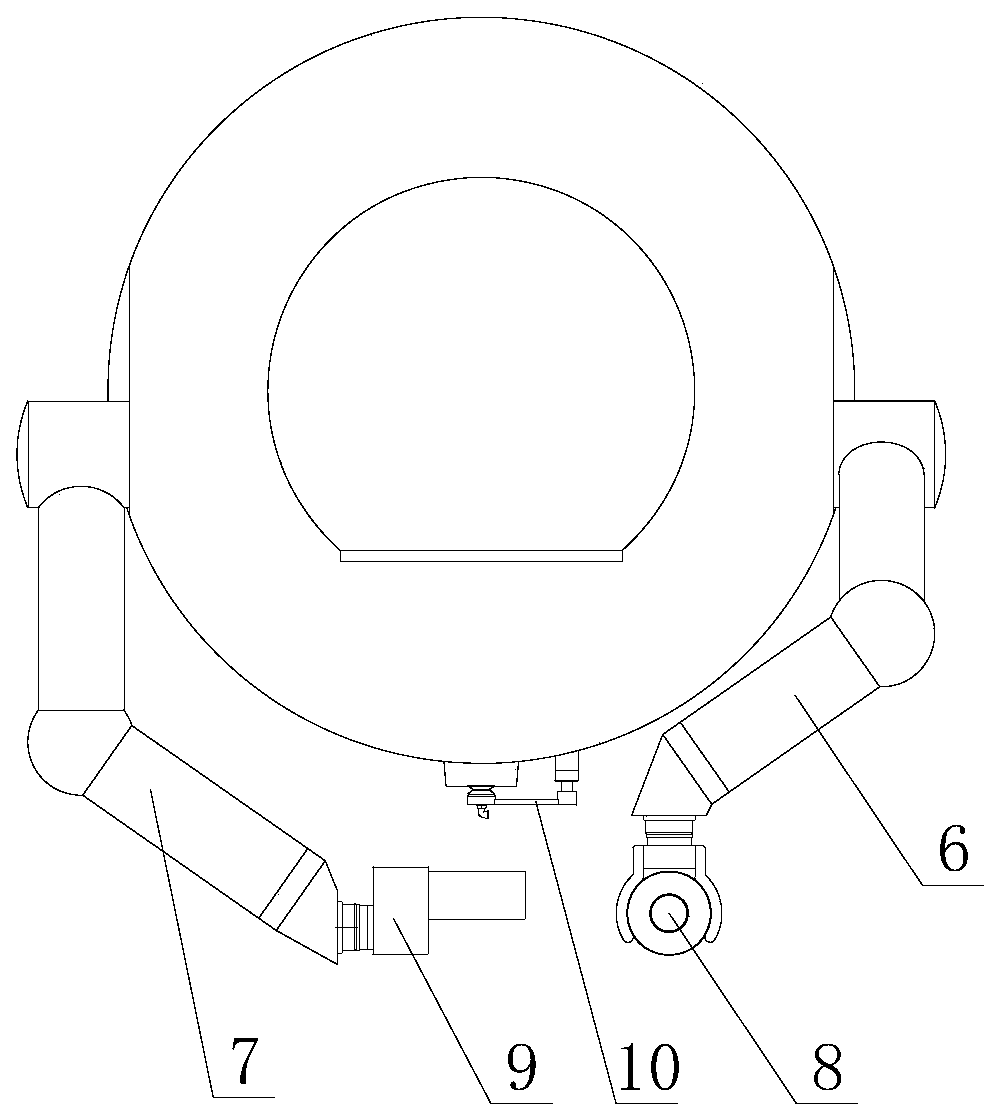

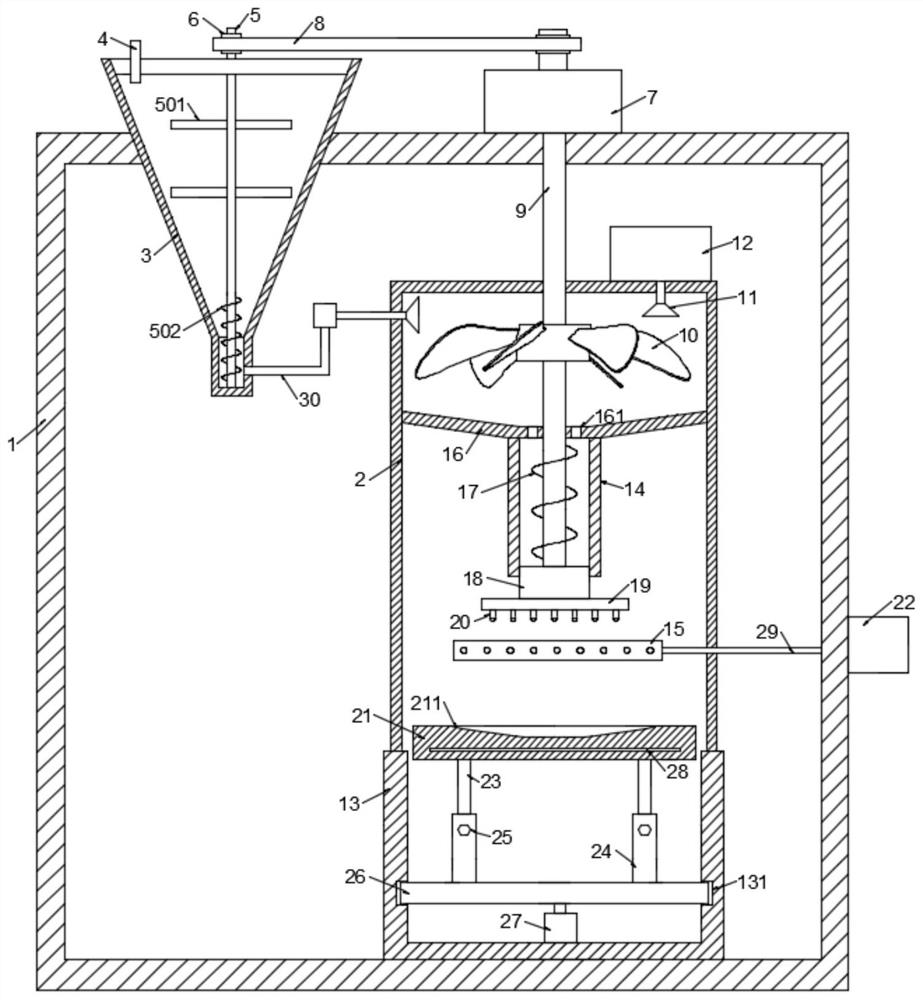

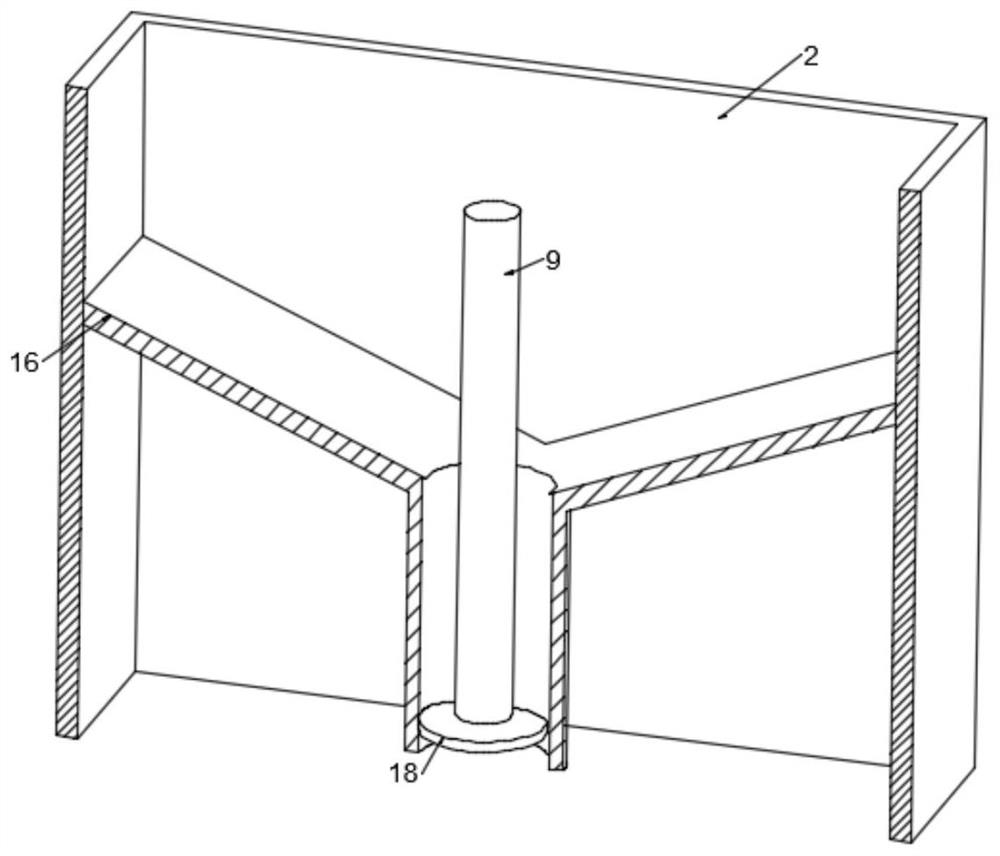

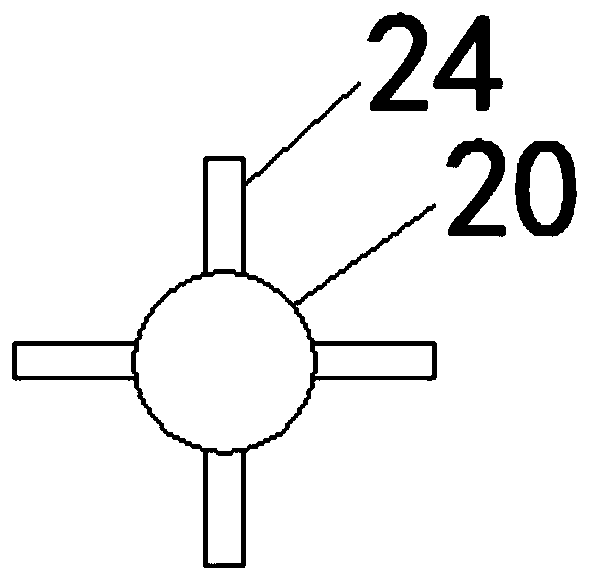

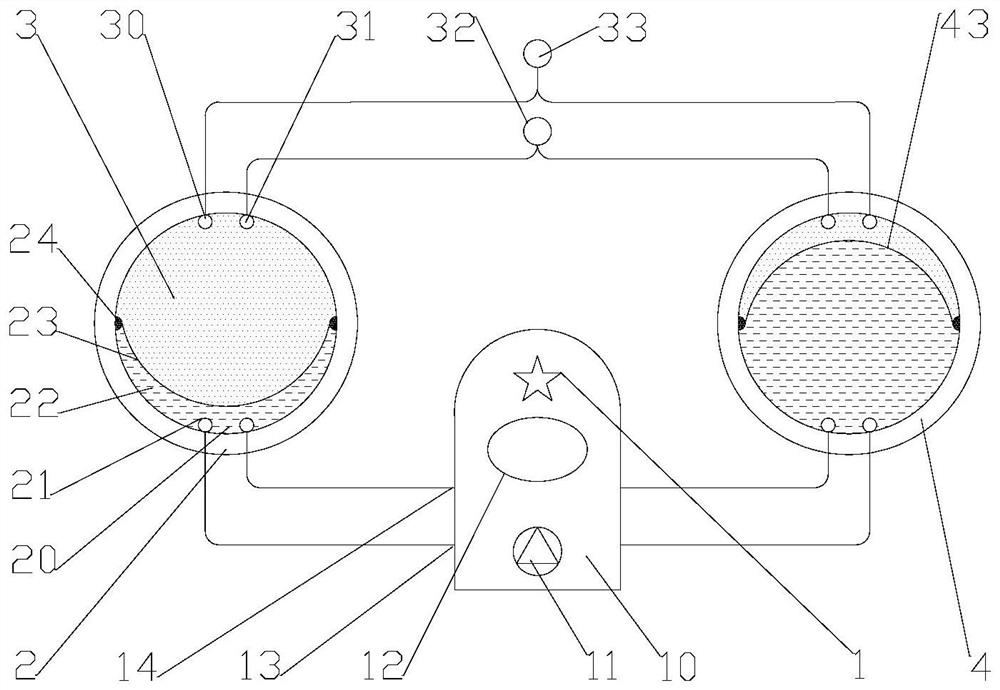

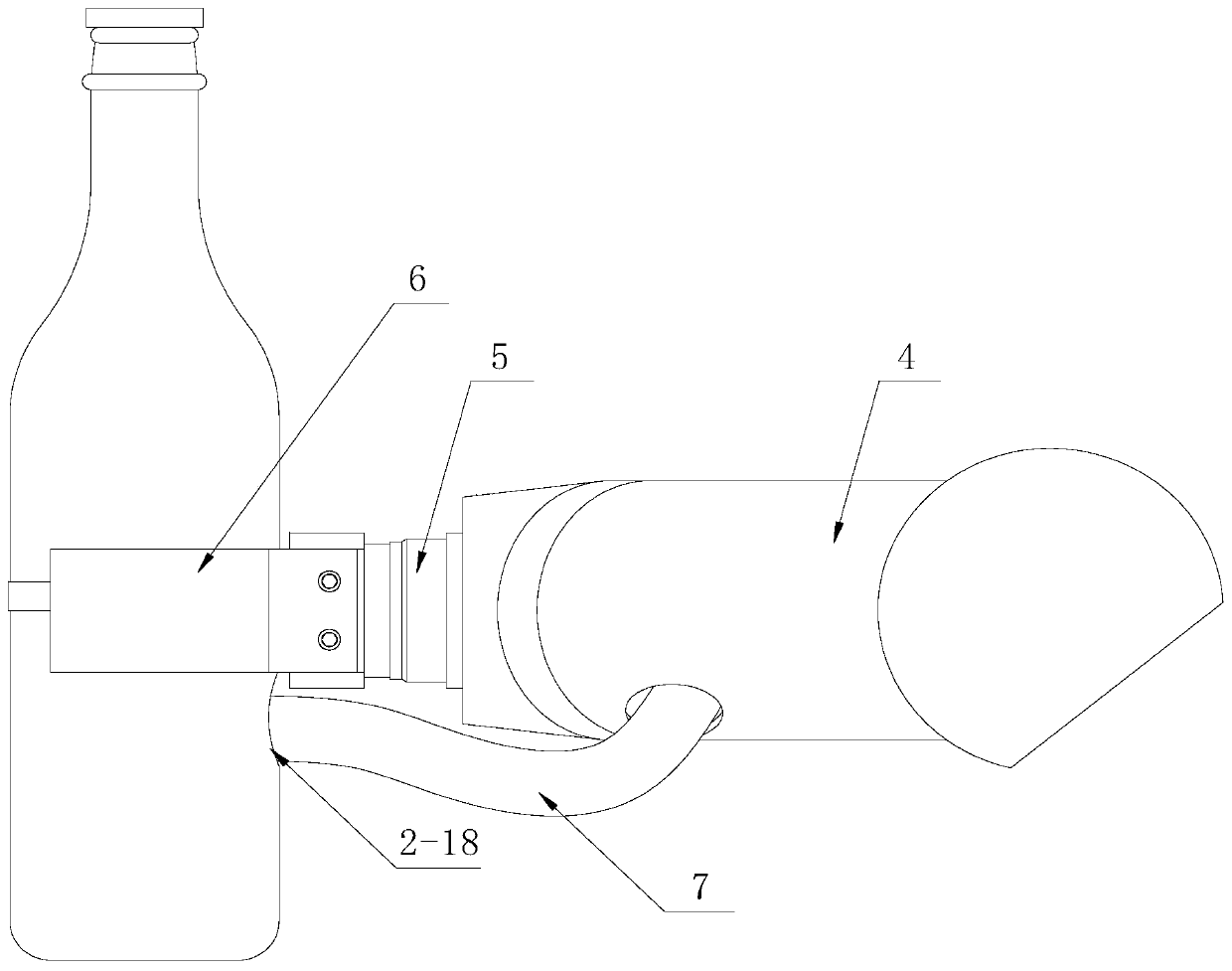

Pouring cup type multi-variety beverage supply robot and using method thereof

InactiveCN110889931AIncrease desire to buyThe method of use is simpleGripping headsApparatus for dispensing fluids/granular materialsRobot handMechanical engineering

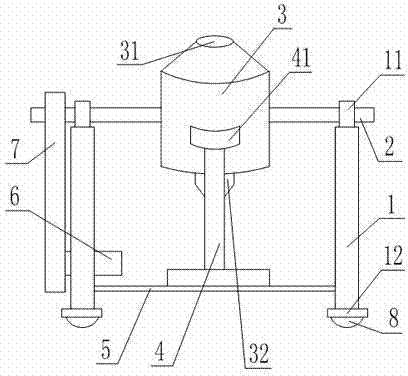

The invention discloses a pouring cup type multi-variety beverage supply robot and a using method thereof. The robot comprises a robot body, a storage device, a discharging device, a cup separator anda cup grabbing manipulator. A first arm and a second arm are arranged at the left side and the right side of the robot body correspondingly. The discharging device is arranged on the wrist of the first arm; the cup grabbing manipulator is arranged on the wrist of the second arm; the storage device and the cup separator are arranged in the robot body; the storage device is connected with the discharging device; and the cup grabbing manipulator is arranged at the outer side of a cup body outlet of the cup separator. In addition, the using method comprises the steps that: when the beverage needsto be output according to the beverage variety selected by a consumer, the storage device outputs the beverage of the corresponding variety to the discharging device; a single cup body is separated out through the cup separator; and after the cup grabbing manipulator grabs the cup body, the discharging device pours out the beverage into the cup body. The robot simulates a human shape and can provide various beverages according to the will of consumers, so that the purchase desire of the consumers can be motivated well.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

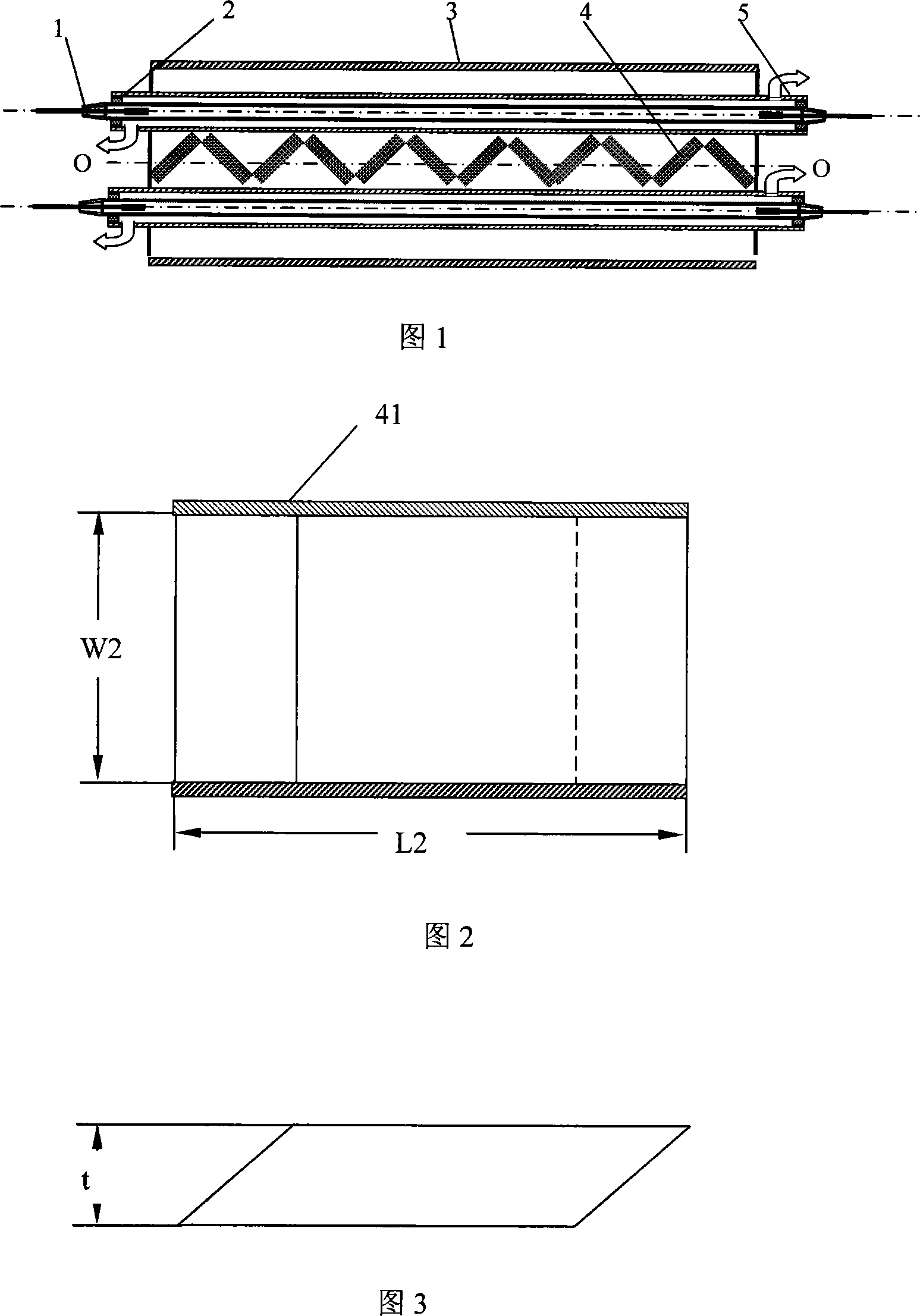

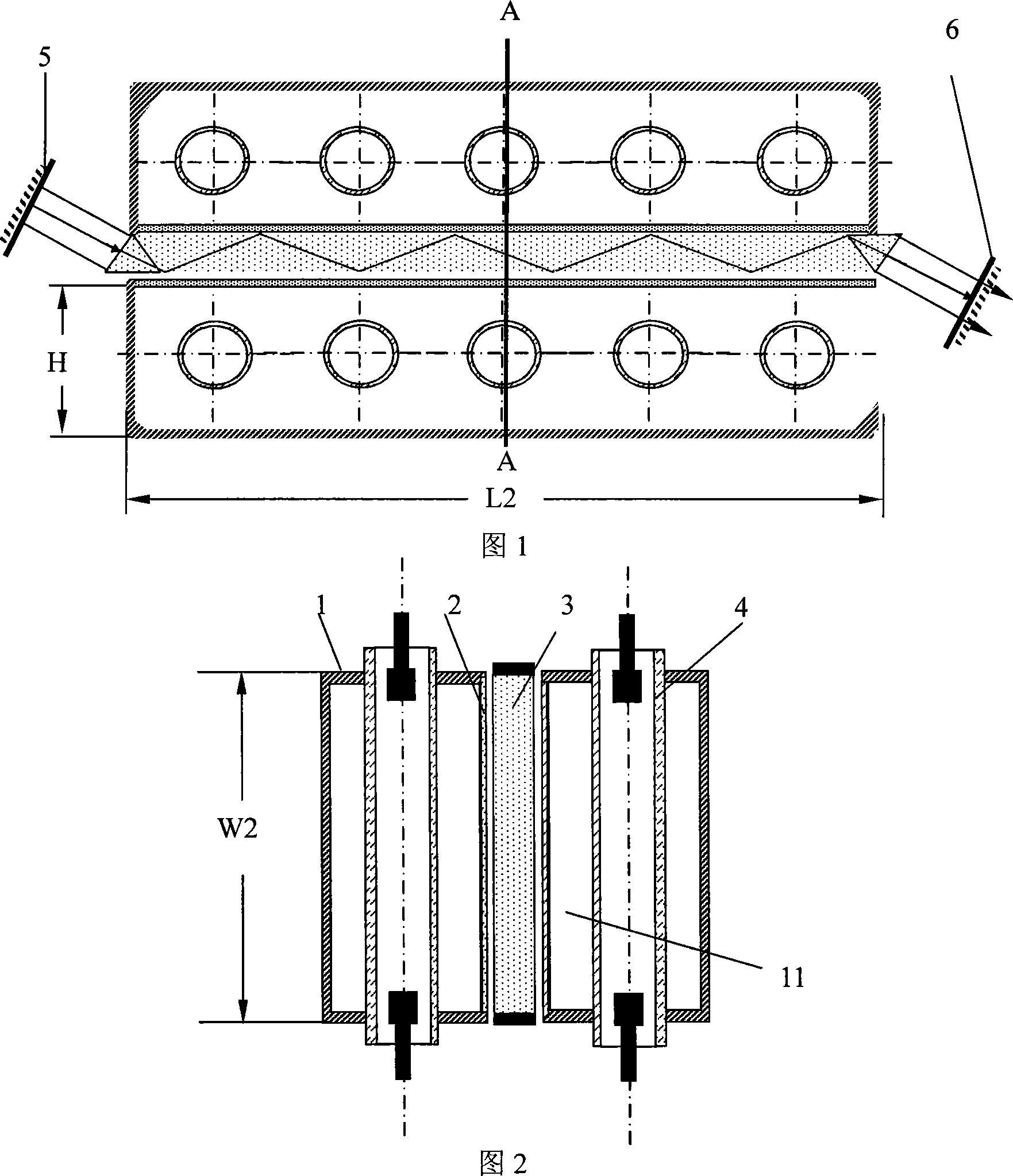

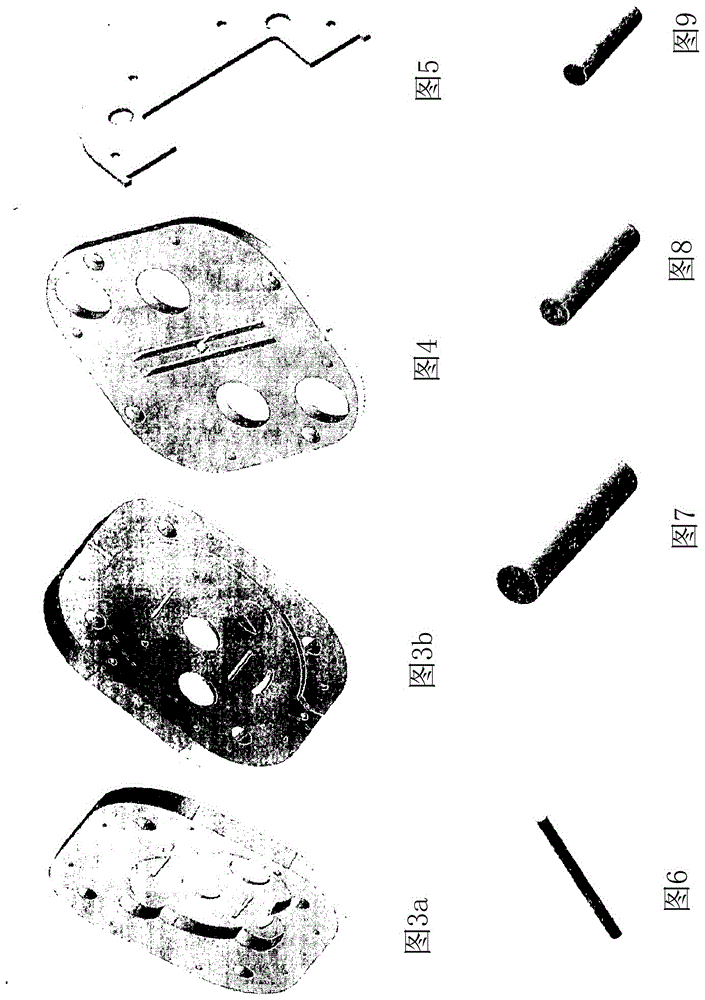

Heat capacity type neodymium glass flaky laser

InactiveCN101202410ASimple structureUniform and stable laser outputOptical resonator shape and constructionActive medium shape and constructionResonant cavityHigh energy

The invention discloses a neophane glass piece laser in heat capacity type. The invention is characterized in that the invention comprises a resonant cavity and an octagonal silvering reflector. The resonant cavity is a virtual confocal cavity which comprises a total reflective mirror and an output mirror; the octagonal silvering reflector is internally provided with a plurality of laser glass pieces which form 45 DEG with an optical axis; the optical axis of the laser glass piece is coincident with the optical axis of the resonant cavity; the upper side and the lower side of the laser glass pieces are respectively provided with pumping lights which are arranged in the reflector; the discharging direction of the pumping light is parallel to the direction of the laser; the pumping light is coaxially and hermetically sleeved with a cerium-doped quartz pipe; cooling water is arranged between the quartz pipe and the pumping light; the invention has the advantages of simple structure, obtaining the laser output with high energy and high power by operation under high repeated frequencies in short time, uniform and stable laser output, recovering the glass working medium to original state in the operation interval of the device and avoiding the thermal lens effect and the thermal stress effect to the laser device.

Owner:NINGBO UNIV

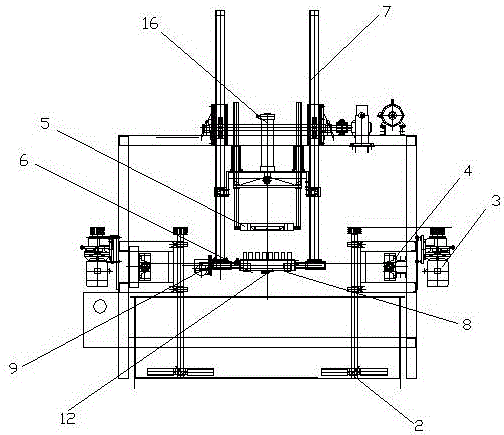

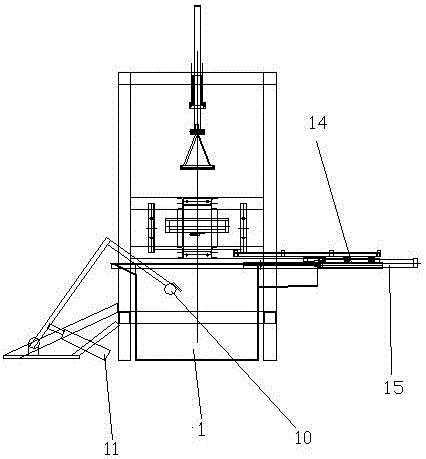

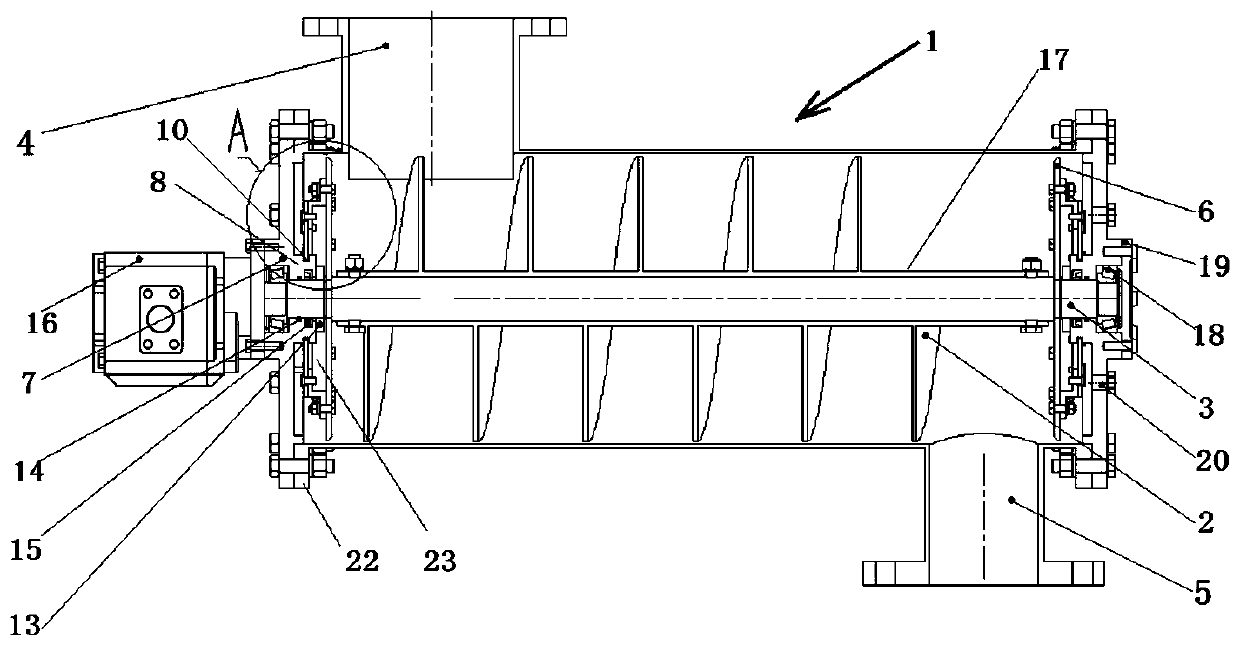

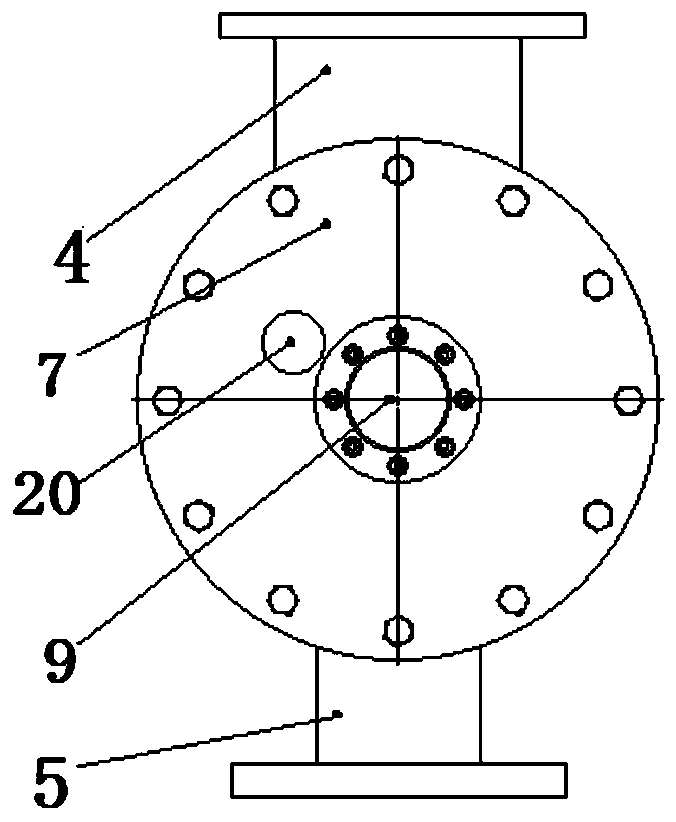

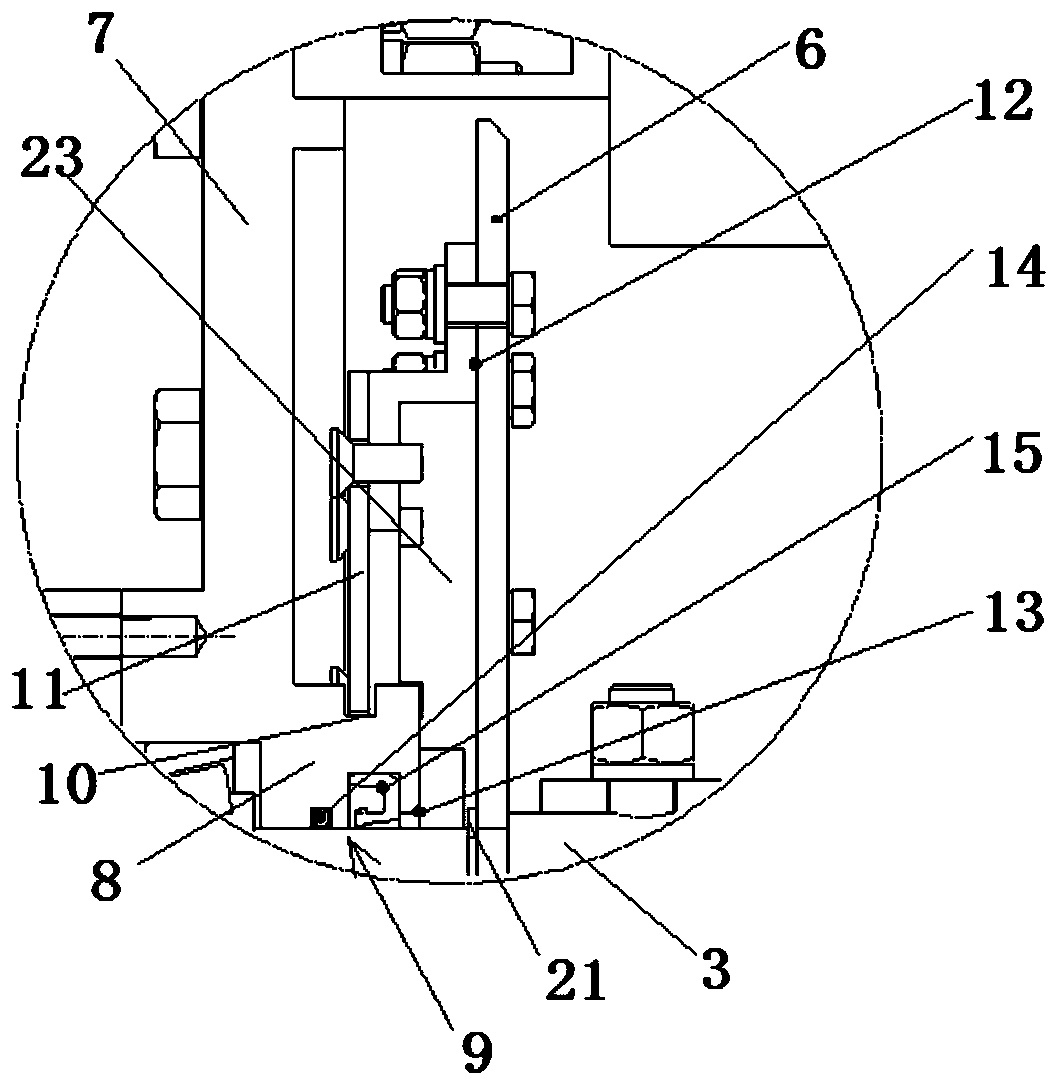

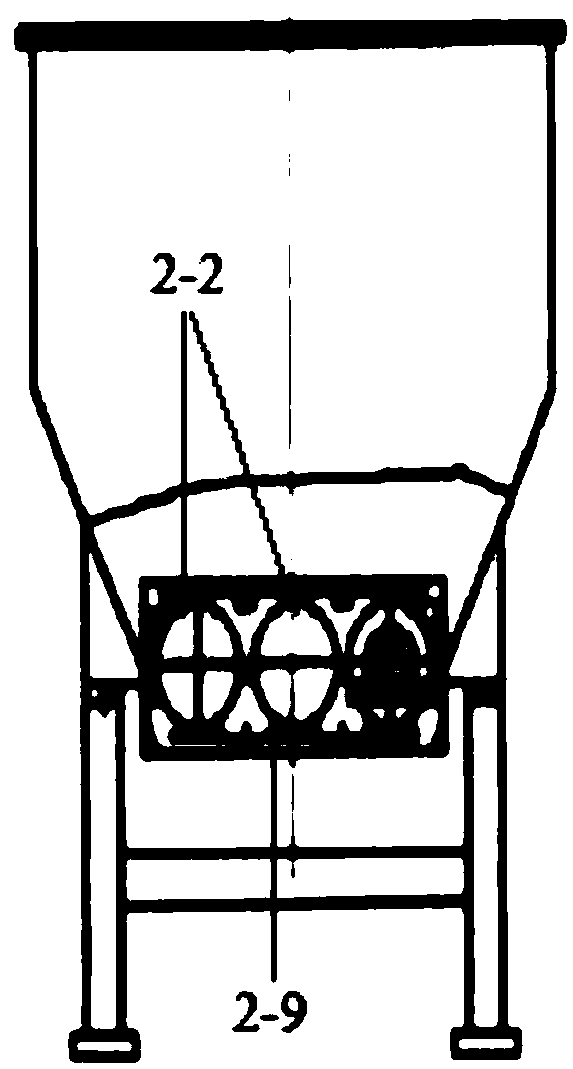

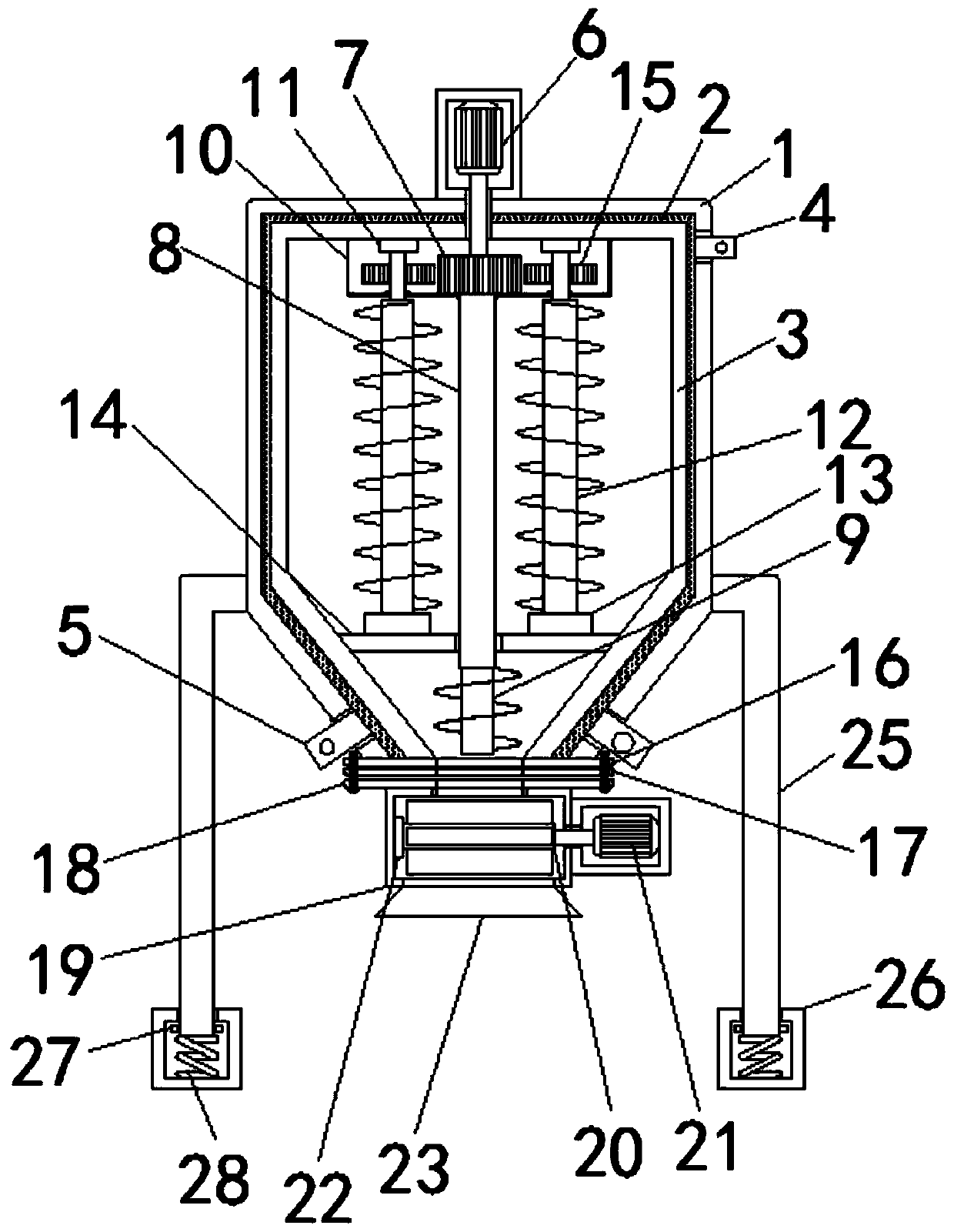

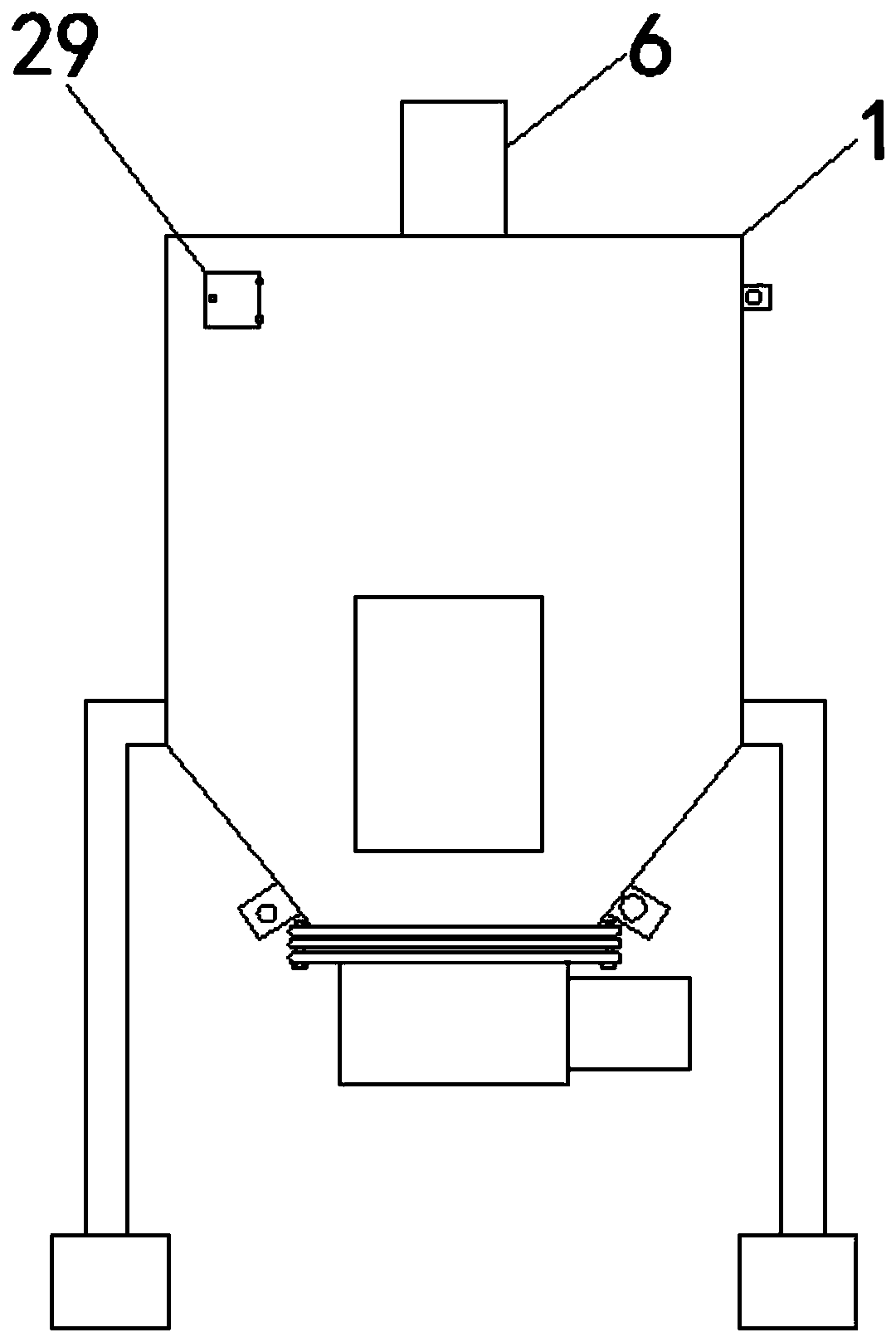

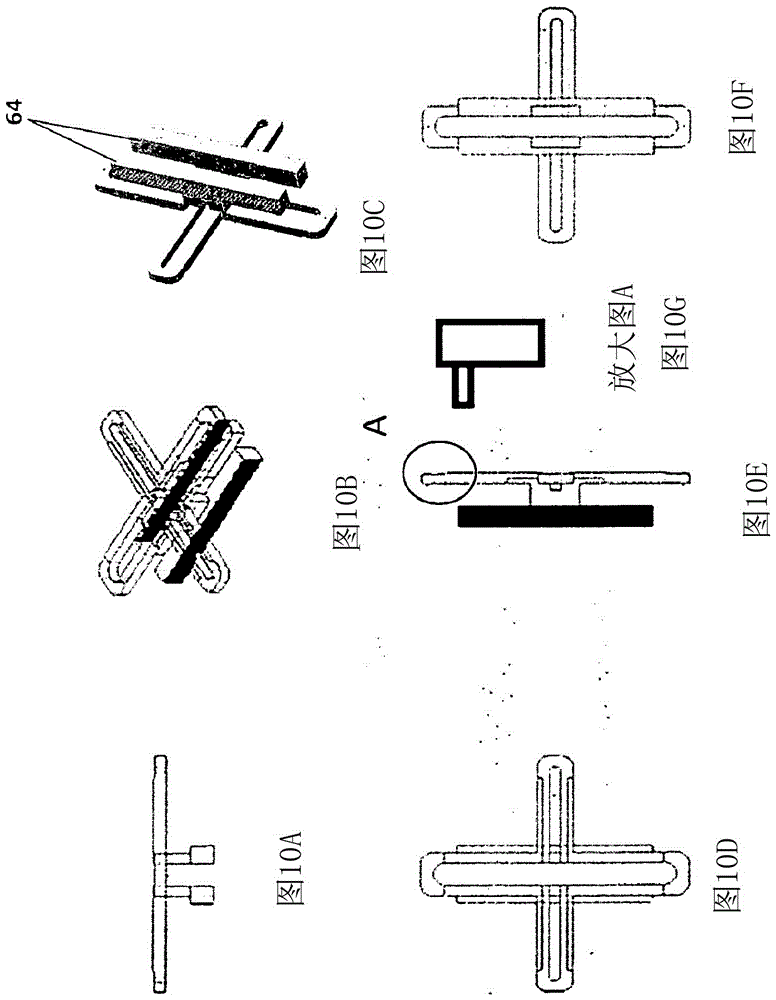

Riser forming machine

InactiveCN105798237AReduce physical laborUniform and stable outputFoundry mouldsFoundry coresEngineeringMaterial storage

The invention discloses a riser forming machine which comprises a slurry tank, a die, a scraping device and a vacuum absorbing device. Two stirring devices opposite in stirring direction are arranged in the slurry tank. The die is arranged on the upper side of the slurry tank through a rack elevating shaft and slides along the rack elevating shaft vertically. The die comprises an inner die body and an outer die body. Four hammers are arranged on the periphery of the inner die body. The die is provided with an exhausting hole. The scraping device is arranged between the slurry tank and the die and comprises a brush oil cylinder, a stainless steel roller and a brush. The vacuum absorbing device comprises a vacuum box and a vacuum settling tank. The vacuum settling tank is provided with a gas inlet hole and a sewage draining opening. The gas inlet hole is connected with the exhausting hole of the die through a hose. The riser forming machine enables whole mixed materials to be turned over upwards, so that the effects of dead-angle-free material storage and uniform mixing are achieved. By means of automatic die releasing, the defects that due to the fact that a die is hammered manually, a riser can not be released from the die easily, and manpower is wasted are overcome, the inner wall and the outer surface of the produced riser are smooth, and the quality and the working efficiency of the riser are improved.

Owner:NANJING NINGJINYAO MACHINERY CO LTD

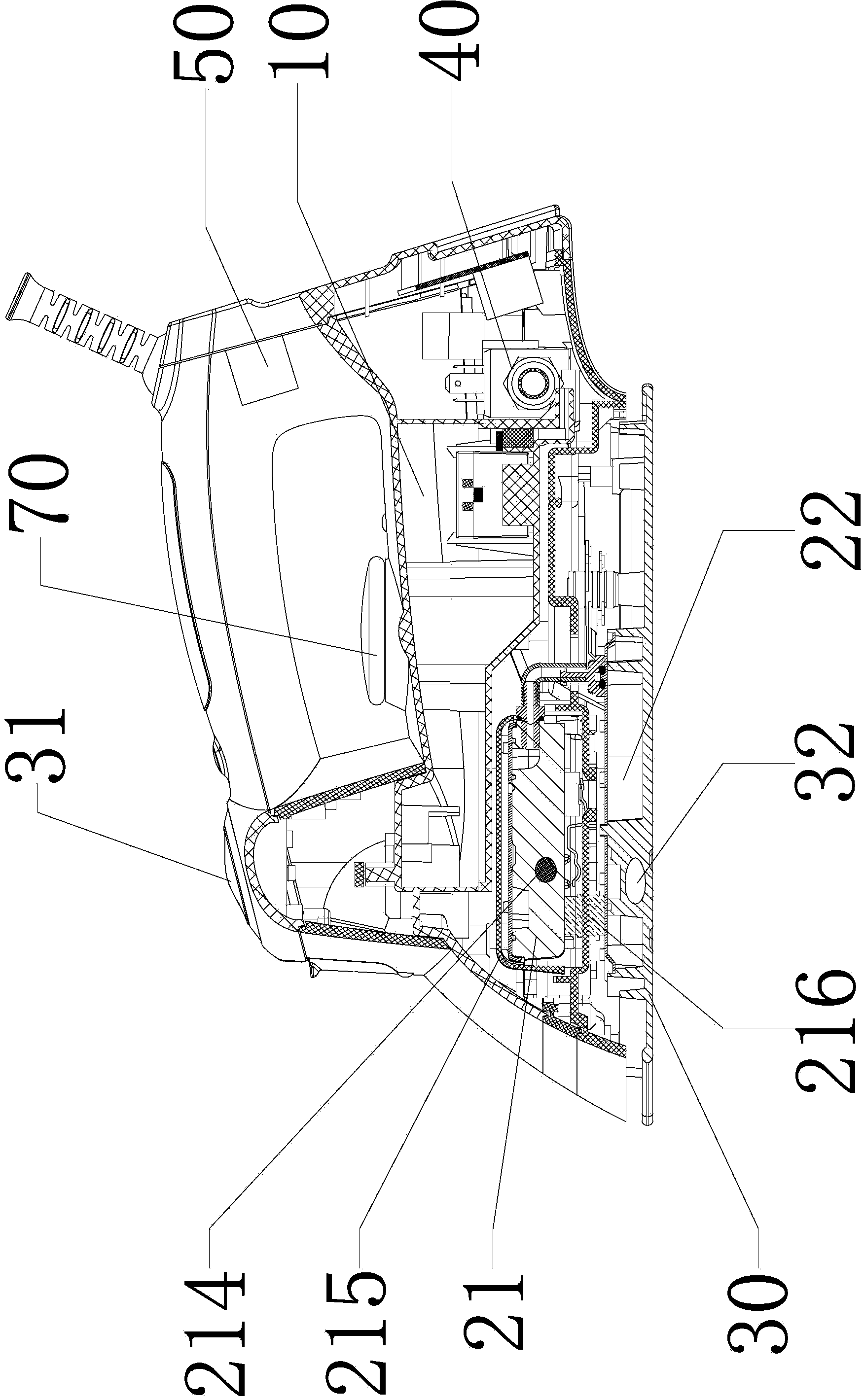

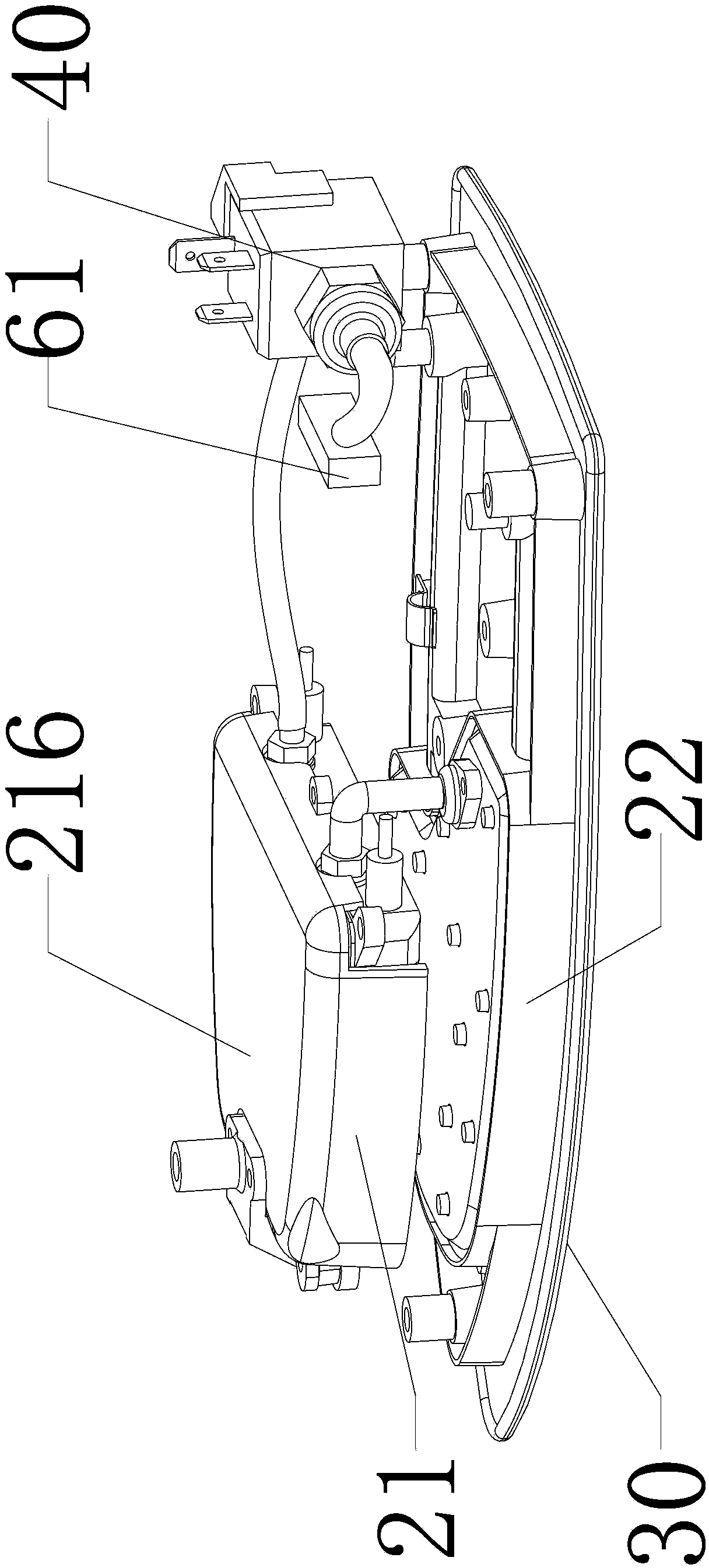

Electric steam iron and method for controlling quantity of steam of electric steam iron

ActiveCN103882668AImprove the heating effectUniform and stable outputHand ironTextiles and paperWork cycleEngineering

The invention provides an electric steam iron which comprises a water tank, a steam generating device, a bottom plate, heating elements, an electromagnetic pump and a controller. The heating elements are used for heating the bottom plate, the water tank is communicated with the steam generating device, the steam generating device is arranged on the upper portion of the bottom plate, the electromagnetic pump and the heating elements are respectively electrically connected with the controller, the water tank is communicated with the steam generating device via the electromagnetic pump, the steam generating device comprises a first steam generator and a second steam generator, and the water tank is communicated with the first steam generator via the electromagnetic pump. A method for controlling the quantity of steam of the electric steam iron includes that the quantity of water pumped by the electromagnetic pump of the electric steam iron is controlled, so that the steam generating quantity can be controlled; a set work cycle of the electromagnetic pump is 20ms, and five tap positions are set for the steam generating quantity. The electric steam iron and the method have the advantages that the steam generating quantity can be effectively controlled, so that the steam can be uniformly and stably outputted, and a suitable quantity of steam and a suitable temperature of the steam can be provided according to different clothes and fabrics.

Owner:ZHEJIANG YUELI ELECTRICAL

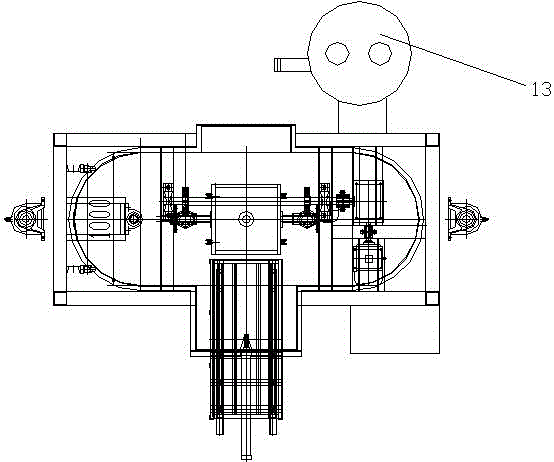

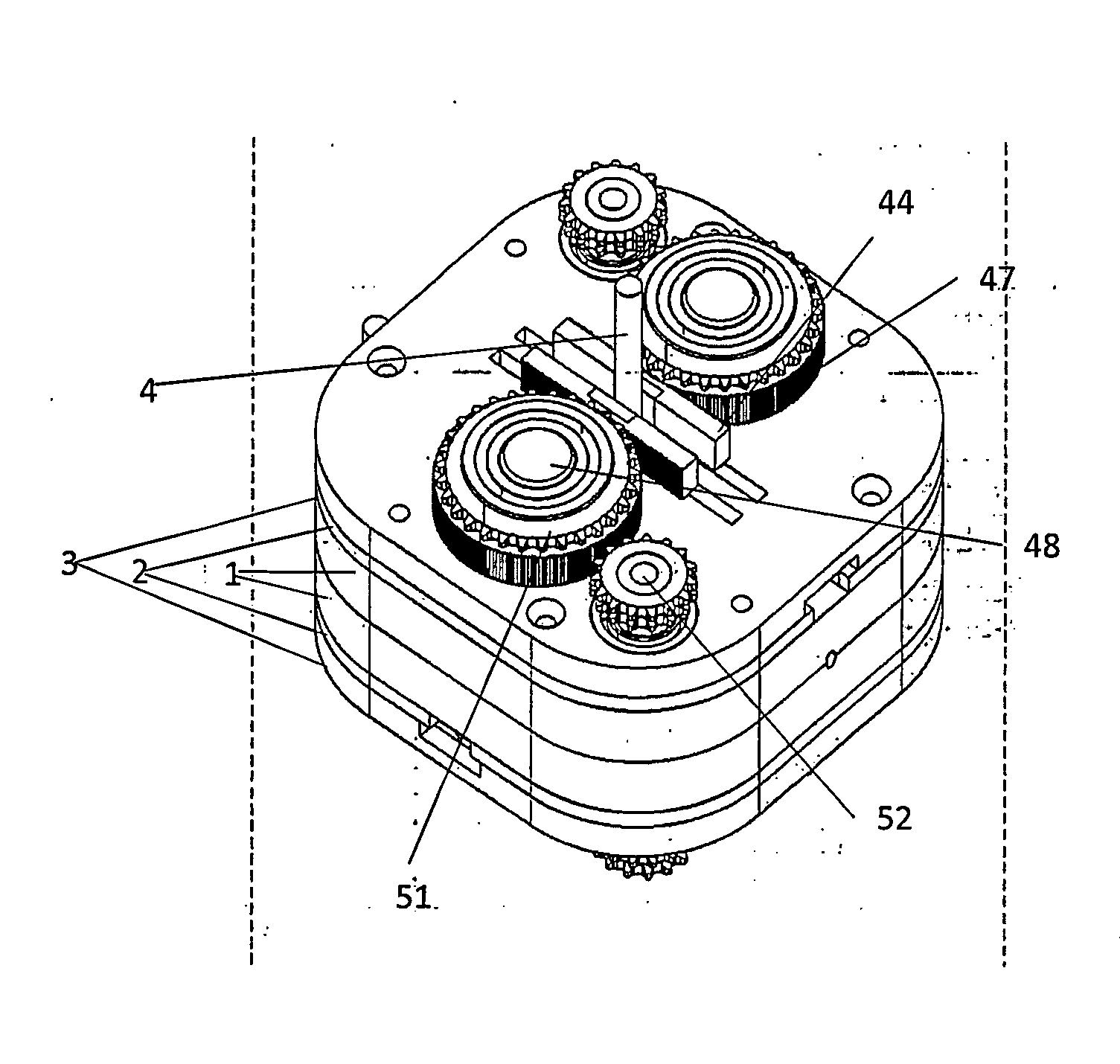

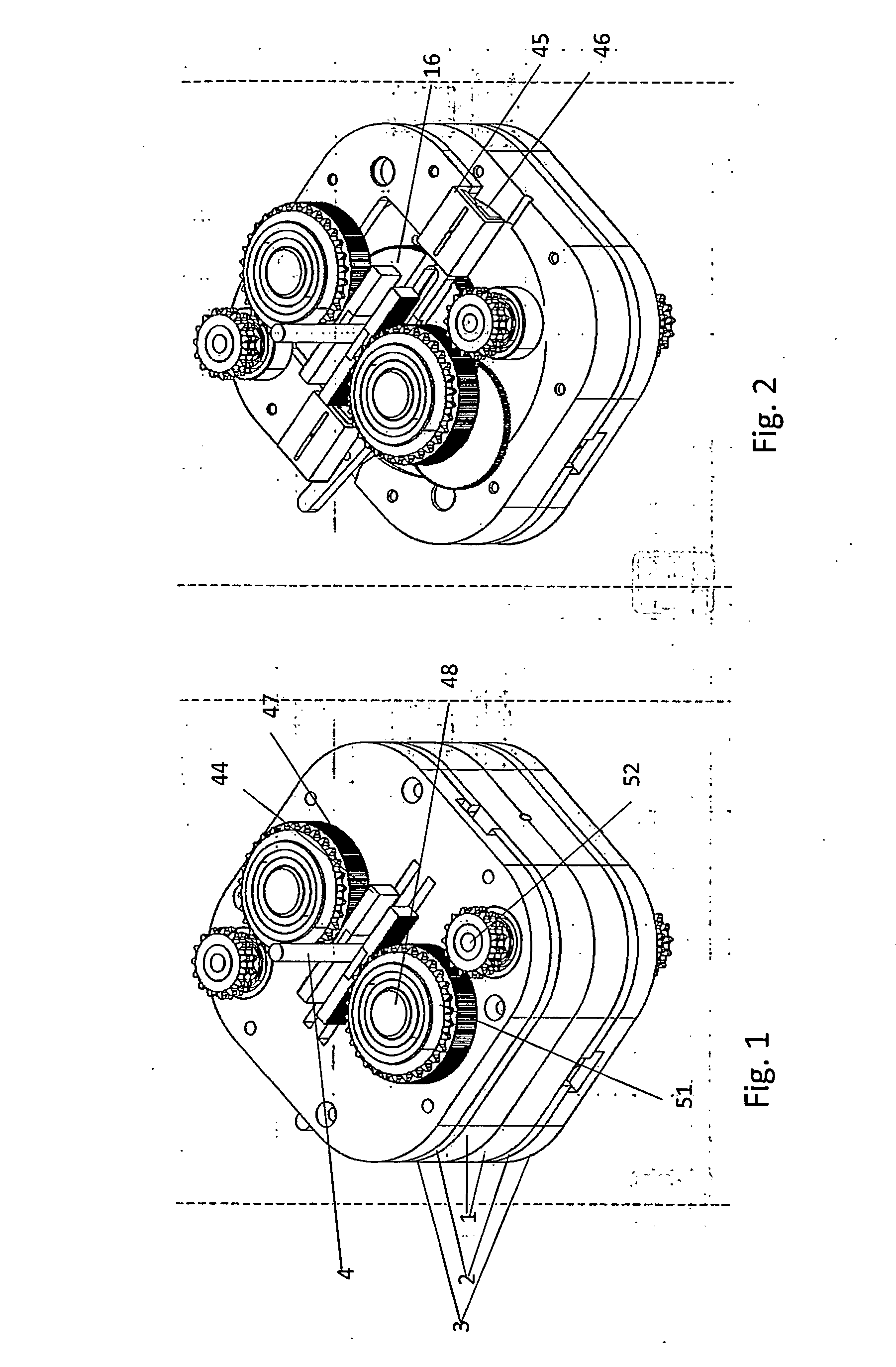

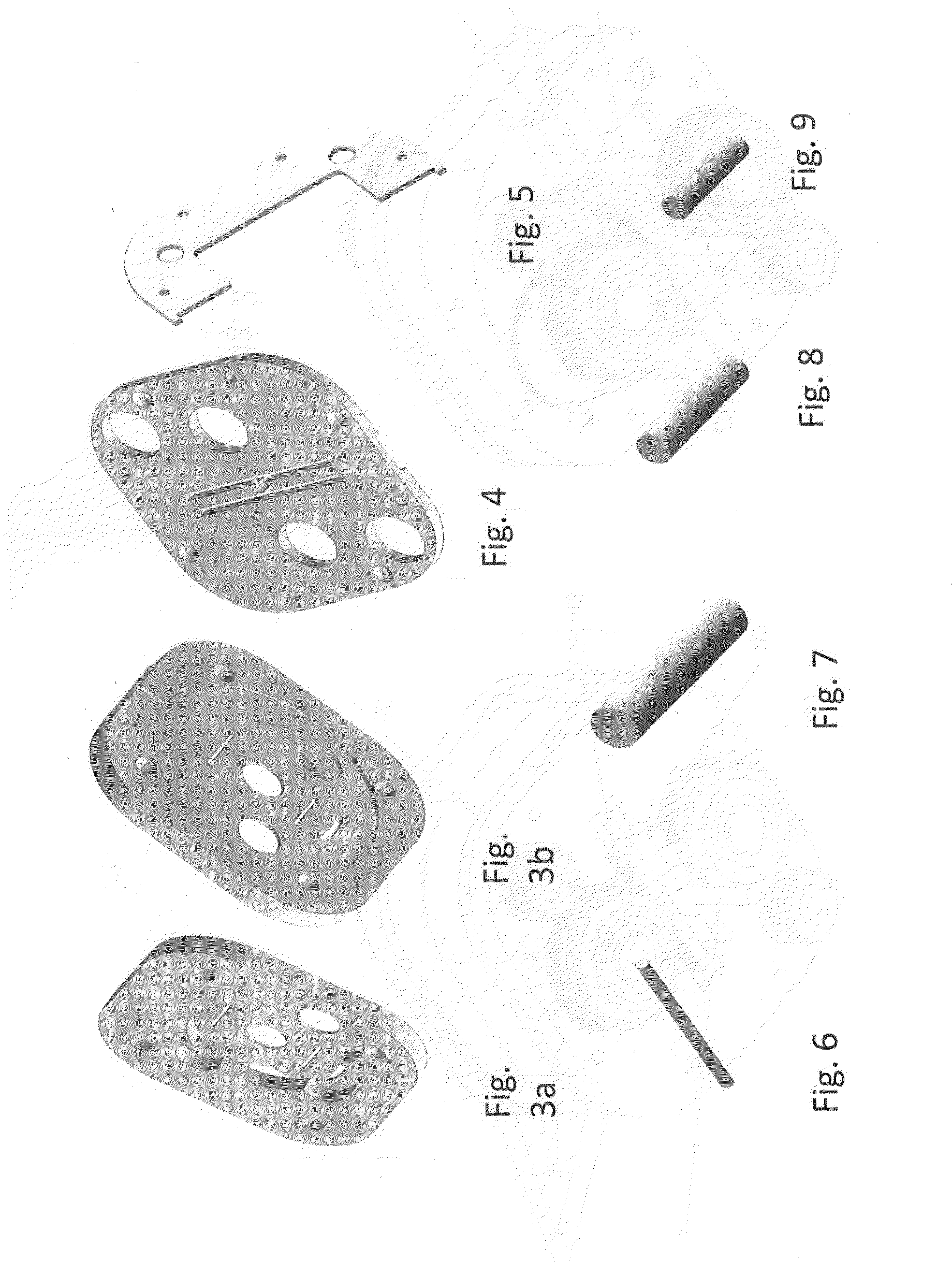

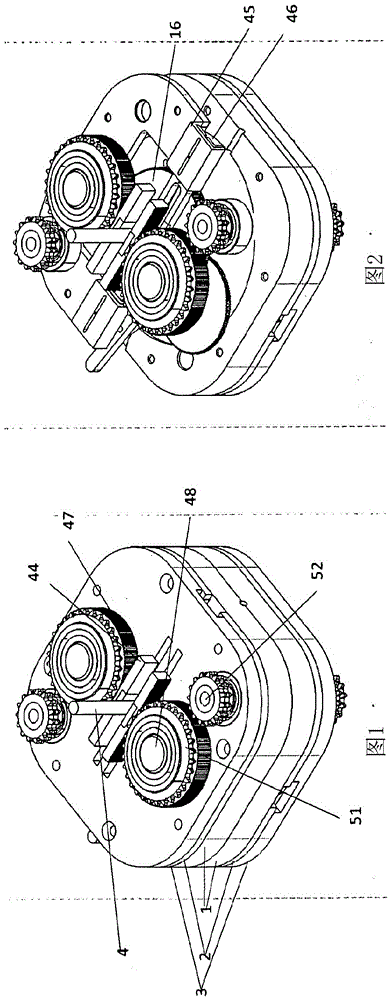

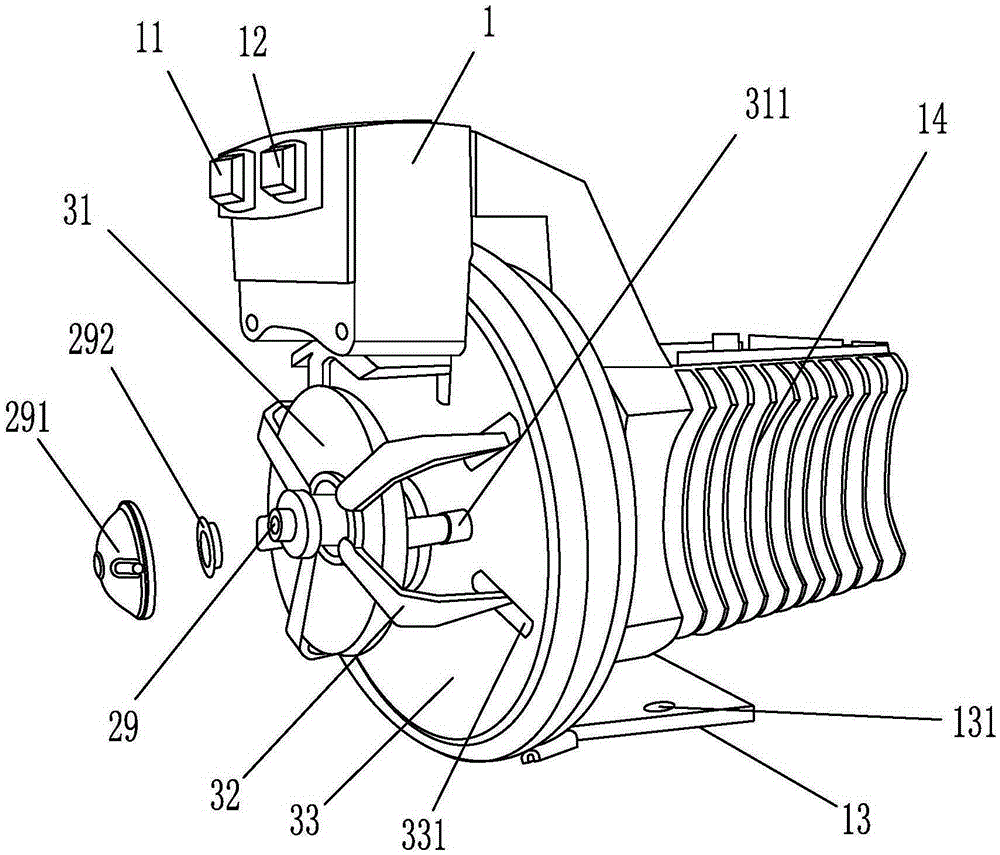

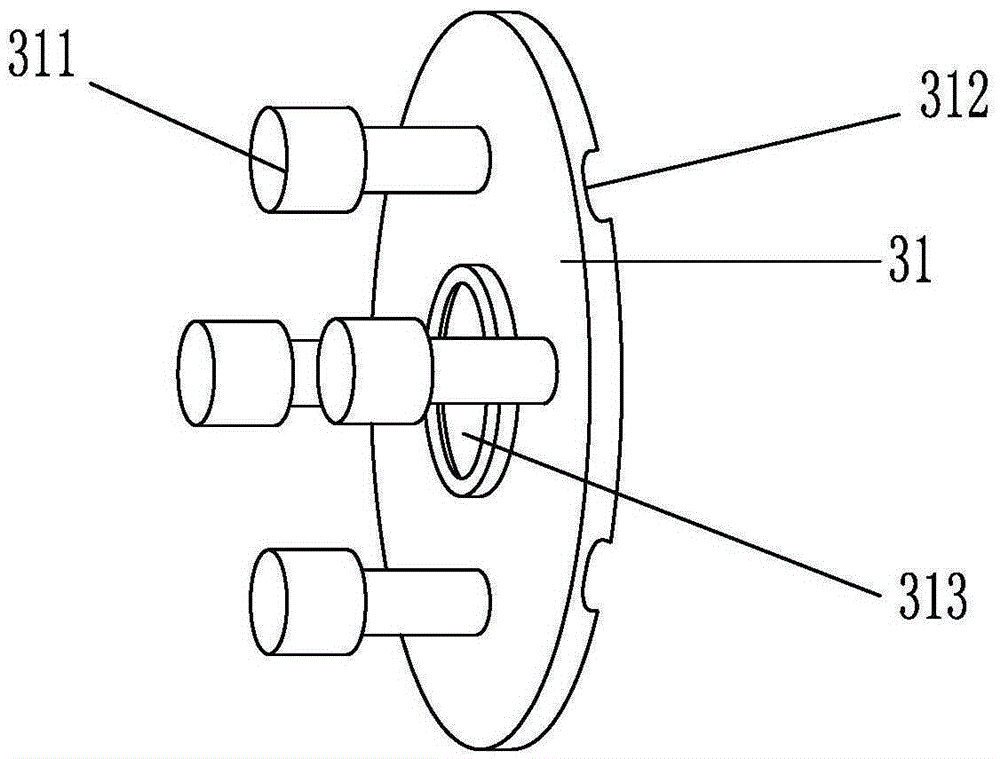

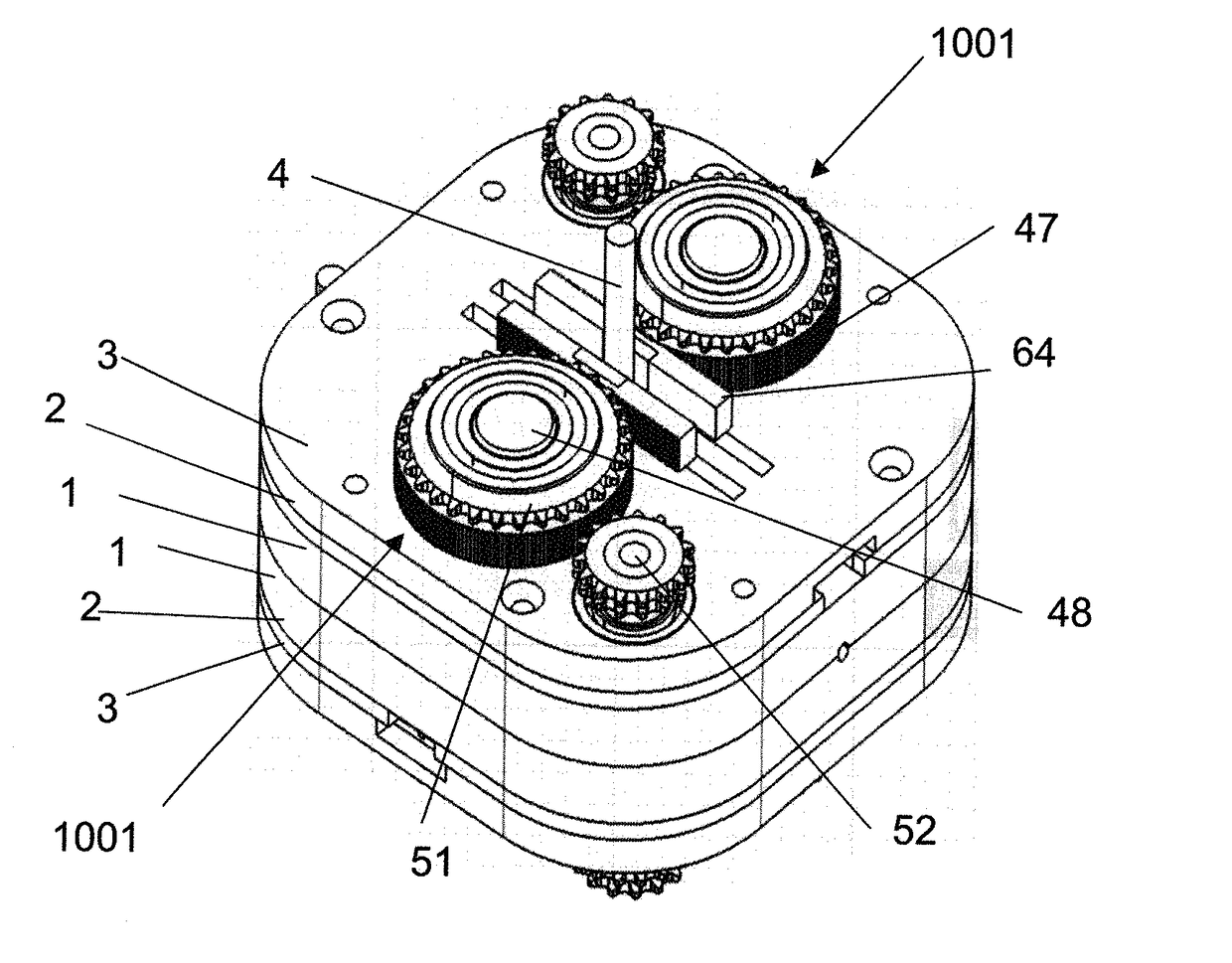

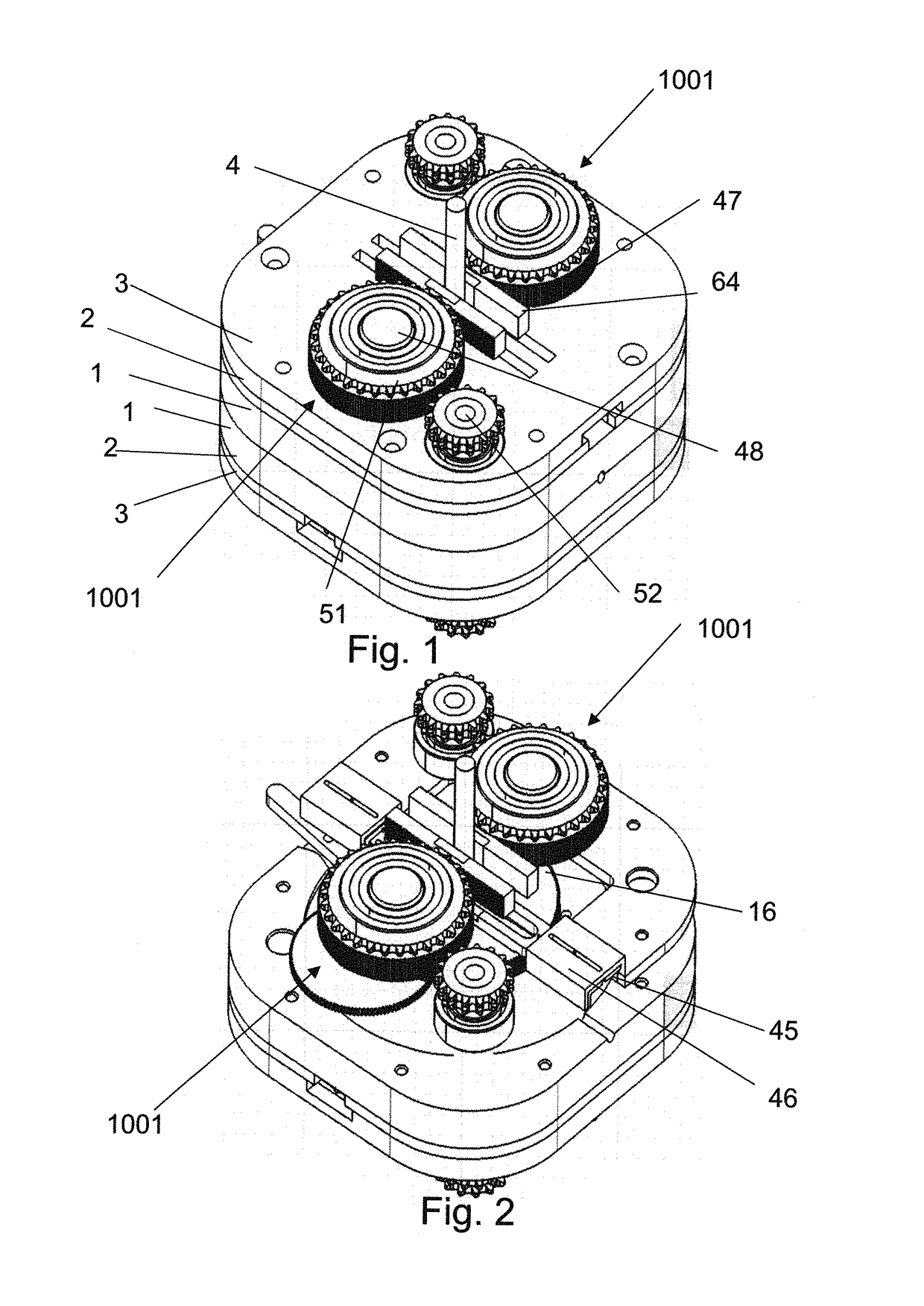

Continuous variable transmission with uniform input-to-output ratio that is non-dependent on friction

ActiveUS20150267794A1Uniform and stable outputSmall sizeFriction gearingsControl theoryContinuous variable

This invention is a continuous variable transmission. This invention uses a mechanism known as “scotch yoke” principle to change the ratio of the input and output in the transmission. This invention uses a set of non-circular gears and circular gears to modify the input received from a system to deliver a steady and uniform output. It employs a unique way to change the ratio between the input and output of the transmission. Three very simple mechanisms are used to achieve changing the ratio. The option of reverse, park, and neutral gear mechanisms are integrated into this design. This invention offers a co-axial input to output feasibility.

Owner:RAJENDRAN RAJA RAMANUJAM +1

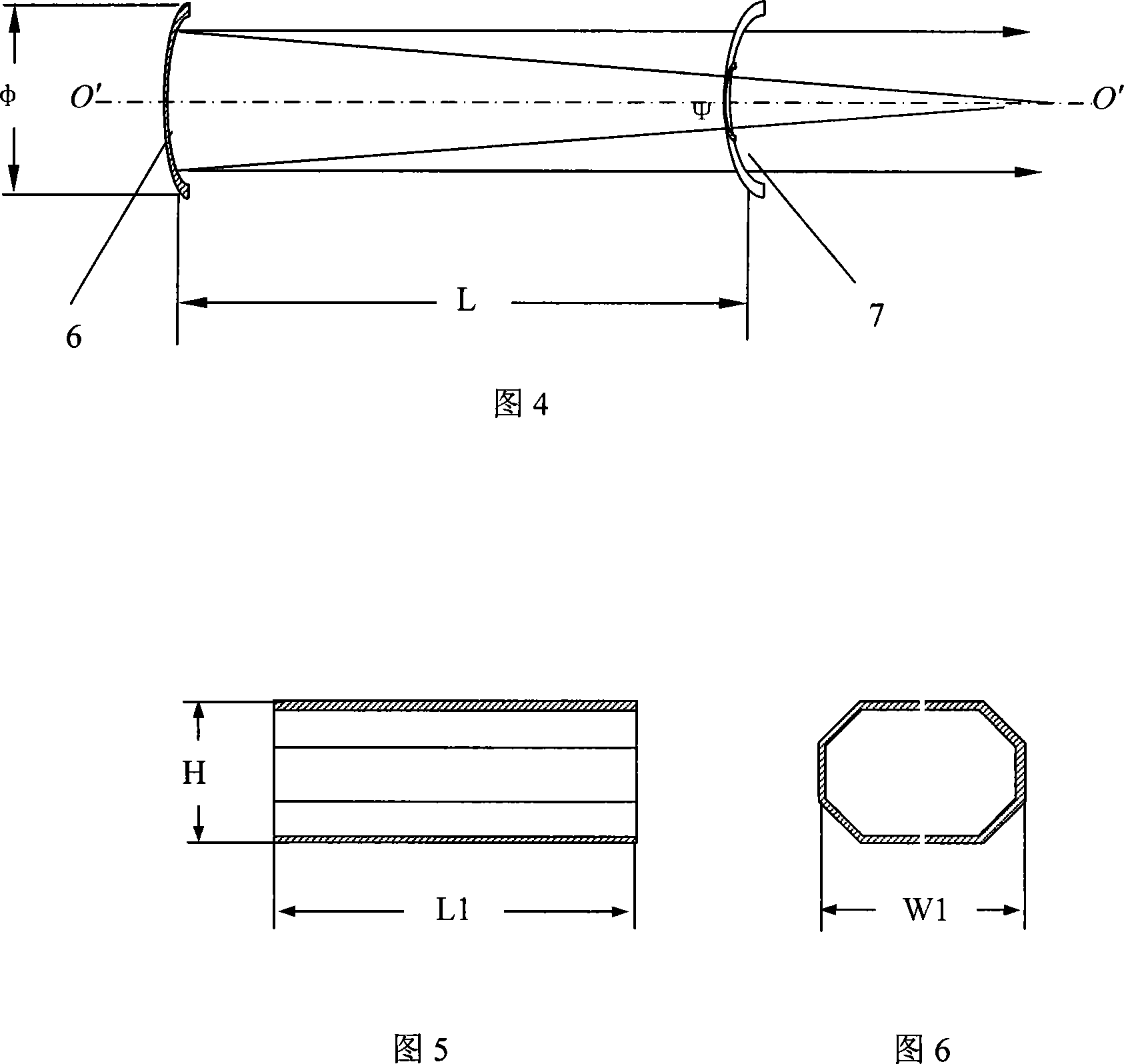

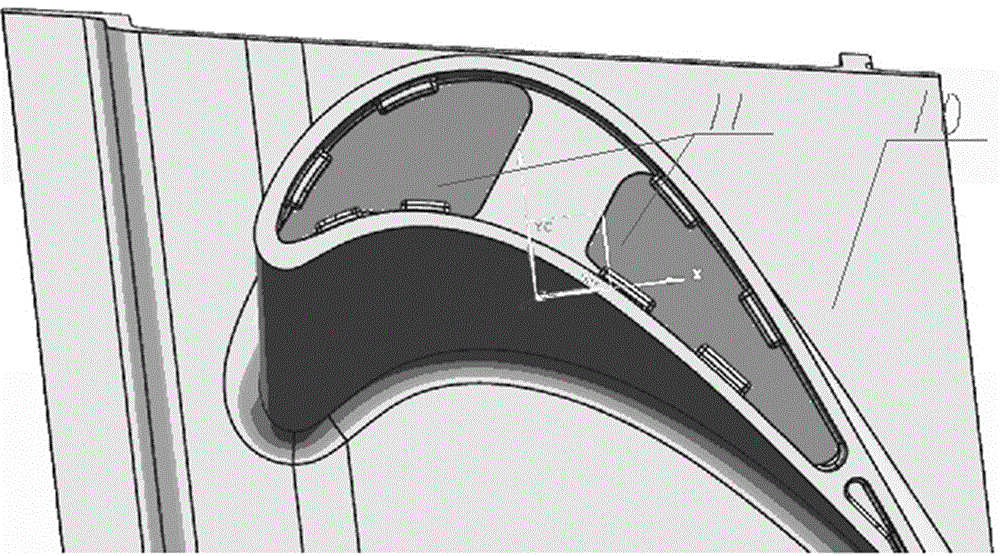

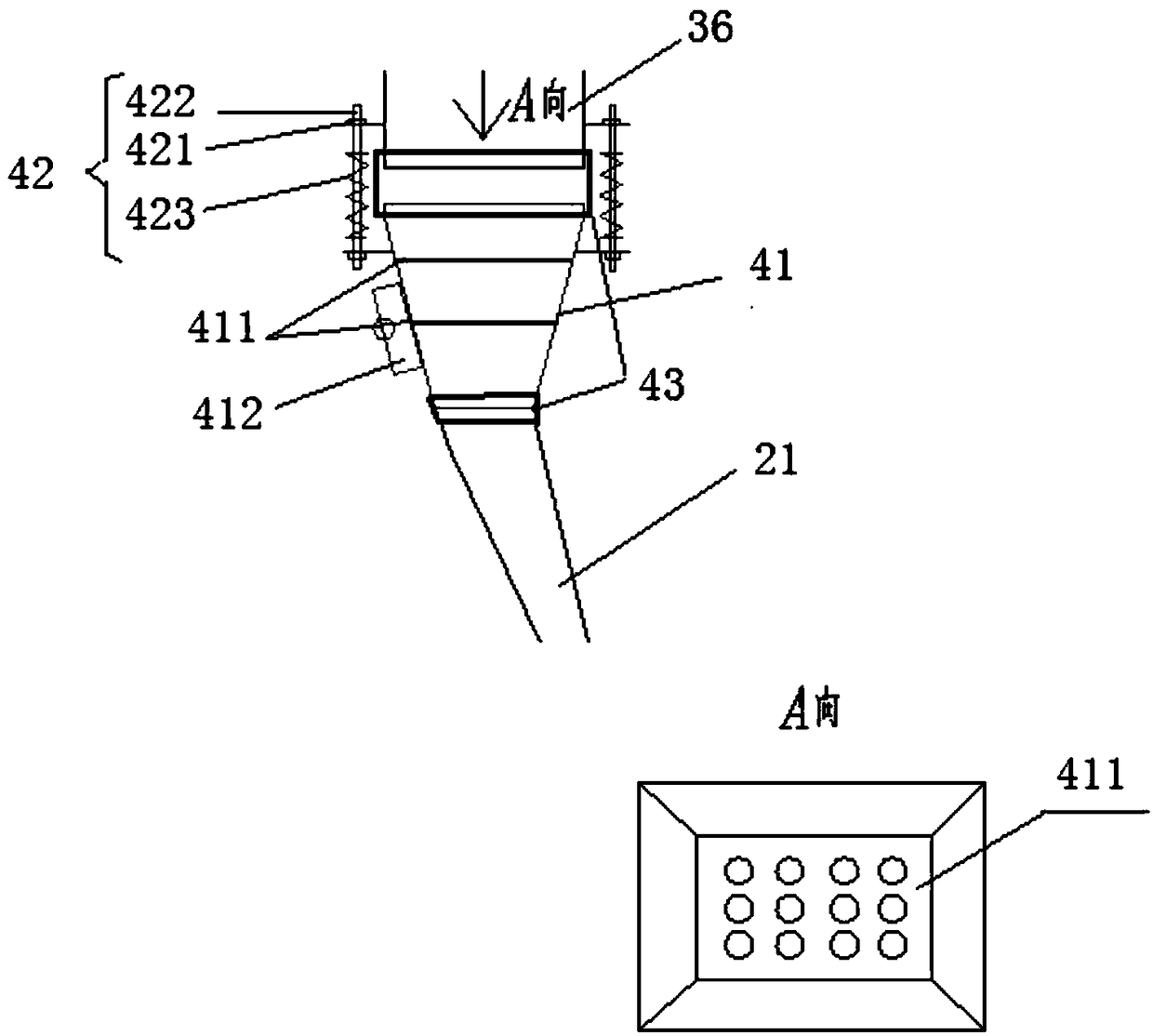

Laser cladding repairing technical method for labyrinth seal of turbine disc

ActiveCN107805806AImprove bindingEasy dischargeMetallic material coating processesSpray nozzleEngineering

The invention discloses a laser cladding repairing technical method for a labyrinth seal of a turbine disc. The laser cladding repairing technical method for the labyrinth seal of the turbine disc comprises the following steps that the turbine disc is clamped in an inert atmosphere protection box, the to-be-repaired labyrinth seal is cleaned and then subjected to laser cladding, and the repaired portion is machined, specifically, cleaning of the to-be-repaired labyrinth seal includes matrix pre-melting and powder supply cladding which are conducted in sequence, as for matrix pre-melting, a laser unit is adopted for irradiating the to-be-repaired labyrinth seal of the turbine disc so that a matrix of the to-be-repaired labyrinth seal can be molten, and as for powder supply cladding, laser cladding is conducted on the to-be-repaired labyrinth seal of the turbine disc in a mode that a powder supply nozzle conducts lateral powder supply. By means of the technical method, the abraded labyrinth seal can recover to the initial geometric shape and technical indexes and can be reused.

Owner:AECC AVIATION POWER CO LTD

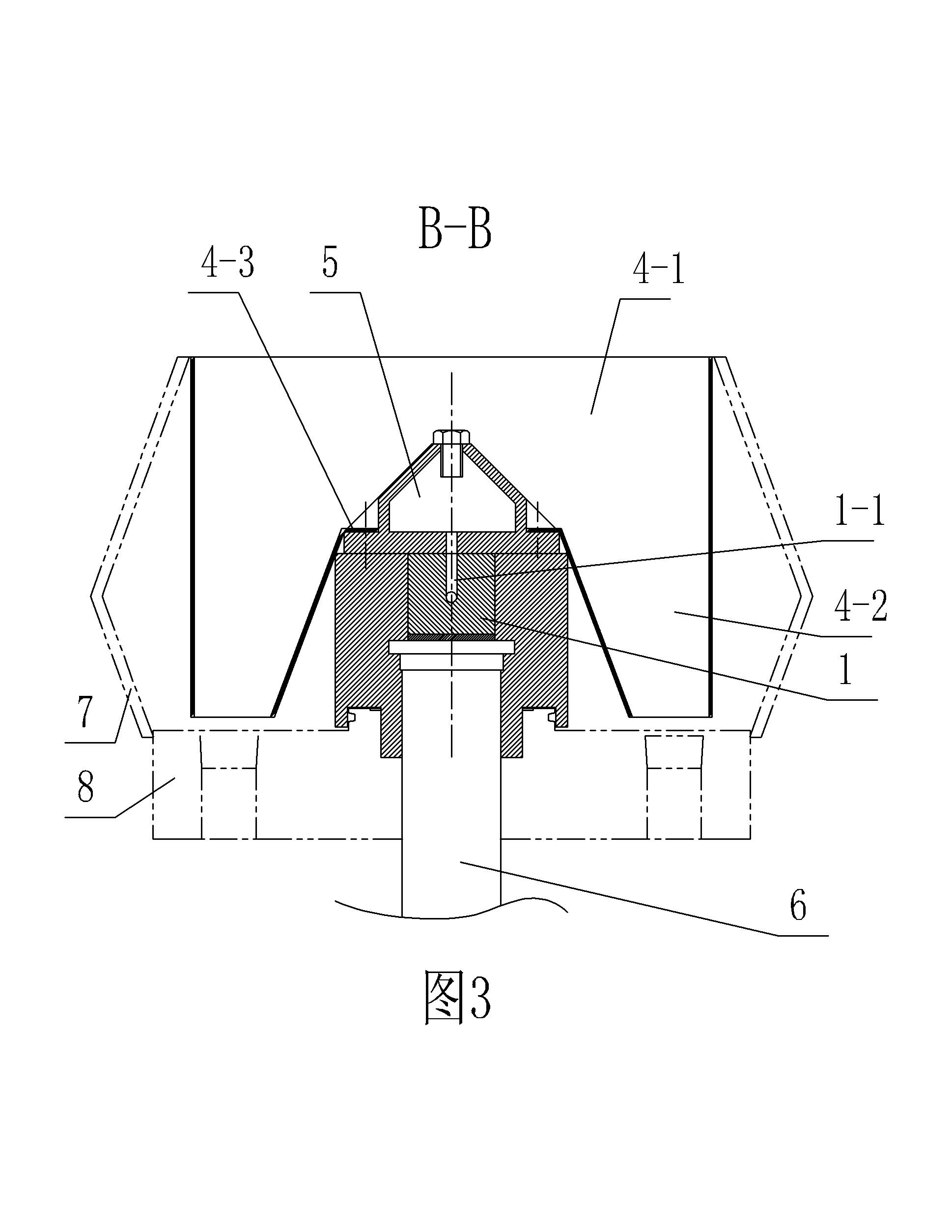

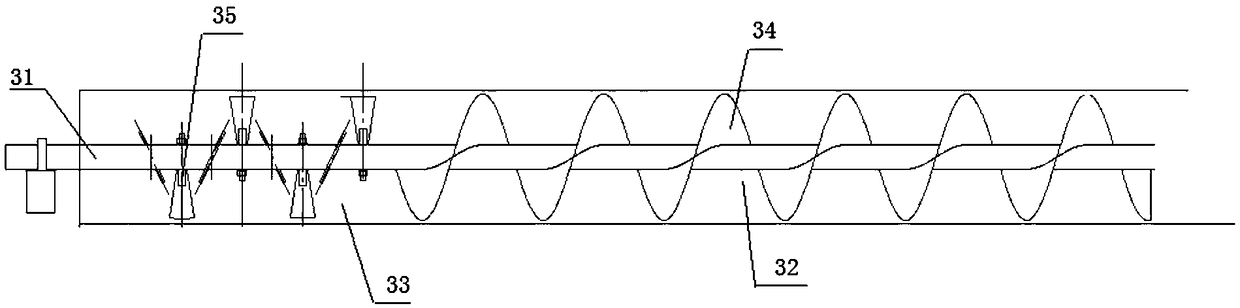

Screw feeder for underwater coarse mineral particles

The invention discloses a screw feeder for underwater coarse mineral particles. The screw feeder for the underwater coarse mineral particles comprises a cylinder and a rotary shaft. The rotary shaft is arranged in the cylinder and provided with screw blades. The two ends of the rotary shaft are pivoted to the cylinder. A feed port and a discharge port are formed in the outer walls of the two endsof the cylinder. The ends, close to the feed port and the discharge port, of the rotary shaft are each sleeved with an annular partition plate. The edges of the annular partition plates extend to positions near the inner wall of the cylinder. According to the screw feeder for the underwater coarse mineral particles, the internal pressure and the external pressure of the screw feeder can be kept balanced, so that uniform conveying of materials is achieved; meanwhile, the service life of the whole screw feeder is prolonged through the multiple sealing technique; and in addition, the adaptabilityof the feeder is improved through the replaceable screw blades.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

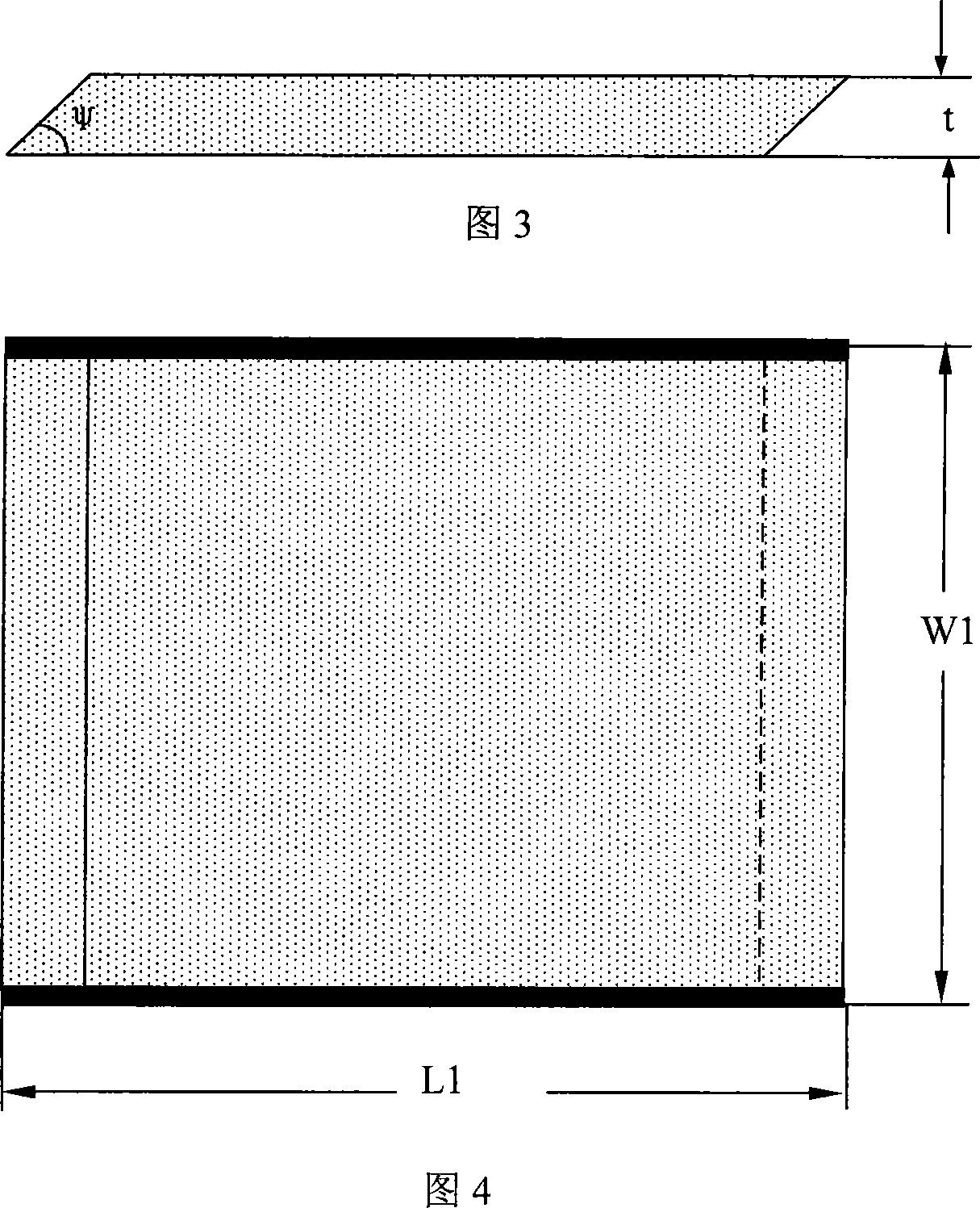

Heat capacity type neodymium glass sheet laser

InactiveCN101202411AAvoid influenceSimple structureExcitation process/apparatusOptical resonator shape and constructionHigh energyOptoelectronics

The invention discloses a neophane glass lath laser in heat capacity type. The invention is characterized in that the invention comprises a resonant cavity and lath laser glass medium. The resonant cavity is a plane-paralleled cavity which comprises a rectangle total reflective mirror and a rectangle output coupling mirror; the transverse size of the plane-paralleled cavity is larger than the width of the lath laser glass medium; the upper side and the lower side of the lath laser glass medium are respectively provided with rectangle silvering optical reflectors which are symmetrical with each other; the optical reflectors are provided with openings which face to the lath laser glass medium; the openings are hermetically provided with a cerium-doped quartz pipe; the optical reflectors are internally provided with a plurality of pumping lights which are arranged along the direction of the laser; the discharging direction of the pumping light is vertical to the arranging direction; cooling water is arranged in the optical reflectors; the invention has the advantages of simple structure, obtaining the laser output with high energy and high power by operating under high repeated frequencies in short time, uniform and stable laser output, recovering the glass working medium to original state in the operation interval of the device, and avoiding the thermal lens effect and the thermal stress effect to the laser device.

Owner:NINGBO UNIV

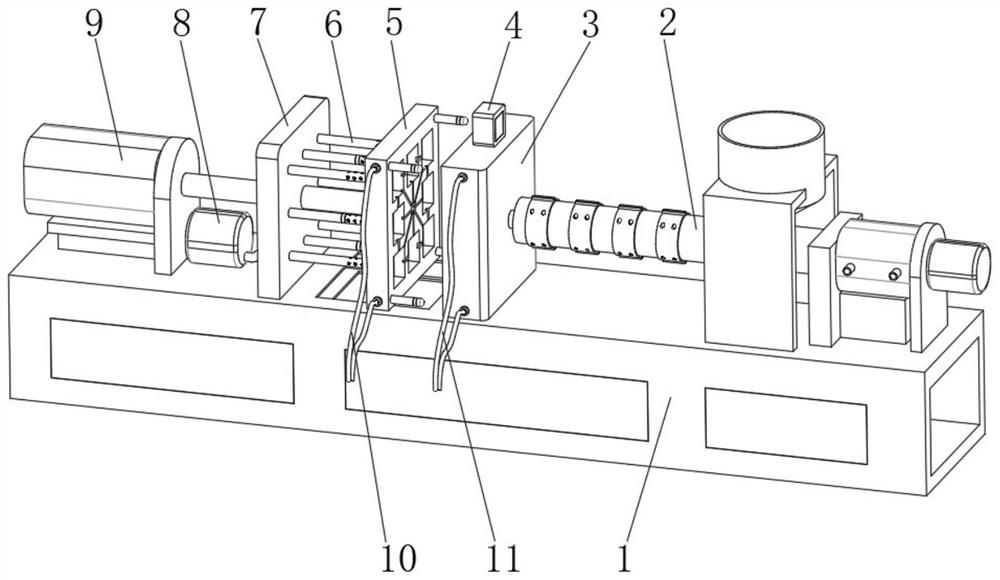

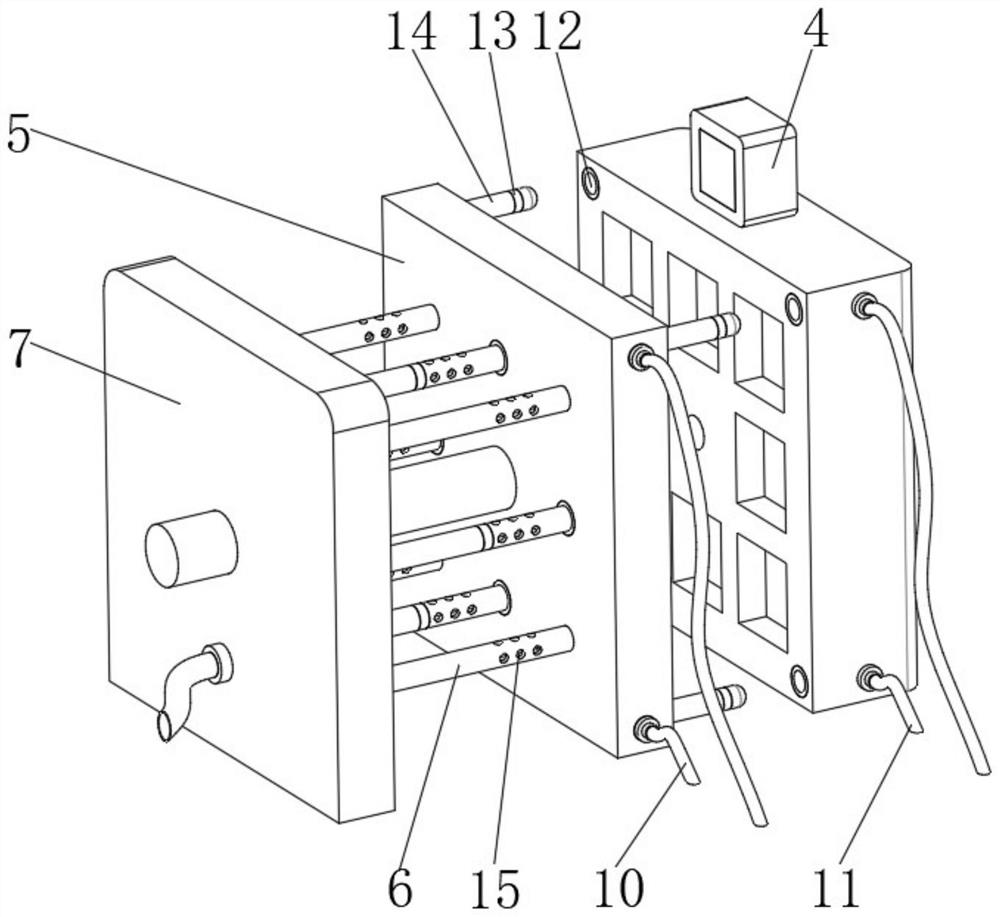

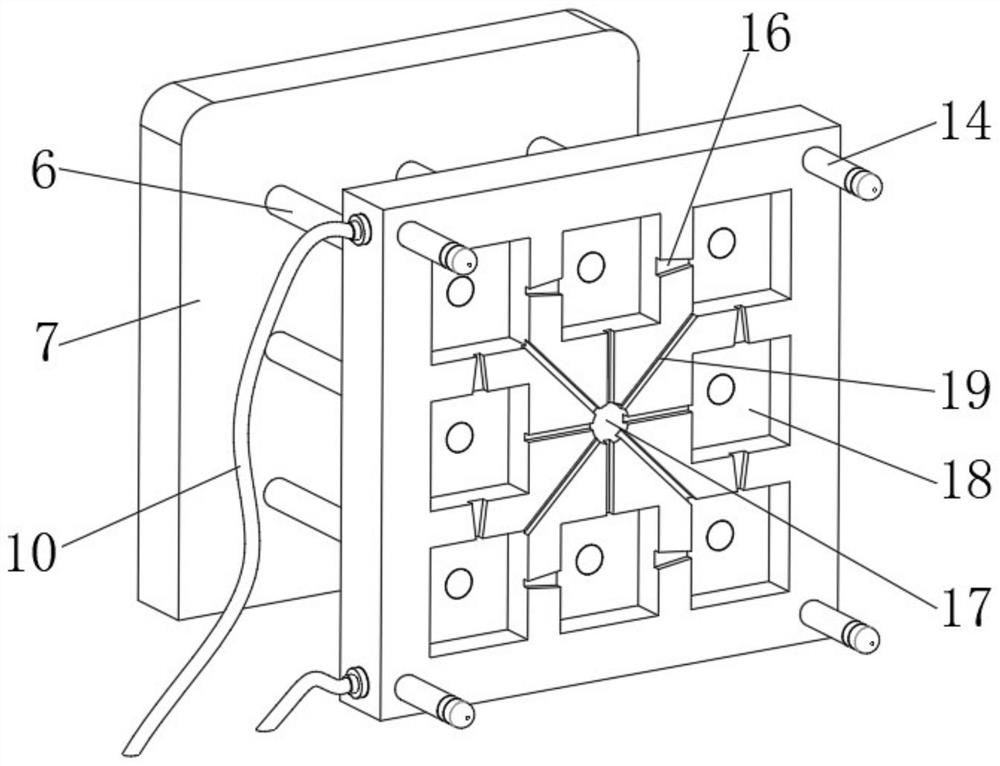

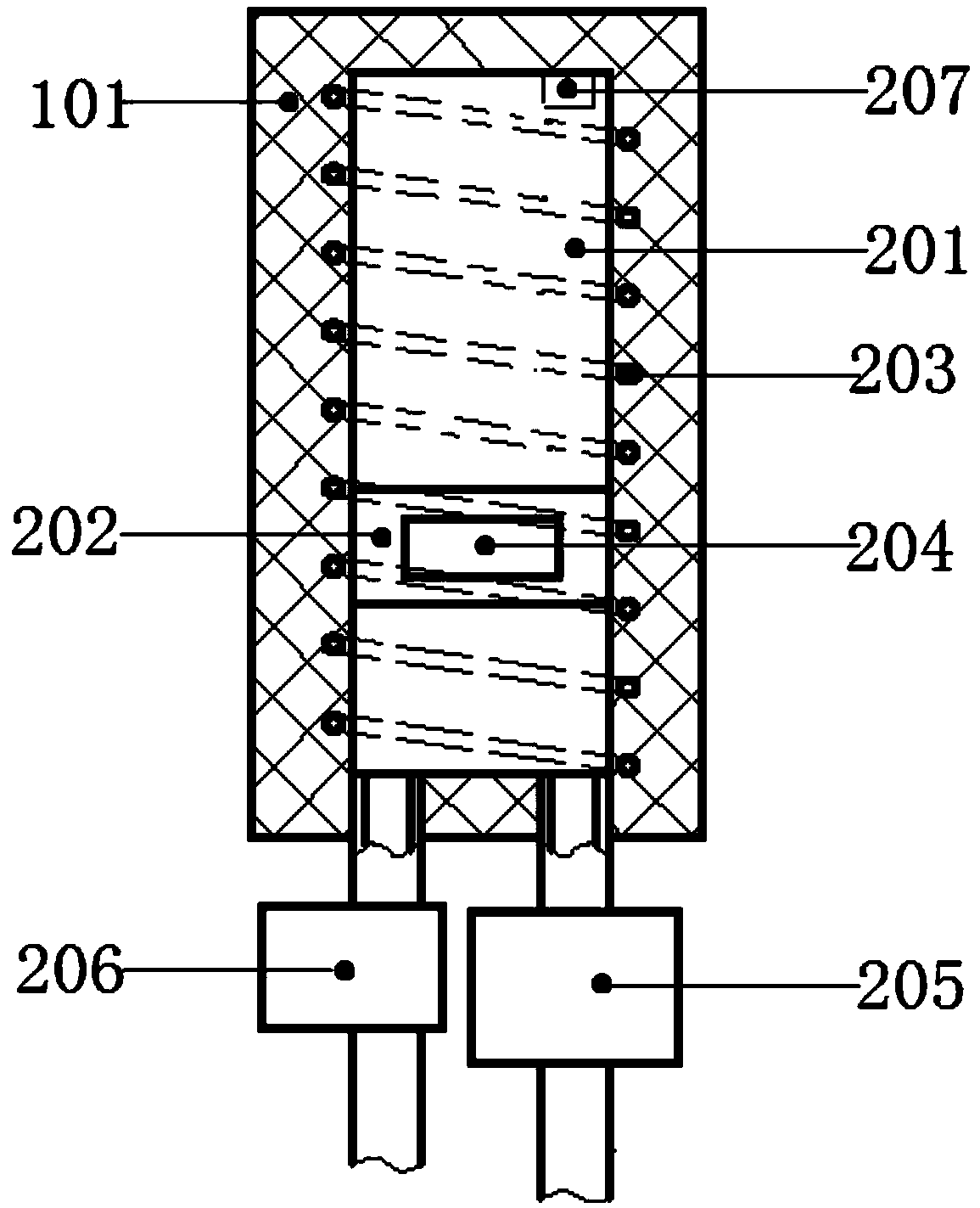

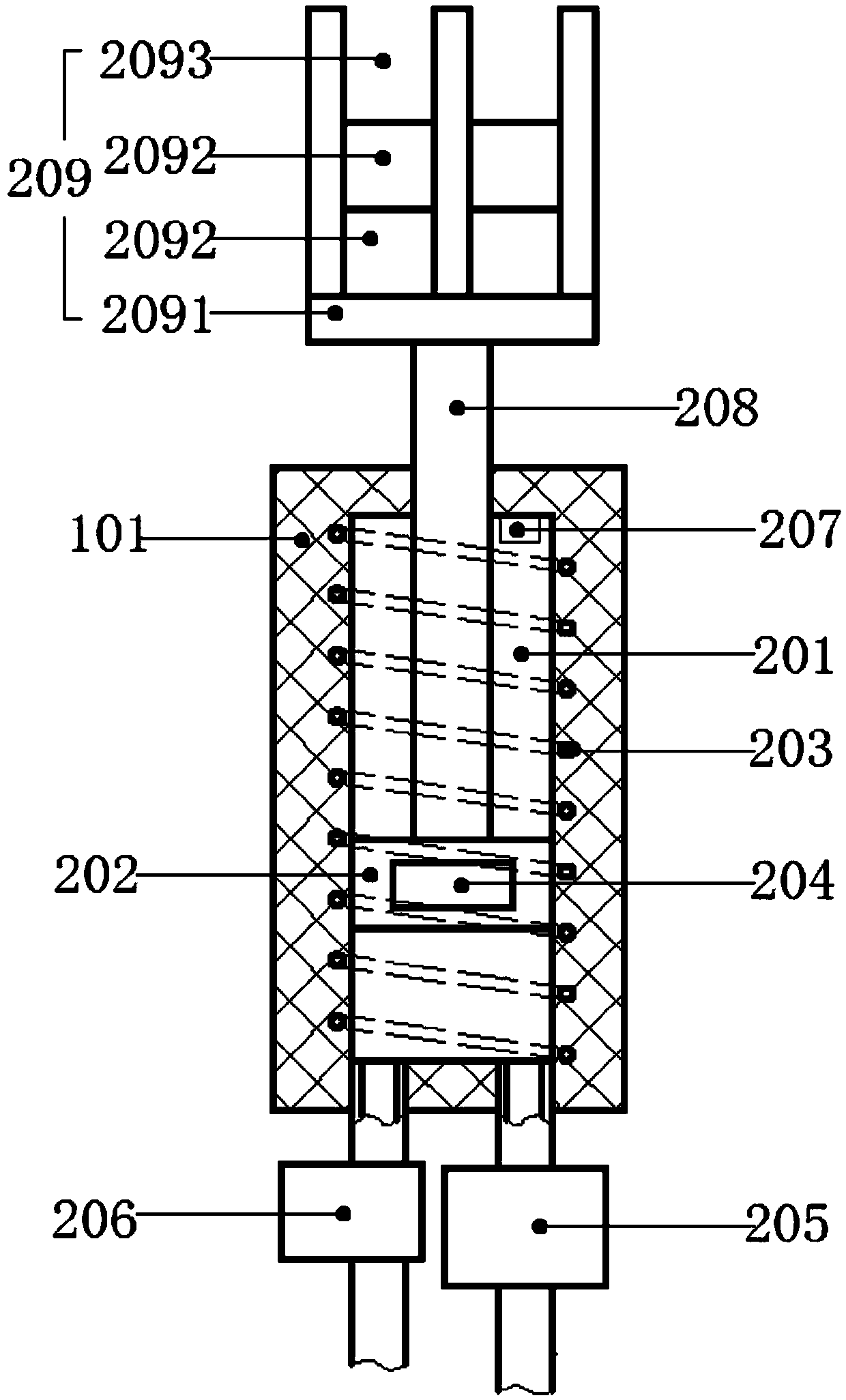

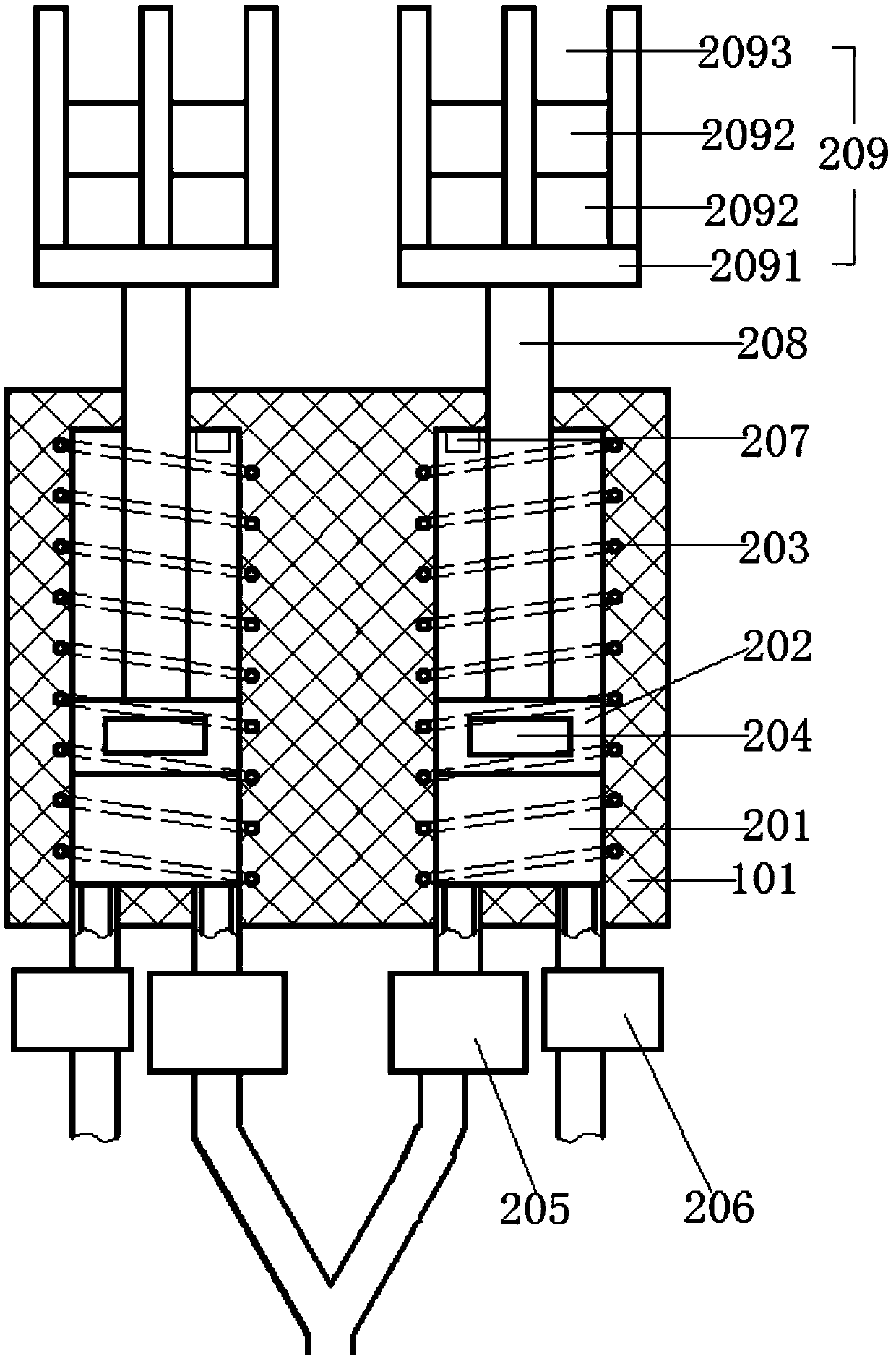

Injection molding machine and control method of injection molding machine

InactiveCN112223699AGuarantee processing qualityRealize automatic blowingTemperature controlMolding machine

The invention discloses an injection molding machine and a control method of the injection molding machine, and relates to the technical field of injection molding machines. The purpose of the invention is to improve the quality of injection molding products. The injection molding machine comprises a workbench; an injection molding mechanism and a mold mechanism are installed on the outer wall ofthe top of the workbench; a control module is arranged in the workbench; the mold mechanism comprises a movable injection mold and a fixed injection mold; and the inner wall of one side of the fixed injection mold is connected to the output end of the injection molding mechanism. The control method of the injection molding machine comprises the following steps: the injection molding mechanism works to extrude materials into a mold core; and in the extrusion process, a timer performs timing synchronously, and an electric control temperature liquid tank performs heat preservation through a firsttemperature control pipeline and a second temperature control pipeline. According to the invention, an air blowing hole and an air pump are arranged; during de-molding, the air pump is used for inflating a hollow ejector rod, and the inner wall of the mold core is cleaned through the air blowing hole; and therefore, the machining quality of the products is guaranteed, the purpose of automatic airblowing is achieved based on the de-molding position of the injection molding movable mold, and convenience and practicability are improved.

Owner:苏州思捷精密模具有限公司

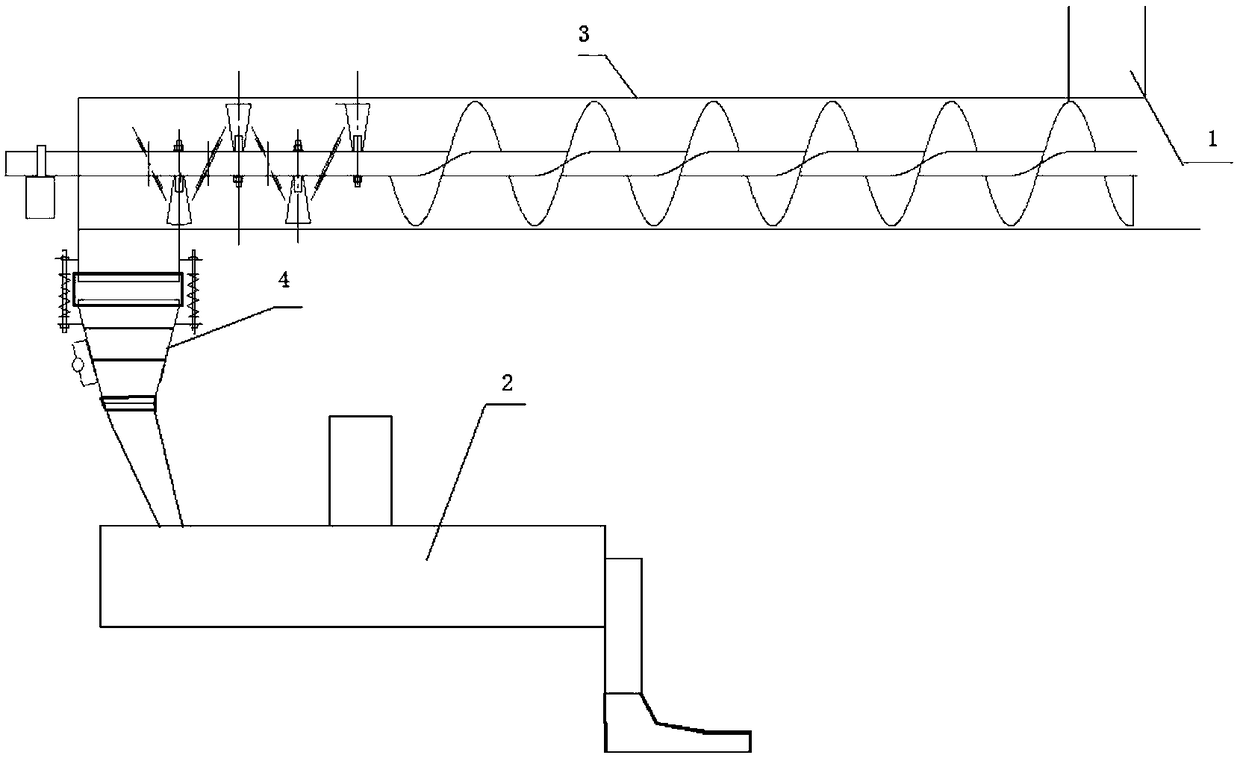

Extraction device used for paper-making reconstituted tobacco and technology for preparing reconstituted tobacco

ActiveCN107692301AImprove purityImprove sensory qualityTobacco preparationTobacco treatmentEngineeringPulp and paper industry

The invention belongs to the field of paper-making reconstituted tobacco, and particularly relates to an extraction device used for the paper-making reconstituted tobacco. The extraction device comprises a first-stage extraction tank, a screw conveyer, a first-stage screw pump, a first-stage spiral discharge centrifugal machine, a second-stage extraction tank, a second-stage screw pump, a second-stage spiral discharge centrifugal machine, a third-stage extraction tank, a third-stage screw pump and a third-stage spiral discharge centrifugal machine. The invention further relates to a technologyfor preparing the reconstituted tobacco through a paper-making method. According to the extraction device and the preparation technology, the tobacco is uniformly and stably discharged, the extraction rate is high, the purity degree of the obtained solid-phase material is high, and the prepared tobacco sheets are high in sensory quality.

Owner:CHINA TOBACCO FUJIAN IND +1

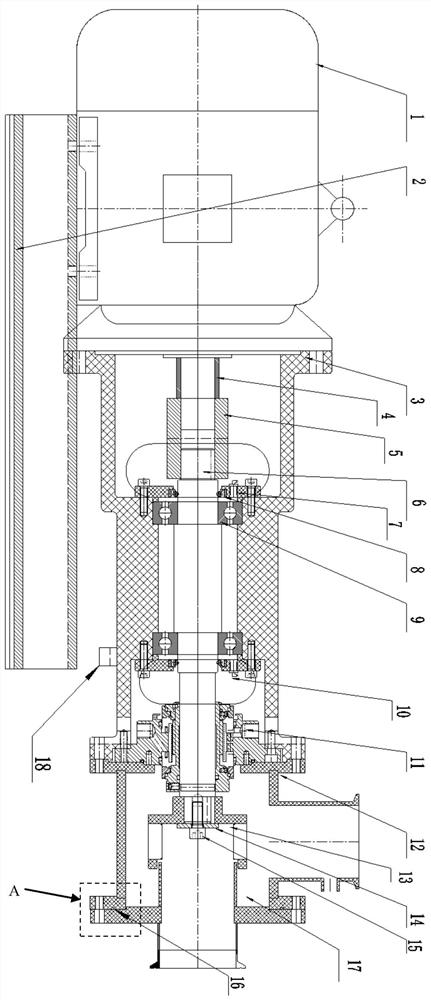

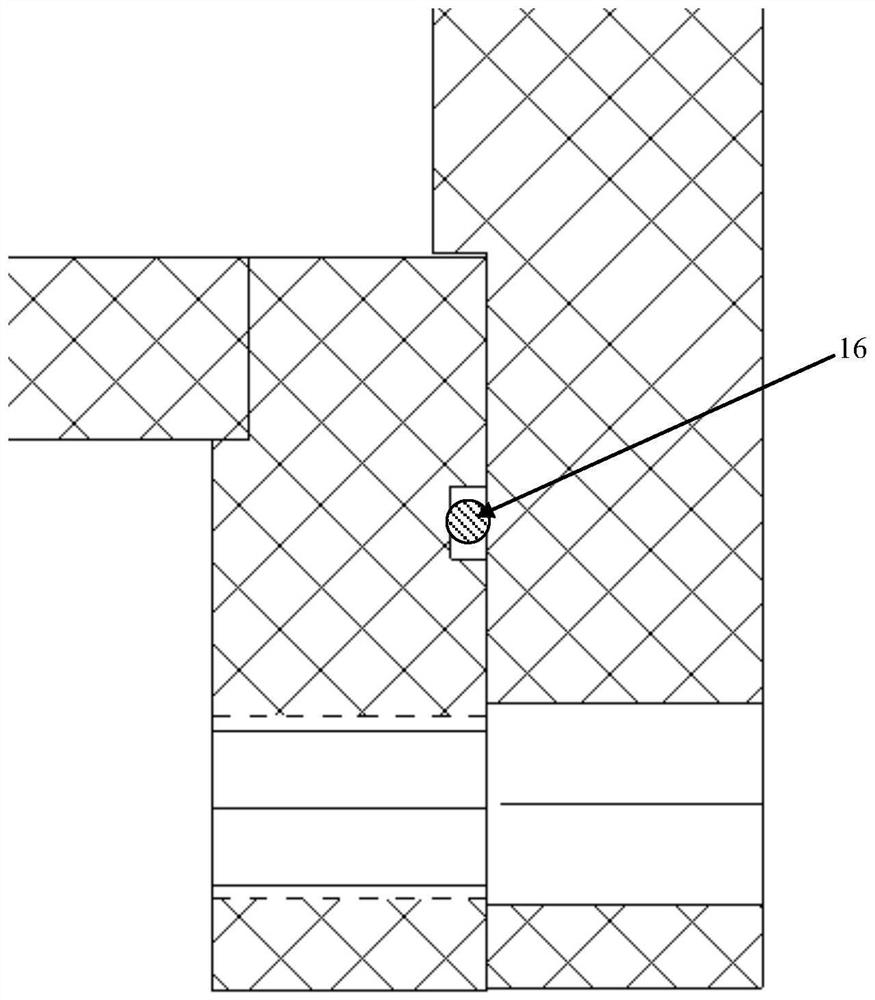

Gas storage device

ActiveCN110857751AEasy and reliable adjustment processEnsure equal outputContainer filling methodsContainer discharging methodsPetrochemicalEngineering

The invention discloses a gas storage device which belongs to the field of petroleum chemical equipment. The gas storage device comprises a gas storage body and a gas storage unit positioned on the gas storage body, wherein the gas storage unit comprises a gas storage cavity positioned inside the gas storage body, a gravity slide block which is dynamically positioned inside the gas storage cavityin a sealing mode and can move up and down along the gas storage cavity, an electrifying coil which surrounds outside the gas storage cavity, a magnetic induction block which is coaxially positioned inside the gravity slide block, a gas inlet valve and a gas outlet valve, which communicate with the bottom of the gas storage cavity separately, wherein the gas inlet valve communicates with a gas supply pipeline, and the gas outlet valve communicates with a gas consumption pipeline. Through the gravity slide block, gas storage amount of the gas storage cavity which is inflated with gas every timecan be the same, so that the quantitative output purpose is achieved, and quantitative output still can be achieved even gas pressure is unstable. The electrifying coil is mutually matched with the magnetic induction block, so that gas pressure in the gas storage cavity can be regulated in real time, and therefore, a gas pressure regulating process is more convenient and reliable.

Owner:PETROCHINA CO LTD

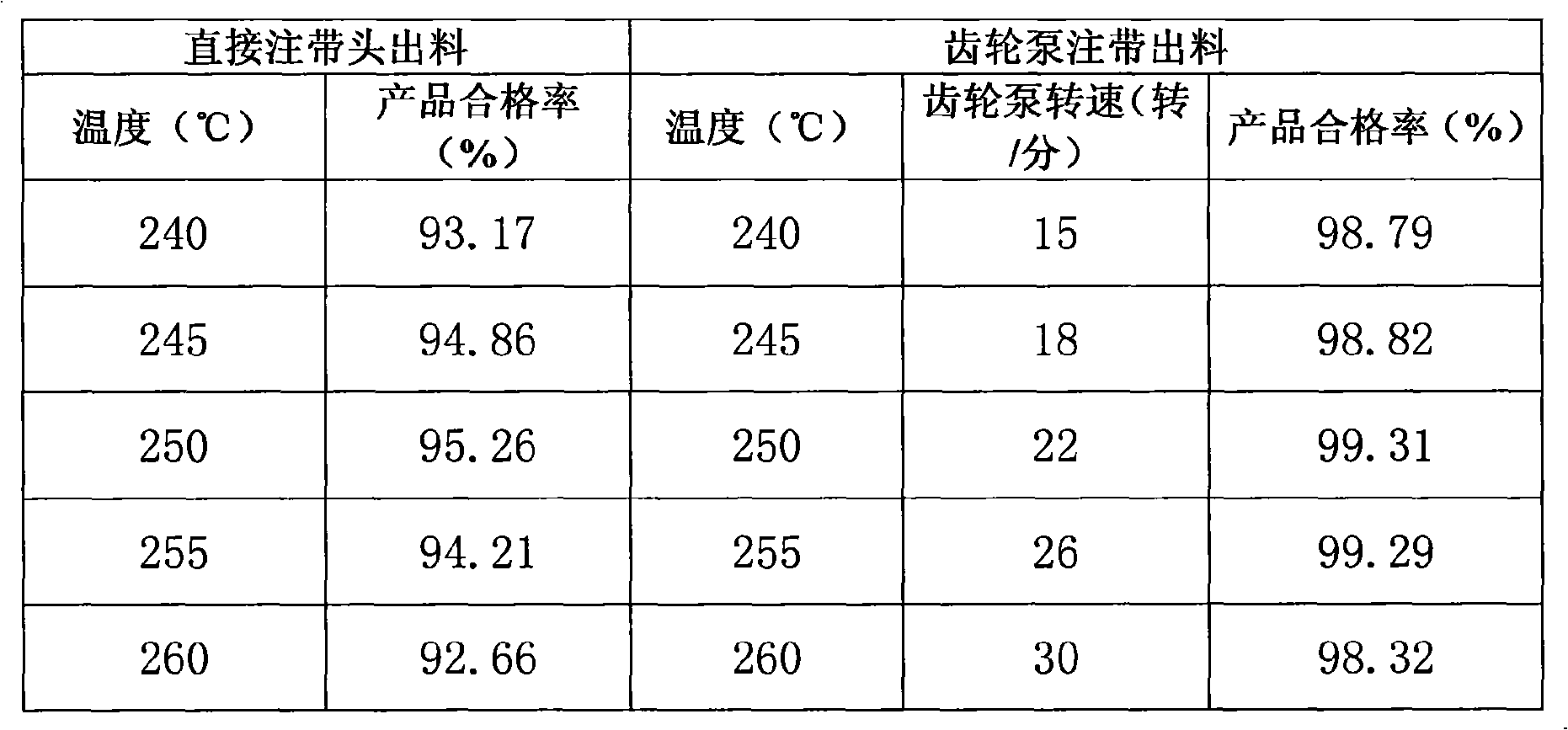

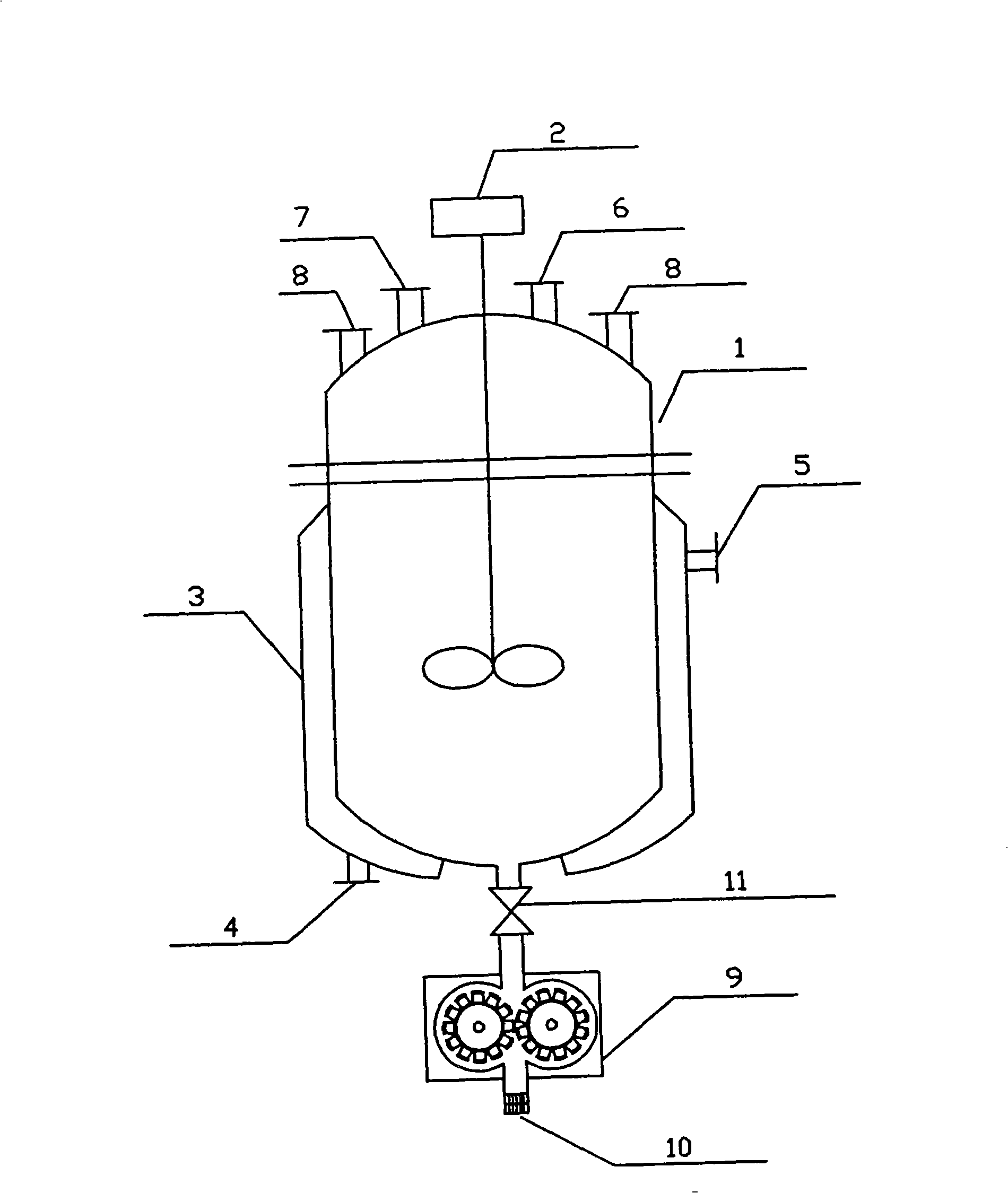

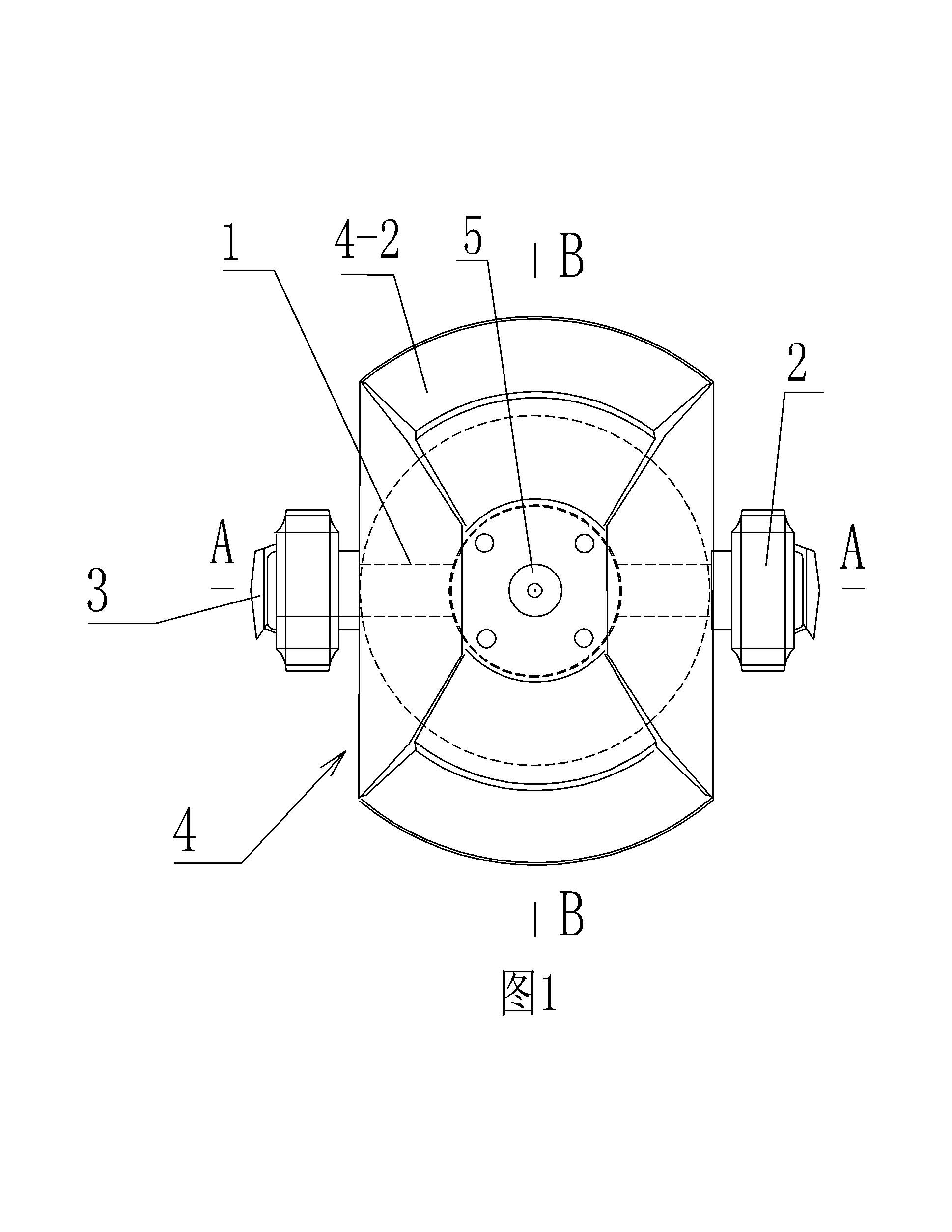

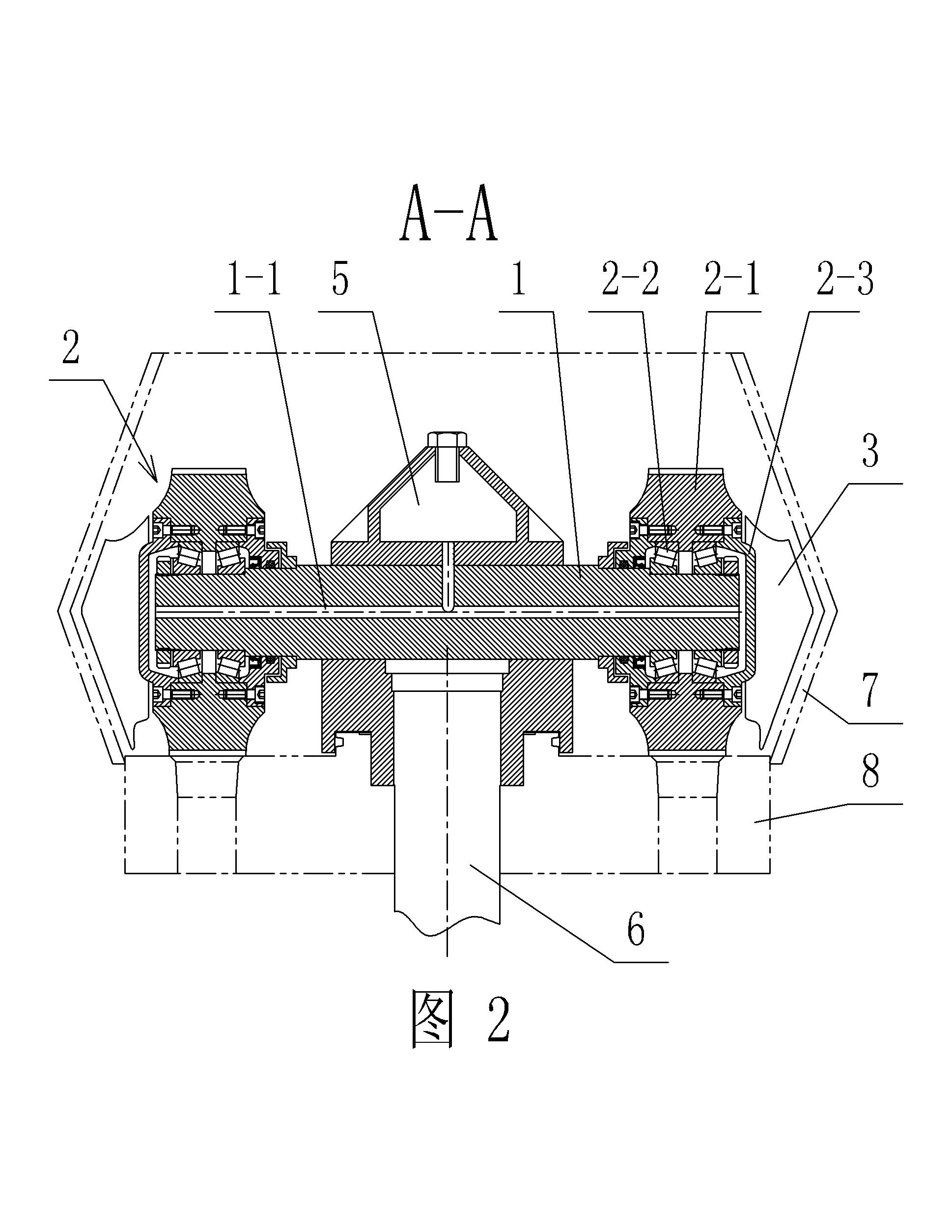

Strand spinneret discharge process for polymerization reaction of 11-amino undecanoic acid monomer

The invention belongs to the castor oil-producing nylon-11 engineering plastic manufacture technical field, in particular to a method for injecting belt discharging after 11-amino undecanoic acid monomer polymerization reaction. The method solves the problems that the prior poly-undecanoyl amine resin adopts the kettle type polymerization, a direct injecting belt head discharging device has low discharging speed, the discharging is not even, and is more viscous and difficult with the discharging time prolonged, the quality of the whole product is not balanced, and the maneuverability is bad, etc. In a polymerization kettle, the 11-amino undecanoic acid monomer is polymerized to generate the poly-undecanoyl amine resin at a temperature of between 230 and 260 DEG C, an injecting belt wheel pump is adopted to pressurize and the discharging injecting belt head produces the product; in the technique, the preserved temperature of the injecting belt wheel pump is between 240 and 260 DEG C, the rotating speed of the wheel pump is between 15 and 30 RPM. The method has the advantages that the discharging speed is high, the discharging is even, the problem of the difficult discharging in the later period is solved, the quality is balanced, the maneuverability is strong, the purchase and installation as well as use are easy, and the investment is saved.

Owner:山西宏远科技股份有限公司

Pressure roller device of fertilizer extrusion molding machine

The invention relates to a pressure roller device of a fertilizer extrusion molding machine, which comprises pressure roller shafts for vertically connected transmission with a dynamic spindle and a pair of pressure roller wheels respectively arranged at two axial ends of the press roller shaft. The device is characterized in that: the device also comprises a material distributing guiding device; the material distributing guiding device comprises a feed chute arranged above the pressure roller shafts and a pair of material distributing tanks which are respectively connected with the underneath of the left and the right sides of the a feed chute and staggeredly distribute with the two pressure roller wheels; a feed inlet is disposed above the feed chute; a spread groove plate used for relatively stationary connecting with the pressure roller wheels is arranged at the lower side of the feed chute; feed openings communicated with the upper notch of the material distributing tank are disposed at the right and the right sides of the feed chute; and the lower notch of the material distributing tank is arranged towards the trace rolled by the pressure roller wheels. The rotation of the pressure roller device allows the materials to be uniformly distributed on a rolling plate on the bottom of the housing cooperated with the pressure roller device, thereby not only reducing the clogging taking place in the fertilizer extrusion molding process, but also lightening the load of the pressure roller device.

Owner:厦工(三明)重型机器有限公司

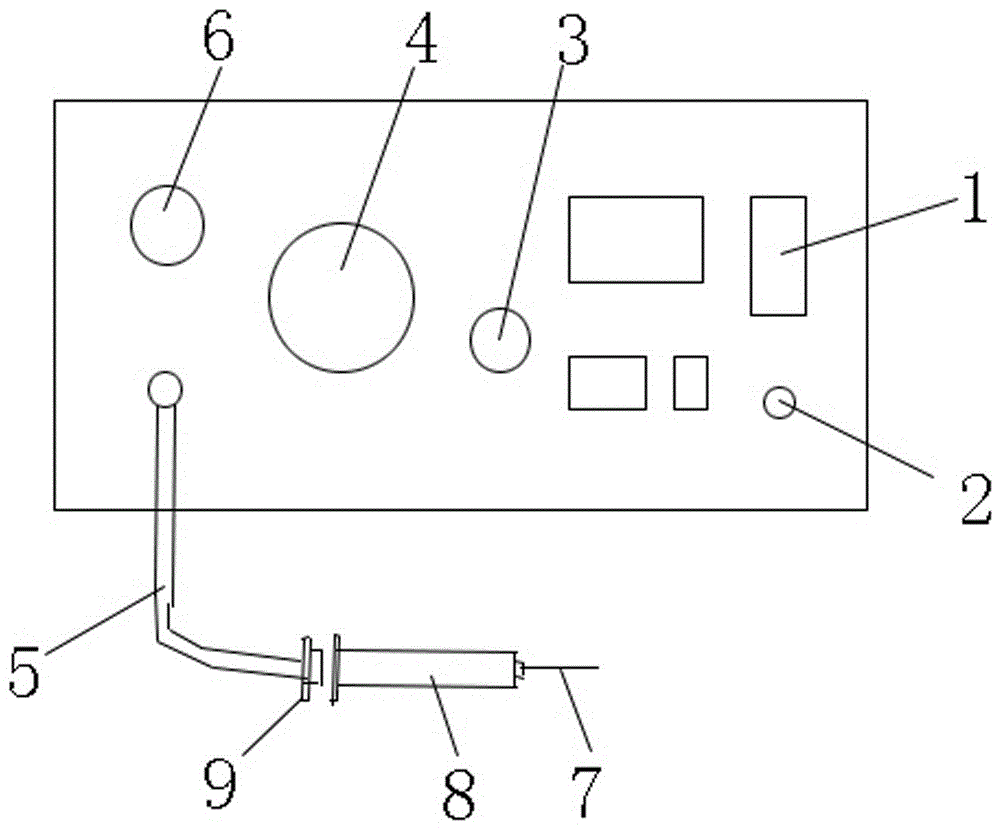

Vacuum brazing semi-automatic brazing material coating method and device

InactiveCN106735695AIncrease productivitySimple structureSoldering auxillary devicesSemi automaticGuide tube

The invention discloses a vacuum brazing semi-automatic brazing material coating method. The vacuum brazing semi-automatic brazing material coating method particularly comprises the following steps: 1) proportioning a brazing material, brazing glue and a diluent according to the ratio of (120-140):(20-30):1, stirring with a spoon and blending into paste; 2) charging: charging the blended brazing material into a medical injector; 3) preparing coating equipment: connecting a compressed air conduit, a transparent hose and a semi-automatic coating device; 4) debugging the coating equipment: starting the semi-automatic coating device, adjusting the pressure of the compressed air and enabling the brazing material to flow out slowly; 5) coating the brazing material: after the brazing material flows out stably, coating a part, which is to be coated with the brazing material, of a workpiece with the brazing material. During coating of the brazing material, the method is uniform and stable in discharging and simple to operate, the production efficiency of vacuum brazing is improved, the problems that the brazing material flows to block holes, the brazing quality is unqualified and the welding repair is conducted again are solved, and remarkable influence on improvement of the vacuum brazing quality is achieved.

Owner:GUIYANG AVIC POWER PRECISION CASTING

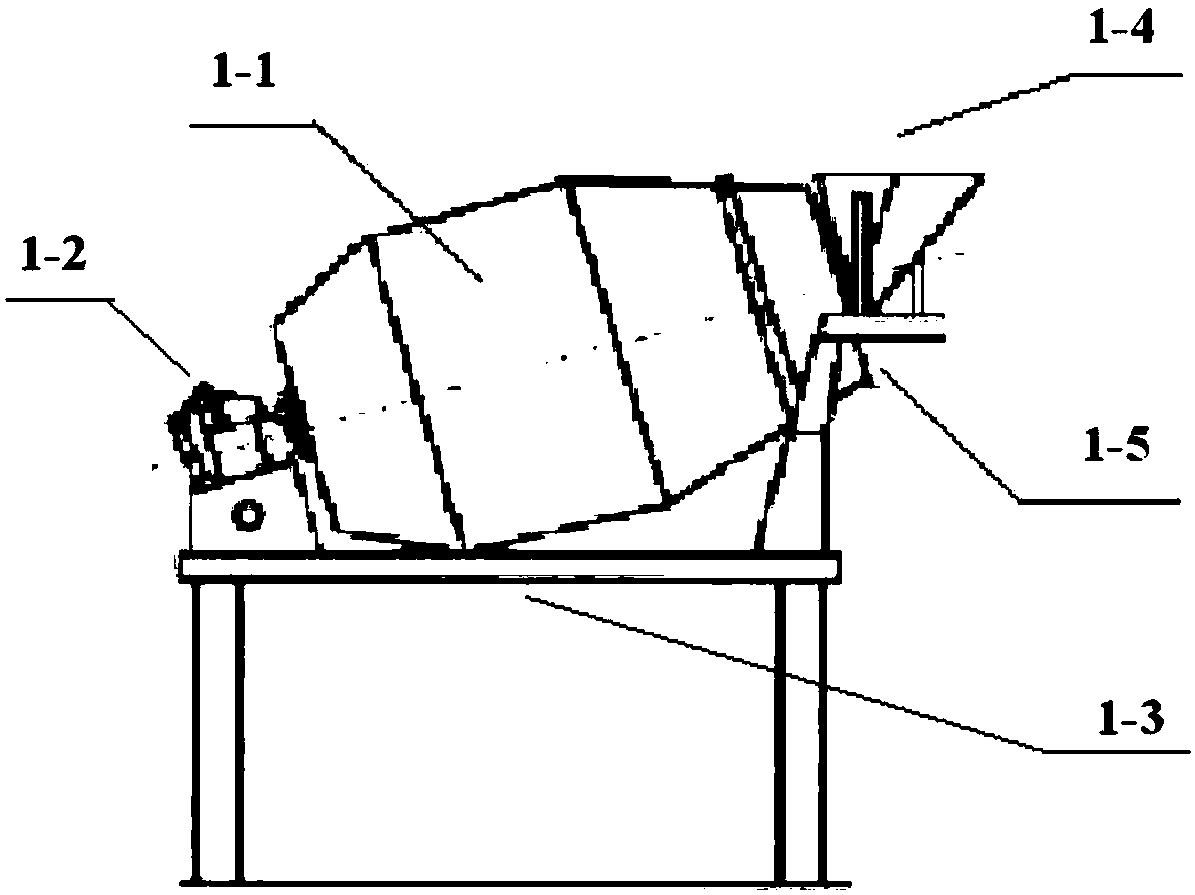

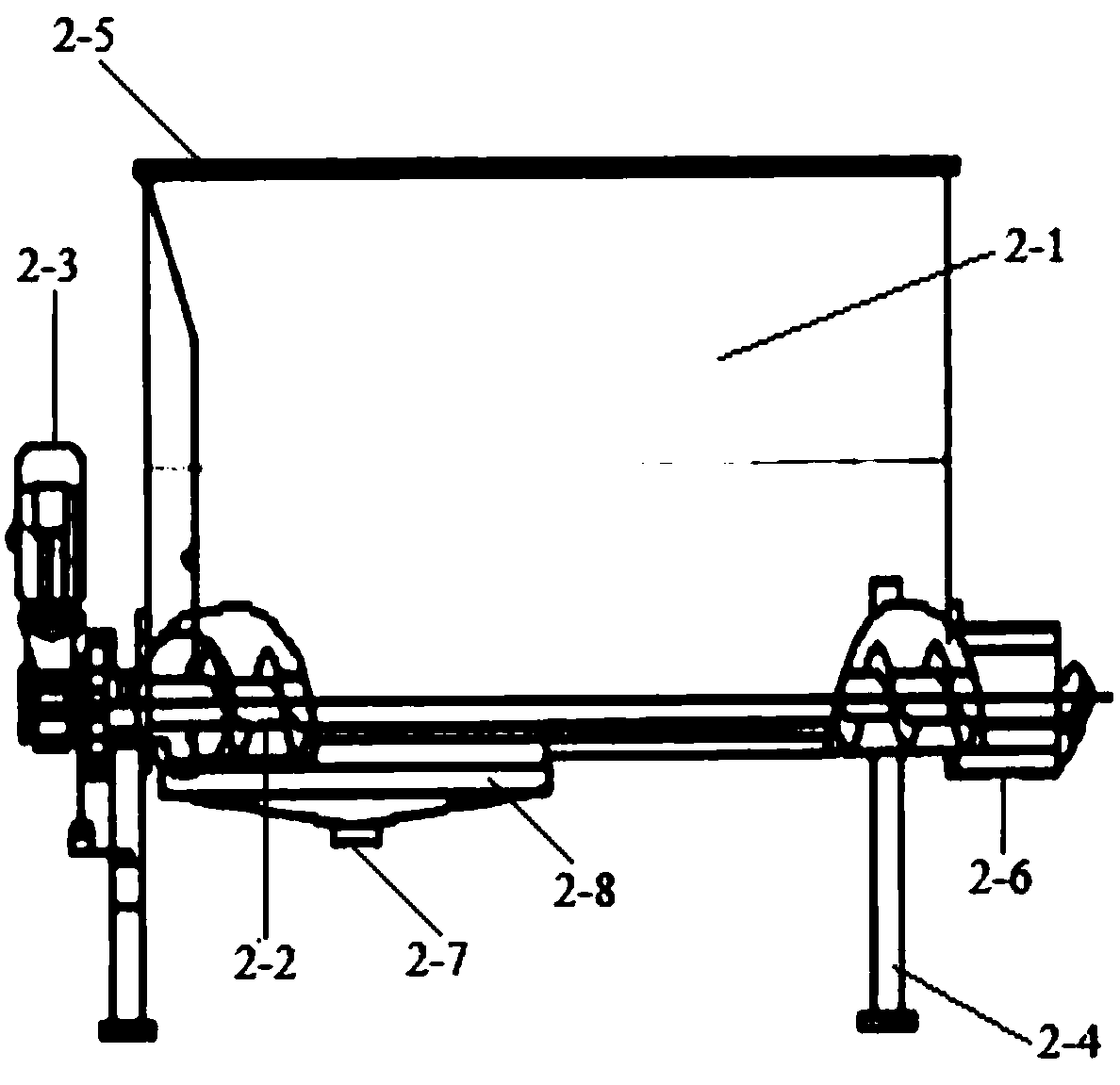

Mixing system for conveying gypsum powder

InactiveCN108890873AStir evenly and stablyReduce volatilityClay mixing apparatusClay processing apparatusReamerGypsum

The invention discloses a mixing system for conveying gypsum powder. The mixing system comprises a reamer machine, a mixing machine, a stirring unit and a conveying unit, wherein the reamer machine isused for conveying the gypsum powder; the mixing machine is used for mixing the gypsum powder with other raw materials; the stirring unit is used for scattering the gypsum powder with higher fluctuation quantity output by the reamer machine into the gypsum powder with smaller fluctuation quantity; the conveying unit is used for uniformly conveying the gypsum powder scattered by the stirring unitto the mixing machine. In the mixing system disclosed by the invention, the stirring unit is arranged for re-stirring and scattering the gypsum powder output by the reamer machine, so that the fluctuation quantity of the gypsum powder output by the reamer machine is eliminated; the conveying unit is arranged between the stirring unit and the mixing machine, so that the scattered gypsum powder canbe uniformly and stably conveyed into the mixing machine; the uniform stirring and stable discharging of the gypsum powder in the mixing machine are realized and the areal density of the produced gypsum board can be guaranteed.

Owner:NINGBO BEIXIN BUILDING MATERIAL +1

Device for growing optical-grade strontium titanate single crystal by flame fusion method

InactiveCN114059147AUniform and stable growthUniform and stable outputPolycrystalline material growthFrom frozen solutionsStrontium titanatePhysical chemistry

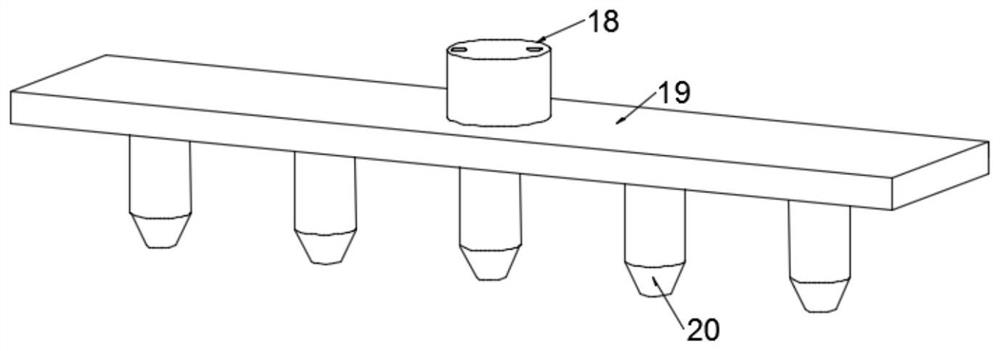

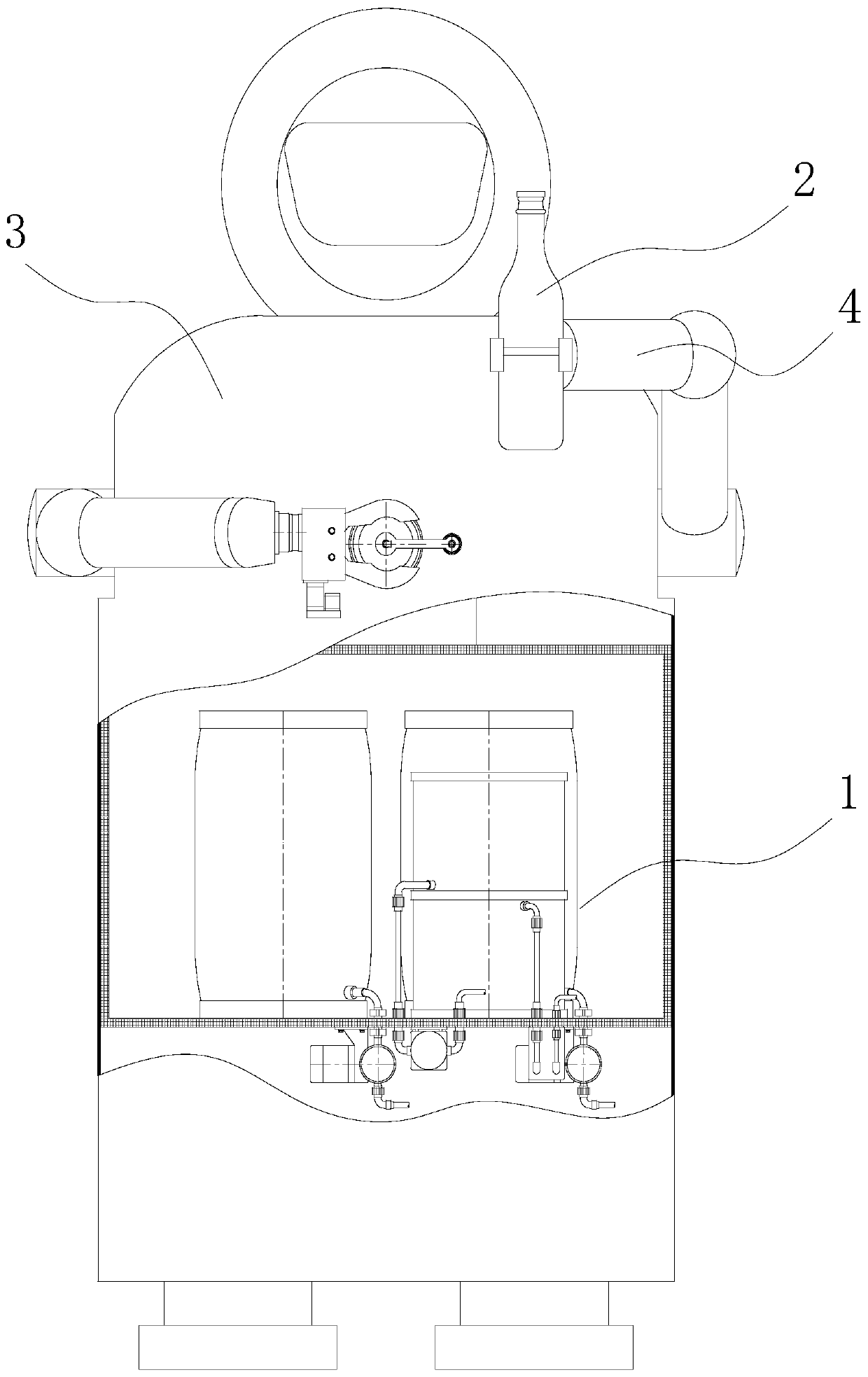

The invention discloses a device for growing an optical-grade strontium titanate single crystal by a flame fusion method. The device for growing an optical-grade strontium titanate single crystal by a flame fusion method comprises: a protection box; a reaction box, wherein the reaction box is arranged in the protection box, a partition plate is fixedly arranged in an inner cavity of the reaction box, a discharge barrel is arranged below the partition plate, a discharge opening for spraying materials is formed in the outer part of the discharge barrel, and a gas storage tank for storing gas is arranged at the top of the reaction box; a crushing cylinder, wherein a rotating rod is arranged in the crushing cylinder, crushing blades used for grinding materials are arranged outside the rotating rod, and the crushing cylinder communicates with the reaction box through a discharging pipe arranged at the bottom end; and a discharge mechanism which can spray gas from a discharge opening. According to the device for growing the optical-grade strontium titanate single crystal through the flame fusion method, powder is stirred and smashed through the crushing blades, powder and hydrogen are sucked into the reaction box at the same time and sprayed out from the discharge opening, and the device guarantees that the powder is discharged evenly and stably.

Owner:SHENYANG INST OF ENG

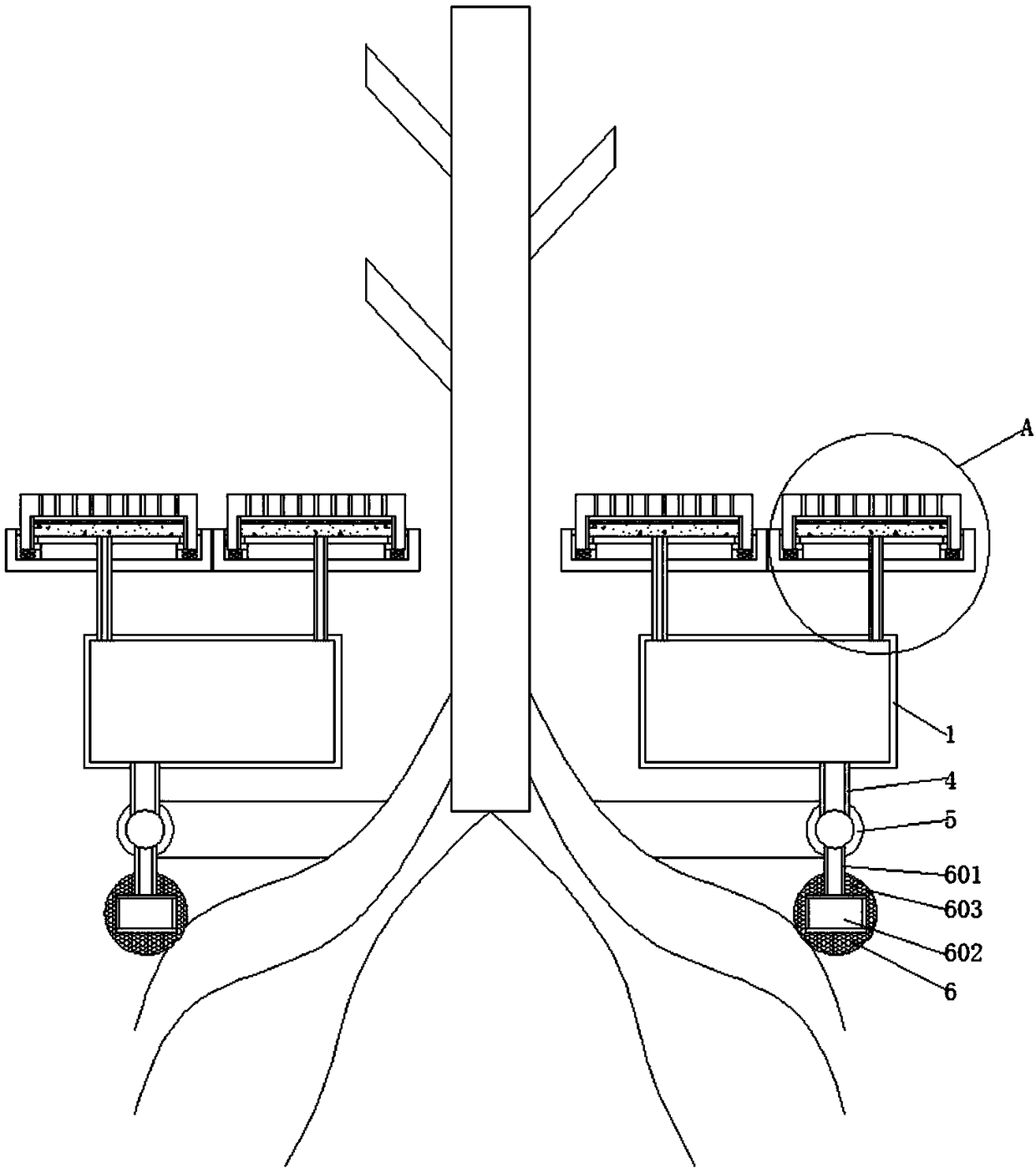

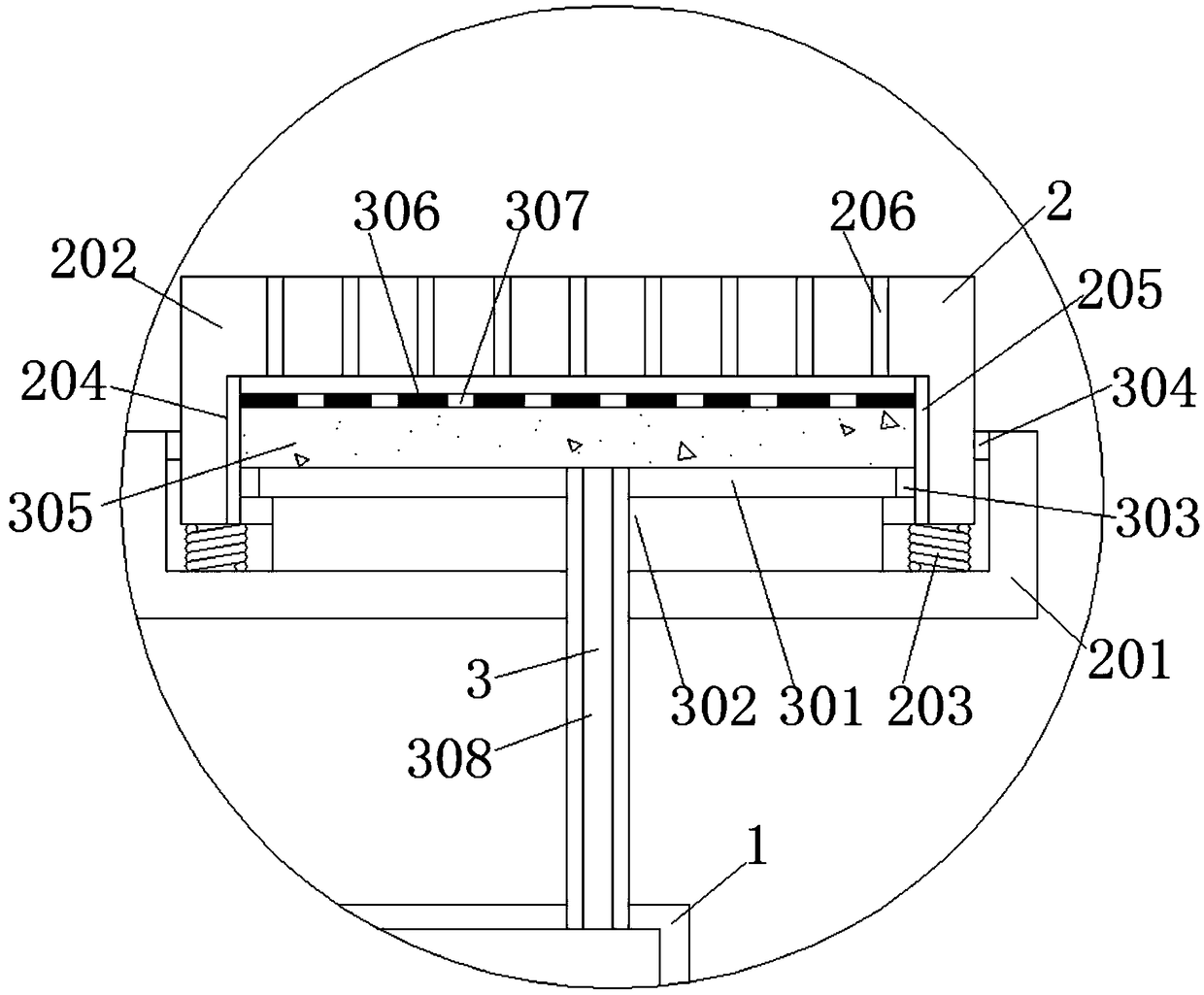

Municipal administration path sidewalk walking irrigation device

ActiveCN109169184AIncrease profitAbsorbentPaving gutters/kerbsWatering devicesWater storageEngineering

The invention provides a municipal administration path sidewalk walking irrigation device and relates to the municipal administration maintenance field. The municipal administration path sidewalk walking irrigation device comprises a water storage warehouse. A floor tile mechanism is arranged above the water storage warehouse. An extrusion device is arranged in the floor tile mechanism. The bottomof the water storage warehouse is connected to a connection pipe. One end of the connection pipe, which is far away from the water storage warehouse, is connected to an annular pipe. The external surface of the annular pipe is connected to an irrigation device. By using the municipal administration path sidewalk walking irrigation device, through laying the floor tile mechanism on sidewalk ground, during a raining process, rainwater enters into a cylinder barrel through a downflow hole and passes through a water storage sponge set in the cylinder barrel; the water storage sponge can absorb water so as to collect the rainwater; and after the rainwater is collected, the rainwater can be stored so that a rainwater utilization rate in a dry area can be increased.

Owner:无锡市正丰建设工程有限公司

Novel anti-blocking mixer with good sealing effect

InactiveCN110064327AImprove sealingWell mixedTransportation and packagingRotary stirring mixersEngineering

The invention relates to the technical field of mixers, and discloses a novel anti-blocking mixer with a good sealing effect. The mixer comprises an outer box body, a water chamber is fixedly connected to the inner wall of the outer box body, an inner box body is fixedly connected to the inner wall of the water chamber, a water inlet one end of which runs through the outer box body and extends tothe exterior of the outer box body is fixedly connected to the top of the right side of the water chamber, water outlets are fixedly connected to the left and right ends of the bottom of the water chamber, one end of each water outlet runs through the outer box body and extends to the exterior of the outer box body, a servo motor is fixedly connected to the top of the outer box body, and an outputshaft of the servo motor penetrates through the inner box body, extends to the interior of the inner box body and is fixedly connected with a driving gear. The novel anti-blocking mixer with the goodsealing effect has the advantages of blocking prevention and good sealing performance, the service life of the mixer is prolonged, the efficiency of mixing materials is improved, dust does not easilyenter the mixer, finished products obtained after mixing is completed cannot be influenced, and the mixer is convenient to use.

Owner:YANGZHOU HAICHENG BIOTECH CO LTD

Continuous variable transmission with uniform input-to-output ratio that is non-dependent on friction

ActiveCN106662230AEven and stable inputUniform and stable outputFriction gearingsHigh torqueHeavy duty

Owner:R R 拉金德兰 +1

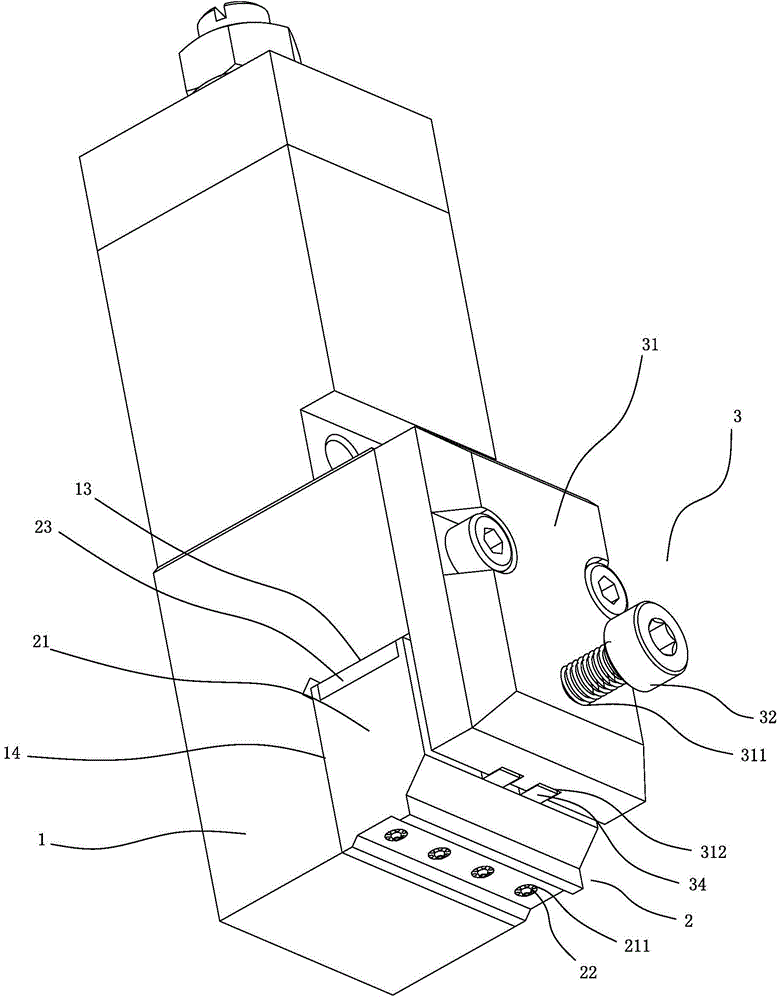

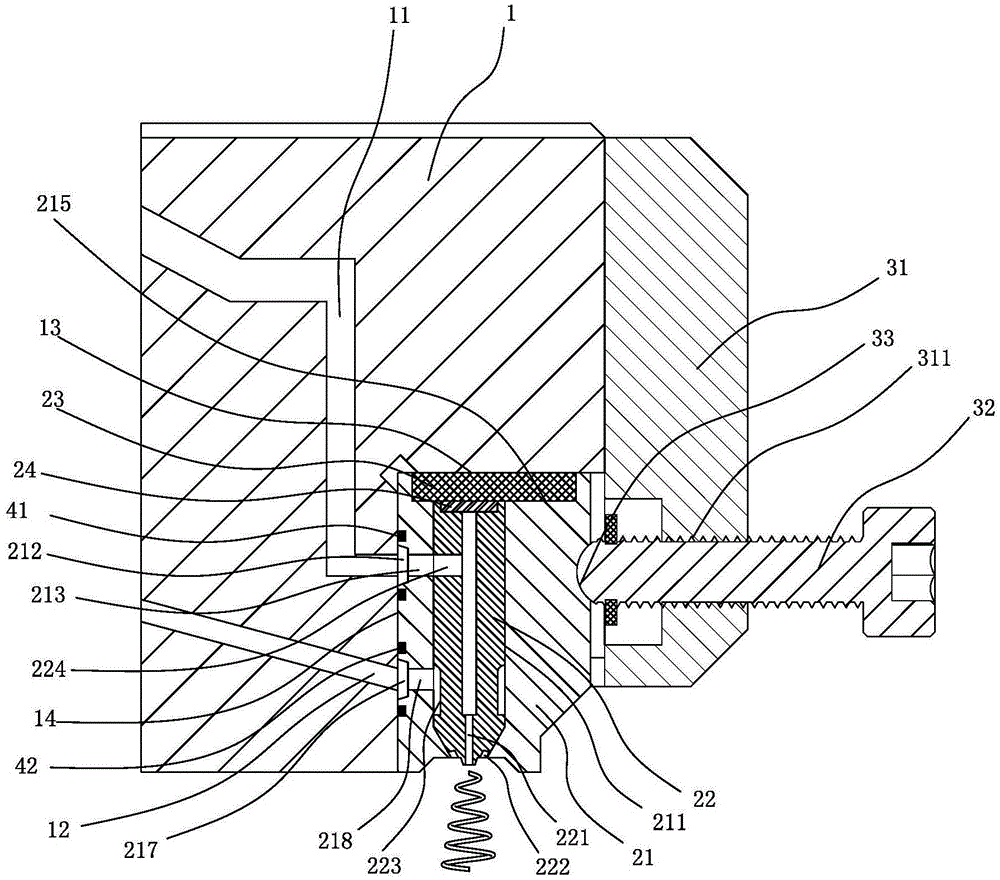

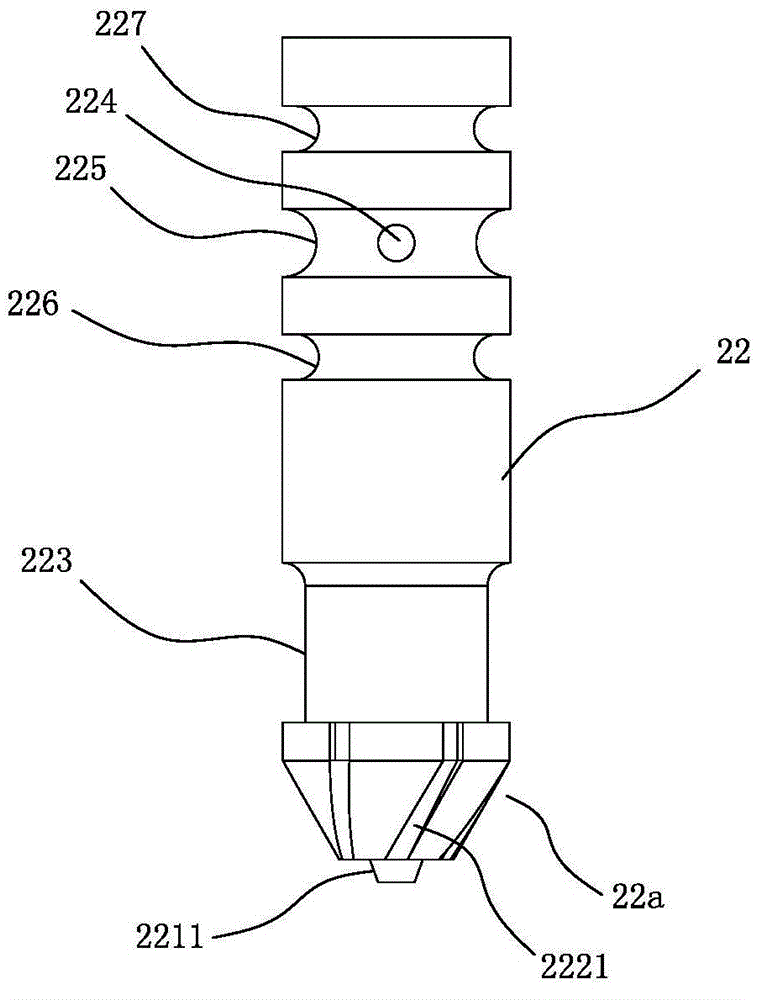

High-precision hot melt glue nozzle and hot melt glue gun

InactiveCN104399645ASimple processingHigh precisionLiquid surface applicatorsCoatingsAirflowHot-melt adhesive

The invention discloses a high-precision hot melt glue nozzle. The high-precision hot melt glue nozzle is mounted on a glue gun body; the glue gun body is provided with a solution supply channel and a gas supply channel; the high-precision hot melt glue nozzle comprises a nozzle body and a core body, wherein a containing hole penetrating the upper and lower parts of the nozzle body is formed inside the nozzle body; the core body is matched with the containing hole and is closely embedded in the containing hole; a glue solution channel with an opening in the lower end surface of the core body is formed inside the core body; at least two gas channels extending to the lower end surface of the core body are formed in the peripheral surface of the core body; a gas channel is formed between the gas channel and the wall of the containing hole. The glue solution channel and the solution supply channel are communicated for outputting an glue solution line during operation, the gas channel and the gas supply channel are communicated for outputting gas flow, the glue solution line is output in a specific shape under the action of the gas flow, and the machining of the gas channel can adopt a mode of milling a groove in the conical peripheral surface of the core body to replace the traditional drilling mode, so that the formation mode of the gas channel is more accurate and efficient than the traditional drilling technology.

Owner:QUANZHOU NDC SPRAY COATING SYST FABTING

Fluid material storing and conveying system and method adopting power fluid membrane tank drive

ActiveCN111637043AReduce temperature riseStable jobPositive displacement pump componentsFlexible member pumpsEngineeringPower apparatus

The invention discloses a fluid material storing and conveying system and method adopting power fluid membrane tank drive. The storing and conveying system comprises a membrane tank and a power device. The membrane tank is internally provided with a membrane for dividing the tank into a power cabin and a material cabin. One end of the power device is connected with a power medium storage system, and the other end of the power device communicates with the power cabin through a power pipe. The power cabin is connected with the power medium storage system through a backflow pipe. The material cabin is provided with a feeding port and a discharging port.

Owner:济南新材料产业技术研究院

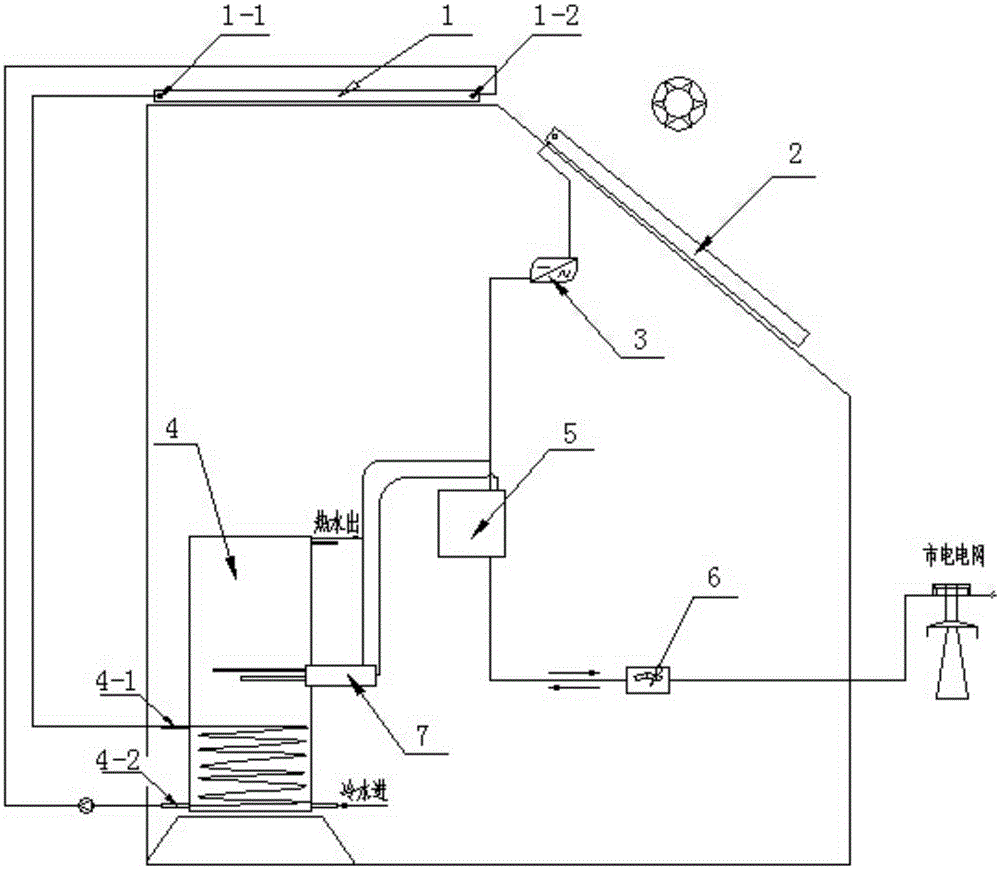

Photovoltaic surplus power auxiliary heating type solar water heater

InactiveCN105066467AEffectively balanced electrical outputIncrease profitSolar heat devicesPhotovoltaicsElectronic controllerElectric power system

The invention discloses a photovoltaic surplus power auxiliary heating type solar water heater which comprises a photo-thermal system and a photovoltaic system. The photo-thermal system comprises a solar thermal collector and a solar water heating tank which are communicated through a pipeline. The photovoltaic system comprises a solar photovoltaic panel, a photovoltaic inverter, a power-provided control type electronic controller and an electric heating type electronic controller. The solar photovoltaic panel is electrically connected with the photovoltaic inverter which is electrically connected with the electric heating type electronic controller and the power-provided control type electronic controller. The electric heating type electronic controller and the power-provided control type electronic controller are electrically connected. An electric heating function hole is formed in the solar water heating tank, and the power-provided control type electronic controller is arranged on the electric heating function hole. The photovoltaic surplus power heat assisting type solar water heater can effectively balance photovoltaic power output, the auxiliary heating purpose of the photo-thermal system can be achieved, electric power generated by the photovoltaic system can be stably output into a power grid in balance, and impact of photovoltaic electricity to the power grid is avoided.

Owner:无锡环特太阳能科技有限公司

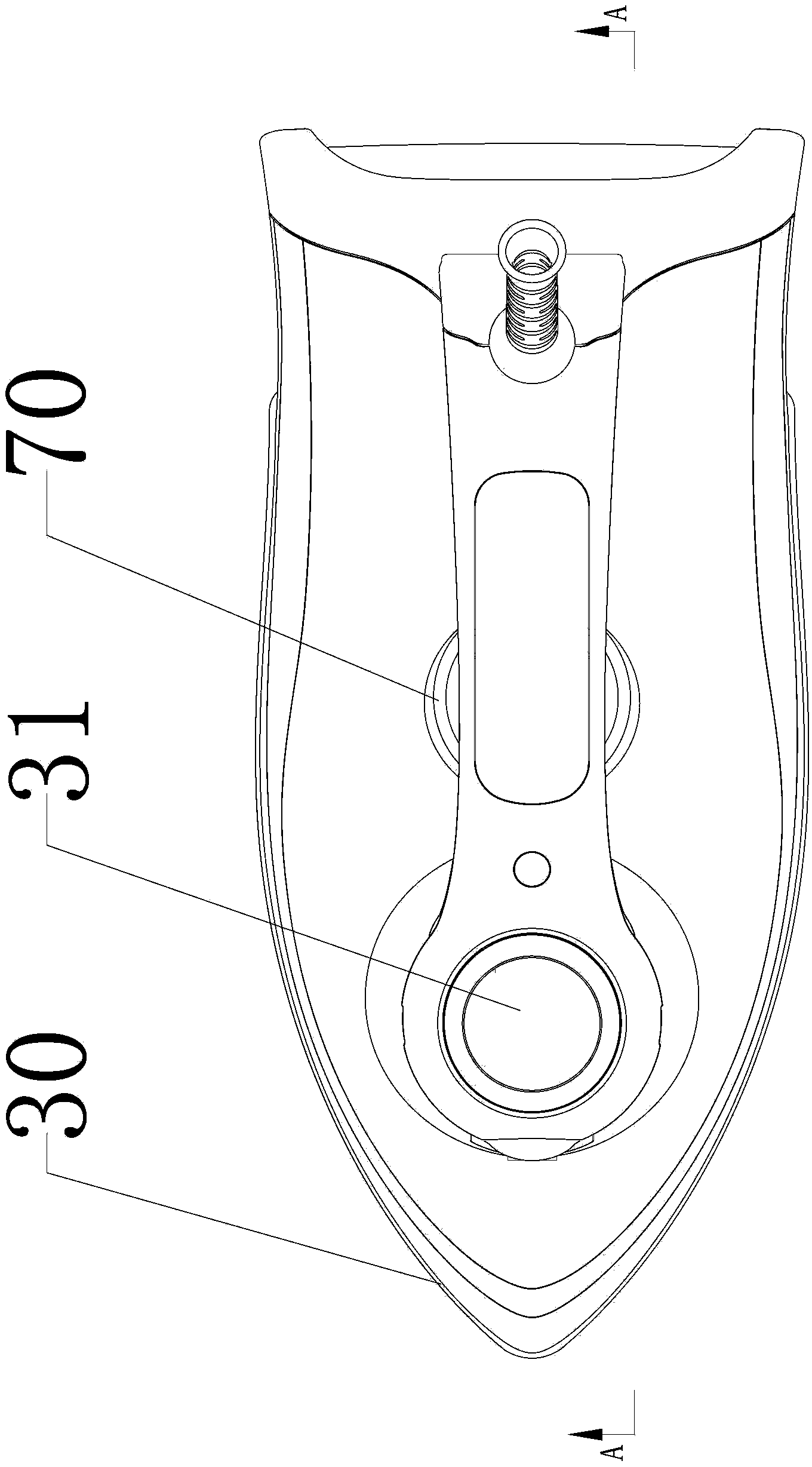

Tension-controllable weft storage unit

The invention discloses a tension-controllable weft storage unit which comprises a shell, a tension control mechanism and a fixing device, wherein the tension control mechanism and the fixing device are arranged in the shell; the tension control mechanism is arranged in the fixing device, and comprises a yarn nose seat, a tension spring device and a sleeve; the tension spring device and the sleeve are arranged in the yarn nose seat; the tension spring device comprises a tension spring, a push plate and a fixing seat; the push plate is fixed at the left side of the tension spring; the fixing seat is fixed at the right side of the tension spring; the fixing device comprises a fixing disk, a positioning tray and a pressing crank; a fixing base plate is arranged in the shell; a moving rail is arranged on the fixing base plate; a heat dissipation groove is formed in the right side of the shell. The tension-controllable weft storage unit is high in practicability, so that the stability of the weft storage unit during working is improved; meanwhile, the tension control effect is guaranteed, the whole process is convenient to operate, the effect is obvious, and the working efficiency is improved.

Owner:苏州迪久纺织有限公司

Mixer improving structure facilitating increasing of discharging speed

InactiveCN104772063AAvoid cloggingUniform and stable outputRotating receptacle mixersTransportation and packagingHydraulic cylinderMixed materials

The invention relates to a mixer improving structure facilitating the increasing of discharging speed. The mixer improving structure facilitating the increasing of the discharging speed comprises fixed bases which are symmetrically arranged, wherein a horizontal plate is arranged between the fixed bases; fixed plates are arranged on the fixed bases; a mixing silo is arranged between the two fixed plates by virtue of a rotating shaft; a material inlet is formed in one end of the mixing silo and a material outlet is formed in the other end; the output end of the rotating shaft is matched with a motor by virtue of a gear rack; a hydraulic cylinder which is matched with the mixing silo is arranged on the horizontal plate; the output end of the hydraulic cylinder forms an included angle being 45 degrees together with the horizontal plate; and a clamping block which is matched with the sidewall of the mixing silo is arranged at the output end of the hydraulic cylinder. According to the improved structure disclosed by the invention, the discharging inclination degree of the mixing silo can be controlled by setting the hydraulic cylinder, so that the discharging speed of mixed materials can be controlled, uniform and sable discharging can be guaranteed, and the blockage of the mixed materials on the material outlet due to direct sliding down in a perpendicular direction can be avoided.

Owner:SICHUAN PHARMA

Ultralow-concentration flowing gas distribution system and gas distribution method

ActiveCN113607882AImprove controllabilityImprove the problem that the gas concentration is not uniform enoughEvaporator accessoriesPreparing sample for investigationThermodynamicsDistribution control

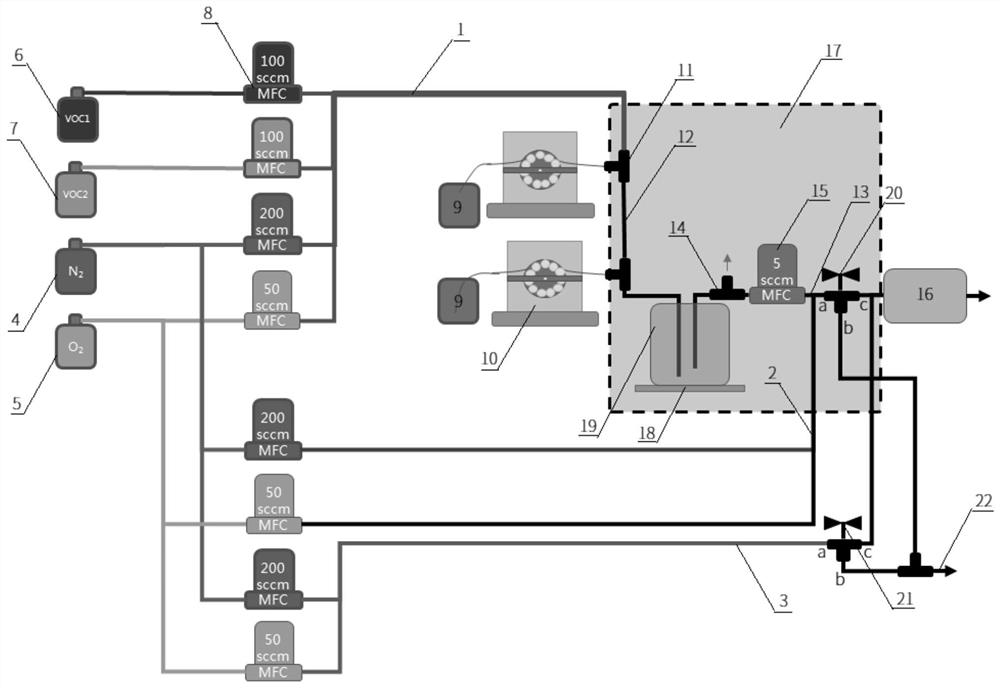

The invention discloses an ultralow-concentration flowing gas distribution system and method. The system is characterized in that the system comprises the following modules of: a gas mass flow control module which is used for controlling background gas and test gas to enter the system at a certain mass flow; a volatile organic compounds (VOCs) injection control module used for injecting liquid VOCs into a pipeline at a certain flow rate; a gas distribution control module which comprises a heating device for vaporizing the liquid VOCs, a constant temperature device for keeping the temperature and a secondary gas distribution device for the test gas; and a main control module which is connected with the gas mass flow control module so as to be used for controlling the mass flow of the background gas and the test gas, is connected with the VOCs injection control module so as to be used for controlling the opening, closing and flow velocity of liquid VOCs injection, is connected with the VOCs distribution control module so as to be used for controlling heating and constant temperature, receiving feedback data and controlling the concentration of secondary gas distribution. According to the ultralow-concentration flowing gas distribution system and gas distribution method, gas and liquid can be blended into any ppb-level test gas with an ultralow concentration value, the gas is distributed in a real-time flowing manner, the control is accurate, the gas distribution is accurate, and the stability is good.

Owner:NINGBO UNIV

Multi-variety beverage feeding system and multi-variety beverage feeding method

InactiveCN110960092AEnsure mutual independenceAvoid mutual contaminationBeverage vesselsManipulatorWater storage tankProcess engineering

The invention relates to a multi-variety beverage feeding system and a multi-variety beverage feeding method. The system comprises a storage device and a discharging device which are connected; a clear water storage tank, a waste water storage tank and at least two beverage storage tanks are arranged in the storage device, and a cleaning mechanism, a waste water through hole and at least two beverage guide pipes are arranged in the discharging device; the cleaning mechanism is connected with the outlet end of the clear water storage tank, the waste water through hole is connected with the inlet end of the waste water storage tank, and each beverage guide pipe is correspondingly connected with the outlet end of one beverage storage tank. According to the method, a plurality of storage tanks, beverage guide pipes and cleaning mechanism are arranged, and different beverages are output according to beverage varieties selected by a user. According to the invention, the discharging switchingamong various different beverages can be realized, and the discharging space is cleaned firstly when different types of beverages are switched, so that the different types of beverages are ensured tobe mutually independent, the cleanliness of the beverages is effectively ensured, and the mutual pollution among different types of beverages is avoided.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

Continuous variable transmission with uniform input-to-output ratio that is non-dependent on friction

ActiveUS9970520B2Easily integrated into any systemUniform and stable outputFriction gearingsTransmitted powerAngular velocity

A continuously variable transmission (CVT) that does not depend on friction to transmit power. A constant and uniform output angular velocity can be achieved when the input angular velocity is constant and uniform by modifying the rate of change of angular displacement of the input disk using a set of non-circular gears. Co-axial input and output can also be achieved.

Owner:RAJENDRAN RAJA RAMANUJAM +1

Lithium battery material powder conveying pump

PendingCN113417864AGuaranteed durabilityExtended service lifeSpecific fluid pumpsPump componentsImpellerBall bearing

The invention relates to the field of lithium battery processing equipment, in particular to a lithium battery material powder conveying pump. The lithium battery material powder conveying pump comprises a power mechanism, a transmission mechanism and a pump body. The power mechanism comprises a motor and a base. The transmission mechanism comprises a bearing pedestal, a coupler, a main shaft and two sets of deep groove ball bearings. The pump body comprises an outer barrel, a mechanical seal, an impeller and a barrel rear cover. The overall structure in a grinding machine form is matched with the impeller for feeding, liquid powder can be continuously conveyed, materials are finer and more uniform through stirring and shearing of the impeller in the conveying process, and durability of the whole structure is guaranteed.

Owner:GUANGZHOU HONGKAI MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com