Vacuum brazing semi-automatic brazing material coating method and device

A brazing material, semi-automatic technology, applied in auxiliary devices, welding equipment, metal processing equipment, etc., to achieve the effects of low manufacturing cost, reduced flow and hole plugging, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

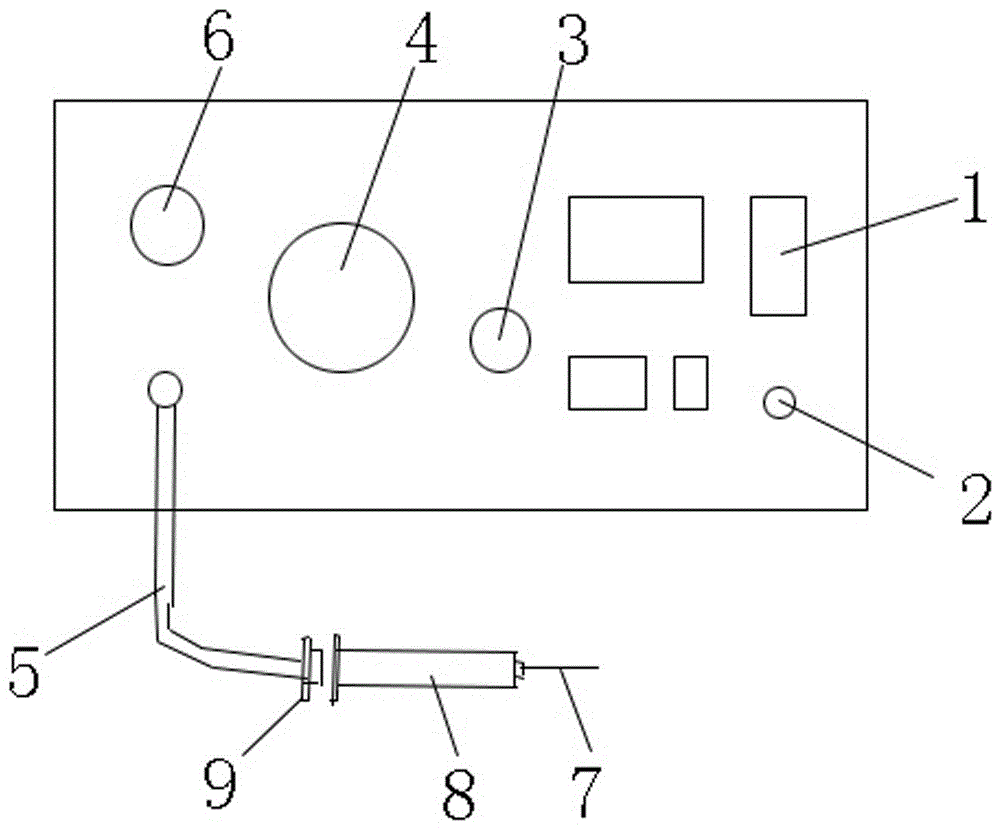

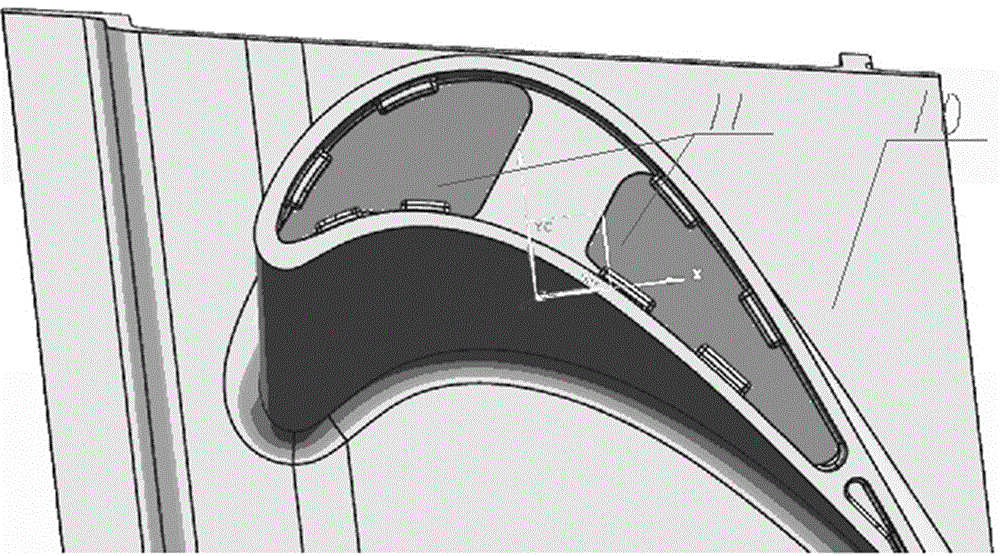

[0027] see figure 2 First, with the part 10 to be coated with brazing material as the main body, the brazing top cover 11 is installed on the corresponding position on the part 10; secondly, the prepared brazing material is placed in the medical syringe 8, and the syringe is used to Tighten the interface 9; again, turn on the switch 1 of the semi-automatic coating equipment, connect the compressed air pipeline to the compressed air inlet 2, adjust the compressed air adjustment knob 3 to the process range, and then adjust to the required pressure through the compressed air fine-tuning knob 6. The compressed air outlet 5 is connected to the parts for applying brazing material; finally, after the brazing material at the tip outlet 7 of the brazing material is uniformly and stably discharged, the installed brazing top cover 11 can be applied. And apply in a clockwise / counterclockwise direction along the perimeter of the top cover.

[0028] Through the application of precision di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com