Tension-controllable weft storage unit

A technology of weft feeder and tension control mechanism, which is applied in the direction of weaving, textiles, papermaking, looms, etc., to achieve the effect of maintaining continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

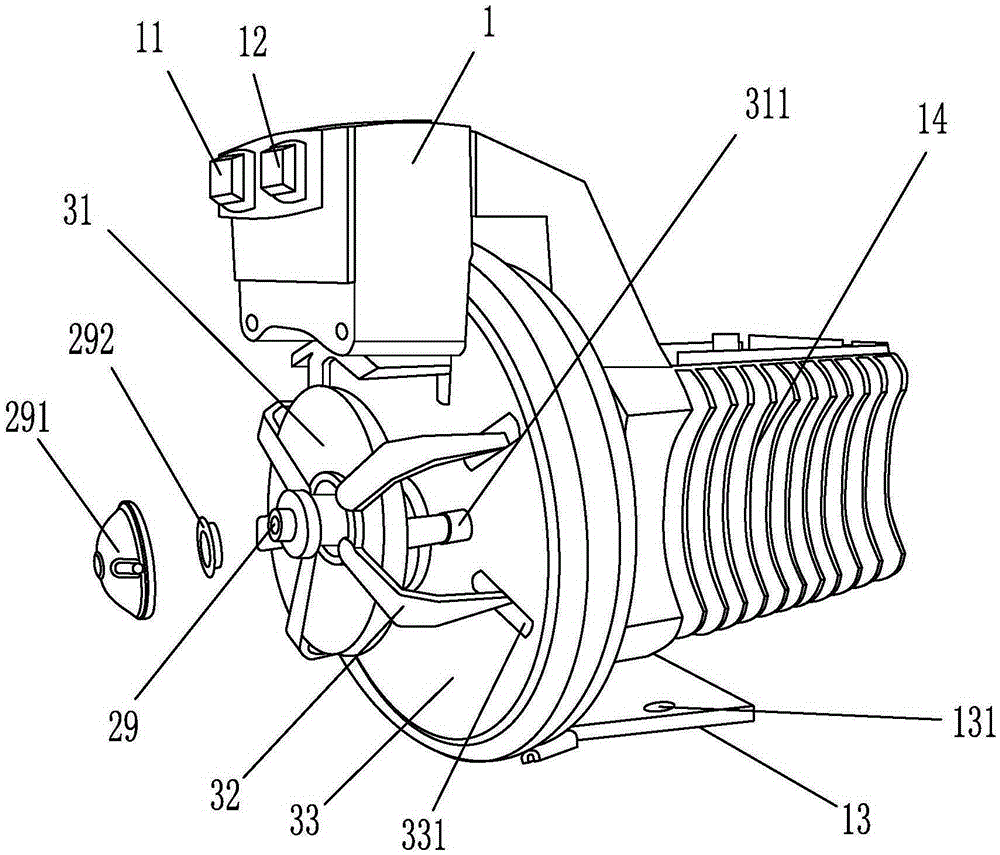

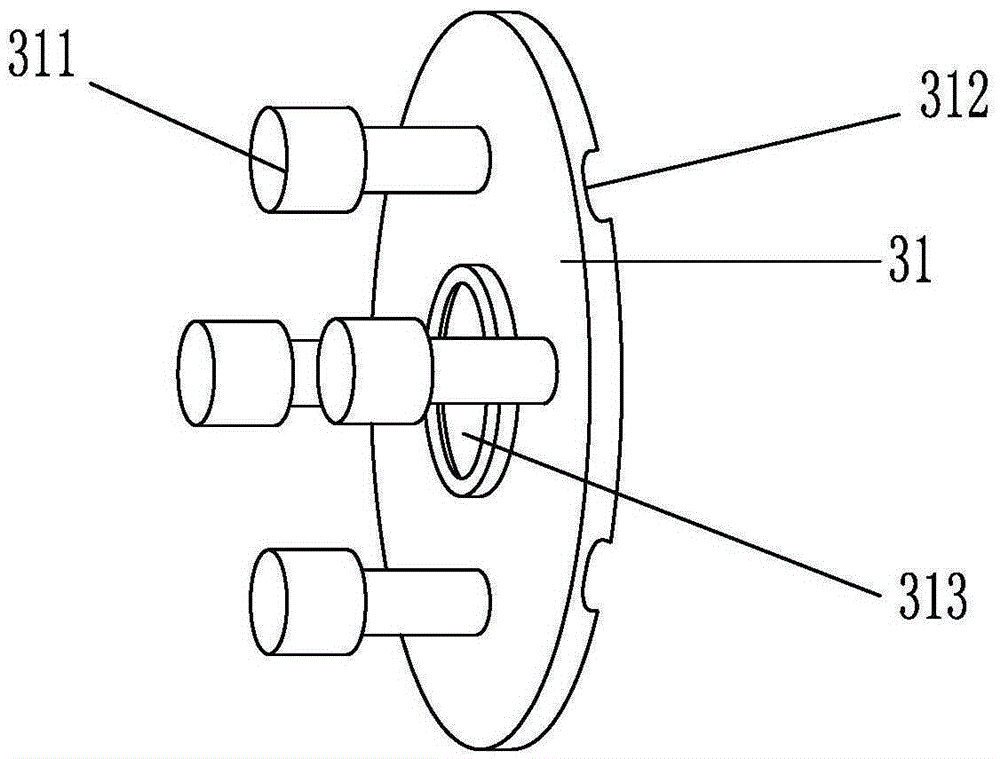

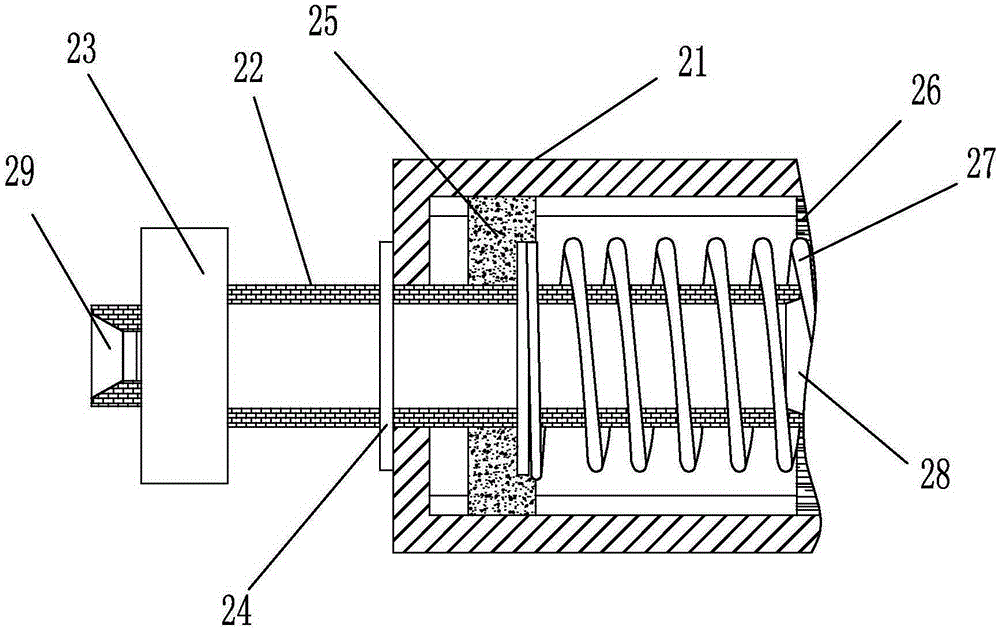

[0028] Such as Figure 1 to Figure 5 As shown, a tension controllable weft feeder includes a casing 1, a tension control mechanism and a fixing device. The casing 1 is provided with a tension control mechanism and a fixing device, and the fixing device is provided with a tension control mechanism and a tension control mechanism. It includes a yarn nose seat 21, a tension spring device and a sleeve 22. The yarn nose seat 21 is equipped with a tension spring device and a sleeve 22. The left side of the sleeve 22 is provided with a limit block 23. By setting the limit block 23, you can The positioning tray 31 is moved between the stop block 23 and the fixed disk 33 to prevent the positioning tray 31 from being separated during the adjustment process, and to ensure the position movement range of the positioning tray 31. A pressure sensor is connected to the sleeve 22, and the internal tension of the sleeve 22 can be obtained through the pressure sensor. At the same time, it can coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com