Screw feeder for underwater coarse mineral particles

A screw feeder and coarse particle technology, applied in packaging and other directions, can solve the problems of unbalanced internal and external pressure, easy blockage of coarse particle materials, and inability to uniformly and stably convey, so as to reduce wear and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

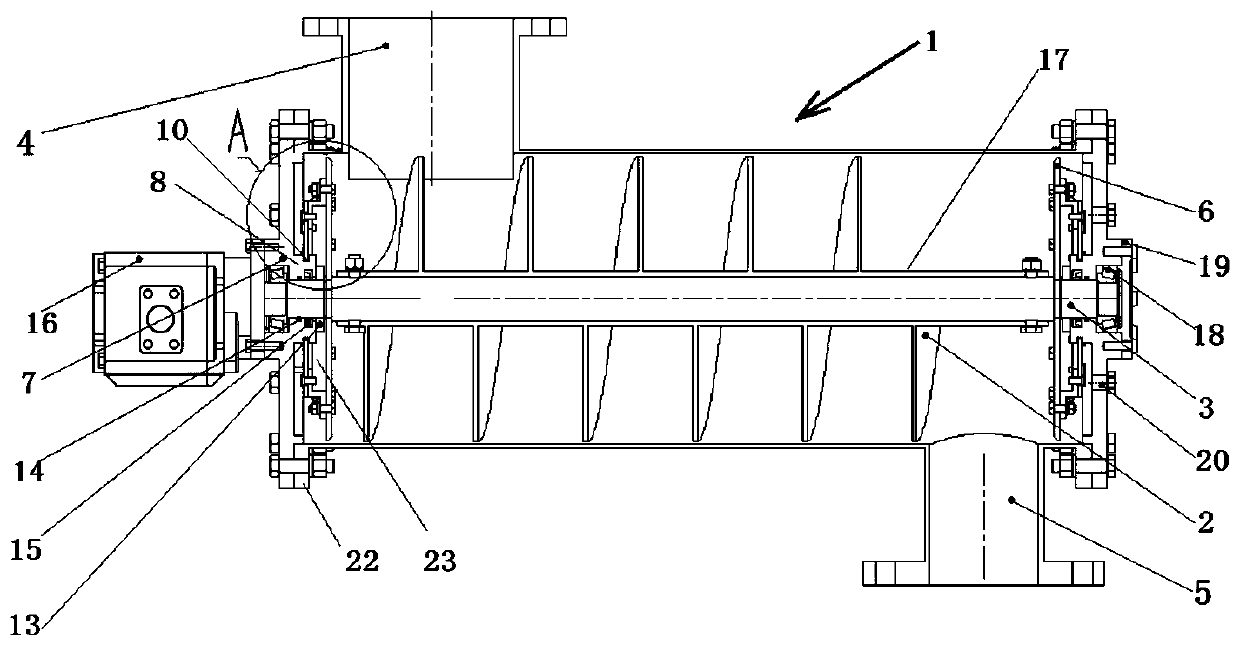

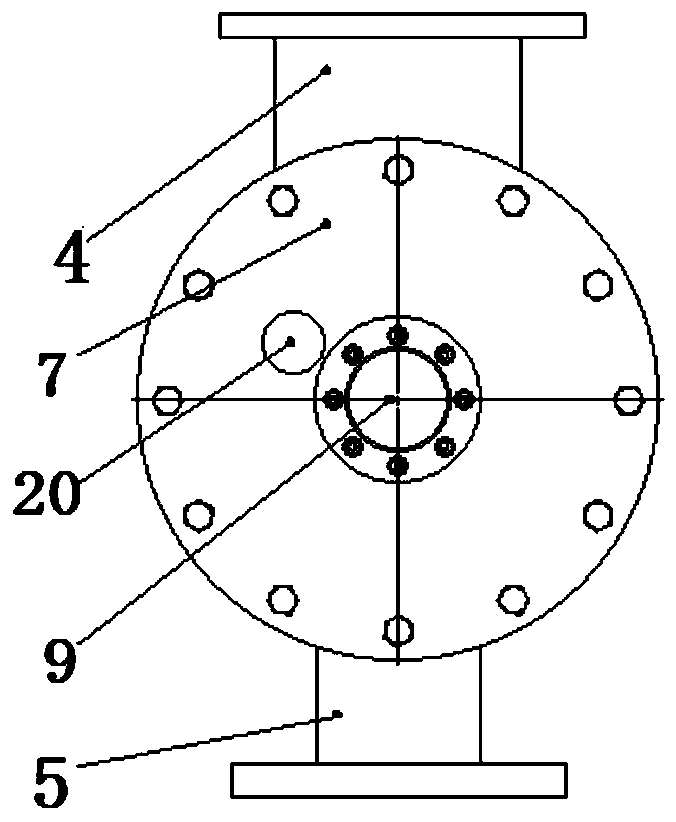

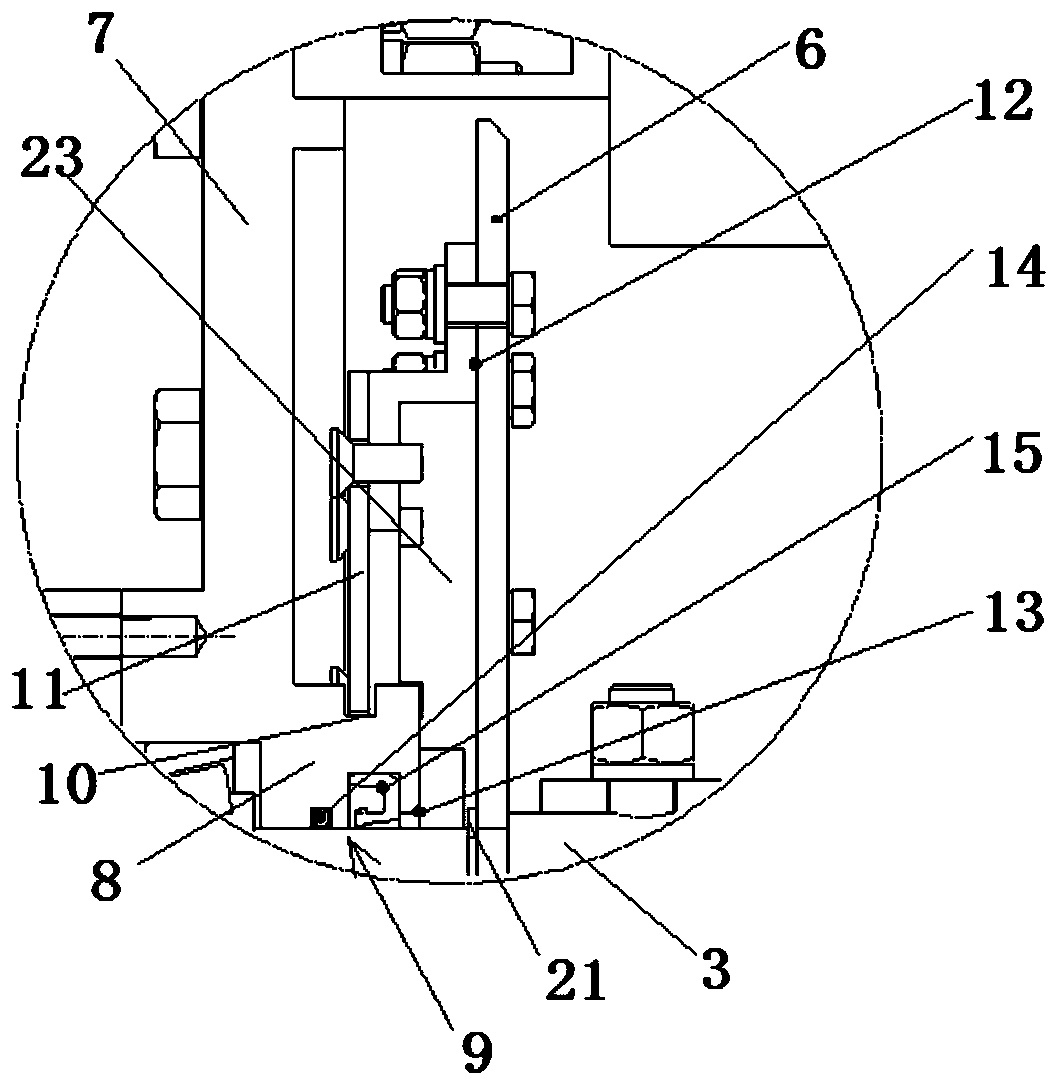

[0029] like Figure 1-Figure 3 As shown, the present invention discloses an underwater coarse-grained mineral screw feeder, which includes a cylinder body 1 and a rotating shaft 3 with a spiral blade 2 arranged in the cylinder body 1, wherein the cylinder body 1 is a welded structural member, Both ends are open, and its edge is provided with a flange 22 that is fastened and sealed with the end cover 7 by bolts. , the outer wall of the cylinder at both ends of the cylinder 1 is provided with a feed port 4 and a discharge port 5, wherein the discharge port 5 is connected to the lift pump, and the feed port 4 is connected to the crusher. In this embodiment, the feed port 4 is connected to the crusher. The inner diameter of the feed port 4 is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com