Mixer improving structure facilitating increasing of discharging speed

A technology of discharging speed and mixer, which is applied to mixers with rotating containers, mixers, mixer accessories, etc., can solve the problem of easy blockage of the discharge port, and achieve the purpose of ensuring discharge, improving stability, and improving convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

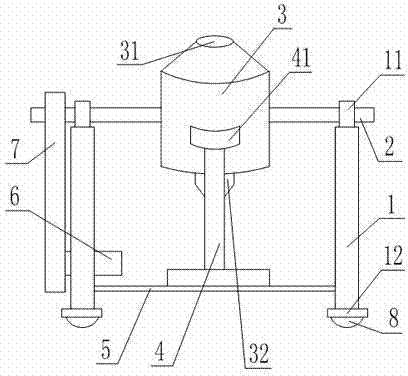

[0018] Such as figure 1 As shown, the improved structure of the mixer that is convenient to increase the discharge speed includes symmetrically arranged fixed seats 1, a horizontal plate 5 is arranged between the fixed seats 1, and a roller 8 is arranged at the bottom of the fixed seat 1, and the fixed seat 1 is connected with the rollers. 8. A reinforcement plate 12 is provided at the matching place, and a fixed plate 11 is provided on the fixed seat 1. The mixing bin 3 is arranged between the two fixing plates 11 through the rotating shaft 2. One end of the mixing bin 3 is provided with a feed port 31, and the other end A discharge port 32 is provided, and the discharge port 32 is a hollow circular table structure, the output end of the rotating shaft 2 cooperates with the motor 6 through the rack 7, and the hydraulic cylinder 4 that cooperates with the mixing bin 3 is provided on the horizontal plate 5, The output end of the hydraulic cylinder 4 is provided with a clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com