Ultralow-concentration flowing gas distribution system and gas distribution method

An ultra-low concentration, gas path technology, used in mixing methods, chemical instruments and methods, mixer accessories, etc., can solve problems such as failure to form a system, poor gas distribution effect, and difficulty in gas distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

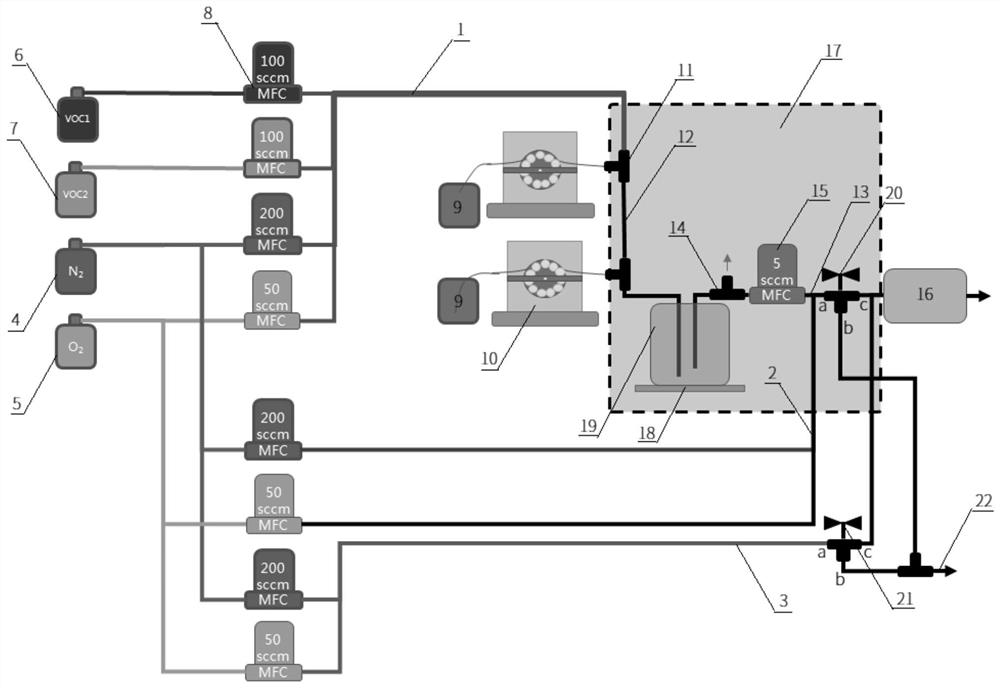

[0039] As shown in the figure, an ultra-low concentration flow gas distribution system includes:

[0040] The gas mass flow control module is used to control the background gas and test gas to enter the gas distribution system with a certain quality and flow;

[0041] The VOCs injection control module is used to inject liquid VOCs into the pipeline at a certain flow rate;

[0042] The gas distribution control module includes a heating device for vaporizing the liquid VOCs injected by the VOCs injection control module, a constant temperature device for maintaining the temperature, and a secondary gas distribution device for secondary concentration adjustment of the test gas;

[0043] The main control module is connected with the gas mass flow control module to control the quality and flow of background gas and test gas, connected with the VOCs injection control module to control the opening and closing and flow rate of liquid VOCs injection, and connected with the gas distribut...

Embodiment 2

[0045] This embodiment proposes an ultra-low concentration flow gas distribution system, which further describes the specific structure of the gas mass flow control module on the basis of the first embodiment. In this embodiment, the gas mass flow control module includes a background gas circuit, a test gas circuit, and a first mass flow controller for respectively controlling the flow values of each gas circuit, the first mass flow controller is connected to the main control module, and the background gas circuit includes At least three channels: the first channel of diluted background gas 1, the second channel of diluted background gas 2 and the third channel of diluted background gas 3. The inlet ends of each background gas circuit are connected to the background gas source, and the inlet ports of the test gas circuit are connected to The test gas source, the test gas path is mixed with the first diluted background gas to form a mixed gas and enters the gas distribution co...

Embodiment 3

[0048] This embodiment proposes an ultra-low concentration flow gas distribution system, which further explains the specific structure of the VOCs injection control module on the basis of the above embodiments. In this embodiment, the VOCs injection control module includes a liquid VOCs source 9, a power propeller 10, a syringe (not shown) and a three-way valve 11. The liquid VOCs source is connected to one end of the three-way valve 11 through the syringe, and the three-way The other two ends of the valve 11 are respectively connected to the first dilute background gas 1, and the power propeller 10 is connected to the main control module for controlling the injection of liquid VOCs into the first dilute background gas 1 at a certain flow rate. Mix to form the liquid-gas mixing path 12. The VOCs injection control module can realize the uniform injection of VOCs into the pipeline in the form of liquid, and make the VOCs vaporize quickly when they reach the boiling point in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com